New Torsional Surface Elastic Waves in Cylindrical Metamaterial Waveguides for Sensing Applications

Abstract

1. Introduction

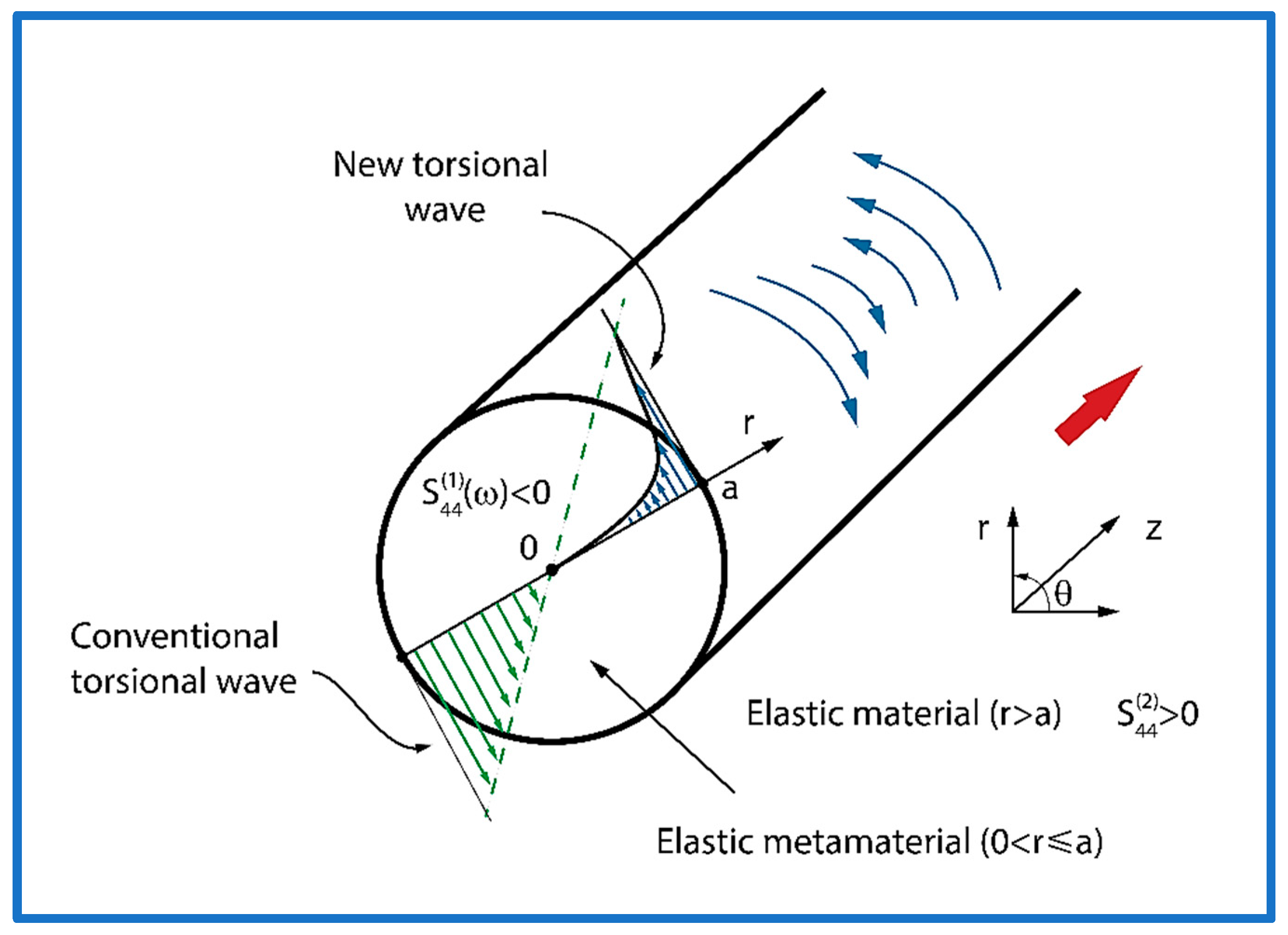

2. Physical Model

2.1. Geometry and Material Parameters of the Waveguide

2.2. Elastic Compliance of the Metamaterial Elastic Cylinder

3. Mathematical Model

3.1. Mechanical Displacement and Shear Stress

3.2. Equations of Motion

3.3. Explicit Analytical Formulas for the Mechanical Displacements and

