Evolution Characteristics of Void in the Caving Zone Using Fiber Optic Sensing

Abstract

1. Introduction

2. Principle of Zoning Monitoring of Voids in Mining Overburden Rock Mass Caving Based on Fiber Optic Monitoring

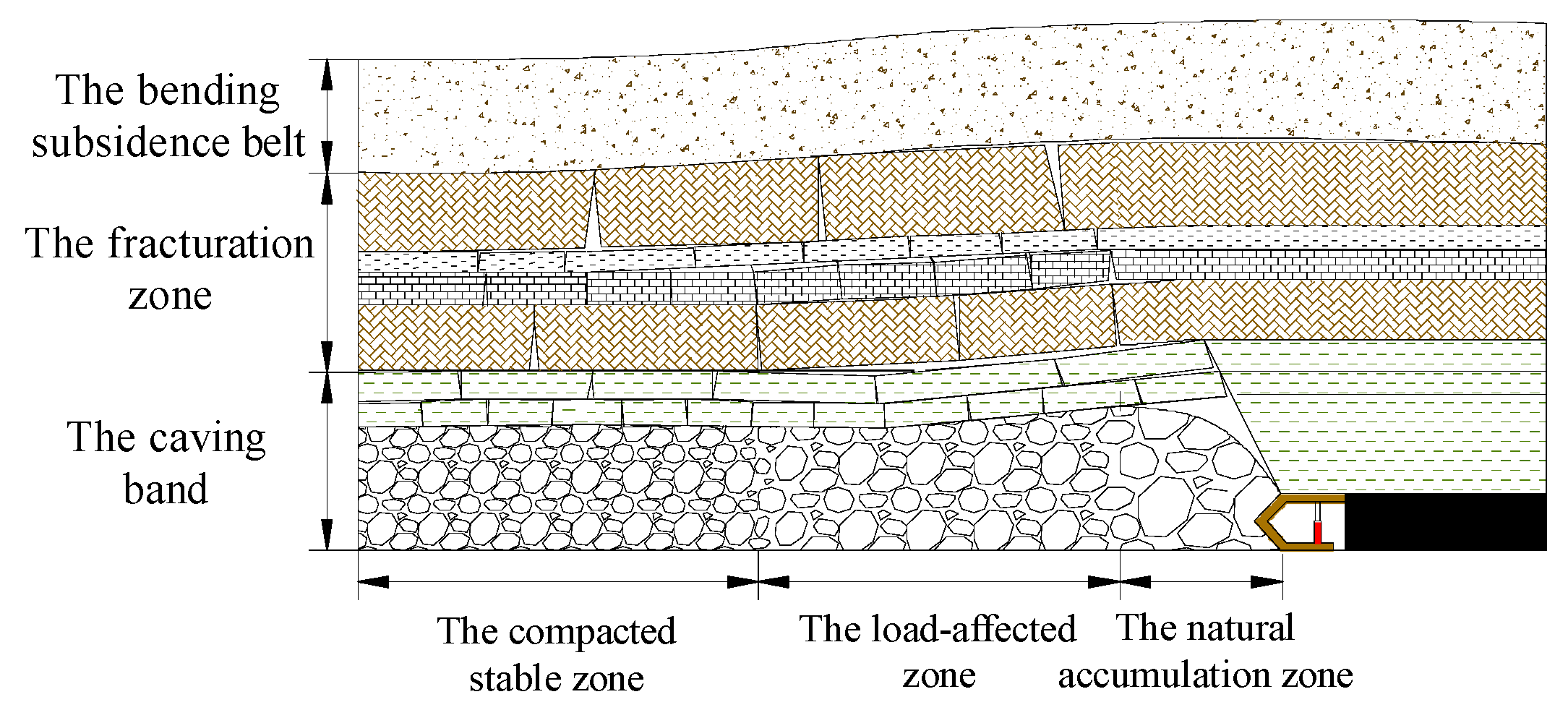

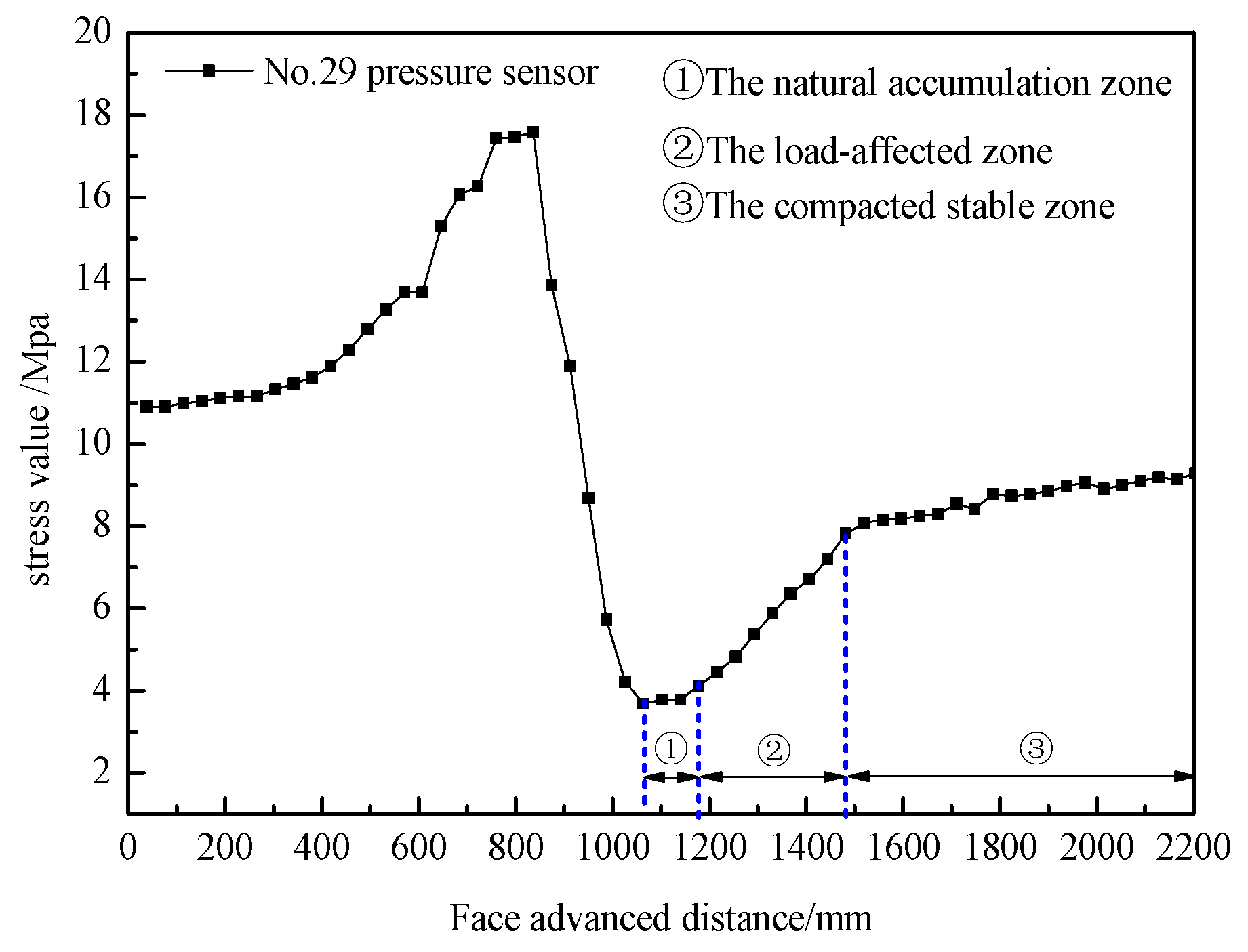

