A 1 × 8 Optical Splitter Based on Polycarbonate Multicore Polymer Optical Fibers

Abstract

:1. Introduction

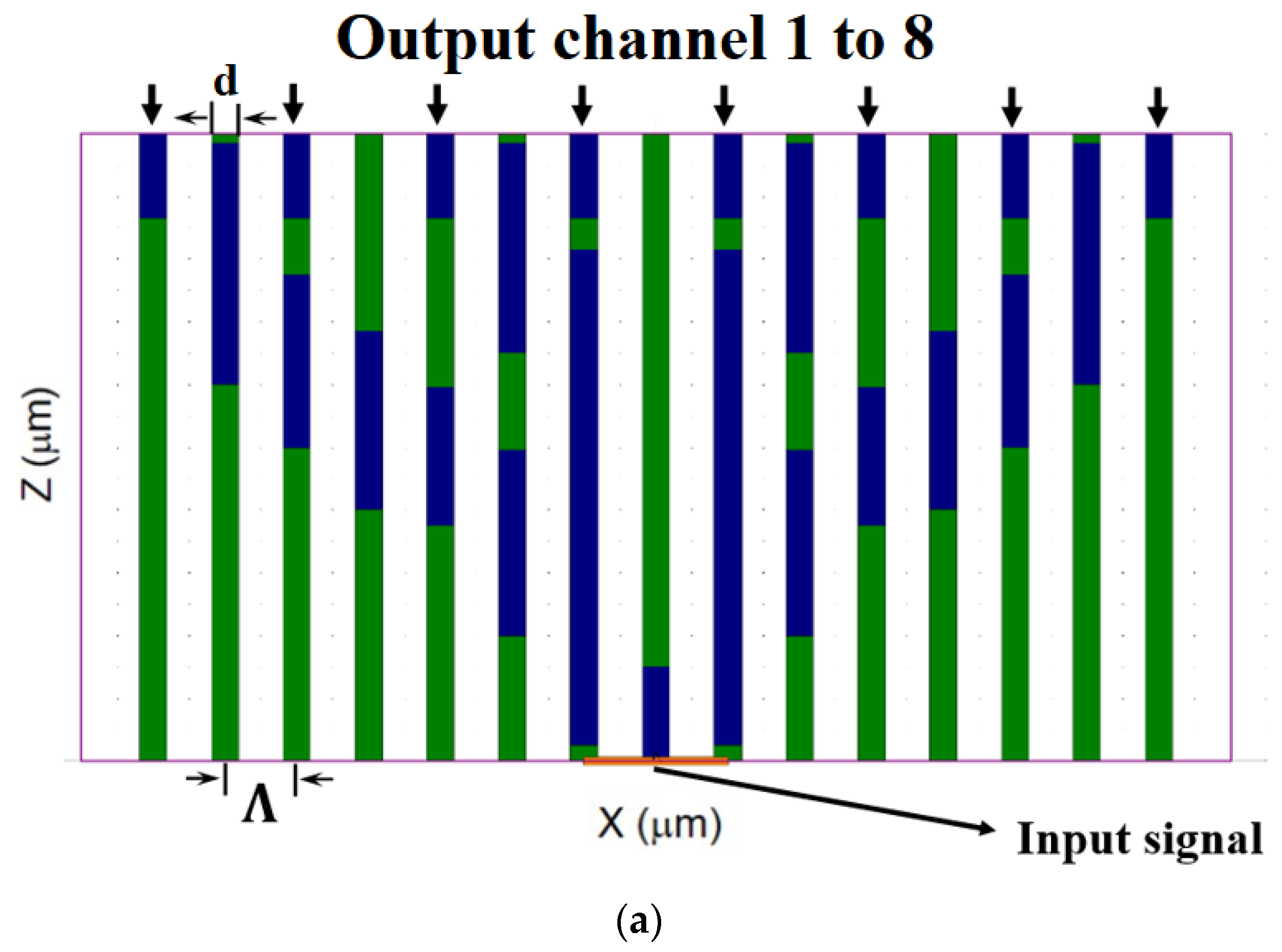

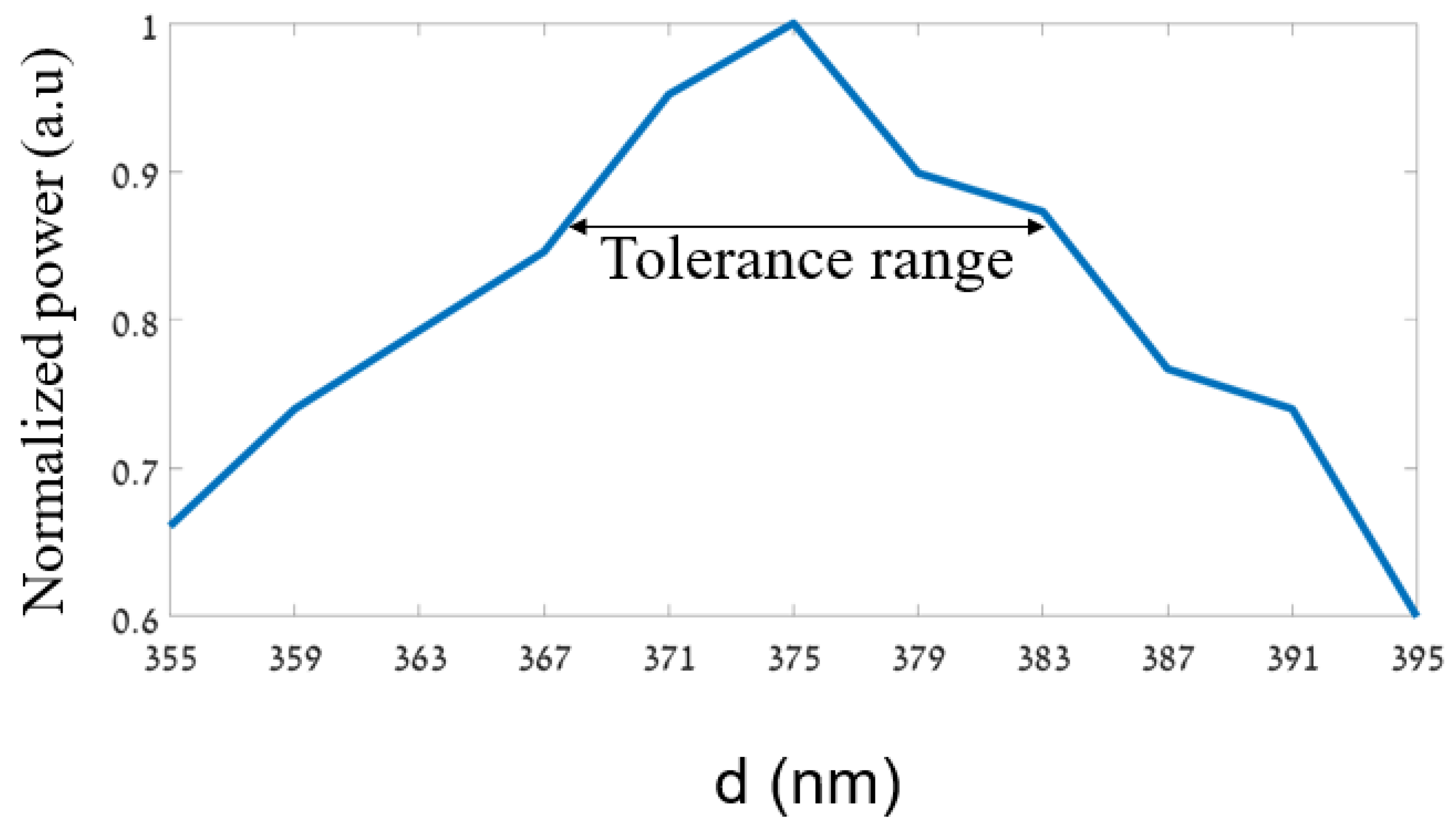

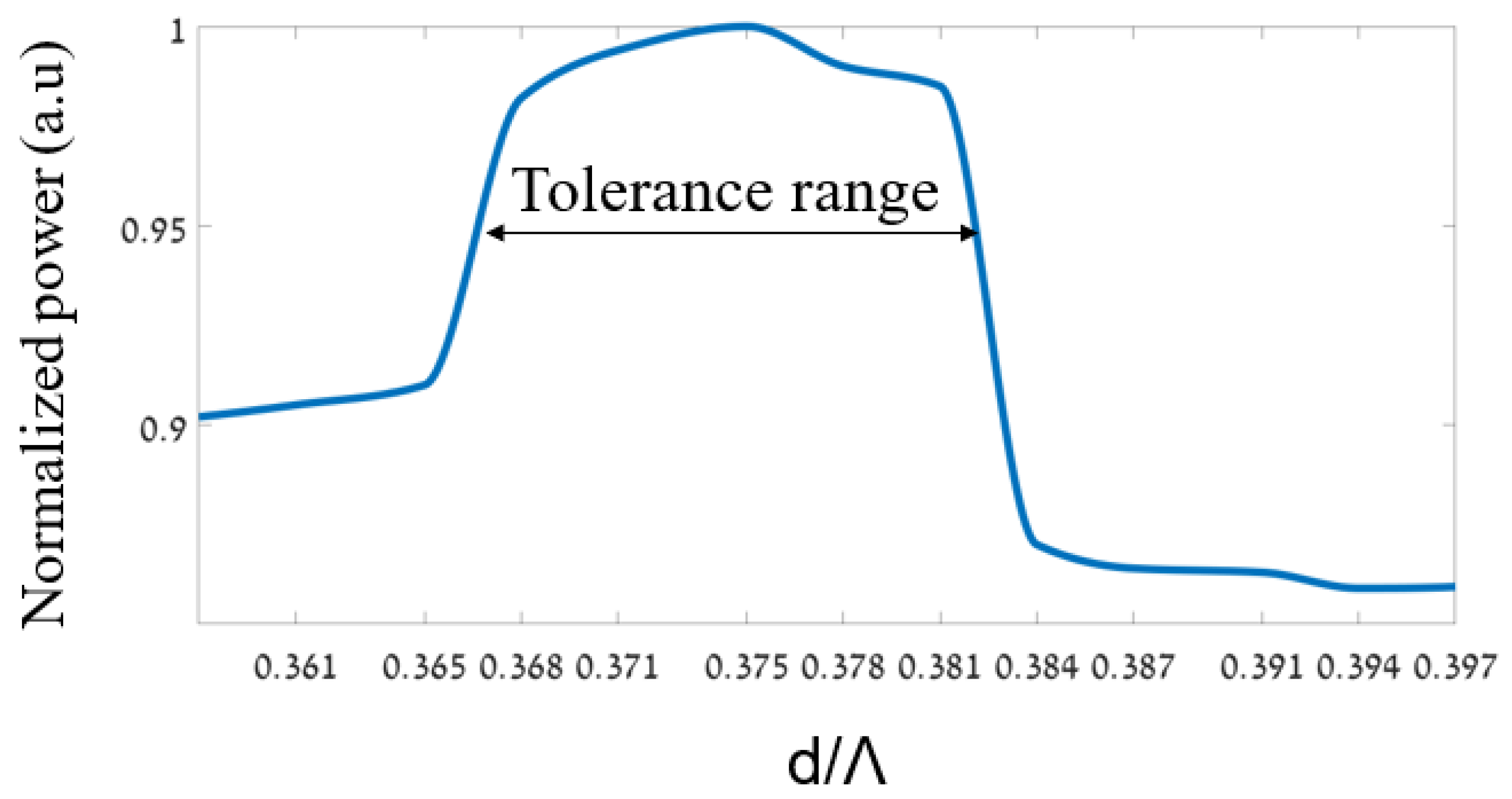

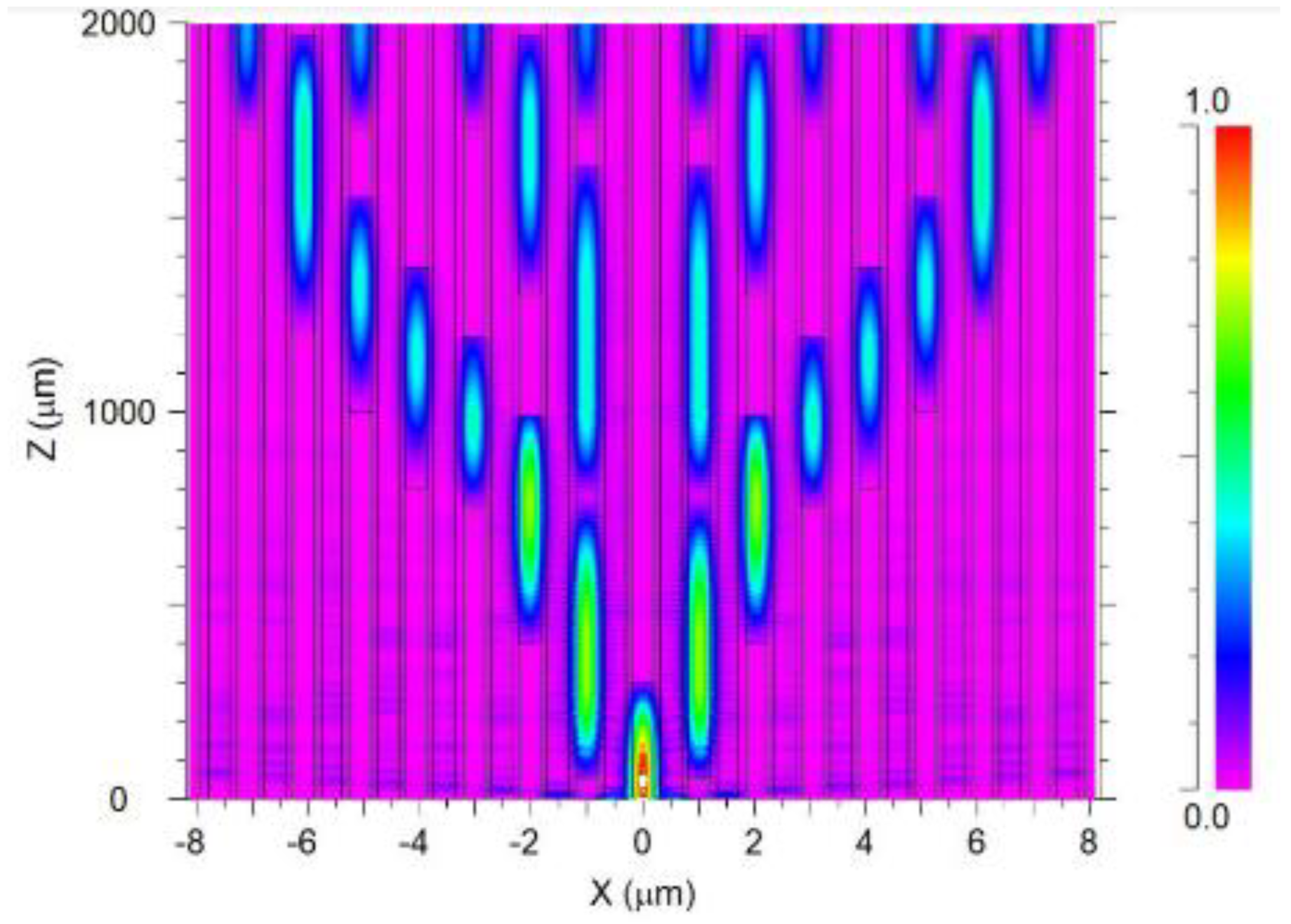

2. PC MC-POF Splitter Structure and Theoretical

3. Simulation Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dadabayev, R.; Malka, D. A visible light RGB wavelength demultiplexer based on polycarbonate multicore polymer optical fiber. Opt. Laser Technol. 2019, 116, 239–245. [Google Scholar] [CrossRef]

