A Non-Source Optical Fiber Sensor for Multi-Point Methane Detection

Abstract

1. Introduction

2. Methodology

2.1. TDLAS Theory

2.2. Wavelength Modulation and Harmonic Detection Theory

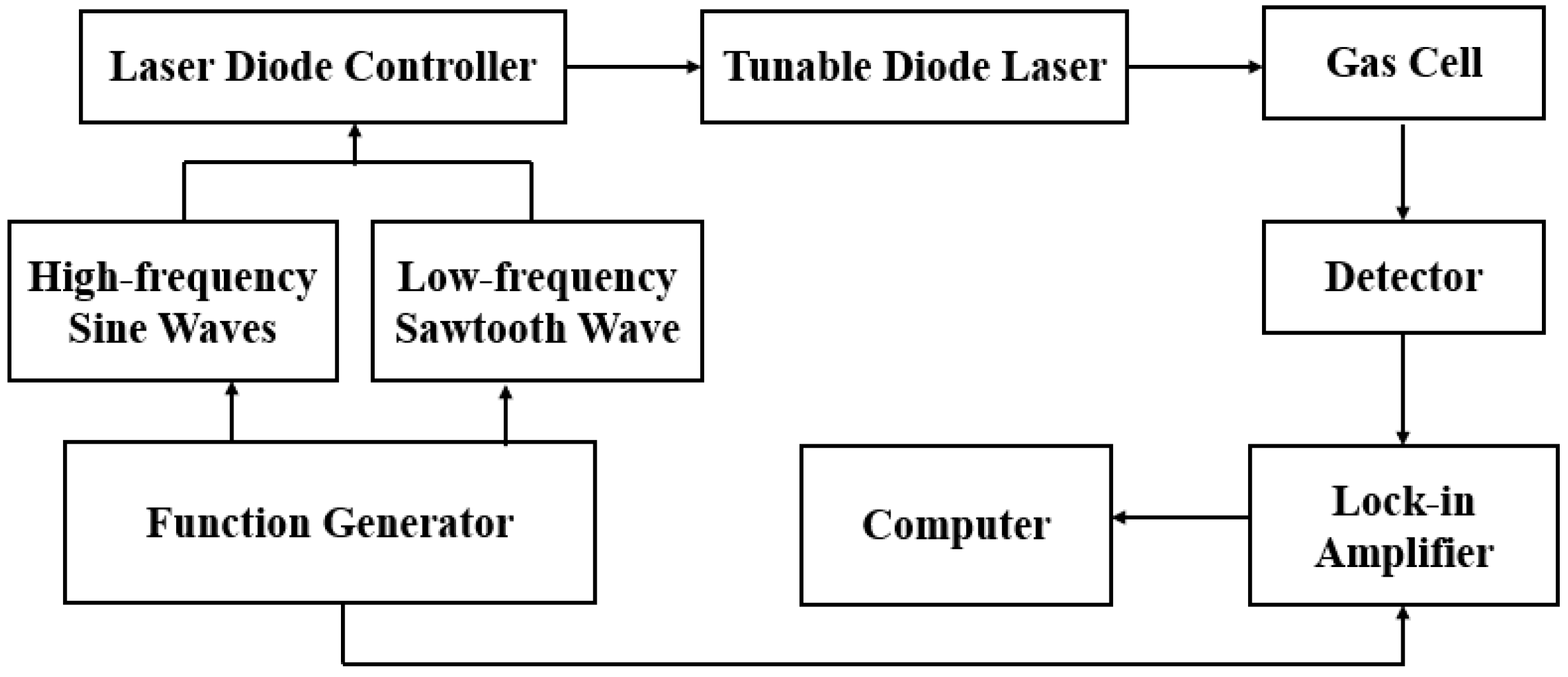

2.3. Experimental Setup Design

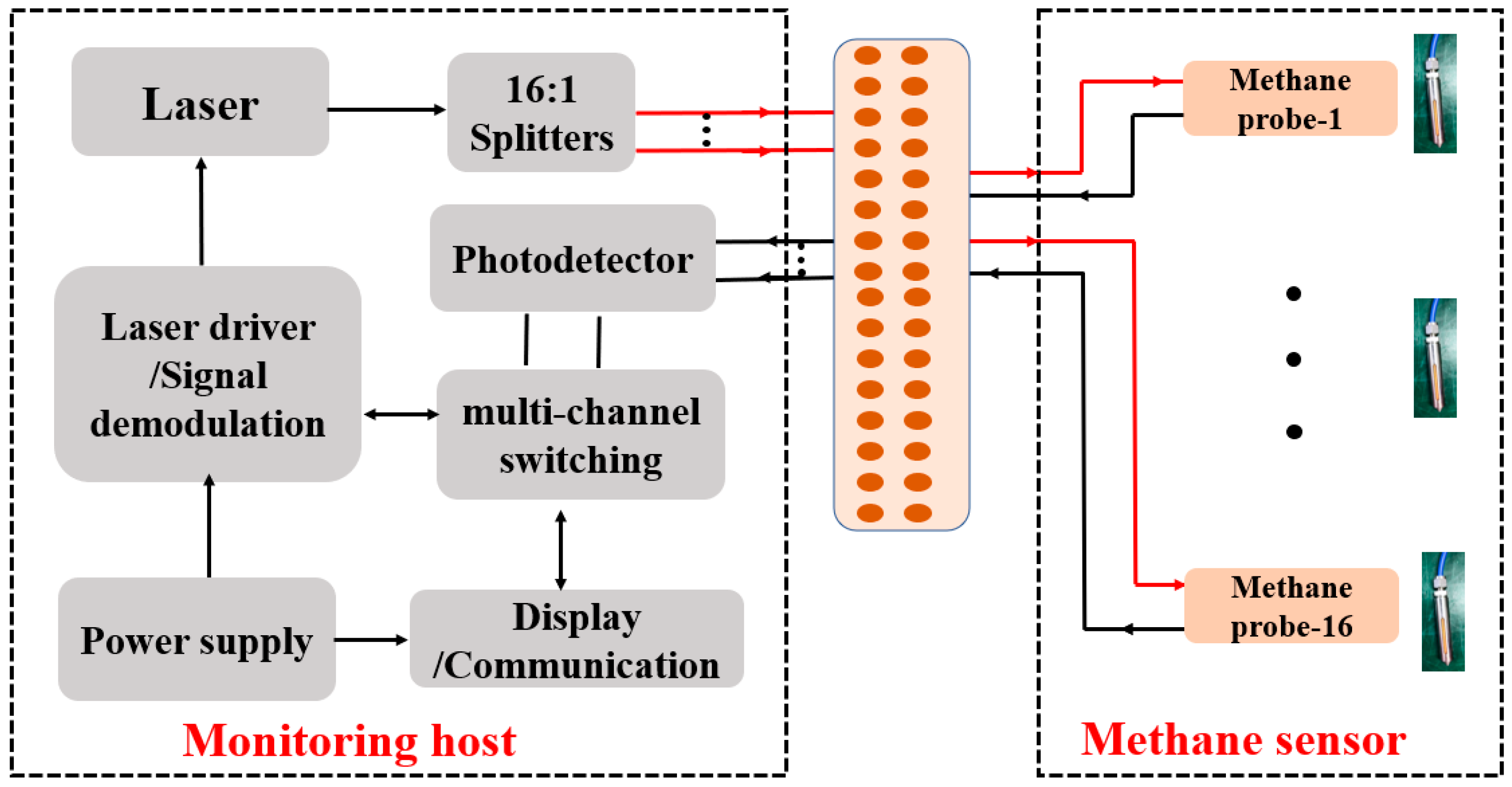

2.3.1. Multi-Channal Optical Fiber Methane Gas Sensor

