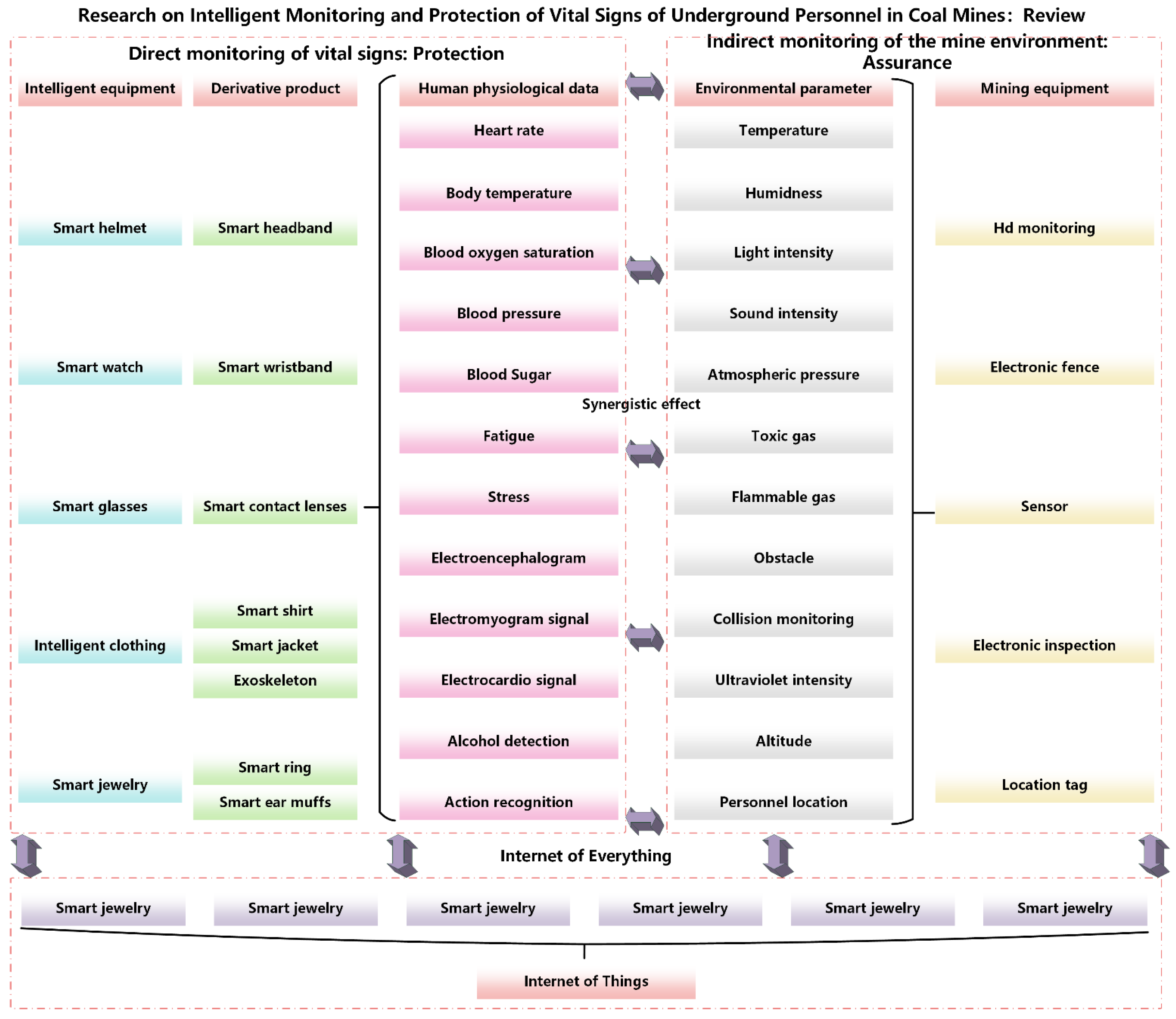

Research on Intelligent Monitoring and Protection Equipment of Vital Signs of Underground Personnel in Coal Mines: Review

