Gas Imaging with Uncooled Thermal Imager

Abstract

1. Introduction

2. Methods

2.1. Passive Imaging Technique

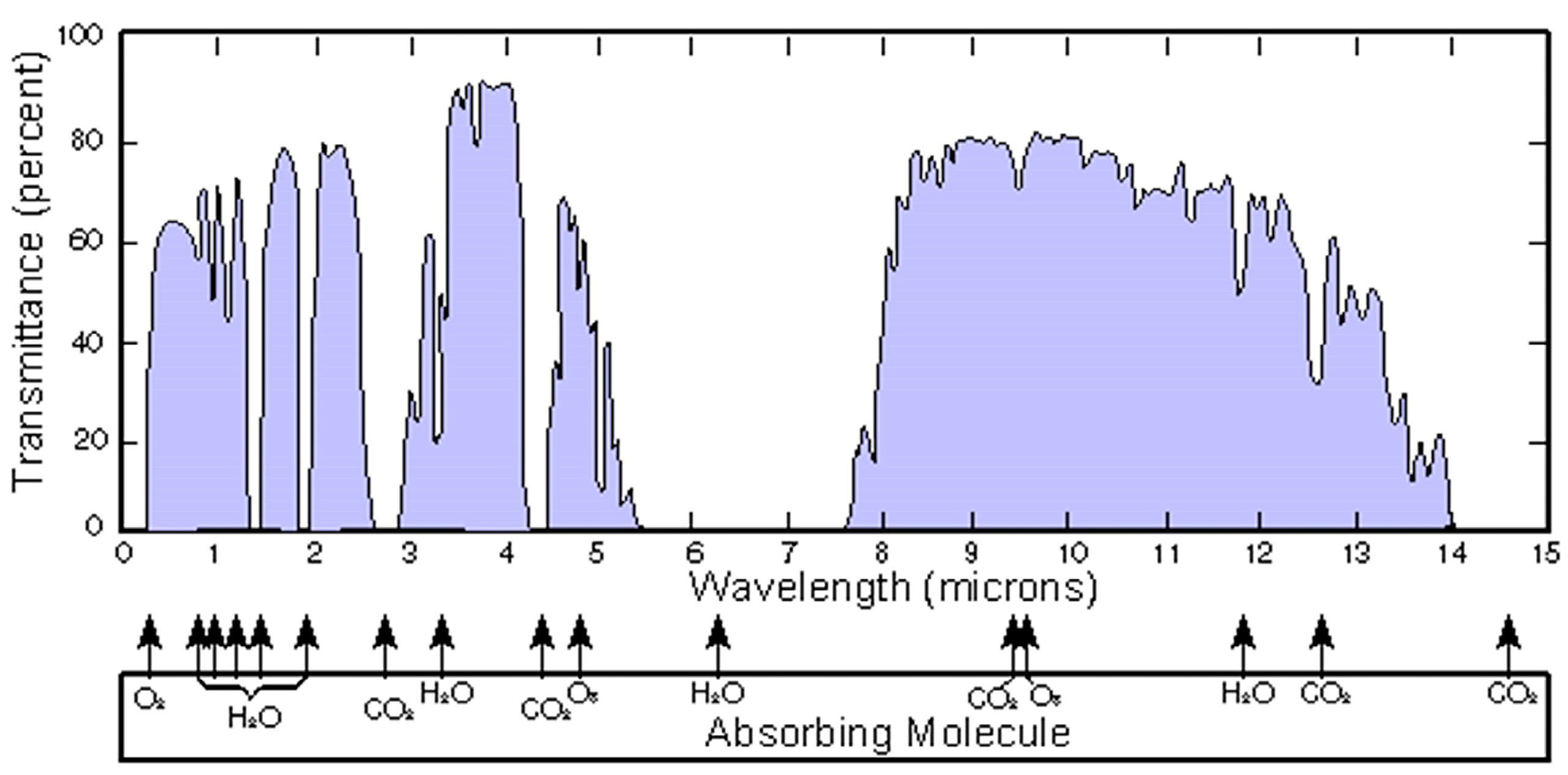

2.1.1. Bandpass Filter

2.1.2. Long-Pass Filter

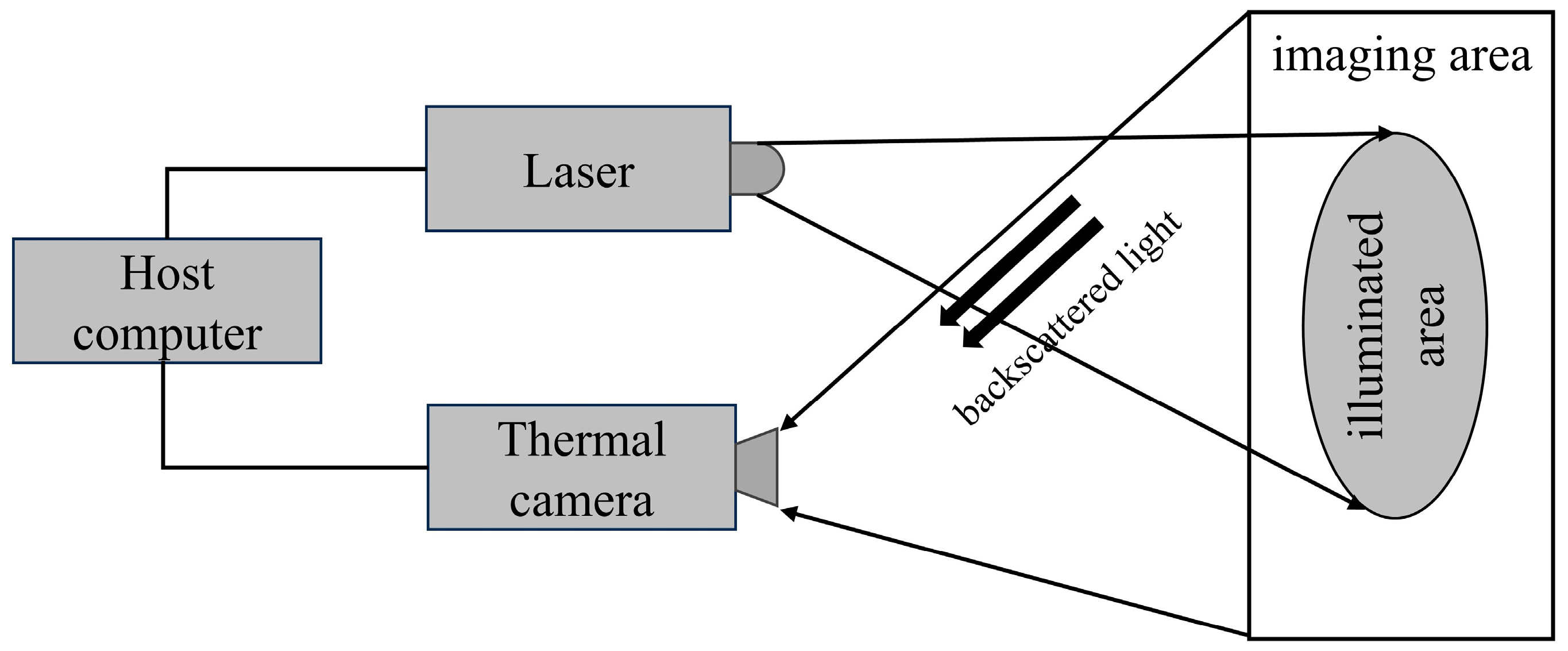

2.2. Active Imaging Technique

3. Application Scenario

3.1. Industrial Source Gases

3.2. Greenhouse Gas

4. Conclusions

- Infrared Gas Intelligent Detection Algorithms: There is a necessity for enhancement in intelligent detection capabilities. Presently, the identification of gas targets predominantly depends on the expertise of professionals. Uncooled thermal imager cameras offer a relatively precise quantification of gas clouds, encompassing measurements of column density, gas path concentration, and leak rate. However, the real-time quantification accuracy for leaked gases requires further improvement. A significant obstacle in the amalgamation of artificial intelligence with optical gas imaging detection is the absence of high-quality, objective public datasets of gas infrared images for training models, rendering subjective datasets inadequate for an objective evaluation of algorithmic performance.

- Infrared Detectors for Optical Gas Imaging: Most existing optical imaging systems employ general-purpose detectors, supplemented with specialized filters and image processing technologies for gas imaging measurements. The efficacy of thermal imaging systems hinges on the application of these professional filters and advanced thermal image processing technologies. Importantly, the development of highly sensitive uncooled infrared detectors, specifically designed for gas imaging measurements, stands as a critical area for advancement and poses considerable challenges.

- Inherent Limitations of Thermal Imaging Cameras: Despite their utility, thermal imaging cameras exhibit inherent limitations, such as low contrast, limited resolution, and indistinct boundaries between targets and backgrounds in the captured thermal images. Furthermore, various noise sources can impair image quality. Addressing these challenges necessitates the preprocessing of the captured thermal images, utilizing specialized algorithms for non-uniformity correction, enhancement, noise reduction, background modeling, and feature extraction.

- Environmental Impact on Thermal Imaging Performance: The operational environment of thermal imaging cameras significantly influences their performance. In extreme heat, lens and window materials may deform or discolor, altering infrared radiation transmission and reflection and potentially leading to measurement inaccuracies. Camera performance can also be affected by thermal effects like thermal drift in high-temperature settings. In high-humidity environments, increased water vapor density can enhance infrared radiation absorption and attenuate radiation from target objects, thereby hampering effective detection, particularly on foggy or rainy days. While wind speed does not directly impact camera performance, it influences gas cloud behavior, accelerating gas diffusion and increasing the Minimum Detectable Leak Rate (MDLR).