- Ayesta, I.; Azkune, M.; Illarramendi, M.A.; Arrospide, E.; Zubia, J.; Durana, G. Fabrication and characterization of active polymer optical fibers with a ring-doped structure. Opt. Fiber Technol. 2023, 75, 103209. [Google Scholar] [CrossRef]

- Gelkop, B.; Aichnboim, L.; Malka, D. RGB wavelength multiplexer based on polycarbonate multicore polymer optical fiber. Opt. Fiber Technol. 2021, 61, 102441. [Google Scholar] [CrossRef]

- Dash, J.N.; Dass, S.; Jha, R. Microfiber Assisted Highly Birefringent PCF-Based Interferometric Sensors. IEEE Sens. J. 2017, 17, 1342–1346. [Google Scholar] [CrossRef]

- Yusufu, A.M.; Noor, A.S.M.; Tamchek, N.; Abidin, Z.Z. MEH-PPV film thickness influenced fluorescent quenching of tip-coated plastic optical fiber sensors. Opt. Fiber Technol. 2017, 39, 21–25. [Google Scholar] [CrossRef]

- Hou, L.; Akutagawa, S. Corrosion Monitoring by Plastic Optic Fiber Sensor Using Bi-Directional Light Transmission. Sensors 2024, 24, 3229. [Google Scholar] [CrossRef]

- Fadhli, R.; Prabowo, M.A.; Apriono, C.; Suwandi, W.R.; Fahrezi, A.; Zuhdi, M.A.; Maulana, M.S.A. Comparison Analysis of Plastic Optical Fiber as a Replacement for Copper Cables for Car Communication Links. In Proceedings of the 2023 6th International