A Review of Digital Twinning for Rotating Machinery

Abstract

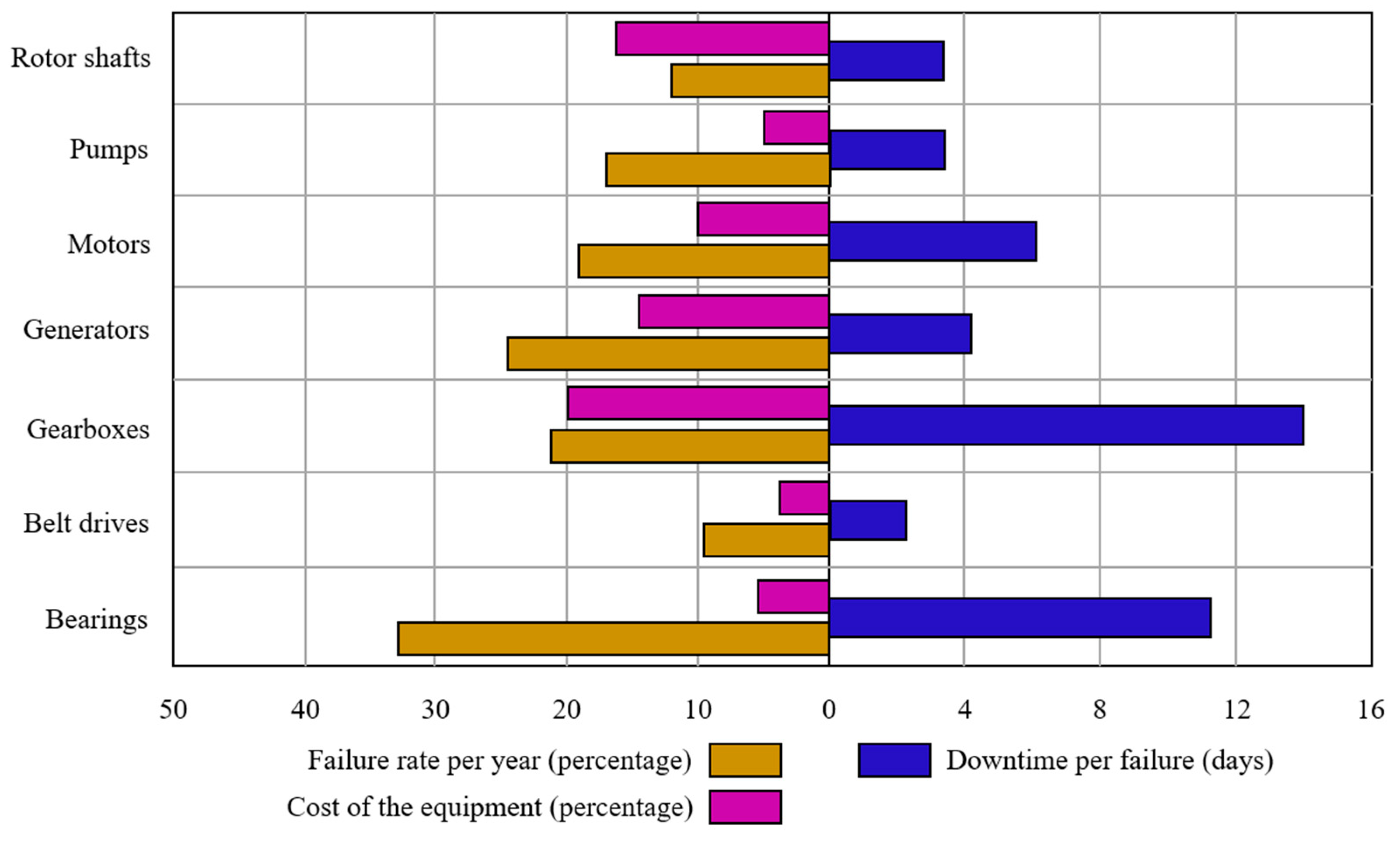

:1. Introduction

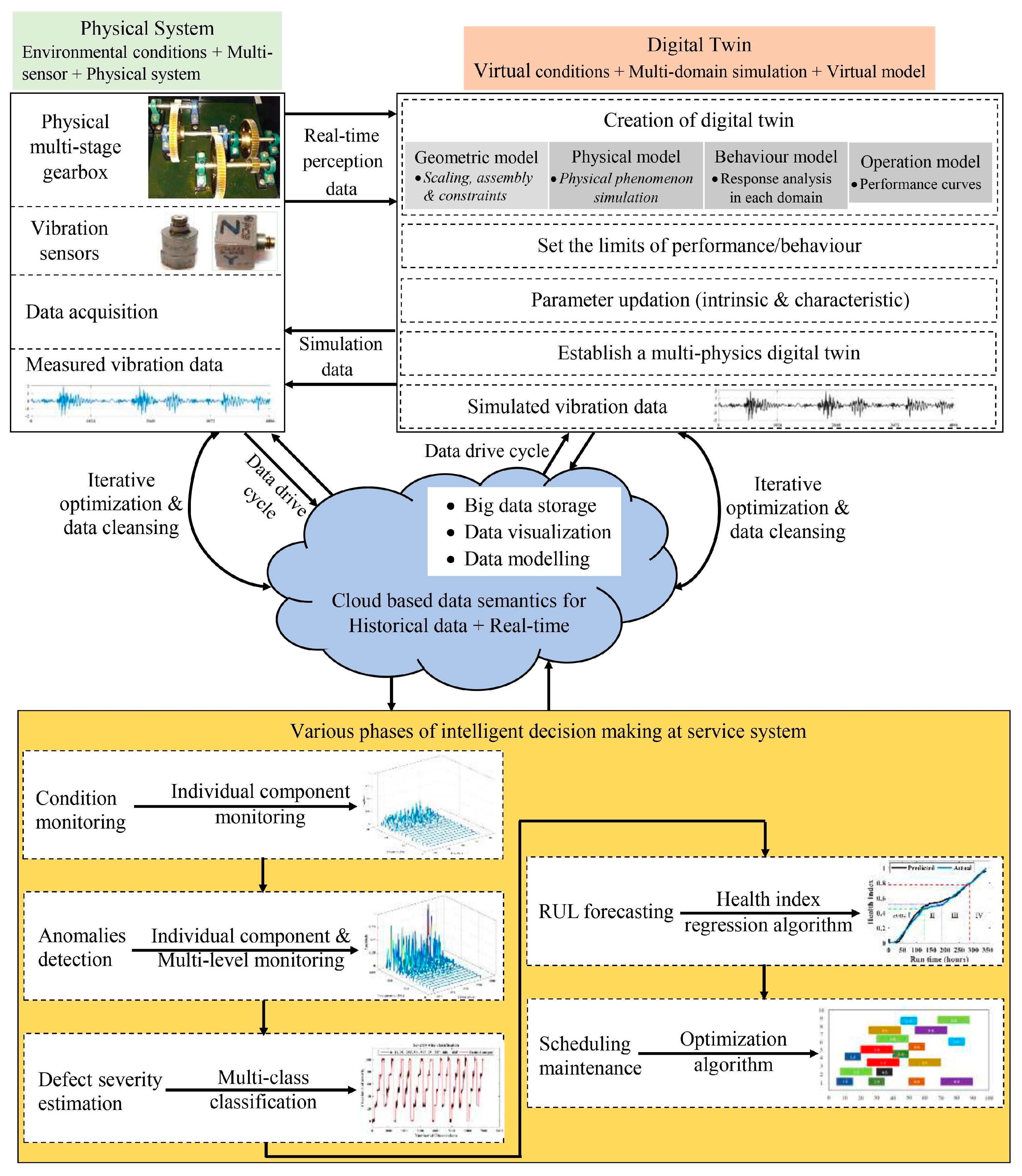

2. Digital Twin

2.1. Definition and Viewpoints of Digital Twins

| Scenarios | Viewpoints | Ref. |

|---|---|---|

| Design | Realize system reconfiguration and redevelopment and improve research and development efficiencies | [48] |

| Production | Realize the autonomy of systems’ production processes and visualization, make the process flexible, enable quality assurance, and improve efficiency | [59,60] |

| Operation | Monitor the system’s installation and system usage, enhance the control of the system, and realize optimal operation | [61,62] |

| Maintenance | Monitor the current state of the system, the configuration of data, fault diagnostics, and prognostics | [63,64] |

