Global Path Planning for Articulated Steering Tractor Based on Multi-Objective Hybrid Algorithm

Abstract

:1. Introduction

2. Kinematic Modeling of Articulated Steering Tractor

- (1)

- Articulated steering tractor turning radius constraint. In order to ensure that the planned path is practicable and avoid the problem that the tractor cannot be steered, the curvature of any point in the planned path should meet the minimum turning radius constraint.

- (2)

- The constraint of curvature continuity of the articulated steering tractor. Unnecessary details and sharp corners in the planning path lead to sharp stops and turns during the operation of the articulated steering tractor, affecting the smoothness and comfort of the articulated steering tractor. The path is smoothed using cubic b-spline curves and the continuity at the nodes is , which is sufficient to satisfy the curvature continuity.

3. Algorithm Description

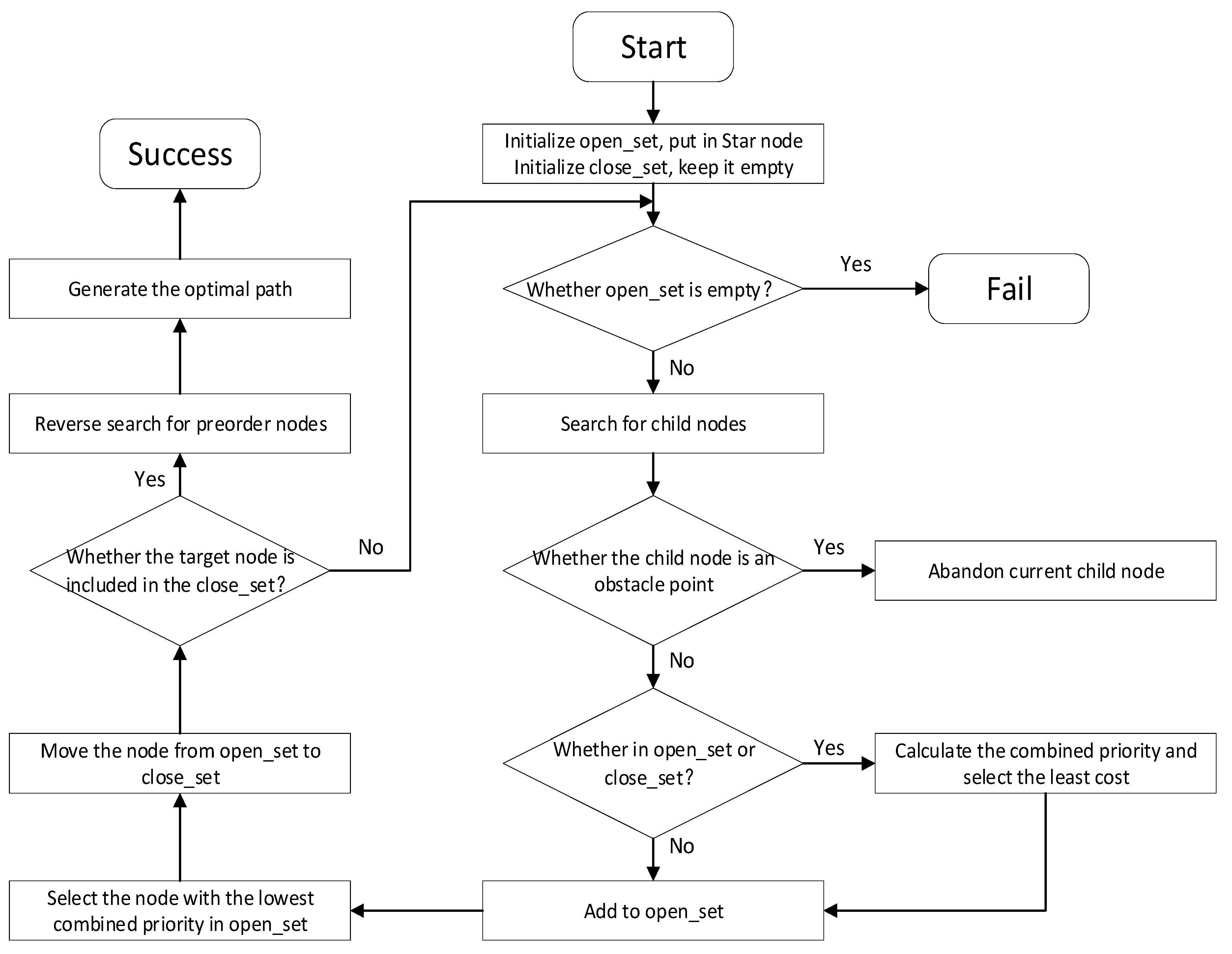

3.1. A* Algorithm

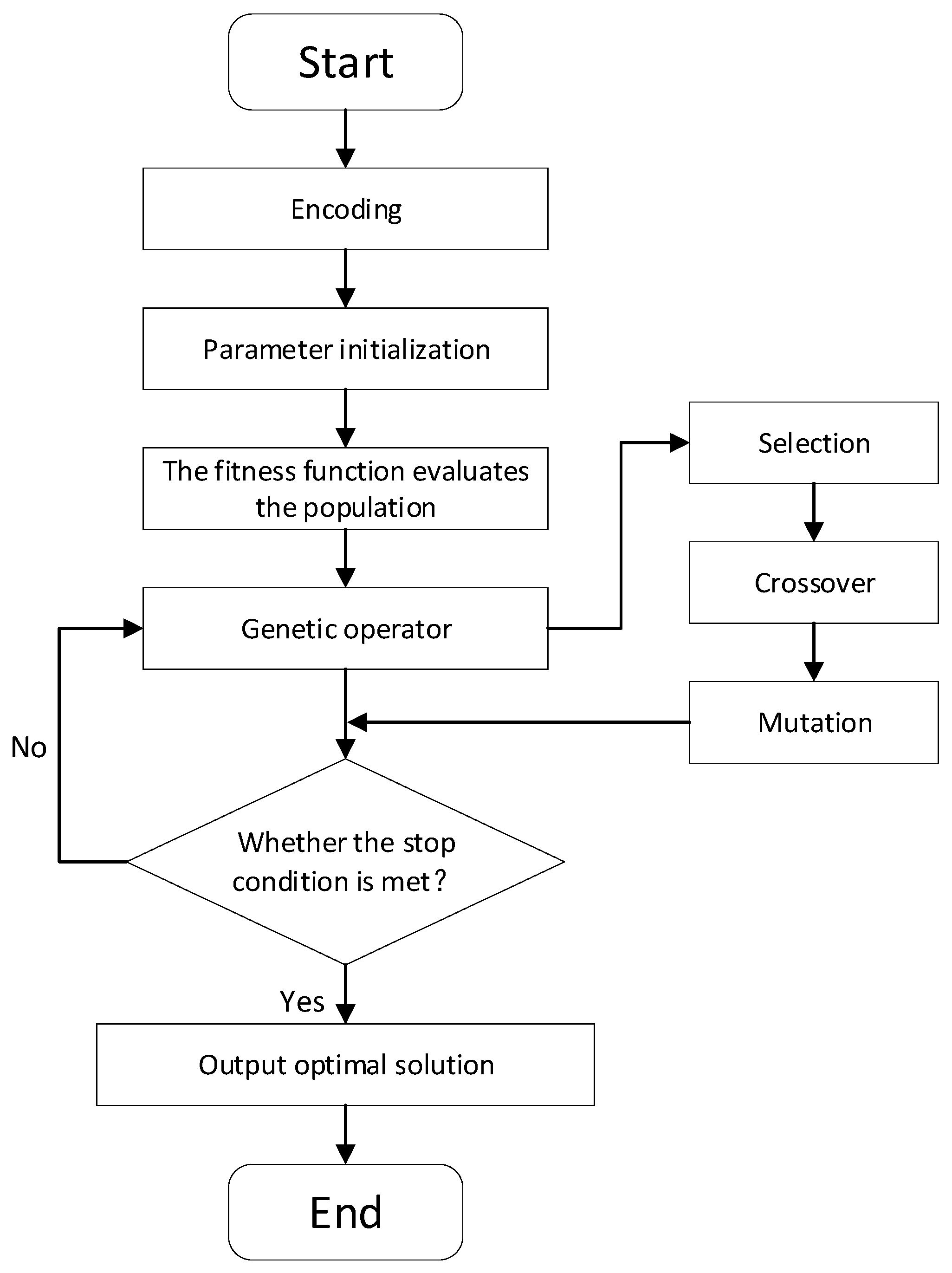

3.2. Genetic Algorithm

- (1)

- Population initialization

- (2)

- Fitness function

- (3)

- Selection

- (4)

- Crossover

- (5)

