High-Sensitivity Differential Sensor for Characterizing Complex Permittivity of Liquids Based on LC Resonators

Abstract

:1. Introduction

2. Sensor Structure, Operation, and Design

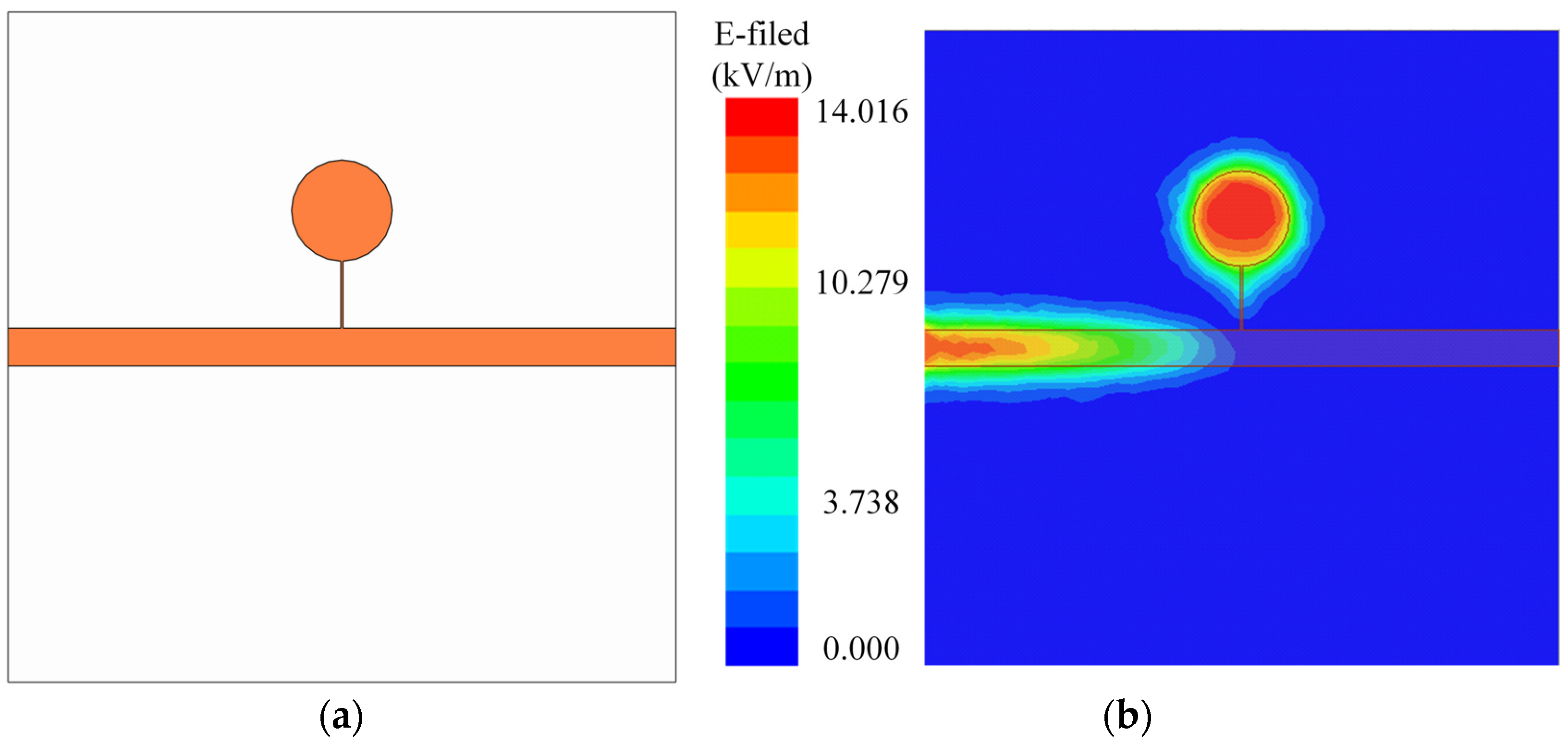

2.1. Sensor Structure

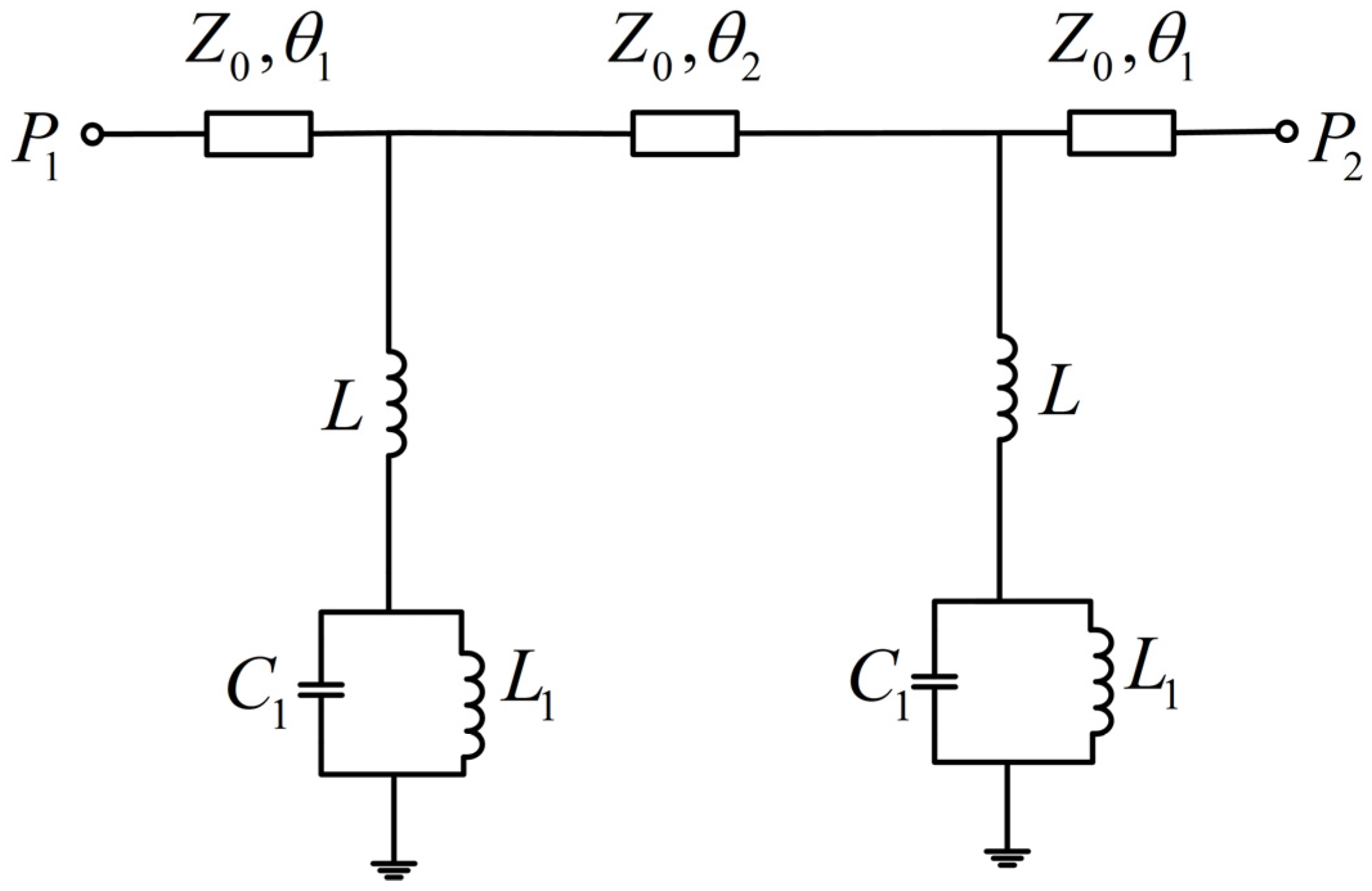

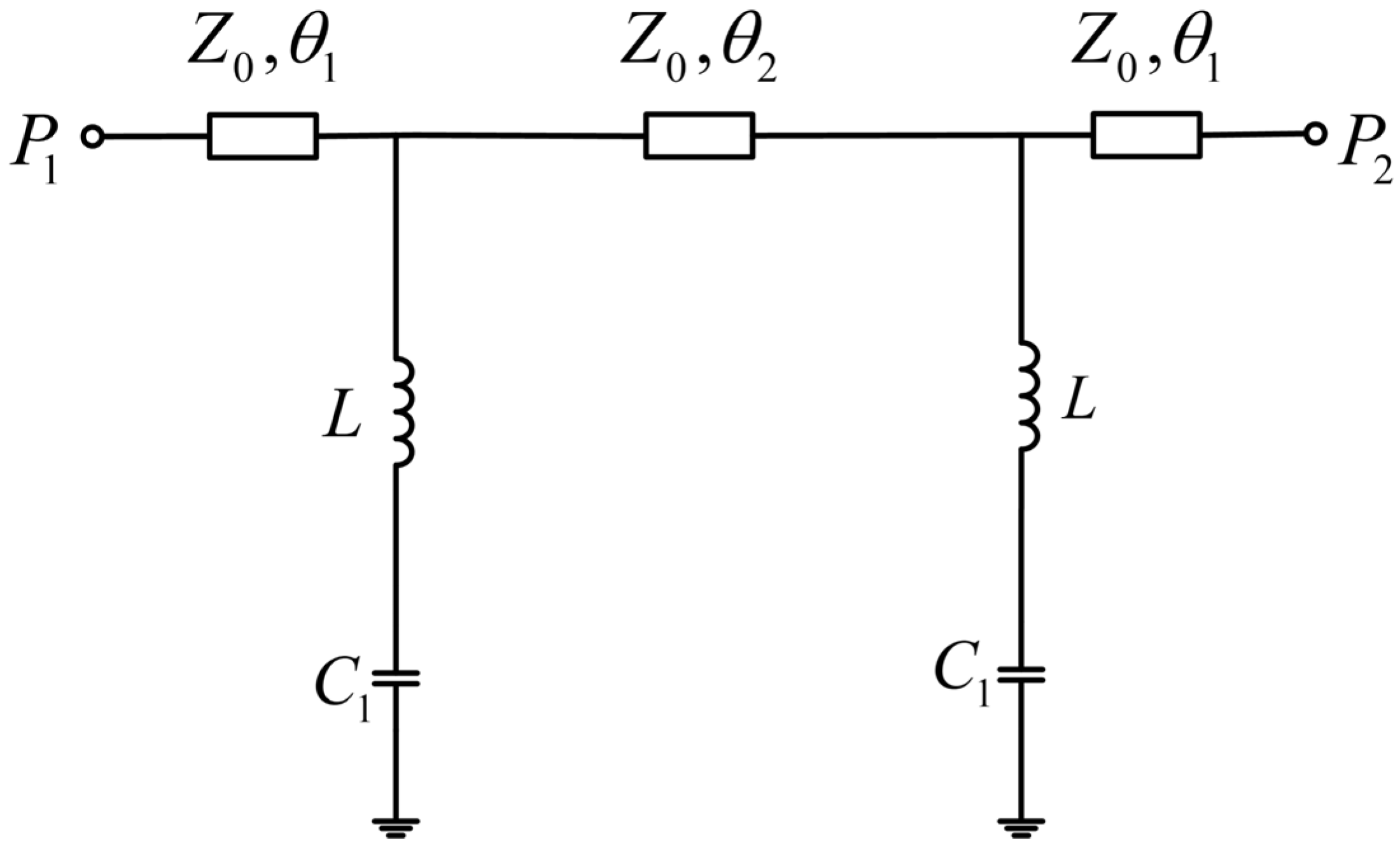

