Fault Diagnosis in Centrifugal Pumps: A Dual-Scalogram Approach with Convolution Autoencoder and Artificial Neural Network

Abstract

:1. Introduction

- (1)

- Integration of signal processing and deep learning: This approach uniquely combines traditional signal processing techniques with deep learning methods to enhance the analysis and classification of vibration signals.

- (2)

- Parallel transformations: The use of two different transformations—the CWT and Stockwell transforms—enables the capture of different yet complementary information from the vibration signal. This dual transformation approach is a distinctive feature of this work.

- (3)

- Scalogram feature extraction via CAE: A CAE is employed to extract relevant features from the scalograms resulting from the CWT and Stockwell transforms. Using a CAE ensures that only the most pertinent features, which might otherwise be hard for traditional methods to capture, are retained.

- (4)

- Amalgamation of features: Features extracted from both the CWT and Stockwell scalograms are combined into a single robust feature pool, which is expected to offer a comprehensive representation of the vibration signal.

- (5)

- ANN-based classification: The consolidated feature pool is then input into an ANN for effective classification into distinct fault categories. This demonstrates the applicability of deep learning in making sense of the complex features derived from vibration signals.

2. Materials and Methods

2.1. Technical Background

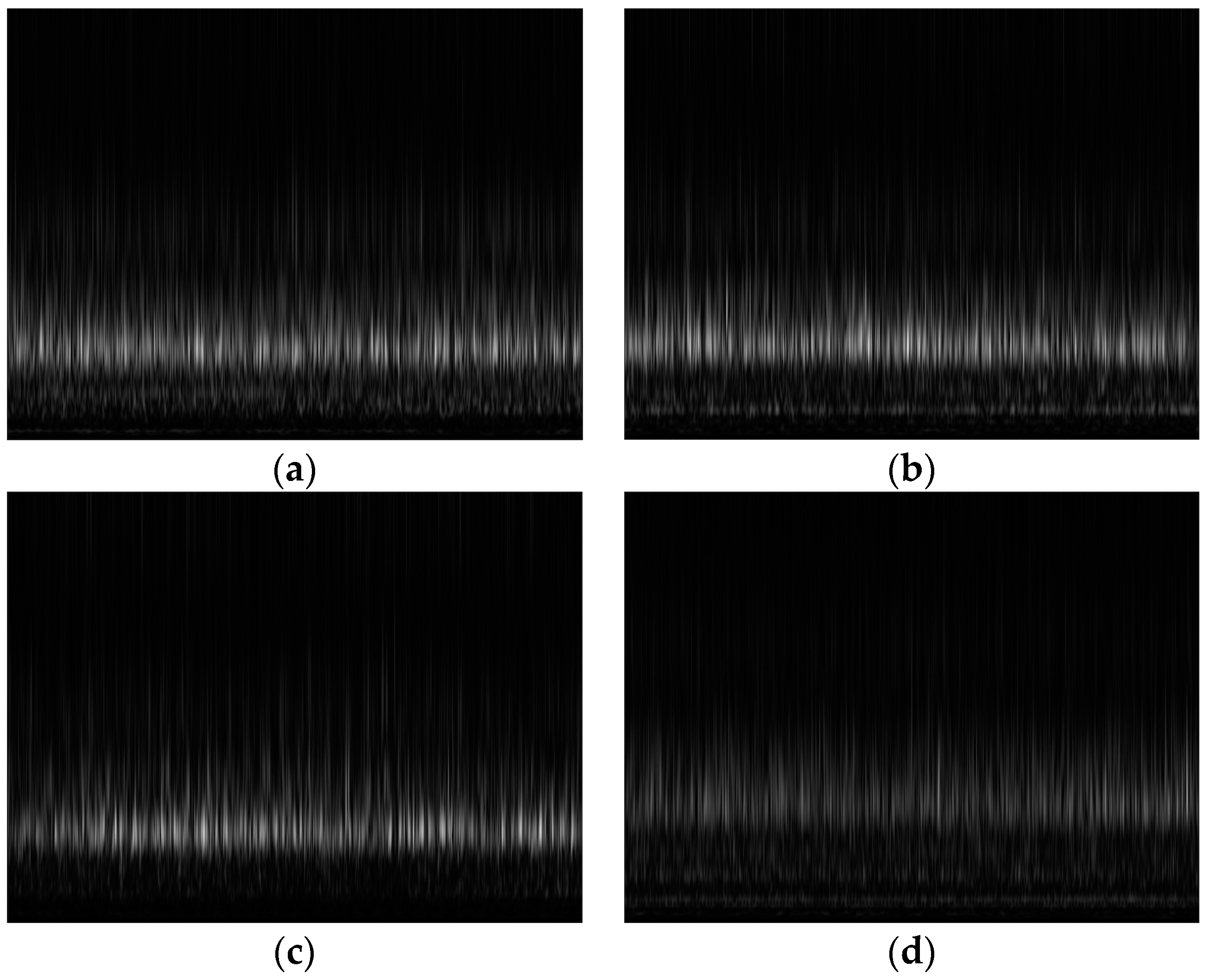

2.1.1. Continuous Wavelet Transform Scalograms

2.1.2. Stockwell Transform Scalograms

2.1.3. Sobel Filter

2.1.4. Convolution Autoencoder

2.1.5. t-SNE Analysis

2.1.6. Hyperparameter Selection

2.2. Proposed Approach

- (1)

- Data acquisition: Gather vibration signals from the CP under various health scenarios using a specialized data acquisition system.

- (2)

- Signal preprocessing: Implement a lowpass filter with a cutoff frequency of 4.6 kHz to isolate and capture fault-specific frequencies from the signals.

- (3)

- Time–frequency analysis: Simultaneously produce two distinct scalograms through the CWT and S-transform methods.

- (4)

- Edge enhancement: Apply the Sobel filter on the scalograms to accentuate edges, thereby mitigating noise.

- (5)

- Feature extraction: Utilize the refined scalograms to train two parallel CAEs, subsequently extracting pertinent features from each.

