Temperature Compensation Method for Piezoresistive Pressure Sensors Based on Gated Recurrent Unit

Abstract

:1. Introduction

2. Failure Mechanism of Pressure Sensors

2.1. Introduction of Piezoresistive Pressure Sensors

2.2. Temperature Effects of Pressure Sensors

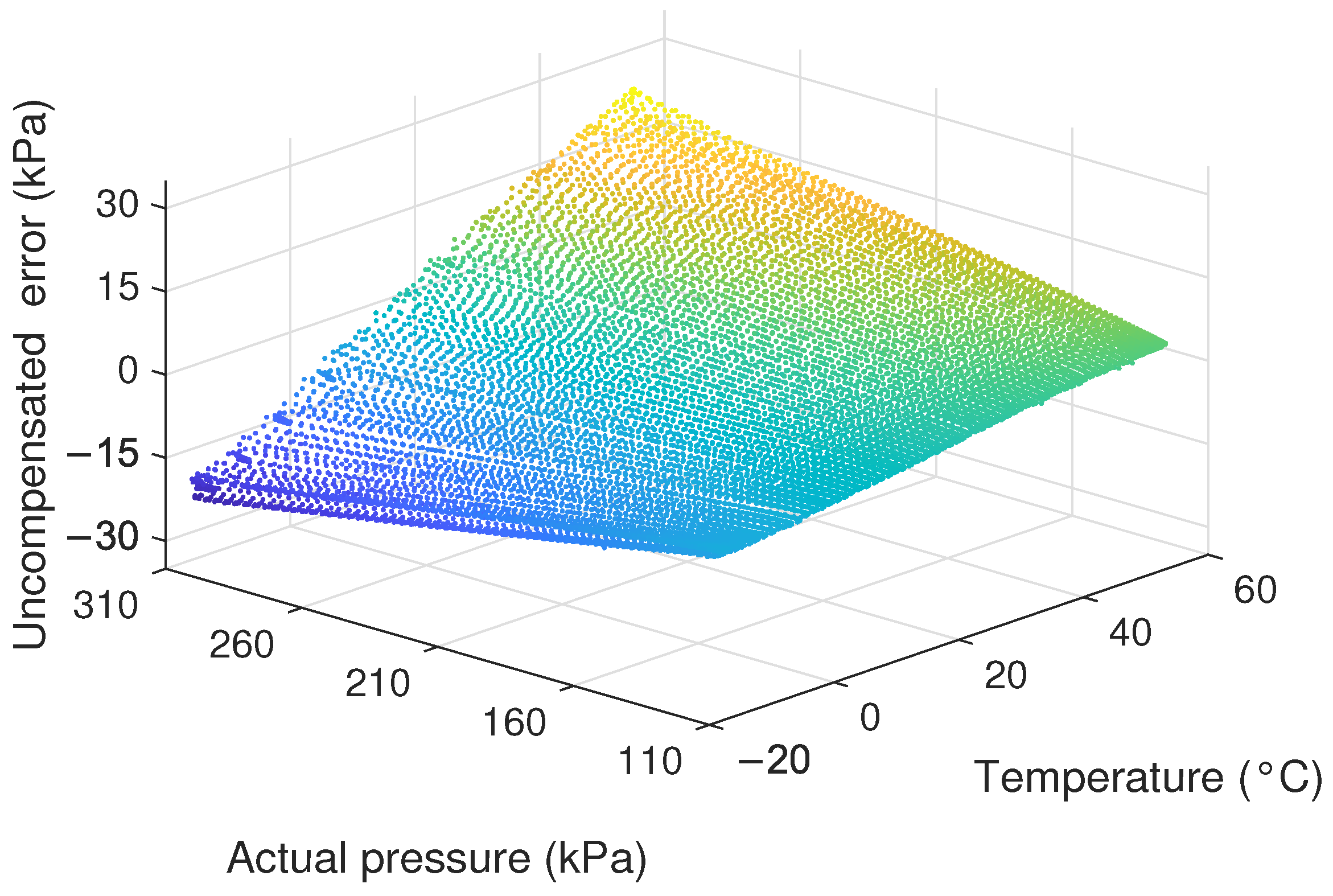

2.3. Factors for Temperature Compensation

3. Compensation Algorithms and Model

3.1. Random Forest

3.2. Gated Recurrent Unit Networks

3.3. WOA and IWOA

3.3.1. Whale Optimization Algorithm

- Contraction EncirclingThis process imitates the behavior of whales surrounding their prey through circular movement. The way the whales shrink their enclosures is modulated by .where r is the random number in the interval , and a is the adjustment factor.At , the algorithm performs a local search.where is the distance between the current whale position and the best whale position, and are the optimal position and the current individual position at the t iteration, respectively, C is the perturbation coefficient, and T is the maximum number of iterations.At , the algorithm performs a global search.where is the random whale position in the current iteration, and is the distance between the random whale position and the current whale position.

- Spiral Updating positionThis process imitates the behavior of whales encircling a target through spiral movement.where is the distance between the current and best whale positions, b is the spiral shape coefficient, and l is the random number in the interval .

3.3.2. Improved Whale Optimization Algorithm