Conference on Information and Communications Technology (ICOIACT), Yogyakarta, Indonesia, 10–11 November 2023; pp. 76–81. [Google Scholar] [CrossRef]

- Malka, D. 1 × 4 Visible Light MMI Wavelength Demultiplexer in GaN slot-Waveguide Structure. In Proceedings of the 2018 IEEE International Conference on the Science of Electrical Engineering in Israel (ICSEE), Eilat, Israel, 12–14 December 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Ahammed, M.T.; Khan, T.; Rahman, M.M.; Fatema, K.; Rahman, M.A. Revolutionizing Air Pollution Detection with PCF-SPR Refractive Index Sensor. In Proceedings of the 2023 International Conference on Information and Communication Technology for Sustainable Development (ICICT4SD), Dhaka, Bangladesh, 21–23 September 2023; pp. 249–253. [Google Scholar] [CrossRef]

- Song, N.; Zhu, Y.; Xu, X.; Xu, S.; Gao, F. Experimental Study of Hollow-Core Photonic Crystal Fiber Optical Switching Effect in Liquid Nitrogen Environment. IEEE Photonics J. 2020, 12, 7101806. [Google Scholar] [CrossRef]

- Yang, X.; Li, Y.; Zhang, S.; Wang, S.; Wu, S. Comparison of Fiber-Based Gas Pressure Sensors Using Hollow-Core Photonic Crystal Fibers. IEEE Photonics J. 2021, 13, 6800209. [Google Scholar] [CrossRef]

