An Approach to Develop Digital Twins in Industry

Abstract

1. Introduction

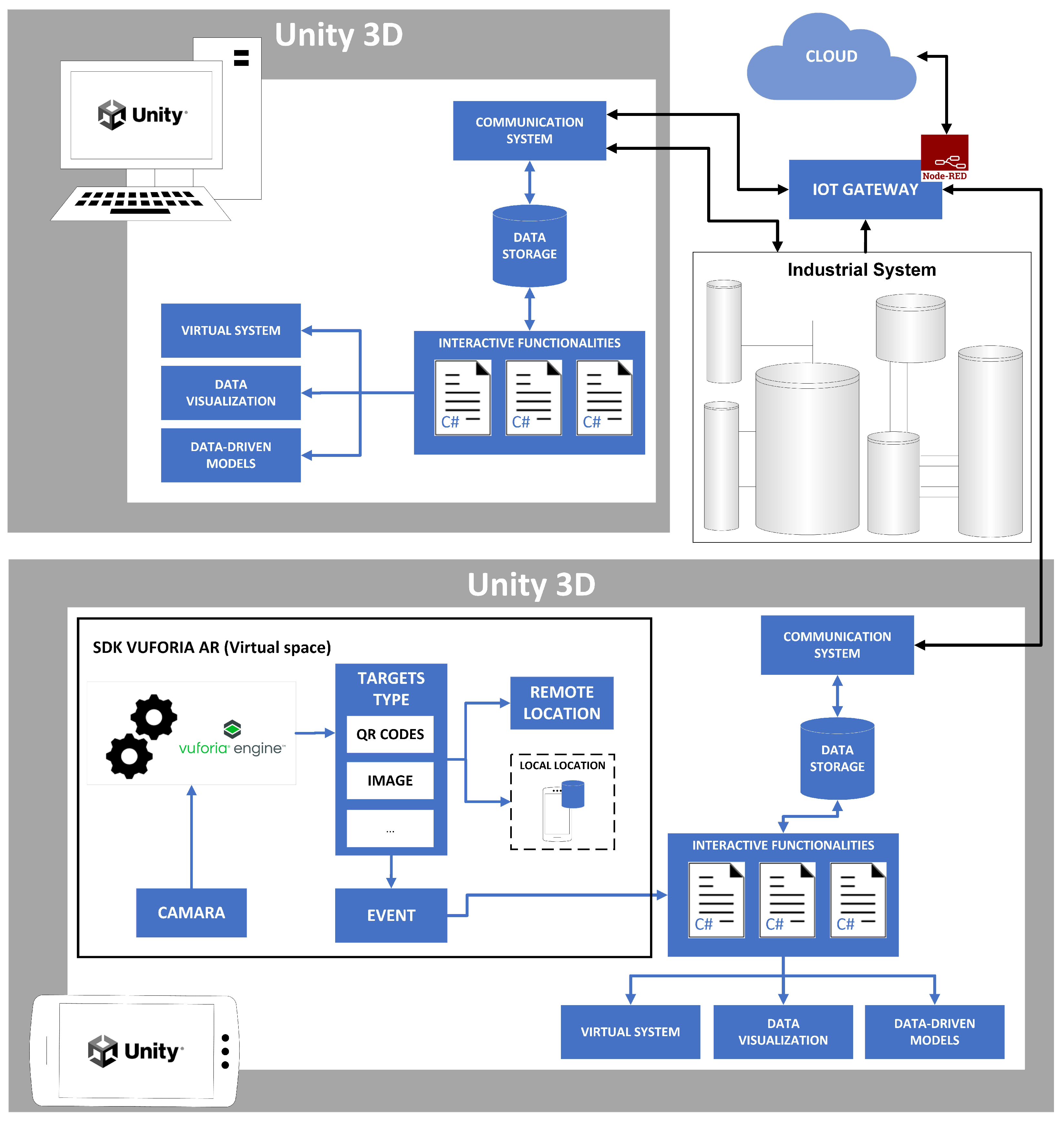

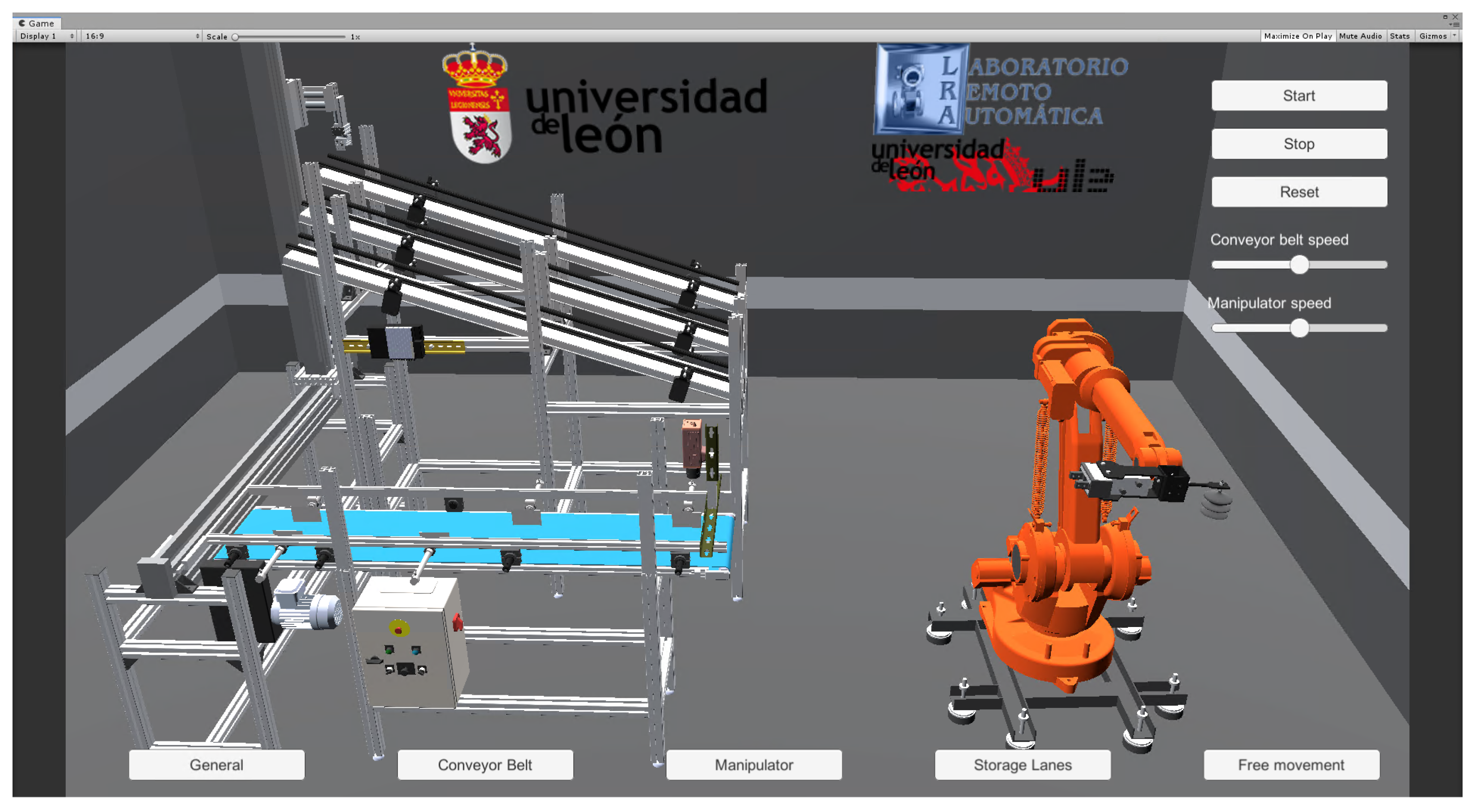

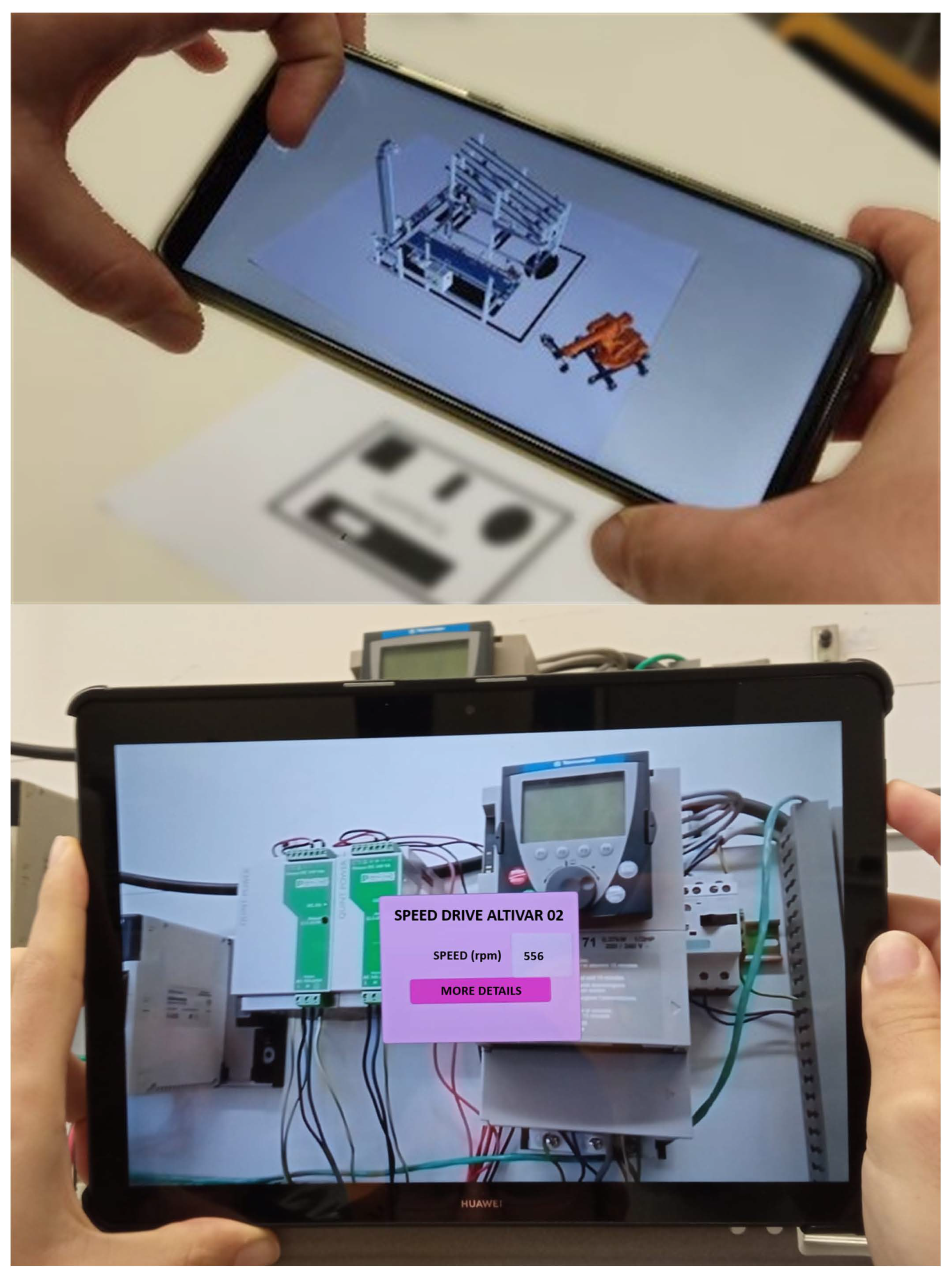

- To develop precise scenarios of virtual and augmented reality. There are open-source graphic engines that, although initially associated with video game development, are progressively being utilized for engineering, marketing, and architectural applications. Additionally, these engines are equipped with a powerful physics engine that streamlines the 3D modeling of industrial systems and enables the adaptation of applications to augmented reality.