2.3.2. Methane Probe

3. Results and Discussion

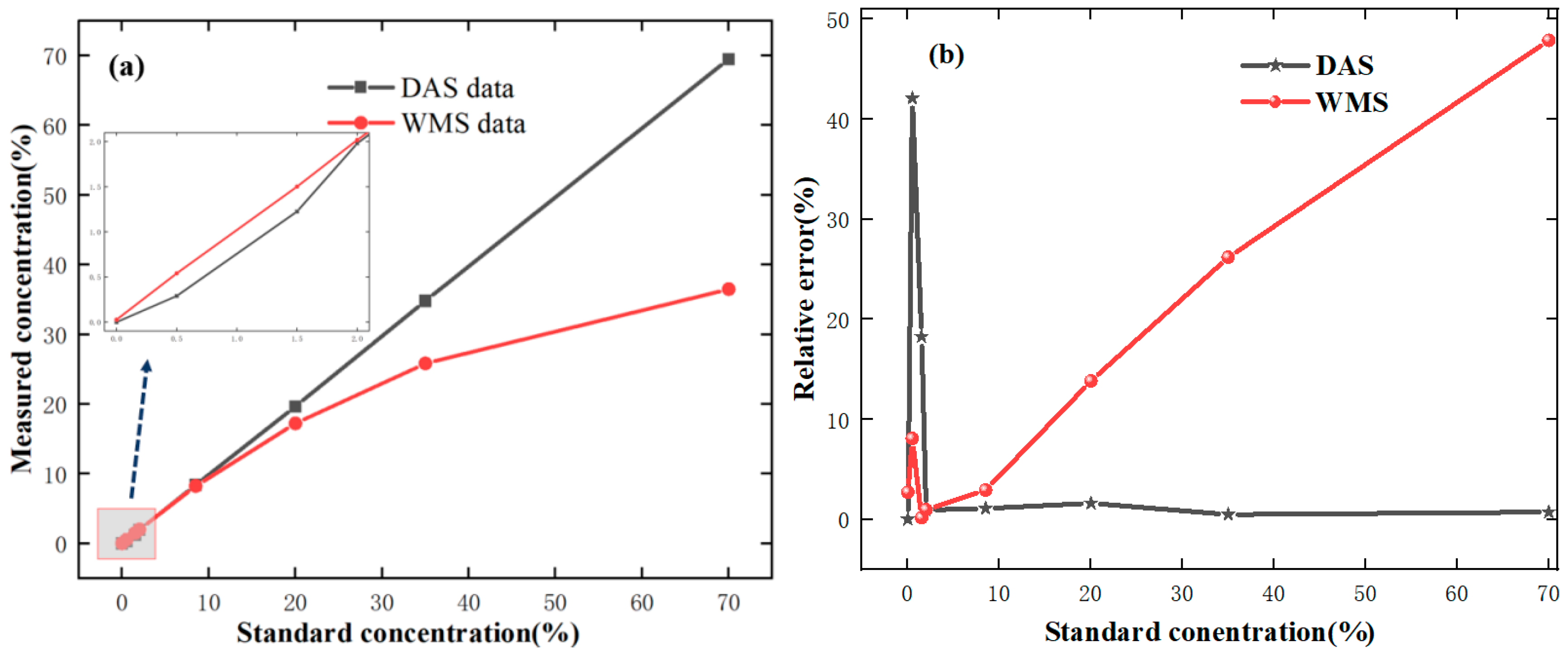

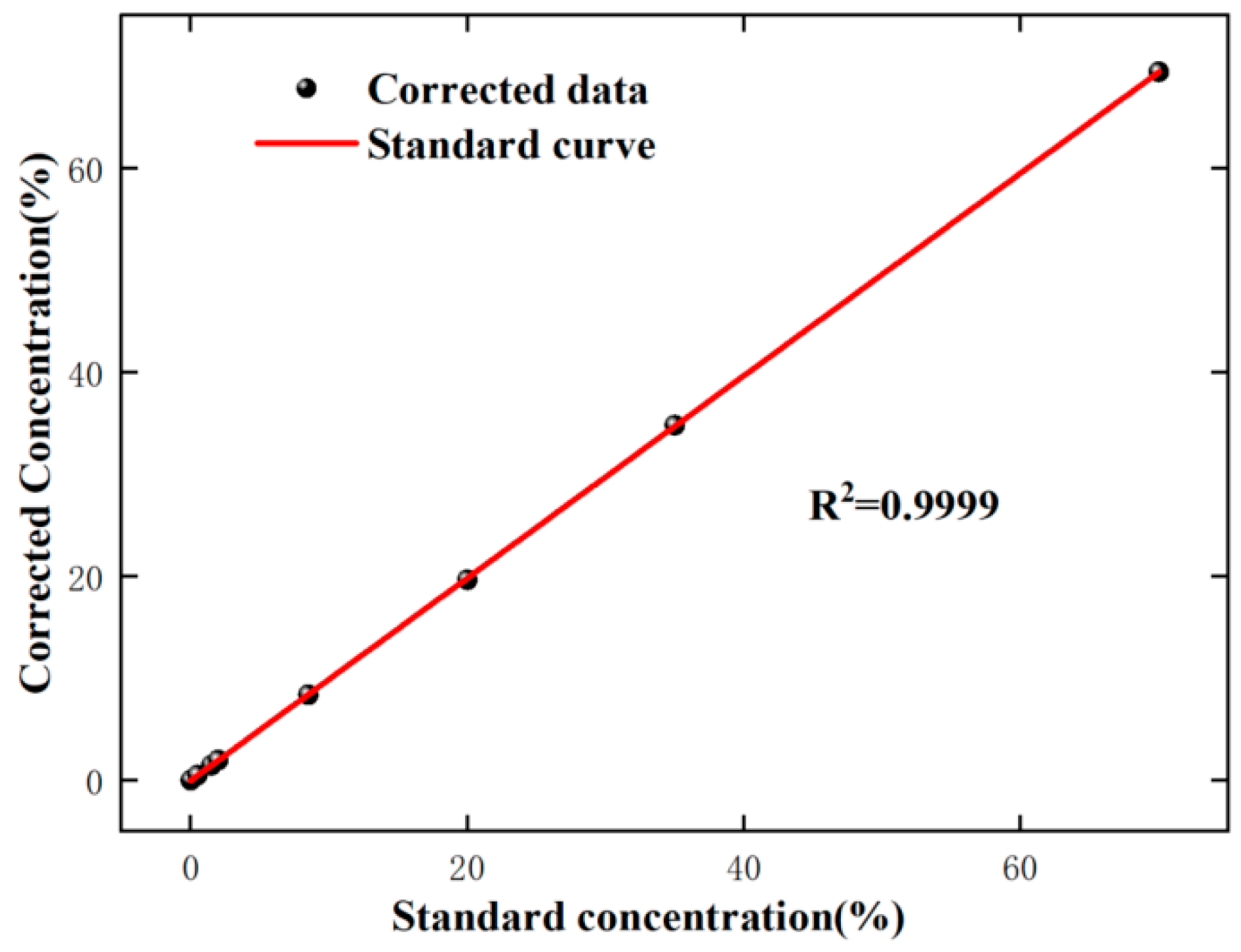

3.1. Methane Concentration Measurement in Full Range

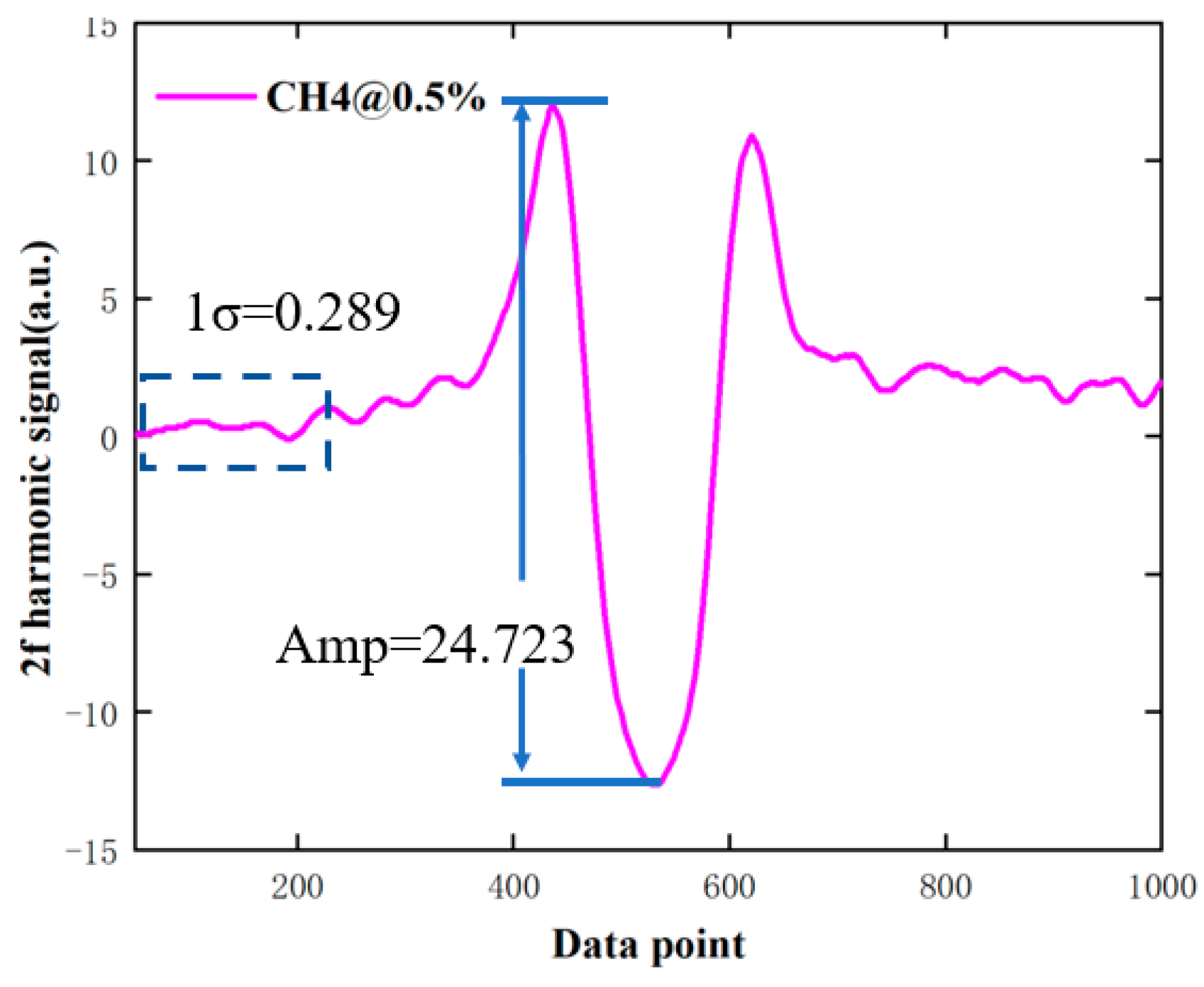

3.2. The Performances of the Methane Sensor

