Closed-Loop Control of Melt Pool Temperature during Laser Metal Deposition

Abstract

:1. Introduction

2. Experimental Setups

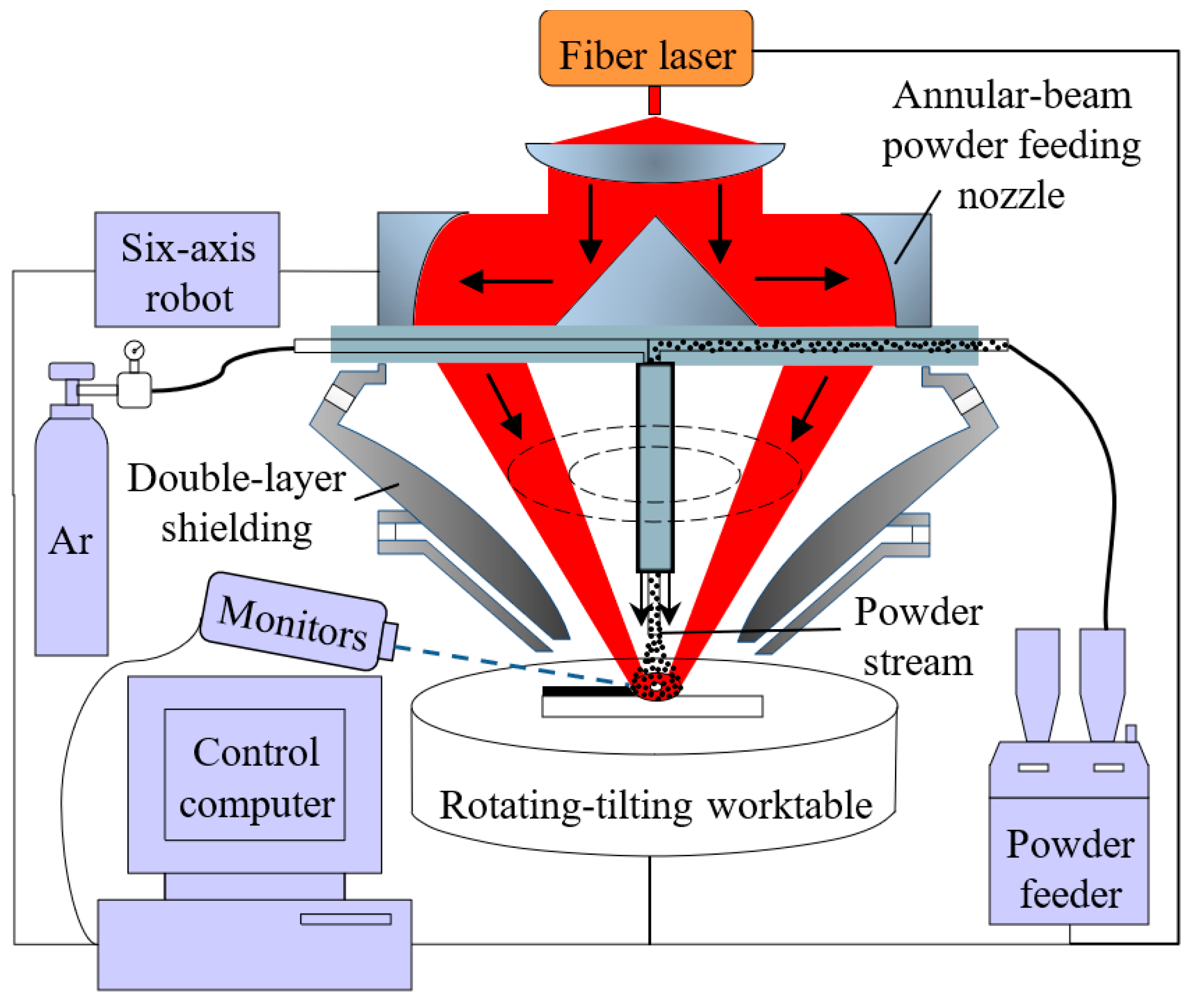

2.1. Annular Laser Metal Deposition (ALMD)