- (6)

- Combining features: Integrate the extracted features from both CAEs into a comprehensive and discriminative feature pool.

- (7)

- Classification: Train an ANN on this feature pool, enabling precise classification across diverse CP health conditions.

3. Experimental Methods and Test Rig Setup

3.1. Dataset

3.2. Impeller Fault

3.3. Mechanical Seal Faults

3.3.1. Mechanical Seal Hole

3.3.2. Mechanical Seal Scratch

4. Results Discussion and Evaluation Metrics

4.1. Data Configuration for Training and Testing

4.2. Evaluation Metrics

4.3. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saranga, H.; Knezevic, J. Reliability prediction for condition-based maintained systems. Reliab. Eng. Syst. Saf. 2001, 71, 219–224. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, C.; Liu, H.; Wang, Y. Fault diagnosis for centrifugal pumps based on complementary ensemble empirical mode decomposition, sample entropy and random forest. In Proceedings of the 2016 12th World Congress on Intelligent Control and Automation (WCICA), Guilin, China, 12–15 June 2016; IEEE: New York, NY, USA, 2016; pp. 1317–1320. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, Z.; Lu, C.; Ma, J.; Li, L. Fault diagnosis for centrifugal pumps using deep learning and softmax regression. In Proceedings of the 2016 12th World Congress on Intelligent Control and Automation (WCICA), Guilin, China, 12–15 June 2016; IEEE: New York, NY, USA, 2016; pp. 165–169. [Google Scholar] [CrossRef]

- Rai, A.; Upadhyay, S. A review on signal processing techniques utilized in the fault diagnosis of rolling element bearings. Tribol. Int. 2016, 96, 289–306. [Google Scholar] [CrossRef]

- Sohaib, M.; Kim, J.-M. Fault Diagnosis of Rotary Machine Bearings Under Inconsistent Working Conditions. IEEE Trans. Instrum. Meas. 2019, 69, 3334–3347. [Google Scholar] [CrossRef]

- Muralidharan, V.; Sugumaran, V. Feature extraction using wavelets and classification through decision tree algorithm for fault diagnosis of mono-block centrifugal pump. Measurement 2013, 46, 353–359. [Google Scholar] [CrossRef]

- Panda, A.K.; Rapur, J.S.; Tiwari, R. Prediction of flow blockages and impending cavitation in centrifugal pumps using Support Vector Machine (SVM) algorithms based on vibration measurements. Measurement 2018, 130, 44–56. [Google Scholar] [CrossRef]