Abstract

:1. Introduction

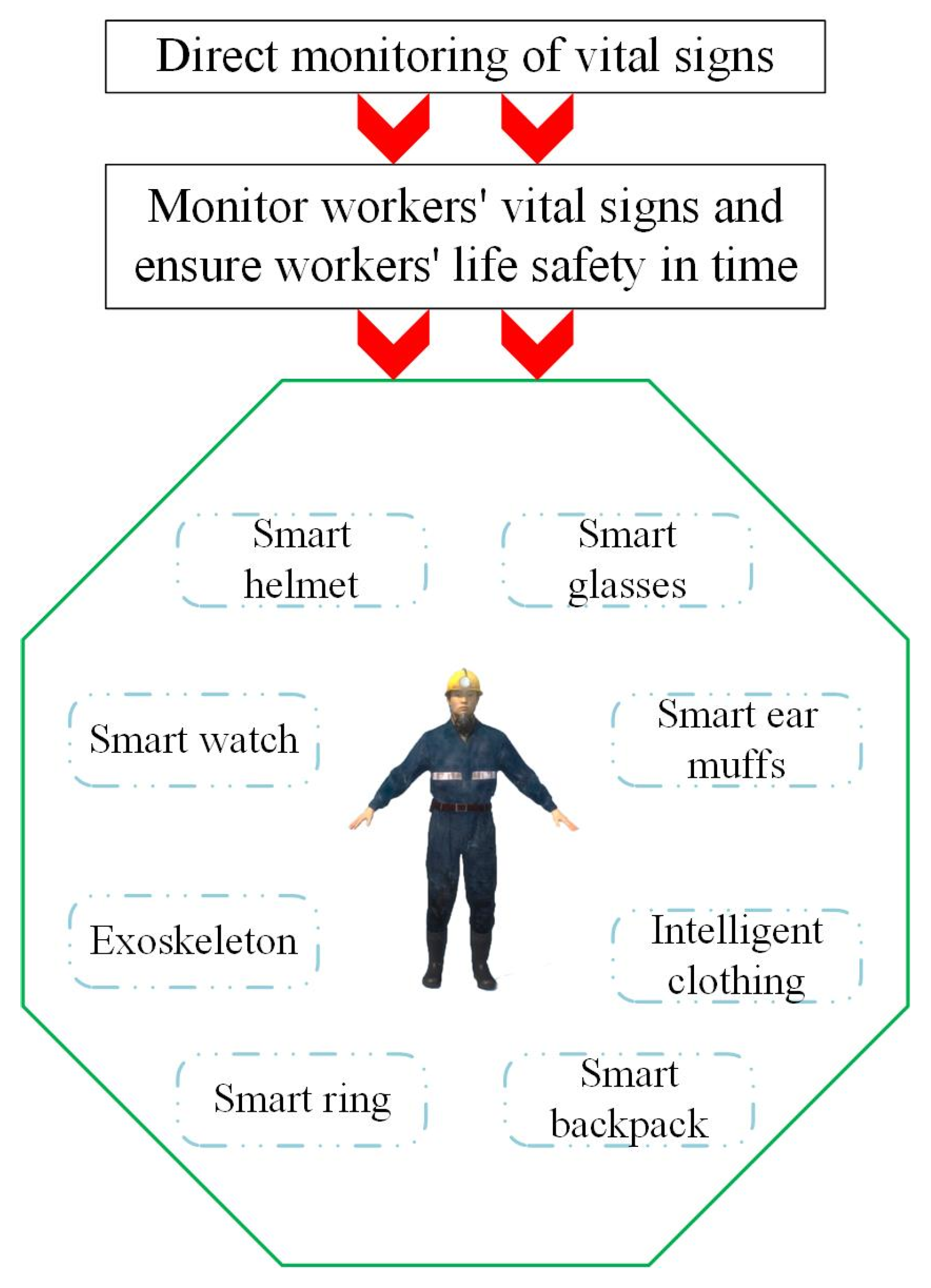

2. Direct Monitoring of Vital Signs

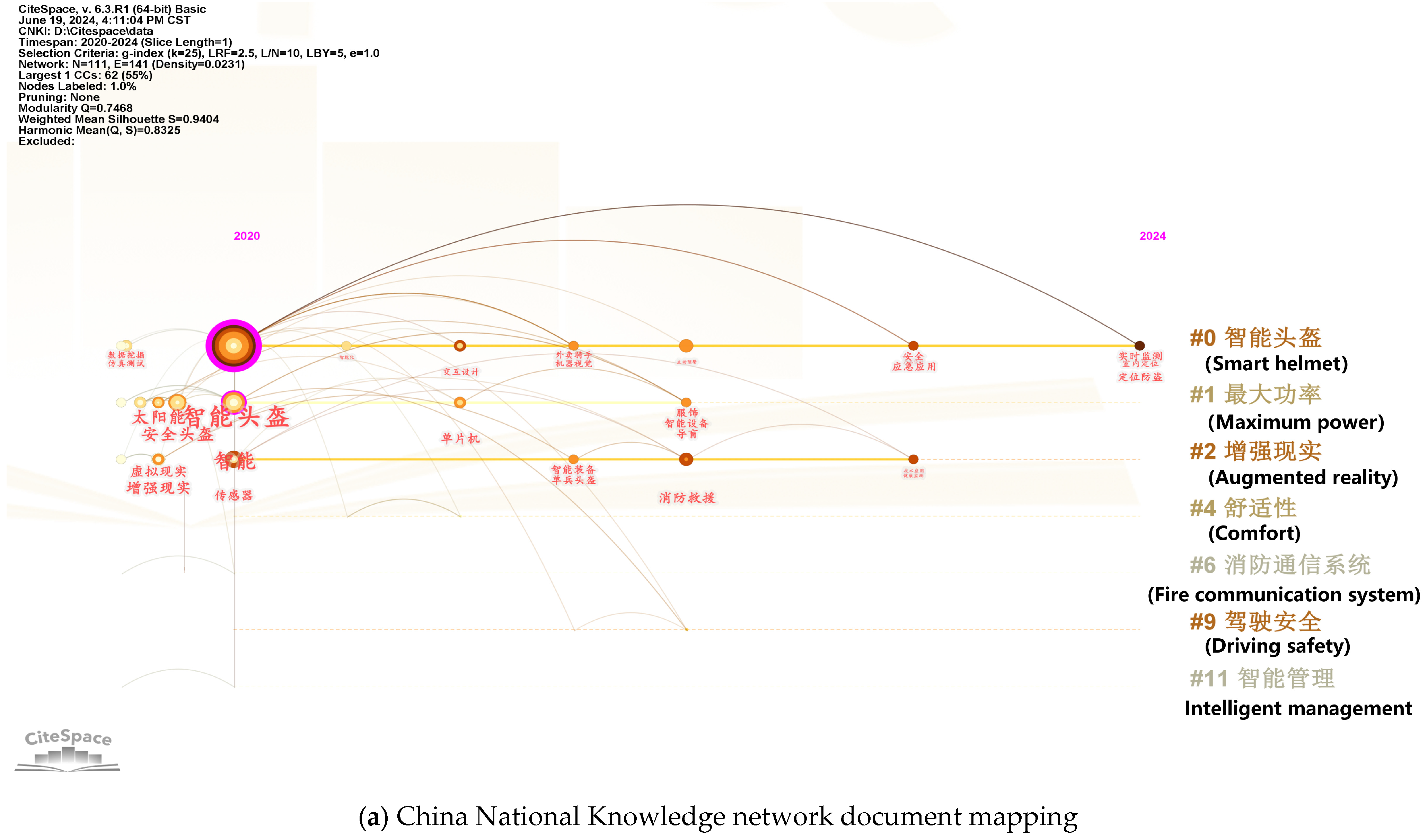

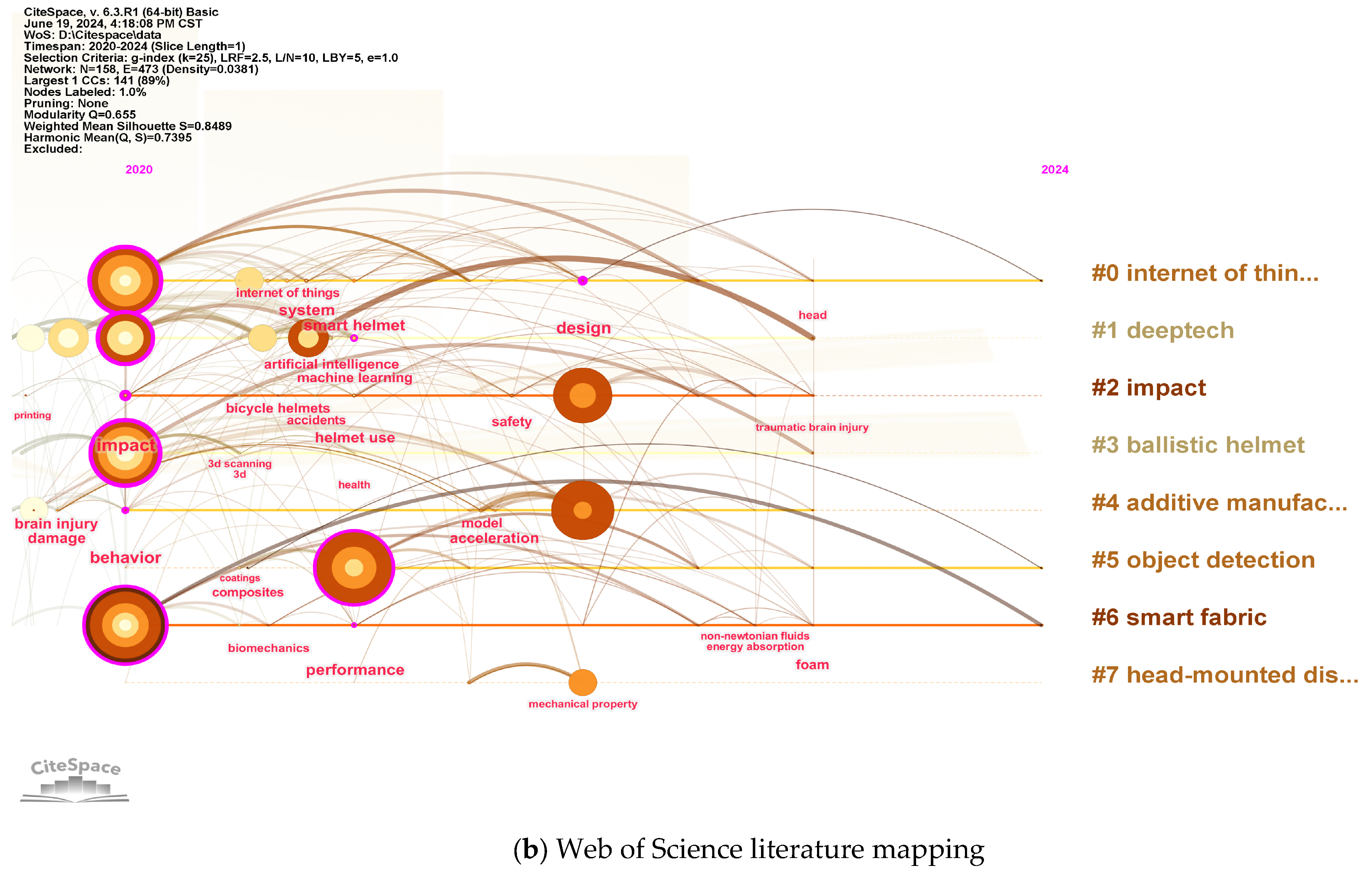

2.1. Smart Helmet

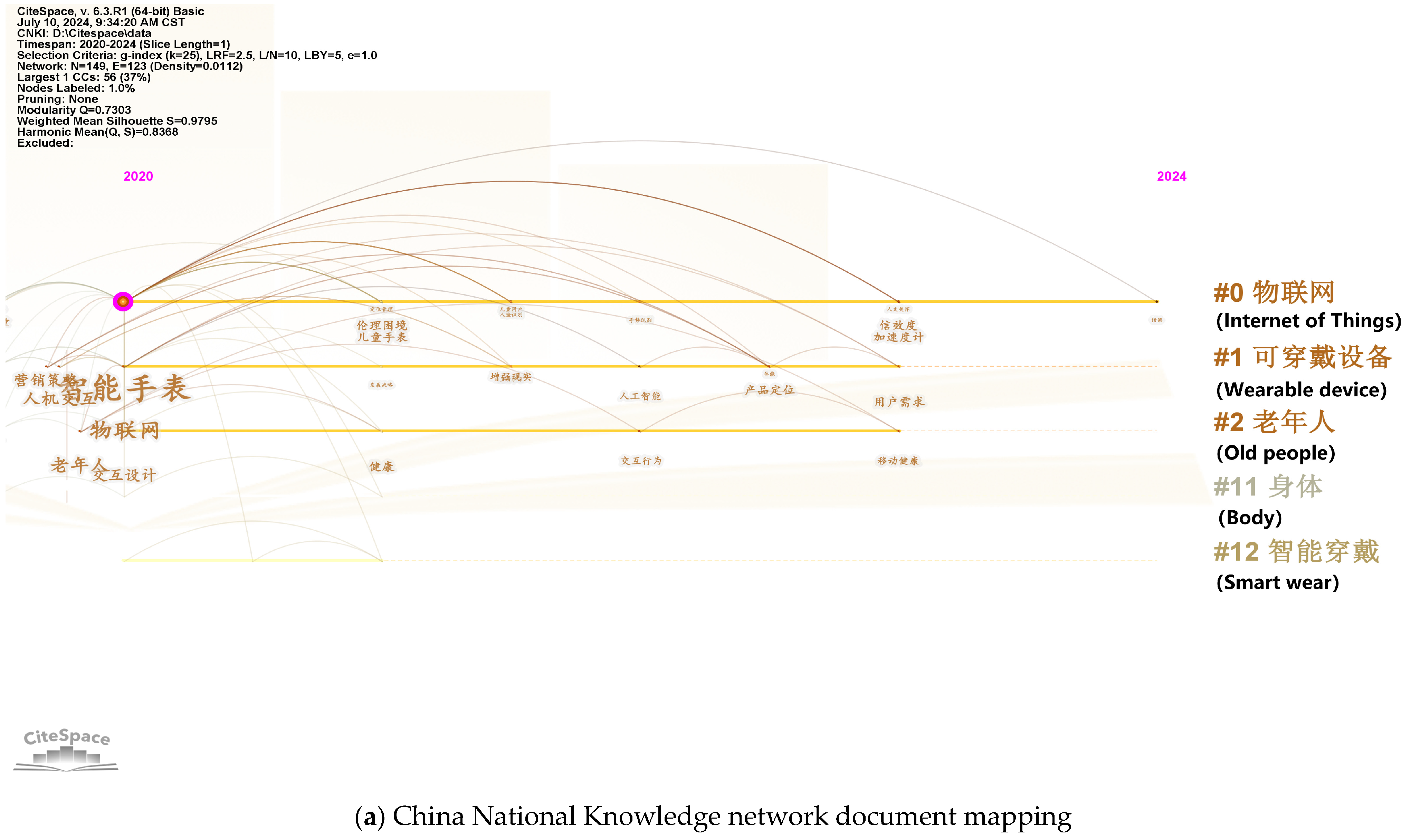

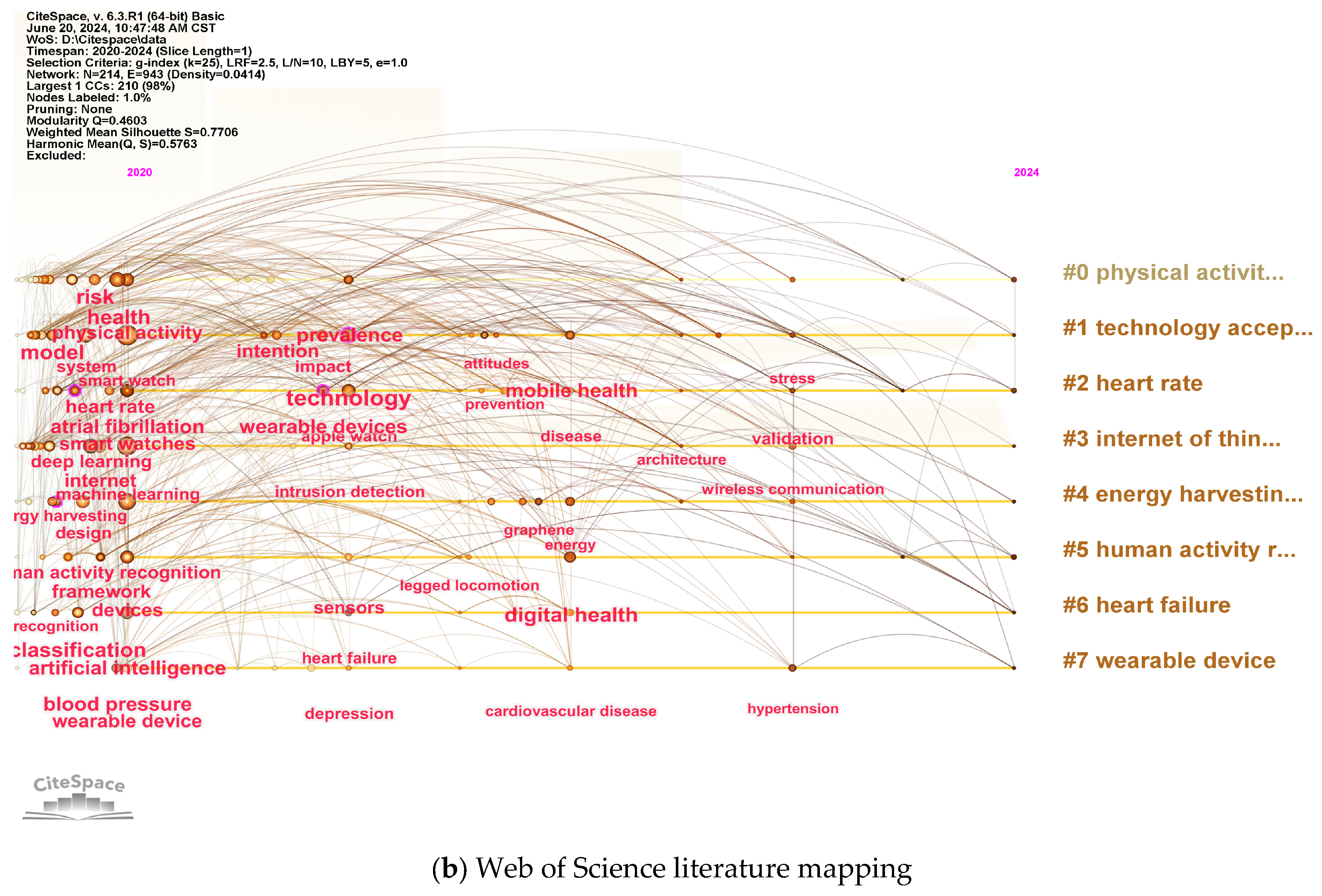

2.2. Smartwatch

2.3. Other Intelligent Equipment

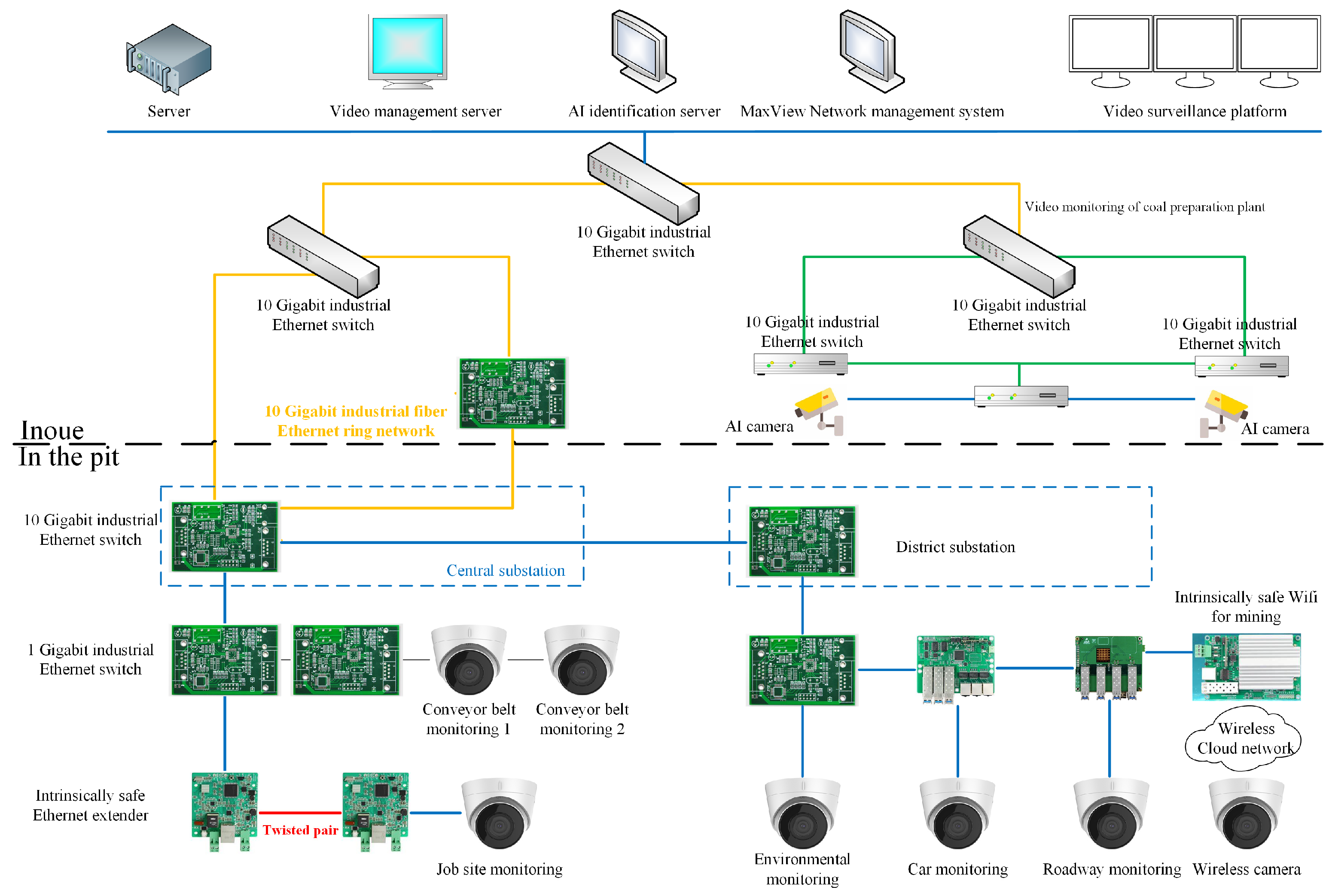

3. Indirect Monitoring of the Mine Environment

4. Research on Internet of Things Assisted Decision-Making in Mines

5. Summary and Prospects

- Development of Integrated Monitoring Devices for Environmental and Vital Sign Data. While existing devices demonstrate proficiency in monitoring either environmental or vital sign parameters independently, the development of systems capable of integrated monitoring remains underexplored. Smart helmets currently lead in combining these functions, but they are often bulky and impractical for prolonged use in underground mining. Miniaturized wearables, such as wristbands and rings, have shown potential for reducing miners’ physical burdens while maintaining essential monitoring functions. Future research should prioritize the design and development of lightweight, compact, and multifunctional wearable technologies. Such advancements could integrate both environmental and physiological monitoring capabilities into a single device or interconnected system, ensuring comprehensive safety while enhancing user comfort and reducing fatigue.