- Chebyshev Chaotic MapThe Chebyshev chaotic map generates chaotic sequences through the repeated application of iterative functions. It exhibits nonlinearity, high sensitivity to initial values, excellent ergodicity, and unpredictability [42]. This map is frequently used for population initialization to enhance algorithmic diversity and randomness [43]. Based on the comparison of chaotic optimization algorithms, the Chebyshev chaotic map has a large Lyapunov exponent, which means its chaotic nature is pronounced, and its degree of chaos is high. Furthermore, considering the optimal, mean, and standard values, the Chebyshev chaotic map exhibits stability and high applicability. Therefore, considering all these factors, we chose the Chebyshev chaotic map to optimize the traditional whale algorithm. The formula is as follows:where and are control parameters.

- Adaptive WeightIn the case of contracting the encircling and spiral updating positions, a large weight value should be selected at the initial stage of the algorithm to improve the optimization speed and global search ability of the algorithm [44]. As the algorithm iterates continuously, the weight values should gradually decrease to reduce the fluctuation amplitude of the search and improve the convergence accuracy of the algorithm. Given the above situation, adaptive weight is introduced to optimize the algorithm so that the contraction encircling and spiral updating positions are adjusted according to the current iteration degree. The mathematical expression of can be expressed as follows:where and are constants. decreases with the number of iterations of the whale population. With the following, we can update Equation (21) to become the following:

3.4. RF-IWOA-GRU Model

4. Experiment and Results Analysis

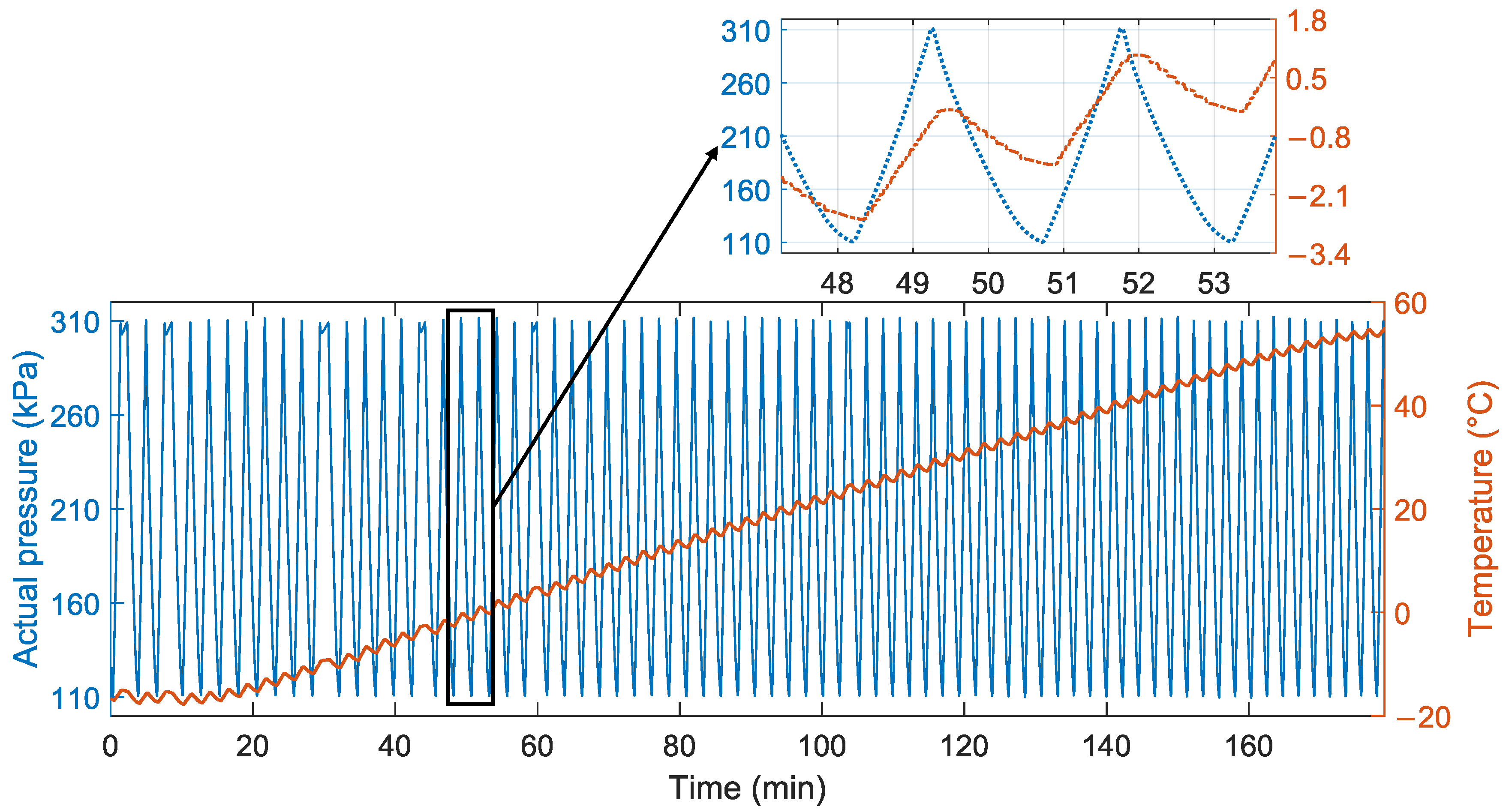

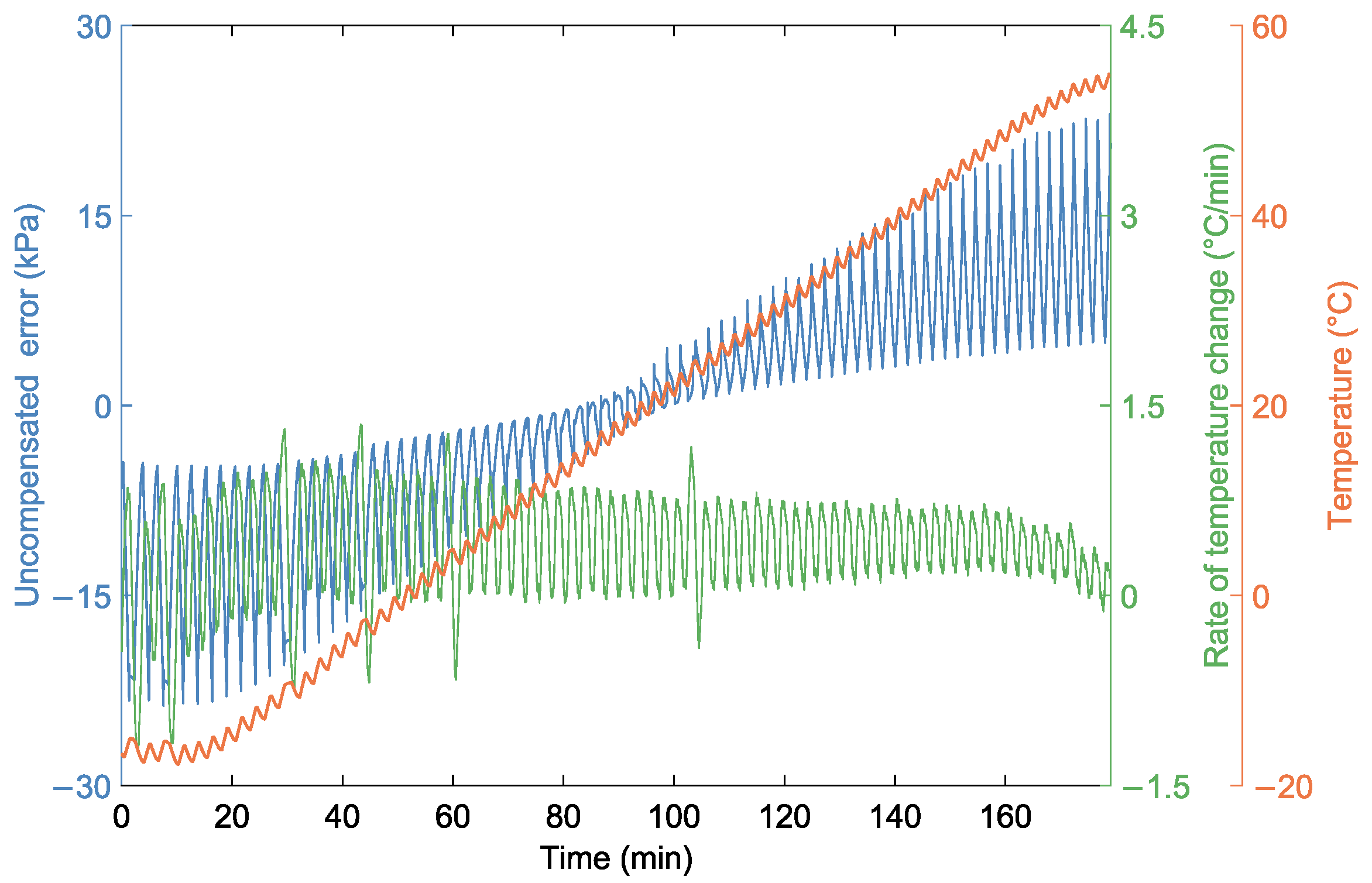

4.1. Experiment and Data Collection

4.2. Data Preprocessing

4.2.1. Calculation of the Rate of Temperature Change

4.2.2. Interpolation of Missing Actual Pressure Data Values

4.3. Modeling and Training

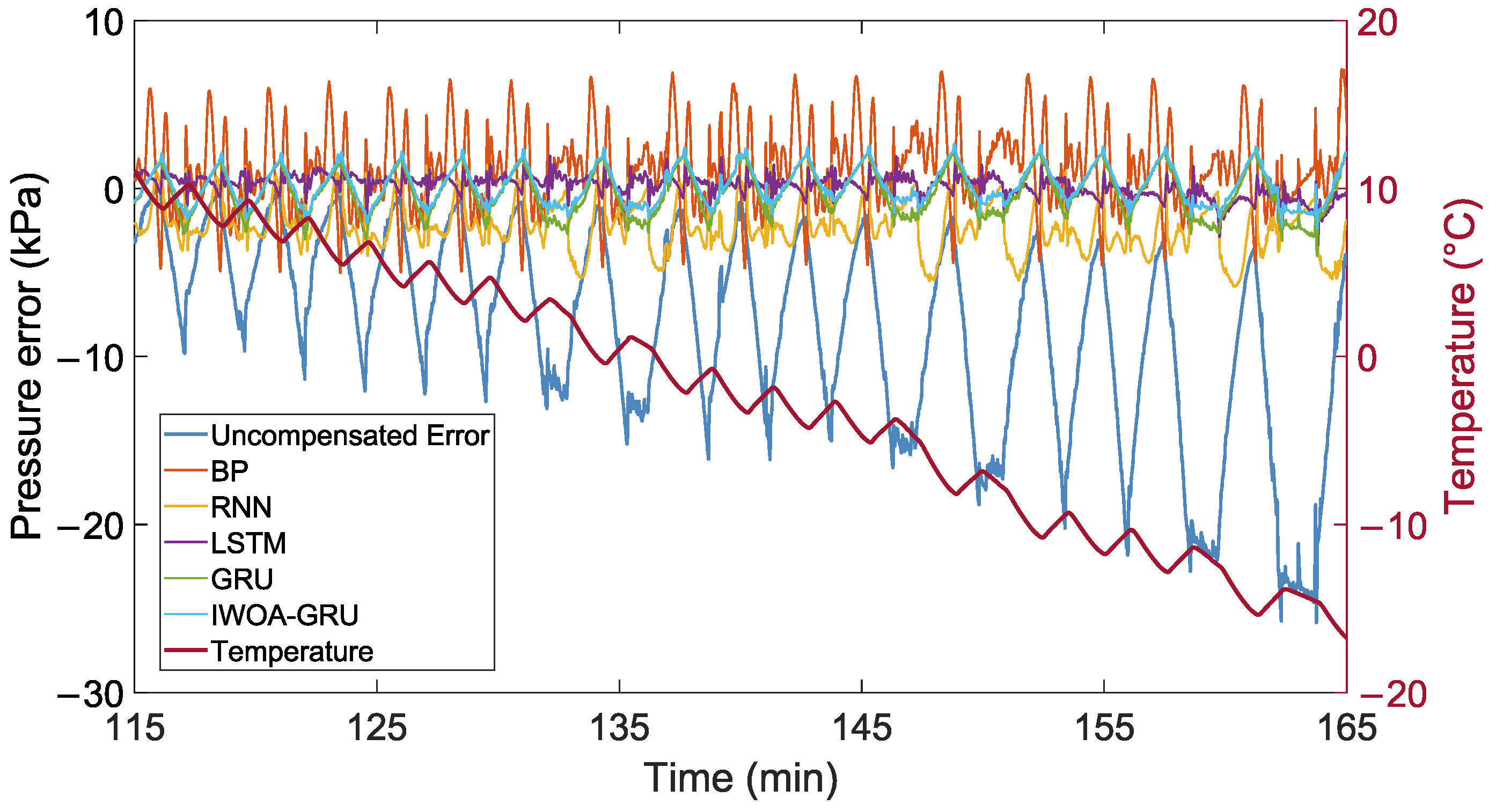

4.4. Results and Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| SVM | Support vector machine |

| ANN | Artificial neural network |

| RF | Random forest |

| GRU | Gated recurrent unit |

| WOA | Whale optimization algorithm |

| IWOA | Improved whale optimization algorithm |

