Embedded Wireless Sensor for In Situ Concrete Internal Relative Humidity Monitoring

Abstract

1. Introduction

- Control of the curing process. Effective curing must ensure keeping the material under specific conditions of temperature and moisture to allow for the correct cement hydration and the development of its mechanical properties. Loss of moisture during curing can significantly slow down cement hydration as drying coarsens the pore structure of the cement paste matrix [1,2]. In fact, it has been observed that the hydration of cement paste might even stop when the relative humidity drops below about 80% [3]. This is particularly relevant in hot-weather concreting [4] and high-performance concrete applications, where low water-to-binder ratios and high binder contents are used.

- Corrosion prevention. Carbonation and chloride ingress rates are moisture-dependent. The progression of carbonation is the highest at intermediate moisture contents (between dry and saturated state) [5], while the diffusion of chlorides needs water in the pores to diffuse.

- Freeze-Thaw. The rising damp and alkali–silica reactions are aggravated by high moisture contents [6]. The prevention of these phenomena may involve the limitation of water availability, and therefore, moisture monitoring in concrete is essential to assess the effectiveness of the corrective actions.

- Shrinkage control. Concrete shrinks as its internal moisture content decreases, either through exchange with the environment (evaporation) or through self-desiccation (hydration of cement particles), with its magnitude proportional to the amount of moisture lost [4,7,8]. The restraint of shrinkage-induced strains caused by moisture gradients is one of the most common causes of early cracking in concrete elements. This phenomenon is particularly relevant in concrete structures with large surface areas, where water evaporation is magnified and might lead to significant shrinkage strain gradients with concrete stresses superior to its early cracking strength.

- Concrete surface finishing quality. When concrete is poured in slabs, water vapor migrates from the bottom to the surface to evaporate. Early applications of impermeable finishes might lead to damage associated with moisture retention such as delamination of the floor adhesive, blistering of the epoxy coating, re-emulsification of the adhesive and curling, cracking or bubbling of flooring materials. ASTM F2170-19a [9] recognizes the need to monitor relative humidity levels before the installation of floor coverings and coatings and define threshold levels [10] to avoid subsequent damages to the system [11].