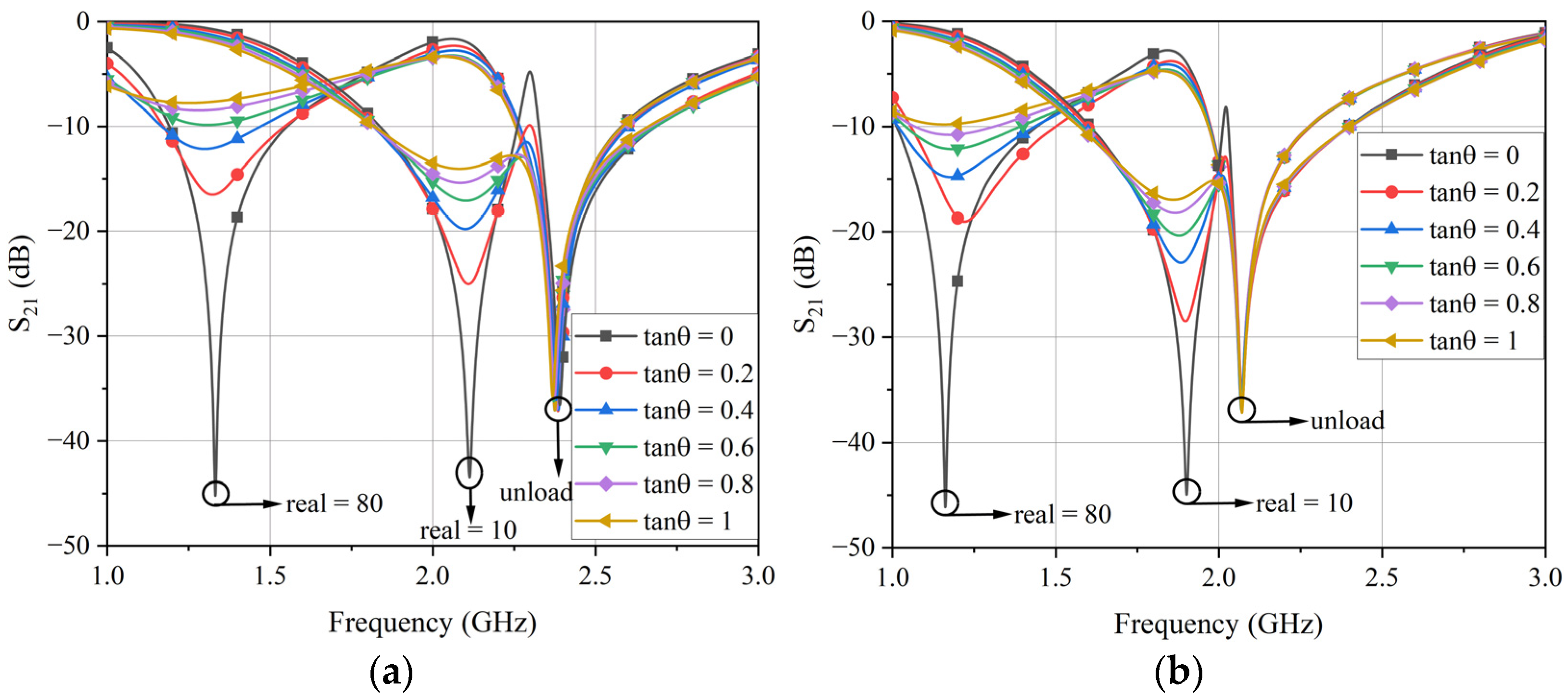

2.2. Operating Principle

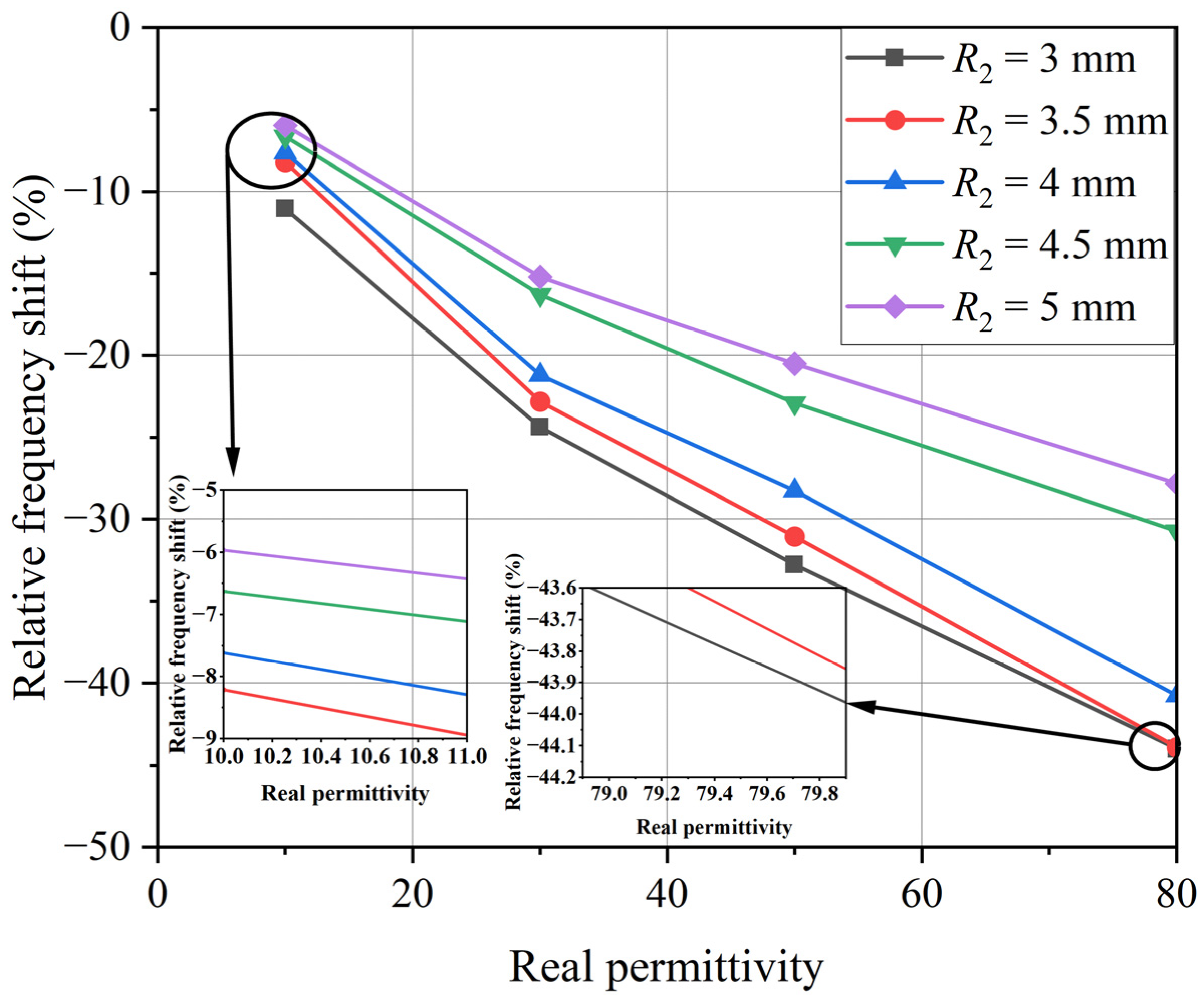

2.3. Design of the Sensor

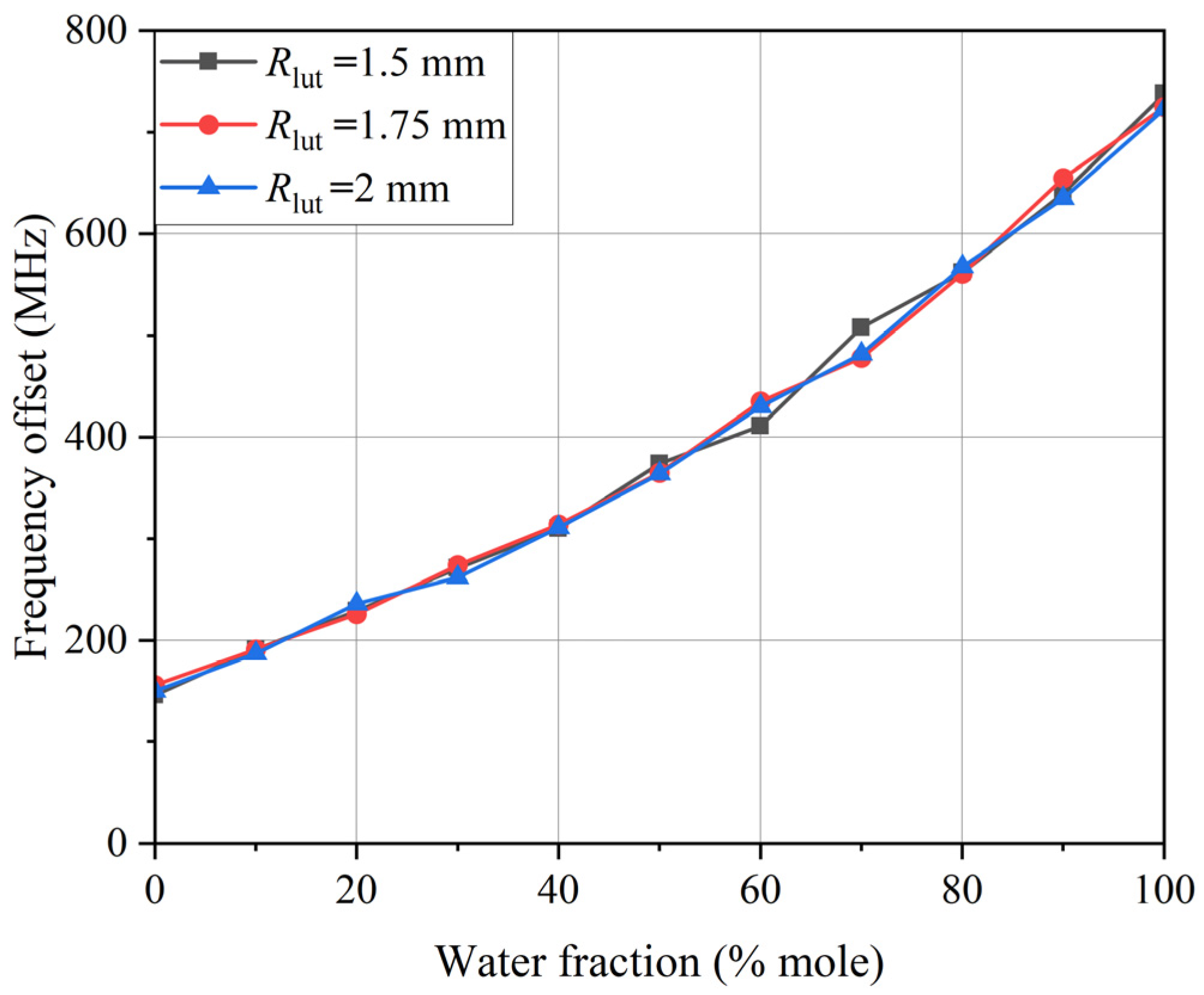

