Flexible Strain Sensors Based on Bionic Parallel Vein-like Structures for Human Motion Monitoring

Abstract

1. Introduction

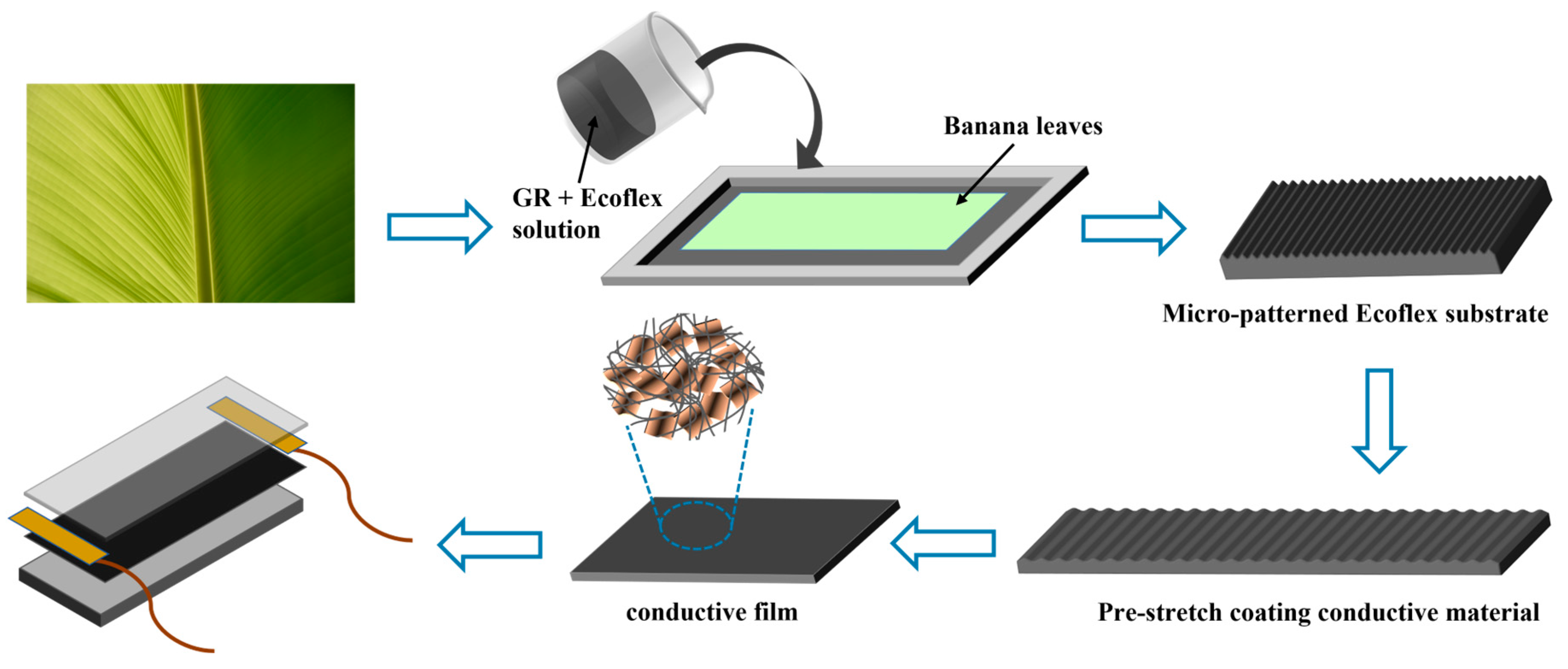

2. Experimental Section

3. Results and Discussion

3.1. Surface Microstructure Characterisation

3.2. Sensing Performance Analysis

3.3. Sensing Mechanism Analysis

3.4. Application of Human Motions Monitoring

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boutry, C.M.; Beker, L.; Kaizawa, Y.; Vassos, C.; Tran, H.; Hinckley, A.C.; Pfattner, R.; Niu, S.; Li, J.; Claverie, J.; et al. Biodegradable and flexible arterial-pulse sensor for the wireless monitoring of blood flow. Nat. Biomed. Eng. 2019, 3, 47–57. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Chhetry, A.; Sharifuzzaman, M.; Yoon, H.; Park, J.Y. Wearable Capacitive Pressure Sensor Based on MXene Composite Nanofibrous Scaffolds for Re-liable Human Physiological Signal Acquisition. ACS Appl. Mater. Interfaces 2020, 12, 22212–22224. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Pan, H.; Xie, G.; Jiang, Y.; Chen, C.; Su, Y.; Wang, Y.; Tai, H. Flexible piezoelectric pressure sensor based on polydopamine-modified BaTiO3/PVDF composite film for human motion monitoring. Sens. Actuators A Phys. 2020, 301, 111789. [Google Scholar] [CrossRef]

