Capacitive Sensors Based on Recycled Carbon Fibre (rCF) Composites

Abstract

:1. Introduction

2. Materials and Methods

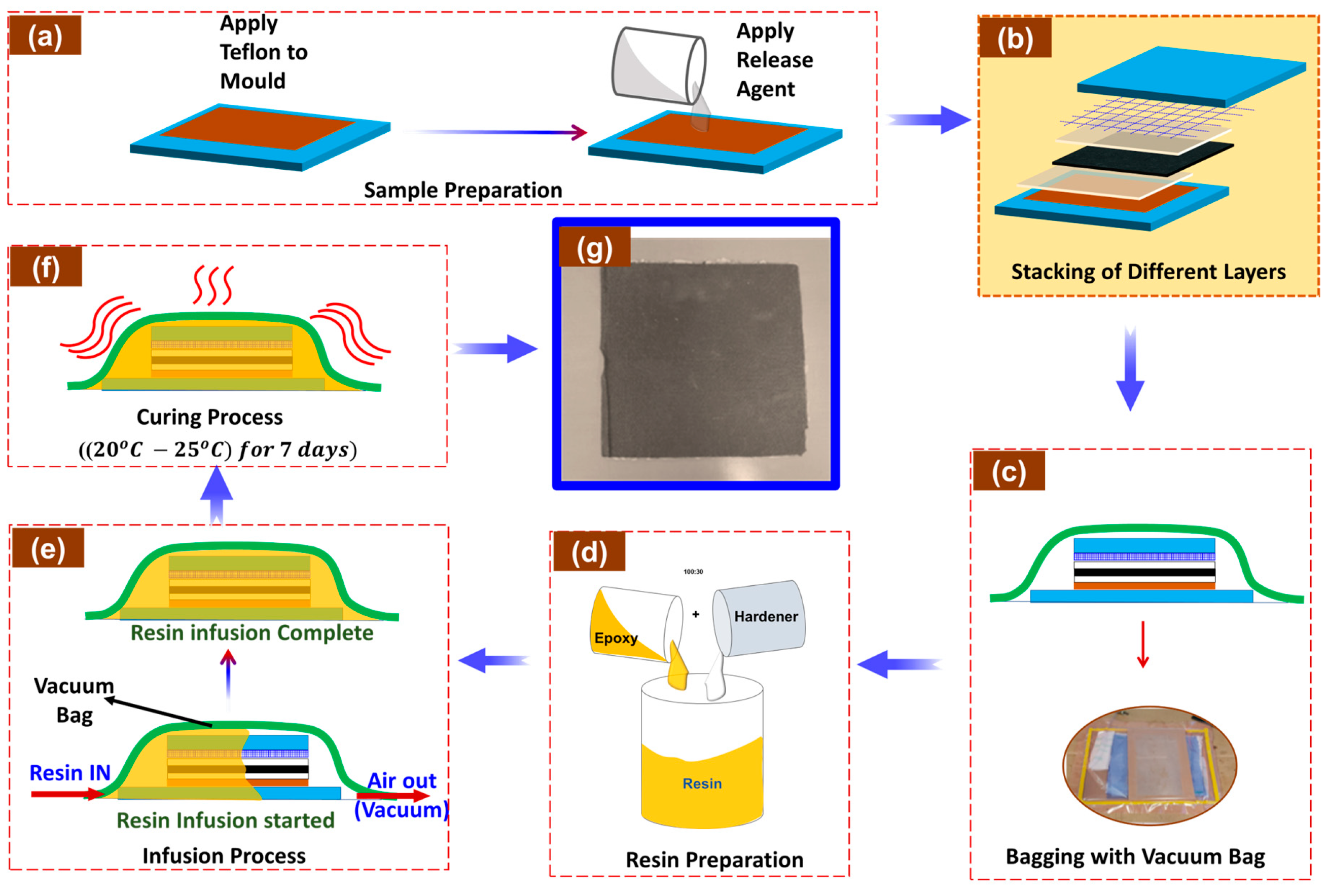

2.1. Fabrication of the Recycled Carbon Fibre Composites

2.2. Determination of Fibre Volume Fraction

2.3. Flexural Strength Test

2.4. Thermo-Mechanical Analysis

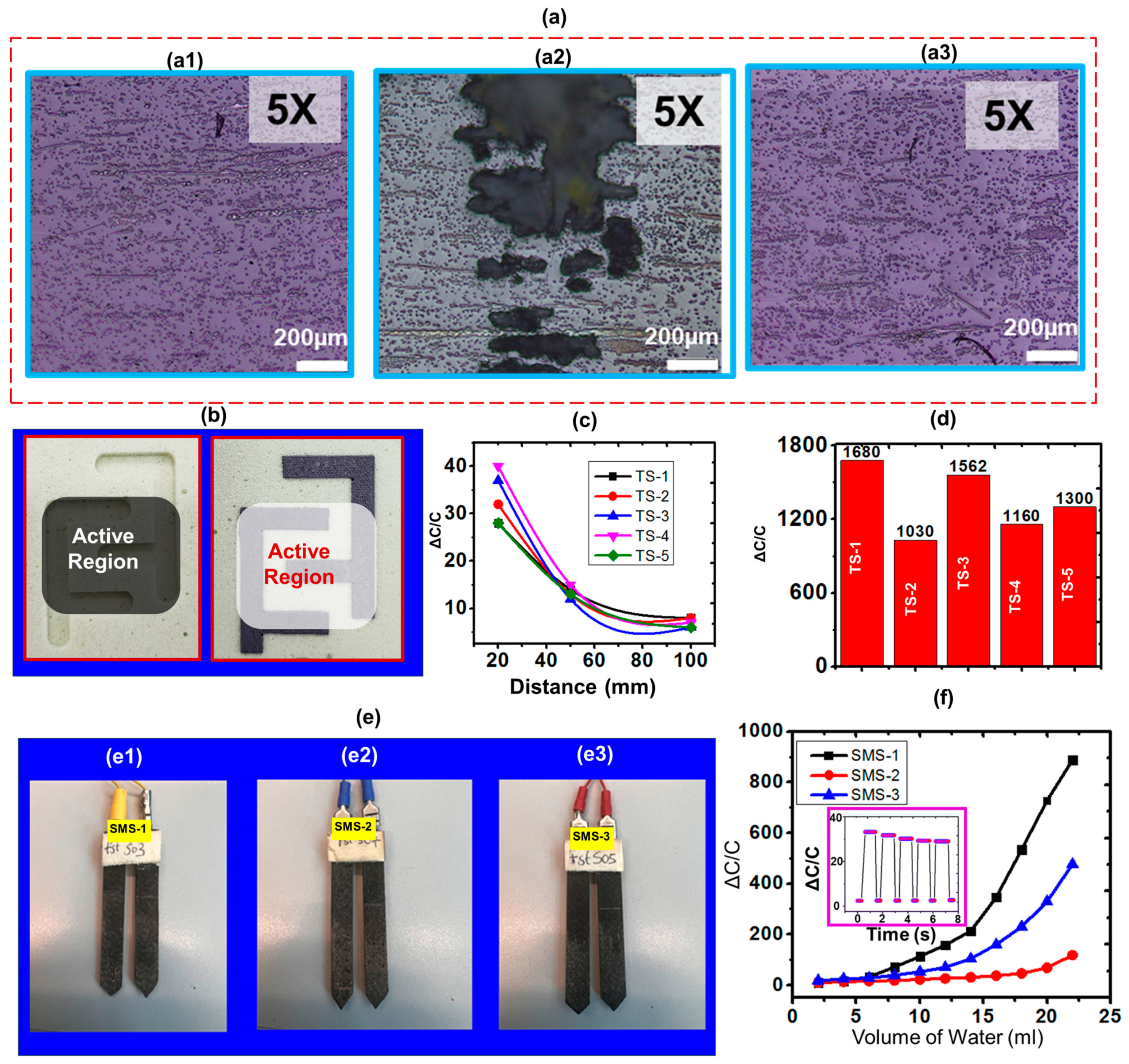

2.5. Fabrication and Characterisation of rCF-Based Capacitive Touch/Proximity Sensors

2.6. Fabrication and Characterisation of rCF-Based Soil Moisture Sensors

3. Results and Discussion

Characterisation of the rCF Sensing Electrode

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fernández, A.; Santangelo-Muro, M.; Fernández-Blázquez, J.P.; Lopes, C.S.; Molina-Aldareguia, J.M. Processing and properties of long recycled-carbon-fibre reinforced polypropylene. Compos. Part B Eng. 2021, 211, 108653. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. Part B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- Balaji, A.B.; Rudd, C.; Liu, X. Recycled carbon fibers (rCF) in automobiles: Towards circular economy. Mater. Circ. Econ. 2020, 2, 4. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Turner, T.; Wong, K.H.; Pickering, S.J. Environmental aspects of use of recycled carbon fiber composites in automotive applications. Environ. Sci. Technol. 2017, 51, 12727–12736. [Google Scholar] [CrossRef] [PubMed]