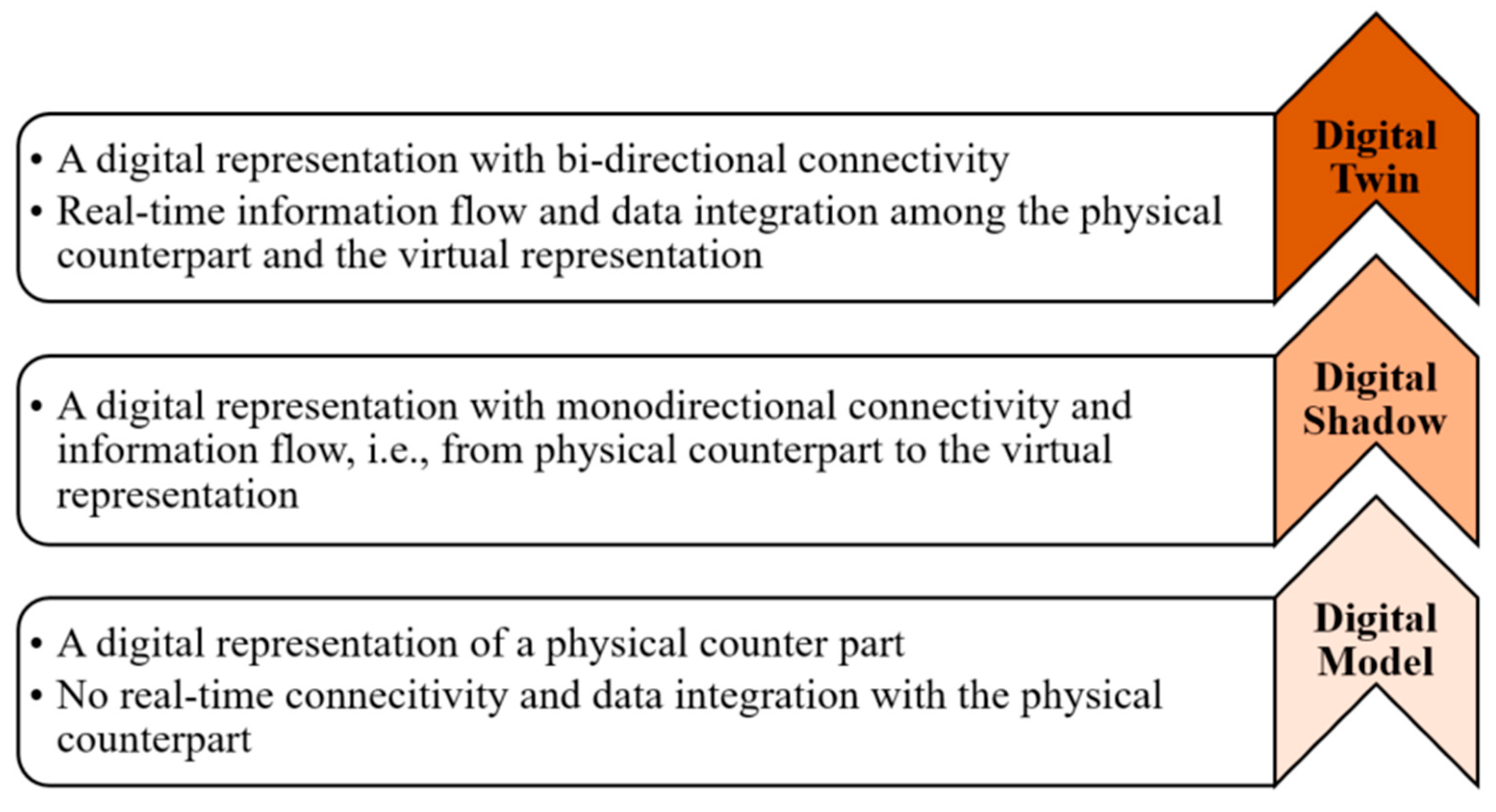

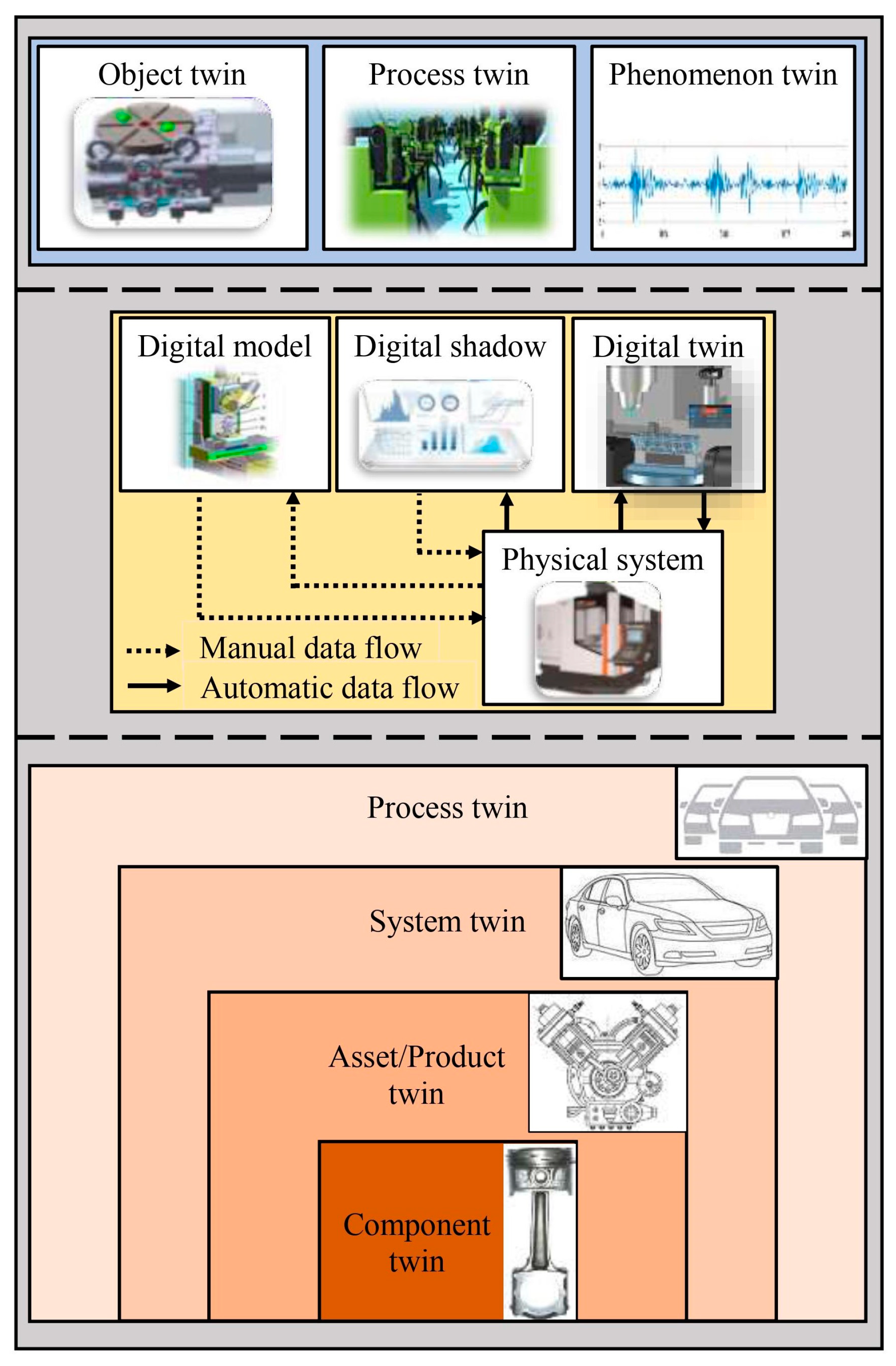

2.2. Modalities of Digital Twins

2.3. Visions and Advantages of Digital Twins

- Re-design and Interoperability: The performance can be predicted as the DT establishes a successful connection with its physical counterpart throughout its life cycle. This enables the engineers to re-evaluate the assumptions involved so that the customization of the product/strategy can be possible [74].

- State Monitoring and Fault Diagnosis: A DT assists in intelligent fault diagnosis by generating simulation data for the physical system’s unavailable/invisible defect scenarios, which have complex structures, multiple parts, and intricate mechanisms [75].

- Fault Prognosis and Optimized Maintenance: Through a DT, the simulated data pertaining to varied operating conditions, degradation mechanisms, and failure modes can be generated, thereby saving much of the cost invested in obtaining the labeled data [46]. Thus, a DT offers the most optimal maintenance strategy by simulating various scenarios.

- Cost-effectiveness: With a DT, the components under investigation can be tested in various operating conditions, and damage scenarios can be simulated without incurring additional costs. Thus, without the need for expensive and time-consuming physical mock-ups, a DT allows for the efficient prediction of the effects of processes and product development on the system’s behavior [76,77].

- Accessibility and Fidelity: A DT provides remote and edge-based solutions by establishing a cyber-physical system that implements high-level cognitive tasks, such as data conversion, data analytics, and self-adoption [78]. In situations where local access is restricted, such as during the COVID-19 pandemic when governments enforced lockdowns, working/monitoring remotely or non-contact is the only practical option.

- Safety and Scalability: Owing to its predictive nature and ability to access its physical counterpart remotely, a DT can help lower the likelihood of hazardous failures and accidents in industries like the mining and oil and gas industries, where working conditions can be hazardous. In light of the global COVID-19 outbreak, nearly one-third of businesses are adopting DTs to improve employee and customer safety through remote monitoring [79,80].