2.1. Analysis of the Characteristics of Void Development in the Overlying Rock Collapse Zone along the Mining Face

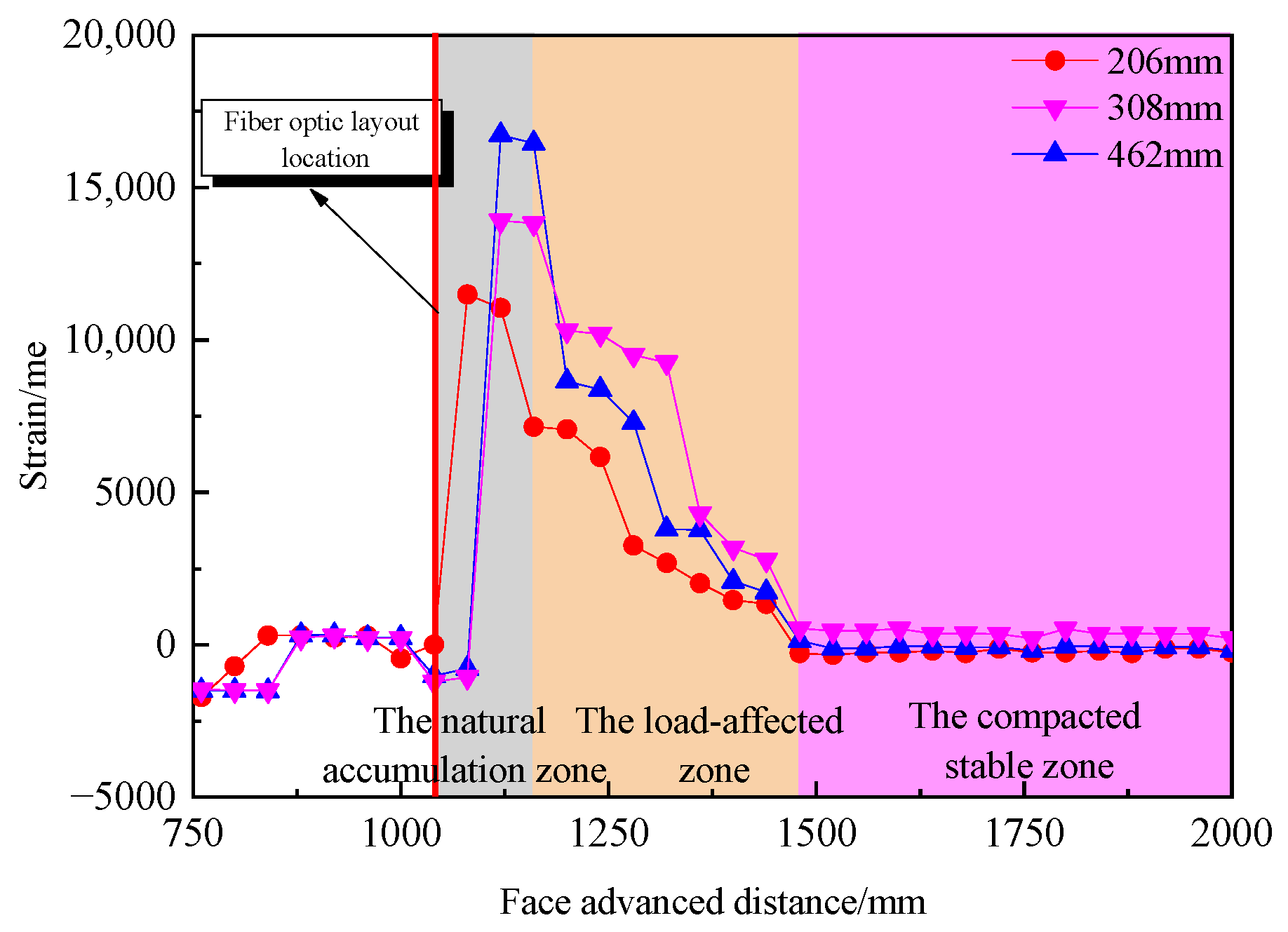

- (1)

- Characteristics of the Natural Accumulation Zone

- (2)

- Characteristics of the Load-Affected Zone

- (3)