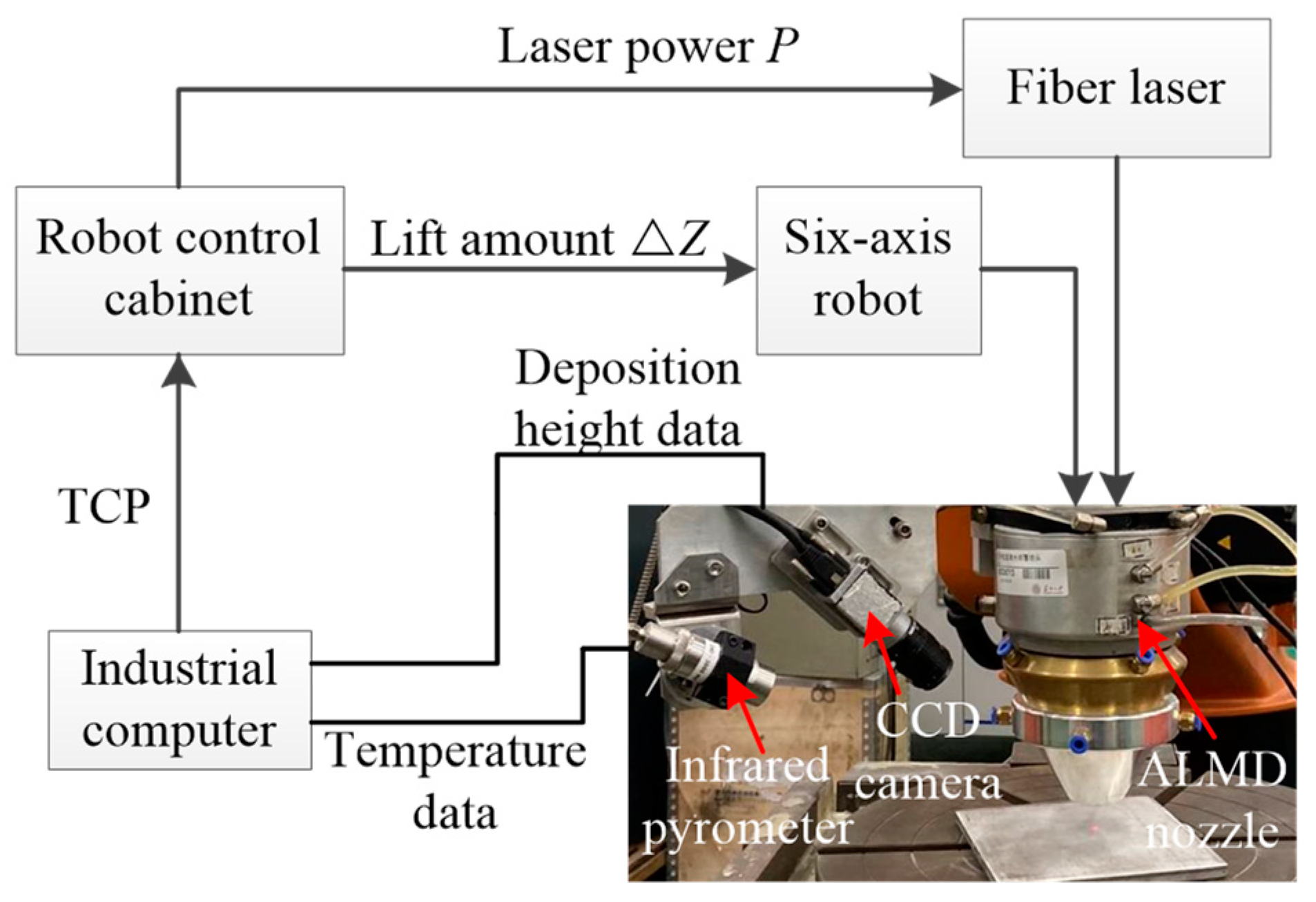

2.2. Closed-Loop Melt Pool Temperature Control System

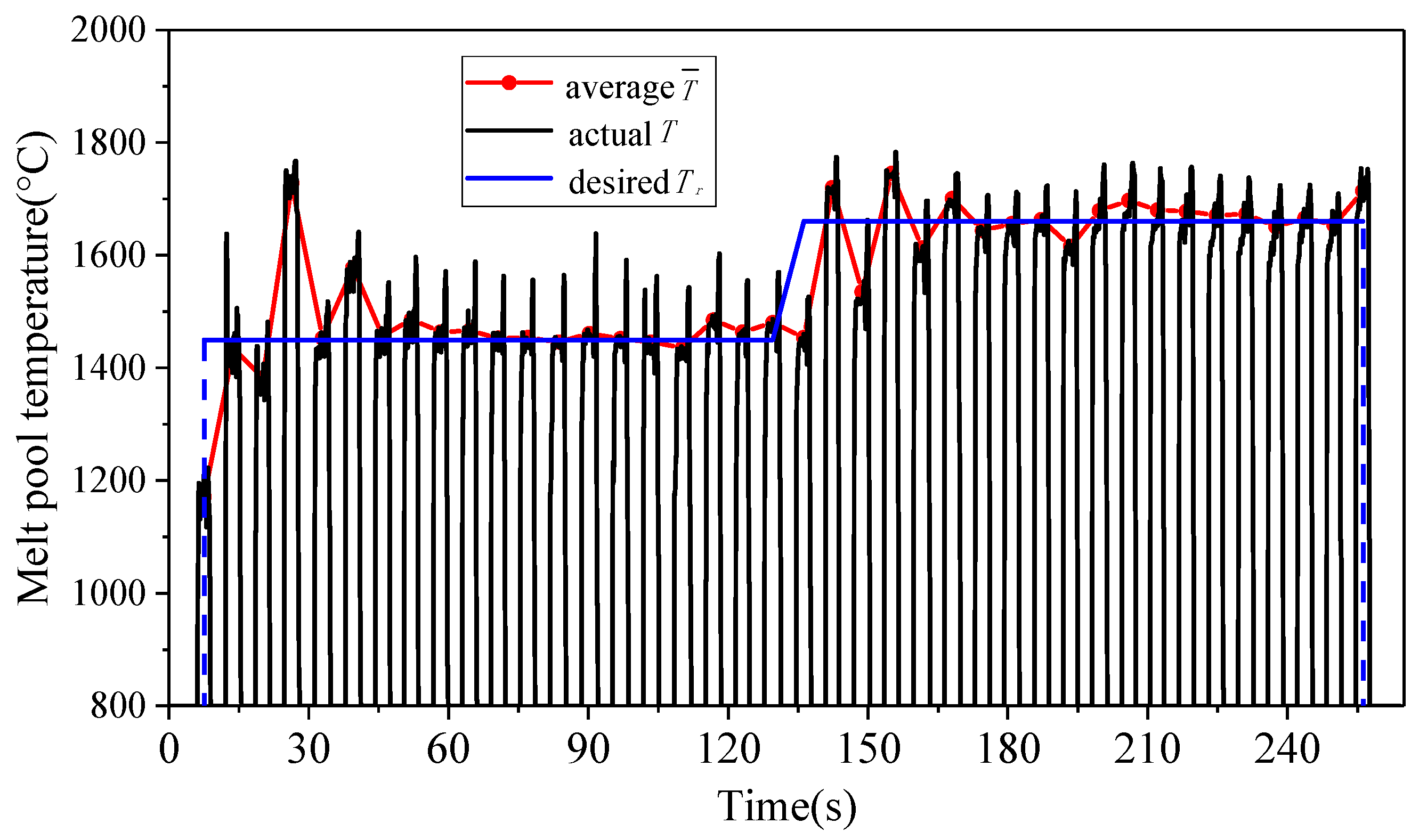

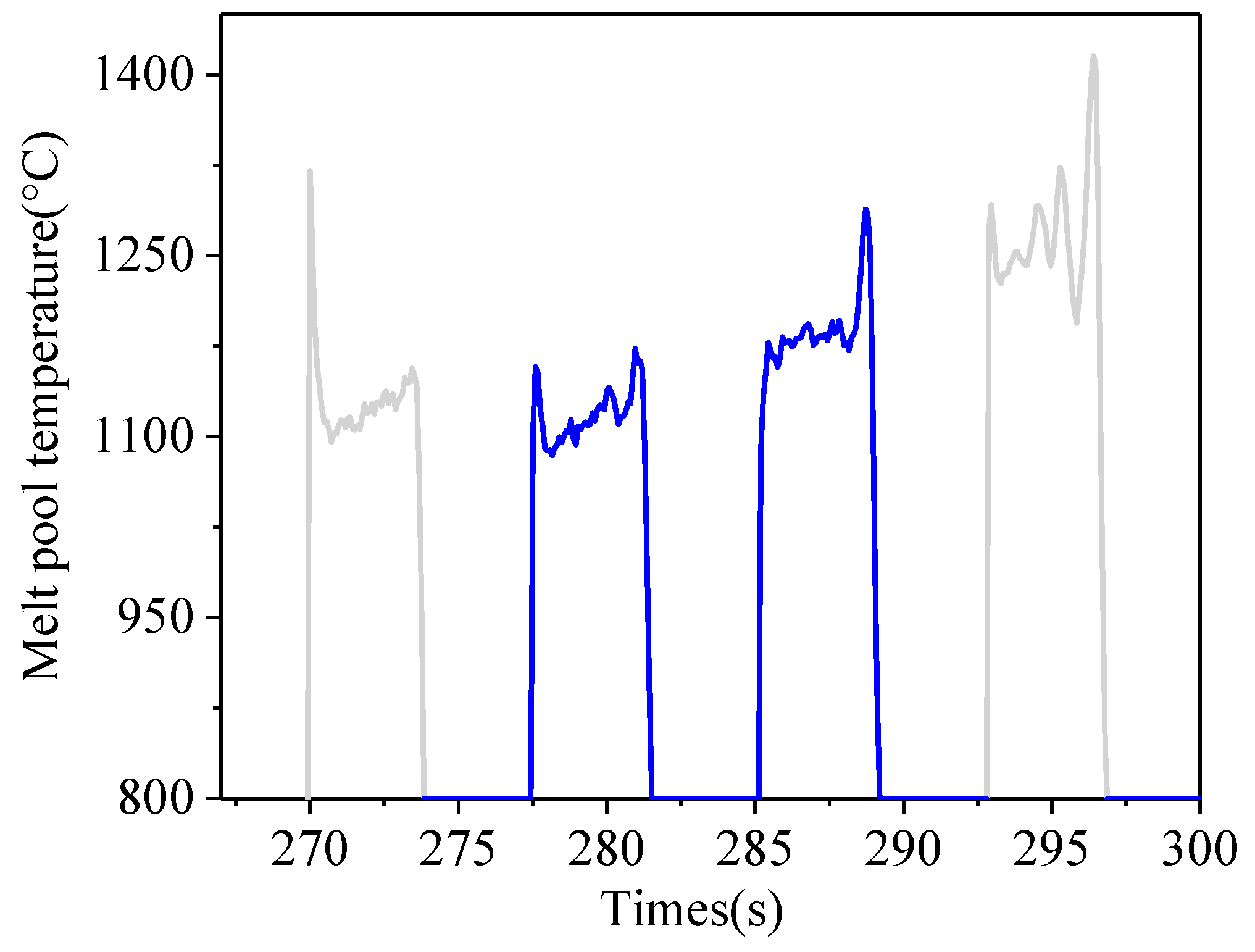