- Sustainability and Disposability: Waste is greatly decreased when product or system prototypes are tested and simulated in a virtual environment using DT. Before a product is manufactured, prototypes can be virtually tested in various conditions to ensure the final design is perfect. This lowers development costs and time to market and prevents material waste [27].

3. Implementation of Digital Twin in Transmission Machinery

4. Implementation of Digital Twin in Industrial Machinery

5. Discussion and Conclusions

- Multi-physics coupling: High-fidelity DT models simulating operating conditions and establishing the interactions between seemingly independent parameters with the interactions across various sub-systems requires a strong multi-physics coupling strategy. This multi-physics approach requires extensive understanding of the fundamental processes and their interactions and guidance of the choice of intrinsic parameters and their ranges of values (e.g., dynamics, mechanical, thermal, structural, and electrical) to obtain coherent simulated responses, leading to more realistic and useful DTs for the entire physical system [135,136].

- Interoperability twinning: A DT is often created by focusing on a single physical asset in a typical manufacturing firm. However, system-level twinning via interoperability twinning ensures that all individual components and/or sub-systems are integrated, and this aggregated DT provides more comprehensive and accurate insights about the system and yields an improved service [137,138]. Consequently, more examples and guidance around interoperability are strong needs.

- Edge computing: Real-time feedback is helpful for several DT applications, but the latency caused by long-distance data transfer impedes performance. Raw data acquired with various sensors are often heterogeneous, impacting the communication between data centers. Raw data cleansing and handling at the edge before transferring to cloud-based data processing can enhance the performance of the DT network by reducing the latency of data transmission. A DT-driven framework assisted by edge or even cloud computing can lead to a significant reduction in data distribution discrepancy while enabling high-frequency and dynamic data storing, transmission, and processing [139,140]. Obtaining data from reliable sources and displaying them in a virtual environment helps identify deviations and/or anomalies (single and multiple defects) of components and related decision making.

- Lack of regulations: A standardized industry-wide data transfer framework is still not realized, and an improved regulatory framework encompassing efficient data flow can enhance accessibility without sacrificing security protocols. Inadequate communication protocols and data collection standards can compromise the quality of the data being computed by the DT, which impacts the overall performance. A standardized framework (ISO 23247) is being developed to offer guidelines, strategies, and evaluation methods for creating and executing DTs in the manufacturing industry [141,142].

- Data safety issues: Data silos might result from improper policies governing data exchange externally (e.g., stakeholders across the industrial firm) and internally (e.g., within an organization). Also, data interoperability across various DTs needs to be examined. There are also concerns about ownership, privacy, transparency, confidentiality, and the security of the data computed [5]. Industrial firms are required to install intelligent security measures to protect the sensitive information of the DTs against cyberattacks [143,144].

- Technological update and cost: The construction of a DT is labor-intensive and demands high-performance computational power, contributing to high investment costs. Additionally, significant knowledge of various technologies (e.g., interactive, edge, ML, and intelligent perception) is required to construct an accurate and real-time DT of a rotating machinery [75,145].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chatti, S.; Laperrière, L.; Reinhart, G.; Tolio, T. CIRP Encyclopedia of Production Engineering; Springer: Heidelberger/Berlin, Germany, 2019. [Google Scholar]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. Ifac-PapersOnline 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Minghui, H.; Ya, H.; Xinzhi, L.; Ziyuan, L.; Jiang, Z.; Bo, M.A. Digital twin model of gas turbine and its application in warning of performance fault. Chin. J. Aeronaut. 2023, 36, 449–470. [Google Scholar]

- Yang, C.; Cai, B.; Wu, Q.; Wang, C.; Ge, W.; Hu, Z.; Zhu, W.; Zhang, L.; Wang, L. Digital twin-driven fault diagnosis method for composite faults by combining virtual and real data. J. Ind. Inf. Integr. 2023, 33, 100469. [Google Scholar] [CrossRef]

- Attaran, M.; Celik, B.G. Digital Twin: Benefits, use cases, challenges, and opportunities. Decis. Anal. J. 2023, 6, 100165. [Google Scholar] [CrossRef]

- Li, X.; Shen, Y.; Cheng, H.; Yuan, F.; Huang, L. Identifying the Development Trends and Technological Competition Situations for Digital Twin: A Bibliometric Overview and Patent Landscape Analysis. IEEE Trans. Eng. Manag. 2022, 71, 1998–2021. [Google Scholar] [CrossRef]

- Pantelidakis, M.; Mykoniatis, K.; Liu, J.; Harris, G. A digital twin ecosystem for additive manufacturing using a real-time development platform. Int. J. Adv. Manuf. Technol. 2022, 120, 6547–6563. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Fu, H.; Zheng, Y.; Tao, F.; Liu, Y. The advance of digital twin for predictive maintenance: The role and function of machine learning. J. Manuf. Syst. 2023, 71, 581–594. [Google Scholar] [CrossRef]

- Peng, F.; Zheng, L.; Peng, Y.; Fang, C.; Meng, X. Digital Twin for rolling bearings: A review of current simulation and PHM techniques. Measurement 2022, 201, 111728. [Google Scholar] [CrossRef]

- Wang, Y.; Tao, F.; Zhang, M.; Wang, L.; Zuo, Y. Digital twin enhanced fault prediction for the autoclave with insufficient data. J. Manuf. Syst. 2021, 60, 350–359. [Google Scholar] [CrossRef]

- Gawde, S.; Patil, S.; Kumar, S.; Kamat, P.; Kotecha, K.; Abraham, A. Multi-fault diagnosis of Industrial Rotating Machines using Data-driven approach: A review of two decades of research. Eng. Appl. Artif. Intell. 2023, 123, 106139. [Google Scholar] [CrossRef]

- Vamsi, I.; Sabareesh, G.R.; Penumakala, P.K. Comparison of condition monitoring techniques in assessing fault severity for a wind turbine gearbox under non-stationary loading. Mech. Syst. Signal Process. 2019, 124, 1–20. [Google Scholar] [CrossRef]

- Moghadam, F.K.; Nejad, A.R. Online condition monitoring of floating wind turbines drivetrain by means of digital twin. Mech. Syst. Signal Process. 2022, 162, 108087. [Google Scholar] [CrossRef]

- Inturi, V.; Shreyas, N.; Chetti, K.; Sabareesh, G.R. Comprehensive fault diagnostics of wind turbine gearbox through adaptive condition monitoring scheme. Appl. Acoust. 2021, 174, 107738. [Google Scholar] [CrossRef]

- Praveen, H.M.; Sabareesh, G.R.; Inturi, V.; Jaikanth, A. Component level signal segmentation method for multi-component fault detection in a wind turbine gearbox. Measurement 2022, 195, 111180. [Google Scholar] [CrossRef]

- Inturi, V.; GR, S.; Penumakala, P.K. Bearing fault severity analysis on a multi-stage gearbox subjected to fluctuating speeds. Exp. Tech. 2020, 44, 541–552. [Google Scholar] [CrossRef]

- Parey, A.; Singh, A. Gearbox fault diagnosis using acoustic signals, continuous wavelet transform and adaptive neuro-fuzzy inference system. Appl. Acoust. 2019, 147, 133–140. [Google Scholar] [CrossRef]

- Pichika, S.N.; Yadav, R.; Rajasekharan, S.G.; Praveen, H.M.; Inturi, V. Optimal sensor placement for identifying multi-component failures in a wind turbine gearbox using integrated condition monitoring scheme. Appl. Acoust. 2022, 187, 108505. [Google Scholar] [CrossRef]

- Nembhard, A.D.; Sinha, J.K.; Pinkerton, A.J.; Elbhbah, K. Combined vibration and thermal analysis for the condition monitoring of rotating machinery. Struct. Health Monit. 2014, 13, 281–295. [Google Scholar] [CrossRef]

- Carroll, J.; McDonald, A.; McMillan, D. Failure rate, repair time and unscheduled O&M cost analysis of offshore wind turbines. Wind Energy 2016, 19, 1107–1119. [Google Scholar]

- Sheng, S.; Yang, W. Wind turbine drivetrain condition monitoring-an overview (presentation). In Proceedings of the 2013 ASME Turbo Expo, San Antonio, TX, USA, 3–7 June 2013. [Google Scholar]

- Javaid, M.; Haleem, A. Digital Twin applications toward Industry 4.0: A Review. Cogn. Robot. 2023, 3, 71–92. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Rathore, M.M.; Shah, S.A.; Shukla, D.; Bentafat, E.; Bakiras, S. The role of ai, machine learning, and big data in digital twinning: A systematic literature review, challenges, and opportunities. IEEE Access 2021, 9, 32030–32052. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Semeraro, C.; Lezoche, M.; Panetto, H.; Dassisti, M. Digital twin paradigm: A systematic literature review. Comput. Ind. 2021, 130, 103469. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital twin: Origin to future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Cui, Z.; Yang, X.; Yue, J.; Liu, X.; Tao, W.; Xia, Q.; Wu, C. A review of digital twin technology for electromechanical products: Evolution focus throughout key lifecycle phases. J. Manuf. Syst. 2023, 70, 264–287. [Google Scholar] [CrossRef]