- Characteristics of the Compacted Stable Zone

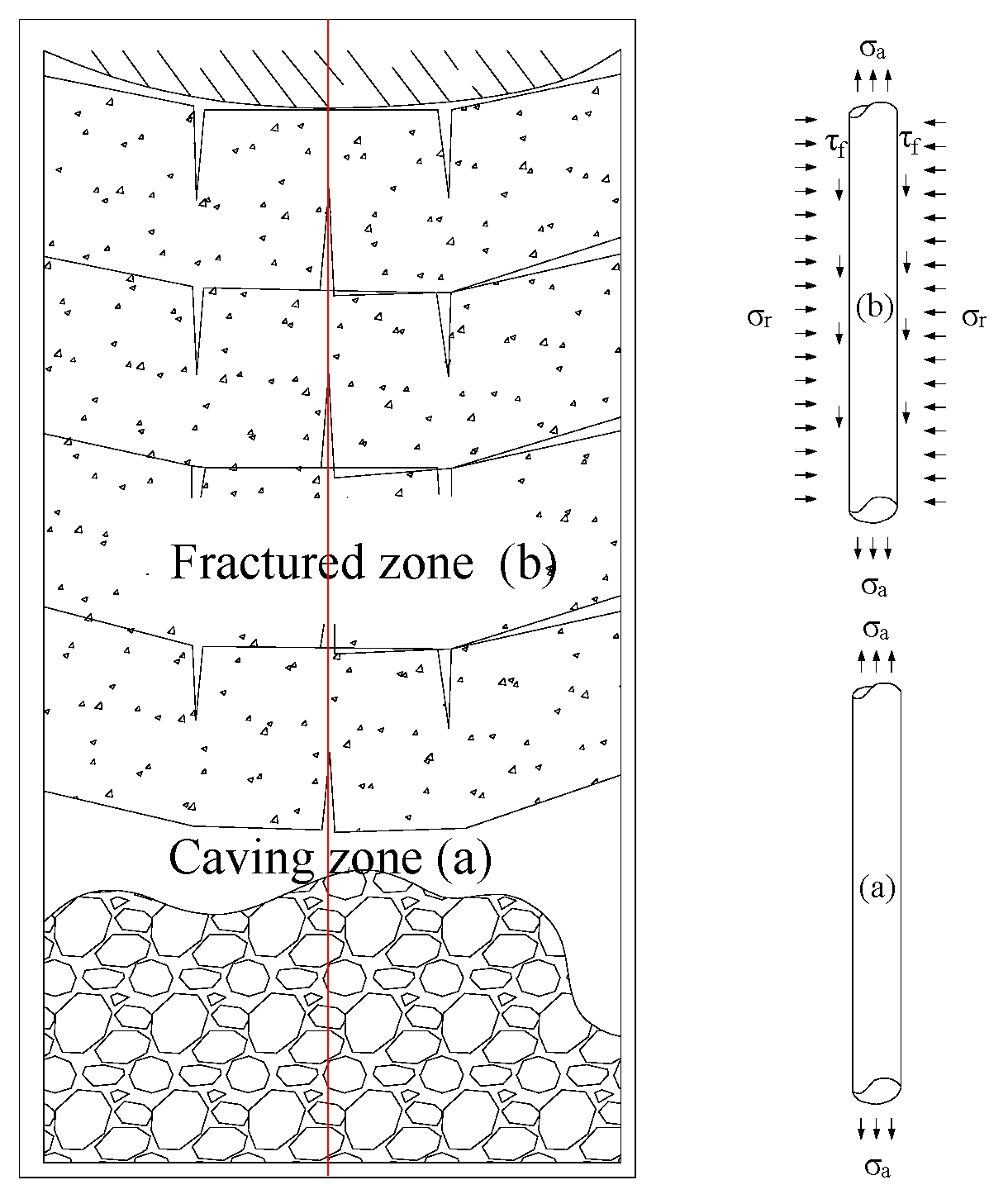

2.2. Principle of Fiber Optic Monitoring for Gap Zoning in Mining Overburden Collapse Rock Mass

