Evaluation of Two Particle Number (PN) Counters with Different Test Protocols for the Periodic Technical Inspection (PTI) of Gasoline Vehicles

Abstract

:1. Introduction

2. Materials and Methods

2.1. PN-PTI Instruments

2.2. Reference Instrument

2.3. Experimental Setup

2.4. Test Procedure

2.5. Vehicles

3. Results and Discussion

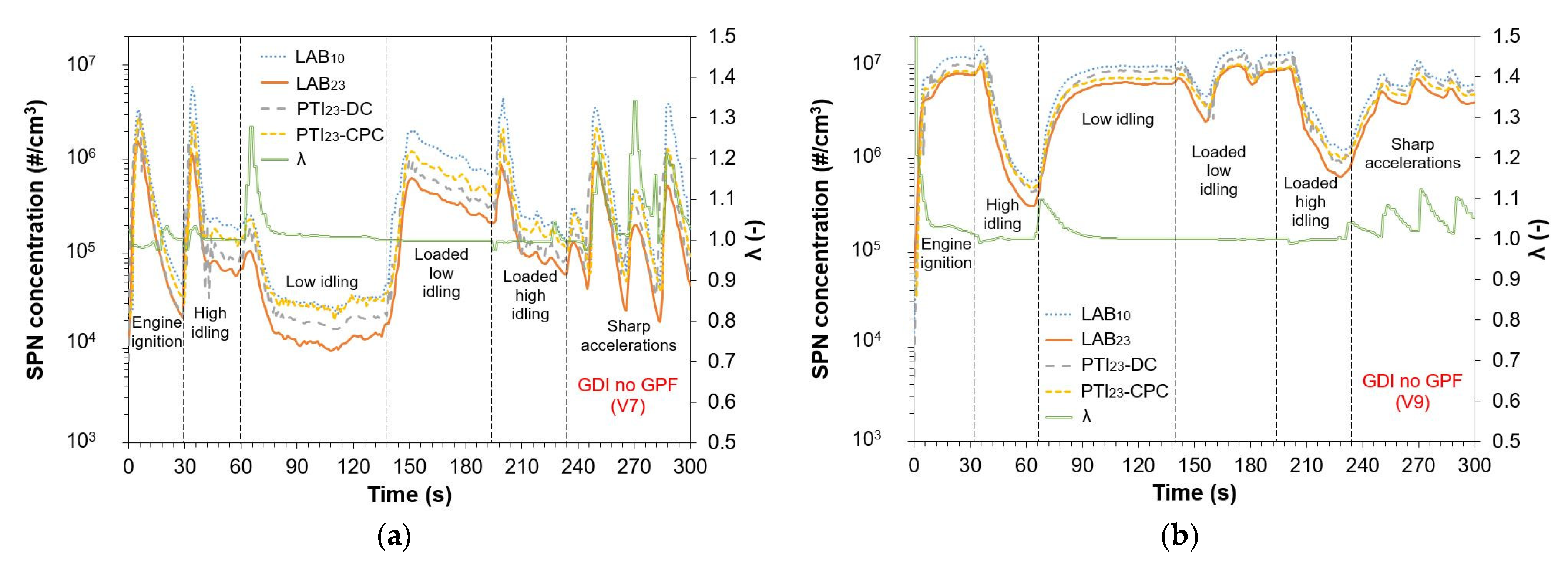

3.1. Examples of Real-Time Concentrations

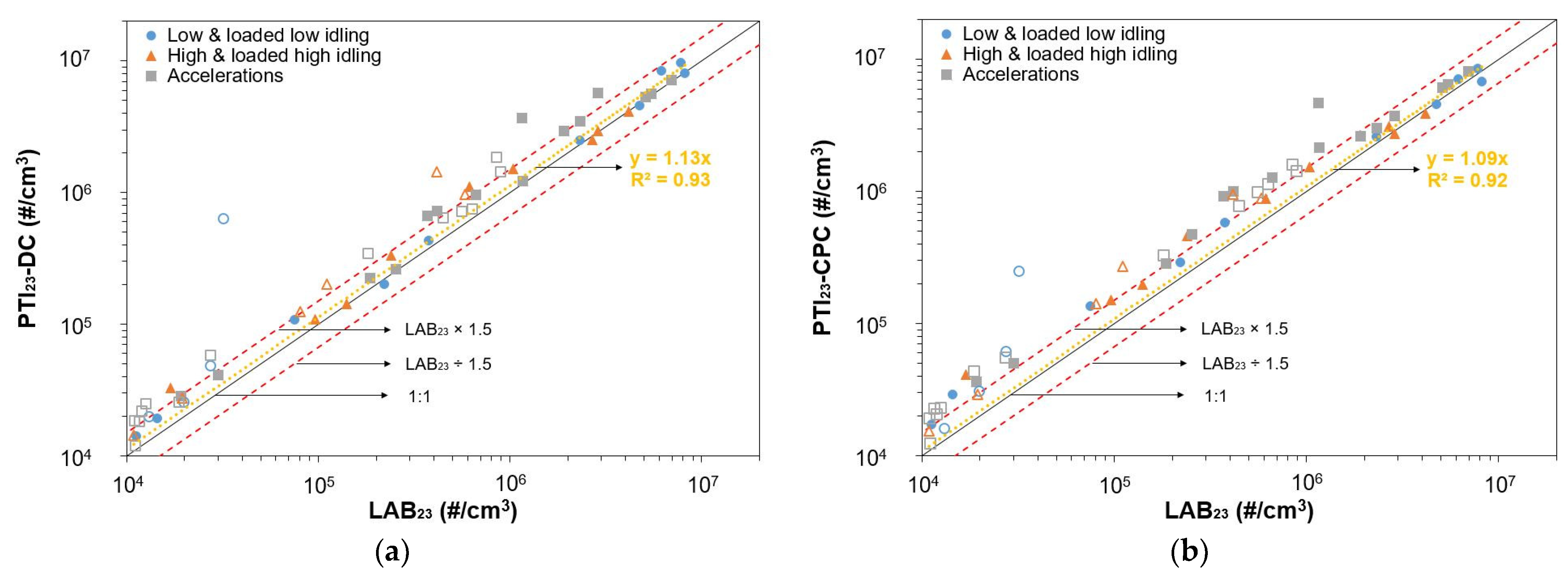

3.2. Comparison of PTI with Reference Instruments

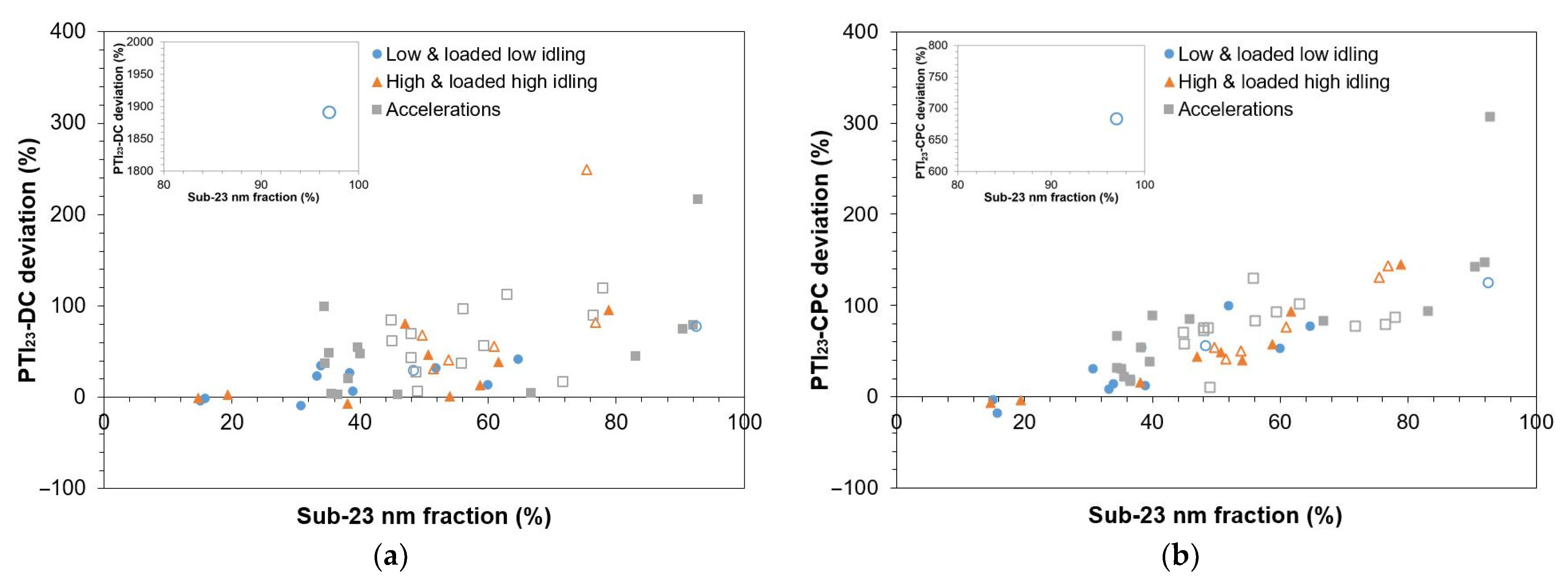

3.3. Sub-23 nm Particles

3.4. Summary of PN-PTI Test Protocol Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hinds, W.C. Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles, 2nd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1999. [Google Scholar]

- Zhang, Z.; Liu, B.Y.H. Performance of TSI 3760 Condensation Nuclei Counter at Reduced Pressures and Flow Rates. Aerosol Sci. Technol. 1991, 15, 228–238. [Google Scholar] [CrossRef]

- Biskos, G.; Vons, V.; Yurteri, C.U.; Schmidt-Ott, A. Generation and Sizing of Particles for Aerosol-Based Nanotechnology. KONA Powder Part. J. 2008, 26, 13–35. [Google Scholar] [CrossRef]