2. Materials and Methods

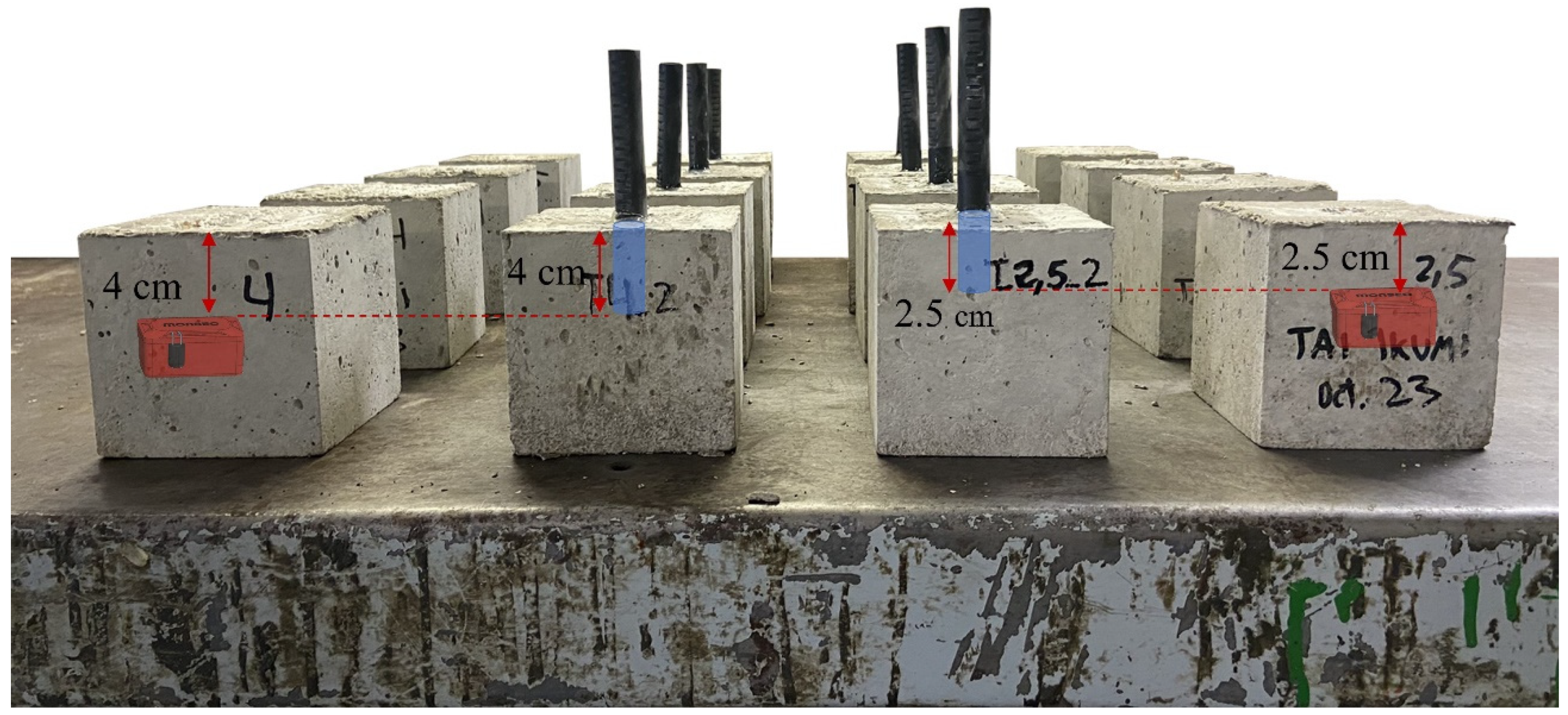

2.1. Mortar Cubes

2.2. Internal Relative Humidity Monitoring

2.2.1. Borehole Method (Conforms to ASTM F2170-19a [9])

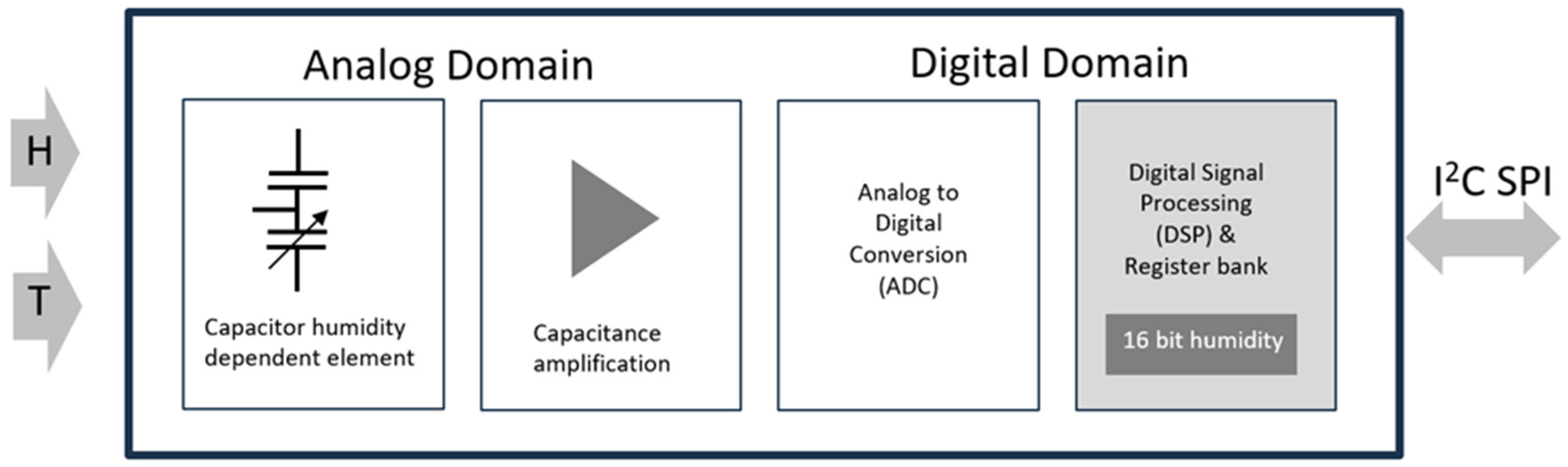

2.2.2. Wireless Totally Embedded Sensor

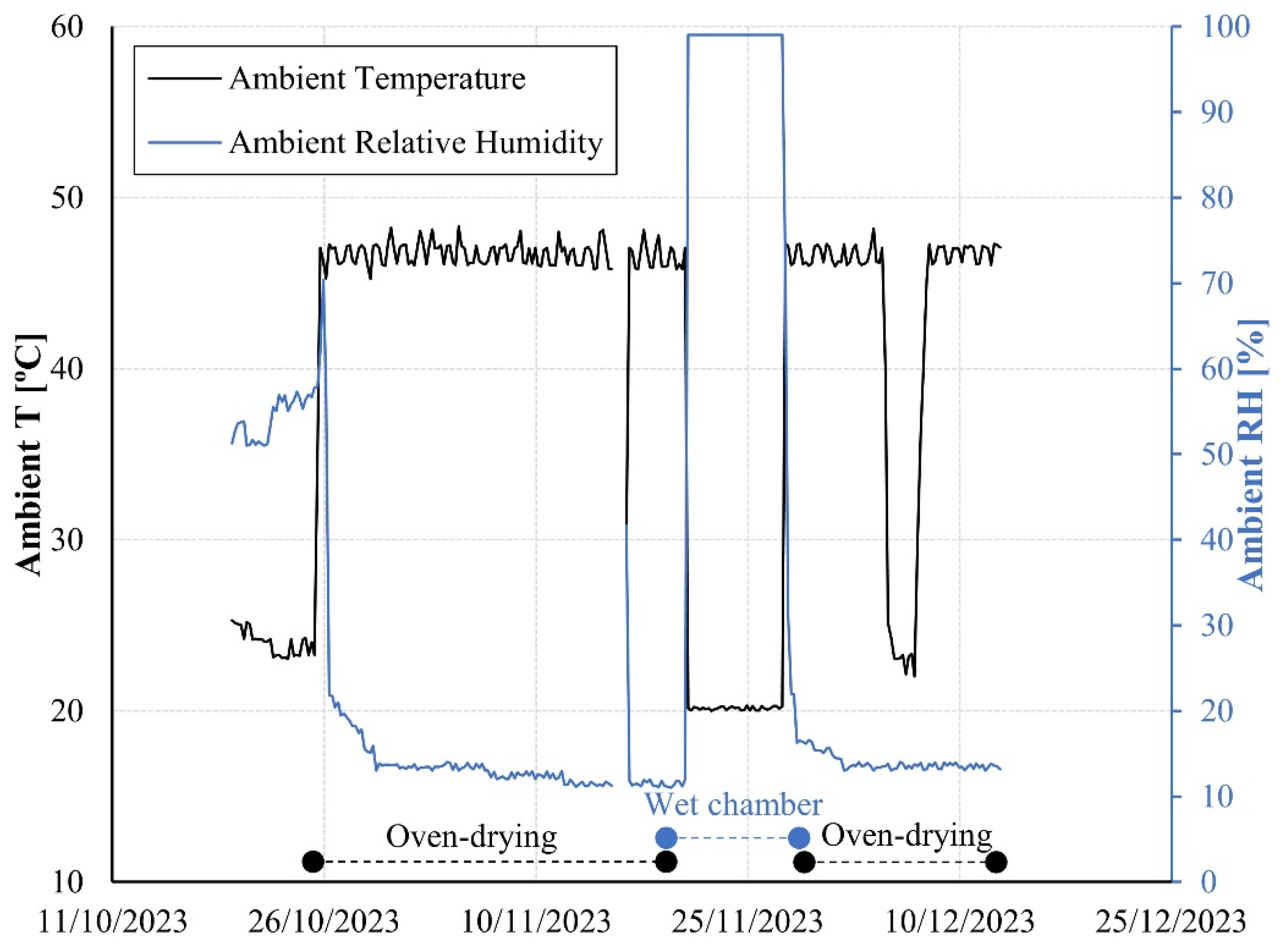

2.3. Exposure Conditions

3. Results

3.1. RH Measurements from the Vaisala Borehole Method

3.2. RH Measurements from the Wireless Embedded Sensors

3.3. RH Measurements from the Borehole Method vs. Wireless Cast-In Sensors

3.4. Temperature Variation Effects

4. Conclusions

- The comparison at various depths and exposure conditions indicates that both systems yield consistent internal relative humidity measurements aligned with the adopted conditions. These results highlight the capability of fully embedded wireless sensors as a practical and reliable alternative to conventional methods.

- The wireless cast-in sensor method has given reliable relative humidity measurements during unintended temperature variations, as this method ensures no temperature difference between the sensor and the concrete. This emphasizes the efficacy of permanently installed sensors over discrete monitoring in promptly detecting unintended curing variations in real time.

