Junction Piezotronic Transistor Arrays Based on Patterned ZnO Nanowires for High-Resolution Tactile and Photo Mapping

Abstract

:1. Introduction

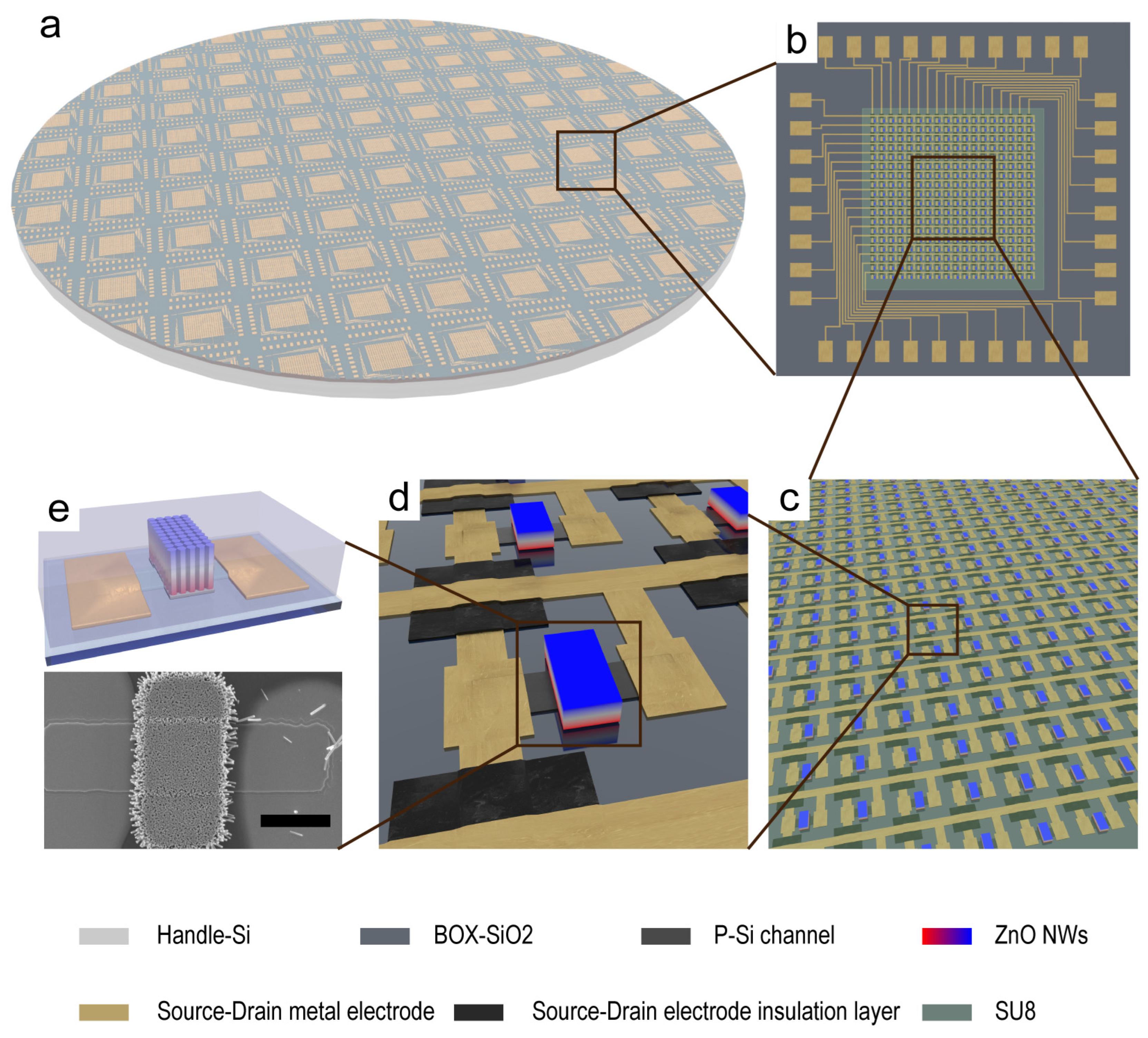

2. Result and Discussions

3. Individual Device Performance

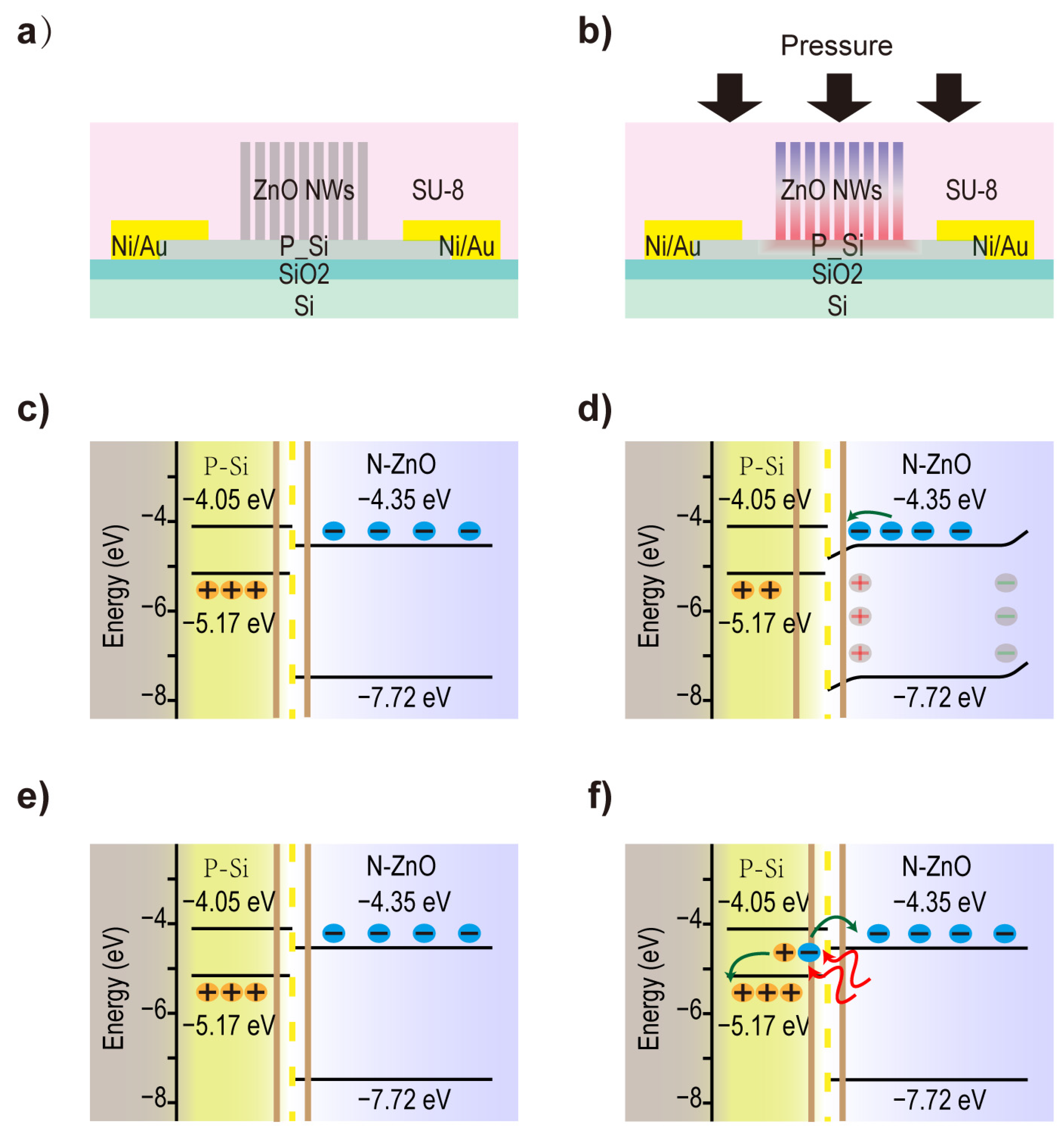

4. Working Principle

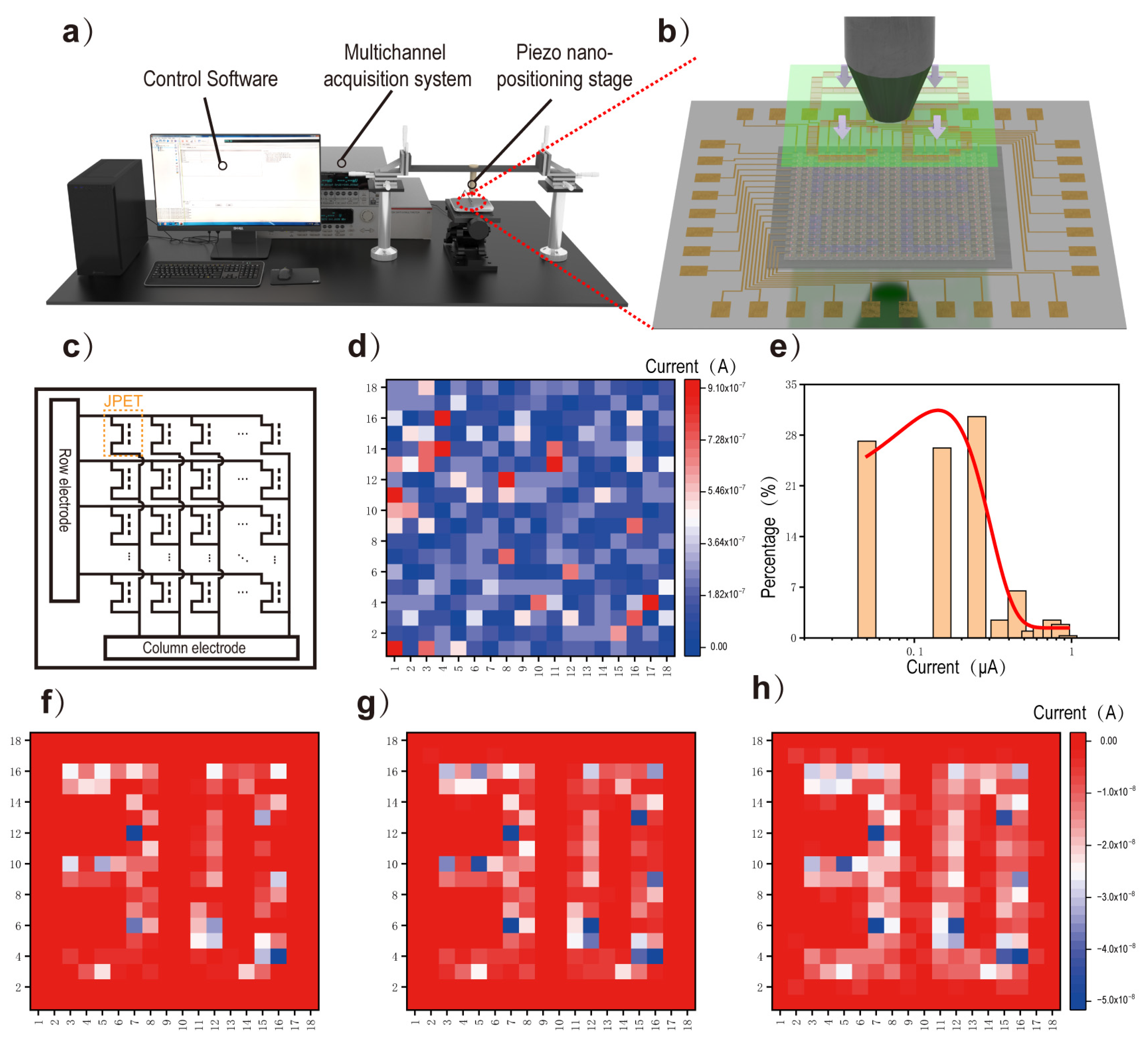