3.3. Methane Detection at Different Locations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, D.; Wang, J.; Lin, Y.; Si, Y.; Huang, C.; Yang, J.; Huang, B.; Li, W. Present situation and future prospect of renewable energy in China. Renew. Sustain. Energy Rev. 2017, 76, 865–871. [Google Scholar] [CrossRef]

- Ray, S.K.; Khan, A.M.; Mohalik, N.K.; Mishra, D.; Mandal, S.; Pandey, J.K. Review of preventive and constructive measures for coal mine explosions: An Indian perspective. Int. J. Min. Sci. Technol. 2022, 32, 471–485. [Google Scholar] [CrossRef]

- Song, W.; Cheng, J.; Wang, W.; Qin, Y.; Wang, Z.; Borowski, M.; Wang, Y.; Tukkaraja, P. Underground mine gas explosion accidents and prevention techniques—An overview. Arch. Min. Sci. 2021, 66, 297–312. [Google Scholar]

- Maher, D.T.; Santos, I.R.; Leuven, J.R.; Oakes, J.M.; Erler, D.V.; Carvalho, M.; Eyre, B. Novel use of cavity ring-down spectroscopy to investigate aquatic carbon cycling from microbial to ecosystem scales. Environ. Sci. Technol. 2013, 47, 12938–12945. [Google Scholar] [CrossRef] [PubMed]