- Miniaturization and Integration: Advancements in technology are driving the trend towards the miniaturization and integration of thermal imaging equipment. Future developments might see these cameras becoming more compact and seamlessly integrated with other surveillance systems, broadening their applicability across diverse applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aldhafeeri, T.; Tran, M.-K.; Vrolyk, R.; Pope, M.; Fowler, M. A Review of Methane Gas Detection Sensors: Recent Developments and Future Perspectives. Inventions 2020, 5, 28. [Google Scholar] [CrossRef]

- Cui, Z.; Li, Y.; Xiao, S.; Tian, S.; Tang, J.; Hao, Y.; Zhang, X. Recent Progresses, Challenges and Proposals on SF6 Emission Reduction Approaches. Sci. Total Environ. 2024, 906, 167347. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Majeed, Y.; Diverres Naranjo, G.; Gambacorta, E.M.T. Assessment for Crop Water Stress with Infrared Thermal Imagery in Precision Agriculture: A Review and Future Prospects for Deep Learning Applications. Comput. Electron. Agric. 2021, 182, 106019. [Google Scholar] [CrossRef]

- Zhang, D.; Mao, Z.; Gong, M.; Ren, J.; Zuo, S.; Chen, X. Study on Optimization of Shelter Locations and Evacuation Routes of Gas Leakage Accidents in Chemical Industrial Park. Process Saf. Environ. Prot. 2023, 177, 556–567. [Google Scholar] [CrossRef]

- Druart, G.; Foucher, P.-Y.; Doz, S.; Watremez, X.; Jourdan, S.; Vanneau, E.; Pinot, H. Test of SIMAGAZ: A LWIR Cryogenic Multispectral Infrared Camera for Methane Gas Leak Detection and Quantification. In Proceedings of the Algorithms, Technologies, and Applications for Multispectral and Hyperspectral Imaging XXVII, Online Only, 12–17 April 2021; Messinger, D.W., Velez-Reyes, M., Eds.; SPIE: Bellingham, WA, USA; p. 9.

- Erbertseder, T.; Chrysoulakis, N.; Zhang, Y. Remote Sensing Technologies and Applications in Urban Environments II; SPIE: Bellingham, WA, USA, 2017. [Google Scholar]

- Liang, J.-G.; Jiang, Y.; Wu, J.-K.; Wang, C.; Von Gratowski, S.; Gu, X.; Pan, L. Multiplex-Gas Detection Based on Non-Dispersive Infrared Technique: A Review. Sens. Actuators Phys. 2023, 356, 114318. [Google Scholar] [CrossRef]

- Salamah, U.; Sakti, S.P.; Soetedjo, H.; Naba, A. Non-Contact Technique for CO2 Gas Monitoring Using Thermal Imaging Camera. J. Phys. Conf. Ser. 2022, 2165, 012019. [Google Scholar] [CrossRef]

- Zhao, Q.; Nie, X.; Luo, D.; Wang, J.; Li, Q.; Chen, W. An Effective Method for Gas-Leak Area Detection and Gas Identification with Mid-Infrared Image. Photonics 2022, 9, 992. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared Thermography for Temperature Measurement and Non-Destructive Testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef]

- Meribout, M. Gas Leak-Detection and Measurement Systems: Prospects and Future Trends. IEEE Trans. Instrum. Meas. 2021, 70, 4505813. [Google Scholar] [CrossRef]

- Safitri, A.; Gao, X.; Mannan, M.S. Dispersion Modeling Approach for Quantification of Methane Emission Rates from Natural Gas Fugitive Leaks Detected by Infrared Imaging Technique. J. Loss Prev. Process Ind. 2011, 24, 138–145. [Google Scholar] [CrossRef]

- Gade, R.; Moeslund, T.B. Thermal Cameras and Applications: A Survey. Mach. Vis. Appl. 2014, 25, 245–262. [Google Scholar] [CrossRef]

- Adamopoulos, E.; Volinia, M.; Girotto, M.; Rinaudo, F. Three-Dimensional Thermal Mapping from IRT Images for Rapid Architectural Heritage NDT. Buildings 2020, 10, 187. [Google Scholar] [CrossRef]

- Deane, S.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Zhang, H.; Yazdani Nezhad, H.; Williamson, A.A.; Mackley, T.; Davis, M.J.; Maldague, X.; Tsourdos, A. Application of NDT Thermographic Imaging of Aerospace Structures. Infrared Phys. Technol. 2019, 97, 456–466. [Google Scholar] [CrossRef]

- Han, S.; Yang, F.; Jiang, H.; Yang, G.; Zhang, N.; Wang, D. A Smart Thermography Camera and Application in the Diagnosis of Electrical Equipment. IEEE Trans. Instrum. Meas. 2021, 70, 5012108. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, E.; Zhang, D.; Sun, D.; Yang, M.; Zheng, Z.; Zhang, Z.; Gao, L.; Panezai, S.; Qiu, K. Free Field of View Infrared Digital Holography for Mineral Crystallization. Cryst. Growth Des. 2023, 23, 7992–8008. [Google Scholar] [CrossRef]

- Modest, M.F.; Mazumder, S. Radiative Heat Transfer; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Sarawade, A.A.; Charniya, N.N. Infrared Thermography and Its Applications: A Review. In Proceedings of the 2018 3rd International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 15–16 October 2018; pp. 280–285. [Google Scholar]