5. High Spatial Resolution Pressure Mapping

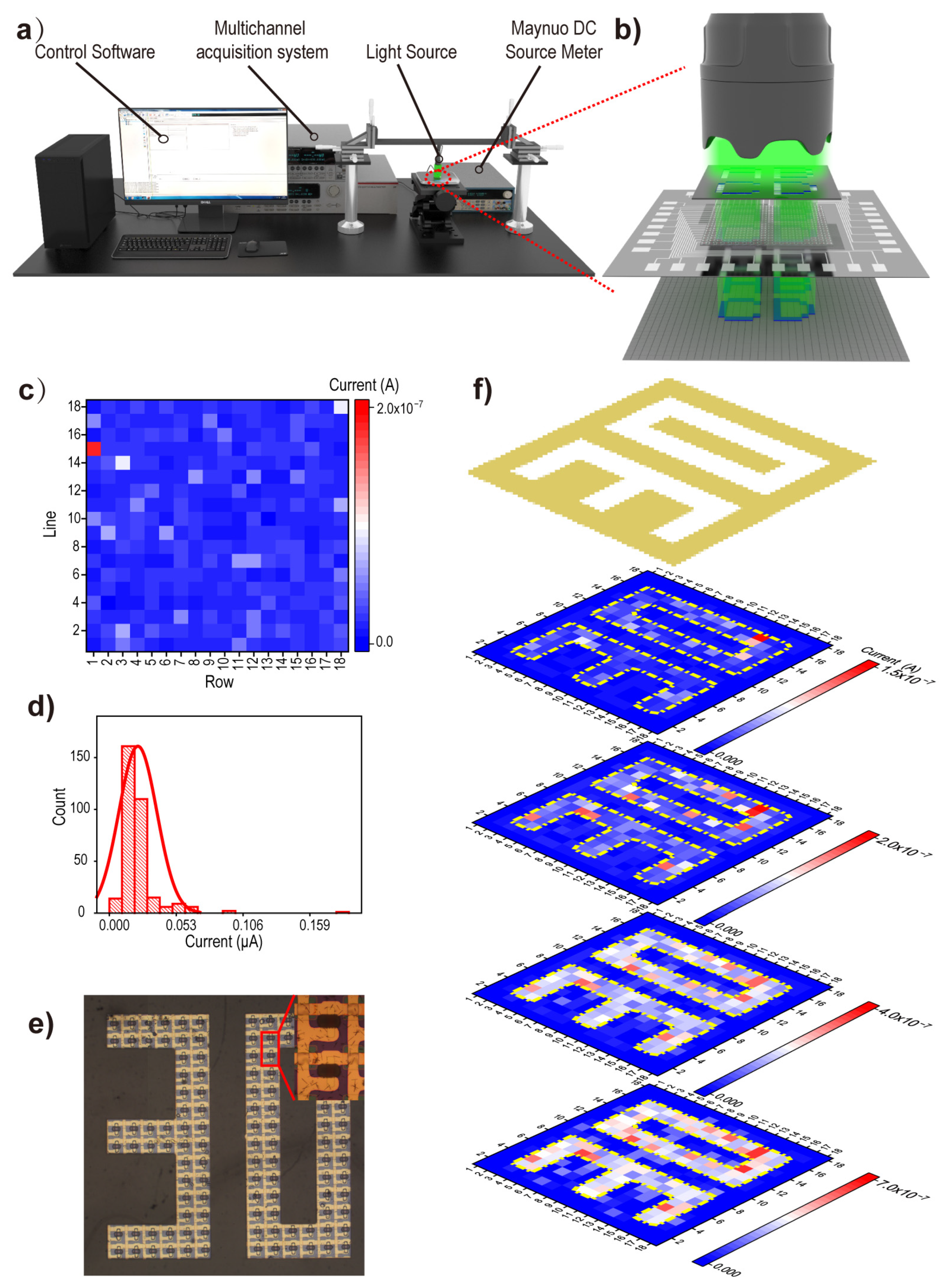

6. High Spatial Resolution Light Mapping

7. Conclusions

8. Experimental Section

8.1. Individual JPT Fabricated

8.2. The Preparation Process for JPT Array Devices

8.3. Experimental Setup and Measurements

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jang, J.; Ji, S.; Grandhi, G.K.; Cho, H.B.; Im, W.B.; Park, J.U. Multimodal Digital X-ray Scanners with Synchronous Mapping of Tactile Pressure Distributions using Perovskites. Adv. Mater. 2021, 33, e2008539. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Xu, Z.; Wu, W.; Liu, X.; Yan, P.; Pan, C. Recent Progress in Optoelectronic Synapses for Artificial Visual-Perception System. Small Struct. 2020, 1, 2000029. [Google Scholar] [CrossRef]

- Ge, G.; Lu, Y.; Qu, X.; Zhao, W.; Ren, Y.; Wang, W.; Wang, Q.; Huang, W.; Dong, X. Muscle-Inspired Self-Healing Hydrogels for Strain and Temperature Sensor. ACS Nano 2020, 14, 218–228. [Google Scholar] [CrossRef] [PubMed]