| ELM | Extreme learning machines |

| LSSVM | Least squares support vector machine |

| BP | Backpropagation |

| RBF | Radial basis function |

| CSO | Chicken swarm optimization |

| WNN | Wavelet neural network |

| RNN | Recurrent neural network |

| LSTM | Long–short-term memory |

| CART | Classification and regression tree |

| MA | Moving average |

| MAE | Mean absolute error |

| MAPE | Mean absolute percentage error |

| RMSE | Root mean square error |

References

- Hommel, M.; Knab, H.; Yousef, S.G. Reliability of automotive and consumer MEMS sensors-An overview. Microelectron. Reliab. 2021, 126, 114252. [Google Scholar] [CrossRef]

- Kim, T.Y.; Suh, W.; Jeong, U. Approaches to deformable physical sensors: Electronic versus iontronic. Mater. Sci. Eng. R Rep. 2021, 146, 100640. [Google Scholar] [CrossRef]

- Huang, Y.; Fan, X.; Chen, S.C.; Zhao, N. Emerging technologies of flexible pressure sensors: Materials, modeling, devices, and manufacturing. Adv. Funct. Mater. 2019, 29, 1808509. [Google Scholar] [CrossRef]

- Balavalad, K.B.; Sheeparamatti, B. Design simulation and analysis of piezoresistive micro pressure sensor for pressure range of 0 to 1 MPa. In Proceedings of the 2016 International Conference on Electrical, Electronics, Communication, Computer and Optimization Techniques (ICEECCOT), Mysuru, India, 9–10 December 2016; pp. 345–349. [Google Scholar]