- Jeon, E.-B.; Ahn, S.; Lee, I.-G.; Koh, H.-I.; Park, J.; Kim, H.-S. Investigation of mechanical/dynamic properties of carbon fiber reinforced polymer concrete for low noise railway slab. Compos. Struct. 2015, 134, 27–35. [Google Scholar] [CrossRef]

- Butenegro, J.A.; Bahrami, M.; Abenojar, J.; Martínez, M. Recent progress in carbon fiber reinforced polymers recycling: A review of recycling methods and reuse of carbon fibers. Materials 2021, 14, 6401. [Google Scholar] [CrossRef] [PubMed]

- Upadhyayula, V.K.; Gadhamshetty, V.; Athanassiadis, D.; Tysklind, M.; Meng, F.; Pan, Q.; Cullen, J.M.; Yacout, D.M. Wind Turbine Blades Using Recycled Carbon Fibers: An Environmental Assessment. Environ. Sci. Technol. 2022, 56, 1267–1277. [Google Scholar] [CrossRef] [PubMed]

- Geier, N.; Poór, D.I.; Pereszlai, C.; Tamás-Bényei, P. Drilling of recycled carbon fibre–reinforced polymer (rCFRP) composites: Analysis of burrs and microstructure. Int. J. Adv. Manuf. Technol. 2022, 120, 1677–1693. [Google Scholar] [CrossRef]

- Kumar, K.K.; Hutchinson, A.R.; Broughton, J.G. Static shear response of recycled carbon fibre composites for structural applications. Compos. Struct. 2020, 246, 112358. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Seidlitz, H.; Krenz, J.; Goracy, K.; Urbaniak, M.; Rösch, J.J. Recycling of carbon fiber reinforced composite polymers—Review—Part 2: Recovery and application of recycled carbon fibers. Polymers 2020, 12, 3003. [Google Scholar] [CrossRef]