- Corbin, J.C.; Smallwood, G.J.; Leroux, I.D.; Oliaee, J.N.; Liu, F.; Sipkens, T.A.; Green, R.G.; Murnaghan, N.F.; Koukoulas, T.; Lobo, P. Systematic Experimental Comparison of Particle Filtration Efficiency Test Methods for Commercial Respirators and Face Masks. Sci. Rep. 2021, 11, 21979. [Google Scholar] [CrossRef]

- Pogacnik Krajnc, A.; Pirker, L.; Gradisar Centa, U.; Gradisek, A.; Mekjavic, I.B.; Godnic, M.; Cebasek, M.; Bregant, T.; Remskar, M. Size- and Time-Dependent Particle Removal Efficiency of Face Masks and Improvised Respiratory Protection Equipment Used during the COVID-19 Pandemic. Sensors 2021, 21, 1567. [Google Scholar] [CrossRef]

- Lowther, S.D.; Jones, K.C.; Wang, X.; Whyatt, J.D.; Wild, O.; Booker, D. Particulate Matter Measurement Indoors: A Review of Metrics, Sensors, Needs, and Applications. Environ. Sci. Technol. 2019, 53, 11644–11656. [Google Scholar] [CrossRef]

- Karagulian, F.; Barbiere, M.; Kotsev, A.; Spinelle, L.; Gerboles, M.; Lagler, F.; Redon, N.; Crunaire, S.; Borowiak, A. Review of the Performance of Low-Cost Sensors for Air Quality Monitoring. Atmosphere 2019, 10, 506. [Google Scholar] [CrossRef]