- Bofill, J.; Abisado, M.; Villaverde, J.; Sampedro, G.A. Exploring Digital Twin-Based Fault Monitoring: Challenges and Opportunities. Sensors 2023, 23, 7087. [Google Scholar] [CrossRef] [PubMed]

- Bisanti, G.M.; Mainetti, L.; Montanaro, T.; Patrono, L.; Sergi, I. Digital twins for aircraft maintenance and operation: A systematic literature review and an IoT-enabled modular architecture. Internet Things 2023, 24, 100991. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Gu, J.; Wang, J. A proactive manufacturing resources assignment method based on production performance prediction for the smart factory. IEEE Trans. Ind. Inform. 2021, 18, 46–55. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Attaran, M. The internet of things: Limitless opportunities for business and society. J. Strateg. Innov. Sustain. 2017, 12, 10–29. [Google Scholar]

- Shu, Z.; Wan, J.; Zhang, D.; Li, D. Cloud-integrated cyber-physical systems for complex industrial applications. Mob. Netw. Appl. 2016, 21, 865–878. [Google Scholar] [CrossRef]

- Lv, Z.; Xie, S. Artificial intelligence in the digital twins: State of the art, challenges, and future research topics. Digit. Twin 2022, 1, 12. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Ye, Y.; Zhang, C.; Wei, Y. A hybrid predictive maintenance approach for CNC machine tool driven by Digital Twin. Robot. Comput. -Integr. Manuf. 2020, 65, 101974. [Google Scholar] [CrossRef]

- Surucu, O.; Gadsden, S.A.; Yawney, J. Condition Monitoring using Machine Learning: A Review of Theory, Applications, and Recent Advances. Expert Syst. Appl. 2023, 221, 119738. [Google Scholar] [CrossRef]

- Penchev, P.; Vitliemov, P.; Georgiev, I. Optimization model for production scheduling taking into account preventive maintenance in an uncertainty-based production system. Heliyon 2023, 9, e17485. [Google Scholar] [CrossRef]

- Huang, H.; Yang, L.; Wang, Y.; Xu, X.; Lu, Y. Digital Twin-driven online anomaly detection for an automation system based on edge intelligence. J. Manuf. Syst. 2021, 59, 138–150. [Google Scholar] [CrossRef]

- Inturi, V.; Penumakala, P.K.; Sabareesh, G.R. Effect of Multiple Defects and Multi-component Failure on the Dynamic Behaviour of a Wind Turbine Gearbox. Arab. J. Sci. Eng. 2022, 47, 8969–8983. [Google Scholar] [CrossRef]

- Cauchi, N.; Macek, K.; Abate, A. Model-based predictive maintenance in building automation systems with user discomfort. Energy 2017, 138, 306–315. [Google Scholar] [CrossRef]

- Chen, C.; Liu, C.; Wang, T.; Zhang, A.; Wu, W.; Cheng, L. Compound fault diagnosis for industrial robots based on dual-transformer networks. J. Manuf. Syst. 2023, 66, 163–178. [Google Scholar] [CrossRef]

- Inturi, V.; Balaji, S.V.; Gyanam, P.; Pragada, B.P.V.; Geetha Rajasekharan, S.; Pakrashi, V. An integrated condition monitoring scheme for health state identification of a multi-stage gearbox through Hurst exponent estimates. Struct. Health Monit. 2023, 22, 730–745. [Google Scholar] [CrossRef]

- Alzghoul, A.; Backe, B.; Löfstrand, M.; Byström, A.; Liljedahl, B. Comparing a knowledge-based and a data-driven method in querying data streams for system fault detection: A hydraulic drive system application. Comput. Ind. 2014, 65, 1126–1135. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, W.; Zhang, C.; Yang, C.; Chu, H. Data super-network fault prediction model and maintenance strategy for mechanical product based on digital twin. IEEE Access 2019, 7, 177284–177296. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Liu, J.; Liu, X.; Vatn, J.; Yin, S. A generic framework for qualifications of digital twins in maintenance. J. Autom. Intell. 2023, 2, 196–203. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the digital twin for design and production engineering. CIRP Ann. 2017, 66, 141–144. [Google Scholar] [CrossRef]

- Awouda, A.; Traini, E.; Bruno, G.; Chiabert, P. IoT-Based Framework for Digital Twins in the Industry 5.0 Era. Sensors 2024, 24, 594. [Google Scholar] [CrossRef] [PubMed]

- Papacharalampopoulos, A.; Foteinopoulos, P.; Stavropoulos, P. Integration of Industry 5.0 requirements in digital twin-supported manufacturing process selection: A framework. Procedia CIRP 2023, 119, 545–551. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Digital Twin for Smart Manufacturing, A Review. Sustain. Manuf. Serv. Econ. 2023, 2, 100017. [Google Scholar]

- Emmert-Streib, F. Defining a Digital Twin: A Data Science-Based Unification. Mach. Learn. Knowl. Extr. 2023, 5, 1036–1054. [Google Scholar] [CrossRef]

- Ayani, M.; Ganebäck, M.; Ng, A.H. Digital Twin: Applying emulation for machine reconditioning. Procedia CIRP 2018, 72, 243–248. [Google Scholar] [CrossRef]

- You, Y.; Chen, C.; Hu, F.; Liu, Y.; Ji, Z. Advances of digital twins for predictive maintenance. Procedia Comput. Sci. 2022, 200, 1471–1480. [Google Scholar] [CrossRef]

- Boschert, S.; Rosen, R. Digital twin—The simulation aspect. In Mechatronic Futures; Springer: Cham, Switzerland, 2016; pp. 59–74. [Google Scholar]

- Zhao, W.; Zhang, C.; Fan, B.; Wang, J.; Gu, F.; Peyrano, O.G.; Wang, S.; Lv, D. Research on rolling bearing virtual-real fusion life prediction with digital twin. Mech. Syst. Signal Process. 2023, 198, 110434. [Google Scholar]

- Yang, X.; Ran, Y.; Zhang, G.; Wang, H.; Mu, Z.; Zhi, S. A digital twin-driven hybrid approach for the prediction of performance degradation in transmission unit of CNC machine tool. Robot. Comput. Integr. Manuf. 2022, 73, 102230. [Google Scholar] [CrossRef]

- He, R.; Chen, G.; Dong, C.; Sun, S.; Shen, X. Data-driven digital twin technology for optimized control in process systems. ISA Trans. 2019, 95, 221–234. [Google Scholar] [PubMed]

- Cai, Y.; Starly, B.; Cohen, P.; Lee, Y.S. Sensor data and information fusion to construct digital-twins virtual machine tools for cyber-physical manufacturing. Procedia Manuf. 2017, 10, 1031–1042. [Google Scholar] [CrossRef]

- Melesse, T.Y.; Di Pasquale, V.; Riemma, S. Digital Twin models in industrial operations: State-of-the-art and future research directions. IET Collab. Intell. Manuf. 2021, 3, 37–47. [Google Scholar]

- Abramovici, M.; Göbel, J.C.; Savarino, P. Reconfiguration of smart products during their use phase based on virtual product twins. CIRP Ann. 2017, 66, 165–168. [Google Scholar]

- Yu, G.; Wang, Y.; Mao, Z.; Hu, M.; Sugumaran, V.; Wang, Y.K. A digital twin-based decision analysis framework for operation and maintenance of tunnels. Tunn. Undergr. Space Technol. 2021, 116, 104125. [Google Scholar]

- Farhat, M.H.; Chiementin, X.; Chaari, F.; Bolaers, F.; Haddar, M. Digital twin-driven machine learning: Ball bearings fault severity classification. Meas. Sci. Technol. 2021, 32, 044006. [Google Scholar] [CrossRef]

- Zhong, D.; Xia, Z.; Zhu, Y.; Duan, J. Overview of predictive maintenance based on digital twin technology. Heliyon 2023, 9, e14534. [Google Scholar] [CrossRef]

- Inturi, V.; Shreyas, N.; Sabareesh, G.R. Anfis-based defect severity prediction on a multi-stage gearbox operating under fluctuating speeds. Neural Process. Lett. 2021, 53, 3445–3466. [Google Scholar] [CrossRef]

- Praveen, H.M.; Jaikanth, A.; Inturi, V.; Sabareesh, G.R. Fingerprinting based data abstraction technique for remaining useful life estimation in a multi-stage gearbox. Measurement 2021, 174, 109021. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.D.J. Digital twin technology challenges and applications: A comprehensive review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Ladj, A.; Wang, Z.; Meski, O.; Belkadi, F.; Ritou, M.; Da Cunha, C. A knowledge-based Digital Shadow for machining industry in a Digital Twin perspective. J. Manuf. Syst. 2021, 58, 168–179. [Google Scholar]