- Advancement and Application of Intelligent Decision Support Technologies. The transition to intelligent mining, propelled by AI and machine learning innovations, underscores the need for smarter decision-making systems. Current efforts focus on improving the intelligence and automation of mining equipment, enabling cross-platform integration, and enhancing data sharing. These developments aim to optimize emergency responses, predictive maintenance, and safety management. Future research could delve deeper into real-time adaptive decision-making frameworks, advanced predictive analytics for equipment lifecycle management, and AI-driven models tailored to complex mining scenarios. The integration of environmental sustainability metrics into these systems is another promising area, aligning technological advancements with ecological considerations.

- Privacy and Security in Big Data Applications. As data collection becomes more pervasive in mining operations, safeguarding the privacy and security of sensitive information is paramount. Data used to monitor miners’ health and safety also often includes proprietary information about mining operations, making it a target for potential misuse. Future research should explore robust encryption methods, secure data-sharing protocols, and advanced intrusion detection systems to protect this data. Additionally, developing frameworks for compliance with global data protection standards and exploring AI-driven anomaly detection for real-time security monitoring are critical directions. Ensuring a balance between data utility and privacy will be essential to maintaining trust and protecting both individual rights and commercial interests.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Da Silva, C.E.; Da Silva, J.M. Utilidade de vestíveis tecnológicos na mineração: Use of computacional wearables in mining industry. Braz. J. Dev. 2022, 8, 78789–78809. [Google Scholar] [CrossRef]

- Pasquale, V.D.; De Simone, V.; Radano, M.; Miranda, S. Wearable devices for health and safety in production systems: A literature review. IFAC Pap. 2022, 55, 341–346. [Google Scholar] [CrossRef]

- Svertoka, E.; Saafi, S.; Rusu-Casandra, A.; Burget, R.; Marghescu, I.; Hosek, J.; Ometov, A. Wearables for Industrial Work Safety: A Survey. Sensors 2021, 21, 3844. [Google Scholar] [CrossRef] [PubMed]

- Jacobs, J.V.; Hettinger, L.J.; Huang, Y.-H.; Jeffries, S.; Lesch, M.F.; Simmons, L.A.; Verma, S.K.; Willetts, J.L. Employee acceptance of wearable technology in the workplace. Appl. Ergon. 2019, 78, 148–156. [Google Scholar] [CrossRef] [PubMed]

- Raad, H. Fundamentals of IoT and Wearable Technology Design; Electrical and Electronics Engineers, Inc.: Hoboken, NJ, USA, 2020. [Google Scholar]

- Hofmann, C.; Patschkowski, C.; Haefner, B.; Lanza, G. Machine Learning Based Activity Recognition to Identify Wasteful Activities In Production. Procedia Manuf. 2020, 45, 171–176. [Google Scholar] [CrossRef]

- Abuwarda, Z.; Mostafa, K.; Oetomo, A.; Hegazy, T.; Morita, P. Wearable devices: Cross benefits from healthcare to construction. Autom. Constr. 2022, 142, 104501. [Google Scholar] [CrossRef]

- Mardonova, M.; Choi, Y. Review of Wearable Device Technology and Its Applications to the Mining Industry. Energies 2018, 11, 547. [Google Scholar] [CrossRef]

- Walsh, M. The Smart Helmet, Department of Electronic Engineering; Cork Institute of Technology: Cork, Ireland, 2007. [Google Scholar]

- Yang, X. Nine Outstanding Inventions in 2014. Encycl. Knowl. 2014, 20. (In Chinese) [Google Scholar]

- Choi, Y.; Kim, Y. Applications of Smart Helmet in Applied Sciences: A Systematic Review. Appl. Sci. 2021, 11, 5039. [Google Scholar] [CrossRef]

- Hamza, A.; Rauf, M.H.; Hashir, M.; Kounain, M. IoT Based Smart Helmet for Unsafe Event Detection for Mining Industry. J. Artif. Intell. Comput. 2023, 1, 13–17. [Google Scholar] [CrossRef]

- Bhuttoa, G.M.; Daudpotoa, J.; Jiskanib, I.M. Development of a wearable safety device for coal miners. Int. J. 2016, 225–229. [Google Scholar]

- Rai, A.; Rai, A.; Upadhyay, A. Smart Wearables for Coal Mine Workers. In Proceedings of the2023 2nd International Conference on Vision Towards Emerging Trends in Communication and Networking Technologies (ViTECoN), Vellore, India, 5–6 May 2023. [Google Scholar]

- Sandaruwan, A.; Hettige, B. A Comparative Study on Smart Helmet Systems for Mining Tracking and Worker Safety in the Mining Industry: A Review. In Proceedings of the The 4th Student Symposium, Beijing, China, 17 January 2024. [Google Scholar]

- Roja, P.; Srihari, D. Iot based smart helmet for air quality used for the mining industry. Int. J. Res. Sci. Eng. Technol. 2018, 4, 514–521. [Google Scholar]

- Behr, C.J.; Kumar, A.; Hancke, G.P. A smart helmet for air quality and hazardous event detection for the mining industry. In Proceedings of the 2016 IEEE International Conference on Industrial Technology, Taipei, Taiwan, 14–17 March 2016. [Google Scholar]

- Paulchamy, B.; Natarajan, C.; Wahith, A.A.; Sharan, P.M.; Vignesh, R.H. An intelligent helmet for miners with air quality and destructive event detection using zigbee. Glob. Res. Dev. J. Eng. 2018, 3, 41–46. [Google Scholar]