- Abu-Zeid, M.A.; Abdel-Rahman, S. Bearing problems’ effects on the dynamic performance of pumping stations. Alex. Eng. J. 2013, 52, 241–248. [Google Scholar] [CrossRef]

- Delgado, M.; Cirrincione, G.; García, A.; Ortega, J.A.; Henao, H. Accurate bearing faults classification based on statistical-time features, curvilinear component analysis and neural networks. In Proceedings of the IECON 2012-38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 3854–3861. [Google Scholar]

- Samanta, B.; Al-Balushi, K.R. Artificial neural network based fault diagnostics of rolling element bearings using time-domain features. Mech. Syst. Signal Process. 2003, 17, 317–328. [Google Scholar] [CrossRef]

- Wang, S.; Xiang, J.; Zhong, Y.; Tang, H. A data indicator-based deep belief networks to detect multiple faults in axial piston pumps. Mech. Syst. Signal Process. 2018, 112, 154–170. [Google Scholar] [CrossRef]

- Rapur, J.S.; Tiwari, R. Automation of multi-fault diagnosing of centrifugal pumps using multi-class support vector machine with vibration and motor current signals in frequency domain. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 278. [Google Scholar] [CrossRef]

- Sun, H.; Yuan, S.; Luo, Y. Characterization of cavitation and seal damage during pump operation by vibration and motor current signal spectra. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 233, 132–147. [Google Scholar] [CrossRef]

- Li, S.; Chu, N.; Yan, P.; Wu, D.; Antoni, J. Cyclostationary approach to detect flow-induced effects on vibration signals from centrifugal pumps. Mech. Syst. Signal Process. 2019, 114, 275–289. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, Z.; Huang, Q.; Gong, Y. Fault Location and Fault Type Recognition of Power System Based on Wavelet Transform. In Proceedings of the 2019 IEEE Innovative Smart Grid Technologies—Asia (ISGT Asia), Chengdu, China, 21–24 May 2019; IEEE: New York, NY, USA, 2019; pp. 689–692. [Google Scholar]

- Muralidharan, V.; Sugumaran, V.; Indira, V. Fault diagnosis of monoblock centrifugal pump using SVM. Eng. Sci. Technol. Int. J. 2014, 17, 152–157. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, N.E. Ensemble empirical mode decomposition: A noise-assisted data analysis method. Adv. Adapt. Data Anal. 2009, 1, 1–41. [Google Scholar] [CrossRef]

- Alabied, S.; Haba, U.; Daraz, A.; Gu, F.; Ball, A.D. Empirical Mode Decomposition of Motor Current Signatures for Centrifugal Pump Diagnostics. In Proceedings of the 2018 24th International Conference on Automation and Computing (ICAC), Newcastle Upon Tyne, UK, 6–7 September 2018. [Google Scholar]

- Lei, Y.; Lin, J.; He, Z.; Zuo, M.J. A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2013, 35, 108–126. [Google Scholar] [CrossRef]

- Yan, R.; Gao, R.X. Energy-Based Feature Extraction for Defect Diagnosis in Rotary Machines. IEEE Trans. Instrum. Meas. 2009, 58, 3130–3139. [Google Scholar] [CrossRef]

- Xia, M.; Li, T.; Xu, L.; Liu, L.; de Silva, C.W. Fault Diagnosis for Rotating Machinery Using Multiple Sensors and Convolutional Neural Networks. IEEE/ASME Trans. Mechatronics 2017, 23, 101–110. [Google Scholar] [CrossRef]

- Altobi, M.A.S.; Bevan, G.; Wallace, P.; Harrison, D.; Ramachandran, K. Fault diagnosis of a centrifugal pump using MLP-GABP and SVM with CWT. Eng. Sci. Technol. Int. J. 2019, 22, 854–861. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Z.; Zhou, L.; Yu, W.; Shao, Y. A statistical feature investigation of the spalling propagation assessment for a ball bearing. Mech. Mach. Theory 2019, 131, 336–350. [Google Scholar] [CrossRef]

- He, M.; He, D. A new hybrid deep signal processing approach for bearing fault diagnosis using vibration signals. Neurocomputing 2020, 396, 542–555. [Google Scholar] [CrossRef]