- Further research is needed to assess the influence of moisture flow disturbance around the cast-in sensor body and how this might affect the reliability of the measurements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Parrot, L.J. Moisture profiles in drying concrete. Adv. Cem. Res. 1988, 1, 164–170. [Google Scholar] [CrossRef]

- Parrot, L.J. Factors influencing relative humidity in concrete. Mag. Concr. Res. 1991, 43, 45–52. [Google Scholar] [CrossRef]

- Flatt, R.J.; Scherer, G.W.; Bullard, J.W. Why alite stops hydrating below 80% relative humidity. Cem. Concr. Res. 2011, 41, 987–992. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Venuat, M. Carbonation—Technical Commission 16-C. Matér. Constr. 1978, II, 142–146. [Google Scholar] [CrossRef]

- Andrade, C.; Sarría, J.; Alonso, C. Relative humidity in the interior of concrete exposed to natural and artificial weathering. Cem. Concr. Res. 1999, 29, 1249–1259. [Google Scholar] [CrossRef]

- Granja, J.L.; Azenha, M.; De Sousa, C.; Faria, R.; Barros, J. Hygrometric assessment of internal relative humidity in concrete: Practical application issues. J. Adv. Concr. Technol. 2014, 12, 250–265. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Y.; Qi, K.; Gao, Y. Interior Relative Humidity of Normal- and High-Strength Concrete at Early Age. J. Mater. Civ. Eng. 2012, 24, 615–622. [Google Scholar] [CrossRef]