- Calvo-Bascones, P.; Voisin, A.; Do, P.; Sanz-Bobi, M.A. A collaborative network of digital twins for anomaly detection applications of complex systems. Snitch Digital Twin concept. Comput. Ind. 2023, 144, 103767. [Google Scholar]

- Ghosh, A.K.; Ullah, A.S.; Kubo, A.; Akamatsu, T.; D’Addona, D.M. Machining phenomenon twin construction for industry 4.0: A case of surface roughness. J. Manuf. Mater. Process. 2020, 4, 11. [Google Scholar] [CrossRef]

- Li, Y.; Tao, Z.; Wang, L.; Du, B.; Guo, J.; Pang, S. Digital twin-based job shop anomaly detection and dynamic scheduling. Robot. Comput. Integr. Manuf. 2023, 79, 102443. [Google Scholar] [CrossRef]

- Redelinghuys, A.J.H.; Basson, A.H.; Kruger, K. A six-layer architecture for the digital twin: A manufacturing case study implementation. J. Intell. Manuf. 2020, 31, 1383–1402. [Google Scholar]

- Xia, P.; Huang, Y.; Tao, Z.; Liu, C.; Liu, J. A digital twin-enhanced semi-supervised framework for motor fault diagnosis based on phase-contrastive current dot pattern. Reliab. Eng. Syst. Saf. 2023, 235, 109256. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, H.; Leng, J.; Chen, X. Digital twin-driven rapid individualised designing of automated flow-shop manufacturing system. Int. J. Prod. Res. 2019, 57, 3903–3919. [Google Scholar]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Chakraborty, S.; Adhikari, S.; Ganguli, R. The role of surrogate models in the development of digital twins of dynamic systems. Appl. Math. Model. 2021, 90, 662–681. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar]

- Xia, M.; Shao, H.; Williams, D.; Lu, S.; Shu, L.; de Silva, C.W. Intelligent fault diagnosis of machinery using digital twin-assisted deep transfer learning. Reliab. Eng. Syst. Saf. 2021, 215, 107938. [Google Scholar] [CrossRef]

- Shen, W.; Yang, C.; Gao, L. Address business crisis caused by COVID-19 with collaborative intelligent manufacturing technologies. IET Collab. Intell. Manuf. 2020, 2, 96–99. [Google Scholar] [CrossRef]

- Gartner Survey Reveals 47% of Organizations Will Increase Investments in IoT Despite the Impact of COVID-19. 2020. Available online: https://www.gartner.com/en/newsroom/press-releases/2020-10-29-gartner-survey-reveals-47-percent-of-organizations-will-increase-investments-in-iot-despite-the-impact-of-covid-19- (accessed on 26 December 2023).

- Ma, J.; Chen, H.; Zhang, Y.; Guo, H.; Ren, Y.; Mo, R.; Liu, L. A digital twin-driven production management system for production workshop. Int. J. Adv. Manuf. Technol. 2020, 110, 1385–1397. [Google Scholar] [CrossRef]

- Wang, J.; Ye, L.; Gao, R.X.; Li, C.; Zhang, L. Digital Twin for rotating machinery fault diagnosis in smart manufacturing. Int. J. Prod. Res. 2019, 57, 3920–3934. [Google Scholar] [CrossRef]

- Chakraborty, S.; Adhikari, S. Machine learning based digital twin for dynamical systems with multiple time-scales. Comput. Struct. 2021, 243, 106410. [Google Scholar] [CrossRef]

- Garg, S.; Gogoi, A.; Chakraborty, S.; Hazra, B. Machine learning based digital twin for stochastic nonlinear multi-degree of freedom dynamical system. Probabilistic Eng. Mech. 2021, 66, 103173. [Google Scholar] [CrossRef]

- Ritto, T.G.; Rochinha, F.A. Digital twin, physics-based model, and machine learning applied to damage detection in structures. Mech. Syst. Signal Process. 2021, 155, 107614. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.; Hnydiuk-Stefan, A.; Feng, S.; Atilla, I.; Li, Z. Recent progress on reliability analysis of offshore wind turbine support structures considering digital twin solutions. Ocean Eng. 2021, 232, 109168. [Google Scholar] [CrossRef]

- Yu, J.; Song, Y.; Tang, D.; Dai, J. A Digital Twin approach based on nonparametric Bayesian network for complex system health monitoring. J. Manuf. Syst. 2021, 58, 293–304. [Google Scholar] [CrossRef]

- Fedorko, G.; Molnar, V.; Vasiľ, M.; Salai, R. Proposal of digital twin for testing and measuring of transport belts for pipe conveyors within the concept Industry 4.0. Measurement 2021, 174, 108978. [Google Scholar] [CrossRef]

- Duan, J.G.; Ma, T.Y.; Zhang, Q.L.; Liu, Z.; Qin, J.Y. Design and application of digital twin system for the blade-rotor test rig. J. Intell. Manuf. 2023, 34, 753–769. [Google Scholar] [CrossRef]

- Liu, C.; Ricardo Mauricio, A.; Qi, J.; Peng, D.; Gryllias, K. Domain adaptation digital twin for rolling element bearing prognostics. Annu. Conf. PHM Soc. 2020, 12, 10. [Google Scholar] [CrossRef]

- Piltan, F.; Kim, J.M. Crack size identification for bearings using an adaptive digital twin. Sensors 2021, 21, 5009. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Zhang, C.; Wang, J.; Peyrano, O.G.; Gu, F.; Wang, S.; Lv, D. Research on main bearing life prediction of direct-drive wind turbine based on digital twin technology. Meas. Sci. Technol. 2022, 34, 025013. [Google Scholar] [CrossRef]

- Li, T.; Shi, H.; Bai, X.; Zhang, K. A Digital Twin Model of Life-Cycle Rolling Bearing With Multiscale Fault Evolution Combined With Different Scale Local Fault Extension Mechanism. IEEE Trans. Instrum. Meas. 2023, 72, 3507211. [Google Scholar] [CrossRef]

- Regis, A.; Arroyave-Tobón, S.; Linares, J.M.; Mermoz, E. Physic-based vs data-based digital twins for bush bearing wear diagnostic. Wear 2023, 526, 204888. [Google Scholar] [CrossRef]

- Zhang, Y.; Ji, J.C.; Ren, Z.; Ni, Q.; Gu, F.; Feng, K.; Yu, K.; Ge, J.; Lei, Z.; Liu, Z. Digital twin-driven partial domain adaptation network for intelligent fault diagnosis of rolling bearing. Reliab. Eng. Syst. Saf. 2023, 234, 109186. [Google Scholar] [CrossRef]

- Shi, H.; Song, Z.; Bai, X.; Hu, Y.; Li, T.; Zhang, K. A novel digital twin model for dynamical updating and real-time mapping of local defect extension in rolling bearings. Mech. Syst. Signal Process. 2023, 193, 110255. [Google Scholar] [CrossRef]

- Xiangjun, Z.; Ming, Y.; Xianglong, Y.; Yifan, B.; Chen, F.; Yu, Z. Anomaly detection of wind turbine gearbox based on digital twin drive. In Proceedings of the 2020 IEEE 3rd Student Conference on Electrical Machines and Systems (SCEMS), Jinan, China, 4–6 December 2020; pp. 184–188. [Google Scholar]

- Hu, J.; Hu, N.; Luo, P.; Yang, Y. Fault Diagnosis of Gearbox Based on Digital Twin Concept Model. In Proceedings of the 2021 4th International Conference on Intelligent Robotics and Control Engineering (IRCE), Lanzhou, China, 18–20 September 2021; pp. 30–34. [Google Scholar]

- Fahim, M.; Sharma, V.; Cao, T.V.; Canberk, B.; Duong, T.Q. Machine learning-based digital twin for predictive modeling in wind turbines. IEEE Access 2022, 10, 14184–14194. [Google Scholar] [CrossRef]

- Zhu, D.; Li, Z.; Hu, N. Multi-Body Dynamics Modeling and Analysis of Planetary Gearbox Combination Failure Based on Digital Twin. Appl. Sci. 2022, 12, 12290. [Google Scholar] [CrossRef]

- Mehlan, F.C.; Pedersen, E.; Nejad, A.R. Modelling of wind turbine gear stages for digital twin and real-time virtual sensing using bond graphs. J. Phys. Conf. Ser. 2022, 2265, 032065. [Google Scholar] [CrossRef]

- Yu, J.; Wang, S.; Wang, L.; Sun, Y. Gearbox fault diagnosis based on a fusion model of virtual physical model and data-driven method. Mech. Syst. Signal Process. 2023, 188, 109980. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, W.; Liu, L.; Wang, B.; Bao, S.; Jiang, R. Fault Diagnosis of Wind Turbine Planetary Gear Based on a Digital Twin. Appl. Sci. 2023, 13, 4776. [Google Scholar] [CrossRef]

- Feng, K.; Ji, J.C.; Zhang, Y.; Ni, Q.; Liu, Z.; Beer, M. Digital twin-driven intelligent assessment of gear surface degradation. Mech. Syst. Signal Process. 2023, 186, 109896. [Google Scholar] [CrossRef]

- The MathWorks, Inc. (R2023b). Available online: https://in.mathworks.com/products/matlab-home.html (accessed on 10 July 2024).