- Lin, Y.; Zhao, Y.; Wang, L.; Park, Y.; Yeh, Y.; Chiang, W.; Loh, K.J. Graphene K-Tape Meshes for Densely Distributed Human Motion Monitoring. Adv. Mater. Technol. 2020, 6, 2000861. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, Y.; Hedenqvist, M.S.; Chen, C.; Cai, C.; Li, H.; Liu, H.; Fu, J. Multifunctional conductive hydrogels and their applications as smart wearable devices. J. Mater. Chem. B 2021, 9, 2561–2583. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Wang, S.; Zhang, K.; Li, Y.; Sui, H.; Bu, X.; Jiang, Y.; Huang, X.; Zhang, P. Research progress of multifunctional flexible proximity sensors. Sens. Actuators A Phys. 2023, 360, 114500. [Google Scholar] [CrossRef]

- Moussaoui, S.C.; Cisneros-Limón, R.; Kaminaga, H.; Benallegue, M.; Nobeshima, T.; Kanazawa, S.; Kanehiro, F. Spatial Calibration of Humanoid Robot Flexible Tactile Skin for Human–Robot Interaction. Sensors 2023, 23, 4569. [Google Scholar] [CrossRef]

- Takei, K.; Takahashi, T.; Ho, J.C.; Ko, H.; Gillies, A.G.; Leu, P.W.; Fearing, R.S.; Javey, A. Nanowire active-matrix circuitry for low-voltage macroscale artificial skin. Nat. Mater. 2010, 9, 821–826. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Hong, Y.; He, W.; Tang, Y.; Zhou, G.; Xu, Z.; He, Y.; Nie, Z.; Zhang, J.; et al. Fabrication and characterization of nano-ZnO/CNTs/PDMS flexible pressure sensor. J. Mater. Sci. Mater. Electron. 2023, 34, 1600. [Google Scholar] [CrossRef]

- Sadiq, H.; Hui, H.; Huang, S.; Mahmood, K.; Sharif, M.H.; Ali, I. A Flexible Pressure Sensor Based on PDMS-CNTs Film for Multiple Applications. IEEE Sens. J. 2022, 22, 3033–3039. [Google Scholar] [CrossRef]

- Kim, H.J.; Thukral, A.; Yu, C.J. Highly Sensitive and Very Stretchable Strain Sensor Based on a Rubbery Sem-iconductor. ACS Appl. Mater. Interfaces 2018, 10, 5000–5006. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhu, X.; Liu, Y.; Liu, L.; Xu, Q.; Liu, H.; Wang, W.; Chen, L. Ultra-Stretchable Monofilament Flexible Sensor with Low Hysteresis and Linearity based on MWCNTs/Ecoflex Composite Materials. Macromol. Mater. Eng. 2021, 306, 2100113. [Google Scholar] [CrossRef]

- Jeong, Y.R.; Park, H.; Jin, S.W.; Hong, S.Y.; Lee, S.; Ha, J.S. Highly Stretchable and Sensitive Strain Sensors Using Fragmentized Graphene Foam. Adv. Funct. Mater. 2015, 25, 4228–4236. [Google Scholar] [CrossRef]

- Wei, C.; Zhou, H.; Li, S.; Zhao, G.; Jin, Z.; Jin, X.; Chen, W.; Zhao, W.; Ma, A. Dipentaerythritol-Derived Hyperbranched Polyurethane Elastomers and Their Applications in Flexible Strain Sensors. Macromol. Mater. Eng. 2022, 307, 2100954. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Q.; Liu, X.; Xia, S.; Gao, Y.; Gao, G. Flexible and wearable strain sensors based on conductive hydrogels. J. Polym. Sci. 2022, 60, 2663–2678. [Google Scholar] [CrossRef]