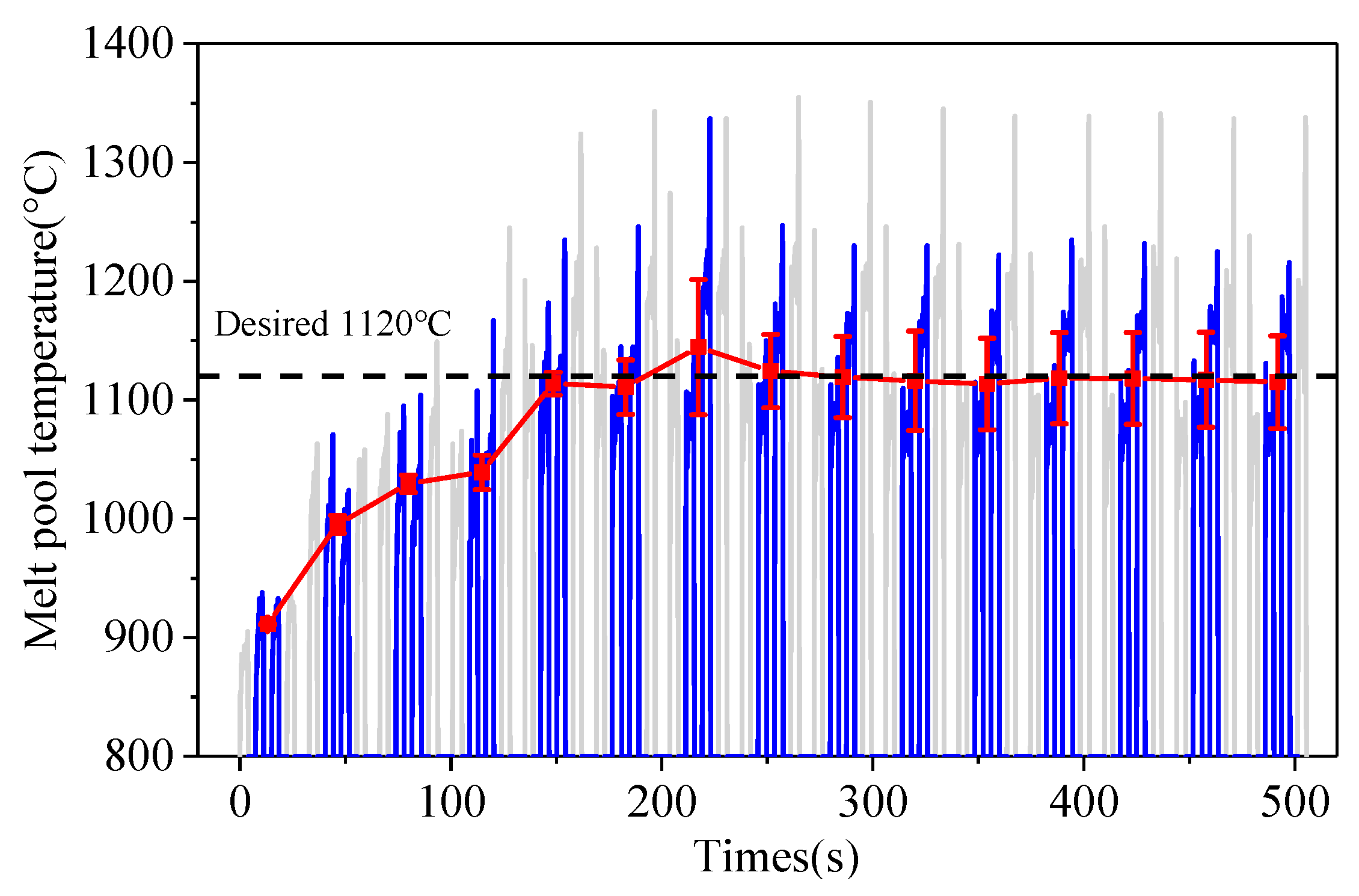

3. Digital PI Controller Design and Test

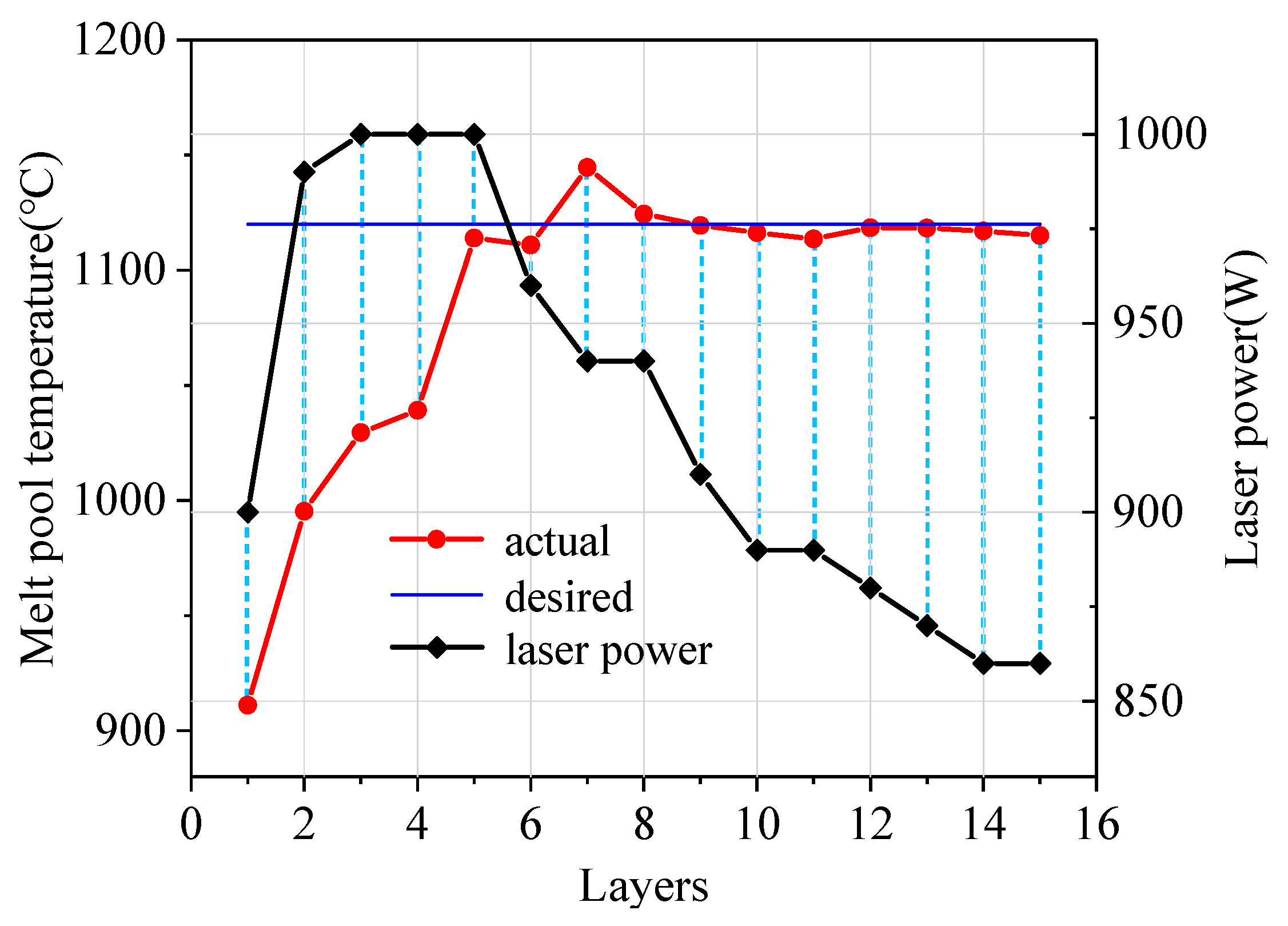

4. Small Block Deposition of Ti6Al4V Alloy

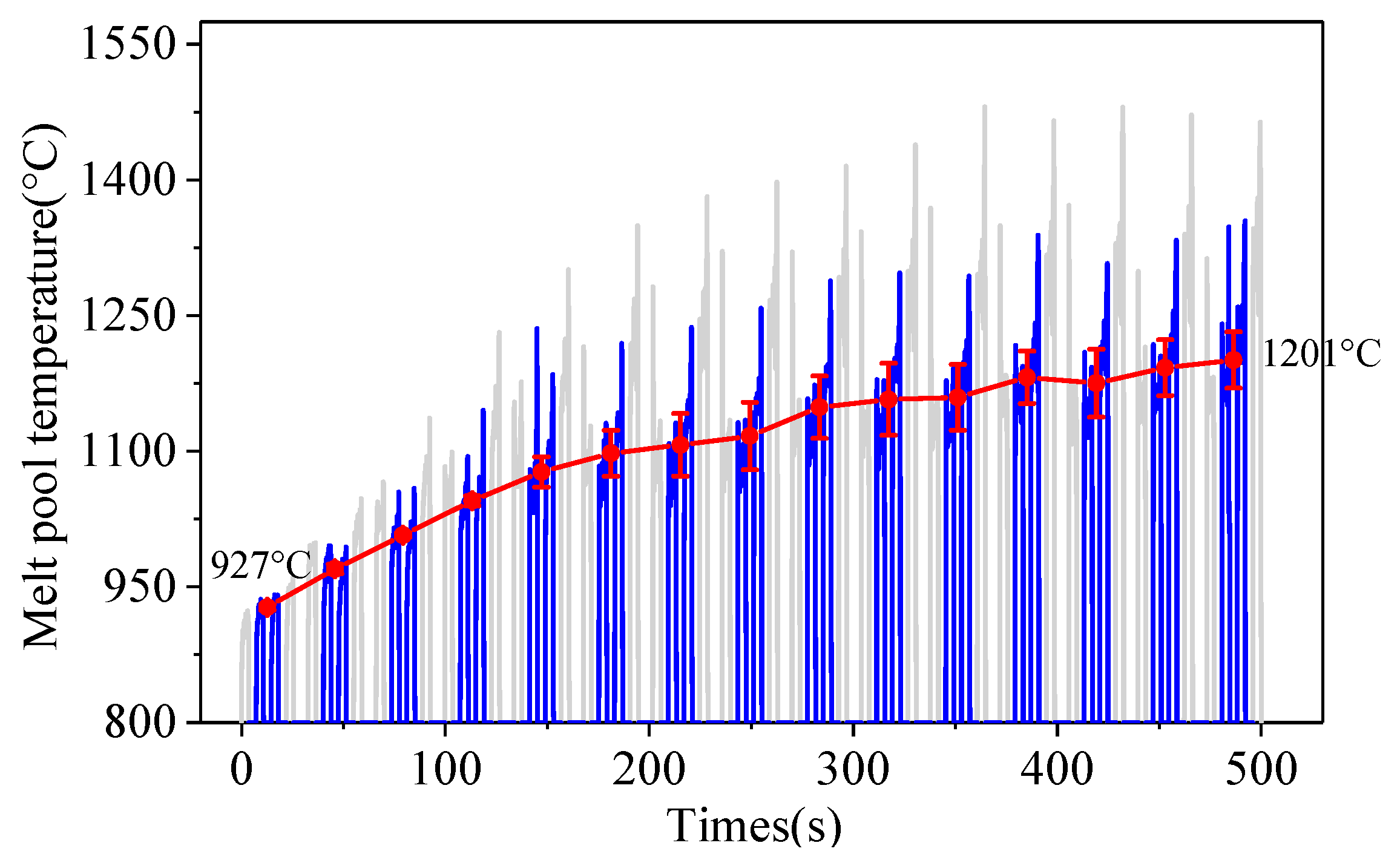