- Malaka, J.; Hetmańczyk, M. Intelligent Drive in Industry 4.0–Protection of Toothed Belt Transmission on the Basis of Its Digital Twin. In Sympozjon Modelowanie w Mechanice; Springer International Publishing: Cham, Switzerland, 2020; pp. 201–210. [Google Scholar]

- Abaqus Unified FEA–SIMULIA by Dassault Systems. Available online: https://www.3ds.com/products/simulia (accessed on 10 July 2024).

- Ansys, Inc. Available online: https://www.ansys.com/en-in (accessed on 10 July 2024).

- Unity Software Inc. Available online: https://unity.com/ (accessed on 10 July 2024).

- Solidworks. Available online: https://www.solidworks.com/ (accessed on 10 July 2024).

- Adamou, A.A.; Alaoui, C. Energy efficiency model-based Digital shadow for Induction motors: Towards the implementation of a Digital Twin. Eng. Sci. Technol. Int. J. 2023, 44, 101469. [Google Scholar] [CrossRef]

- Söderäng, E.; Hautala, S.; Mikulski, M.; Storm, X.; Niemi, S. Development of a digital twin for real-time simulation of a combustion engine-based power plant with battery storage and grid coupling. Energy Convers. Manag. 2022, 266, 115793. [Google Scholar] [CrossRef]

- Mertes, J.; Glatt, M.; Schellenberger, C.; Klar, M.; Schotten, H.D.; Aurich, J.C. Development of a 5G-enabled Digital Twin of a Machine Tool. Procedia CIRP 2022, 107, 173–178. [Google Scholar] [CrossRef]

- Nguyen, T.N.; Ponciroli, R.; Bruck, P.; Esselman, T.C.; Rigatti, J.A.; Vilim, R.B. A digital twin approach to system-level fault detection and diagnosis for improved equipment health monitoring. Ann. Nucl. Energy 2022, 170, 109002. [Google Scholar] [CrossRef]

- Tshoombe, B.K.; Dos Santos, J.F.; Araújo, R.C.; Fonseca, W.D.S. Implementation of DT-based monitoring system of induction motors. In Proceedings of the 2021 14th IEEE International Conference on Industry Applications (INDUSCON), São Paulo, Brazil, 15–18 August 2021; pp. 161–166. [Google Scholar]

- Bondarenko, O.; Fukuda, T. Development of a diesel engine’s digital twin for predicting propulsion system dynamics. Energy 2020, 196, 117126. [Google Scholar] [CrossRef]

- Bouzid, S.; Viarouge, P.; Cros, J. Real-time digital twin of a wound rotor induction machine based on finite element method. Energies 2020, 13, 5413. [Google Scholar] [CrossRef]

- Dos Santos, J.F.; Tshoombe, B.K.; Santos, L.H.; Araújo, R.C.; Manito, A.R.; Fonseca, W.S.; Silva, M.O. Digital Twin-Based Monitoring System of Induction Motors Using IoT Sensors and Thermo-Magnetic Finite Element Analysis. IEEE Access 2022, 11, 1682–1693. [Google Scholar] [CrossRef]

- Huang, Y.; Yuan, B.; Xu, S.; Han, T. Fault Diagnosis of Permanent Magnet Synchronous Motor of Coal Mine Belt Conveyor Based on Digital Twin and ISSA-RF. Processes 2022, 10, 1679. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Z.; Liu, Z.; Han, B.; Bao, H.; Ji, S. Digital twin aided adversarial transfer learning method for domain adaptation fault diagnosis. Reliab. Eng. Syst. Saf. 2023, 234, 109152. [Google Scholar] [CrossRef]

- Kohtz, S.; Zhao, J.; Renteria, A.; Lalwani, A.; Xu, Y.; Zhang, X.; Haran, K.S.; Senesky, D.; Wang, P. Optimal sensor placement for permanent magnet synchronous motor condition monitoring using a digital twin-assisted fault diagnosis approach. Reliab. Eng. Syst. Saf. 2024, 242, 109714. [Google Scholar] [CrossRef]

- Altair Engineering Inc. Available online: https://altair.com/flux (accessed on 10 July 2024).

- Wang, C.P.; Erkorkmaz, K.; McPhee, J.; Engin, S. In-process digital twin estimation for high-performance machine tools with coupled multibody dynamics. CIRP Ann. 2020, 69, 321–324. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Ullah, A.S.; Teti, R.; Kubo, A. Developing sensor signal-based digital twins for intelligent machine tools. J. Ind. Inf. Integr. 2021, 24, 100242. [Google Scholar] [CrossRef]

- Zhu, Z.; Xi, X.; Xu, X.; Cai, Y. Digital Twin-driven machining process for thin-walled part manufacturing. J. Manuf. Syst. 2021, 59, 453–466. [Google Scholar] [CrossRef]

- Wei, Y.; Hu, T.; Wei, S.; Ma, S.; Wang, Y. Digital twin technology applicability evaluation method for CNC machine tool. Int. J. Adv. Manuf. Technol. 2024, 131, 5607–5623. [Google Scholar] [CrossRef]

- Xue, R.; Zhang, P.; Huang, Z.; Wang, J. Digital twin-driven fault diagnosis for CNC machine tool. Int. J. Adv. Manuf. Technol. 2024, 131, 5457–5470. [Google Scholar] [CrossRef]

- Wang, J.; Niu, X.; Gao, R.X.; Huang, Z.; Xue, R. Digital twin-driven virtual commissioning of machine tool. Robot. Comput. -Integr. Manuf. 2023, 81, 102499. [Google Scholar] [CrossRef]

- Guo, J.; Yang, Z.; Chen, C.; Luo, W.; Hu, W. Real-time prediction of remaining useful life and preventive maintenance strategy based on digital twin. J. Comput. Inf. Sci. Eng. 2021, 21, 031003. [Google Scholar] [CrossRef]

- Finite Element Method Magnetics. Available online: https://www.femm.info/wiki/HomePage (accessed on 10 July 2024).

- Liu, Z.; Chen, W.; Zhang, C.; Yang, C.; Cheng, Q. Intelligent scheduling of a feature-process-machine tool supernetwork based on digital twin workshop. J. Manuf. Syst. 2021, 58, 157–167. [Google Scholar] [CrossRef]

- Hu, W.; Wang, T.; Chu, F. A novel Ramanujan digital twin for motor periodic fault monitoring and detection. IEEE Trans. Ind. Inform. 2023, 19, 11564–11572. [Google Scholar] [CrossRef]

- Liu, Z.; Lang, Z.Q.; Gui, Y.; Zhu, Y.P.; Laalej, H. Digital twin-based anomaly detection for real-time tool condition monitoring in machining. J. Manuf. Syst. 2024, 75, 163–173. [Google Scholar] [CrossRef]

- Guerra-Zubiaga, D.; Kuts, V.; Mahmood, K.; Bondar, A.; Nasajpour-Esfahani, N.; Otto, T. An approach to develop a digital twin for industry 4.0 systems: Manufacturing automation case studies. Int. J. Comput. Integr. Manuf. 2021, 34, 933–949. [Google Scholar] [CrossRef]

- Li, T.J.; Wang, M.Z.; Zhao, C.Y. Study on real-time thermal–mechanical–frictional coupling characteristics of ball bearings based on the inverse thermal network method. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 2335–2349. [Google Scholar] [CrossRef]

- Ye, Z.; Wang, L.; Chen, G.; Tang, D. Analysis of thermo-mechanical coupling of high-speed angular-contact ball bearings. Adv. Mech. Eng. 2017, 9, 1687814017702812. [Google Scholar] [CrossRef]

- He, B.; Bai, K.J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2021, 9, 1–21. [Google Scholar] [CrossRef]

- Adamenko, D.; Kunnen, S.; Pluhnau, R.; Loibl, A.; Nagarajah, A. Review and comparison of the methods of designing the Digital Twin. Procedia CIRP 2020, 91, 27–32. [Google Scholar] [CrossRef]

- Zhao, C.; Shen, W. Dual adversarial network for cross-domain open set fault diagnosis. Reliab. Eng. Syst. Saf. 2022, 221, 108358. [Google Scholar] [CrossRef]

- Sittón-Candanedo, I.; Alonso, R.S.; Corchado, J.M.; Rodríguez-González, S.; Casado-Vara, R. A review of edge computing reference architectures and a new global edge proposal. Future Gener. Comput. Syst. 2019, 99, 278–294. [Google Scholar] [CrossRef]

- Shao, G.; Helu, M. Framework for a digital twin in manufacturing: Scope and requirements. Manuf. Lett. 2020, 24, 105–107. [Google Scholar] [CrossRef] [PubMed]