- Schwarze, P.E.; Øvrevik, J.; Låg, M.; Refsnes, M.; Nafstad, P.; Hetland, R.B.; Dybing, E. Particulate Matter Properties and Health Effects: Consistency of Epidemiological and Toxicological Studies. Hum. Exp. Toxicol. 2006, 25, 559–579. [Google Scholar] [CrossRef]

- Xing, Y.-F.; Xu, Y.-H.; Shi, M.-H.; Lian, Y.-X. The Impact of PM2.5 on the Human Respiratory System. J. Thorac. Dis. 2016, 8, 69–74. [Google Scholar]

- Kelly, F.J.; Fussell, J.C. Size, Source, and Chemical Composition as Determinants of Toxicity Attributable to Ambient Particulate Matter. Atmos. Environ. 2012, 60, 504–526. [Google Scholar] [CrossRef]

- Chauhan, B.V.S.; Corada, K.; Young, C.; Smallbone, K.L.; Wyche, K.P. Review on Sampling Methods and Health Impacts of Fine (PM2.5, ≤2.5 Μm) and Ultrafine (UFP, PM0.1, ≤0.1 Μm) Particles. Atmosphere 2024, 15, 572. [Google Scholar] [CrossRef]

- Ramanathan, V.; Feng, Y. Air Pollution, Greenhouse Gases and Climate Change: Global and Regional Perspectives. Atmos. Environ. 2009, 43, 37–50. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.; Martini, G.; Dilara, P. Overview of Vehicle Exhaust Particle Number Regulations. Processes 2021, 9, 2216. [Google Scholar] [CrossRef]