- Mutation

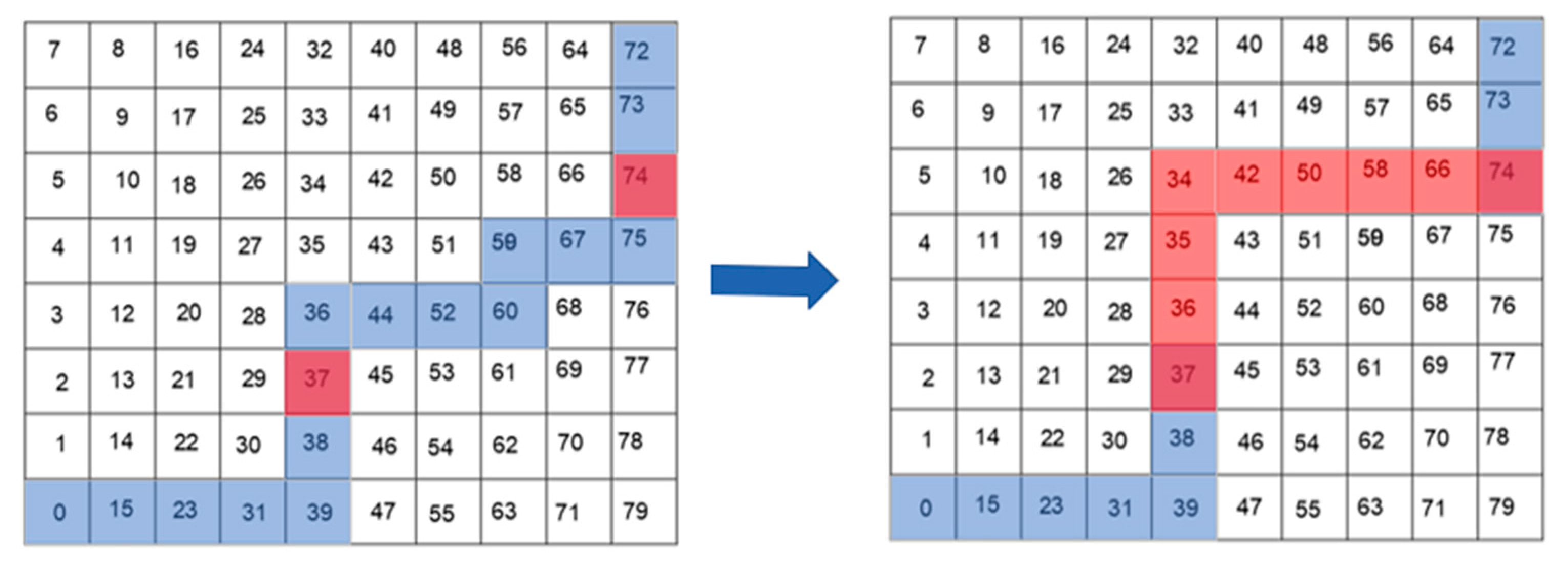

3.3. Improved Hybrid A* and Differential Evolution Genetic Algorithm

3.3.1. Improvement of the A* Algorithm

- (1)

- Improvement of the integrated priority function

- (2)

- Improvement of the search method

3.3.2. Improvement of Genetic Algorithm

- (1)

- Improvement of the fitness function

- (2)

- Improvement of the search strategy

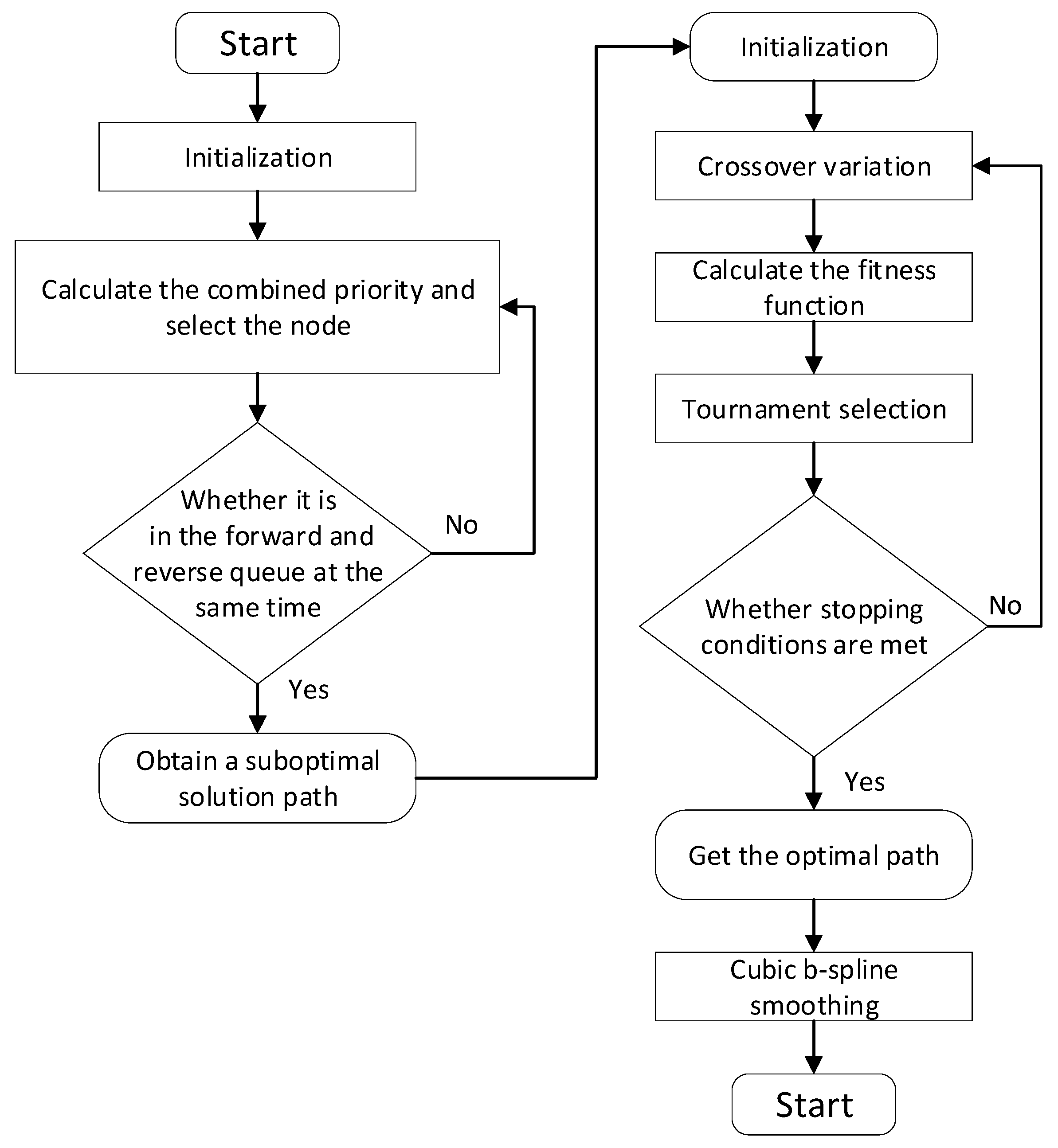

3.3.3. Hybrid Algorithm

- (1)