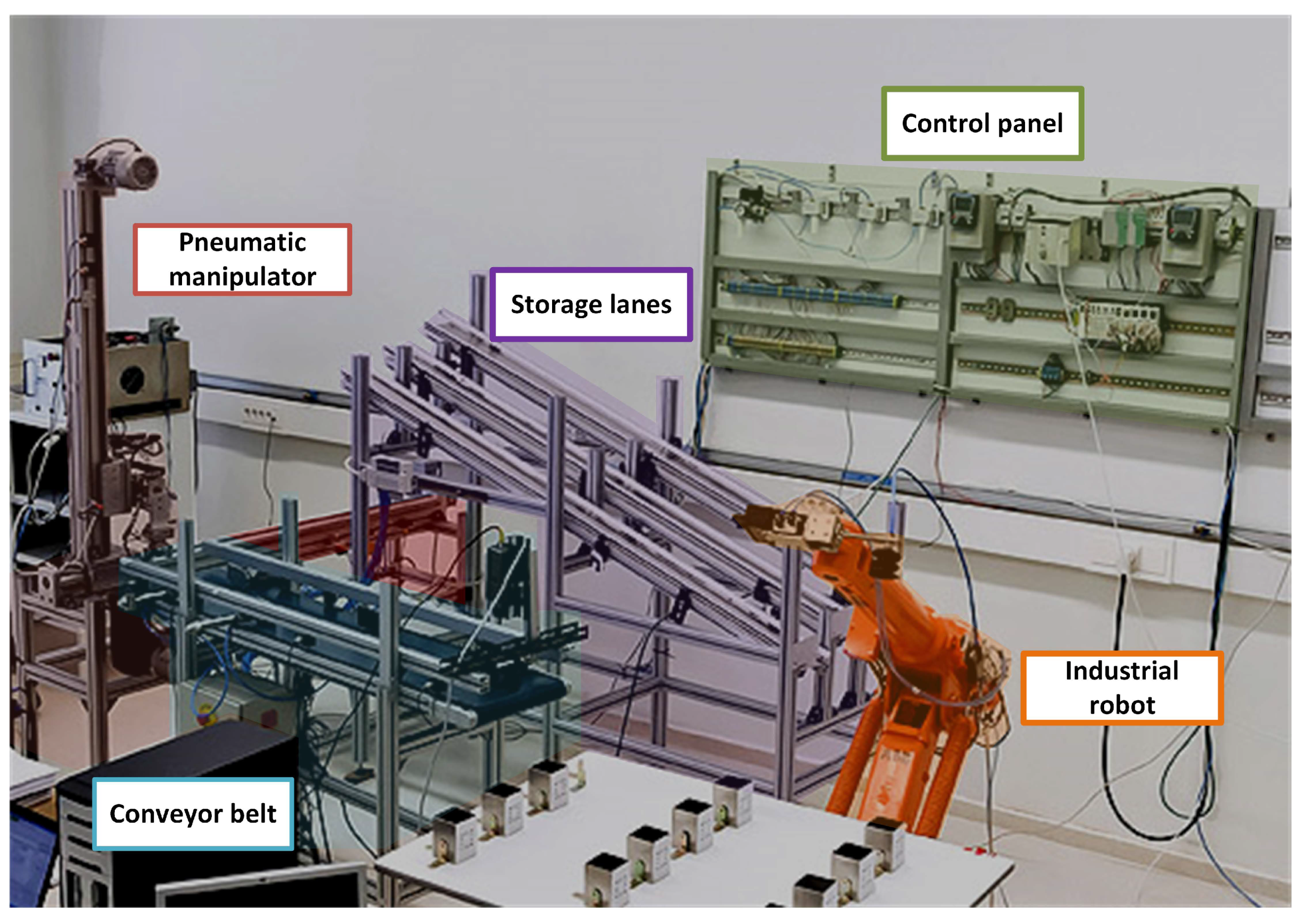

- To manage automation and robotic systems based on distributed and decentralized architectures where control systems communicate with each other through standard industrial communication protocols, aiming to enhance efficiency, speed, and repeatability.

- To ensure connectivity using standard communication protocols, such as Message Queuing Telemetry Transport (MQTT), and specific industrial protocols that are traditionally used for the operation or configuration of control systems, such as PROFINET, Modbus TCP, etc. Also connectivity with OPC UA, which is a modern industrial communication standard, is based on the classic client/server architecture.