- Farjam, P.; Hekman, E.; Rouwkema, J.; Verkerke, G. Bone fixation techniques for managing joint disorders and injuries: A review study. J. Mech. Behav. Biomed. Mater. 2022, 126, 104982. [Google Scholar] [CrossRef] [PubMed]

- Min, J.; Jung, Y.; Ahn, J.; Lee, J.G.; Lee, J.; Ko, S.H. Recent advances in biodegradable green electronic materials and sensor applications. Adv. Mater. 2023, 35, e2211273. [Google Scholar] [CrossRef] [PubMed]

- Xia, S.; Fu, W.; Liu, J.; Gao, G. Recyclable hydrogel for human-machine interface of multi-mode human vital signal acquisition. Sci. China Mater. 2023, 66, 2843–2851. [Google Scholar] [CrossRef]

- Sfragano, P.S.; Laschi, S.; Palchetti, I. Sustainable printed electrochemical platforms for greener analytics. Front. Chem. 2020, 8, 644. [Google Scholar] [CrossRef] [PubMed]

- Khatib, M.; Zohar, O.; Haick, H. Self-healing soft sensors: From material design to implementation. Adv. Mater. 2021, 33, 2004190. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, G.; Das, S.; Rego, A.; Silva, R.R.; Gaspar, D.; Goswami, S.; Pereira, R.N.; Fortunato, E.; Pereira, L.; Martins, R.; et al. Eco-designed recycled newspaper for energy harvesting and pressure sensor applications. Chem. Eng. J. 2024, 480, 147995. [Google Scholar] [CrossRef]

