High Sensitivity Bi2O3/Ti3C2Tx Ammonia Sensor Based on Improved Synthetic MXene Method at Room Temperature

Abstract

:1. Introduction

2. Experiments

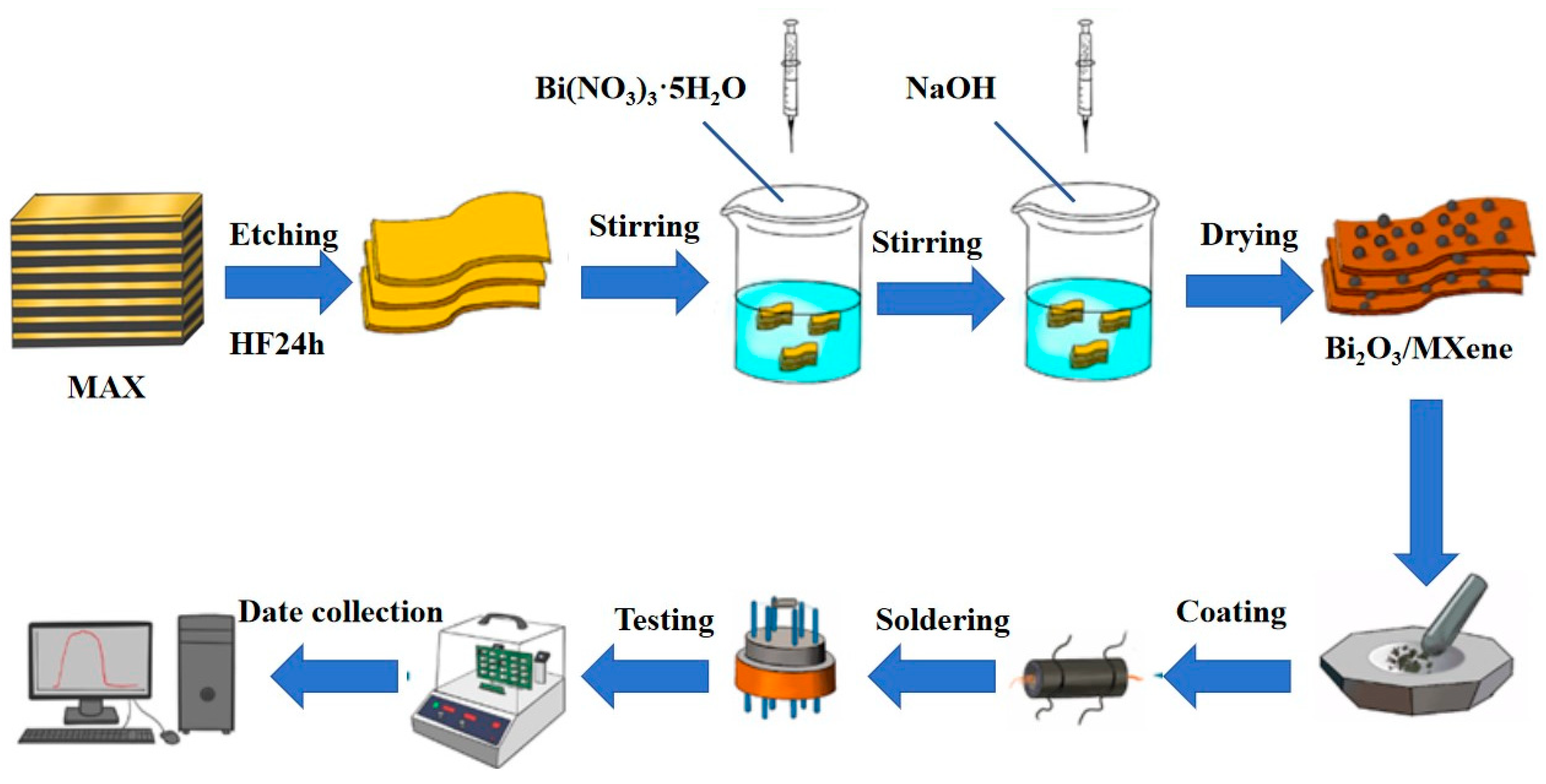

2.1. Synthesis of Multilayer Ti3C2Tx MXene

2.2. Synthesis of Bi2O3/Ti3C2Tx Nanocomposites

2.3. Material Characterization

2.4. Fabrication and Measurement of Gas Sensor

3. Results

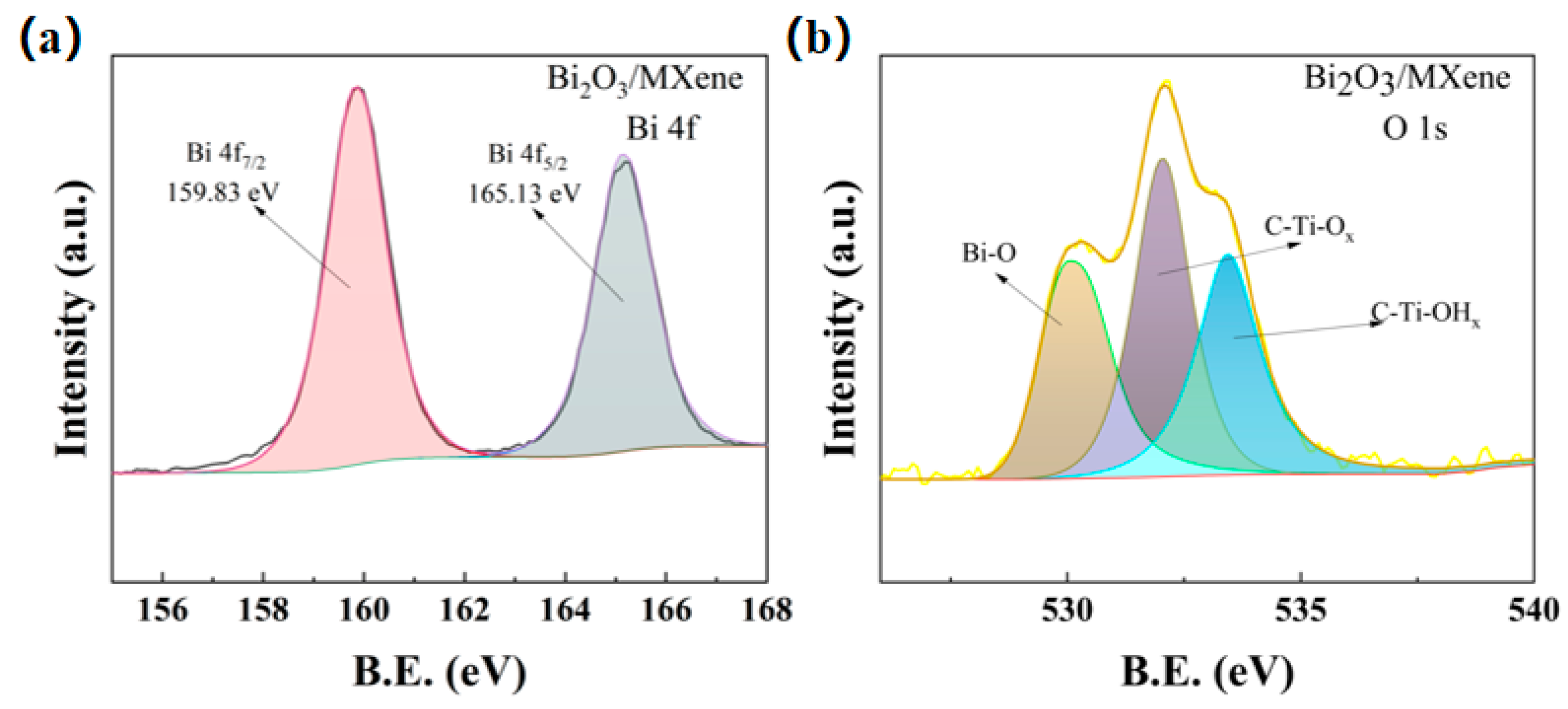

3.1. Characterization Results

3.2. Gas Sensing Performance

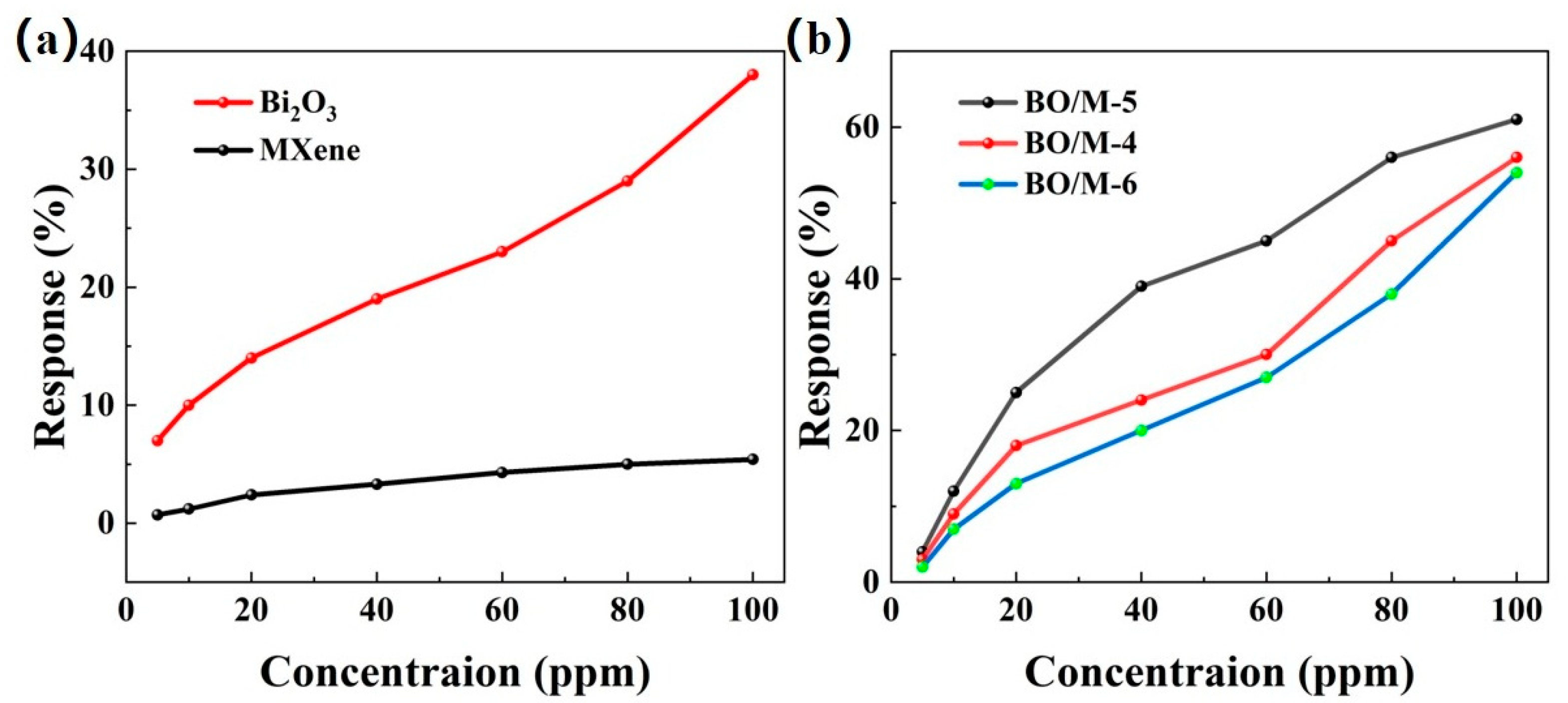

3.2.1. Comparison of Gas Sensitivity Performance of Sensors with Different Ratios to Ammonia