- Cubic B-spline smoothing path

- (2)

- Algorithmic hybrid

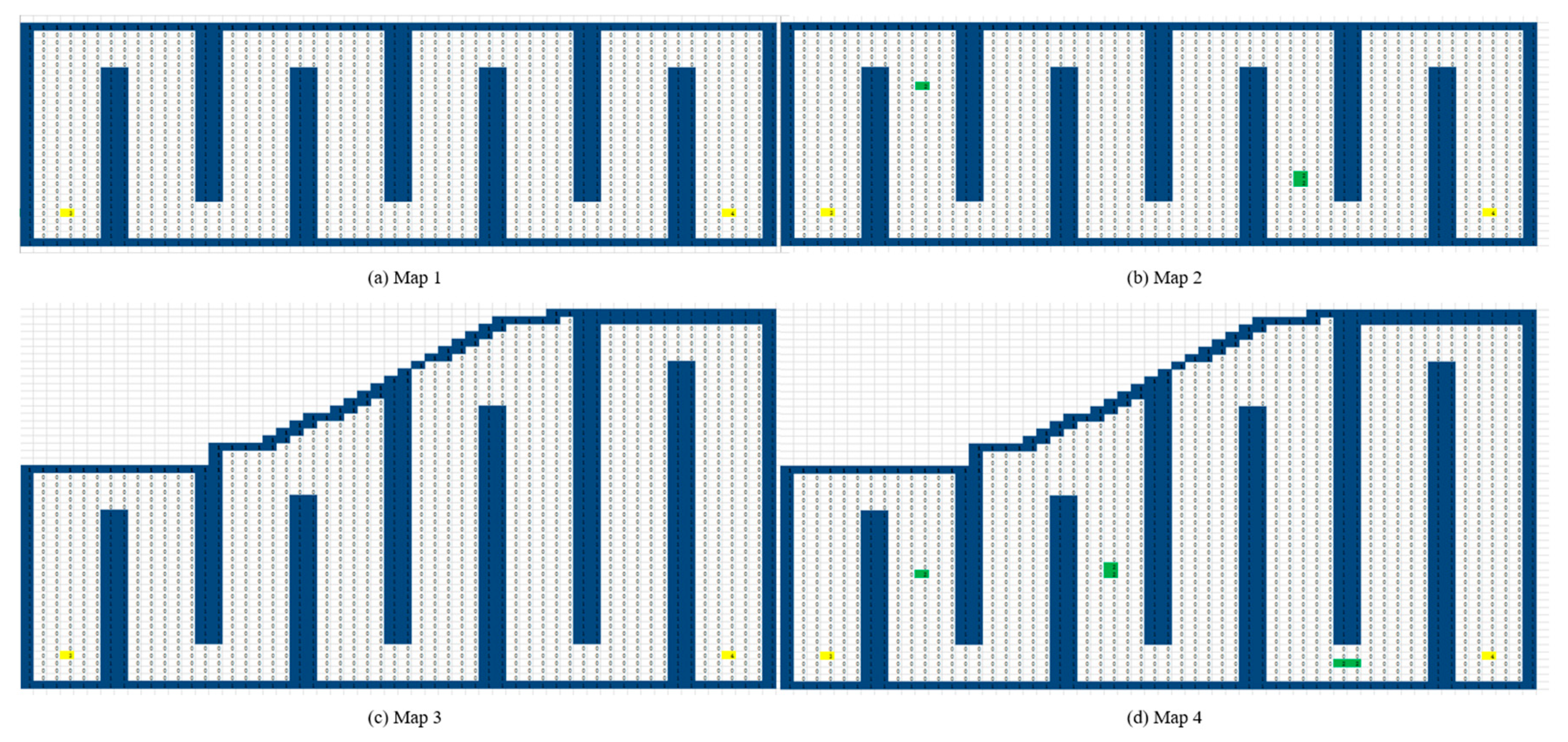

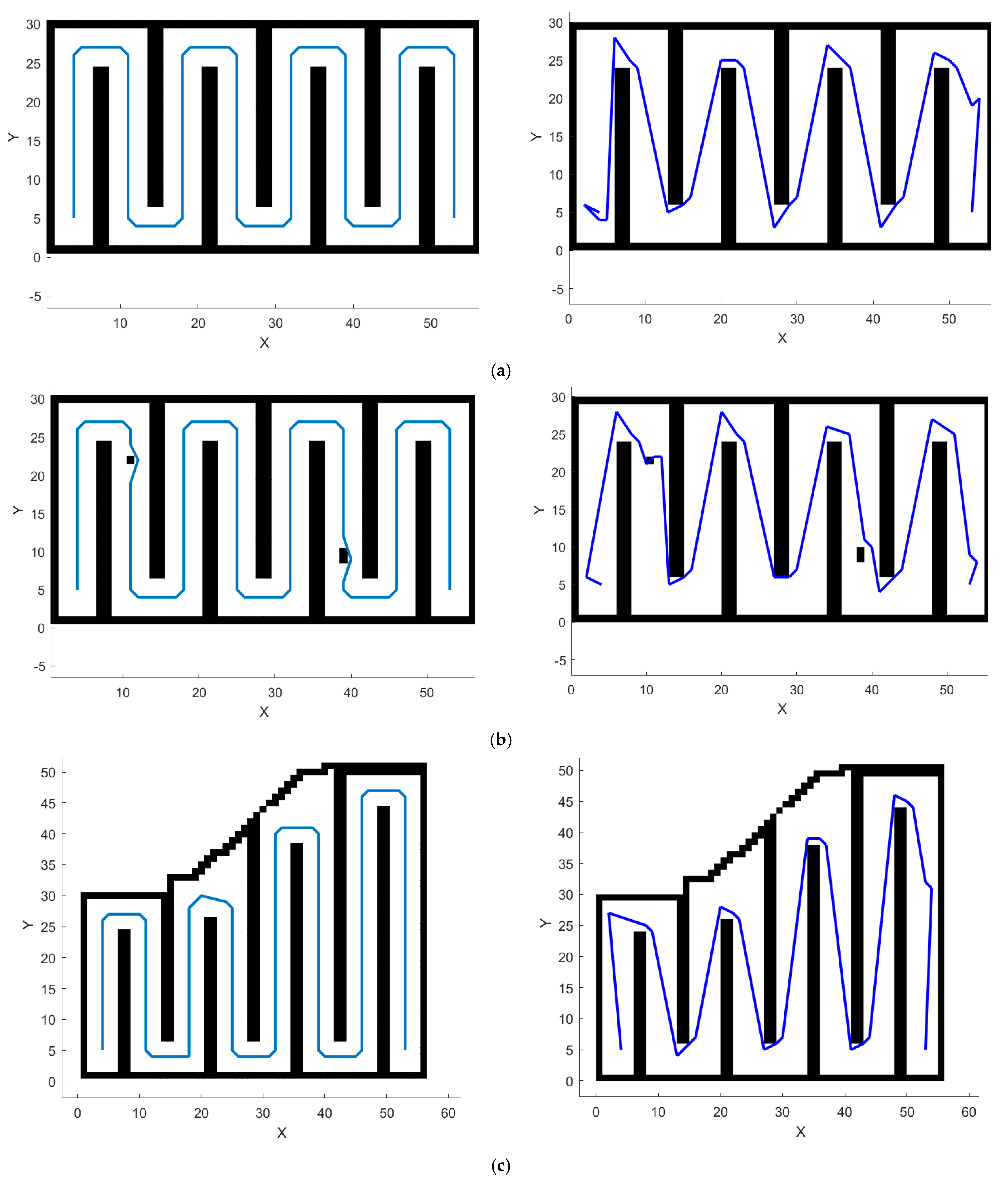

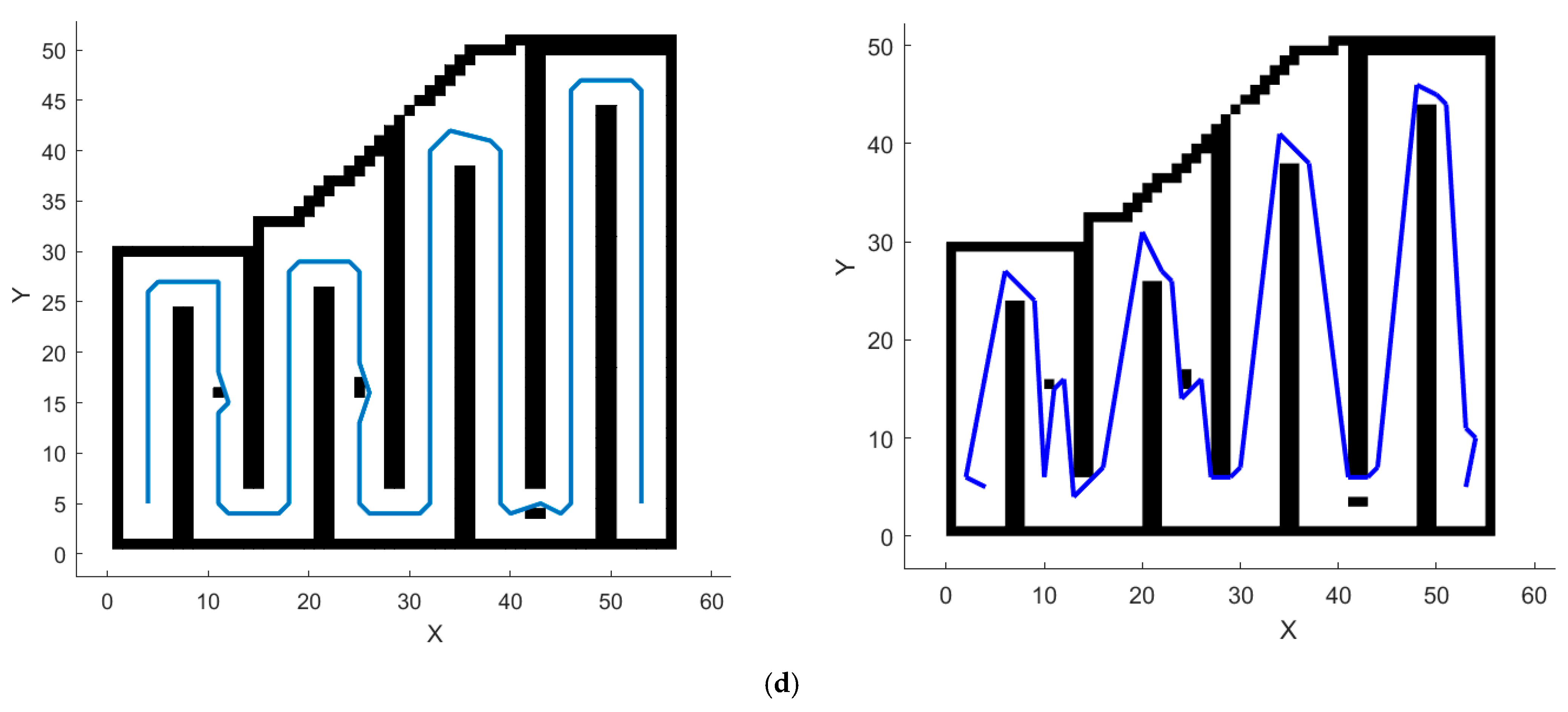