- Szajewska, A. Development of the Thermal Imaging Camera (TIC) Technology. Procedia Eng. 2017, 172, 1067–1072. [Google Scholar] [CrossRef]

- Nguyen, T.X.; Rosser, K.; Chahl, J. A Review of Modern Thermal Imaging Sensor Technology and Applications for Autonomous Aerial Navigation. J. Imaging 2021, 7, 217. [Google Scholar] [CrossRef]

- Bareła, J.; Kastek, M.; Firmanty, K.; Krupiński, M. Comparison of Parameters of Modern Cooled and Uncooled Thermal Cameras. In Proceedings of the Electro-Optical and Infrared Systems: Technology and Applications XIV, Warsaw, Poland, 11–14 September 2017; Volume 10433, p. 1043307. [Google Scholar]

- Viers, J.; Niu, H.; Zhao, T.; Anderson, A.; Chen, Y. A Detailed Study on Accuracy of Uncooled Thermal Cameras by Exploring the Data Collection Workflow. In Proceedings of the Autonomous Air and Ground Sensing Systems for Agricultural Optimization and Phenotyping III, Orlando, FL, USA, 15–19 April 2018; Thomasson, J.A., McKee, M., Moorhead, R.J., Eds.; SPIE: Bellingham, WA, USA, 2018; p. 13. [Google Scholar]

- Torun, E. UAV Requirements and Design Consideration; Turkish Land Forces Command: Ankara, Turkey, 2000. [Google Scholar]

- Yu, Y. Technology Development and Application of IR Camera: Current Status and Challenges. Infrared Millim. Wave 2023, 1, 1–7. [Google Scholar]

- Zeng, Y.; Morris, J.; Sanders, A.; Mutyala, S.; Zeng, C. Methods to Determine Response Factors for Infrared Gas Imagers Used as Quantitative Measurement Devices. J. Air Waste Manag. Assoc. 2017, 67, 1180–1191. [Google Scholar] [CrossRef] [PubMed]

- Hou, F.; Zhang, Y.; Zhou, Y.; Zhang, M.; Lv, B.; Wu, J. Review on Infrared Imaging Technology. Sustainability 2022, 14, 11161. [Google Scholar] [CrossRef]

- Barber, R.; Rodriguez-Conejo, M.A.; Melendez, J.; Garrido, S. Design of an Infrared Imaging System for Robotic Inspection of Gas Leaks in Industrial Environments. Int. J. Adv. Robot. Syst. 2015, 12, 23. [Google Scholar] [CrossRef]

- Hudson, R.D. Infrared System Engineering; Wiley-Interscience: New York, NY, USA, 1969; Volume 1. [Google Scholar]

- Du, Y.; Zhou, S.; Jing, X.; Peng, Y.; Wu, H.; Kwok, N. Damage Detection Techniques for Wind Turbine Blades: A Review. Mech. Syst. Signal Process. 2020, 141, 106445. [Google Scholar] [CrossRef]

- Gowen, A.A.; Tiwari, B.K.; Cullen, P.J.; McDonnell, K.; O’Donnell, C.P. Applications of Thermal Imaging in Food Quality and Safety Assessment. Trends Food Sci. Technol. 2010, 21, 190–200. [Google Scholar] [CrossRef]

- Balakrishnan, G.K.; Yaw, C.T.; Koh, S.P.; Abedin, T.; Raj, A.A.; Tiong, S.K.; Chen, C.P. A Review of Infrared Thermography for Condition-Based Monitoring in Electrical Energy: Applications and Recommendations. Energies 2022, 15, 6000. [Google Scholar] [CrossRef]

- Murvay, P.-S.; Silea, I. A Survey on Gas Leak Detection and Localization Techniques. J. Loss Prev. Process Ind. 2012, 25, 966–973. [Google Scholar] [CrossRef]

- Kang, R.; Liatsis, P.; Kyritsis, D.C. Emission Quantification via Passive Infrared Optical Gas Imaging: A Review. Energies 2022, 15, 3304. [Google Scholar] [CrossRef]

- Ma, D.; Liu, A.; Fan, Z.; Wu, R.; Gao, J.; Zhao, H.; Zhang, Z.; Zuo, X. Gas Leakage Recognition Based on Wide-Band Infrared Imaging with the Auxiliary Excitation Method and Machine Learning Model. ACS Chem. Health Saf. 2022, 29, 455–466. [Google Scholar] [CrossRef]

- Olbrycht, R.; Kaluza, M. Optical Gas Imaging with Uncooled Thermal Imaging Camera—Impact of Warm Filters and Elevated Background Temperature. IEEE Trans. Ind. Electron. 2020, 67, 9824–9832. [Google Scholar] [CrossRef]