3.4. Boundary Conditions

3.5. Dispersion Equation

3.6. Group Velocity

4. Results of Numerical Calculations

4.1. Material Parameters of the Waveguide

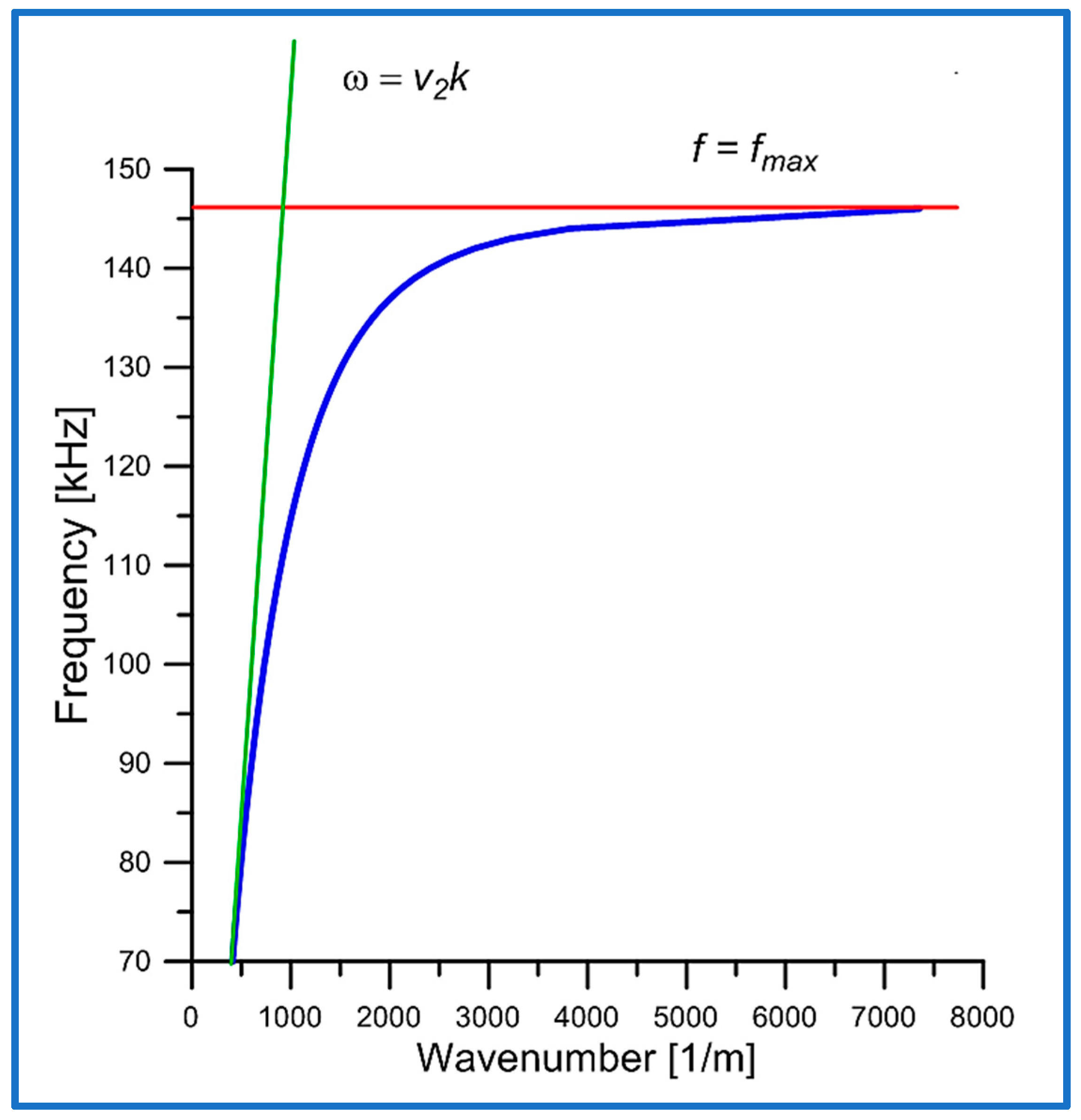

4.2. Dispersion Curve

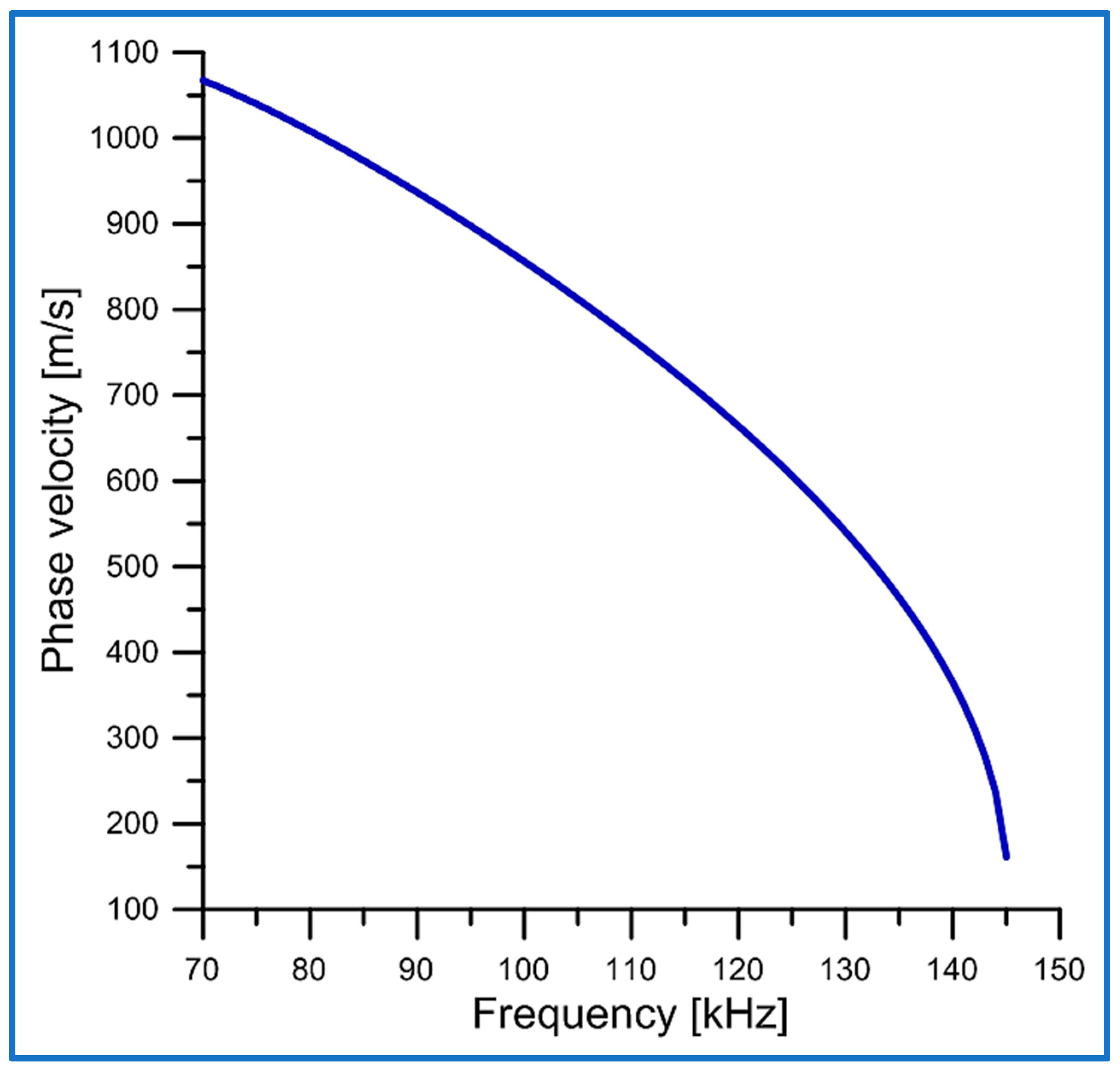

4.3. Phase Velocity

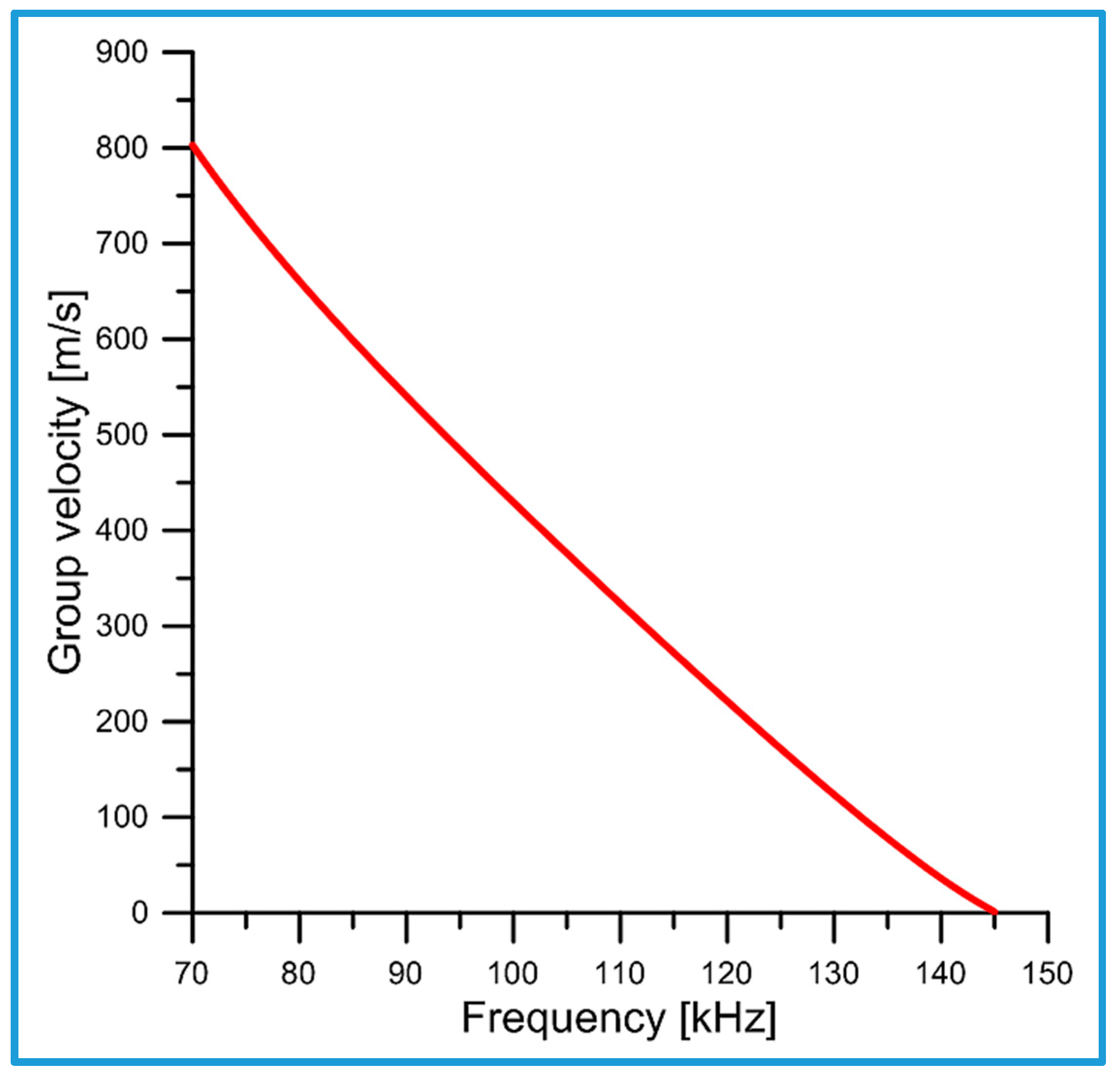

4.4. Group Velocity

5. Discussion

5.1. Group Velocity

5.2. Phase Velocity

5.3. Dispersion Curve

- Very high concentration of the wave energy in the vicinity of the cylindrical guiding surface () of the waveguide;

- Subwavelength penetration depth in both directions from the cylindrical guiding surface ();

6. Conclusions

- They constitute an elastic analog of the Surface Plasmon Polariton (SPP) electromagnetic (optical) waves propagating in layered dielectric-metal cylindrical waveguides;

- New torsional elastic waves can inherit fascinating properties of SPP optical waves, such as (a) superlensing, (b) superresolution, and (c) the ability to break the diffraction limit;

- They have only one component of the mechanical displacement polarized along the angular coordinate;

- The energy of the wave is strongly confined in the vicinity of the guiding cylindrical surface (r = a) of the metamaterial rod;

- The penetration depth of the wave in both directions from the guiding cylindrical surface of the metamaterial rod can be a subwavelength;