3. Similar Model Test for Overlying Rock Movement

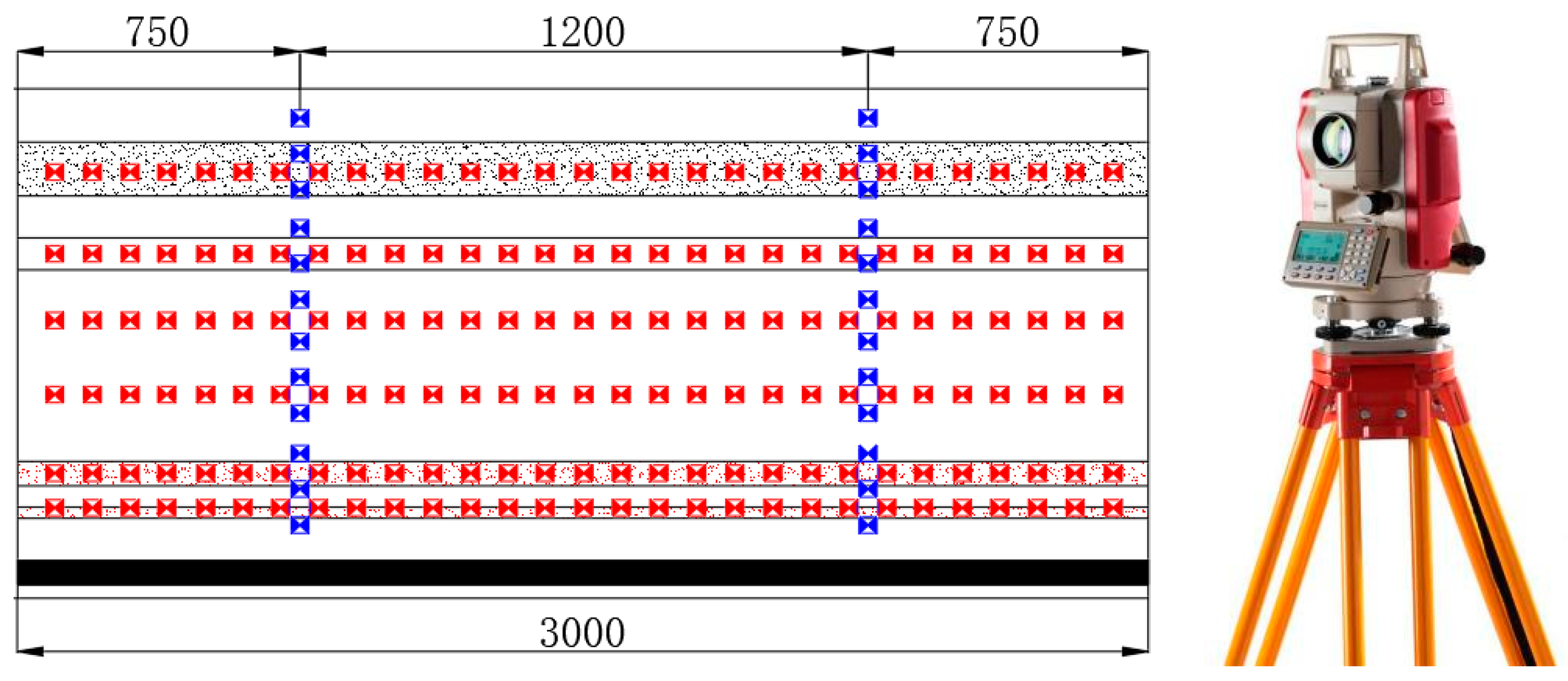

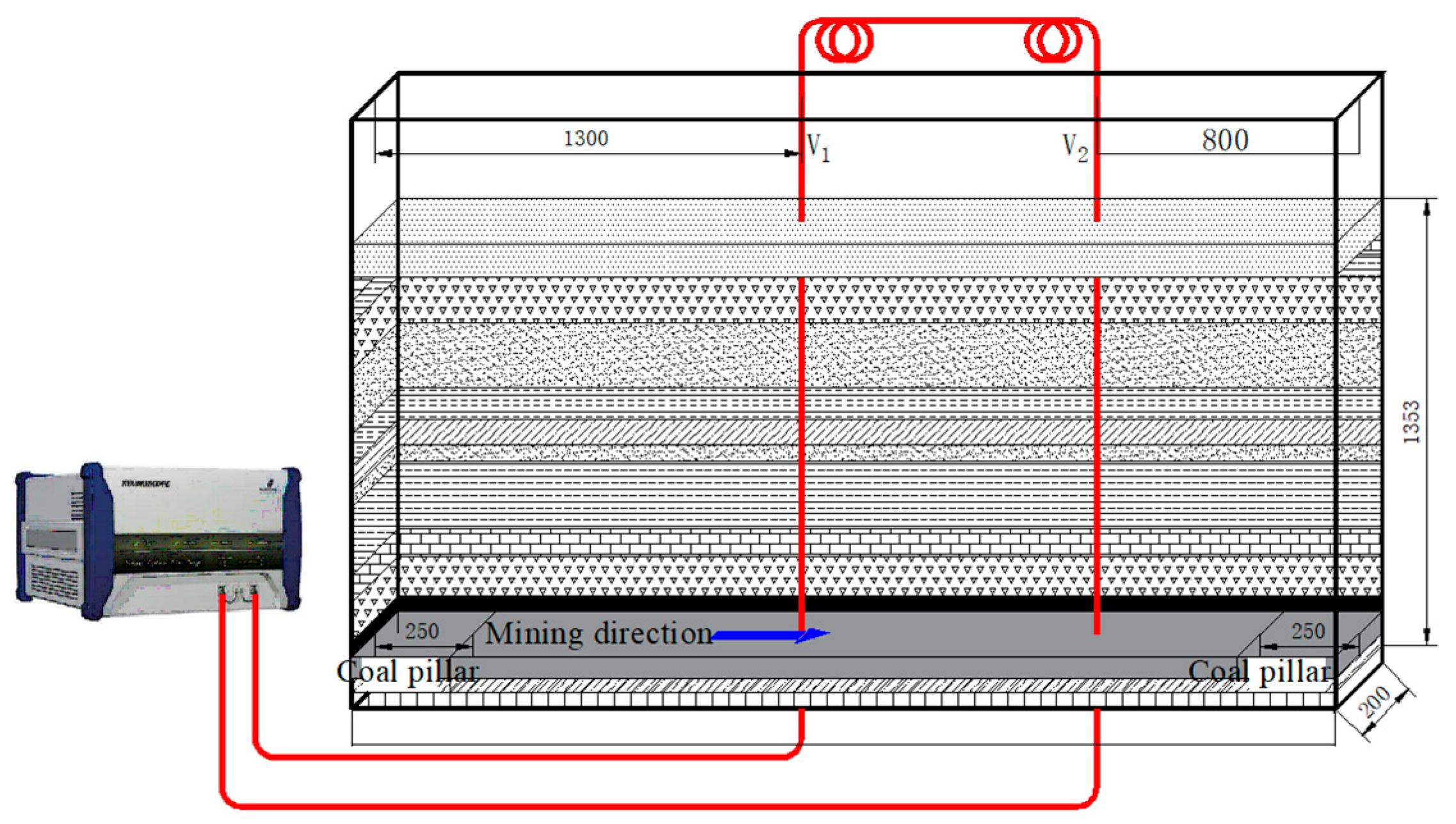

3.1. Overview of Similar Simulation Test

3.2. Test Measurement Systems