- Silva-Neto, H.A.; Duarte-Junior, G.F.; Rocha, D.S.; Bedioui, F.; Varenne, A.; Coltro, W.K.T. Recycling 3D Printed Residues for the Development of Disposable Paper-Based Electrochemical Sensors. ACS Appl. Mater. Interfaces 2023, 15, 14111–14121. [Google Scholar] [CrossRef]

- Wu, S.; Hsu, S.; Ketelsen, B.; Bittinger, S.C.; Schlicke, H.; Weller, H.; Vossmeyer, T. Fabrication of Eco-Friendly Wearable Strain Sensor Arrays via Facile Contact Printing for Healthcare Applications. Small Methods 2023, 7, e2300170. [Google Scholar] [CrossRef]

- Alsaadi, A.; Shi, Y.; Pan, L.; Tao, J.; Jia, Y. Vibration energy harvesting of multifunctional carbon fibre composite laminate structures. Compos. Sci. Technol. 2019, 178, 1–10. [Google Scholar] [CrossRef]

- Forintos, N.; Czigany, T. Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers—A short review. Compos. Part B Eng. 2019, 162, 331–343. [Google Scholar] [CrossRef]

- Montazerian, H.; Dalili, A.; Milani, A.; Hoorfar, M. Piezoresistive sensing in chopped carbon fiber embedded PDMS yarns. Compos. Part B Eng. 2019, 164, 648–658. [Google Scholar] [CrossRef]

- van de Werken, N.; Reese, M.S.; Taha, M.R.; Tehrani, M. Investigating the effects of fiber surface treatment and alignment on mechanical properties of recycled carbon fiber composites. Part A Appl. Sci. Manuf. 2019, 119, 38–47. [Google Scholar] [CrossRef]

- Roveda, L.M.; Ottoni, V.F.; de Carvalho, C.T.; Rodrigues, R.; Corazza, M.Z.; Trindade, M.A.G. Merging 3D-printing technology and disposable materials for electrochemical purposes: A sustainable alternative to ensure greener electroanalysis. Talanta 2024, 272, 125814. [Google Scholar] [CrossRef] [PubMed]

- Hannan, A.N.; Seidlitz, H.; Hartung, D.; Kuke, F.; Ambrosio, M.; Müller, M. Sustainability and Circular Economy in Carbon Fiber-Reinforced Plastics. Mater. Circ. Econ. 2024, 6, 26. [Google Scholar] [CrossRef]

- Pozegic, T.R.; Anguita, J.V.; Hamerton, I.; Jayawardena, K.D.G.I.; Chen, J.-S.; Stolojan, V.; Ballocchi, P.; Walsh, R.; Silva, S.R.P. Multi-functional carbon fibre composites using carbon nanotubes as an alternative to polymer sizing. Sci. Rep. 2016, 6, 37334. [Google Scholar] [CrossRef] [PubMed]

- Harnden, R.; Carlstedt, D.; Zenkert, D.; Lindbergh, G. Multifunctional Carbon Fiber Composites: A Structural, Energy Harvesting, Strain-Sensing Material. ACS Appl. Mater. Interfaces 2022, 14, 33871–33880. [Google Scholar] [CrossRef] [PubMed]

- Pan, D.; Dai, F.; Li, H. Piezoelectric energy harvester based on bi-stable hybrid symmetric laminate. Compos. Sci. Technol. 2015, 119, 34–45. [Google Scholar] [CrossRef]

- Yu, L.; Gao, W.; Shamshiri, R.R.; Tao, S.; Ren, Y.; Zhang, Y.; Su, G. Review of research progress on soil moisture sensor technology. Int. J. Agric. Biol. Eng. 2021, 14, 32–42. [Google Scholar] [CrossRef]

- Chakraborty, M.; Kalita, A.; Biswas, K. PMMA-coated capacitive type soil moisture sensor: Design, fabrication, and testing. IEEE Trans. Instrum. Meas. 2018, 68, 189–196. [Google Scholar] [CrossRef]