- To achieve system integration, with tools such as Node-RED, an open-source visualization tool created by the IBM Emerging Technology team that allows for interconnecting all the elements of the Internet of Things.

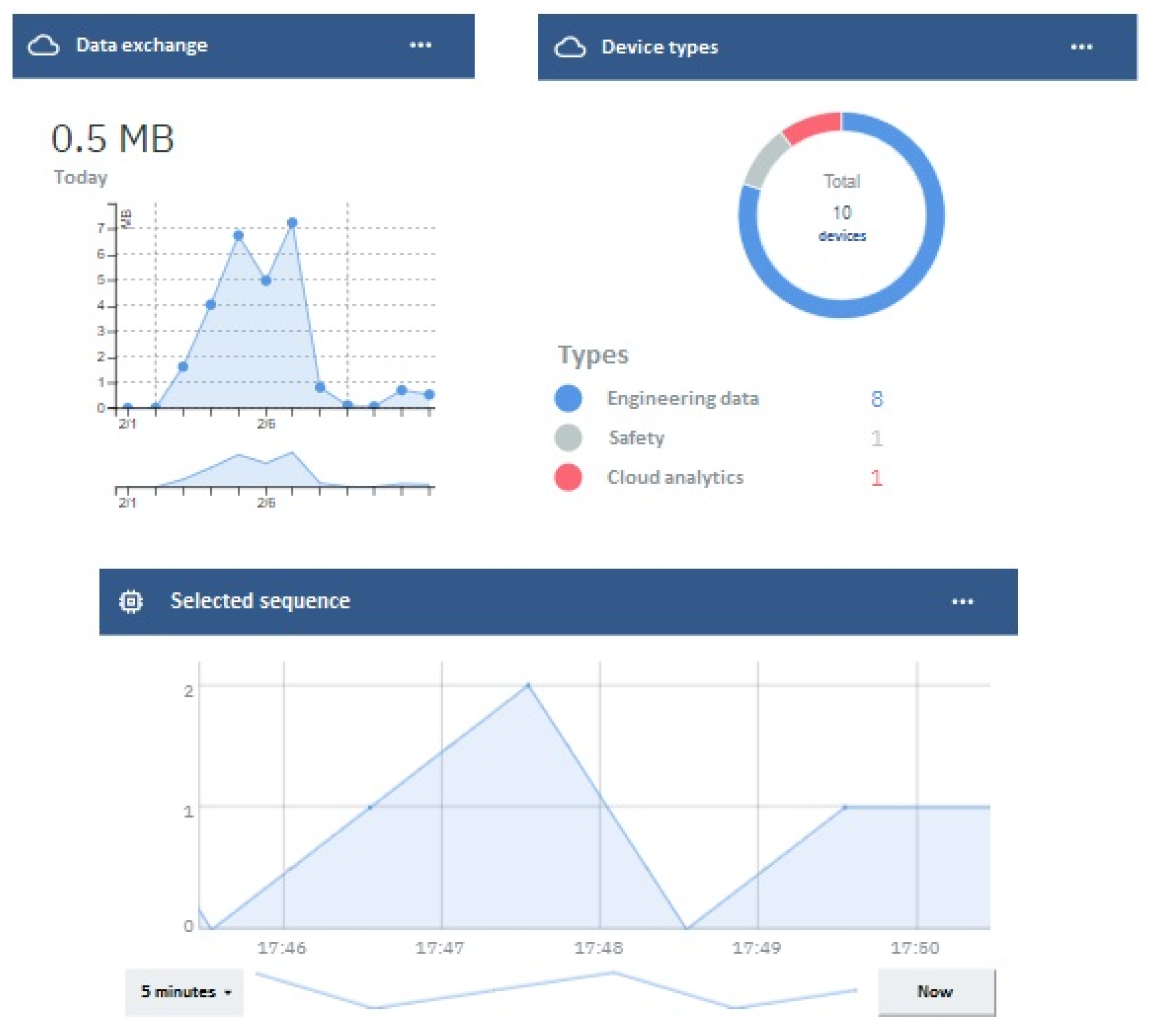

- To store and process data in the cloud. Virtual machines or services allocated in the cloud have advantages over other local tools, including cost-effectiveness, flexibility, continuous support, and heightened security. Furthermore, cloud services enable the implementation of data analysis techniques by facilitating real-time and decentralized decision making.