- Melas, A.; Selleri, T.; Suarez-Bertoa, R.; Giechaskiel, B. Evaluation of Measurement Procedures for Solid Particle Number (SPN) Measurements during the Periodic Technical Inspection (PTI) of Vehicles. Int. J. Environ. Res. Public Health 2022, 19, 7602. [Google Scholar] [CrossRef]

- Burtscher, H.; Lutz, T.; Mayer, A. A New Periodic Technical Inspection for Particle Emissions of Vehicles. Emiss. Control Sci. Technol. 2019, 5, 279–287. [Google Scholar] [CrossRef]

- Kadijk, G. Particles Matter, Getting a Grip on Diesel Particulate Filters with an Effective Particle Number Test; Emission Training Services: Werkendam, The Netherlands, 2021. [Google Scholar]

- Vasilatou, K.; Kok, P.; Pratzler, S.; Nowak, A.; Waheed, A.; Buekenhoudt, P.; Auderset, K.; Andres, H. New Periodic Technical Inspection of Diesel Engines Based on Particle Number Concentration Measurements. OIML Bull. 2022, LXIII, 11–16. [Google Scholar]

- Vasilatou, K.; Wälchli, C.; Auderset, K.; Burtscher, H.; Hammer, T.; Giechaskiel, B.; Melas, A. Effects of the Test Aerosol on the Performance of Periodic Technical Inspection Particle Counters. J. Aerosol Sci. 2023, 172, 106182. [Google Scholar] [CrossRef]

- Melas, A.; Vasilatou, K.; Suarez-Bertoa, R.; Giechaskiel, B. Laboratory Measurements with Solid Particle Number Instruments Designed for Periodic Technical Inspection (PTI) of Vehicles. Measurement 2023, 215, 112389. [Google Scholar] [CrossRef]

- European Commission. Commission Recommendation of 20.3.2023 on Particle Number Measurement for the Periodic Technical Inspection of Vehicles Equipped with Compression Ignition Engines; European Commission: Brussels, Belgium, 2023. [Google Scholar]

- Sinclair, D.; Hoopes, G.S. A Continuous Flow Condensation Nucleus Counter. J. Aerosol Sci. 1975, 6, 1–7. [Google Scholar] [CrossRef]

- Liu, B.Y.H.; Pui, D.Y.H. On the Performance of the Electrical Aerosol Analyzer. J. Aerosol Sci. 1975, 6, 249–254. [Google Scholar] [CrossRef]

- Samaras, Z.; Rieker, M.; Papaioannou, E.; van Dorp, W.F.; Kousoulidou, M.; Ntziachristos, L.; Andersson, J.; Bergmann, A.; Hausberger, S.; Keskinen, J.; et al. Perspectives for Regulating 10 Nm Particle Number Emissions Based on Novel Measurement Methodologies. J. Aerosol Sci. 2022, 162, 105957. [Google Scholar] [CrossRef]

- Brilke, S.; Resch, J.; Leiminger, M.; Steiner, G.; Tauber, C.; Wlasits, P.J.; Winkler, P.M. Precision Characterization of Three Ultrafine Condensation Particle Counters Using Singly Charged Salt Clusters in the 1–4 Nm Size Range Generated by a Bipolar Electrospray Source. Aerosol Sci. Technol. 2020, 54, 396–409. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A. Impact of Material on Response and Calibration of Particle Number Systems. Atmosphere 2022, 13, 1770. [Google Scholar] [CrossRef]

- Krasa, H.; Kupper, M.; Schriefl, M.A.; Bergmann, A. Toward a Simplified Calibration Method for 23 Nm Automotive Particle Counters Using Atomized Inorganic Salt Particles. Aerosol Sci. Technol. 2023, 57, 329–341. [Google Scholar] [CrossRef]

- Fierz, M.; Scherrer, L.; Burtscher, H. Real-Time Measurement of Aerosol Size Distributions with an Electrical Diffusion Battery. J. Aerosol Sci. 2002, 33, 1049–1060. [Google Scholar] [CrossRef]

- Shin, W.G.; Wang, J.; Mertler, M.; Sachweh, B.; Fissan, H.; Pui, D.Y.H. The Effect of Particle Morphology on Unipolar Diffusion Charging of Nanoparticle Agglomerates in the Transition Regime. J. Aerosol Sci. 2010, 41, 975–986. [Google Scholar] [CrossRef]