- Xu, D.; Dai, S.; You, C.; Wang, Y.; Han, X.; Lin, C.; Liu, Y.; Liu, Z.; Wang, X.; Xu, Y.; et al. Optimization of draw processing parameters for As2Se3 glass fiber. Opt. Fiber Technol. 2017, 38, 46–50. [Google Scholar] [CrossRef]

- Yuan, T.; Zhang, X.; Xia, Q.; Wang, Y.; Yuan, L. A Twin-Core and Dual-Hole Fiber Design and Fabrication. J. Light. Technol. 2021, 39, 4028–4033. [Google Scholar] [CrossRef]

- Sariki, R.K.; Kambavalasa, S.K.; Bandari, N.K.; Moningi, R.K. Design and fabrication of POF Couplers/Splitters for Networking and Displacement Sensing. In Proceedings of the 2021 International Symposium of Asian Control Association on Intelligent Robotics and Industrial Automation (IRIA), Goa, India, 20–22 September 2021; pp. 183–186. [Google Scholar] [CrossRef]

- López, A.; Ramón, S.; Chueca, M.; Losada, M.Á.; Domínguez-Chapman, F.A.; Mateo, J. Experimental characterization of transmission properties in multi-core plastic optical fibers. In Proceedings of the 2016 18th International Conference on Transparent Optical Networks (ICTON), Trento, Italy, 10–14 July 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Supian, L.S.; Ab-Rahman, M.S.; Arsad, N. The study on pressure effect on characterization of directional coupler for different thickness of fiber cores in POF splitter development. In Proceedings of the 2014 IEEE 2nd International Symposium on Telecommunication Technologies (ISTT), Langkawi, Malaysia, 24–26 November 2014; pp. 288–292. [Google Scholar] [CrossRef]

- Mohamed-Kassim, N.S.; Abd-Rahman, M.K. High resolution tunable POF multimode power splitter. Opt. Commun. 2017, 400, 136–143. [Google Scholar] [CrossRef]

- Wood, A.; Jung, Y.; Richardson, D.J. Multiport Fiber Optic Beam Splitters for Space Division Multiplexed (SDM) Systems. IEEE Photonics Technol. Lett. 2020, 32, 795–798. [Google Scholar] [CrossRef]

- Kumari, M.; Arya, V. Integrated long reach and energy-efficient NGPON-VLC system with OCDM/WDM for smart green buildings. Optik 2023, 289, 171280. [Google Scholar] [CrossRef]

- Fuada, S.; Putra, A.P.; Aska, Y.; Adiono, T. Trans-impedance amplifier (HA) design for Visible Light Communication (VLC) using commercially available OP-AMP. In Proceedings of the 2016 3rd International Conference on Information Technology, Computer, and Electrical Engineering (ICITACEE), Semarang, Indonesia, 19–21 October 2016; pp. 31–36. [Google Scholar] [CrossRef]

- Elbaz, D.; Malka, D.; Zalevsky, Z. Photonic Crystal Fiber Based 1 × N Intensity and Wavelength Splitters/Couplers. Electromagnetics 2012, 32, 209–220. [Google Scholar] [CrossRef]

- Haque, E.; Noman, A.A.; Ahmed, F. Numerical Investigation of Photonic Crystal Fiber-Based Biosensor for Pathogens Detection in Water. IEEE Access 2022, 10, 88885–88893. [Google Scholar] [CrossRef]

- Yasli, A.; Ademgil, H.; Haxha, S.; Aggoun, A. Multi-Channel Photonic Crystal Fiber Based Surface Plasmon Resonance Sensor for Multi-Analyte Sensing. IEEE Photonics J. 2020, 12, 6800515. [Google Scholar] [CrossRef]

- Wang, F.; Liu, C.; Sun, Z.; Sun, T.; Liu, B.; Chu, P.K. A Highly Sensitive SPR Sensors Based on Two Parallel PCFs for Low Refractive Index Detection. IEEE Photonics J. 2018, 10, 7104010. [Google Scholar] [CrossRef]