- Gong, Z.; Chen, K.; Yang, Y.; Zhou, X.; Yu, Q. Photoacoustic spectroscopy based multi-gas detection using high-sensitivity fiber-optic low-frequency acoustic sensor. Sens. Actuators 2018, 260, 357–363. [Google Scholar] [CrossRef]

- Sugumaran, V.; Prakash, S.; Ramu, E.; Arora, A.K.; Bansal, V.; Kagdiyal, V. Detailed characterization of bio-oil from pyrolysis of non-edible seed-cakes by Fourier Transform Infrared Spectroscopy (FTIR) and gas chromatography mass spectrometry (GC–MS) techniques. J. Chromatogr. B 2017, 1058, 47–56. [Google Scholar] [CrossRef]

- Sun, P.; Zhang, Z.; Li, Z.; Guo, Q.; Dong, F. A Study of Two Dimensional Tomography Reconstruction of Temperature and Gas Concentration in a Combustion Field Using TDLAS. Appl. Sci. 2017, 7, 990. [Google Scholar] [CrossRef]

- Hong, Y.; Song, J.; Wang, G.; Liu, Z. Review on the research of non-uniform combustion field measurement using laser absorption spectroscopy technique. Acta Aeronaut. Astronaut. Sin. 2015, 36, 724–736. [Google Scholar]

- Qiu, X.; Wei, Y.; Li, J.; Zhang, E.; Wei, J. Early detection system for coal spontaneous combustion by laser dual-species sensor of CO and CH4. Opt. Laser Technol. 2020, 121, 105832. [Google Scholar] [CrossRef]

- Li, Y.; Ma, Y.; Zheng, C. Near-infrared wide-range dual-gas sensor system for simultaneous detection of methane and carbon monoxide in coal mine environment. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2024, 307, 123581. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, T.; Wei, Y.; Liu, T. Highly sensitive and reliable optical fiber TDLAS gas detection system for methane in situ monitoring in near space. Appl. Opt. 2023, 62, 4409–4414. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Jiang, T.; Jin, G.; Zhao, Y.; Wei, Y.; Zhang, T.; Liu, T.; Sun, T.; Grattan, K.T.V. Quasi-distributed multipoint laser methane detection system and its application in cable trench safety monitoring. J. Phys. Conf. Ser. 2018, 1065, 252020. [Google Scholar] [CrossRef]

- Yang, S.; Talbot, R.W.; Frish, M.B.; Golston, L.M.; Aubut, N.F.; Zondlo, M.A.; Gretencord, C.; McSpiritt, J. Natural gas fugitive leak detection using an unmanned aerial vehicle: Measurement system description and mass balance approach. Atmosphere 2018, 9, 383. [Google Scholar] [CrossRef]

- Yang, J.; Yang, R.; Dong, X. Multipoint gas detection based on intrapulse absorption spectroscopy. IEEE Photonics Technol. Lett. 2023, 35, 1086–1089. [Google Scholar] [CrossRef]

- Cui, X.; Dong, F.; Zhang, Z.; Sun, P.; Xia, H.; Fertein, E. Simultaneous detection of ambient methane, nitrous oxide, and water vapor using an external-cavity quantum cascade laser. Atmos. Environ. 2018, 189, 125–132. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Z.; Sun, P. Design of high precision temperature and pressure closed-loop controlsystem for methane carbon isotope ratio measurement by laser absorption spectroscopy. Pol. J. Environ. Stud. 2022, 31, 1–10. [Google Scholar]

- Zhang, Z.; Xia, H.; Sun, P. Stable Gaseous Isotope Measurement Method Based on Highly Sensitive Laser Absorption Spectroscopy and Its Applications. Acta Photonica Sin. 2023, 52, 0352108. (In Chinese) [Google Scholar]

- Sun, P.; Zhang, Z.; Li, J. Research on natural gas leakage monitoring technology based on the open-path measurement technique of methane. Opt. Optoelectron. Technol. 2016, 14, 62–67. (In Chinese) [Google Scholar]