- Yogesh, M.; Nilay, S.; Suhas, P.; Sonali, K.; Sonali, K. Smart Helmet for Coal Mining. Int. J. Adv. Res. Sci. Commun. Technol. 2023, 3, 17–23. [Google Scholar]

- Kim, Y.; Baek, J.; Choi, Y. Smart Helmet-Based Personnel Proximity Warning System for Improving Underground Mine Safety. Appl. Sci. 2021, 11, 4342. [Google Scholar] [CrossRef]

- Zhuang, Y.; Yang, Q.; Han, T.; OMalley, R.; Kumar, A.; Gerald, R.E.; Huang, J. Fiber optic sensor embedded smart helmet for real-time impact sensing and analysis through machine learning. J. Neurosci. Methods 2021, 351, 109073. [Google Scholar] [CrossRef]

- Lalitha, K.; GRamya, M. AI-Based Safety Helmet for Mining Workers Using IoT Technology and ARM Cortex-M. IEEE Sens. J. 2023, 23, 21355–21362. [Google Scholar]

- Wang, L.; Xiong, Y.; Li, G. Design and Implementation of Intelligent Safety Helmet Based on mine. Electron. Prod. 2022, 30. (In Chinese) [Google Scholar]

- Kong, L.; Yi, C. Design of Intelligent Safety helmet for mining. China Min. 2020, 29, 95–98. (In Chinese) [Google Scholar]

- Jesudoss, A.; Vybhavi, R.; Anusha, B. Design of Smart Helmet for Accident Avoidance. In Proceedings of the 2019 International Conference on Communication and Signal Processing (ICCSP), Chennai, India, 4 June 2019. [Google Scholar]

- Li, Y.; Feng, J.; Yang, H. Intelligent Voice Helmet. Electron. Prod. 2023, 31. (In Chinese) [Google Scholar]

- Lee, P.; Kim, H.; Zitouni, M.S.; Khandoker, A.; Jelinek, H.F.; Hadjileontiadis, L.; Lee, U.; Jeong, Y. Trends in smart helmets with multimodal sensing for health and safety: Scoping review. JMIR Mhealth Uhealth 2022, 10, e40797. [Google Scholar] [CrossRef] [PubMed]

- Yixuan, L. Smart watches will be worn on the wrist. Commun. World 2012, 14, e40797. (In Chinese) [Google Scholar]

- Chandel, R.S.; Sharma, S.; Kaur, S.; Singh, S.; Kumar, R. Smart watches: A review of evolution in bio-medical sector. Mater. Today Proc. 2022, 50, 1053–1066. [Google Scholar] [CrossRef]

- Chakrabarti, S.; Biswas, N.; Jones, L.D.; Kesari, S.; Ashili, S. Smart Consumer Wearables as Digital Diagnostic Tools: A Review. Diagnostics 2022, 12, 2110. [Google Scholar] [CrossRef]

- Huang, L.; Yang, M.; Wang, J.; Meng, H.; Li, J. Smart Watch (Coal Intrinsic Safety Type). Patent No. CN306510397S, 2021. [Google Scholar]

- Athota, R.K.; Sumathi, D. Human activity recognition based on hybrid learning algorithm for wearable sensor data. Meas. Sens. 2022, 24, 100512. [Google Scholar] [CrossRef]

- Kamišalić, A.; Fister, I.; Turkanović, M.; Karakatič, S. Sensors and Functionalities of Non-Invasive Wrist-Wearable Devices: A Review. Sensors 2018, 18, 1714. [Google Scholar] [CrossRef]

- Sarkar, S.; Ghosh, A.; Ghosh, S.S. Study of Cardiorespiratory and Sweat Monitoring Wearable Architecture for Coal Mine Workers. In Proceedings of the 2020 IEEE Region 10 Conference (Tencon), Osaka, Japan, 16–19 November 2020. [Google Scholar]

- Rogers, W.P.; Marques, J.; Talebi, E.; Drews, F.A. IoT-Enabled Wearable Fatigue-Tracking System for Mine Operators. Minerals 2023, 13, 287. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, W.; Zhang, X.; Zhang, X.; Yang, G. Real-Time Monitoring of Underground Miners Status Based on Mine IoT System. Sensors 2024, 24, 739. [Google Scholar] [CrossRef]

- Leone, A.; Rescio, G.; Siciliano, P.; Papetti, A.; Brunzini, A.; Germani, M. Multi sensors platform for stress monitoring of workers in smart manufacturing context. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020. [Google Scholar]

- Khowaja, S.A.; Prabono, A.G.; Setiawan, F.; Yahya, B.N.; Lee, S.-L. Toward soft real-time stress detection using wrist-worn devices for human workspaces. Soft Comput. 2021, 25, 2793–2820. [Google Scholar] [CrossRef]

- Sanchez, W.; Martinez, A.; Hernandez, Y.; Estrada, H.; Gonzalez-Mendoza, M. A predictive model for stress recognition in desk jobs. J. Ambient. Intell. Humaniz. Comput. 2023, 14, 17–29. [Google Scholar] [CrossRef]

- González, V.; Godoy, J.; Arroyo, P.; Meléndez, F.; Díaz, F.; López, Á.; Suárez, J.I.; Lozano, J. Development of a Smartwatch with Gas and Environmental Sensors for Air Quality Monitoring. Sensors 2024, 24, 3808. [Google Scholar] [CrossRef] [PubMed]

- Parate, A.; Ganesan, D. Detecting eating and smoking behaviors using smartwatches. Mob. Health Sens. Anal. Methods Appl. 2017, 175–201. [Google Scholar] [CrossRef]

- Andun. Life and Health Warning System. Available online: https://www.iandun.com/home (accessed on 28 October 2024).