- Zhang, X.; Jin, W.; Yuan, P.; Qin, C.; Wang, H.; Chen, J.; Jia, X. Research on Passive Wide-Band Uncooled Infrared Imaging Detection Technology for Gas Leakage. In Proceedings of the 2019 International Conference on Optical Instruments and Technology: Optical Systems and Modern Optoelectronic Instruments, Beijing, China, 2–4 November 2019; Nomura, T., Liu, J., Jia, B., Yao, X., Wang, Y., Eds.; SPIE: Bellingham, WA, USA, 2020; p. 30. [Google Scholar]

- Jiakun, L.; Xiong, D.; Minglei, J.; Weiqi, J.; Xia, W.; Runqiu, X. Design of Wide-Band Gas Leak Infrared Imaging Detection System. Infrared Laser Eng. 2014, 43, 1966–1971. [Google Scholar]

- Benson, R.G.; Panek, J.A.; Drayton, P. Direct Measurements of Minimum Detectable Vapor Concentrations Using Passive Infrared Optical Imaging Systems. In Proceedings of the 99th Annual Conference and Exhibition of the Air and Waste Management Association (AWMA), New Orleans, LA, USA, 20–23 June 2006. [Google Scholar]

- Jin, W.; Li, J.; Dun, X.; Jin, M.; Wang, X. Wide-Band Gas Leak Imaging Detection System Using UFPA. In Proceedings of the International Symposium on Optoelectronic Technology and Application 2014: Image Processing and Pattern Recognition, Beijing, China, 13–15 May 2014; Sharma, G., Zhou, F., Liu, J., Eds.; SPIE: Bellingham, WA, USA, 2014; p. 930102. [Google Scholar]

- Sandsten, J.; Weibring, P.; Edner, H.; Svanberg, S. Real-Time Gas-Correlation Imaging Employing Thermal Background Radiation. Opt. Express 2000, 6, 92. [Google Scholar] [CrossRef]

- Kabadeh, A.; Al Kamali, A. Gas Leak Detection Through Infrared Camera. In Proceedings of the SPE International Conference and Exhibition on Health, Safety, Environment, and Sustainability, Nice, France, 15–17 April 2008; p. SPE-111619. [Google Scholar]

- Ding, K.; Hong, H.; Huang, L. Dangerous Gas Detection Based on Infrared Video. In Proceedings of the MIPPR 2017: Remote Sensing Image Processing, Geographic Information Systems, and Other Applications, Xiangyang, China, 28–29 October 2017; SPIE: Bellingham, WA, USA, 2018; p. 11. [Google Scholar]

- Prata, A.J.; Bernardo, C. Retrieval of Volcanic Ash Particle Size, Mass and Optical Depth from a Ground-Based Thermal Infrared Camera. J. Volcanol. Geotherm. Res. 2009, 186, 91–107. [Google Scholar] [CrossRef]

- Prata, A.J.; Bernardo, C. Retrieval of Sulfur Dioxide from a Ground-Based Thermal Infrared Imaging Camera. Atmos. Meas. Tech. 2014, 7, 2807–2828. [Google Scholar] [CrossRef]

- Bogue, R. Detecting Gases with Light: A Review of Optical Gas Sensor Technologies. Sens. Rev. 2015, 35, 133–140. [Google Scholar] [CrossRef]

- Weiqi, J.; Jing, S.; Liquan, D. Progress of Researches in Scene-Based Nonuniformity Correction for IRFPA. J. Infrared Laser Eng. 2007, 36, 70–75. [Google Scholar]

- Fan, Y.; Jin, W.; Liu, C.; Chen, Y.; Liu, B.; Li, J.; Jin, M. IRFPA Image Detail Enhancement and Dynamic Compression Technique Based on FPGA. Infrared Laser Eng. 2012, 41, 3113–3117. [Google Scholar]

- Naranjo, E.; Baliga, S.; Bernascolle, P. IR Gas Imaging in an Industrial Setting. In Proceedings of the Thermosense XXXII, Orlando, FL, USA, 5–9 April 2010; Dinwiddie, R.B., Safai, M., Eds.; SPIE: Bellingham, WA, USA, 2010; p. 76610K. [Google Scholar]

- Bernascolle, P.F.; Elichabe, A.; Fervel, F.; Haumonté, J.-B. Stand-off CWA Imaging System: Second Sight MS. In Proceedings of the Chemical, Biological, Radiological, Nuclear, and Explosives (CBRNE) Sensing XIII, Baltimore, MD, USA, 23–27 April 2012; SPIE: Bellingham, WA, USA, 2012; Volume 8358, pp. 333–339. [Google Scholar]

- Olbrycht, R. A Novel Method for Sensitivity Modelling of Optical Gas Imaging Thermal Cameras with Warm Filters. Quant. InfraRed Thermogr. J. 2022, 19, 331–346. [Google Scholar] [CrossRef]

- Ding, L.; Dong, D.; Jiao, L.; Zheng, W. Potential Using of Infrared Thermal Imaging to Detect Volatile Compounds Released from Decayed Grapes. PLoS ONE 2017, 12, e0180649. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Jin, W.; Li, L.; Wang, X.; Chen, J.; Jia, Y. Band Optimization of Passive Methane Gas Leak Detection Based on Uncooled Infrared Focal Plane Array. Appl. Opt. 2018, 57, 3991. [Google Scholar] [CrossRef] [PubMed]