- Zhang, L.; Zhang, Z.; Sun, P.; Pang, T.; Shu, Z. A dual-gas sensor for simultaneous detection of methane and acetylene based on time-sharing scanning assisted wavelength modulation spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 239, 118495. [Google Scholar] [CrossRef]

- Rao, W.; Song, J.; Wang, G.; Xin, M.; Zhang, N. Resolution analysis of Tunable Diode Laser Absorption Spectroscopy system for velocity measurement of the scramjet combustion flow. Int. Astronaut. Congr. 2019, 58, 114101.1–114101.5. [Google Scholar] [CrossRef]

- Xin, F.; Li, J.; Guo, J.; Yang, D.; Liu, Z. Measurement of atmospheric CO2 column concentrations based on open-path TDLAS. Sensors 2021, 21, 1722. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Li, M.; Yang, T.; Zang, Z.; Li, N.; Zheng, R. Seconds-scale response sensor for in situ oceanic carbon dioxide detection. Anal. Chem. 2023, 95, 3577–3586. [Google Scholar] [CrossRef] [PubMed]

- Lan, L.; Ghasemifard, H.; Yuan, Y.; Hachinger, S.; Chen, J. Assessment of urban CO2 measurement and source attribution in munich based on TDLAS-WMS and trajectory analysis. Atmosphere 2020, 11, 58. [Google Scholar] [CrossRef]

- Wang, F.; Wu, J.; Liang, R.; Wang, Q.; Wei, Y.; Cheng, Y.; Li, Q.; Cao, D.; Xue, Q. Ultra-Stable Temperature Controller-Based Laser Wavelength Locking for Improvement in WMS Methane Detection. Sensors 2023, 23, 5107. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Wu, J.; Wang, Q.; Li, Q.; Cao, D.; Xue, Q. Self-calibrated Method for WMS Gas Sensor Immune to Optical and Electronic Drift. IEEE Sens. J. 2024, 24, 21964–21971. [Google Scholar] [CrossRef]

| Standard Concentration (%) | DAS | WMS | DAS/WMS | |||||

|---|---|---|---|---|---|---|---|---|

| Measurement Concentration (%) | Error (%) | AVG (%) | Measurement Concentration (%) | Error (%) | AVG (%) | Error (%) | AVG (%) | |

| 0 | 0 | 0 | 8.22 | 0.02 | 2.0 | 12.69 | 2.0 | 1.84 |

| 0.5 | 0.29 | 42.08 | 0.54 | 8.07 | 8.07 | |||

| 1.5 | 1.22 | 18.67 | 1.50 | 0.14 | 0.14 | |||

| 2.0 | 1.98 | 1.00 | 2.01 | 0.5 | 0.5 | |||

| 8.5 | 8.40 | 1.18 | 8.25 | 2.94 | 1.18 | |||

| 20 | 19.68 | 1.61 | 17.23 | 13.85 | 1.61 | |||

| 35 | 34.83 | 0.49 | 25.84 | 26.17 | 0.49 | |||

| 70 | 69.49 | 0.73 | 36.50 | 47.86 | 0.73 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Liu, X.; Si, G. A Non-Source Optical Fiber Sensor for Multi-Point Methane Detection. Sensors 2024, 24, 5031. https://doi.org/10.3390/s24155031

Ma L, Liu X, Si G. A Non-Source Optical Fiber Sensor for Multi-Point Methane Detection. Sensors. 2024; 24(15):5031. https://doi.org/10.3390/s24155031

Chicago/Turabian StyleMa, Li, Xu Liu, and Ganshang Si. 2024. "A Non-Source Optical Fiber Sensor for Multi-Point Methane Detection" Sensors 24, no. 15: 5031. https://doi.org/10.3390/s24155031

APA StyleMa, L., Liu, X., & Si, G. (2024). A Non-Source Optical Fiber Sensor for Multi-Point Methane Detection. Sensors, 24(15), 5031. https://doi.org/10.3390/s24155031