- To add industrial cybersecurity. Although industrial cybersecurity, as well as other main enabling technologies in digital industry, have not been incorporated into our functional digital twin proposal, the robotic electro-pneumatic cell used for experimentation currently features an industrial firewall to ensure network security. The plan for incorporating this aspect into the digital twin in future work is described.

2. Digital Twins

3. Methodology to Develop Digital Twins

3.1. Implementation and Functionality Definition

3.2. Virtual Space

3.3. Communication System

3.4. Data Storage and Processing

3.5. Interactive Functionalities

4. Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bigliardi, B.; Bottani, E.; Casella, G. Enabling technologies, application areas and impact of industry 4.0: A bibliographic analysis. Procedia Manuf. 2020, 42, 322–326. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Ustundag, A.; Cevikcan, E. Industry 4.0: Managing the Digital Transformation; Springer Series in Advanced Manufacturing: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- de la Peña, D.M.; Domínguez, M.; Gomez-Estern, F.; Reinoso, Ó.; Torres, F.; Dormido, S. Estado del arte de la educación en automática. Rev. Iberoam. AutomáTica InformáTica Ind. 2022, 19, 117–131. [Google Scholar] [CrossRef]

- Boyes, H.; Watson, T. Digital twins: An analysis framework and open issues. Comput. Ind. 2022, 143, 103763. [Google Scholar] [CrossRef]

- Guerra-Zubiaga, D.; Kuts, V.; Mahmood, K.; Bondar, A.; Nasajpour-Esfahani, N.; Otto, T. An approach to develop a digital twin for industry 4.0 systems: Manufacturing automation case studies. Int. J. Comput. Integr. Manuf. 2021, 34, 933–949. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital twin: Origin to future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Errandonea, I.; Beltrán, S.; Arrizabalaga, S. Digital Twin for maintenance: A literature review. Comput. Ind. 2020, 123, 103316. [Google Scholar] [CrossRef]

- Grieves, M. Back to the future: Product lifecycle management and the virtualization of product information. In Product Realization: A Comprehensive Approach; Springer: Berlin/Heidelberg, Germany, 2009; pp. 1–13. [Google Scholar]

- Grieves, M.W. Product lifecycle management: The new paradigm for enterprises. Int. J. Prod. Dev. 2005, 2, 71–84. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Nasirahmadi, A.; Hensel, O. Toward the next generation of digitalization in agriculture based on digital twin paradigm. Sensors 2022, 22, 498. [Google Scholar] [CrossRef] [PubMed]

- Bado, M.F.; Tonelli, D.; Poli, F.; Zonta, D.; Casas, J.R. Digital twin for civil engineering systems: An exploratory review for distributed sensing updating. Sensors 2022, 22, 3168. [Google Scholar] [CrossRef] [PubMed]

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer: Berlin/Heidelberg, Germany, 2017; pp. 85–113. [Google Scholar]

- Zhu, Z.; Liu, C.; Xu, X. Visualisation of the digital twin data in manufacturing by using augmented reality. Procedia Cirp 2019, 81, 898–903. [Google Scholar] [CrossRef]

- Schroeder, G.; Steinmetz, C.; Pereira, C.E.; Muller, I.; Garcia, N.; Espindola, D.; Rodrigues, R. Visualising the digital twin using web services and augmented reality. In Proceedings of the 2016 IEEE 14th International Conference on Industrial Informatics (INDIN), Poitiers, France, 19–21 July 2016; pp. 522–527. [Google Scholar]

- Botín-Sanabria, D.M.; Mihaita, A.S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.d.J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Parlikad, A.K.; Schooling, J.M. Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Autom. Constr. 2020, 118, 103277. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Ye, Y.; Zhang, C.; Wei, Y. A hybrid predictive maintenance approach for CNC machine tool driven by Digital Twin. Robot. Comput. Integr. Manuf. 2020, 65, 101974. [Google Scholar] [CrossRef]

- Aivaliotis, P.; Georgoulias, K.; Chryssolouris, G. The use of Digital Twin for predictive maintenance in manufacturing. Int. J. Comput. Integr. Manuf. 2019, 32, 1067–1080. [Google Scholar] [CrossRef]