- Their phase and group velocities tend to zero as the wave frequency approaches the upper cut-off frequency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| A computer program written in Scilab programming language to solve the dispersion equation (Equation (14)), evaluate the dispersion curve, and calculate the group velocity (Equation (15)) is given below. //THIS PROGRAM SOLVES THE DISPERSION EQUATION //AND EVALUATES THE PHASE AND GROUP VELOCITIES //OF THE NEW ELASTIC TORSIONAL WAVE //MATERIAL DATA c442 = 1.43*10^9 //PMMA = CONVENTIONAL ELASTIC MEDIUM s442 = 1/c442 ro2 = 1.18*10^3 v2 = sqrt(c442/ro2) a = 1*10^-2 //RADIUS OF THE METAMATERIAL CYLINDER IN [m] c0 = 6.785*10^10 //QUARTZ=METAMATERIAL CYLINDER s0 = 1/c0 ro1 = 2.65*10^3 v0 = sqrt(c0/ro1) fp = 1*10^6 //FREQUENCY OF LOCAL RESONATORS omp = 2*%pi*fp //ANGULAR FREQUENCY OF LOCAL RESONATORS //THIS FUNCTION CALCULATES THE ELASTIC COMPLIANCE s441 //OF THE METAMATERIAL CYLINDER FOR GIVEN ANGULAR FREQUENCY om, EQ.1 function F = s441(x) om = x X1 = s0*(1-(omp/om)^2) F = X1 endfunction //THIS FUNCTION EVALUATES THE DISPERSION EQUATION FOR THE TORSIONAL WAVE, EQ.14 //FOR KNOWN ANGULAR FREQUENCY om AND THE WAVENUMBER k function F = T_Dysp_2(z) k = z gamma1 = sqrt(k*k-om*om*ro1*s441(om)) gamma2 = sqrt(k*k-om*om*ro2*s442) x = gamma1*a y = gamma2*a // besseli(2,x) and besseli(1,x) ARE MODIFIED BESSEL FUNCTIONS // OF THE FIRST KIND OF ORDER 2 AND 1 // besselk(2,y) and besselk(1,y) ARE MODIFIED BESSEL FUNCTIONS // OF THE SECOND KIND OF ORDER 2 AND 1 X1 = besseli(2,x)/besseli(1,x) X2 = besselk(2,y)/besselk(1,y) X3 = s442/s441(om)*gamma1/gamma2 F = X2+X3*X1 endfunction //THIS FUNCTION EVALUATES THE GROUP VELOCITY FOR THE TORSIONAL WAVE, EQ.15 function G = Group_Vel_2(x,y) om = x k = y gamma1 = sqrt(k*k-om*om*ro1*s441(om)) gamma2 = sqrt(k*k-om*om*ro2*s442) X = gamma1*a Y = gamma2*a dg1dk = k/gamma1 dg2dk = k/gamma2 dg1dom = (-om*ro1*s441(om)-ro1*s0*omp*omp/om)/gamma1 dg2dom = (-om*ro2*s442)/gamma2 // DERIVATIVE OF THE ELASTIC COMPLIANCE S441 ON THE ANGULAR FREQUENCY om ds441dom = 2*s0*omp*omp/om^3 L1 = s441(om)*dg2dk+s441(om)*Y*(dg1dk/X-dg2dk*2/Y) L2 = s442*dg1dk-s442*X*(dg1dk*2/X-dg2dk/Y) L3 = -s441(om)*Y*dg2dk+s442*X*dg1dk L4 = s441(om)*Y*dg1dk-s442*X*dg2dk M1 = ds441dom*gamma2+s441(om)*dg2dom+s441(om)*Y*(dg1dom/X-dg2dom*2/Y) M2 = s442*dg1dom-s442*X*(dg1dom*2/X-dg2dom/Y) M3 = -s441(om)*Y*dg2dom+s442*X*dg1dom M4 = s441(om)*Y*dg1dom-s442*X*dg2dom K2DK1 = besselk(2,Y)/besselk(1,Y) I2DI1 = besseli(2,X)/besseli(1,X) I2DI1RK2DK1 = besseli(2,X)/besseli(1,X)*besselk(2,Y)/besselk(1,Y) // L = NUMERATOR IN EQ.15 // M = DENOMINATOR IN EQ.15 L = L1*K2DK1+L2*I2DI1+L3*1+L4*I2DI1RK2DK1 M = M1*K2DK1+M2*I2DI1+M3*1+M4*I2DI1RK2DK1 G = -L/M endfunction //RESULTS aa = 0 x0 = 2*%pi*0.7*10^5/v2*1.05 //STARTING POINT FOR WAVENUMBER k //SET UP A LOOP FOR EVALUATION THE PHASE AND GROUP //VELOCITIES AS A FUNCTION OF THE WAVE FREQUENCY f for i = 1:1:77 f = 0.7*10^5+(i-1)*1*10^3 //WAVE FREQUENCY IN KHz om = f*2*%pi //ANGULAR FREQUENCY [xs,fxs,m] = fsolve(x0,T_Dysp_2,10^-12) k = xs //WAVENUMBER vp = om/k //PHASE VELOCITY x = om y = k vgr = Group_Vel_2(x,y) //GROUP VELOCITY x0 = k*1.05 //STORE THE RESULTS OF CALCULATIONS IN THE MATRIX aa aa(i,1) = f/1000 aa(i,2) = vp aa(i,3) = vgr aa(i,4) = k end //WRITE THE MATRIX aa INTO AN OUTPUT TXT FILE write(’Torsional_2024_4.txt’,aa,’(e15.6,2x,e16.7,2x,e16.7,2x,e16.7)’) |

References

- Kiełczyński, P. New Surface-Plasmon-Polariton-Like Acoustic Surface Waves at the Interface Between Two Semi-Infinite Media. Arch. Acoust. 2022, 47, 363–371. [Google Scholar] [CrossRef]