3.2.1. Overlying Rock Settlement Displacement Monitoring System

3.2.2. Distributed Fiber Optic Testing System

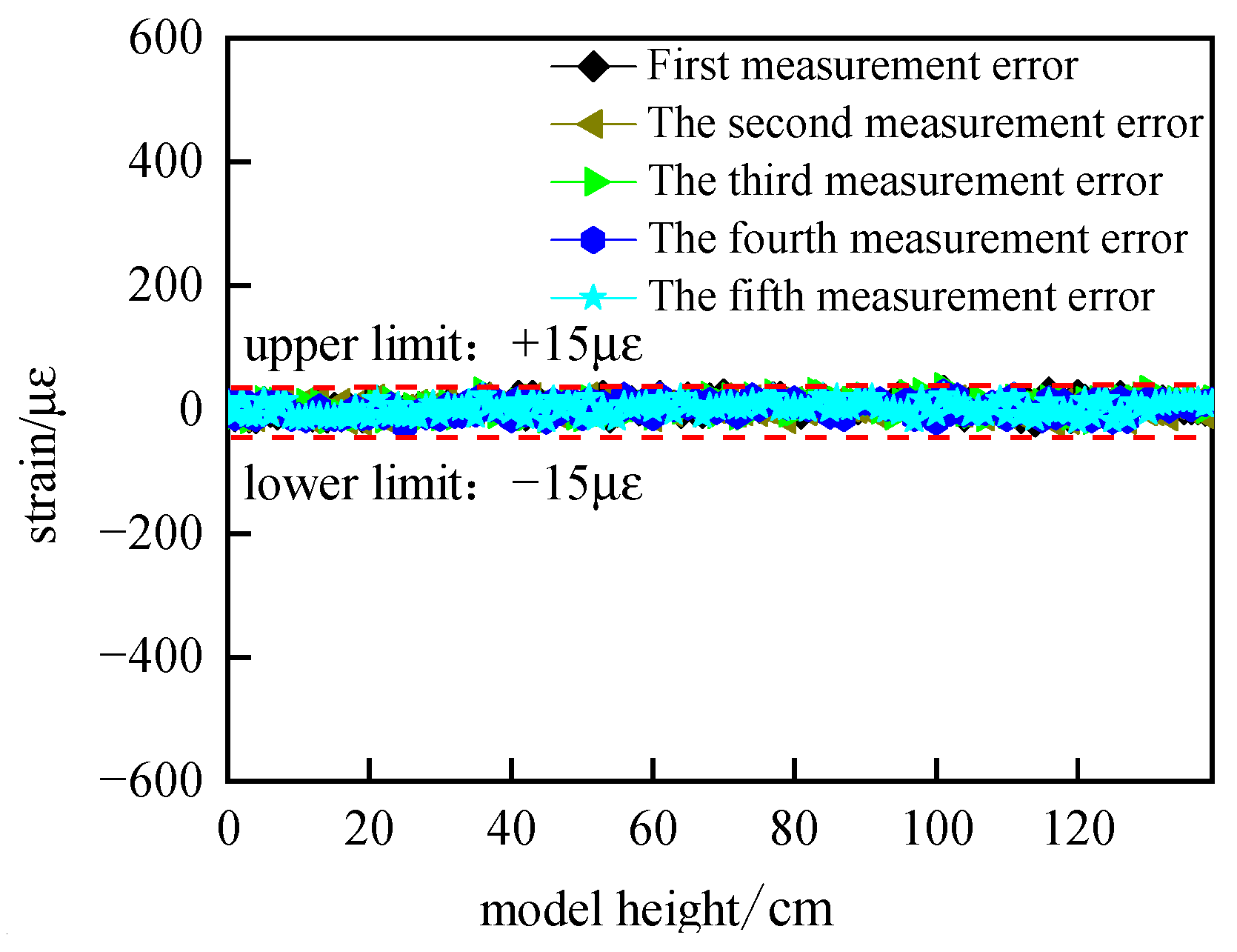

- (1)

- Testing System

- (2)