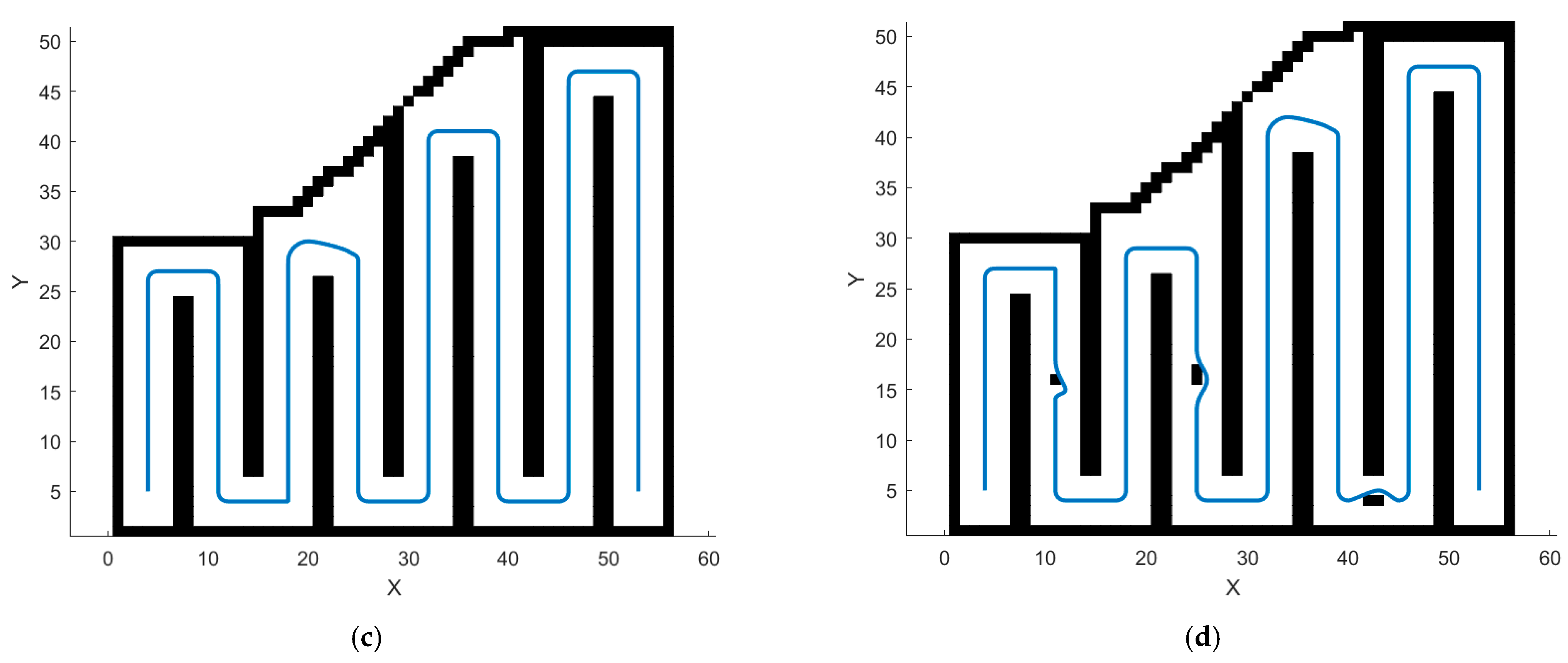

4. Simulation and Analysis

5. Conclusions

- (1)

- Improved bidirectional A* algorithm: considers the effect of weights in the integrated priority function of the A* algorithm and changes the unidirectional search of the traditional A* algorithm to a bidirectional search, which reduces the number of search nodes and improves the search speed.