- Wagner, R.; Schleich, B.; Haefner, B.; Kuhnle, A.; Wartzack, S.; Lanza, G. Challenges and potentials of digital twins and industry 4.0 in product design and production for high performance products. Procedia CIRP 2019, 84, 88–93. [Google Scholar] [CrossRef]

- Falekas, G.; Karlis, A. Digital twin in electrical machine control and predictive maintenance: State-of-the-art and future prospects. Energies 2021, 14, 5933. [Google Scholar] [CrossRef]

- Khan, S.; Farnsworth, M.; McWilliam, R.; Erkoyuncu, J. On the requirements of digital twin-driven autonomous maintenance. Annu. Rev. Control 2020, 50, 13–28. [Google Scholar] [CrossRef]

- Krüger, S.; Borsato, M. Developing knowledge on digital manufacturing to digital twin: A bibliometric and systemic analysis. Procedia Manuf. 2019, 38, 1174–1180. [Google Scholar] [CrossRef]

- Sleiti, A.K.; Kapat, J.S.; Vesely, L. Digital twin in energy industry: Proposed robust digital twin for power plant and other complex capital-intensive large engineering systems. Energy Rep. 2022, 8, 3704–3726. [Google Scholar] [CrossRef]

- de Wilde, P. Building performance simulation in the brave new world of artificial intelligence and digital twins: A systematic review. Energy Build. 2023, 292, 113171. [Google Scholar] [CrossRef]

| S. No. | Definition of DT | Contribution | Implementing Avenues/Use-Cases | Period and No. of Citations | Focal Points/Tasks | Ref. |

|---|---|---|---|---|---|---|

| 1 | “The DT consists of a virtual representation of production system that is able to run on different simulation disciplines that is characterized by the synchronization between the virtual and real system, thanks to sensed data and connected smart devices, mathematical models and real time data elaboration” | Paid attention to the practical implementation of DT integration with a control system to monitor production in an assembly line manufacturing execution system. | Manufacturing execution system | 2015–2019 (~85) | A DT is constructed to suit a single environment for a laboratory assembly line. | [23] |

| 2 | “A set of virtual information constructs that fully describes a potential or actual physical manufactured product from the micro atomic level to the macro geometric level. At its optimum, any information that could be obtained from inspecting a physical manufactured product can be obtained from its digital twin” | Emphasized the significance of AI, ML, and big data in the development of DTs by providing instances from the state-of-the-art deployments already in use for a range of industrial applications. | Manufacturing systems, industrial components, transportation, healthcare, power plants | 2015–2020 (~175) | An AI-ML and big-data enabled DT architecture to facilitate a complete DT-enabled system for various industrial avenues is proposed. | [24] |

| 3 | “A digital twin is an integrated multi-physics and multi-scale simulation of a product/system that can model the mechanical, electrical, software, and other discipline-specific properties across its life cycle” | Highlighted the use of DT technologies in conjunction with important enabling technologies to advance the design of smart manufacturing systems, which include function, structure, behavior, control, intelligence models, and performance designs. | Manufacturing systems | 2014–2020 (~192) | DT technologies implemented towards the design of a smart manufacturing system to assist Industry 4.0 are reviewed. | [25] |

| 4 | “A set of adaptive models that emulate the behavior of a physical system in a virtual system getting real time data to update itself along its life cycle. The digital twin replicates the physical system to predict failures and opportunities for changing, to prescribe real time actions for optimizing and/or mitigating unexpected events observing and evaluating the operating profile system” | Attempted to provide a thorough overview of the key elements of DTs and the issues arising from their interactions while highlighting the technical difficulties in designing and developing DTs that are appropriate for a variety of application domains and related technologies. | Manufacturing, aerospace, healthcare, maritime, shipping | 2002–2020 (~158) | The features, components, architectures, and functionalities of existing DTs are discussed; however, discussions related to the modularity feature of DTs are not explored. | [26] |

| 5 | “A digital twin is a dynamic and self-evolving digital/virtual model or simulation of a real-life subject or object (part, machine, process, human, etc.) representing the exact state of its physical twin at any given point of time via exchanging the real time data as well as keeping the historical data. It is not just the digital twin which mimics its physical twin but any changes in the digital twin are mimicked by the physical twin too” | Intended to consolidate the types of DTs and the definitions of DTs. | NA | 2011–2020 (~107) | A brief discussion related to the advantages, classifications, level of integrations, and manifestations of DTs is carried out. | [27] |

| 6 | “Digital twin is a kind of simulation that can dynamically mirror the state of a corresponding twin based on the data integrated from the available physical models, sensor updates and operating history, in a multi-physics, multi-scale and probabilistic manner” | Investigated the methods and core technologies (detection, modeling, prognosis, and health management) implemented in the construction of DTs in order to successfully achieve prognostics and health monitoring (PHM) of bearings. | Rolling bearings | 2003–2021 (~190) | A comprehensive review regarding the detection, dynamic modeling, and PHM of bearings is performed. The need for the construction of DTs considering the multi-physics coupling and the scope of real, online detection is proliferated briefly. | [9] |

| 7 | “DT is a set of virtual information constructs that fully describes a potential or actual physical manufactured product from the micro atomic level to macro geometric level” | Complied and summarized the evolution and developments of DTs and identified the emerging DT types and manifestations for the evolution focus (comprising design, manufacturing, operation, and maintenance) of an electromechanical product life cycle. | Electromechanical products | 2011–2022 (~239) | The six emerging core DT technologies distributed and supporting the product life cycle of electromechanical components are discussed. | [28] |

| 8 | “Digital twins are digital counterparts of physical entities such as equipment and systems supplied with real-time data that can span from its atomic to geometric level, enabling a more holistic approach to understanding and optimizing the performance of these physical entities” | Reviewed the diverse range of DT predictive models implemented for the fault monitoring (component level and system level) across various industries. | Manufacturing, aviation, transportation, maritime, shipping | 2018–2022 (~87) | The exploitation of DT technology for the single fault monitoring of components and systems is reviewed; however, the operating scenarios and simulated/emulated environments need to be disclosed. | [29] |

| 9 | “The DT is a representation of an active/unique ‘product’ which can be a real device, object, component, intangible asset, service, or a system consisting of a product and its related services” | Emphasized the application of DTs for streamlining intelligent automation across a range of industrial sectors. | Manufacturing, agriculture, healthcare, aviation, construction | 2015–2023 (~92) | The technologies and applications of DTs in various industrial sectors are reviewed briefly. | [5] |

| 10 | “The integration of a multidisciplinary, multi-scale simulation process that makes full use of physical models, sensors, operational history, and other data, which serves as a mirror image of the physical product in virtual space and reflects the full life-cycle process of the corresponding physical entity product” | Reviewed the systematic and state-of-the-art approach of a DT assisted with ML algorithms to achieve predictive maintenance, health indicator construction, and RUL prediction. | Civil infrastructure, industrial components | 2011–2022 (~125) | The ML-enabled DT architectures proposed to achieve a single component fault diagnosis for various industrial components are reviewed. | [8] |

| 11 | “A virtual representation of a physical asset, whose condition is reflected through historical or real-time data captured by sensors” | Focused on the comprehensive review of the applied state-of-the-art DT technologies for the operation and maintenance of an aircraft. | Aircraft | 2018–2023 (~72) | The currently implemented DTs for aircraft operation and maintenance are reviewed, and the necessity of an IoT-enabled modular architecture of a DT is highlighted. | [30] |

| 12 | “A digital twin is a virtual model duplicating an IoT device’s physical components and behaviors across all phases of its lifespan” | Highlighted the need, process, and features of a DT in Industry 4.0 alongside its major applications. | Industrial applications | 2016–2022 (~286) | The applications of DTs for assisting various aspects of Industry 4.0, such as simulating processes, product development, automation, real-time monitoring, better product quality, etc., are reviewed. | [22] |

| S. No. | Company | Research Efforts |

|---|---|---|

| 1 | ANSYS | Enhances the physical implementation of various real-time systems through ‘ANSYS twin builder’ |

| 2 | Bosch | ‘Eclipse Ditto’ is an IoT hub which offers communication to various devices over an application programming interface |

| 3 | Cisco | Places emphasis on promoting and boosting the performance of a business process through ‘Kinetic IoT platform’ |

| 4 | Dassault | Optimizes the performance of their products (cars or planes) over its complete life cycle using ‘3DEXPERIENCE’ |

| 5 | General Electric | Carries out condition monitoring, predicts the performance index, and forecasts the lives of the systems by developing DTs through ‘Predix’ |

| 6 | IBM | ‘DT exchange’ offers technical assistance and cognitive solutions for their clients to develop their industry-centric DTs for the monitoring and prediction of the performance of the systems of their interest |

| 7 | Microsoft | Designs and models various environments through ‘Azure DTs’ and uses ‘DT definition language’ to describe the features and events of the DTs |

| 8 | Oracle | ‘Oracle cloud’ combines the virtual, physical, and augmented reality and IoT knowledge to create DTs for forecasting the condition of various environments |