3.2.2. Selectivity Test of BO/M-5 Gas Sensor

3.2.3. Gas Sensitivity Performance of BO/M-5 Gas Sensor at Different Humidities

3.2.4. Response Recovery Performance of the BO/M-5 Gas Sensor

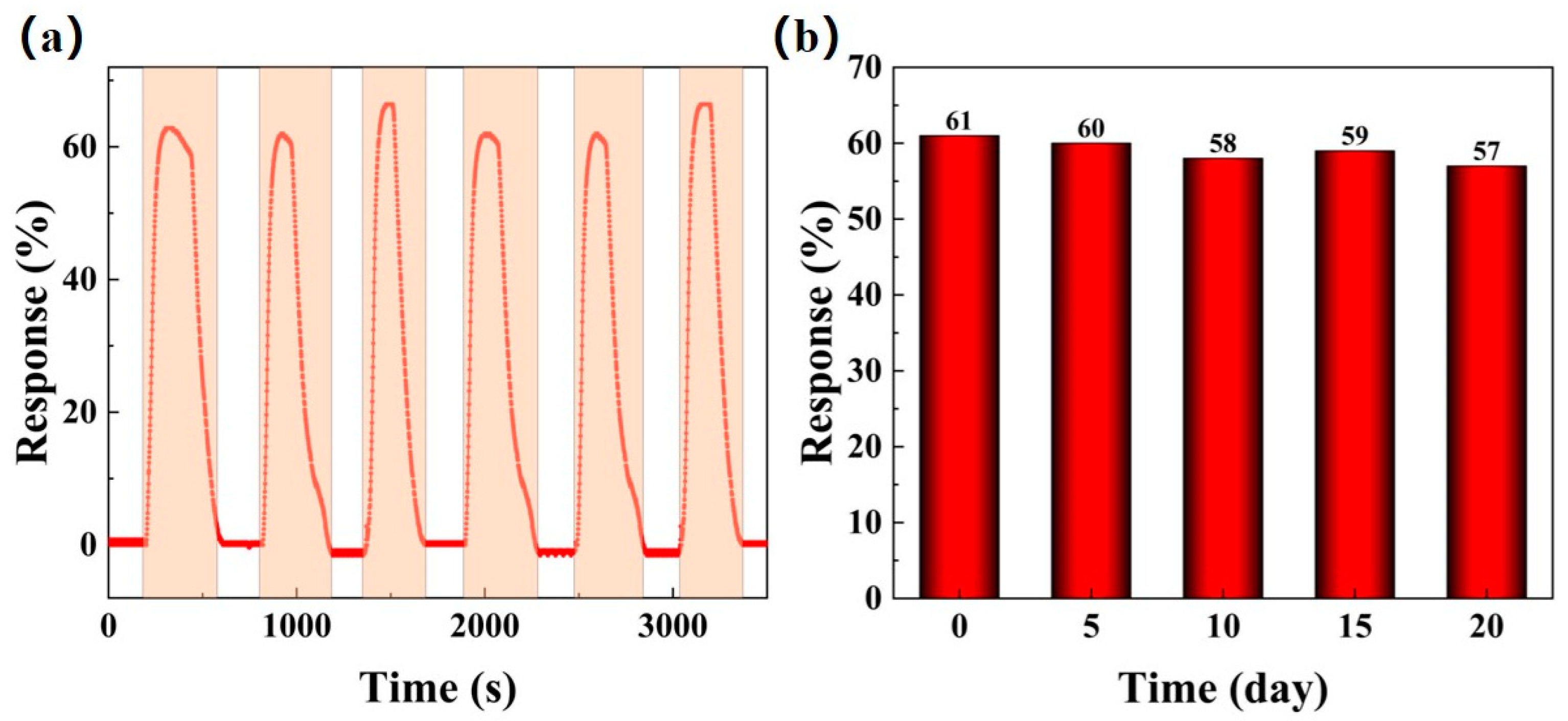

3.2.5. Repeatability and Long-Term Stability of BO/M-5 Gas Sensor

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, M.; He, M.; Hu, Q.; Wu, Q.; Sun, G.; Xie, L.; Zhang, Z.; Zhu, Z.; Zhou, A. Ti3C2Tx MXene-Based Sensors with High Selectivity for NH3 Detection at Room Temperature. ACS Sens. 2019, 4, 2763–2770. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Kumar, A.; Sim, U.; Im, H.; Song, S. Synergistic enhancement in the sensing performance of a mixed-potential NH3 sensor using SnO2@CuFe2O4 sensing electrode. Sens. Actuators B Chem. 2020, 308, 127748. [Google Scholar] [CrossRef]

- Meng, W.; Dai, L.; Meng, W.; Zhou, H.; Li, Y.; He, Z.; Wang, L. Mixed-potential type NH3 sensor based on TiO2 sensing electrode with a phase transformation effect. Sens. Actuators B Chem. 2017, 240, 962–970. [Google Scholar] [CrossRef]

- Li, H.; Lee, C.; Kim, D.; Lee, J. Flexible room-temperature NH3 sensor for ultrasensitive, selective, and humidity-independent gas detection. ACS Appl. Mater. Interfaces 2018, 10, 27858–27867. [Google Scholar] [CrossRef]

- Kim, S.; Koh, H.; Ren, C.; Kwon, O.; Maleski, K.; Cho, S.; Anasori, B.; Kim, C.; Choi, Y.; Kim, J.; et al. Metallic Ti3C2Tx MXene gas sensors with ultrahigh signal-to-noise ratio. ACS Nano 2018, 12, 986–993. [Google Scholar] [CrossRef]

- Naderi, H.; Hajati, S.; Ghaedi, M.; Dashtian, K.; Sabzehmeidani, M. Sensitive, selective and rapid ammonia-sensing by gold nanoparticle-sensitized V2O5/CuWO4 heterojunctions for exhaled breath analysis. Appl. Surf. Sci. 2020, 501, 144270. [Google Scholar] [CrossRef]