- Haghshenas, A.; Hasan, A.; Osen, O.; Mikalsen, E.T. Predictive digital twin for offshore wind farms. Energy Inform. 2023, 6, 1. [Google Scholar] [CrossRef]

- Wang, Z.; Han, K.; Tiwari, P. Digital twin simulation of connected and automated vehicles with the unity game engine. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2021; pp. 1–4. [Google Scholar]

- Dormido, R.; Vargas, H.; Duro, N.; SÁnchez, J.; Dormido-Canto, S.; Farias, G.; Esquembre, F.; Dormido, S. Development of a Web-Based Control Laboratory for Automation Technicians: The Three-Tank System. IEEE Trans. Educ. 2008, 51, 35–44. [Google Scholar] [CrossRef]

- Chacon, J.; Goncalves, D.; Besada, E.; López-Orozco, J.A. Un laboratorio remoto de código abierto y bajo coste para el brazo robótico educativo Dobot Magician. Rev. Iberoam. Automática Informática Ind. 2023, 20, 124–136. [Google Scholar] [CrossRef]

- Lee, A.; Chang, Y.S.; Jang, I. Planetary-scale geospatial open platform based on the Unity3D environment. Sensors 2020, 20, 5967. [Google Scholar] [CrossRef]

- Schluse, M.; Rossmann, J. From simulation to experimentable digital twins: Simulation-based development and operation of complex technical systems. In Proceedings of the 2016 IEEE International Symposium on Systems Engineering (ISSE), Edinburgh, UK, 3–5 October 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnline 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Sarosa, M.; Chalim, A.; Suhari, S.; Sari, Z.; Hakim, H. Developing augmented reality based application for character education using unity with Vuforia SDK. Proc. J. Phys. Conf. Ser. 2019, 1375, 012035. [Google Scholar] [CrossRef]

- Fuertes, J.J.; González-Herbón, R.; Rodríguez-Ossorio, J.R.; González-Mateos, G.; Alonso, S.; Morán, A. Guidelines to develop demonstration models on industry 4.0 for engineering training. Int. J. Comput. Integr. Manuf. 2023, 36, 1465–1481. [Google Scholar] [CrossRef]

- Banks, A.; Gupta, R. MQTT Version 3.1.1 OASIS Standard. 2014, Volume 29, p. 89. Available online: https://webstore.iec.ch/preview/info_isoiec20922%7Bed1.0%7Den.pdf (accessed on 30 January 2024).

- Iglesias-Urkia, M.; Orive, A.; Barcelo, M.; Moran, A.; Bilbao, J.; Urbieta, A. Towards a lightweight protocol for Industry 4.0: An implementation based benchmark. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and Their Application to Mechatronics (ECMSM), Donostia, Spain, 24—26 May 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Profanter, S.; Tekat, A.; Dorofeev, K.; Rickert, M.; Knoll, A. OPC UA versus ROS, DDS, and MQTT: Performance Evaluation of Industry 4.0 Protocols. In Proceedings of the 2019 IEEE International Conference on Industrial Technology (ICIT), Melbourne, Australia, 13–15 February 2019; pp. 955–962. [Google Scholar] [CrossRef]

- Ray, P.P. A Survey on Visual Programming Languages in Internet of Things. Sci. Program. 2017, 2017, 1231430. [Google Scholar] [CrossRef]

- Steinmetz, C.; Schroeder, G.N.; Binotto, A.; Panikkar, S.; Papenfuß, B.; Schmidt, C.; Rettberg, A.; Pereira, C.E. Digital Twins modeling and simulation with Node-RED and Carla. IFAC-PapersOnLine 2022, 55, 97–102. [Google Scholar] [CrossRef]

- Balducci, F.; Buono, P.; Desolda, G.; Impedovo, D.; Piccinno, A. Improving smart interactive experiences in cultural heritage through pattern recognition techniques. Pattern Recognit. Lett. 2020, 131, 142–149. [Google Scholar] [CrossRef]