- ASTM F2170-19a; Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using In Situ Probes. ASTM International: West Conshohocken, PA, USA, 2019.

- SisäRYL 2000 Code of Building Practice, RT 14-10668; Rakennustieto Oy: Helsinki, Finland, 2000; p. 318. ISBN 951-682-506-0.

- Åhs, M. Moisture Redistribution in Screeded Concrete Slabs. Ph.D. Thesis, Lund Institute of Technology, Lund University, Lund, Sweden, 2007. [Google Scholar]

- Baroghel-Bouny, V.; Mainguy, M.; Lassabatere, T.; Coussy, O. Characterization and identification of equilibrium and transfer moisture properties for ordinary and high-performance cementitious materials. Cem. Concr. Res. 1999, 29, 1225–1238. [Google Scholar] [CrossRef]

- Wang, J.; Yio, M.H.N.; Zhou, T.; Wong, H.S.; Davie, C.T.; Masoero, E. Water sorption isotherms and hysteresis of cement paste at moderately high temperature, up to 80 °C. Cem. Concr. Res. 2023, 165, 107076. [Google Scholar] [CrossRef]

- RILEM Technical Committee 248-MMB. Methods of Measuring Moisture in Building Materials and Structures, State of the Art Report; Nilsson, L.O., Ed.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Gause, G.R.; Tucker, J., Jr. Method For Determining the Moisture Condition in Hardened Concrete. J. Res. Natl. Bur. Stand. 1940, 25, 403–416. [Google Scholar] [CrossRef][Green Version]