- Bangi, U.K.H.; Bachuwar, V.D.; Park, H.-H. Zirconia Coatings as Efficient Soil Moisture Sensors for Water Irrigation. IEEE Sens. J. 2021, 21, 21205–21211. [Google Scholar] [CrossRef]

- Kalita, H.; Palaparthy, V.S.; Baghini, M.S.; Aslam, M. Graphene quantum dot soil moisture sensor. Sens. Actuators B Chem. 2016, 233, 582–590. [Google Scholar] [CrossRef]

- Xu, Z.; Zhou, W.; Zhang, H.; Shen, M.; Liu, Y.; Cai, D.; Li, Y.; Lei, Y.; Wang, G.; Bagtzoglou, A.C.; et al. Flat thin mm-sized soil moisture sensor (MSMS) fabricated by gold compact discs etching for real-time in situ profiling. Sens. Actuators B Chem. 2018, 255, 1166–1172. [Google Scholar] [CrossRef]

- Goswami, M.P.; Montazer, B.; Sarma, U. Design and characterization of a fringing field capacitive soil moisture sensor. IEEE Trans. Instrum. Meas. 2018, 68, 913–922. [Google Scholar] [CrossRef]

- Surya, S.G.; Yuvaraja, S.; Varrla, E.; Baghini, M.S.; Palaparthy, V.S.; Salama, K.N. An in-field integrated capacitive sensor for rapid detection and quantification of soil moisture. Sens. Actuators B Chem. 2020, 321, 128542. [Google Scholar] [CrossRef]

- Kumaresan, Y.; Ozioko, O.; Dahiya, R. Effect of Dielectric and Stiffness of Soft Material between the Electrodes of a Capacitive Pressure Sensor on its Performance. In Proceedings of the 2020 IEEE International Conference on Flexible and Printable Sensors and Systems (FLEPS), Manchester, UK, 16–19 August 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Chakraborty, M.; Ozioko, O.; Dahiya, R. Flexible interfacing circuits for wearable sensors and wireless communication. In Systems for Printed Flexible Sensors; IOP Publishing: Bristol, UK, 2022; pp. 7-1–7-19. [Google Scholar] [CrossRef]

- Hrisko, J. Capacitive soil moisture sensor theory, calibration, and testing. Tech. Rep. 2020, 2, 1–12. [Google Scholar]

- ASTM D3171-99; Standard Test Methods for Constituent Content of Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017. Available online: https://www.astm.org/d3171-99.html (accessed on 18 July 2024).

- ISO 14127:2024(en); Carbon-Fibre-Reinforced Composites—Determination of the Resin, Fibre and Void Contents. ISO: Geneva, Switzerland, 2024. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14127:ed-2:v1:en (accessed on 18 July 2024).

- Zypman, F.R. Mathematical expression for the capacitance of coplanar strips. J. Electrost. 2019, 101, 103371. [Google Scholar] [CrossRef]

- Li, N.; Zhu, H.; Wang, W.; Gong, Y. Parallel double-plate capacitive proximity sensor modelling based on effective theory. AIP Adv. 2014, 4, 027119. [Google Scholar] [CrossRef]

- Sha, Z.; Cheng, X.; Islam, M.S.; Sangkarat, P.; Chang, W.; Brown, S.A.; Wu, S.; Zhang, J.; Han, Z.; Peng, S.; et al. Synergistically enhancing the electrical conductivity of carbon fibre reinforced polymers by vertical graphene and silver nanowires. Compos. Part A Appl. Sci. Manuf. 2023, 168, 107463. [Google Scholar] [CrossRef]

- Pickering, S.; Liu, Z.; Turner, T.; Wong, K. Applications for carbon fibre recovered from composites. IOP Conf. Ser. Mater. Sci. Eng. 2016, 139, 012005. [Google Scholar] [CrossRef]

- Kim, D.-C.; Choi, J.S.; Shin, H.-S.; Jung, I.; Heo, Y.W. Effect of the manufacturing process on the equivalency qualification of glass fiber reinforced polymer. Sci. Eng. Compos. Mater. 2022, 29, 403–411. [Google Scholar] [CrossRef]