- Ahmad, Z.; Rai, A.; Hasan, J.; Kim, C.H.; Kim, J.-M. A Novel Framework for Centrifugal Pump Fault Diagnosis by Selecting Fault Characteristic Coefficients of Walsh Transform and Cosine Linear Discriminant Analysis. IEEE Access 2021, 9, 150128–150141. [Google Scholar] [CrossRef]

- Ahmad, Z.; Nguyen, T.-K.; Ahmad, S.; Nguyen, C.D.; Kim, J.-M. Multistage Centrifugal Pump Fault Diagnosis Using Informative Ratio Principal Component Analysis. Sensors 2022, 22, 179. [Google Scholar] [CrossRef] [PubMed]

- Cabrera, D.; Villacís, M.; Cerrada, M.; Sánchez, R.-V.; Li, C.; Sancho, F.; Long, J.; Estupinan, E. Adversarial Fault Detector Guided by One-Class Learning for a Multistage Centrifugal Pump. IEEE/ASME Trans. Mechatron. 2023, 28, 1395–1403. [Google Scholar] [CrossRef]

- Siddique, M.F.; Ahmad, Z.; Ullah, N.; Kim, J. A Hybrid Deep Learning Approach: Integrating Short-Time Fourier Transform and Continuous Wavelet Transform for Improved Pipeline Leak Detection. Sensors 2023, 23, 8079. [Google Scholar] [CrossRef]

- Ullah, N.; Ahmad, Z.; Siddique, M.F.; Im, K.; Shon, D.-K.; Yoon, T.-H.; Yoo, D.-S.; Kim, J.-M. An Intelligent Framework for Fault Diagnosis of Centrifugal Pump Leveraging Wavelet Coherence Analysis and Deep Learning. Sensors 2023, 23, 8850. [Google Scholar] [CrossRef]

- Zaman, W.; Ahmad, Z.; Siddique, M.F.; Ullah, N.; Kim, J.-M. Centrifugal Pump Fault Diagnosis Based on a Novel SobelEdge Scalogram and CNN. Sensors 2023, 23, 5255. [Google Scholar] [CrossRef]

- Yan, X.; Jia, M. A novel optimized SVM classification algorithm with multi-domain feature and its application to fault diagnosis of rolling bearing. Neurocomputing 2018, 313, 47–64. [Google Scholar] [CrossRef]

- Wang, J.; Mo, Z.; Zhang, H.; Miao, Q. A Deep Learning Method for Bearing Fault Diagnosis Based on Time-Frequency Image. IEEE Access 2019, 7, 42373–42383. [Google Scholar] [CrossRef]

- Khan, S.U.; Jan, S.U.; Koo, I. Robust Epileptic Seizure Detection Using Long Short-Term Memory and Feature Fusion of Compressed Time–Frequency EEG Images. Sensors 2023, 23, 9572. [Google Scholar] [CrossRef]

- YanPing, Z.; ShuHong, H.; JingHong, H.; Tao, S.; Wei, L. Continuous wavelet grey moment approach for vibration analysis of rotating machinery. Mech. Syst. Signal Process. 2006, 20, 1202–1220. [Google Scholar] [CrossRef]

- Türk, Ö.; Özerdem, M.S. Epilepsy Detection by Using Scalogram Based Convolutional Neural Network from EEG Signals. Brain Sci. 2019, 9, 115. [Google Scholar] [CrossRef] [PubMed]

- Lapins, S.; Roman, D.C.; Rougier, J.; De Angelis, S.; Cashman, K.V.; Kendall, J.-M. An examination of the continuous wavelet transform for volcano-seismic spectral analysis. J. Volcanol. Geotherm. Res. 2020, 389, 106728. [Google Scholar] [CrossRef]

- Daubechies, I. The wavelet transform, time-frequency localization and signal analysis. IEEE Trans. Inf. Theory 1990, 36, 961–1005. [Google Scholar] [CrossRef]

- Stockwell, R.G.; Mansinha, L.; Lowe, R.P. Localization of the complex spectrum: The S transform. IEEE Trans. Signal Process. 1996, 44, 998–1001. [Google Scholar] [CrossRef]