- Zhang, X.; Xiang, D.; Zhu, W.; Zheng, Y.; Harkin-Jones, E.; Wang, P.; Zhao, C.; Li, H.; Wang, B.; Li, Y. Flexible and high-performance piezoresistive strain sensors based on carbon nanoparti-cles@polyurethane sponges. Compos. Sci. Technol. 2020, 200, 108437. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly Stretchable and Sensitive Strain Sensor Based on Silver Nanowire-Elastomer Nanocom-posite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Lee, C.J.; Park, K.H.; Han, C.J.; Oh, M.S.; You, B.; Kim, Y.S.; Kim, J.W. Crack-induced Ag nanowire networks for transparent, stretchable, and highly sensitive strain sensors. Sci. Rep. 2017, 7, 7959. [Google Scholar] [CrossRef]

- Kumar, S.; Pavelyev, V.; Tripathi, N.; Platonov, V.; Sharma, P.; Ahmad, R.; Mishra, P.; Khosla, A. Review—Recent Advances in the Development of Carbon Nanotubes Based Flexible Sensors. J. Electrochem. Soc. 2020, 167, 047506. [Google Scholar] [CrossRef]

- Wang, R.; Jiang, N.; Su, J.; Yin, Q.; Zhang, Y.; Liu, Z.; Lin, H.; Moura, F.A.; Yuan, N.; Roth, S.; et al. A Bi-Sheath Fiber Sensor for Giant Tensile and Torsional Displacements. Adv. Funct. Mater. 2017, 27, 1702134. [Google Scholar] [CrossRef]

- Kong, M.; Yang, M.; Li, R.; Long, Y.Z.; Zhang, J.; Huang, X.; Cui, X.; Zhang, Y.; Said, Z.; Li, C. Graphene-based flexible wearable sensors: Mechanisms, challenges, and future directions. Int. J. Adv. Manuf. Technol. 2023. [Google Scholar] [CrossRef]

- Xu, R.; Wang, D.; Zhang, H.; Xie, N.; Lu, S.; Qu, K. Simultaneous Detection of Static and Dynamic Signals by a Flexible Sensor Based on 3D Graphene. Sensors 2017, 17, 1069. [Google Scholar] [CrossRef]

- Wang, D.-Y.; Tao, L.-Q.; Liu, Y.; Zhang, T.-Y.; Pang, Y.; Wang, Q.; Jiang, S.; Yang, Y.; Ren, T.-L. High performance flexible strain sensor based on self-locked overlapping graphene sheets. Nanoscale 2016, 8, 20090–20095. [Google Scholar] [CrossRef]

- Yang, Y.; Shi, L.; Cao, Z.; Wang, R.; Sun, J. Strain Sensors with a High Sensitivity and a Wide Sensing Range Based on a Ti3C2Tx (MXene) Nanoparticle-Nanosheet Hybrid Network. Adv. Funct. Mater. 2019, 29, 1807882. [Google Scholar] [CrossRef]

- Xu, X.; Chen, Y.; He, P.; Wang, S.; Ling, K.; Liu, L.; Lei, P.; Huang, X.; Zhao, H.; Cao, J.; et al. Wearable CNT/Ti3C2Tx MXene/PDMS composite strain sensor with enhanced stability for real-time human healthcare monitoring. Nano Res. 2021, 14, 2875–2883. [Google Scholar] [CrossRef]

- Huang, Z.; Gao, M.; Yan, Z.; Pan, T.; Khan, S.A.; Zhang, Y.; Zhang, H.; Lin, Y. Pyramid microstructure with single walled carbon nanotubes for flexible and transparent mi-cro-pressure sensor with ultra-high sensitivity. Sens. Actuators A Phys. 2017, 266, 345–351. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Hong, J.; Lee, Y.; Ha, M.; Jung, Y.; Lim, H.; Kim, S.Y.; Ko, H. Tactile-Direction-Sensitive and Stretchable Electronic Skins Based on Human-Skin-Inspired Inter-locked Microstructures. ACS Nano 2014, 8, 12020–12029. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wei, Y.; Qiu, Y.Y. Advanced Flexible Skin-Like Pressure and Strain Sensors for Human Health Moni-toring. Micromachines 2021, 12, 695. [Google Scholar] [CrossRef]

- Lu, N.; Lu, C.; Yang, S.; Rogers, J. Highly Sensitive Skin-Mountable Strain Gauges Based Entirely on Elastomers. Adv. Funct. Mater. 2012, 22, 4044–4050. [Google Scholar] [CrossRef]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Mengüç, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D Printing of Strain Sensors within Highly Stretchable Elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef]