- Gu, W.; Wu, H.; Kampe, S.; Lu, G.-Q. Volume fraction effects on interfacial adhesion strength of glass-fiber-reinforced polymer composites. Mater. Sci. Eng. A 2000, 277, 237–243. [Google Scholar] [CrossRef]

- Moheimani, R.; Hosseini, P.; Mohammadi, S.; Dalir, H. Recent advances on capacitive proximity sensors: From design and materials to creative applications. C 2022, 8, 26. [Google Scholar] [CrossRef]

- Nagahage, E.A.A.D.; Nagahage, I.S.P.; Fujino, T. Calibration and validation of a low-cost capacitive moisture sensor to integrate the automated soil moisture monitoring system. Agriculture 2019, 9, 141. [Google Scholar] [CrossRef]

- Oliveira, P.R.; May, M.; Panzera, T.H.; Hiermaier, S. Bio-based/green sandwich structures: A review. Thin-Walled Struct. 2022, 177, 109426. [Google Scholar] [CrossRef]

- Oliveira, J.; Correia, V.; Castro, H.; Martins, P.; Lanceros-Mendez, S. Polymer-based smart materials by printing technologies: Improving application and integration. Addit. Manuf. 2017, 21, 269–283. [Google Scholar] [CrossRef]

- Srinivasan, K.P.; Muthuramalingam, T.; Elsheikh, A.H. A review of flexible printed sensors for automotive infotainment systems. Arch. Civ. Mech. Eng. 2023, 23, 67. [Google Scholar] [CrossRef]

- Edberg, J.; Boda, U.; Mulla, M.Y.; Brooke, R.; Pantzare, S.; Strandberg, J.; Fall, A.; Economou, K.; Beni, V.; Armgarth, A. A Paper-Based Triboelectric Touch Interface: Toward Fully Green and Recyclable Internet of Things. Adv. Sens. Res. 2023, 2, 2200015. [Google Scholar] [CrossRef]

- Liu, W.; Xiang, F.; Mei, D.; Wang, Y. A Flexible Dual-Mode Capacitive Sensor for Highly Sensitive Touchless and Tactile Sensing in Human-Machine Interactions. Adv. Mater. Technol. 2024, 9, 2301685. [Google Scholar] [CrossRef]