- Uncertainty Analysis

3.2.3. Bottom Plate Pressure Testing System

3.3. Test Procedure and Observations

4. Experimental Results Analysis

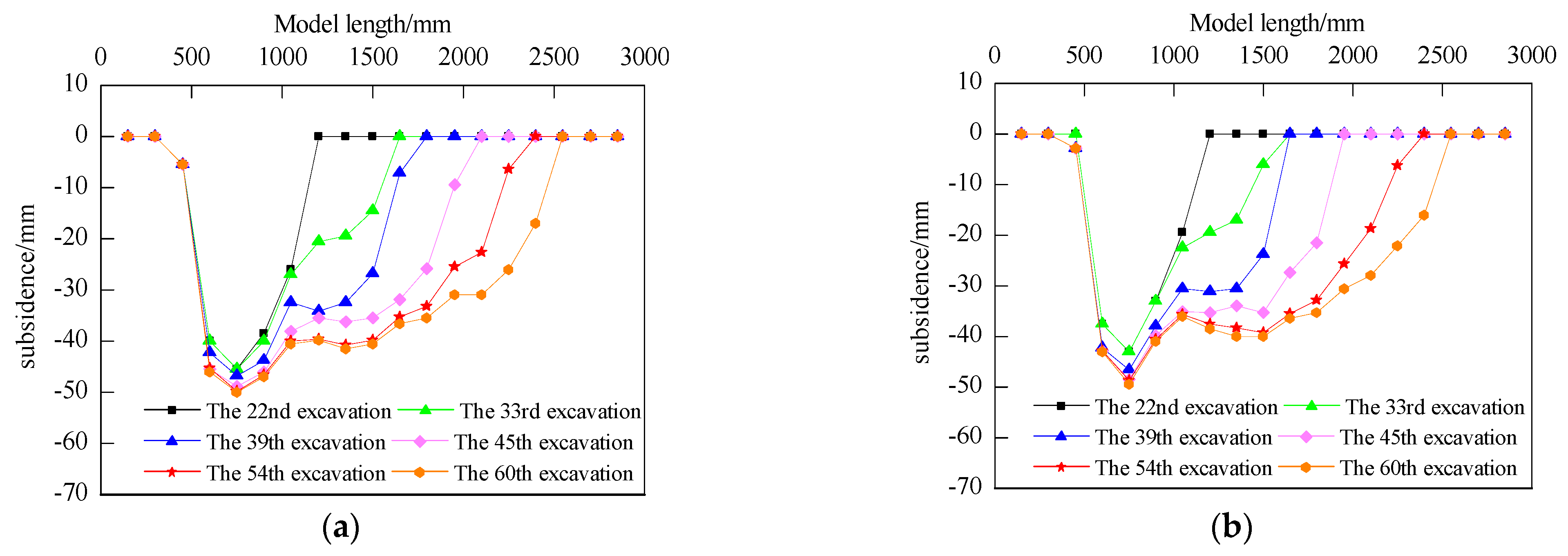

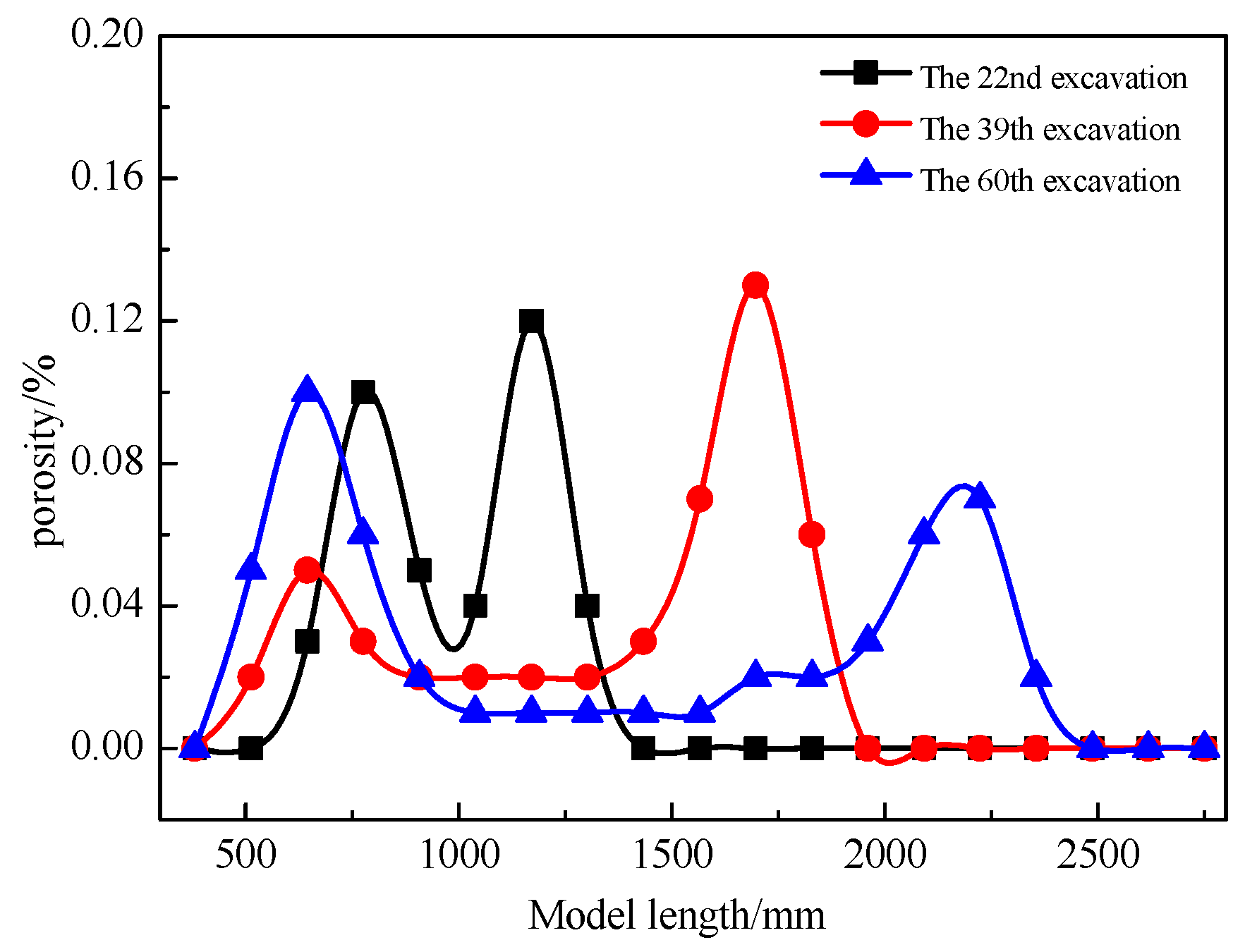

4.1. Analysis of Overlying Strata Settlement Displacement and Porosity

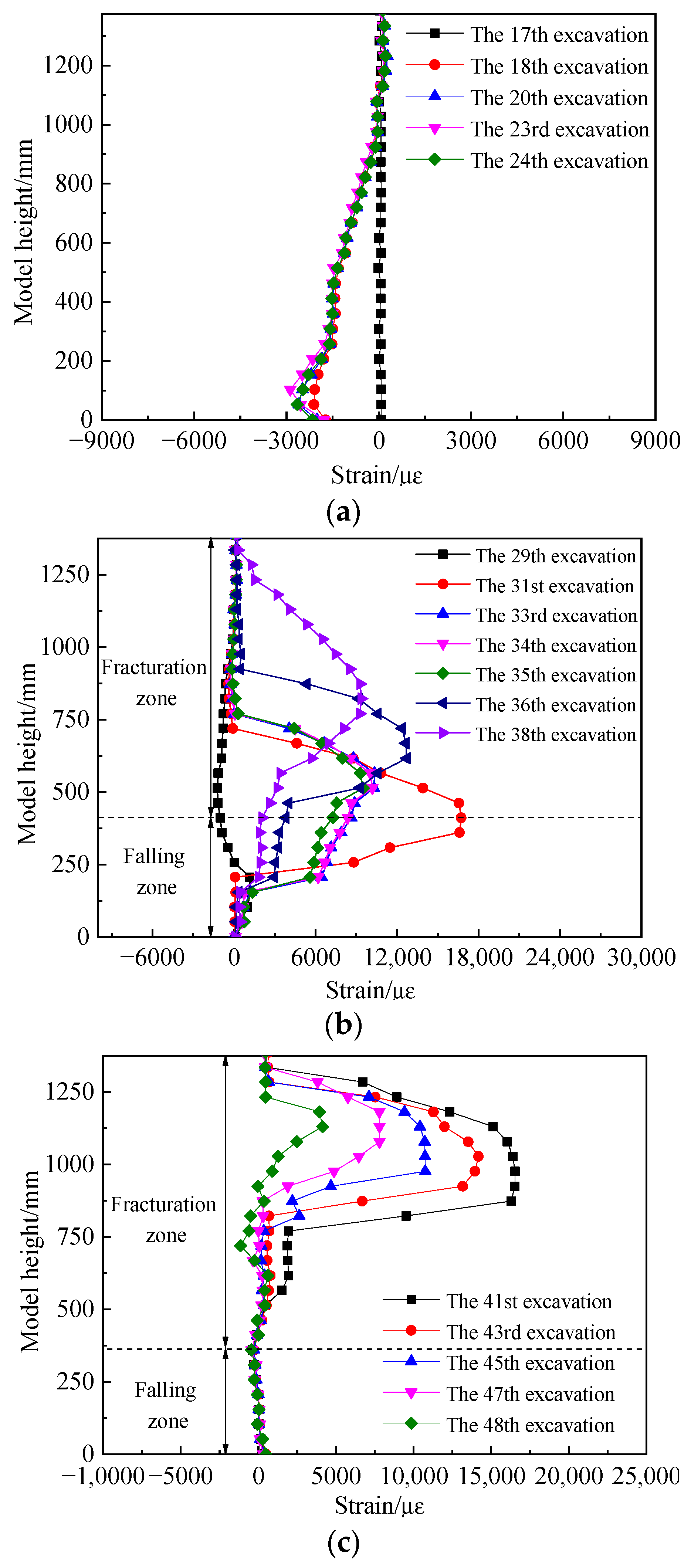

4.2. Characteristics of Overlying Rock Deformation Zoning

4.3. Characteristics of Stress Zoning in Collapse Zone

5. Characterizing Fiber Optic Data in the Collapse Zone

6. Conclusions

- (1)

- This study delves into the evolution characteristics of cavity collapse in overhanging rock masses during the mining process through the application of fiber optic sensing technology. Real-time monitoring using fiber optic sensing reveals the dynamic changes in internal rock cavities, the proposed calculation method for zoning overlying rock cavities based on fiber optic sensing is reliable, providing essential information for the development and assessment of coal mine slurry filling solutions.

- (2)

- During the mining process, the expansion of cavities within overhanging rock masses is closely linked to the stress state of the rock. The rate of cavity expansion is influenced by stress variations, and stress control may become a crucial factor in preventing cavity expansion and rock mass instability.

- (3)

- The changes in cavity zones at different stages of overhanging rock mining can be characterized through segmented strain curves obtained via fiber optic monitoring. Fiber optic strain monitoring results accurately delineate the boundaries of the natural accumulation zone, the load-affected zone, and the compacted stable zone.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Huang, Y.; Pu, H.; Gao, H.; Li, Y.; Ouyang, S.; Guo, Y. Influence of block shapeonmacroscopic deformation response and mesofabric evolutionof crushed gangue under the triaxial compression. Powder Technol. 2021, 384, 112–124. [Google Scholar] [CrossRef]

- Zheng, J.; Zhou, G.; Zhou, Y.; Yuan, D.; Zhao, T. Bed Separation Characteristics of an LTCC Panel and Subsidence Controlling Grouting: Case Study of Longquan Coal Mine, China. Shock. Vib. 2022, 2022, 3837625. [Google Scholar] [CrossRef]