- Zhou, J.K.; Chen, X.; Zhang, J.; Wang, Y. Internal relative humidity distribution in concrete considering self-desiccation at early ages. Int. J. Phys. Sci. 2011, 6, 1604–1610. [Google Scholar]

- Chang, C.Y.; Hung, S.S. Implementing RFIC and sensor technology to measure temperature and humidity inside concrete structures. Constr. Build. Mater. 2012, 26, 628–637. [Google Scholar] [CrossRef]

- Grasley, Z.C.; Lange, D.A.; D’Ambrosia, M.D. Internal relative humidity and drying stress gradients in concrete. Mater. Struct. 2006, 39, 901–909. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Z.; Wang, P. Autogenous relative humidity change and autogenous shrinkage of high-performance cement pastes. Cem. Concr. Res. 2005, 35, 1539–1545. [Google Scholar] [CrossRef]

- Shen, D.; Liu, C.; Wang, M.; Jin, X.; Tang, H. Prediction model for internal relative humidity in early-age concrete under different curing humidity conditions. Constr. Build. Mater. 2020, 265, 119987. [Google Scholar] [CrossRef]

- Zhou, S.; Deng, F.; Yu, L.; Li, B.; Wu, X.; Yin, B. A Novel Passive Wireless Sensor for Concrete Humidity Monitoring. Sensors 2016, 16, 1535. [Google Scholar] [CrossRef] [PubMed]

- Strangfeld, C.; Johann, S.; Bartholmai, M. Smart RFID Sensors Embedded in Building Structures for Early Damage Detection and Long-Term Monitoring. Sensors 2019, 19, 5514. [Google Scholar] [CrossRef] [PubMed]

- Cabezas, J.; Sánchez-Rodríguez, T.; Gómez-Galán, J.A.; Cifuentes, H.; Carvajal, R.G. Compact Embedded Wireless Sensor-Based Monitoring of Concrete Curing. Sensors 2018, 18, 876. [Google Scholar] [CrossRef] [PubMed]

- Converge. Available online: https://converge.io/ (accessed on 1 March 2024).

- WAKE Inc. Available online: https://www.wakeinc.com/ (accessed on 1 March 2024).

- AOMS Technologies. Available online: https://lumicon.io/ (accessed on 1 March 2024).

- Giatec. Available online: https://www.giatecscientific.com/ (accessed on 1 March 2024).

- Quadrel. Available online: https://vorb.io/ (accessed on 1 March 2024).

- Liu, Y.; Bao, Y. Real-time remote measurement of distance using ultra-wideband (UWB) sensors. Autom. Constr. 2023, 150, 104849. [Google Scholar] [CrossRef]

- Liu, Y.; Bao, Y. Review of electromagnetic waves-based distance measurement technologies for remote monitoring of civil engineering structures. Measurement 2021, 176, 10919. [Google Scholar] [CrossRef]

- Ikumi, T.; Monserrat López, A.; Aidarov, S.; Aguado, A.; de la Fuente, A. Design-oriented method for concrete pavements with volumetric stability admixtures: An integrated experimental and analytical approach. Case Stud. Constr. Mater. 2023, 19, e02583. [Google Scholar] [CrossRef]

- UNE-EN 196-1:2005; Métodos de Ensayo de Cementos. Parte 1: Determinación de Resistencias Mecánicas. AENOR: Madrid, Spain, 2005.

- Vaisala. Vaisala Structural Humidity Measurement Kit SHM40. User’s Guide; Vaisala Oyj: Helsinki, Finland, 2015. [Google Scholar]

- ISO 12570:2000; Hygrothermal Performance of Building Materials and Products: Determination of Moisture Content by Drying at Elevated Temperature. International Organization for Standardization: Geneva, Switzerland, 2000.