- Kiełczyński, P. New Shear Horizontal (SH) Surface-Plasmon-Polariton-like Elastic Surface Waves for Sensing Applications. Sensors 2023, 23, 9879. [Google Scholar] [CrossRef] [PubMed]

- Devaux, E.; Dereux, A.; Bourillot, E.; Weeber, J.-C.; Lacroute, Y.; Goudonnet, J.-P.; Girard, C. Local detection of the optical magnetic field in the near zone of dielectric samples. Phys. Rev. B 2000, 62, 10504. [Google Scholar] [CrossRef]

- Schroter, U.; Dereux, A. Surface plasmon polaritons on metal cylinders with dielectric core. Phys. Rev. B 2001, 64, 125420. [Google Scholar] [CrossRef]

- Achenbach, J.D. Wave Propagation in Elastic Solids; North-Holland: Amsterdam, The Netherlands, 1973. [Google Scholar]

- Auld, B.A. Acoustic Fields and Waves in Solids; Krieger Publishing Company: Malabar, FL, USA, 1990; Volume I, II. [Google Scholar]

- Ballantine, D.S.; White, R.M.; Martin, S.J.; Ricco, A.J.; Frye, G.C.; Wohltjen, H.H. Acoustic Wave Sensors: Theory, Design, & Physico-Chemical Applications; Academic Press: San Diego, CA, USA, 1997. [Google Scholar]

- Royer, D.; Dieulesaint, E. Elastic Waves in Solids; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2000; Volume I. [Google Scholar]

- Maerfeld, C.; Tournois, P. Pure Shear Elastic Surface Wave Guided by the Interface of Two Semi-Infinite Media. Appl. Phys. Lett. 1971, 19, 117–118. [Google Scholar] [CrossRef]

- Pajewski, W.; Kiełczyński, P.; Szalewski, M. Resonant piezoelectric ring transformer. In Proceedings of the IEEE Ultrasonics Symposium Proceedings, Sendai, Japan, 5–8 October 1998; pp. 977–980. [Google Scholar]

- Kiełczyński, P.; Pajewski, W.; Szalewski, M. Piezoelectric sensors for investigations of microstructures. Sens. Actuators A Phys. 1998, 65, 13–18. [Google Scholar] [CrossRef]

- Kiełczyński, P.; Szalewski, M.; Balcerzak, A.; Wieja, K. Group and phase velocity of Love waves propagating in elastic functionally graded materials. Arch. Acoust. 2015, 40, 273–281. [Google Scholar] [CrossRef][Green Version]

- Kiełczyński, P. Direct Sturm–Liouville problem for surface Love waves propagating in layered viscoelastic waveguides. Appl. Math. Model. 2018, 53, 419–432. [Google Scholar] [CrossRef]

- Kiełczyński, P. New Fascinating Properties and Potential Applications of Love Surface Waves. In Proceedings of the International Ultrasonic Symposium, Xi’an, China, 11–16 September 2021; Available online: http://zbae.ippt.pan.pl/library/IUS_2021_Piotr_Kielczynski.mp4 (accessed on 26 December 2024).

- Mason, W.P. Piezoelectric Crystals and Their Application to Ultrasonics; Van Nostrand: New York, NY, USA, 1950. [Google Scholar]

- Kim, J.O.; Piao, C. Effect of an interior viscous fluid on the propagation of torsional waves in an elastic pipe. J. Mech. Sci. Technol. 2013, 27, 3615–3623. [Google Scholar] [CrossRef]

- Rabani, A. Design and Implementation of an Electronic Front-End Based on Square Wave Excitation for Ultrasonic Torsional Guided Wave Viscosity. Sensor 2016, 16, 1681. [Google Scholar] [CrossRef] [PubMed]