- Triantafyllou, A.; Sarigiannidis, P.; Lagkas, T.D. Network Protocols, Schemes, and Mechanisms for Internet of Things (IoT): Features, Open Challenges, and Trends. Wirel. Commun. Mob. Comput. 2018, 2018, 5349894. [Google Scholar] [CrossRef]

- Lipp, J.; Rath, M.; Rudack, M.; Vroomen, U.; Bührig-Polaczek, A. Flexible OPC UA Data Load Optimizations on the Edge of Production. In Proceedings of the Enterprise Information Systems; Filipe, J., Śmiałek, M., Brodsky, A., Hammoudi, S., Eds.; Springer: Cham, Switzerland, 2021; pp. 43–61. [Google Scholar]

- Derhamy, H.; Eliasson, J.; Delsing, J.; Priller, P. A survey of commercial frameworks for the internet of things. In Proceedings of the 20th IEEE Conference on Emerging Technologies & Factory Automation (ETFA), Luxembourg, 8–11 September 2015; pp. 1–8. [Google Scholar]

- Chickerur, S.; Goudar, A.; Kinnerkar, A. Comparison of Relational Database with Document-Oriented Database (MongoDB) for Big Data Applications. In Proceedings of the 2015 8th International Conference on Advanced Software Engineering & Its Applications (ASEA), Jeju, Republic of Korea, 25–28 November 2015; pp. 41–47. [Google Scholar] [CrossRef]

- Fraczek, K.; Plechawska-Wojcik, M. Comparative Analysis of Relational and Non-relational Databases in the Context of Performance in Web Applications. In Beyond Databases, Architectures and Structures. Towards Efficient Solutions for Data Analysis and Knowledge Representation; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 153–164. [Google Scholar] [CrossRef]

| Referenced Work | Enabling Technologies | |

|---|---|---|

| VR | Software BIM | |

| [21] | Automation | Centrifugal pumps |

| Connectivity | Industry Foundation Classes (IFCs) | |

| VR | CAD/CAE software | |

| [22] | Automation | CNC machine tool |

| Connectivity | Mapping interface (OPC UA, Sockets, …) | |

| Automation | Six-axis robotic structure | |

| [23] | Connectivity | MQTT |

| System integration | Signal processing gateway | |

| VR | Unity | |

| Automation | Sensors for monitoring | |

| [24] | Connectivity | OPC UA |

| System integration | Node-RED | |

| AR | Vuforia Engine with Unity | |

| VR | Unity | |

| Automation | Connected and automated vehicles (CAVs) | |

| [25] | Connectivity | MQTT and sockets |

| System integration | Unity Scripting API | |

| Cloud | Computing with AWS | |

| VR | Unity | |

| Automation | Robot and distributed architecture | |

| Connectivity | Modbus TCP, OPC UA and MQTT | |

| Current work | System integration | IoT Gateway with Node-RED |

| AR | Vuforia Engine with Unity | |

| Cloud | Storage and computing with IBM Cloud | |

| Cybersecurity | Industrial firewall | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González-Herbón, R.; González-Mateos, G.; Rodríguez-Ossorio, J.R.; Domínguez, M.; Alonso, S.; Fuertes, J.J. An Approach to Develop Digital Twins in Industry. Sensors 2024, 24, 998. https://doi.org/10.3390/s24030998

González-Herbón R, González-Mateos G, Rodríguez-Ossorio JR, Domínguez M, Alonso S, Fuertes JJ. An Approach to Develop Digital Twins in Industry. Sensors. 2024; 24(3):998. https://doi.org/10.3390/s24030998

Chicago/Turabian StyleGonzález-Herbón, Raúl, Guzmán González-Mateos, José R. Rodríguez-Ossorio, Manuel Domínguez, Serafín Alonso, and Juan J. Fuertes. 2024. "An Approach to Develop Digital Twins in Industry" Sensors 24, no. 3: 998. https://doi.org/10.3390/s24030998

APA StyleGonzález-Herbón, R., González-Mateos, G., Rodríguez-Ossorio, J. R., Domínguez, M., Alonso, S., & Fuertes, J. J. (2024). An Approach to Develop Digital Twins in Industry. Sensors, 24(3), 998. https://doi.org/10.3390/s24030998