- Ge, G.; Yuan, W.; Zhao, W.; Lu, Y.; Zhang, Y.; Wang, W.; Chen, P.; Huang, W.; Si, W.; Dong, X. Highly stretchable and autonomously healable epidermal sensor based on multi-functional hydrogel frameworks. J. Mater. Chem. A 2019, 7, 5949–5956. [Google Scholar] [CrossRef]

- Lu, Y.; Qu, X.; Zhao, W.; Ren, Y.; Si, W.; Wang, W.; Wang, Q.; Huang, W.; Dong, X. Highly Stretchable, Elastic, and Sensitive MXene-Based Hydrogel for Flexible Strain and Pressure Sensors. Research 2020, 2020, 2038560. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, W.; Wang, Y.; Wang, Y.; Zhou, J.; Dai, L.; Xu, M. A graphene rheostat for highly durable and stretchable strain sensor. InfoMat 2019, 1, 396–406. [Google Scholar] [CrossRef]

- Hua, Q.; Shen, G. A wearable sweat patch for non-invasive and wireless monitoring inflammatory status. J. Semicond. 2023, 44, 100401. [Google Scholar] [CrossRef]

- Lin, Q.; Wang, L. Layered double hydroxides as electrode materials for flexible energy storage devices. J. Semicond. 2023, 44, 041601. [Google Scholar] [CrossRef]

- Liu, C.; Lin, H.; Ji, D.; Yu, Q.; Chen, S.; Guo, Z.; Luo, Q.; Liu, X.; Lai, W. Wavelength-tunable organic semiconductor lasers based on elastic distributed feedback gratings. J. Semicond. 2023, 44, 032601. [Google Scholar] [CrossRef]

- Kwok, H.-S.; Fan, Z. Preface to Special Issue on Advanced Optoelectronic and Electronic Devices toward Future Displays. J. Semicond. 2023, 44, 090101. [Google Scholar] [CrossRef]

- Yin, R.; Li, L.; Wang, L.; Lou, Z. Self-healing Au/PVDF-HFP composite ionic gel for flexible underwater pressure sensor. J. Semicond. 2023, 44, 032602. [Google Scholar] [CrossRef]

- Zhao, S.; Ran, W.; Wang, L.; Shen, G. Interlocked MXene/rGO aerogel with excellent mechanical stability for a health-monitoring device. J. Semicond. 2022, 43, 082601. [Google Scholar] [CrossRef]

- Chen, L.; Xue, F.; Li, X.; Huang, X.; Wang, L.; Kou, J.; Wang, Z.L. Strain-Gated Field Effect Transistor of a MoS2-ZnO 2D-1D Hybrid Structure. ACS Nano 2016, 10, 1546–1551. [Google Scholar] [CrossRef] [PubMed]

- Goossens, S.; Navickaite, G.; Monasterio, C.; Gupta, S.; Piqueras, J.J.; Pérez, R.; Burwell, G.; Nikitskiy, I.; Lasanta, T.; Galán, T.; et al. Broadband image sensor array based on graphene–CMOS integration. Nat. Photonics 2017, 11, 366–371. [Google Scholar] [CrossRef]

- Hills, G.; Lau, C.; Wright, A.; Fuller, S.; Bishop, M.D.; Srimani, T.; Kanhaiya, P.; Ho, R.; Amer, A.; Stein, Y.; et al. Modern microprocessor built from complementary carbon nanotube transistors. Nature 2019, 572, 595–602. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, M.; Wan, Y.; Xu, X.; Wong, M.; Kwok, H.-S. Advances in mobility enhancement of ITZO thin-film transistors: A review. J. Semicond. 2023, 44, 091602. [Google Scholar] [CrossRef]

- Shi, R.; Lei, T.; Xia, Z.; Wong, M. Low-temperature metal–oxide thin-film transistor technologies for implementing flexible electronic circuits and systems. J. Semicond. 2023, 44, 091601. [Google Scholar] [CrossRef]

- Tam, B.S.T.; Dong, S.-C.; Tang, C.W. Low-temperature conformal vacuum deposition of OLED devices using close-space sublimation. J. Semicond. 2023, 44, 092602. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Liu, F.; Luo, D.; Wang, Y.; Zhang, S.; Lu, L. Fluorination-mitigated high-current degradation of amorphous InGaZnO thin-film transistors. J. Semicond. 2023, 44, 092601. [Google Scholar] [CrossRef]