2.4. Influence of the Test Liquid Shape

3. Measurement and Results

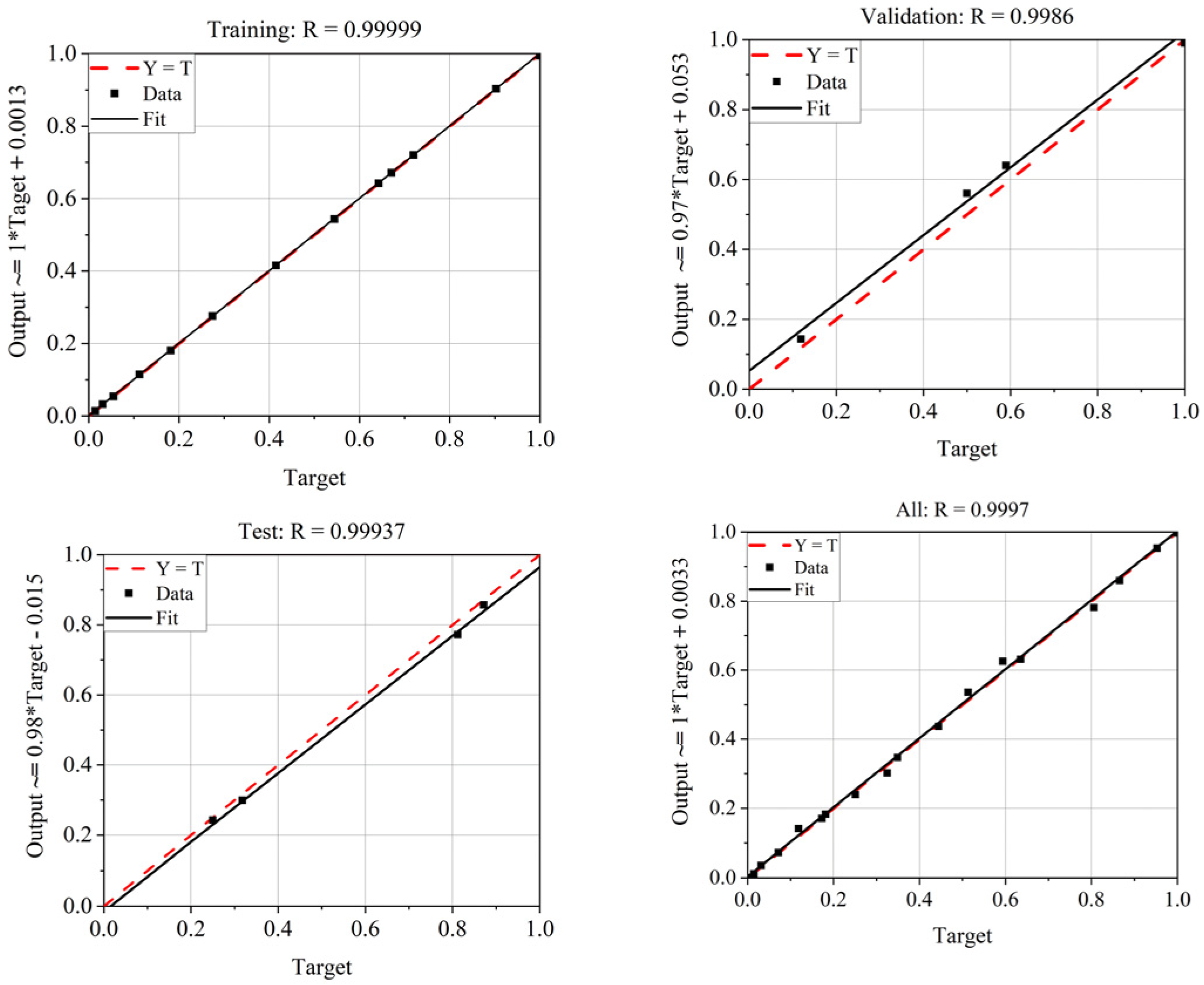

3.1. Sensor Calibration

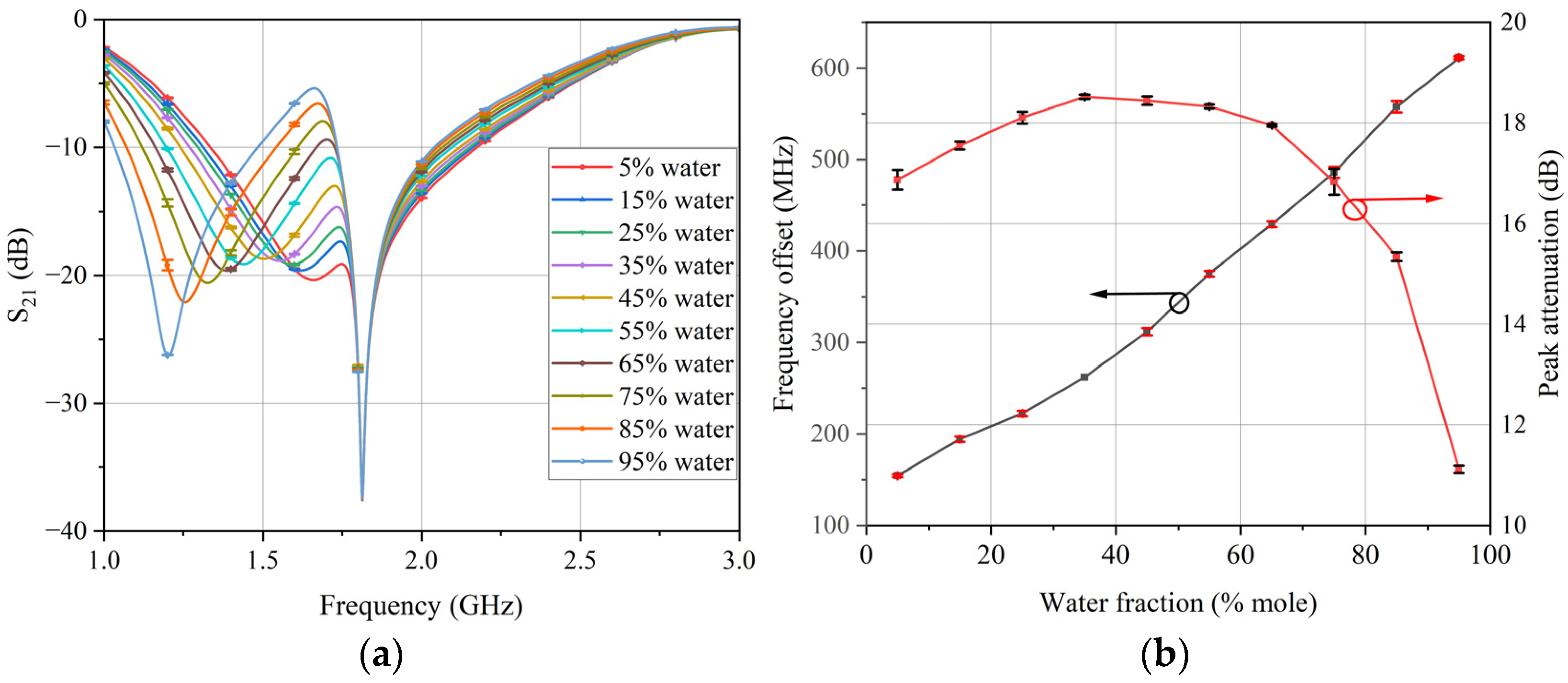