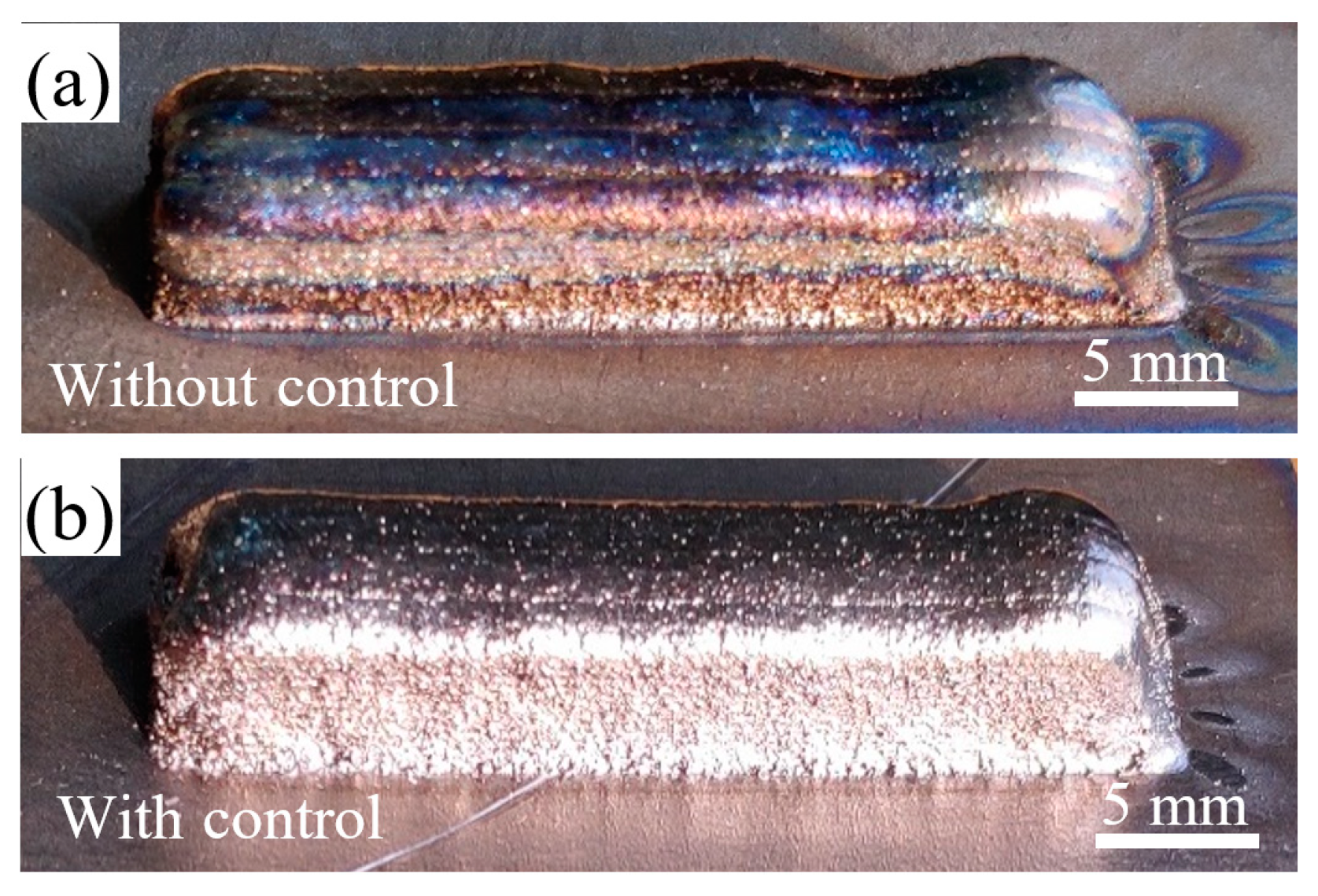

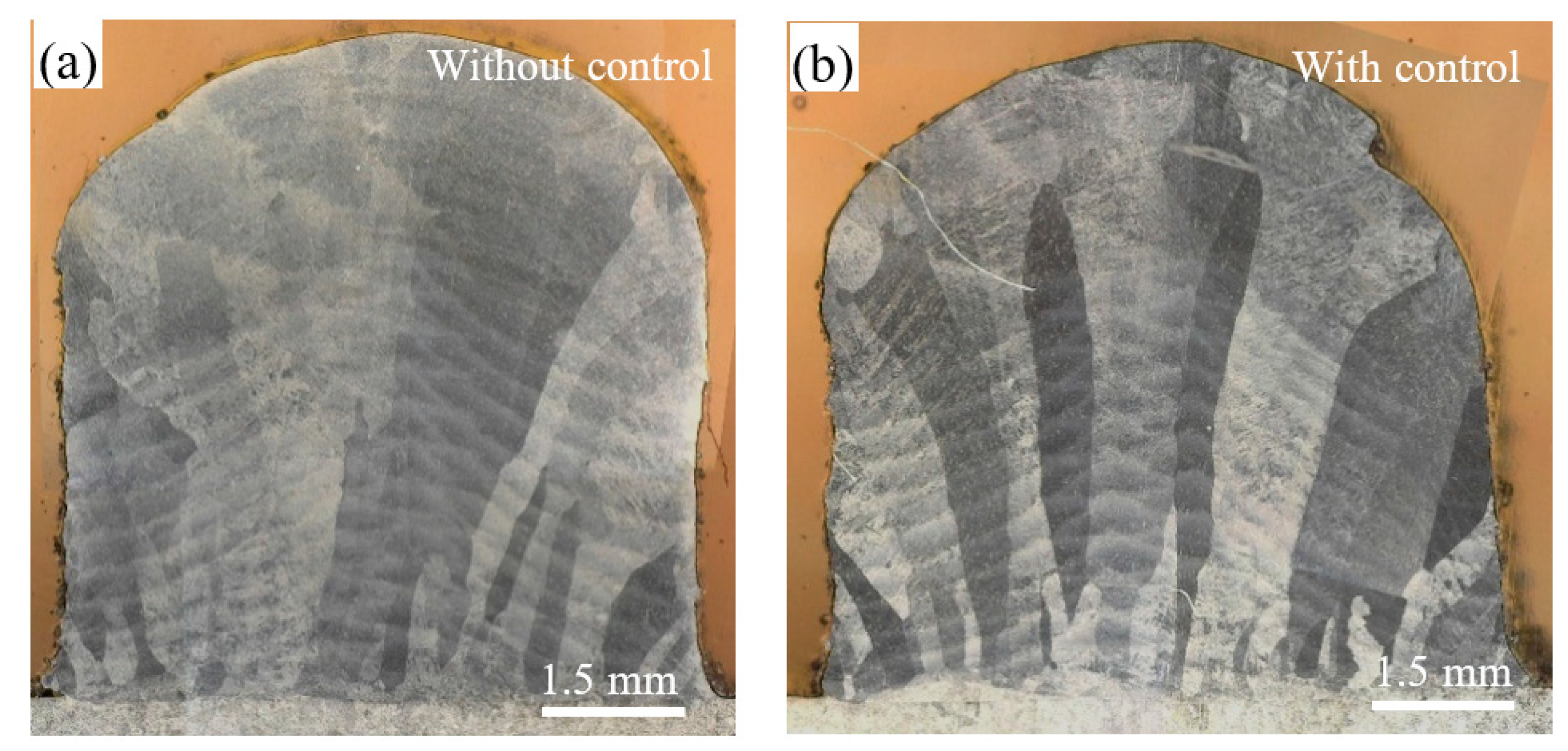

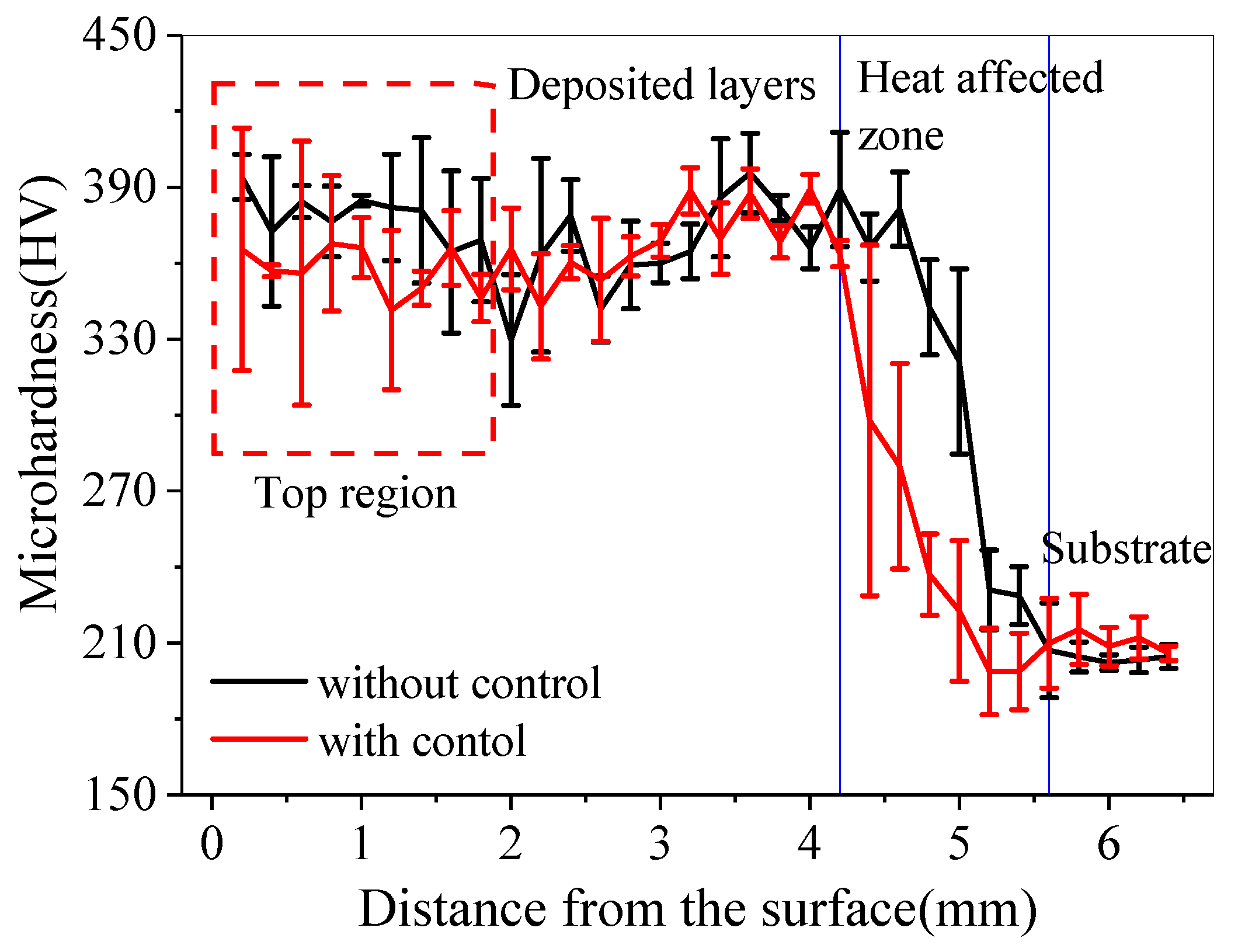

4.1. Comparison between Deposited Layers with and without Closed-Loop Control

4.2. Analysis of the Deposition Quality

5. Conclusions

- In the ALMD technology, a closed-loop control method of melt pool temperature for the deposition of small blocks in an open environment was proposed. Compared with the traditional constant parameter deposition method, a layer with variable parameters can reduce heat accumulation, and improve deposition quality.