- Gong, J.; Yang, X.; Pan, F.; Liu, W.; Zhou, F. An Integrated Fault Diagnosis Method for Rotating Machinery Based on Improved Multivariate Multiscale Amplitude-Aware Permutation Entropy and Uniform Phase Empirical Mode Decomposition. Shock. Vib. 2021, 2021, 1–22. [Google Scholar] [CrossRef]

- Ravivarma, G.; Gavaskar, K.; Malathi, D.; Asha, K.; Ashok, B.; Aarthi, S. Implementation of Sobel operator based image edge detection on FPGA. Mater. Today Proc. 2021, 45, 2401–2407. [Google Scholar] [CrossRef]

- Dong, X.; Li, J.; Wu, J.; Liu, J. A Window Detection Algorithm for Remote Laser Gas Leakage Detection System. Procedia Comput. Sci. 2020, 174, 720–728. [Google Scholar] [CrossRef]

- Chen, M.; Shi, X.; Zhang, Y.; Wu, D.; Guizani, M. Deep Feature Learning for Medical Image Analysis with Convolutional Autoencoder Neural Network. IEEE Trans. Big Data 2017, 7, 750–758. [Google Scholar] [CrossRef]

- Hinton, G.; van der Maaten, L. Visualizing data using t-SNE. J. Mach. Learn. Res. 2008, 9, 2579–2605. [Google Scholar]

- Ahmad, Z.; Rai, A.; Maliuk, A.S.; Kim, J.-M. Discriminant Feature Extraction for Centrifugal Pump Fault Diagnosis. IEEE Access 2020, 8, 165512–165528. [Google Scholar] [CrossRef]

- Hossin, M.; Sulaiman, M.N. A Review on Evaluation Metrics for Data Classification Evaluations. Int. J. Data Min. Knowl. Manag. Process. 2015, 5, 1–11. [Google Scholar] [CrossRef]

- Tran, M.-Q.; Liu, M.-K.; Tran, Q.-V.; Nguyen, T.-K. Effective Fault Diagnosis Based on Wavelet and Convolutional Attention Neural Network for Induction Motors. IEEE Trans. Instrum. Meas. 2021, 71, 3501613. [Google Scholar] [CrossRef]

- Manikandan, S.; Duraivelu, K. Vibration-Based Fault Diagnosis of Broken Impeller and Mechanical Seal Failure in Industrial Mono-Block Centrifugal Pumps Using Deep Convolutional Neural Network. J. Vib. Eng. Technol. 2022, 11, 141–152. [Google Scholar] [CrossRef]

| Encoder | Decoder | ||

|---|---|---|---|

| Layer Name | Output Dimension | Layer Name | Output Dimension |

| Input | 128 × 128 × 1 | Dense | 2048 |

| Conv2D | 64 × 64 × 16 | Reshape | 4 × 4 × 128 |

| Conv2D | 32 × 32 × 32 | Conv2DTranspose | 8 × 8 × 128 |

| Conv2D | 16 × 16 × 64 | Conv2DTranspose | 16 × 16 × 64 |

| Conv2D | 8 × 8 × 128 | Conv2DTranspose | 32 × 32 × 32 |

| Conv2D | 4 × 4 × 128 | Conv2DTranspose | 64 × 64 × 16 |

| Flatten | 2048 | Conv2DTranspose | 128 × 128 × 1 |

| Deep Learning Model | Hyperparameter | Value/Setting |

|---|---|---|

| Autoencoder | Batch size | 32 |

| Hidden layers | 11 (encoder 6, decoder 5) | |

| Optimizer type | Adam | |

| Loss function | MSE | |

| Learning rate | 0.001 | |

| Number of epochs | 10 | |

| t-SNE | Number of components | 2 |

| Perplexity | 30 | |

| Learning rate | 200 |

| CP’s Health Condition | Dataset_1 (3.0 BAR) No. of Samples | Dataset_2 (3.5 BAR) No. of Samples | Dataset_3 (4.0 BAR) No. of Samples |

|---|---|---|---|

| IF | 304 | 307 | 303 |

| MSH | 311 | 312 | 313 |

| MSS | 315 | 291 | 346 |

| Normal | 317 | 414 | 319 |

| Dataset_1 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Accuracy | Precision | Recall | F1 Score | |||||||||||||

| Model | IF | MSH | MSS | Normal | IF | MSH | MSS | Normal | IF | MSH | MSS | Normal | IF | MSH | MSS | Normal |