| 9 | Parametric Technology Corporation | Bridges the digital and physical worlds to realize the visualization of innovative products through ‘ThingWorx’ |

| 10 | Siemens | Focuses on the creation of a smart factory loop in which ‘Siemens Digital Enterprise’ digitalizes the production systems and ‘MindSphere’ develops novel business models |

| Transmission Machinery | Objective | Type of DT | Platform Used | Input Physics Involved | Output Domain Representation | DT Modality | Observations/Remarks | Period and Ref. |

|---|---|---|---|---|---|---|---|---|

| Rotor shaft | Fault detection and severity prediction | Analytical | MATLAB/Scilab [105] | Multi-physics (Mechanical + dynamics) | Single domain (Time-domain) | Object twin | The location and progression of the unbalance defect of the rotor shaft are achieved with an error of ~5%. | 2019 and [82] |

| WT gearbox | Anomaly detection | Simulation | MATLAB [105] | Multi-physics (Structural + mechanical + dynamics) | Single domain (Time-domain) | Asset twin | The output torque-based anomaly discrimination is achieved for a three-stage WT transmission system. | 2020 and [97] |

| Toothed belt | Health monitoring | Numerical | Siemens NX MATLAB [105] | Multi-physics (Mechanical + dynamics) | Single domain (Time-domain) | Object twin | The condition of the toothed belt is monitored automatically to enhance the reliability of the machine. | 2020 and [106] |

| Belt drives | Damage identification | Numerical | Abaqus [107] | Multi-physics (Mechanical + dynamics) | Single domain (Time-domain) | Object twin | The combination of parameters causing belt drift is identified. | 2021 and [88] |

| Roller bearing | Fault detection and severity prediction | Analytical | MATLAB [105] | Multi-physics (Mechanical + dynamics) | Single domain (Time-domain and frequency-domain) | Object twin | Through the proposed DT assisted with an ML classifier, five severity levels of bearing outer race defect are classified with an accuracy of 84%. | 2021 and [63] |

| Roller bearing | RUL prediction | Numerical | ANSYS [108] | Multi-physics (Structural + thermal) | Single domain (Time-domain) | Object twin | The RUL prediction of the main bearing with the small datasets is achieved with an accuracy of 85%. | 2022 and [92] |

| Planetary gearbox | Fault diagnosis | Simulation | MATLAB [105] | Multi-physics (Structural + mechanical + dynamics) | Single domain (Time-domain and frequency-domain) | Object twin | The progression of gear tooth degradation is realized. | 2022 and [100] |

| Bush bearing | Fault diagnosis | Analytical | MATLAB [105] | Multi-physics (Mechanical + dynamics) | Single domain (Time-domain) | Object twin | Multi-scale fault (outer race defect) evolution is predicted by examining the vibration response simulated. | 2023 and [94] |

| Production process of shaft | Anomaly detection | Numerical | 3D Max Unity [109] | Single physics (Process parameters) | Single domain (Time-domain) | Process twin | Multi-level process parameter monitoring is achieved for identifying the abnormal events in the production process of the transmission shaft. | 2023 and [93] |

| WT gearbox | Monitoring wear progression | Analytical | MATLAB [105] | Multi-physics (Mechanical + dynamics) | Single domain (Time-domain) | Object twin | The gear wear progression is monitored, and the severity of gear tooth degradation of a single-stage spur gearbox is assessed with an accuracy of ~92%. | 2023 and [104] |

| Rotor test rig | Health monitoring | Numerical | SolidWorks 3D Max [109,110] | Multi-physics (Mechanical + thermal + friction) | Multi-domain (Time-domain and rotation) | System twin | Real-time mapping from a physical system to a virtual model is established, and the visual monitoring of the rotor blade rig is achieved. | 2023 and [89] |

| Transmission Machinery | Objective | Type of DT | Platform Used | Input Physics Involved | Output Domain Representation | DT Modality | Observations/Remarks | Period and Ref. |

|---|---|---|---|---|---|---|---|---|

| Induction motor | Health monitoring | Numerical + simulation | FLUX2D + MATLAB [105,122] | Single physics (Electrical) | Single domain (Time-domain) | Object twin | Waveforms of electromagnetic torque, coil voltage, stator, and rotor current were analyzed for the identification of stator defects of an induction motor from the real-time measurements. | 2020 and [117] |

| Milling machine | Health monitoring | Functional | JavaTM | Single physics (Structural + mechanical + dynamics) | Multi-domain (Time-domain and delay-domain) | Phenomenon twin | Simulated torque profiles of the milling tool were examined to perform in-process, intelligent health state monitoring. | 2020 and [70] |

| Machine tool | Tool life prediction | Numerical | ANSYS [108] | Multi-physics (Mechanical + thermal + electrical) | Multi-domain (Time-domain and frequency-domain) | Object twin | Simulated tool wear rates were channeled as inputs to the ML algorithms for estimating the RUL progression of a CNC machine tool with an overall error ratio of ~4%. | 2020 and [36] |

| Drilling machine | Health monitoring | Analytical (parametric) | MATLAB/Scilab [105] | Multi-physics (Mechanical + dynamics + electrical) | Single domain (Time-domain) | Object twin | Multi-body dynamical interactions of a drilling machine tool were simulated with an RMS error of ~2%. | 2020 and [123] |

| Machine tool | RUL prediction | Analytical | MATLAB/Scilab [105] | Multi-physics (Mechanical + friction) | Single domain (Time-domain) | Object twin | Degradation parameters (stress, forces, speed, etc.) pertaining to various operating conditions were estimated for the accurate RUL prediction of a CNC machine tool. | 2021 and [129] |

| Triplex pump | Fault diagnosis | Simulation | MATLAB [105] | Multi-physics (Mechanical + thermal) | Single domain (Time-domain) | Asset twin | The pressure signal database was simulated for all the probable defect scenarios of a triplex pump, and fault diagnosis under various operating conditions was achieved with an overall accuracy of ~93%. | 2021 and [78] |

| Induction motor | Health monitoring | Numerical | FEM Magnetics + Python [131] | Multi-physics (Thermal + electromagnetic) | Single domain (Time-domain) | Asset twin | The health state of the machine was monitored by analyzing the simulated electrical conductivity, torque, and temperature profiles. | 2022 and [118] |

| Machine tool | Tool life prediction | Numerical | ANSYS [108] | Multi-physics (Mechanical + hydraulic + electrical) | Single domain (Time-domain) | Phenomenon twin | An evolution model based on fuzzy values to synthesize the evaluation indicators for the successful prediction of the cutting tool life was realized. | 2022 and [126] |

| Machine tool | Fault detection and severity prediction | Numerical | Modelica | Multi-physics (Mechanical + control + electrical) | Single domain (Time-domain) | Object twin | Machine tool spindle stiffness deterioration was assessed with an overall error of ~2%. | 2022 and [127] |

| Triplex pump | Fault diagnosis | Simulation | MATLAB [105] | Multi-physics (Mechanical + thermal) | Single domain (Time-domain) | Asset twin | Intelligent fault diagnosis of the triplex pump subjected to various operating conditions was achieved with an accuracy of ~99%. | 2023 and [128] |

| Induction motor | Anomaly detection | Analytical (phenomenon driven) | MATLAB/Scilab [105] | Single physics (Electrical) | Single domain (Time-domain) | Object twin | Ramanujan periodic transform was implemented on the simulated motor current signature profiles for extracting the features; furthermore, the damage index was constructed for the damage diagnosis of an induction motor. | 2023 and [132] |

| AC synchronous motor | Health monitoring and fault diagnosis | Numerical | FLUX [122] | Multi-physics (Thermal + electromagnetic) | Single domain (Time-domain and frequency-domain) | Asset twin | Through the proposed DT assisted with an ML classifier, eight prominent defects of motor were diagnosed with an overall accuracy of ~94%. | 2024 and [121] |

| Milling machine tool | Condition monitoring | Analytical | MATLAB/Scilab [105] | Multi-physics (Mechanical + friction) | Multi-domain (Time-domain and frequency-domain) | Phenomenon twin | A successful data drive cycle was established among the acquired vibration signals and machine tool control signals through an ML algorithm to predict the machining tool wear rate within the error rate of ~20 μm. | 2024 and [133] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Inturi, V.; Ghosh, B.; Rajasekharan, S.G.; Pakrashi, V. A Review of Digital Twinning for Rotating Machinery. Sensors 2024, 24, 5002. https://doi.org/10.3390/s24155002

Inturi V, Ghosh B, Rajasekharan SG, Pakrashi V. A Review of Digital Twinning for Rotating Machinery. Sensors. 2024; 24(15):5002. https://doi.org/10.3390/s24155002

Chicago/Turabian StyleInturi, Vamsi, Bidisha Ghosh, Sabareesh Geetha Rajasekharan, and Vikram Pakrashi. 2024. "A Review of Digital Twinning for Rotating Machinery" Sensors 24, no. 15: 5002. https://doi.org/10.3390/s24155002