- A double-color infrared pyrometer was developed to measure the melt pool temperature. A PI temperature controller was designed to control melt pool temperature by adjusting the laser power after each layer. A CCD-based sensor was used to monitor the deposition height, and the lift amount remained the same as the deposition height.

- The step response test indicated that the PI temperature controller had a stable and convergent control performance. With a PI controller, a small block with no oxidation was successfully manufactured in an open environment. The melt pool temperature tended to the desired value and the heat accumulation was reduced. Compared to the deposition results without the controller, a flatter surface and no oxidation phenomenon were obtained with the controller.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Urhal, P.; Weightman, A.; Diver, C.; Bartolo, P. Robot assisted additive manufacturing: A review. Robot. Comput.-Integr. Manuf. 2019, 59, 335–345. [Google Scholar] [CrossRef]

- Ghasempour-Mouziraji, M.; Lagarinhos, J.; Afonso, D.; de Sousa, R.A. A review study on metal powder materials and processing parameters in Laser Metal Deposition. Opt. Laser Technol. 2023, 170, 110226. [Google Scholar] [CrossRef]

- Yang, Z.C.; Wang, S.H.; Zhu, L.D.; Ning, J.S.; Xin, B.; Dun, Y.C.; Yan, W.T. Manipulating molten pool dynamics during metal 3D printing by ultrasound. Appl. Phys. Rev. 2022, 9, 021416. [Google Scholar] [CrossRef]

- Li, K.; Zhan, J.B.; Zhang, M.; Ma, R.J.; Tang, Q.; Zhang, D.Z.; Murr, L.E.; Cao, H.J. A functionally graded material design from stainless steel to Ni-based superalloy by laser metal deposition coupled with thermodynamic prediction. Mater. Des. 2022, 217, 110612. [Google Scholar] [CrossRef]

- Epifanov, E.O.; Shubnyi, A.G.; Minayev, N.V.; Rybaltovskiy, A.O.; Yusupov, V.I.; Parenago, O.P. Synthesis of heterogeneous catalysts by laser ablation of metallic palladium with deposition on alumina in supercritical carbon dioxide. Russ. J. Phys. Chem. B 2020, 14, 1103–1107. [Google Scholar] [CrossRef]

- Glavicic, M.G.; Venkatesh, V. Integrated computational materials engineering of titanium: Current capabilities being developed under the metals affordability initiative. JOM 2014, 66, 1310–1320. [Google Scholar] [CrossRef]

- Liu, D.; Yang, H.Y.; Li, J.H.; Li, J.Q.; Dong, Y.Z.; Yang, C.T.; Jin, Y.T.; Yassir, L.; Li, Z.; Hernandez, D.; et al. Electron transfer mediator PCN secreted by aerobic marine Pseudomonas aeruginosa accelerates microbiologically influenced corrosion of TC4 titanium alloy. J. Mater. Sci. Technol. 2021, 79, 101–108. [Google Scholar] [CrossRef]

- Sarraf, M.; Ghomi, E.R.; Alipour, S.; Ramakrishna, S.; Sukiman, N.L. A state-of-the-art review of the fabrication and characteristics of titanium and its alloys for biomedical applications. Bio-Des. Manuf. 2022, 5, 371–395. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.F.; Ding, J.L.; Ganguly, S.; Diao, C.; Williams, S. Oxide accumulation effects on wire plus arc layer-by-layer additive manufacture process. J. Mater. Process. Technol. 2018, 252, 739–750. [Google Scholar] [CrossRef]

- Yan, M.; Dargusch, M.S.; Ebel, T.; Qian, M. A transmission electron microscopy and three-dimensional atom probe study of the oxygen-induced fine microstructural features in as-sintered Ti-6Al-4V and their impacts on ductility. Acta Mater. 2014, 68, 196–206. [Google Scholar] [CrossRef]

- Sibisi, P.N.; Popoola, A.P.I.; Arthur, N.K.K.; Pityana, S.L. Review on direct metal laser deposition manufacturing technology for the Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2020, 107, 1163–1178. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Feng, Z.; Wang, C.J.; Liu, Z.; Dong, D.D.; Zhou, Y.; Wu, R. Modeling of temperature field evolution during multilayered direct laser metal deposition. J. Therm. Spray Technol. 2017, 26, 831–845. [Google Scholar] [CrossRef]

- Heilemann, M.; Prakash, V.J.; Beulting, L.; Emmelmann, C. Effect of heat accumulation on the single track formation during laser metal deposition and development of a framework for analyzing new process strategies. J. Laser Appl. 2021, 33, 012003. [Google Scholar] [CrossRef]

- Yu, M.; Zhu, L.D.; Yang, Z.C.; Ning, J.S. In situ monitoring and innovative feature fusion neural network for enhanced laser-directed energy deposition track geometry prediction and control. IEEE Trans. Instrum. Meas. 2024, 73, 5022110. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Martina, F.; Williams, S.; Wiktorowicz, R.; Palt, M.R. Development of a laminar flow local shielding device for wire plus arc additive manufacture. J. Mater. Process. Technol. 2015, 226, 99–105. [Google Scholar] [CrossRef]

- Bermingham, M.J.; Thomson-Larkins, J.; St John, D.H.; Dargusch, M.S. Sensitivity of Ti-6Al-4V components to oxidation during out of chamber Wire plus Arc Additive Manufacturing. J. Mater. Process. Technol. 2018, 258, 29–37. [Google Scholar] [CrossRef]

- Zhang, J.C.; Wang, H.; Cao, Y.P.; Su, B.Y.; Hua, G.R.; Shi, T.; Shi, J.J. Effect of oxygen content in local shielding atmosphere on cladding quality of Ti6Al4V during annular laser metal deposition. Int. J. Adv. Manuf. Technol. 2023, 128, 925–935. [Google Scholar] [CrossRef]

- Cheng, D.J.; Zhang, J.C.; Shi, T.; Li, G.; Shi, J.J.; Lu, L.; Fu, G.Y. Microstructure and mechanical properties of additive manufactured Ti-6Al-4V components by annular laser metal deposition in a semi-open environment. Opt. Laser Technol. 2021, 135, 106640. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.C.; Shi, T.; Shi, J.J.; Cheng, D.J.; Lu, L.; Shi, S.H. Experimental Investigation on Laser Metal Deposition of Ti-6Al-4V Alloy with Coaxial Local Shielding Gas Nozzle. J. Mater. Eng. Perform. 2020, 29, 7821–7829. [Google Scholar] [CrossRef]