- Li, L.; Gopalakrishnan, R. An Experimentally Validated Model of Diffusion Charging of Arbitrary Shaped Aerosol Particles. J. Aerosol Sci. 2021, 151, 105678. [Google Scholar] [CrossRef]

- Qi, C.; Asbach, C.; Shin, W.G.; Fissan, H.; Pui, D.Y.H. The Effect of Particle Pre-Existing Charge on Unipolar Charging and Its Implication on Electrical Aerosol Measurements. Aerosol Sci. Technol. 2009, 43, 232–240. [Google Scholar] [CrossRef]

- Knoll, M.; Schriefl, M.A.; Nishida, R.T.; Bergmann, A. Impact of Pre-Charged Particles on Steady State and Pulsed Modes of Unipolar Diffusion Chargers. Aerosol Sci. Technol. 2021, 55, 512–525. [Google Scholar] [CrossRef]

- Fierz, M.; Houle, C.; Steigmeier, P.; Burtscher, H. Design, Calibration, and Field Performance of a Miniature Diffusion Size Classifier. Aerosol Sci. Technol. 2011, 45, 1–10. [Google Scholar] [CrossRef]

- Fierz, M.; Meier, D.; Steigmeier, P.; Burtscher, H. Aerosol Measurement by Induced Currents. Aerosol Sci. Technol. 2014, 48, 350–357. [Google Scholar] [CrossRef]

- Laakkonen, E.; Arffman, A.; Rostedt, A.; Keskinen, J. Effect of Operation Pressure on the Response of EPNC Particle Number Concentration Sensor. IEEE Sens. J. 2024, 24, 3329519. [Google Scholar] [CrossRef]

- Gallus, J.; Kirchner, U.; Vogt, R.; Borensen, C.; Benter, T. On-Road Particle Number Measurements Using a Portable Emission Measurement System (PEMS). Atmos. Environ. 2016, 124, 37–45. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Melas, A.; Broekaert, S.; Gioria, R.; Suarez-Bertoa, R. Solid Particle Number (SPN) Portable Emission Measurement Systems (PEMS) for Heavy-Duty Applications. Appl. Sci. 2024, 14, 654. [Google Scholar] [CrossRef]

- Melas, A.; Selleri, T.; Suarez-Bertoa, R.; Giechaskiel, B. Evaluation of Solid Particle Number Sensors for Periodic Technical Inspection of Passenger Cars. Sensors 2021, 21, 8325. [Google Scholar] [CrossRef]

- Schriefl, M.A.; Nishida, R.T.; Knoll, M.; Boies, A.; Bergmann, A. Characterization of Particle Number Counters Based on Pulsed-Modediffusion Charging. Aerosol Sci. Technol. 2020, 54, 772–789. [Google Scholar] [CrossRef]

- Melas, A.; Trikka, M.; Valentini, S.; Cotogno, G.; Giechaskiel, B. Calibrations, Validations, and Checks of a Dual 23 Nm and 10 Nm Diffusion Charger-Based Portable Emissions Measurement System (PEMS). Nanomaterials 2024, 14, 1258. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Lähde, T.; Suarez-Bertoa, R.; Valverdre, V.; Clairotte, M. Comparisons of Laboratory and On-Road Type-Approval Cycles with Idling Emissions. Implications for Periodical Technical Inspection (PTI) Sensors. Sensors 2020, 20, 5790. [Google Scholar] [CrossRef]

- Kadijk, G.; Elstgeest, M.; Ligterink, N.E.; Van der Mark, P.J. Investigation into a Periodic Technical Inspection (PTI) Test Method to Check for Presence and Proper Functioning of Diesel Particulate Filters in Light-Duty Diesel Vehicles—Part 2. TNO Rep. 2017, 2017, R10530. [Google Scholar]

- Jang, J.; Lee, J.; Kim, J.; Park, S. Comparisons of the Nanoparticle Emission Characteristics between GDI and PFI Vehicles. J. Nanoparticle Res. 2015, 17, 486. [Google Scholar] [CrossRef]

- Joshi, A. Review of Vehicle Engine Efficiency and Emissions. SAE Int. J. Adv. Curr. Pract. Mobil. 2019, 1, 734–761. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Joshi, A.; Ntziachristos, L.; Dilara, P. European Regulatory Framework and Particulate Matter Emissions of Gasoline Light-Duty Vehicles: A Review. Catalysts 2019, 9, 586. [Google Scholar] [CrossRef]