- Gong, S.; Lai, D.T.; Wang, Y.; Yap, L.W.; Si, K.J.; Shi, Q.; Jason, N.N.; Sridhar, T.; Uddin, H.; Cheng, W. Tattoo like Polyaniline Microparticle-Doped Gold Nanowire Patches as Highly Durable Wearable Sensors. ACS Appl. Mater. Interfaces 2015, 7, 19700–19708. [Google Scholar] [CrossRef] [PubMed]

- Roh, E.; Hwang, B.U.; Kim, D.; Kim, B.Y.; Lee, N.E. Stretchable, Transparent, Ultrasensitive, and Patchable Strain Sensor for Human-Machine Interfaces Comprising a Nanohybrid of Carbon Nanotubes and Conductive Elastomers. ACS Nano 2015, 9, 6252–6261. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Wen, L.; Wang, H.; Zhu, K.; Zhang, M. Vertical CNT–Ecoflex nanofins for highly linear broad-range-detection wearable strain sensors. J. Mater. Chem. C 2018, 6, 5132–5139. [Google Scholar] [CrossRef]

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-stretchable and skin-mountable strain sensors using carbon nano-tubes-Ecoflex nanocomposites. Nanotechnology 2015, 26, 375501. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Deng, H.; Gao, X.; Zhang, S.; Bilotti, E.; Peijs, T.; Fu, Q. Modified resistivity–strain behavior through the incorporation of metallic particles in conductive polymer composite fibers containing carbon nanotubes. Polym. Int. 2013, 62, 134–140. [Google Scholar] [CrossRef]

- Duan, L.; Fu, S.; Deng, H.; Zhang, Q.; Wang, K.; Chen, F.; Fu, Q. The resistivity–strain behavior of conductive polymer composites: Stability and sensitivity. J. Mater. Chem. A 2014, 2, 17085–17098. [Google Scholar] [CrossRef]

- Dong, M.; Wang, C.; Liu, H.; Liu, C.; Shen, C.; Zhang, J.; Jia, C.; Ding, T.; Guo, Z. Enhanced Solid Particle Erosion Properties of Thermoplastic Polyurethane-Carbon Nanotube Nanocomposites. Macromol. Mater. Eng. 2019, 304, 1900010. [Google Scholar] [CrossRef]

- Li, Y.; Han, D.; Jiang, C.; Xie, E.; Han, W. A Facile Realization Scheme for Tactile Sensing with a Structured Silver Nanowire㏄DMS Composite. Adv. Mater. Technol. 2019, 4, 1800504. [Google Scholar] [CrossRef]

- Jian, M.; Xia, K.; Wang, Q.; Yin, Z.; Wang, H.; Wang, C.; Xie, H.; Zhang, M.; Zhang, Y. Flexible and Highly Sensitive Pressure Sensors Based on Bionic Hierarchical Structures. Adv. Funct. Mater. 2017, 27, 1606066. [Google Scholar] [CrossRef]

- Mannsfeld, S.C.B.; Tee, B.C.-K.; Stoltenberg, R.M.; Chen, C.V.H.-H.; Barman, S.; Muir, B.V.O.; Sokolov, A.N.; Reese, C.; Bao, Z. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, B.; Liu, F.; Chen, Q.; Liu, M.; Wang, F. Flexible Strain Sensors Based on Bionic Parallel Vein-like Structures for Human Motion Monitoring. Sensors 2024, 24, 468. https://doi.org/10.3390/s24020468

Yin B, Liu F, Chen Q, Liu M, Wang F. Flexible Strain Sensors Based on Bionic Parallel Vein-like Structures for Human Motion Monitoring. Sensors. 2024; 24(2):468. https://doi.org/10.3390/s24020468

Chicago/Turabian StyleYin, Boshuo, Furong Liu, Qingyuan Chen, Ming Liu, and Feiying Wang. 2024. "Flexible Strain Sensors Based on Bionic Parallel Vein-like Structures for Human Motion Monitoring" Sensors 24, no. 2: 468. https://doi.org/10.3390/s24020468

APA StyleYin, B., Liu, F., Chen, Q., Liu, M., & Wang, F. (2024). Flexible Strain Sensors Based on Bionic Parallel Vein-like Structures for Human Motion Monitoring. Sensors, 24(2), 468. https://doi.org/10.3390/s24020468