- Hieu, D.H.; Duyen, D.Q.; Tai, N.P.; Thang, N.V.; Vinh, N.C.; Hung, N.Q. Crystal structure and mechanical properties of 3D printing parts using bound powder deposition method. In Modern Mechanics and Applications: Select Proceedings of ICOMMA 2020, Ho Chi Minh City, Vietnam, 2–4 December 2020; Springer Nature: Singapore, 2022; pp. 54–62. [Google Scholar]

- Bernauer, C.; Zapata, A.; Zaeh, M.F. Toward defect-free components in laser metal deposition with coaxial wire feeding through closed-loop control of the melt pool temperature. J. Laser Appl. 2022, 34, 042044. [Google Scholar] [CrossRef]

- Petrat, T.; Winterkorn, R.; Graf, B.; Gumenyuk, A.; Rethmeier, M. Build-up strategies for temperature control using laser metal deposition for additive manufacturing. Weld. World 2018, 62, 1073–1081. [Google Scholar] [CrossRef]

- Devesse, W.; De Baere, D.; Hinderdael, M.; Guillaume, P. Hardware-in-the-loop control of additive manufacturing processes using temperature feedback. J. Laser Appl. 2016, 28, 022302. [Google Scholar] [CrossRef]

- Mazzarisi, M.; Angelastro, A.; Latte, M.; Colucci, T.; Palano, F.; Campanelli, S.L. Thermal monitoring of laser metal deposition strategies using infrared thermography. J. Manuf. Process. 2023, 85, 594–611. [Google Scholar] [CrossRef]

- Donadello, S.; Motta, M.; Demir, A.G.; Previtali, B. Monitoring of laser metal deposition height by means of coaxial laser triangulation. Opt. Lasers Eng. 2019, 112, 136–144. [Google Scholar] [CrossRef]

- Yu, M.; Zhu, L.D.; Ning, J.S.; Yang, Z.C.; Jiang, Z.Z.; Xu, L.; Wang, Y.Q.; Meng, G.R.; Huang, Y.M. Machine vision and novel attention mechanism TCN for enhanced prediction of future deposition height in directed energy deposition. Mech. Syst. Signal Proc. 2024, 216, 111492. [Google Scholar] [CrossRef]

- Song, L.J.; Bagavath-Singh, V.; Dutta, B.; Mazumder, J. Control of melt pool temperature and deposition height during direct metal deposition process. Int. J. Adv. Manuf. Technol. 2012, 58, 247–256. [Google Scholar] [CrossRef]

- Shi, S.H.; Shi, T.; Fu, G.Y.; Zhu, G.X.; Shi, J.J.; Lei, D.Z.; Meng, W.D. Synchronous Powder-Feeding Space Laser Machining and Three-Dimensional Forming Method and Device. U.S. Patent CN201410391618.5, 17 August 2017. [Google Scholar]

- Liu, S.; Kong, F.R.; Shi, S.H.; Kovacevic, R. Study of a hollow laser beam for cladding. Int. J. Adv. Manuf. Technol. 2014, 73, 147–159. [Google Scholar] [CrossRef]

- Zhang, J.C.; Cao, Y.P.; Wang, H.; Shi, T.; Su, B.Y.; Zhang, L. Effect of annular laser metal deposition (ALMD) process parameters on track geometry and thermal history on ti6al4v alloy clad. Materials 2023, 16, 4062. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.C.; Shi, S.H.; Fu, G.Y.; Shi, J.J.; Zhu, G.X.; Cheng, D.J. Analysis on surface finish of thin-wall parts by laser metal deposition with annular beam. Opt. Laser Technol. 2019, 119, 105605. [Google Scholar] [CrossRef]

- Shi, T.; Lu, B.H.; Shen, T.; Zhang, R.; Shi, S.H.; Fu, G.Y. Closed-loop control of variable width deposition in laser metal deposition. Int. J. Adv. Manuf. Technol. 2018, 97, 4167–4178. [Google Scholar] [CrossRef]

- Falcón, J.C.P.; Echeverría, A.; Afonso, C.R.M.; Carrullo, J.C.Z.; Borrás, V.A. Microstructure assessment at high temperature in NiCoCrAlY overlay coating obtained by laser metal deposition. J. Mater. Res. Technol. JMRT 2019, 8, 1761–1772. [Google Scholar] [CrossRef]

- AWS D17.1/D17.1M; Specification for Fusion Welding for Aerospace Applications, 3rd ed.; American Welding Society: Doral, FL, USA, 2017.

- Harooni, A.; Nasiri, A.M.; Gerlich, A.P.; Khajepour, A.; Khalifa, A.; King, J.M. Processing window development for laser cladding of zirconium on zirconium alloy. J. Mater. Process. Technol. 2016, 230, 263–271. [Google Scholar] [CrossRef]

- Tan, H.; Guo, M.L.; Clare, A.T.; Lin, X.; Chen, J.; Huang, W.D. Microstructure and properties of Ti-6Al-4V fabricated by low-power pulsed laser directed energy deposition. J. Mater. Sci. Technol. 2019, 35, 2027–2037. [Google Scholar] [CrossRef]

- Choi, Y.R.; Sun, S.D.; Liu, Q.C.; Brandt, M.; Qian, M. Influence of deposition strategy on the microstructure and fatigue properties of laser metal deposited Ti-6Al-4V powder on Ti-6Al-4V substrate. Int. J. Fatigue 2020, 130, 105236. [Google Scholar] [CrossRef]

| Ti | Al | V | O | N | |

|---|---|---|---|---|---|

| Without control | 46 | 5 | 2.6 | 46.3 | 0 |

| With control | 56.7 | 5.9 | 1.9 | 26.6 | 8.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Zhang, J.; Zhu, Q.; Cao, Y. Closed-Loop Control of Melt Pool Temperature during Laser Metal Deposition. Sensors 2024, 24, 5020. https://doi.org/10.3390/s24155020

Wang Q, Zhang J, Zhu Q, Cao Y. Closed-Loop Control of Melt Pool Temperature during Laser Metal Deposition. Sensors. 2024; 24(15):5020. https://doi.org/10.3390/s24155020

Chicago/Turabian StyleWang, Qing, Jinchao Zhang, Qingqing Zhu, and Yue Cao. 2024. "Closed-Loop Control of Melt Pool Temperature during Laser Metal Deposition" Sensors 24, no. 15: 5020. https://doi.org/10.3390/s24155020