- (2)

- Improved differential evolution genetic algorithm: the method of differential evolution is used to replace the cross mutation of the genetic algorithm, which improves the algorithm’s ability to explore the solution space and the algorithm’s global search ability, and avoids the problem of falling into the local optimal solution. The fitness function of the genetic algorithm is improved by adding the tree row center offset factor, the smoothing factor, and the safety coefficient, and the weighting method is used to transform the multi-objective optimization into single-objective realization.

- (3)

- Improved bidirectional A* and improved differential evolution genetic hybrid algorithm: the path planned by the improved bidirectional search A* algorithm is used as the initial population of the differential evolution genetic algorithm, iterative optimization obtains the path trajectory curve, and the three-times B-spline curve is used to smooth the curve, obtaining the optimal path that is smooth and satisfies the constraints.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, B. Optimization design of the waist-steering mechanism based on the interior point method. J. Chin. Agric. Mech. 2020, 41, 116–122. [Google Scholar]

- Yue, C.; Huang, J.; Deng, L. Research on improved ant colony algorithm in AGV path planning. Comput. Eng. Des. 2022, 43, 2533–2541. [Google Scholar]

- Shen, Y.; Liu, Z.; Liu, H.; Du, W. Orchard Spray Robot Planning Algorithm Based on Multiple Constraints. Trans. Chin. Soc. Agric. Mach. 2023, 54, 56–67. [Google Scholar]

- Shi, W.; Ning, N.; Song, C.; Ning, W. Path Planning of Mobile Robots Based on Ant Colony Algorithm and Artificial Potential Field Algorithm. Trans. Chin. Soc. Agric. Mach. 2023, 54, 407–416. [Google Scholar]

- Liu, H.; Zhang, Y. ASL-DWA: An Improved A-Star Algorithm for Indoor Cleaning Robots. IEEE Access 2022, 10, 99498–99515. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, J.; Shen, X.; Li, Y. Autonomous land vehicle path planning algorithm based on improved heuristic function of A-Star. Int. J. Adv. Robot. Syst. 2021, 18, 1–10. [Google Scholar] [CrossRef]

- Huang, C.; Ji, F.; Liu, Y.; Li, H.; Liu, X. Smooth Path Planning Method Based on Dynamic Feedback A* Ant Colony Algorithm. Trans. Chin. Soc. Agric. Mach. 2017, 48, 34–40+102. [Google Scholar]

- Wang, H.; Zhao, X.; Yuan, X. Robot path planning based on improved adaptive Genetic Algorithm. Electron. Opt. Control 2022, 29, 72–76. [Google Scholar]

- Ab Wahab, M.N.; Nazir, A.; Khalil, A.; Ho, W.J.; Akbar, M.F.; Noor, M.H.M.; Mohamed, A.S.A. Improved genetic algorithm for mobile robot path planning in static environments. Expert Syst. Appl. 2024, 249, 123762. [Google Scholar] [CrossRef]

- Liang, C. Application of ant Colony Genetic Algorithm to Pathplanning of Substation Inspection Robot. Master’s Thesis, East China Jiaotong University, Nanchang, China, 2023. [Google Scholar]

- Shi, K.; Huang, L.; Jiang, D.; Sun, Y.; Tong, X.; Xie, Y.; Fang, Z. Path planning optimization of intelligent vehicle based on improved genetic and ant colony hybrid algorithm. Front. Bioeng. Biotechnol. 2022, 10, 905983. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, J.; Chen, Z.; Xiong, G.; Liu, S. A robot path planning method based on improved genetic algorithm and improved dynamic window approach. Sustainability 2023, 15, 4656. [Google Scholar] [CrossRef]

- Wang, Q.; He, J.; Lu, C.; Wang, C.; Lin, H.; Yang, H.; Li, H.; Wu, Z. Modelling and control methods in path tracking control for autonomous agricultural vehicles: A review of state of the art and challenges. Appl. Sci. 2023, 13, 7155. [Google Scholar] [CrossRef]

- Viadero-Monasterio, F.; Nguyen, A.T.; Lauber, J.; Boada, M.J.L.; Boada, B.L. Event-triggered robust path tracking control considering roll stability under network-induced delays for autonomous vehicles. IEEE Trans. Intell. Transp. Syst. 2023, 24, 14743–14756. [Google Scholar] [CrossRef]

- He, J.; Hu, L.; Wang, P.; Liu, Y.; Man, Z.; Tu, T.; Yang, L.; Li, Y.; Yi, Y.; Li, W.; et al. Path tracking control method and performance test based on agricultural machinery pose correction. Comput. Electron. Agric. 2022, 200, 107185. [Google Scholar] [CrossRef]

- Chen, J.; Niao, C.; Zhu, Z. Study on Automatic Guidance for Tractor on Grassland. Trans. Chin. Soc. Agric. Mach. 2005, 36, 104–107. [Google Scholar]

- Zhang, Q.; Zhou, B.; Zhao, J.; You, Y.; Wang, D.C. An Adaptive Parametric Model Predictive Path Tracking Control Method for Articulated Steering Tractor. Beijing CN115373287A, 22 November 2022. [Google Scholar]

- Liu, W.L. Research on Multi-Robot Motion Planning for Nonholonomic Kinematic Constraint Mobile Robots. Master’s Thesis, Zhejiang University, Hangzhou, China, 2023. [Google Scholar]