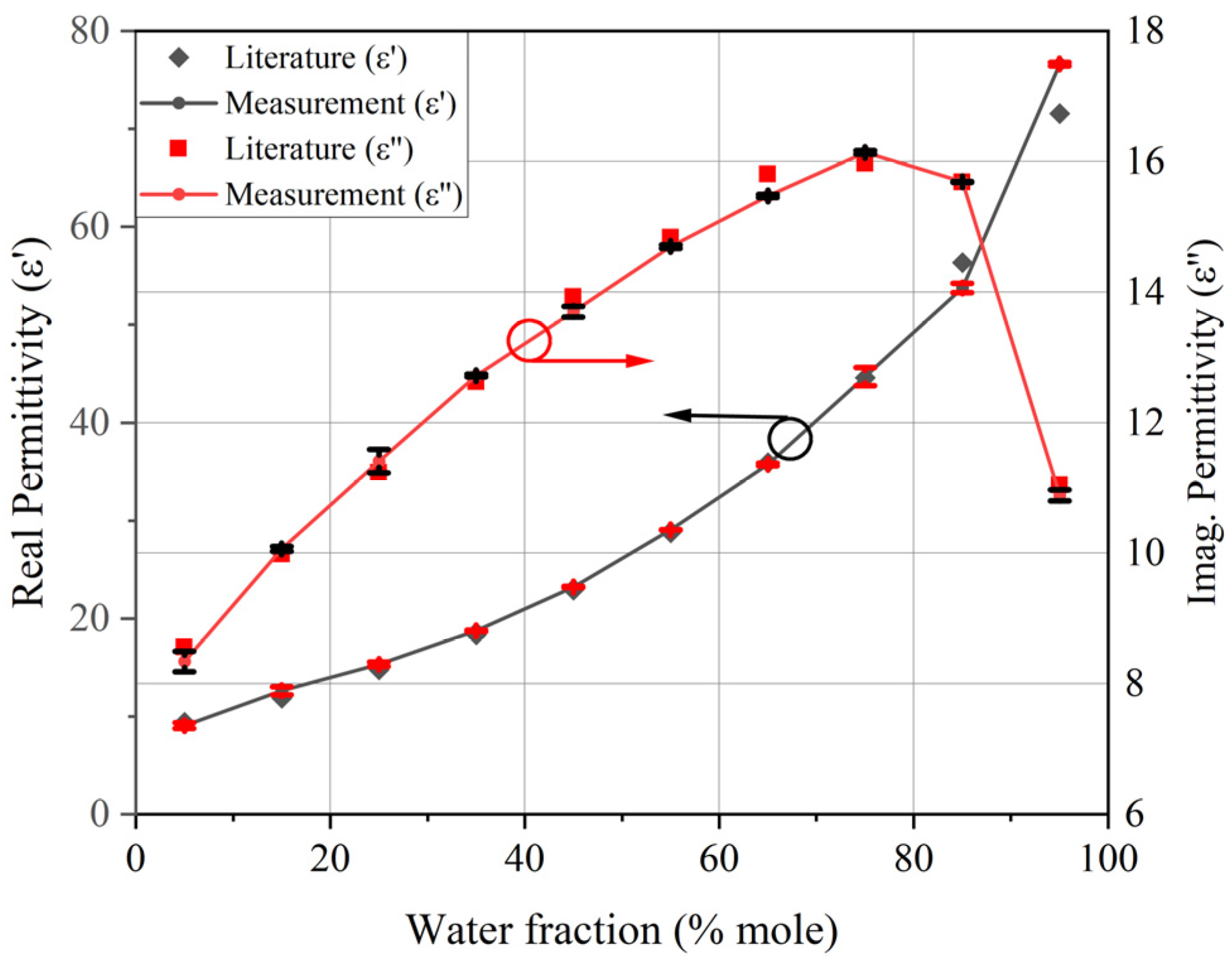

3.2. Sensor Performance Validation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mosavirik, T.; Soleimani, M.; Nayyeri, V.; Mirjahanmardi, S.H. Permittivity characterization of dispersive materials using power measurements. IEEE Trans. Instrum. Meas. 2021, 70, 1–8. [Google Scholar] [CrossRef]