- Cui, F.-X.; Zhao, Y.; Wang, A.-J.; Ma, F.-X.; Wu, J.; Li, Y.-Y.; Li, D.-C.; Dong, W.-C. A Multi-Spectral Thermal Gas Detection Imager Using Uncooled Infrared Camera. Optics 2022, 3, 473–482. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, S.; Lu, X.; Wang, Z.; Chen, C.; He, H. Classification of Urban Hyperspectral Remote Sensing Imagery Based on Optimized Spectral Angle Mapping. J. Indian Soc. Remote Sens. 2019, 47, 289–294. [Google Scholar] [CrossRef]

- Luo, X.; Chen, Y.; Ma, J.; Lu, Y.; Cai, Y.; Wang, L. Leakage Gas Enhancement for Infrared Dual-Band Spectral Differential Imaging. In Proceedings of the Seventh Symposium on Novel Photoelectronic Detection Technology and Applications, Kunming, China, 5–7 November 2020; Chu, J., Yu, Q., Jiang, H., Su, J., Eds.; SPIE: Bellingham, WA, USA, 2021; p. 170. [Google Scholar]

- Ma, J.; Chen, Y.; Luo, X.; Chen, D.; Cai, Y.; Xue, W.; Wang, L. Identification of Industrial Gas by Sparse Infrared Absorption Spectrum Characteristics and Support Vector Machine. In Proceedings of the Global Intelligent Industry Conference 2020, Guangzhou, China, 16–18 November 2020; Wang, L., Ed.; SPIE: Bellingham, WA, USA, 2021; p. 94. [Google Scholar]

- Li, K.; Hu, Y.; Wang, L.; Yang, Z.; Wang, B.; Yuan, M.; Li, W.; Yu, C.; Zheng, W. Detecting Unknown Gas Clouds with Multispectral Imagery Based on Spectral Angle Matching. In Proceedings of the Conference on Infrared, Millimeter, Terahertz Waves and Applications (IMT2022), Shanghai, China, 8–10 November 2022; Zhuang, S., Chu, J., Eds.; SPIE: Bellingham, WA, USA, 2023; p. 122. [Google Scholar]

- Liger-Belair, G.; Bourget, M.; Pron, H.; Polidori, G.; Cilindre, C. Monitoring Gaseous CO2 and Ethanol above Champagne Glasses: Flute versus Coupe, and the Role of Temperature. PLoS ONE 2012, 7, e30628. [Google Scholar] [CrossRef]

- Meribout, M.; Khezzar, L.; Azzi, A.; Ghendour, N. Leak Detection Systems in Oil and Gas Fields: Present Trends and Future Prospects. Flow Meas. Instrum. 2020, 75, 101772. [Google Scholar] [CrossRef]

- Nutt, K.J.; Hempler, N.; Maker, G.T.; Malcolm, G.P.A.; Padgett, M.J.; Gibson, G.M. Developing a Portable Gas Imaging Camera Using Highly Tunable Active-Illumination and Computer Vision. Opt. Express 2020, 28, 18566. [Google Scholar] [CrossRef]

- Li, Z.; Yuan, M.; Xu, Y.; Yang, R.; Sun, S.; Yang, B. Imaging Detection of Methane Gas Leakage Based on TDLAS Technology. Laser J. 2023, 1–9. [Google Scholar]

- Lu, Y.; Zhang, X.; Wu, R.; Yang, Y. Design of Laser Uniform Illumination System Based on Aspheric Lens and Compound Ellipsoidal Cavity. arXiv 2023, arXiv:2309.14227. [Google Scholar]

- Kasai, N.; Tsuchiya, C.; Fukuda, T.; Sekine, K.; Sano, T.; Takehana, T. Propane Gas Leak Detection by Infrared Absorption Using Carbon Infrared Emitter and Infrared Camera. NDT E Int. 2011, 44, 57–60. [Google Scholar] [CrossRef]

- Singh, T.P.P. Use of Optical Gas Imaging for Visualizing Gas Leakage and Other Thermal Camera Applications in Oil & Gas Sector. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019; p. D011S011R002. [Google Scholar]

- Lewis, A.W.; Yuen, S.T.S.; Smith, A.J.R. Detection of Gas Leakage from Landfills Using Infrared Thermography—Applicability and Limitations. Waste Manag. Res. J. Sustain. Circ. Econ. 2003, 21, 436–447. [Google Scholar] [CrossRef]

- Shirley, C.P.; Raja, J.I.J.; Evangelin Sonia, S.V.; Titus, I. Recognition and Monitoring of Gas Leakage Using Infrared Imaging Technique with Machine Learning. Multimed. Tools Appl. 2023. [Google Scholar] [CrossRef]

- Faraz Khan, M.; Dalli, J.; Cahill, R.A. Dynamic Near-Infrared Carbon Dioxide Leak Visualization Detection during Surgery Using the FLIR GF343 Optical Imaging System. Surg. Endosc. 2020, 34, 5208–5210. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Duan, S.; Pang, L.; Li, W.; Yang, Z.; Hu, Y.; Yu, C. Chemical Gas Telemetry System Based on Multispectral Infrared Imaging. Toxics 2023, 11, 83. [Google Scholar] [CrossRef] [PubMed]