- Cao, R.; Zhang, Z.; Li, S.; Zhang, M.; Li, H.; Li, M. Multi-machine Cooperation Global Path Planning Based on A-star Algorithm and Bezier Curve. Trans. Chin. Soc. Agric. Mach. 2021, 52, 548–554. [Google Scholar]

- Ye, X.; Zhong, H.; Deng, K. A Path Planning Method of Indoor Navigation Based on lmproved A-Star Algorithm. Comput. Technol. Dev. 2022, 32, 202–206. [Google Scholar]

- Hu, Y.; Yang, S. A knowledge based genetic algorithm for path planning of a mobile robot. In Proceedings of the IEEE International Conference on Robotics and Automation, 2004. Proceedings. ICRA’04. 2004, New Orleans, LA, USA, 26 April–1 May 2004; IEEE: Piscataway, NJ, USA, 2004; Volume 5, pp. 4350–4355. [Google Scholar]

- Zhan, W.; Li, Y. Summary of Related Research on Path Planning Based on lmproved Genetic Algorithm. Comput. Digit. Eng. 2023, 51, 1544–1550. [Google Scholar]

- Kumar, R.; Kumar, M. Exploring genetic algorithm for shortest path optimization in data networks. Glob. J. Comput. Sci. Technol. 2010, 10, 8–12. [Google Scholar]

- Liu, X. Research on Logistics Delivery Path Optimization Based on Improved Genetic Algorithm. Master’s Thesis, Changchun University of Technology, Changchun, China, 2024. [Google Scholar]

- Qiu, L. Research on Vehicle Routing Problem Based on Improved Genetic Algorithm. In Proceedings of the 2019 Chinese Automation Congress (CAC), Hangzhou, China, 22–24 November 2019; IEEE: Piscataway, NJ, USA, 2024. [Google Scholar]

- Wang, H.; Yin, P.; Zheng, W.; Wang, H.; Zuo, J. Mobile Robot Path Planning Based on lmproved A* Algorithm and Dynamic Window Method. Robot 2020, 42, 346–353. [Google Scholar]

- Li, J. Research on Path Planning of Mobile RobotBased on Improved A * Algorithm. Master’s Thesis, Jianghan University, Wuhan, China, 2024. [Google Scholar]

- Zhang, H.; Tao, Y.; Zhu, W. Global Path Planning of Unmanned Surface Vehicle Based on Improved A-Star Algorithm. Sensors 2023, 23, 6647. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, X.; Tian, Q.; Sun, A.; Zhang, X.; Yuan, L. Mobile Robot Path Planning Based on lmproved Fuzzy Adaptive Genetic Algorithm. Mach. Tool Hydraul. 2021, 49, 18–23. [Google Scholar]

- Li, Y.; Huang, Z.; Xie, Y. Path planning of mobile robot based on improved genetic algorithm. In Proceedings of the 2020 3rd International Conference on Electron Device and Mechanical Engineering (ICEDME), Suzhou, China, 1–3 May 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 691–695. [Google Scholar]

- Zhao, P.; Ding, X.; Cheng, T.; Mo, X. Improved Genetic Algorithm for UUV Path Planning Based on Differential Evolution Algorithm. Autom. Appl. 2024, 65, 25–28. [Google Scholar]

- Xing, N.; Di, H.; Yin, W.; Han, Y.; Zhou, Y. Path planning for agents based on adaptive polymorphic ant colony optimization. J. Beijing Univ. Aeronaut. Astronaut. 2023, 1–12. [Google Scholar] [CrossRef]

| Basic Parameters | Data | Traditional Genetic Algorithm | Data | Differential Evolution Genetic Algorithm | Data |

|---|---|---|---|---|---|

| Initial population size | 50 | Multipoint crossover probability | 0.9 | Number of iterations of differential evolution | 10 |

| Maximum number of iterations | 50 | Single-point crossover probability | 0.1 |

| Serial Number | Algorithms | Path Lengths | Number of Iterative Convergence Curves |

|---|---|---|---|

| 1 | AGADE | 222.8 | 2 |

| GA | 171.0 | 28 | |

| 2 | AGADE | 223.5 | 11 |

| GA | 169.9 | 31 | |

| 3 | AGADE | 295.9 | 6 |

| GA | 243.6 | 12 | |

| 4 | AGADE | 297.2 | 5 |

| GA | 241.8 | 24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, N.; Li, Z.; Guo, N.; Wang, T.; Li, A.; Song, Y. Global Path Planning for Articulated Steering Tractor Based on Multi-Objective Hybrid Algorithm. Sensors 2024, 24, 4832. https://doi.org/10.3390/s24154832

Xu N, Li Z, Guo N, Wang T, Li A, Song Y. Global Path Planning for Articulated Steering Tractor Based on Multi-Objective Hybrid Algorithm. Sensors. 2024; 24(15):4832. https://doi.org/10.3390/s24154832

Chicago/Turabian StyleXu, Ning, Zhihe Li, Na Guo, Te Wang, Aijuan Li, and Yumin Song. 2024. "Global Path Planning for Articulated Steering Tractor Based on Multi-Objective Hybrid Algorithm" Sensors 24, no. 15: 4832. https://doi.org/10.3390/s24154832