| Type of Electrode | Sensing Mechanism | Reference |

|---|---|---|

| Copper | Capacitive | [29] |

| Gold | Resistive | [31] |

| Gold | Resistive | [32] |

| Copper | Capacitive | [33] |

| Graphene Oxide | Capacitive | [34] |

| Stainless Steel | Resistive | [30] |

| Sample No. | Fibre Volume Percent (%) | Void Content (%) |

|---|---|---|

| Sample 1 | 10.00 | 2.00 |

| Sample 2 | 11.00 | 10.00 |

| Sample 3 | 17.00 | 2.00 |

| Property | Specimen ID | ||

|---|---|---|---|

| Sample 1 | Sample 2 | Sample 3 | |

| Flexural Strength (MPa) | 231.42 | 71.69 | 219.35 |

| Flexural Modulus (GPa) | 9.97 | 6.08 | 9.86 |

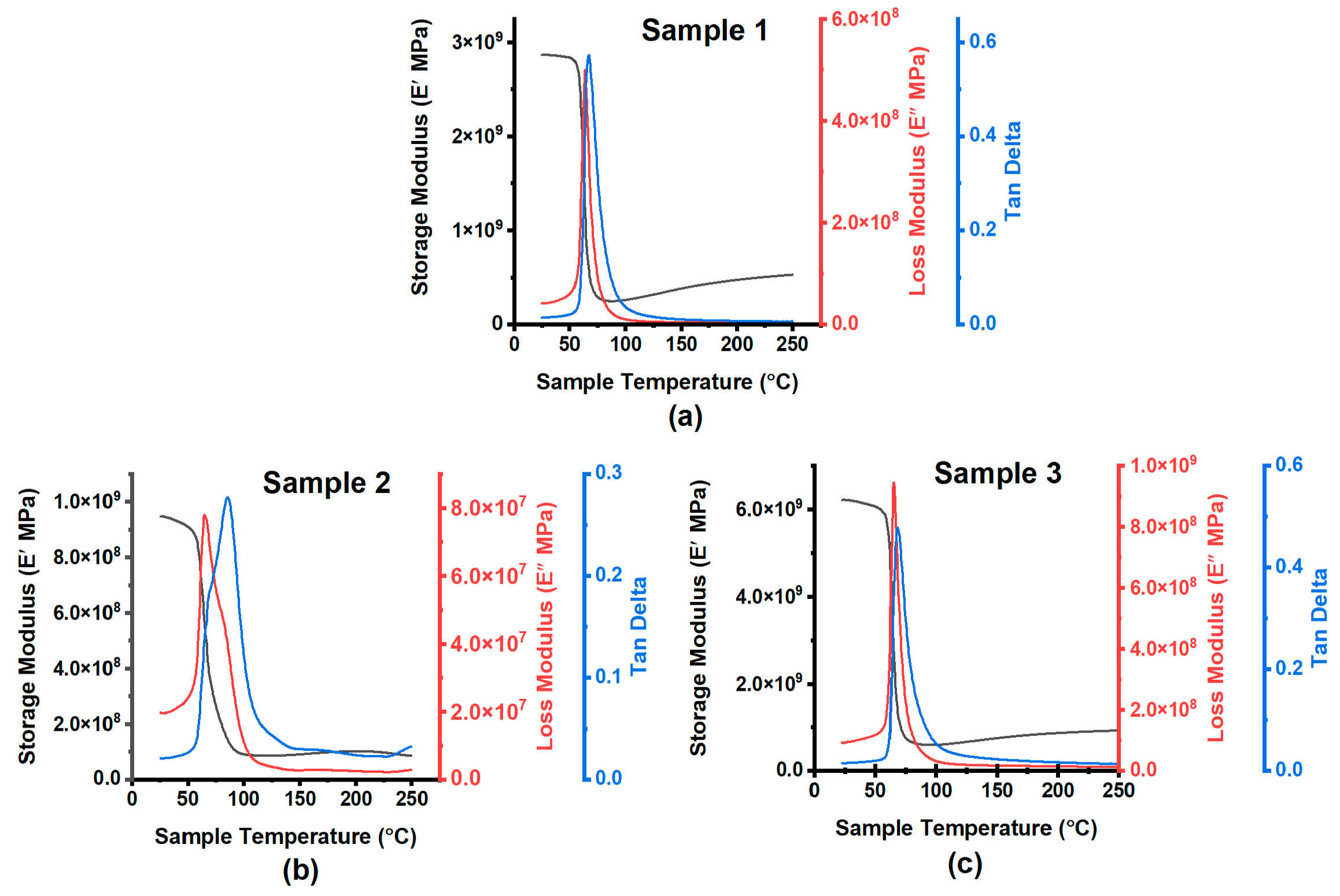

| Sample No. | Storage Modulus (MPa) @ 25 °C | Loss Modulus (Peak) (MPa) | Tan Delta (Peak) | Glass Transition Temperature, Tg (°C) |

|---|---|---|---|---|

| Sample 1 | 0.57 | 66.5 | ||

| Sample 2 | 0.27 | 62.4 | ||

| Sample 3 | 0.48 | 67.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozioko, O.; Odiyi, D.C.; Diala, U.; Akinbami, F.; Emu, M.; Shafik, M. Capacitive Sensors Based on Recycled Carbon Fibre (rCF) Composites. Sensors 2024, 24, 4731. https://doi.org/10.3390/s24144731

Ozioko O, Odiyi DC, Diala U, Akinbami F, Emu M, Shafik M. Capacitive Sensors Based on Recycled Carbon Fibre (rCF) Composites. Sensors. 2024; 24(14):4731. https://doi.org/10.3390/s24144731

Chicago/Turabian StyleOzioko, Oliver, Daniel C. Odiyi, Uchenna Diala, Fiyinfoluwa Akinbami, Marshal Emu, and Mahmoud Shafik. 2024. "Capacitive Sensors Based on Recycled Carbon Fibre (rCF) Composites" Sensors 24, no. 14: 4731. https://doi.org/10.3390/s24144731