- Zhu, L.; Gu, W.; Liu, Z.; Qiu, F. Application of Artificial Intelligence Models to Predict the Tensile Strength of Glass Fiber-Modified Cemented Backfill Materials during the Mine Backfill Process. Geofluids 2022, 2022, 4100638. [Google Scholar] [CrossRef]

- Zhu, L.; Gu, W.; Pan, H.; Liu, Z.; Chai, J.; Ouyang, Y. Calculation model of overburden rock failure volume in mined-out area based on Brillouin optical time-domain analysis technology. Opt. Fiber Technol. 2021, 66, 102640. [Google Scholar] [CrossRef]

- Wang, J.; Ma, J.; Yang, K.; Yao, S.; Shi, X. Effects and laws analysis for the mining technique of grouting into the overburden bedding separation. J. Clean. Prod. 2021, 288, 125121. [Google Scholar] [CrossRef]

- Zhu, L.; Gu, W.; Song, T.; Qiu, F. Experimental Investigation of Particle Size Alteration and the Selective Crushing Phenomenon of Gangue during the Jaw Crushing Process. Sustainability 2022, 14, 12395. [Google Scholar] [CrossRef]

- Zheng, K.; Xuan, D.; Li, J.; Gang, Z. Experimental Study on Compaction Law of Rock Mass in the Caving Zone under the Grouting Pressure of Overburden Isolation Grouting Filling. Geotech. Geol. Eng. 2023, 41, 1647–1659. [Google Scholar] [CrossRef]

- Zhu, L.; Gu, W.; Ouyang, Y.; Qiu, F. Grouting mechanism and experimental study of goaf considering filtration effect. PLoS ONE 2023, 18, e0282190. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Guo, X.; Sun, G. Grouting reinforcement mechanism and multimodel simulation analysis of longwall goaf. Geofluids 2021, 2021, 9943596. [Google Scholar] [CrossRef]

- Zhu, D.; Guo, Y.; Wang, W.; Guo, G.; An, T. Grouting reinforcement technique in wind oxidation zone by power law superfine cement slurry considering the time-varying rheological param. Adv. Civ. Eng. 2019, 2019, 7306850. [Google Scholar]

- Lei, W.; Chai, J.; Zhang, Y.; Ding, G.; Yao, R.; Chen, Y.; Wang, Z.; Ma, C. Study on pressure relief effect of upper protective coal seam mining based on distributed optical fiber sensing monitoring. Opt. Fiber Technol. 2022, 68, 102830. [Google Scholar] [CrossRef]