- Więcek, P. A Method for Automatic Gas Detection Using Wide-Band 3–14 Μm Bolometer Camera. In Proceedings of the 14th International Conference on Quantitative Infrared Thermography, Berlin, Germany, 25–29 June 2018; pp. 115–121. [Google Scholar]

- Tomić, L.; Damnjanović, V.; Aleksandrović, S. The Testing of Harmful Gases Using Passive Infrared Thermography. Podzemn. Rad. 2013, 22, 99–109. [Google Scholar]

- Schiermeier, Q. Global Methane Levels Soar to Record High. Nature 2020. [Google Scholar] [CrossRef]

- Asadzadeh, S.; Oliveira, W.J.D.; Souza Filho, C.R.D. UAV-Based Remote Sensing for the Petroleum Industry and Environmental Monitoring: State-of-the-Art and Perspectives. J. Pet. Sci. Eng. 2022, 208, 109633. [Google Scholar] [CrossRef]

- Steele, J.P.H.; Han, Q.; Karki, H.; Al-Wahedi, K.; Ayoade, A.A.; Sweatt, M.R.; Albert, D.P.; Yearsley, W.A. Development of an Oil and Gas Refinery Inspection Robot. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014; Volume 4A: Dynamics, Vibration, and Control; American Society of Mechanical Engineers: New York, NY, USA, 2014; p. V04AT04A016. [Google Scholar]

- Bortnowski, P.; Gondek, H.; Król, R.; Marasova, D.; Ozdoba, M. Detection of Blockages of the Belt Conveyor Transfer Point Using an RGB Camera and CNN Autoencoder. Energies 2023, 16, 1666. [Google Scholar] [CrossRef]

- Prabhu, V.; Vairavel, K.S.; Velnath, R. Leakage Detection in High Pressure Vessels Using Non Invasive Method. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1059, 012015. [Google Scholar] [CrossRef]

- Bhavani, N.P.G.; Sujatha, K.; Ponmagal, R.S.; Reddy, T.K. Monitoring of SO2 Emissions in Power Plants Using Internet of Things. In Proceedings of the International Conference on Energy, Communication, Data Analytics and Soft Computing (ICECDS), Chennai, India, 1–2 August 2017. [Google Scholar]

- Kariminezhad, H.; Parvin, P.; Borna, F.; Bavali, A. SF6 Leak Detection of High-Voltage Installations Using TEA-CO2 Laser-Based DIAL. Opt. Lasers Eng. 2010, 48, 491–499. [Google Scholar] [CrossRef]

- Salamah, U.; Sakti, S.P.; Soetedjo, H.; Naba, A. Optical Imaging Identification of CO2 and SO2 in Non-Contact Detection System Using Infrared Camera. AIP Conf. Proc. 2023, 2619, 050014. [Google Scholar]

- Notsu, K.; Mori, T.; Igarashi, G.; Tohjima, Y.; Wakita, H. Infrared Spectral Radiometer: A New Tool for Remote Measurement of SO2 of Volcanic Gas. Geochem. J. 1993, 27, 361–366. [Google Scholar] [CrossRef]

- Mori, T.; Hashimoto, T.; Terada, A.; Yoshimoto, M.; Kazahaya, R.; Shinohara, H.; Tanaka, R. Volcanic Plume Measurements Using a UAV for the 2014 Mt. Ontake Eruption. Earth Planets Space 2016, 68, 49. [Google Scholar] [CrossRef]

- Figueroa, J.D.; Fout, T.; Plasynski, S.; McIlvried, H.; Srivastava, R. Advances in CO2 Capture Technology—The US Department of Energy’s Carbon Sequestration Program. Int. J. Greenh. Gas Control 2008, 2, 9–20. [Google Scholar] [CrossRef]

- Yang, H.; Xu, Z.; Fan, M.; Gupta, R.; Slimane, R.; Bland, A.; Wright, I. Progress in Carbon Dioxide Capture and Separation: A Review. J. Env. Sci. 2008, 20, 14–27. [Google Scholar] [CrossRef]

- Friedmann, S.J. Geological Carbon Dioxide Sequestration. Elements 2007, 3, 179–184. [Google Scholar] [CrossRef]

- Johnson, J.E.; Shaw, J.A.; Lawrence, R.L.; Nugent, P.W.; Hogan, J.A.; Dobeck, L.M.; Spangler, L.H. Comparison of Long-Wave Infrared Imaging and Visible/Near-Infrared Imaging of Vegetation for Detecting Leaking CO2 Gas. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2014, 7, 1651–1657. [Google Scholar] [CrossRef]

- Lu, Q.; Li, Q.; Hu, L.; Huang, L. An Effective Low-Contrast SF₆ Gas Leakage Detection Method for Infrared Imaging. IEEE Trans. Instrum. Meas. 2021, 70, 5009009. [Google Scholar] [CrossRef]