- Shaji, M.; Akhtar, M.J. Microwave coplanar sensor system for detecting contamination in food products. In Proceedings of the IEEE MTT-S International Microwave and RF Conference, New Delhi, India, 14–16 December 2013. [Google Scholar]

- Torrealba-Meléndez, R.; Sosa-Morales, M.E.; Olvera-Cervantes, J.L.; Corona-Chávez, A. Dielectric properties of beans at ultra-wide band frequencies. J. Microw. Power Electromagn. Energy 2014, 48, 104–112. [Google Scholar] [CrossRef]

- Ismail, R.; Dahim, M.; Jaradat, A.; Hatamlet, R.; Telfah, D.; Abuaddous, M.; Al-Mattarneh, H. Field Dielectric Sensor for Soil Pollution Application. In IOP Conference Series: Earth and Environmental Science, Proceedings of the 2021 11th International Conference on Future Environment and Energy, Tokyo, Japan, 28–30 January 2021; IOP Publishing Ltd.: Bristol, UK, 2021. [Google Scholar]

- Kiani, S.; Rezaei, P.; Fakhr, M. Dual-frequency microwave resonant sensor to detect noninvasive glucose-level changes through the fingertip. IEEE Trans. Instrum. Meas. 2021, 70, 1–8. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Tovar-Lopez, F.J.; Scott, J.; Ghorbani, K. Differential microwave sensor for characterization of glycerol–water solutions. Sens. Actuators B Chem. 2020, 321, 128561. [Google Scholar] [CrossRef]

- Kazemi, N.; Abdolrazzaghi, M.; Musilek, P.; Daneshmand, M. A temperature-compensated high-resolution microwave sensor using artificial neural network. IEEE Microw. Wirel. Compon. Lett. 2020, 30, 919–922. [Google Scholar] [CrossRef]

- Varshney, P.K.; Akhtar, M.J. Permittivity estimation of dielectric substrate materials via enhanced SIW sensor. IEEE Sens. J. 2021, 21, 12104–12112. [Google Scholar] [CrossRef]

- Chen, Z.; Lin, X.Q.; Yan, Y.H.; Xiao, F.; Khan, M.T.; Zhang, S. Noncontact group-delay-based sensor for metal deformation and crack detection. IEEE Trans. Ind. Electron. 2020, 68, 7613–7619. [Google Scholar] [CrossRef]

- Valantina, S.R. Measurement of dielectric constant: A recent trend in quality analysis of vegetable oil—A review. Trends Food Sci. Technol. 2021, 113, 1–11. [Google Scholar] [CrossRef]

- Nelson, S.O.; Trabelsi, S. Dielectric spectroscopy measurements on fruit, meat, and grain. Trans. ASABE 2008, 51, 1829–1834. [Google Scholar] [CrossRef]

- Gan, H.Y.; Zhao, W.S.; Liu, Q.; Wang, D.W.; Dong, L.; Wang, G.; Yin, W.Y. Differential microwave microfluidic sensor based on microstrip complementary split-ring resonator (MCSRR) structure. IEEE Sens. J. 2020, 20, 5876–5884. [Google Scholar] [CrossRef]

- Rocco, G.M.; Bozzi, M.; Schreurs, D.; Perregrini, L.; Marconi, S.; Alaimo, G.; Auricchio, F. 3-D printed microfluidic sensor in SIW technology for liquids’ characterization. IEEE Trans. Microw. Theory Tech. 2019, 68, 1175–1184. [Google Scholar] [CrossRef]

- Song, X.; Yan, S. A miniaturized SIW circular cavity resonator for microfluidic sensing applications. Sens. Actuators A Phys. 2020, 313, 112183. [Google Scholar] [CrossRef]

- Allah, A.H.; Eyebe, G.A.; Domingue, F. Fully 3D-printed microfluidic sensor using substrate integrated waveguide technology for liquid permittivity characterization. IEEE Sens. J. 2022, 22, 10541–10550. [Google Scholar] [CrossRef]

- Mohammadi, P.; Mohammadi, A.; Kara, A. T-junction loaded with interdigital capacitor for differential measurement of permittivity. IEEE Trans. Instrum. Meas. 2022, 71, 1–8. [Google Scholar] [CrossRef]

- Chuma, E.L.; Iano, Y.; Fontgalland, G.; Roger, L.L.B. Microwave sensor for liquid dielectric characterization based on metamaterial complementary split ring resonator. IEEE Sens. J. 2018, 18, 9978–9983. [Google Scholar] [CrossRef]

- Vélez, P.; Muñoz-Enano, J.; Grenier, K.; Mata-Contreras, J.; Dubuc, D.; Martín, F. Split ring resonator-based microwave fluidic sensors for electrolyte concentration measurements. IEEE Sens. J. 2018, 19, 2562–2569. [Google Scholar] [CrossRef]

- Han, X.; Liu, K.; Zhang, S.; Peng, P.; Fu, C.; Qiao, L.; Ma, Z. CSRR Metamaterial Microwave Sensor for Measuring Dielectric Constants of Solids and Liquids. IEEE Sens. J. 2024, 24, 14167–14176. [Google Scholar] [CrossRef]

- Alharbi, F.T.; Haq, M.; Udpa, L.; Deng, Y. Magnetodielectric material characterization using stepped impedance resonators. IEEE Sens. J. 2022, 23, 2093–2104. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Withayachumnankul, W.; Al-Sarawi, S.; Abbott, D. High-sensitivity metamaterial-inspired sensor for microfluidic dielectric characterization. IEEE Sens. J. 2013, 14, 1345–1351. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Scott, J.; Ghorbani, K. Ultrahigh-sensitivity microwave sensor for microfluidic complex permittivity measurement. IEEE Trans. Microw. Theory Tech. 2019, 67, 4269–4277. [Google Scholar] [CrossRef]