- Wu, S.; Zhang, T.; Li, Z.; Jia, J.; Deng, Y.; Xu, P.; Shao, Y.; Deng, D.; Hu, B. Temperature characteristic and compensation algorithm for a marine high accuracy piezoresistive pressure sensor. J. Mar. Eng. Technol. 2020, 19, 207–214. [Google Scholar] [CrossRef]

- Tufte, O.; Stelzer, E. Piezoresistive properties of silicon diffused layers. J. Appl. Phys. 1963, 34, 313–318. [Google Scholar] [CrossRef]

- Chou, T.L.; Chu, C.H.; Lin, C.T.; Chiang, K.N. Sensitivity analysis of packaging effect of silicon-based piezoresistive pressure sensor. Sens. Actuators A Phys. 2009, 152, 29–38. [Google Scholar] [CrossRef]

- Wang, H.; Zeng, Q.; Zhang, Z.; Zou, Y. A novel whale-based algorithm for optimizing the ANN approach: Application to temperature compensation in pressure scanner calibration systems. Meas. Sci. Technol. 2023, 34, 095904. [Google Scholar] [CrossRef]

- Barlian, A.A.; Park, W.T.; Mallon, J.R.; Rastegar, A.J.; Pruitt, B.L. Semiconductor piezoresistance for microsystems. Proc. IEEE 2009, 97, 513–552. [Google Scholar] [CrossRef] [PubMed]

- Tran, A.V.; Zhang, X.; Zhu, B. The development of a new piezoresistive pressure sensor for low pressures. IEEE Trans. Ind. Electron. 2017, 65, 6487–6496. [Google Scholar] [CrossRef]

- Jeong, T. Design and modeling of sensor behavior for improving sensitivity and performance. Measurement 2015, 62, 230–236. [Google Scholar] [CrossRef]

- Samy, I.; Postlethwaite, I.; Gu, D.W. Unmanned air vehicle air data estimation using a matrix of pressure sensors: A comparison of neural networks and look-up tables. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2011, 225, 807–820. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, Y.; Wei, G.; Pang, L.; Xu, C. A comprehensive compensation method for piezoresistive pressure sensor based on surface fitting and improved grey wolf algorithm. Measurement 2023, 207, 112387. [Google Scholar] [CrossRef]

- Wang, J.; Hu, G.; Li, J.; Zhou, Y.; Zou, C.; Jahangir Alam, S.M. Research on temperature compensation of piezo-resistive pressure sensor based on Newton interpolation and spline interpolation. In Proceedings of the 2021 IEEE 15th International Conference on Electronic Measurement & Instruments (ICEMI), Nanjing, China, 29–31 October 2021; pp. 109–113. [Google Scholar]

- Suykens, J.A.; Vandewalle, J. Least squares support vector machine classifiers. Neural Process. Lett. 1999, 9, 293–300. [Google Scholar] [CrossRef]

- Li, X.; Ke, S.; Li, Y.; Jin, W.; Fu, X.; Fu, G.; Bi, W. Temperature compensation based on BP neural network with small sample data for chloride ions optical fiber probe. Opt. Laser Technol. 2024, 176, 110973. [Google Scholar] [CrossRef]

- Wang, H.; Zeng, Q.; Zhang, Z.; Wang, H. Research on temperature compensation of multi-channel pressure scanner based on an improved cuckoo search optimizing a BP neural network. Micromachines 2022, 13, 1351. [Google Scholar] [CrossRef] [PubMed]

- Fu, G.; Gong, H.; Gao, H.; Gu, T.; Cao, Z. Integrated thermal error modeling of machine tool spindle using a chicken swarm optimization algorithm-based radial basic function neural network. Int. J. Adv. Manuf. Technol. 2019, 105, 2039–2055. [Google Scholar] [CrossRef]