- Vardhan, D.; Devi, C.; Nagaraju, P.; Muralikrishna, P.; Kumar, B.; Upender, G. Room temperature sensing of ammonia and formaldehyde gases through novel anisotype heterojunction of p-Co3O4/n-Gd0.1Ce0.9O2-δ as highly responsive and stable sensors. Mater. Chem. Phys. 2024, 313, 128694. [Google Scholar] [CrossRef]

- Atkare, S.; Kaushik, S.; Jagtap, S.; Rout, C.S. Room-temperature chemiresistive ammonia sensors based on 2D MXenes and their hybrids: Recent developments and future prospects. Dalton Trans. 2023, 52, 13831–13851. [Google Scholar] [CrossRef]

- Wu, R.; Guo, S.; Li, Y.; Qi, M.; Ge, B.; Song, J. Improving the sensing performance of rambutan-like W18O49 based gas sensor for n-butanol by Ni doping. Sens. Actuators B Chem. 2024, 410, 135671. [Google Scholar] [CrossRef]

- Brophy, R.; Junker, B.; Fakhri, E.; Arnason, H.; Svavarsson, H.; Weimar, U.; Bârsan, N.; Manolescu, A. Ultra Responsive NO2 silicon nanowires gas sensor. Sens. Actuators B Chem. 2024, 410, 135648. [Google Scholar] [CrossRef]

- Hjiri, M.; Algessair, S.; Dhahri, R.; Albargi, H.; Ben Mansour, N.; Assadi, A.; Neri, G. Ammonia gas sensors based on undoped and Ca-doped ZnO nanoparticles. RSC Adv. 2024, 14, 5001–5011. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Shi, T.; Chen, T.; He, W.; Chen, M.; Cao, D. The naked-eye NH3 sensor based on fluorinated graphene. Sens. Actuators B Chem. 2019, 281, 789–794. [Google Scholar] [CrossRef]

- Lorencova, L.; Bertok, T.; Filip, J.; Jerigova, M.; Velic, D.; Kasak, P.; Mahmoud, K.; Tkac, J. Highly stable Ti3C2Tx (MXene)/Pt nanoparticles-modified glassy carbon electrode for H2O2 and small molecules sensing applications. Sens. Actuators B Chem. 2018, 263, 360–368. [Google Scholar] [CrossRef]

- Qin, Q.; Olimov, D.; Yin, L. Semiconductor-Type Gas Sensors Based on γ-Fe2O3 Nanoparticles and Its Derivatives in Conjunction with SnO2 and Graphene. Chemosensors 2022, 10, 267. [Google Scholar] [CrossRef]

- Ma, Y.; Yue, Y.; Zhang, H.; Cheng, F.; Zhao, W.; Rao, J.; Luo, S.; Wang, J.; Jiang, X.; Liu, Z.; et al. 3D synergistical Mxene/reduced grapheme oxide aerogel for a piezoresistive sensor. ACS Nano 2018, 12, 3209–3216. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Liu, C.; Wang, F.; Yang, L.; Han, A.; Gao, J. The applicantion progress of two-dimensional Mxene material in the field of gas sensor. J. Funct. Mater. 2022, 53, 3058–3065. [Google Scholar] [CrossRef]

- Liu, X.; Ma, T.; Pinna, N.; Zhang, J. Two-dimensional nanostructured materials for gas sensing. Adv. Funct. Mater. 2017, 27, 1702168. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater. 2011, 23, 4248–4253. [Google Scholar] [CrossRef]

- Lu, L.; Zhang, C.; Zou, Y.; Xu, F.; Sun, L.; Xiang, C. Room-temperature humidity-resistant highly sensitive ammonia sensor based on a porous MXene/Na2Ti3O7 @polyaniline composite. Sens. Actuators B Chem. 2024, 405, 135323. [Google Scholar] [CrossRef]

- Wang, T.; Zhu, L.; Kanda, H. Ti3C2 MXene-TiO2 hybrid-modified U-bend fiberoptic sensor for improved refractive index sensitivity and ammonia detection. Sens. Actuators B Chem. 2023, 393, 134136. [Google Scholar] [CrossRef]

- Yu, H.; Dai, L.; Liu, Y.; Zhou, Y.; Fan, P.; Luo, J.; Zhong, A. Ti3C2Tx MXene-SnO2 nanocomposite for superior room temperature ammonia gas sensor. J. Alloys Compd. 2023, 962, 171170. [Google Scholar] [CrossRef]