- Kim, J.K.; Lee, C.S. Moisture diffusion of concrete considering self-desiccation at early ages. Cem. Concr. Res. 1999, 29, 1921–1927. [Google Scholar] [CrossRef]

- Ryu, D.W.; Ko, J.W.; Noguchi, T. Effects of simulated environmental conditions on the internal relative humidity and relative moisture content distribution of exposed concrete. Cem. Concr. Compos. 2011, 33, 142–153. [Google Scholar] [CrossRef]

- Oxfall, M.; Johansson, P.; Hassanzadeh, M. Long-term hygrothermal performance of nuclear reactor concrete containments–Laboratory evaluations of measurement setup, in situ sampling, and moisture flux calculations. Cem. Concr. Compos. 2016, 65, 128–138. [Google Scholar] [CrossRef]

- Oxfall, M.; Hassanzadeh, M.; Johansson, P. Moisture levels and drying potential of the concrete in Swedish reactor containments. Eur. Phys. J. Web Conf. 2013, 56, 03002. [Google Scholar] [CrossRef]

- Nilsson, L.O.; Fredlund, P. Cast-in Probe for Measuring Drying of Concrete—Simulation of the Effect of the Size and Orientation of the Sensor; Sensobyg D4. Report TVBM-7198; Laboratory of Building Materials, University of Lund: Lund, Sweden, 2009. (In Swedish) [Google Scholar]

- Fredin, H.; Skoog, H. Temperature effects and corrections on relative humidity measurements. In Proceedings of the 7th Symposium on Building Physics in the Nordic Countries, Reykjavik, Iceland, 13–15 June 2005; pp. 1–3. [Google Scholar]

- Paroll, H.; Nykanen, E. Measurement of relative humidity and temperature in a new concrete bridge vs. laboratory samples. Nord. Concr. Res.-Publ. 1998, 21, 103–119. [Google Scholar]

- Jensen, O.M.; Hansen, P.F. Influence of temperature on autogenous deformation and relative humidity change in hardening cement paste. Cem. Concr. Res. 1999, 29, 567–575. [Google Scholar] [CrossRef]

| Material | [kg/m3] |

|---|---|

| CEM II/A-L 42.5 N (Promsa, Barcelona, Spain) | 330 |

| Coarse agg. 4/10 mm (Promsa, Barcelona, Spain) | 260 |

| Sand 0/4 mm (Promsa, Barcelona, Spain) | 1543 |

| Water | 165 |

| Water/cement ratio | 0.50 |

| Master Ease 3850 Superplasticiser | 0.90% by cement weight |

| Master Pozzolith 7003 Plasticiser | 0.18% by cement weight |

| Sieve Size [mm] | 4–10 | 0–4 |

|---|---|---|

| [% Passing] | ||

| 40 | 100.0 | 100.0 |

| 20 | 100.0 | 100.0 |

| 10 | 96.1 | 100.0 |

| 4 | 0.8 | 99.9 |

| 2 | 0.40 | 83.3 |

| 1 | 0.4 | 52.1 |

| 0.5 | 0.4 | 33.7 |

| 0.25 | 0.4 | 22.4 |

| 0.125 | 0.4 | 17.6 |

| 0.063 | 0.4 | 14.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ikumi, T.; Cairó, I.; Groeneveld, J.; Aguado, A.; de la Fuente, A. Embedded Wireless Sensor for In Situ Concrete Internal Relative Humidity Monitoring. Sensors 2024, 24, 1756. https://doi.org/10.3390/s24061756

Ikumi T, Cairó I, Groeneveld J, Aguado A, de la Fuente A. Embedded Wireless Sensor for In Situ Concrete Internal Relative Humidity Monitoring. Sensors. 2024; 24(6):1756. https://doi.org/10.3390/s24061756

Chicago/Turabian StyleIkumi, Tai, Ignasi Cairó, Jan Groeneveld, Antonio Aguado, and Albert de la Fuente. 2024. "Embedded Wireless Sensor for In Situ Concrete Internal Relative Humidity Monitoring" Sensors 24, no. 6: 1756. https://doi.org/10.3390/s24061756

APA StyleIkumi, T., Cairó, I., Groeneveld, J., Aguado, A., & de la Fuente, A. (2024). Embedded Wireless Sensor for In Situ Concrete Internal Relative Humidity Monitoring. Sensors, 24(6), 1756. https://doi.org/10.3390/s24061756