- Ji, S.; Zhong, L.; Liu, K.; Li, J.; Cui, Y.; Wang, Y.; Guo, J.; Ji, G. Research Status and Development of SF6 Decomposition Components Analysis under Discharge and Its Application. Proc. CSEE 2015, 35, 2318–2332. [Google Scholar]

- Zhang, X.; Yao, Y.; Tang, J.; Sun, C.-X.; Wan, L.-Y. Actuality and Perspective of Proximate Analysis of SF6 Decomposed Products under Partial Discharge. High Volt. Eng. 2008, 34, 664–669. [Google Scholar]

- Peng, J.; Liu, M.; Jiao, F. Power Grid Equipment Charging Detection Technology. China Electr. Power Press 2014, 12, 235–240. [Google Scholar]

- Cheng, M.; Xiang, D. The Design and Application of a Track-Type Autonomous Inspection Robot for Electrical Distribution Room. Robotica 2020, 38, 185–206. [Google Scholar] [CrossRef]

- Jain, A.; Sharma, A.; Borana, S.; Ravindra, B.; Mangalhara, J. Study and Analysis of Exhaust Emission of Diesel Vehicles Using Thermal IR Imagers. Def. Sci. J. 2018, 68, 533. [Google Scholar] [CrossRef]

- Liang, L.; Yu, L.; Duan, L.; Ding, L.; Yu, Y.; Shi, H.; Li, Y. Real-Time Gas Image Enhancement Algorithm Based on Guided Filter Simplification Kernel. In Proceedings of the 2021 International Conference on Electronic Information Engineering and Computer Science (EIECS), Changchun, China, 23–26 September 2021; pp. 267–271. [Google Scholar]

- Wang, J.; Tchapmi, L.P.; Ravikumar, A.P.; McGuire, M.; Bell, C.S.; Zimmerle, D.; Savarese, S.; Brandt, A.R. Machine Vision for Natural Gas Methane Emissions Detection Using an Infrared Camera. Appl. Energy 2020, 257, 113998. [Google Scholar] [CrossRef]

- Jing, W.; Pan, Y.; Minghe, W. Thermal Imaging Detection Method of Leak Gas Clouds Based on Support Vector Machine. Acta Opt. Sin. 2022, 42, 0911002. [Google Scholar]

- Hong, S.; Hu, Y.; Yu, H. Infrared Imaging VOCs Gas Detection Based on Multi-Feature. Comput. Simul. 2021, 38, 374–379. [Google Scholar]

| Target Gas | Absorption Peak Band | Detection Limit/Concentration | Detection Distances | Application Scenario | Detection Reasons | Ref. |

|---|---|---|---|---|---|---|

| Methane | 6.6 μm–8.6 μm | 5 mL/min | 300 m | Petrochemistry | Greenhouse gases, explosion-proof, reduced product loss | [12,53,60,61,66,67] |

| Natural gas transportation | ||||||

| Kitchen | ||||||

| Landfill | ||||||

| Sulfur hexafluoride | 10.56 μm | ≤0.1 L/min | 200 m | Substations | greenhouse gas | [37,54] |

| Carbon dioxide | 9.5 μm, 10.5 μm | 5 L/min | 600 m | Hospital guardianship | Asphyxiation, greenhouse gases | [8,59,68] |

| Volcanic research | ||||||

| Ethanol | 9–10 μm | 300 ppm·m | 10 m | Fruit decay monitoring | Food quality testing | [52] |

| Sulfur dioxide | 7.3 μm | 3 ppm·m | 600 m | Chemical plant | acid rain | [45,49] |

| Volcano monitoring | ||||||

| Ethylene | 10.5 μm | 10–100 L/min | 5 m | Fruit Transportation | gaseous phytohormone | [37,41,57] |

| Ammonia | 5.6 µm, 10 µm | 200 ppm·m | 20 m | Chemical manufacturing | Toxic to the human body | [58,69,70] |

| Refrigerant | ||||||

| Carbon tetrachloride | 7.8 μm | - | 20 m | Low-temperature refrigeration | Toxic to the human body | [9] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Chen, G.; Lin, P.; Dong, D.; Jiao, L. Gas Imaging with Uncooled Thermal Imager. Sensors 2024, 24, 1327. https://doi.org/10.3390/s24041327

Zhang M, Chen G, Lin P, Dong D, Jiao L. Gas Imaging with Uncooled Thermal Imager. Sensors. 2024; 24(4):1327. https://doi.org/10.3390/s24041327

Chicago/Turabian StyleZhang, Mengjie, Guanghai Chen, Peng Lin, Daming Dong, and Leizi Jiao. 2024. "Gas Imaging with Uncooled Thermal Imager" Sensors 24, no. 4: 1327. https://doi.org/10.3390/s24041327

APA StyleZhang, M., Chen, G., Lin, P., Dong, D., & Jiao, L. (2024). Gas Imaging with Uncooled Thermal Imager. Sensors, 24(4), 1327. https://doi.org/10.3390/s24041327