- Rabani, A.A.; Pinfield, V.J.; Challis, R.E. Rate of shear of an ultrasonic oscillating rod viscosity probe. Ultrasonics 2016, 65, 18–22. [Google Scholar] [CrossRef][Green Version]

- Huang, J.; Cegla, F.; Wickenden, A.; Coomber, M. Simultaneous Measurements of Temperature and Viscosity for Viscous Fluids Using an Ultrasonic Waveguide. Sensors 2021, 21, 5543. [Google Scholar] [CrossRef] [PubMed]

- Junker, C.; Meier, K. Analysis of the electrical field in viscosity sensors with torsionally vibrating quartz cylinder. J. Appl. Phys. 2020, 128, 044505. [Google Scholar] [CrossRef]

- de Castro, C.A.N.; Richardson, S.M.; Wakeham, W.A. The Torsional Quartz-Crystal Viscometer. Int. J. Thermophys. 2024, 45, 103. [Google Scholar] [CrossRef]

- Tao, H.; Chieffo, L.R.; Brenckle, M.A.; Siebert, S.M.; Liu, M.; Strikwerda, A.C.; Fan, K.; Kaplan, D.L.; Zhang, X.; Averitt, R.D. Metamaterials on Paper as a Sensing Platform. Adv. Mater. 2011, 23, 3197–3201. [Google Scholar] [CrossRef]

- Chen, T.; Li, S.; Sun, H. Metamaterials Application in Sensing. Sensors 2012, 12, 2742–2765. [Google Scholar] [CrossRef]

- Yang, J.J.; Huang, M.; Tang, H.; Zeng, J.; Ling, D. Metamaterial Sensors. Int. J. Antennas Propag. 2013, 2013, 637270. [Google Scholar] [CrossRef]

- Prakash, D.; Gupta, N. Applications of metamaterial sensors: A review. Int. J. Microw. Wirel. Technol. 2022, 14, 19–33. [Google Scholar] [CrossRef]

- Pyo, S.; Park, K. Mechanical Metamaterials for Sensor and Actuator Applications. Int. J. Precis. Eng. Manuf. Green Technol. 2024, 11, 291–320. [Google Scholar] [CrossRef]

- Nkoma, J.; Loudon, R.; Tilley, D.R. Elementary properties of surface polaritons. J. Phys. C Solid State Phys. 2001, 7, 3547–3559. [Google Scholar] [CrossRef]

- Born, M.; Wolf, E. Principles of Optics, 6th ed.; Cambridge University Press: Cambridge, UK, 1980; p. 625. [Google Scholar]

| Material | Density [kg/m3] | Elastic Compliance [GPa] | Bulk Shear Wave Velocity [m/s] |

|---|---|---|---|

| ST-Quartz | ρ1 = 2650 | s0 = 1.474 | v0 = 5060 |

| PMMA | ρ2 = 1180 | = 70.03 | v2 = 1100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiełczyński, P.; Wieja, K.; Balcerzak, A. New Torsional Surface Elastic Waves in Cylindrical Metamaterial Waveguides for Sensing Applications. Sensors 2025, 25, 143. https://doi.org/10.3390/s25010143

Kiełczyński P, Wieja K, Balcerzak A. New Torsional Surface Elastic Waves in Cylindrical Metamaterial Waveguides for Sensing Applications. Sensors. 2025; 25(1):143. https://doi.org/10.3390/s25010143

Chicago/Turabian StyleKiełczyński, Piotr, Krzysztof Wieja, and Andrzej Balcerzak. 2025. "New Torsional Surface Elastic Waves in Cylindrical Metamaterial Waveguides for Sensing Applications" Sensors 25, no. 1: 143. https://doi.org/10.3390/s25010143

APA StyleKiełczyński, P., Wieja, K., & Balcerzak, A. (2025). New Torsional Surface Elastic Waves in Cylindrical Metamaterial Waveguides for Sensing Applications. Sensors, 25(1), 143. https://doi.org/10.3390/s25010143