- Ge, Y.; Shen, L.; Sun, M. Temperature compensation for optical fiber graphene micro-pressure sensor using genetic wavelet neural networks. IEEE Sens. J. 2021, 21, 24195–24201. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Ribeiro, A.H.; Tiels, K.; Aguirre, L.A.; Schön, T. Beyond exploding and vanishing gradients: Analysing RNN training using attractors and smoothness. In Proceedings of the International Conference on Artificial Intelligence and Statistics, PMLR, Online, 26–28 August 2020; pp. 2370–2380. [Google Scholar]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Li, L.; Xiang, S.; Han, M.; Yan, J. Performance Improvement of Multisensor Systems Using Autocompensation Strategy-based LSTM. IEEE Trans. Instrum. Meas. 2024, 73, 2511511. [Google Scholar] [CrossRef]

- Ouyang, M.; Gao, J.; Li, A.; Zhang, X.; Shen, C.; Cao, H. Micromechanical gyroscope temperature compensation based on combined LSTM-SVM-DBN algorithm. Sens. Actuators A Phys. 2024, 369, 115128. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, Y.; Wu, X.; Dong, H.; Wang, C.; Tang, J.; Shen, C.; Liu, J. Attitude-Induced error modeling and compensation with GRU networks for the polarization compass during UAV orientation. Measurement 2022, 190, 110734. [Google Scholar] [CrossRef]

- Thaysen, J.; Boisen, A.; Hansen, O.; Bouwstra, S. Atomic force microscopy probe with piezoresistive read-out and a highly symmetrical Wheatstone bridge arrangement. Sens. Actuators A Phys. 2000, 83, 47–53. [Google Scholar] [CrossRef]

- Tran, A.V.; Zhang, X.; Zhu, B. Mechanical structural design of a piezoresistive pressure sensor for low-pressure measurement: A computational analysis by increases in the sensor sensitivity. Sensors 2018, 18, 2023. [Google Scholar] [CrossRef]

- Nagarajan, P.R.; George, B.; Kumar, V.J. A linearizing digitizer for wheatstone bridge based signal conditioning of resistive sensors. IEEE Sens. J. 2017, 17, 1696–1705. [Google Scholar] [CrossRef]

- Meena, K.; Mathew, R.; Leelavathi, J.; Sankar, A.R. Performance comparison of a single element piezoresistor with a half-active Wheatstone bridge for miniaturized pressure sensors. Measurement 2017, 111, 340–350. [Google Scholar] [CrossRef]

- Park, Y.; Luan, H.; Kwon, K.; Chung, T.S.; Oh, S.; Yoo, J.Y.; Chung, G.; Kim, J.; Kim, S.; Kwak, S.S.; et al. Soft, full Wheatstone bridge 3D pressure sensors for cardiovascular monitoring. npj Flex. Electron. 2024, 8, 6. [Google Scholar] [CrossRef]

- Singh, K.; Alvi, P. Influence of the pressure range on temperature coefficient of resistivity (TCR) for polysilicon piezoresistive MEMS pressure sensor. Phys. Scr. 2020, 95, 075005. [Google Scholar]

- Kanda, Y. A graphical representation of the piezoresistance coefficients in silicon. IEEE Trans. Electron Devices 1982, 29, 64–70. [Google Scholar] [CrossRef]

- Ali, I.; Asif, M.; Shehzad, K.; Rehman, M.R.U.; Kim, D.G.; Rikan, B.S.; Pu, Y.; Yoo, S.S.; Lee, K.Y. A highly accurate, polynomial-based digital temperature compensation for piezoresistive pressure sensor in 180 nm CMOS technology. Sensors 2020, 20, 5256. [Google Scholar] [CrossRef]

- Xie, J.; Li, Z.; Zou, X. Dynamic Temperature Compensation of Pressure Sensors in Migratory Bird Biologging Applications. Electronics 2023, 12, 4373. [Google Scholar] [CrossRef]

- Yue, Y.L.; Xu, S.J.; Zuo, X. Nonlinear correction method of pressure sensor based on data fusion. Measurement 2022, 199, 111303. [Google Scholar]