- Sardar, M.R.; Faisal, M. Dual-Core Dual-Polished PCF-SPR Sensor for Cancer Cell Detection. IEEE Sens. J. 2024, 24, 9843–9854. [Google Scholar] [CrossRef]

- Gao, Y.; Li, J.F.; Wang, Y.Z.; Shi, Y.W.; Liu, F.; Li, K.; Yang, J.; Liu, Y. Design of Ultra Large Normal Dispersion ZBLAN Photonic Crystal Fiber and Its Application in Mid-IR Ultra Short Fiber Lasers. IEEE Photonics J. 2018, 10, 1504509. [Google Scholar] [CrossRef]

- Malka, D.; Peled, A. Power splitting of 1 × 16 in multicore photonic crystal fibers. Appl. Surf. Sci. 2017, 417, 34–39. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, S.; Wang, X.; Gou, D.; Chen, W.; Luo, W.; Xie, S. Photonic Crystal Fiber Based Wavelength-Tunable Optical Parametric Amplifier and Picosecond Pulse Generation. IEEE Photonics J. 2014, 6, 1501908. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Diaz, C.A.R.; Avellar, L.M.; Pontes, M.J.; Marques, C.; Frizera, A. Polymer Optical Fiber Sensors in Healthcare Applications: A Comprehensive Review. Sensors 2019, 19, 3156. [Google Scholar] [CrossRef] [PubMed]

- Mohamed-Kassim, N.S.; Ibrahim, A.-b.M.A.; Abd-Rahman, M.K. Low Loss and Dynamically Tunable Power Splitter Based on Circular-to-Rectangular POF Converter. J. Light. Technol. 2016, 34, 1306–1312. [Google Scholar] [CrossRef]

- Kominami, Y.; Yoshida, S.; Tanaka, S.; Sanomura, Y.; Hirakawa, T.; Raytchev, B.; Tamaki, T.; Koide, T.; Kaneda, K.; Chayama, K. Computer-aided diagnosis of colorectal polyp histology by using a real-time image recognition system and narrow-band imaging magnifying colonoscopy. Gastrointest. Endosc. 2016, 83, 643–649. [Google Scholar] [CrossRef]

- Leal-Junior, A.; Avellar, L.; Jaimes, J.; Díaz, C.; dos Santos, W.; Siqueira, A.A.G.; Pontes, M.J.; Marques, C.; Frizera, A. Polymer Optical Fiber-Based Integrated Instrumentation in a Robot-Assisted Rehabilitation Smart Environment: A Proof of Concept. Sensors 2020, 20, 3199. [Google Scholar] [CrossRef]

- Teng, C.; Deng, H.; Liu, H.; Yang, H.; Yuan, L.; Zheng, J.; Deng, S. Refractive Index Sensor Based on Twisted Tapered Plastic Optical Fibers. Photonics 2019, 6, 40. [Google Scholar] [CrossRef]

- Tavoletta, I.; Arcadio, F.; Renzullo, L.P.; Oliva, G.; Del Prete, D.; Verolla, D.; Marzano, C.; Alberti, G.; Pesavento, M.; Zeni, L.; et al. Splitter-Based Sensors Realized via POFs Coupled by a Micro-Trench Filled with a Molecularly Imprinted Polymer. Sensors 2024, 24, 3928. [Google Scholar] [CrossRef]

- Hou, Y.L.; Liu, W.Y.; Su, S.; Zhang, H.X.; Zhang, J.W.; Liu, J.; Xiong, J.J. Polymer optical fiber twisted macro-bend coupling system for liquid level detection. Opt. Express 2014, 22, 23231–23241. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, H.A.B.; Xiao, F.; Alameh, K. A 1×4 adaptive optical splitter based on Opto-VLSI processor. In Proceedings of the 8th International Conference on High-capacity Optical Networks and Emerging Technologies, Riyadh, Saudi Arabia, 19–21 December 2011; pp. 346–349. [Google Scholar] [CrossRef]