- Hu, T.; Hou, G.; Li, Z. The Field Monitoring Experiment of the Roof Strata Movement in Coal Mining Based on DFOS. Sensors 2020, 20, 1318. [Google Scholar] [CrossRef]

- Liu, J.; Yuan, S.; Luo, B.; Biondi, B.; Noh, H. Turning Telecommunication Fiber-Optic Cables into Distributed Acoustic Sensors for Vibration-Based Bridge Health Monitoring. Struct. Control Health Monit. 2023, 2023, 3902306. [Google Scholar] [CrossRef]

- Chai, J.; Ouyang, Y.; Liu, J.; Zhang, D.; Du, W. Experimental evaluation of precise monitoring of multi-scale deformation failure of rock mass based on distributed optical fiber. Measurement 2022, 199, 111381. [Google Scholar] [CrossRef]

- Chai, J.; Ouyang, Y.; Liu, J.; Zhang, D.; Du, W.; Lei, W. Experimental study on a new method to forecasting goaf pressure based key strata deformation detected using optic fiber sensors. Opt. Fiber Technol. 2021, 67, 102706. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Li, M.; Sartaj, M.; Wang, Y. A Numerical Simulation of the Interaction of Aggregate and Rockfill in a Gangue Fluidized Filling Method. Sustainability 2022, 14, 12838. [Google Scholar] [CrossRef]

- Xiong, X.; Ouyang, Y.; Dai, J.; Ling, Z. Analysis and control of self stable balance circle of surrounding rock of roadway in inclined coal seam. Appl. Math. Model. 2023, 124, 749–767. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, N.; Shen, B.; Sun, X.; Zhang, B.; Lu, Y.; Li, Y. Distribution and evolution of residual voids in longwall old goaf. Geomech. Eng. 2019, 19, 105–114. [Google Scholar]

- Wang, W.; Yao, Q.; Xu, Q.; Chen, X.; Liu, H.; Li, X. Experimental Study on the Evolution Law of Coal Mine Underground Reservoir Water Storage Space under the Disturbance and Water-Rock Interaction Effect. Minerals 2022, 12, 1491. [Google Scholar] [CrossRef]

- Guo, Y.; Qin, Y.; Chen, P.; Xu, N. Simulation of the Compaction Behavior and the Water Permeability Evolution of Broken Rock Masses of Different Shapes in a Goaf. Water 2023, 15, 1190. [Google Scholar] [CrossRef]

| Serial Number | Rock Type | Thickness /m | Cumulative Thickness /m | Bulk Densit /kN·m−3 |

|---|---|---|---|---|

| 18 | Loess | 23.00 | 412 | 17.9 |

| 17 | Fine Sandstone | 22.38 | 389 | 26.5 |

| 16 | Coarse Sandstone | 19.25 | 366.62 | 25.6 |

| 15 | Fine Sandstone | 42.03 | 345.51 | 26.5 |

| 14 | Coarse Sandstone | 35.22 | 303.48 | 25.6 |

| 13 | Fine Sandstone | 25.07 | 268.26 | 26.5 |

| 12 | Sandy Mudstone | 13.84 | 243.19 | 26.0 |

| 11 | Fine Sandstone | 14.03 | 229.35 | 26.5 |

| 10 | Sandy Mudstone | 21.88 | 209.46 | 26.0 |

| 9 | Coarse Sandstone | 25.51 | 184.62 | 25.6 |

| 8 | Mudstone | 11.43 | 159.11 | 23.3 |

| 7 | Coarse Sandstone | 24.71 | 139.41 | 25.6 |

| 6 | Sandy Mudstone | 5.36 | 113.4 | 26.0 |

| 5 | Coarse Sandstone | 42.43 | 108.04 | 25.6 |

| 4 | Sandy Mudstone | 4.85 | 51.5 | 26.0 |

| 3 | Coal #6 | 19.60 | 31.6 | 14.0 |

| 2 | Mudstone | 3.14 | 10.3 | 23.3 |

| 1 | Coarse Sandstone | 7.16 | 7.16 | 25.6 |

| Project | Parameter | Project | Parameter |

|---|---|---|---|

| Model Length | 300 cm | Excavation Distance | 240 cm |

| Model Thickness | 20 cm | Model Boundary | 30 cm |

| Model Height | 135.3 cm | Excavation Steps | 60 |

| Coal Thickness | 6.7 cm | Single Excavation Distance | 4 cm |

| Geometric Ratio | 1:300 | Excavation Time Interval | 0.5 h |

| Bulk Density Ratio | 1.56:1 | Excavation Time | 30 h |

| Stress Ratio | 380:1 | Upper Load | 0 MPa |

| Parameter | Technical Specifications |

|---|---|

| Measurement Range (km) | 0.05 to 25 |

| Pulse Width (ns) | 0.5, 1, 2, 5, 10 |

| Spatial Resolution (cm) | 5, 10, 20, 50, 100 |

| Strain Measurement Accuracy (με) | ±7.5 |

| Temperature Measurement Accuracy (°C) | ±0.75 |

| Strain Monitoring Range (με) | −3000 to +4000 |

| Temperature Monitoring Range (°C) | −270 to +800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, J.; Qiu, F.; Zhu, L.; Zhang, D. Evolution Characteristics of Void in the Caving Zone Using Fiber Optic Sensing. Sensors 2024, 24, 478. https://doi.org/10.3390/s24020478

Chai J, Qiu F, Zhu L, Zhang D. Evolution Characteristics of Void in the Caving Zone Using Fiber Optic Sensing. Sensors. 2024; 24(2):478. https://doi.org/10.3390/s24020478

Chicago/Turabian StyleChai, Jing, Fengqi Qiu, Lei Zhu, and Dingding Zhang. 2024. "Evolution Characteristics of Void in the Caving Zone Using Fiber Optic Sensing" Sensors 24, no. 2: 478. https://doi.org/10.3390/s24020478

APA StyleChai, J., Qiu, F., Zhu, L., & Zhang, D. (2024). Evolution Characteristics of Void in the Caving Zone Using Fiber Optic Sensing. Sensors, 24(2), 478. https://doi.org/10.3390/s24020478