- Hou, M.; Jiang, G.; Guo, S.; Gao, J.; Shen, Z.; Wang, Z.; Ye, X.; Yang, L.; Du, Q.; Yi, J.; et al. Mxene Ti3C2Tx derived lamellar Ti3C2Tx-TiO2-CuO heterojunction: Significantly improved ammonia sensor performance. Arab. J. Chem. 2023, 16, 104808. [Google Scholar] [CrossRef]

- Yuan, G.; Wang, D. A piezoelectric six-DOF vibration energy harvester based on parallel mechanism: Dynamic modeling, simulation, and experiment. Smart Mater. Struct. 2017, 26, 035022. [Google Scholar] [CrossRef]

- You, J.; Wang, L.; Xi, F.; Shen, J. Decoupling algorithm and maximum operation frequency of a novel parallel type six-axis accelerometer. IEEE Sens. J. 2020, 20, 12637–12651. [Google Scholar] [CrossRef]

- Hassanein, S.; Ali, R. Investigation of the Morphological, Optical, and D.C Electrical Characteristics of Synthesized (Bi2O3/ZnO) Nanocomposites, as Well as Their Potential Use in Hydrogen Sulfide Gas Sensor. Trans. Electr. Electron. Mater. 2023, 24, 205–216. [Google Scholar] [CrossRef]

- Wang, C.; Niu, Q.; Liu, D.; Dong, X.; You, T. Electrochemical sensor based on Bi/Bi2O3 doped porous carbon composite derived from Bi-MOFs for Pb2+ sensitive detection. Talanta 2023, 258, 124281. [Google Scholar] [CrossRef]

- Chang, C.; Xue, Q.; Wang, R.; Liu, Z.; Liu, Y.; He, L.; Liu, F.; Xie, H. Development of a novel sensor based on Bi2O3 and carbonized UIO-66-NH2 nanocomposite for efficient detection of Pb(II) ion in water environment. Appl. Surf. Sci. 2023, 616, 156510. [Google Scholar] [CrossRef]

- Hieu, N.; Van Phuoc, C.; Hung, N.; Anh, C.; Phan, A.; Nah, J.; Jeong, J.; Huy, P.; Kim, D. A highly stable humidity sensor based on a new Bi2O3/CNT hybrid nanostructure. Sens. Actuators A Phys. 2023, 351, 114141. [Google Scholar] [CrossRef]

- Pandeeswari, R.; Sonia, T.; Balamurugan, D.; Jeyaprakash, B. Highly Selective Dimethylamine Vapour Sensors Based on Spray Deposited β-Bi2O3 Nanospheres at Low Temperature. Sens. Imaging 2022, 23, 1. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar] [CrossRef]

- Kuang, D.; Guo, X.; Zhu, Z.; Ding, Y.; Sun, X.; Wu, Z.; Zhang, L.; Zhou, Y.; He, Y. Enhanced room temperature ammonia response of 2D-Ti3C2Tx MXene decorated with Ni(OH)2 nanoparticles. Ceram. Int. 2021, 47, 19471–19480. [Google Scholar] [CrossRef]

- Chaudhary, N.; Singh, A.; Aswal, D.; Debnath, A.; Samanta, S.; Koiry, S.; Sharma, S.; Shah, K.; Acharya, S.; Muthe, K.P.; et al. Electron beam modified zinc phthalocyanine thin films for radiation dosimeter application. Synth. Met. 2017, 231, 143–152. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, B.; Zhao, Z.; Lv, Z.; Chen, Z.; Kang, S. High Sensitivity Bi2O3/Ti3C2Tx Ammonia Sensor Based on Improved Synthetic MXene Method at Room Temperature. Sensors 2024, 24, 6514. https://doi.org/10.3390/s24206514

Zhou B, Zhao Z, Lv Z, Chen Z, Kang S. High Sensitivity Bi2O3/Ti3C2Tx Ammonia Sensor Based on Improved Synthetic MXene Method at Room Temperature. Sensors. 2024; 24(20):6514. https://doi.org/10.3390/s24206514

Chicago/Turabian StyleZhou, Baocang, Zhihua Zhao, Zhenli Lv, Zhuo Chen, and Sibo Kang. 2024. "High Sensitivity Bi2O3/Ti3C2Tx Ammonia Sensor Based on Improved Synthetic MXene Method at Room Temperature" Sensors 24, no. 20: 6514. https://doi.org/10.3390/s24206514