- Kumar Shukla, A.; Gandhi, B.; Narayan Pandey, G. A Novel Design of 1 × 3 Optical Splitter Based on 2D Photonic Crystal. Macromol. Symp. 2023, 419, 2100517. [Google Scholar] [CrossRef]

- Malka, D.; Berkovic, G.; Tischler, Y.; Zalevsky, Z. Super-Resolved Raman Spectra of Toluene and Toluene–Chlorobenzene Mixture. Spectrosc. Lett. 2014, 48, 431–435. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, D.; Zhang, X.; Ding, S.; Wang, J.; Cheng, R.; Wang, F.; Cui, Z.; Chen, C. Bottom-metal-printed thermo-optic waveguide switches based on low-loss fluorinated polycarbonate materials. Opt. Express 2020, 28, 20773–20784. [Google Scholar] [CrossRef] [PubMed]

- Eshaghi, A.; Graeli, A. Optical and electrical properties of indium tin oxide (ITO) nanostructured thin films deposited on polycarbonate substrates “thickness effect”. Optik 2014, 125, 1478–1481. [Google Scholar] [CrossRef]

- Kuang, R.; Ye, Y.; Chen, Z.; He, R.; Savović, I.; Djordjevich, A.; Savović, S.; Ortega, B.; Marques, C.; Li, X.; et al. Low-cost plastic optical fiber integrated with smartphone for human physiological monitoring. Opt. Fiber Technol. 2022, 72, 102947. [Google Scholar] [CrossRef]

- Prajzler, V.; Mastera, R.; Jerabek, V. Design, fabrication and properties of optical large core polymer planar 1 × 2 splitter. In Proceedings of the 2013 Conference on Lasers and Electro-Optics Pacific Rim (CLEOPR), Kyoto, Japan, 30 June–4 July 2013; pp. 1–2. [Google Scholar] [CrossRef]

- Bayer MaterialScience, A.G. Optical Properties of Makrolon and Apec for Non-Imaging Optics; Bayer MaterialScience AG: Leverkusen, Germany, 2014. [Google Scholar]

- Si, Z.Z.; Dai, C.Q.; Liu, W. Tunable three-wavelength fiber laser and transient switching between three-wavelength soliton and q-switched mode-locked states. Chin. Phys. Lett. 2024, 41, 020502. [Google Scholar] [CrossRef]

| Splitter Type | Device Footprint (Length × Width (mm)) | Ratio of Splitting | Power Loss (dB) | Operated Wavelength (nm) | Year of Publication |

|---|---|---|---|---|---|

| Y-tunable POF multimode Splitter [17] | 40 × 20 | 1 × 2 | ≤1.85 | 632.8 | 2017 |

| Circular-to-rectangular POF converter [30] | 1 × 0.785 | 1 × 2 | ≤0.7 | 632.8 | 2016 |

| SDM fiber beam splitters [18] | 12 × 19 | 1 × 3 | ≤0.5 | 1550 | 2020 |

| Polycarbonate multicore POF | 2 × 0.014 | 1 × 8 | ≤0.18 | 530 | In this work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lanziano, L.; Sherf, I.; Malka, D. A 1 × 8 Optical Splitter Based on Polycarbonate Multicore Polymer Optical Fibers. Sensors 2024, 24, 5063. https://doi.org/10.3390/s24155063

Lanziano L, Sherf I, Malka D. A 1 × 8 Optical Splitter Based on Polycarbonate Multicore Polymer Optical Fibers. Sensors. 2024; 24(15):5063. https://doi.org/10.3390/s24155063

Chicago/Turabian StyleLanziano, Liora, Ilay Sherf, and Dror Malka. 2024. "A 1 × 8 Optical Splitter Based on Polycarbonate Multicore Polymer Optical Fibers" Sensors 24, no. 15: 5063. https://doi.org/10.3390/s24155063