| Proposed | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| Tran et al. [47]. | 1.00 | 0.98 | 0.83 | 1.00 | 0.95 | 0.90 | 1.00 | 0.99 | 1.00 | 0.98 | 0.83 | 1.00 | 0.97 | 0.94 | 0.91 | 0.99 |

| Manikandan et al. [48]. | 1.00 | 0.87 | 0.85 | 1.00 | 0.90 | 0.89 | 0.95 | 1.00 | 1.00 | 0.88 | 0.85 | 1.00 | 0.95 | 0.88 | 0.90 | 1.00 |

| Dataset_2 | ||||||||||||||||

| Proposed | 1.00 | 0.96 | 1.00 | 1.00 | 0.97 | 1.00 | 1.00 | 1.00 | 1.00 | 0.96 | 1.00 | 1.00 | 0.98 | 0.98 | 1.00 | 1.00 |

| Tran et al. [47]. | 0.87 | 1.00 | 1.00 | 1.00 | 1.00 | 0.93 | 0.94 | 1.00 | 0.87 | 1.00 | 1.00 | 1.00 | 0.93 | 0.96 | 0.97 | 1.00 |

| Manikandan et al. [48] | 0.96 | 0.84 | 1.00 | 1.00 | 1.00 | 0.98 | 0.85 | 0.98 | 0.96 | 0.84 | 1.00 | 1.00 | 0.98 | 0.91 | 0.92 | 0.99 |

| Dataset_3 | ||||||||||||||||

| Proposed | 0.95 | 1.00 | 1.00 | 1.00 | 1.00 | 0.98 | 0.97 | 1.00 | 0.95 | 1.00 | 1.00 | 1.00 | 0.97 | 0.99 | 0.98 | 1.00 |

| Tran et al. [47]. | 0.90 | 1.00 | 0.93 | 1.00 | 1.00 | 0.92 | 0.94 | 1.00 | 0.90 | 1.00 | 0.94 | 1.00 | 0.95 | 0.96 | 0.94 | 1.00 |

| Manikandan et al. [48] | 0.94 | 0.84 | 1.00 | 0.93 | 1.00 | 0.93 | 0.86 | 0.98 | 0.95 | 0.84 | 1.00 | 0.93 | 0.97 | 0.88 | 0.93 | 0.96 |

| Dataset_1 | ||||

|---|---|---|---|---|

| Model | Accuracy | Precision | Recall | F1 Score |

| Proposed | 1.00 | 1.00 | 1.00 | 1.00 |

| Tran et al. [47]. | 0.955 | 0.958 | 0.954 | 0.953 |

| Manikandan et al. [48] | 0.932 | 0.933 | 0.932 | 0.931 |

| Dataset_2 | ||||

| Proposed | 0.992 | 0.993 | 0.992 | 0.992 |

| Tran et al. [47]. | 0.969 | 0.966 | 0.967 | 0.965 |

| Manikandan et al. [48] | 0.946 | 0.953 | 0.951 | 0.949 |

| Dataset_3 | ||||

| Proposed | 0.988 | 0.988 | 0.989 | 0.988 |

| Tran et al. [47]. | 0.960 | 0.964 | 0.959 | 0.961 |

| Manikandan et al. [48] | 0.933 | 0.943 | 0.930 | 0.935 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaman, W.; Ahmad, Z.; Kim, J.-M. Fault Diagnosis in Centrifugal Pumps: A Dual-Scalogram Approach with Convolution Autoencoder and Artificial Neural Network. Sensors 2024, 24, 851. https://doi.org/10.3390/s24030851

Zaman W, Ahmad Z, Kim J-M. Fault Diagnosis in Centrifugal Pumps: A Dual-Scalogram Approach with Convolution Autoencoder and Artificial Neural Network. Sensors. 2024; 24(3):851. https://doi.org/10.3390/s24030851

Chicago/Turabian StyleZaman, Wasim, Zahoor Ahmad, and Jong-Myon Kim. 2024. "Fault Diagnosis in Centrifugal Pumps: A Dual-Scalogram Approach with Convolution Autoencoder and Artificial Neural Network" Sensors 24, no. 3: 851. https://doi.org/10.3390/s24030851