- Li, D.; Ma, J.; Liu, W.; Xiang, G.; Qu, X.; Jia, S.; Gu, M.; Wei, J.; Liu, P.; Wang, K.; et al. Enhancing performance of inverted quantum-dot light-emitting diodes based on a solution-processed hole transport layer via ligand treatment. J. Semicond. 2023, 44, 092603. [Google Scholar] [CrossRef]

- Qu, X.; Sun, X. Impedance spectroscopy for quantum dot light-emitting diodes. J. Semicond. 2023, 44, 091603. [Google Scholar] [CrossRef]

- Wu, L.; Dai, J.; Kong, Y.; Chen, T.; Zhang, T. RF characterization of InP double heterojunction bipolar transistors on a flexible substrate under bending conditions. J. Semicond. 2022, 43, 092601. [Google Scholar] [CrossRef]

- Long, Z.; Ding, Y.; Qiu, X.; Zhou, Y.; Kumar, S.; Fan, Z. A dual-mode image sensor using an all-inorganic perovskite nanowire array for standard and neuromorphic imaging. J. Semicond. 2023, 44, 092604. [Google Scholar] [CrossRef]

- Qammar, M.; Zou, B.; Halpert, J.E. Organic-inorganic halide perovskites for memristors. J. Semicond. 2023, 44, 091604. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, Z.; Huang, Q.; Lin, Y.; Zheng, Z. Wearable sweat biosensors on textiles for health monitoring. J. Semicond. 2023, 44, 021601. [Google Scholar] [CrossRef]

- Wong, M.H. A landscape of β-Ga2O3 Schottky power diodes. J. Semicond. 2023, 44, 091605. [Google Scholar] [CrossRef]

- Mantini, G.; Gao, Y.; D’Amico, A.; Falconi, C.; Wang, Z.L. Equilibrium piezoelectric potential distribution in a deformed ZnO nanowire. Nano Res. 2009, 2, 624–629. [Google Scholar] [CrossRef]

- Wang, Z.L. Piezopotential gated nanowire devices: Piezotronics and piezo-phototronics. Nano Today 2010, 5, 540–552. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, Z.L. Electrostatic potential in a bent piezoelectric nanowire. The fundamental theory of nanogenerator and nanopiezotronics. Nano Lett. 2007, 7, 2499–2505. [Google Scholar] [CrossRef]

- Wang, Z.L.; Yang, R.; Zhou, J.; Qin, Y.; Xu, C.; Hu, Y.; Xu, S. Lateral nanowire/nanobelt based nanogenerators, piezotronics and piezo-phototronics. Mater. Sci. Eng. R Rep. 2010, 70, 320–329. [Google Scholar] [CrossRef]

- Hosseini Teherani, F.; Yi, S.-H.; Litton, C.W.; Choi, S.-K.; Jang, J.-M.; Ko, S.-H.; Kim, J.-A.; Jung, W.-G. Patterned growth of ZnO nanorod by solution chemical method. In Zinc Oxide Materials and Devices II; SPIE: San Francisco, CA, USA, 2007. [Google Scholar]

- Xu, S.; Lao, C.; Weintraub, B.; Wang, Z.L. Density-controlled growth of aligned ZnO nanowire arrays by seedless chemical approach on smooth surfaces. J. Mater. Res. 2011, 23, 2072–2077. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Zhou, R.; Ma, W.; Lu, H.; Mo, Y.; Wang, Y.; Bao, R.; Pan, C. Junction Piezotronic Transistor Arrays Based on Patterned ZnO Nanowires for High-Resolution Tactile and Photo Mapping. Sensors 2024, 24, 4775. https://doi.org/10.3390/s24154775

Zhang L, Zhou R, Ma W, Lu H, Mo Y, Wang Y, Bao R, Pan C. Junction Piezotronic Transistor Arrays Based on Patterned ZnO Nanowires for High-Resolution Tactile and Photo Mapping. Sensors. 2024; 24(15):4775. https://doi.org/10.3390/s24154775

Chicago/Turabian StyleZhang, Li, Runhui Zhou, Wenda Ma, Hui Lu, Yepei Mo, Yi Wang, Rongrong Bao, and Caofeng Pan. 2024. "Junction Piezotronic Transistor Arrays Based on Patterned ZnO Nanowires for High-Resolution Tactile and Photo Mapping" Sensors 24, no. 15: 4775. https://doi.org/10.3390/s24154775