- Saito, C.; Nakatani, T.; Miyairi, Y.; Yuuki, K.; Makino, M.; Kurachi, H.; Heuss, W.; Kuki, T.; Furuta, Y.; Kattuah, P.; et al. New Particulate Filter Concept to Reduce Particle Number Emissions; SAE Technical Paper 2011-01-0814; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Catapano, F.; Di Iorio, S.; Magno, A.; Sementa, P.; Vaglieco, B.M. Measurement of Sub-23 Nm Particles Emitted from PFI/DI SI Engine Fueled with Oxygenated Fuels: A Comparison between Conventional and Novel Methodologies. Energies 2022, 15, 2021. [Google Scholar] [CrossRef]

- Chen, L.; Liang, Z.; Zhang, X.; Shuai, S. Characterizing Particulate Matter Emissions from GDI and PFI Vehicles under Transient and Cold Start Conditions. Fuel 2017, 189, 131–140. [Google Scholar] [CrossRef]

- Tauber, C.; Brilke, S.; Wlasits, P.J.; Bauer, P.S.; Koberl, G.; Steiner, G.; Winkler, P.M. Humidity Effects on the Detection of Soluble and Insoluble Nanoparticles in Butanol Operated Condensation Particle Counters. Atmos. Meas. Tech. 2019, 12, 3659–3671. [Google Scholar] [CrossRef]

- Toropainen, A.; Kangasluoma, J.; Kurten, T.; Vehkamaki, H.; Keshavarz, F.; Kubecka, J. Heterogeneous Nucleation of Butanol on NaCl: A Computational Study of Temperature, Humidity, Seed Charge, and Seed Size Effects. J. Phys. Chem. A 2021, 125, 3025–3036. [Google Scholar] [CrossRef]

- Zheng, C.; Duan, D.; Chang, Q.; Liu, S.; Yang, Z.; Liu, X.; Weng, W.; Gao, X. Experiments on Enhancing the Particle Charging Performance of an Electrostatic Precipitator. Aerosol Air Qual. Res. 2019, 19, 1411–1420. [Google Scholar] [CrossRef]

- Lee, H.M.; Kim, C.S.; Shimada, M.; Okuyama, K. Effects of Mobility Changes and Distribution of Bipolar Ions on Aerosol Nanoparticle Diffusion Charging. J. Chem. Eng. Jpn. 2005, 38, 486–496. [Google Scholar] [CrossRef]

- Pui, D.Y.H. Experimental Study of Diffusion Charging of Aerosols; Technical Report; University of Minnesota: Minneapolis, MN, USA, 1976. [Google Scholar]

- Bergmann, M.; Vogt, R.; Szente, J.; Maricq, M.; Benter, T. Using Ejector Diluters to Sample Vehicle Exhaust at Elevated Pressures and Temperatures. SAE Int. J. Engines 2009, 1, 1167–1178. [Google Scholar] [CrossRef]

- Kadijk, G.; Elstgeest, M.; Ligterink, N.E.; Van der Mark, P.J. Emissions of Six Petrol Vehicles with High Mileages; TNO Report; TNO: Delft, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Jarosinski, W.; Wisniowski, P. Verifying the Efficiency of a Diesel Particulate Filter Using Particle Counters with Two Different Measurements in Periodic Technical Inspection of Vehicles. Energies 2021, 14, 5128. [Google Scholar] [CrossRef]

- Boveroux, F.; Cassiers, S.; Buekenhoudt, P.; Chavatte, L.; De Meyer, P.; Jeanmart, H.; Verhelst, S.; Contino, F. Feasibility Study of a New Test Procedure to Identify High Emitters of Particulate Matter during Periodical Technical Inspection; SAE Technical Paper 2019-01-1190; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Bainschab, M.; Schriefl, M.A.; Bergmann, A. Particle Number Measurements within Periodic Technical Inspections: A First Quantitative Assessment of the Influence of Size Distributions and the Fleet Emission Reduction. Atmos. Environ. X 2020, 8, 100095. [Google Scholar] [CrossRef]

- PTB. PTB-Anforderungen 12.16 “Partikelz Ahler” (05/2021) 2021; PTB: Berlin, Germany, 2021. [Google Scholar]

- VAMV. Verordnung Des EJPD Über Abgasmessmittel Für Verbrennungsmotoren (VAMV). Available online: https://www.fedlex.admin.ch/eli/cc/2006/251 (accessed on 10 September 2024).