- Xia, J.; Zhang, S.; Cai, G.; Li, L.; Pan, Q.; Yan, J.; Ning, G. Adjusted weight voting algorithm for random forests in handling missing values. Pattern Recognit. 2017, 69, 52–60. [Google Scholar]

- Feng, R.; Grana, D.; Balling, N. Imputation of missing well log data by random forest and its uncertainty analysis. Comput. Geosci. 2021, 152, 104763. [Google Scholar]

- Chung, J.; Gulcehre, C.; Cho, K.; Bengio, Y. Empirical evaluation of gated recurrent neural networks on sequence modeling. arXiv 2014, arXiv:1412.3555. [Google Scholar]

- Chen, Y.; Xu, C.; Zhao, X. Research on soft compensation of the potential drift signal of a pH electrode based on a gated recurrent neural network. Meas. Sci. Technol. 2022, 34, 025107. [Google Scholar] [CrossRef]

- Han, S.; Meng, Z.; Zhang, X.; Yan, Y. Hybrid deep recurrent neural networks for noise reduction of MEMS-IMU with static and dynamic conditions. Micromachines 2021, 12, 214. [Google Scholar] [CrossRef] [PubMed]

- Mirjalili, S.; Lewis, A. The whale optimization algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar]

- Chatterjee, S.; Roy, S.; Das, A.K.; Chattopadhyay, S.; Kumar, N.; Vasilakos, A.V. Secure biometric-based authentication scheme using Chebyshev chaotic map for multi-server environment. IEEE Trans. Dependable Secur. Comput. 2016, 15, 824–839. [Google Scholar] [CrossRef]

- Wu, G.; Li, Y. Non-maximum suppression for object detection based on the chaotic whale optimization algorithm. J. Vis. Commun. Image Represent. 2021, 74, 102985. [Google Scholar]

- Nickabadi, A.; Ebadzadeh, M.M.; Safabakhsh, R. A novel particle swarm optimization algorithm with adaptive inertia weight. Appl. Soft Comput. 2011, 11, 3658–3670. [Google Scholar] [CrossRef]

| Model Parameter | Numerical Value |

|---|---|

| Initial learning rate | 0.001–0.01 |

| Batch size | 10–250 |

| Number of neurons | 2–50 |

| Model | MAE | MAPE | RMSE |

|---|---|---|---|

| BP | 2.089 | 0.0129 | 2.616 |

| RNN | 1.786 | 0.0103 | 2.169 |

| LSTM | 0.976 | 0.0063 | 1.230 |

| GRU | 0.928 | 0.0060 | 1.089 |

| IWOA-GRU | 0.661 | 0.0043 | 0.826 |

| Model | MAE | MAPE | RMSE |

|---|---|---|---|

| Uncompensated | 8.260 | 0.0402 | 10.18 |

| BP | 4.259 | 0.0267 | 5.403 |

| RNN | 3.561 | 0.0198 | 4.244 |

| LSTM | 2.896 | 0.0156 | 3.616 |

| GRU | 2.787 | 0.0172 | 3.338 |

| IWOA-GRU | 2.027 | 0.0124 | 2.428 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Wang, Z.; Jiang, P.; Yan, G. Temperature Compensation Method for Piezoresistive Pressure Sensors Based on Gated Recurrent Unit. Sensors 2024, 24, 5394. https://doi.org/10.3390/s24165394

Liu M, Wang Z, Jiang P, Yan G. Temperature Compensation Method for Piezoresistive Pressure Sensors Based on Gated Recurrent Unit. Sensors. 2024; 24(16):5394. https://doi.org/10.3390/s24165394

Chicago/Turabian StyleLiu, Mian, Zhiwu Wang, Pingping Jiang, and Guozheng Yan. 2024. "Temperature Compensation Method for Piezoresistive Pressure Sensors Based on Gated Recurrent Unit" Sensors 24, no. 16: 5394. https://doi.org/10.3390/s24165394

APA StyleLiu, M., Wang, Z., Jiang, P., & Yan, G. (2024). Temperature Compensation Method for Piezoresistive Pressure Sensors Based on Gated Recurrent Unit. Sensors, 24(16), 5394. https://doi.org/10.3390/s24165394