- Al-Behadili, A.A.; Mocanu, I.A.; Petrescu, T.M.; Elwi, T.A. Differential microstrip sensor for complex permittivity characterization of organic fluid mixtures. Sensors 2021, 21, 7865. [Google Scholar] [CrossRef] [PubMed]

- Vélez, P.; Muñoz-Enano, J.; Gil, M.; Mata-Contreras, J.; Martín, F. Differential microfluidic sensors based on dumbbell-shaped defect ground structures in microstrip technology: Analysis, optimization, and applications. Sensors 2019, 19, 3189. [Google Scholar] [CrossRef] [PubMed]

- Naqui, J.; Damm, C.; Wiens, A.; Jakoby, R.; Su, L.; Mata-Contreras, J.; Martin, F. Transmission lines loaded with pairs of stepped impedance resonators: Modeling and application to differential permittivity measurements. IEEE Trans. Microw. Theory Tech. 2016, 64, 3864–3877. [Google Scholar] [CrossRef]

- Naqui, J.; Durán-Sindreu, M.; Bonache, J.; Martín, F. Implementation of shunt-connected series resonators through stepped-impedance shunt stubs: Analysis and limitations. IET Microw. Antennas Propag. 2011, 5, 1336–1342. [Google Scholar] [CrossRef]

- Palandoken, M.; Gocen, C.; Khan, T.; Zakaria, Z.; Elfergani, I.; Zebiri, C.; Rodriguez, J.; Abd-Alhameed, R.A. Novel microwave fluid sensor for complex dielectric parameter measurement of ethanol–water solution. IEEE Sens. J. 2023, 23, 14074–14083. [Google Scholar] [CrossRef]

- Sato, T.; Chiba, A.; Nozaki, R. Dynamical aspects of mixing schemes in ethanol–water mixtures in terms of the excess partial molar activation free energy, enthalpy, and entropy of the dielectric relaxation process. J. Chem. Phys. 1999, 110, 2508–2521. [Google Scholar] [CrossRef]

- Chong, C.; Hong, T.; Huang, K. Design of the Complex Permittivity Measurement System Based on the Waveguide Six-Port Reflectometer. IEEE Trans. Instrum. Meas. 2022, 71, 6002812. [Google Scholar] [CrossRef]

- Liu, C.; Tong, F. An SIW Resonator Sensor for Liquid Permittivity Measurements at C Band. IEEE Microw. Wirel. Compon. Lett. 2015, 25, 751–753. [Google Scholar]

- Ding, S.; Su, C.; Yu, J. An optimizing BP neural network algorithm based on genetic algorithm. Artif. Intell. Rev. 2011, 36, 153–162. [Google Scholar] [CrossRef]

- Tang, R.; Zhang, R.; Xu, Y.; Yuen, C. Deep reinforcement learning-based resource allocation for multi-UAV-assisted full-duplex wireless-powered IoT networks. IEEE Trans. Cogn. Commun. Netw. 2024; early access. [Google Scholar] [CrossRef]

- Tang, R.; Zhang, R.; Xu, Y.; He, J. Energy-efficient optimization algorithm in NOMA-based UAV-assisted data collection systems. IEEE Wirel. Commun. Lett. 2023, 12, 158–162. [Google Scholar] [CrossRef]

| Water Molar Fractions/% | ||

|---|---|---|

| 0 | 8.12 | 7.92 |

| 10 | 10.49 | 9.32 |

| 20 | 13.08 | 10.70 |

| 30 | 16.46 | 12.00 |

| 40 | 20.33 | 13.09 |

| 50 | 25.89 | 14.52 |

| 60 | 31.49 | 15.04 |

| 70 | 39.55 | 15.69 |

| 80 | 50.01 | 16.08 |

| 90 | 63.11 | 14.08 |

| 100 | 79.57 | 7.83 |

| Ref. | Type of Liquid | f0 (GHz) | Range | Sav (%) | Differential |

|---|---|---|---|---|---|

| [6] | Glycerol–water | 2.3 | 8.22–79.5 | 0.389 | Yes |

| [12] | Ethanol–water | 1.618 | 4–78 | 0.626 | Yes |

| [14] | Ethanol–water | 2.61 | 8–77.2 | 0.215 | No |

| [15] | Ethanol–water | 3.98 | 5.46–67.2 | 0.345 | No |

| [17] | Ethanol–water | 2.364 | 9–79 | 0.049 | No |

| [19] | Ethanol–water | 2.44 | 9.02–77.3 | 0.78 | No |

| [21] | Ethanol–water | 2 | 7.55–80.8 | 0.318 | No |

| [22] | Ethanol–water | 1.91 | 10.47–78 | 0.578 | No |

| [23] | Urine–water | 1.25 | 66–74 | 0.279 | Yes |

| [24] | Isopropanol–water | 1.05 | 8.4–80 | 0.059 | Yes |

| This work | Ethanol–water | 1.811 | 8.12–79.57 | 0.76 | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Tian, S.; Tang, J.; Yang, W.; Hong, T.; Zhu, H. High-Sensitivity Differential Sensor for Characterizing Complex Permittivity of Liquids Based on LC Resonators. Sensors 2024, 24, 4877. https://doi.org/10.3390/s24154877

Li Z, Tian S, Tang J, Yang W, Hong T, Zhu H. High-Sensitivity Differential Sensor for Characterizing Complex Permittivity of Liquids Based on LC Resonators. Sensors. 2024; 24(15):4877. https://doi.org/10.3390/s24154877

Chicago/Turabian StyleLi, Zhongjun, Shuang Tian, Jiaxin Tang, Weichao Yang, Tao Hong, and Huacheng Zhu. 2024. "High-Sensitivity Differential Sensor for Characterizing Complex Permittivity of Liquids Based on LC Resonators" Sensors 24, no. 15: 4877. https://doi.org/10.3390/s24154877