- Hammer, T.; Roos, D.; Giechaskiel, B.; Melas, A.; Vasilatou, K. Influence of Soot Aerosol Properties on the Counting Efficiency of Instruments Used for the Periodic Technical Inspection of Diesel Vehicles. Aerosol Res. 2024, 2, 261–270. [Google Scholar] [CrossRef]

- Khalek, I.S.; Kittelson, D.B. Real Time Measurement of Volatile and Solid Exhaust Particles Using a Catalytic Stripper; SAE Technical Paper 950236; SAE International: Warrendale, PA, USA, 1995. [Google Scholar] [CrossRef]

- European Commission. 2017 Commission Regulation (EU) 2017/1151, OJ L 175; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- European Union. Directive 2009/30/EC of the European Parliament and of the Council of 23 April 2009 Amending Directive 98/70/EC as Regards the Specification of Petrol, Diesel and Gas-Oil and Introducing a Mechanism to Monitor and Reduce Greenhouse Gas Emissions and Amending Council Directive 1999/32/EC as Regards the Specification of Fuel Used by Inland Waterway Vessels and Repealing Directive 93/12/EEC; European Union: Maastricht, The Netherlands, 2009. [Google Scholar]

- Mamakos, A.; Rose, D.; Besch, M.C.; He, S.; Gioria, R.; Melas, A.; Suarez-Bertoa, R.; Giechaskiel, B. Evaluation of Advanced Diesel Particulate Filter Concepts for Post Euro VI Heavy-Duty Applications. Atmosphere 2022, 13, 1682. [Google Scholar] [CrossRef]

| Code | Euro | Engine | Year | Mileage (km) | Engine Displacement (cm3) | Power (kW) | Particulate Filter |

|---|---|---|---|---|---|---|---|

| V1 | 6d | GDI-Hybrid | 2023 | 12,006 | 999 | 81 | Yes |

| V2 | 6d-TEMP | GDI | 2020 | 62,004 | 999 | 85 | Yes |

| V3 | 6d | GDI | 2021 | 47,925 | 1498 | 96 | Yes |

| V4 | 6d | GDI | 2022 | 17,325 | 999 | 92 | Yes |

| V5 | 6d-TEMP | GDI | 2020 | 25,544 | 1332 | 100 | Yes |

| V6 | 5b | GDI | 2012 | 188,435 | 998 | 49 | No |

| V7 | 6b | GDI | 2016 | 77,853 | 1197 | 81 | No |

| V8 | 6b | GDI | 2016 | 60,136 | 1395 | 92 | No |

| V9 | 6b | GDI | 2017 | 81,510 | 1197 | 85 | No |

| V10 | 6b | GDI | 2018 | 65,132 | 999 | 77 | No |

| V11 | 5b | PFI | 2015 | 172,301 | 1199 | 60 | No |

| V12 | 6d-TEMP | PFI | 2019 | 12,657 | 1242 | 66 | No |

| V13 | 6b | PFI | 2017 | 32,761 | 1400 | 70 | No |

| V14 | 6b | PFI | 2017 | 72,690 | 999 | 55 | No |

| V15 | 6b | PFI | 2017 | 32,373 | 1396 | 66 | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melas, A.; Franzetti, J.; Suarez-Bertoa, R.; Giechaskiel, B. Evaluation of Two Particle Number (PN) Counters with Different Test Protocols for the Periodic Technical Inspection (PTI) of Gasoline Vehicles. Sensors 2024, 24, 6509. https://doi.org/10.3390/s24206509

Melas A, Franzetti J, Suarez-Bertoa R, Giechaskiel B. Evaluation of Two Particle Number (PN) Counters with Different Test Protocols for the Periodic Technical Inspection (PTI) of Gasoline Vehicles. Sensors. 2024; 24(20):6509. https://doi.org/10.3390/s24206509

Chicago/Turabian StyleMelas, Anastasios, Jacopo Franzetti, Ricardo Suarez-Bertoa, and Barouch Giechaskiel. 2024. "Evaluation of Two Particle Number (PN) Counters with Different Test Protocols for the Periodic Technical Inspection (PTI) of Gasoline Vehicles" Sensors 24, no. 20: 6509. https://doi.org/10.3390/s24206509