- Thomas, P.C.; David, W. Augmented reality: An application of heads-up display technology to manual manufacturing processes. In Proceedings of the Hawaii International Conference on System Sciences, Kauai, HI, USA, 7 January 1992. [Google Scholar]

- Lee, L.H.; Hui, P. Interaction Methods for Smart Glasses: A Survey. IEEE Access 2018, 6, 28712–28732. [Google Scholar] [CrossRef]

- Turkan, Y.; Radkowski, R.; Karabulut-Ilgu, A.; Behzadan, A.H.; Chen, A. Mobile augmented reality for teaching structural analysis. Adv. Eng. Inform. 2017, 34, 90–100. [Google Scholar] [CrossRef]

- Kim, D.; Choi, Y. Applications of Smart Glasses in Applied Sciences: A Systematic Review. Appl. Sci. 2021, 11, 4956. [Google Scholar] [CrossRef]

- Jacobs, J.; Webber-Youngman, R.; van Wyk, E. Potential Augmented Reality Applications in the Mining Industry. Retrieved January 2016, 16, 2023. [Google Scholar]

- Zhang, C.; Wang, H.; Zhang, X.; Xiao, Y.; Ren, C. The Design and Implementation of AR Glass for Coal Mine Application. Procedia Comput. Sci. 2022, 214, 1617–1623. [Google Scholar] [CrossRef]

- Baek, J.; Choi, Y. Smart Glasses-Based Personnel Proximity Warning System for Improving Pedestrian Safety in Construction and Mining Sites. Int. J. Environ. Res. Public Health 2020, 17, 1422. [Google Scholar] [CrossRef]

- Kim, D.; Choi, Y. Application of Smart Glasses for Field Workers Performing Soil Contamination Surveys with Portable Equipment. Sustainability 2022, 14, 12370. [Google Scholar] [CrossRef]

- Chen, C.; Lei, Y.; Han, X.; Li, J.; Tang, K. Study and design of an equipment-fault-diagnosis system based on wearable smart glasses. In Proceedings of the 2019 IEEE 8th Joint International Information Technology and Artificial Intelligence Conference (ITAIC), Chongqing, China, 24–26 May 2019. [Google Scholar]

- Yang, X. AR smart glasses make training and practice the same frequency resonance. Team World 2023, 84–85. (In Chinese) [Google Scholar]

- De Fazio, R.; Al-Hinnawi, A.-R.; De Vittorio, M.; Visconti, P. An Energy-Autonomous Smart Shirt Employing Wearable Sensors for Users Safety and Protection in Hazardous Workplaces. Appl. Sci. 2022, 12, 2926. [Google Scholar] [CrossRef]

- Sankaran, S.; Britto, P.I.; Petchimuthu, P.; Sushmitha, M.; Rathinakumar, S.; Mallaiyan, V.M.; Ayyavu, S.G. Monitoring of Physiological and Atmospheric Parameters of People Working in Mining Sites Using a Smart Shirt: A Review of Latest Technologies and Limitations; Springer Nature: Singapore, 2023; pp. 721–735. [Google Scholar]

- Chandrasekaran, M.; Akshaya, R.; Ashwini, U.; Kamali, V.; Sakthi, G.M. Smart Wearable Safety Jacket Design for Coal Miners. IJPREMS 2023, 3, 709–713. [Google Scholar]

- Li, M.; Xiong, W.; Li, Y. Wearable Measurement of ECG Signals Based on Smart Clothing. Int. J. Telemed. Appl. 2020, 2020, 6329360. [Google Scholar] [CrossRef]

- Karthika, S.; Jayabaskaran, G.; Hariharan, M.; Poonthamizhan, M.; Poongothai, G. Realtime Embedded Smart Jacket System for Coal Miners. In Proceedings of the 2023 9th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 17–18 March 2023. [Google Scholar]

- Ma, Y.; Wan, Q.; Gong, Z.; Wu, Y.; Zhou, J. Current Research Status and Development Trends of Cooling Suits in High-Temperature Mine Environments: A Review. Processes 2023, 11, 3256. [Google Scholar] [CrossRef]

- Dempsey, P.G.; Kocher, L.M.; Nasarwanji, M.F.; Pollard, J.P.; Whitson, A.E. Emerging Ergonomics Issues and Opportunities in Mining. Int. J. Environ. Res. Public Health 2018, 15, 2449. [Google Scholar] [CrossRef]

- Yan, Z.; Han, B.; Du, Z.; Huang, T.; Bai, O.; Peng, A. Development and testing of a wearable passive lower-limb support exoskeleton to support industrial workers. Biocybern. Biomed. Eng. 2021, 41, 221–238. [Google Scholar]

- Lu, C.; Qi, Q.; Liu, Y.; Li, D.; Xian, W.; Wang, Y.; Chen, C.; Xu, X. Exoskeleton Recognition of Human Movement Intent Based on Surface Electromyographic Signals. IEEE Access 2024, 12, 53986–54004. [Google Scholar] [CrossRef]

- Huysamen, K.; de Looze, M.; Bosch, T.; Ortiz, J.; Toxiri, S.; O’Sullivan, L.W. Assessment of an active industrial exoskeleton to aid dynamic lifting and lowering manual handling tasks. Appl. Ergon. 2018, 68, 125–131. [Google Scholar] [CrossRef]

- Dahmen, C.; Wöllecke, F.; Constantinescu, C. Challenges and Possible Solutions for Enhancing the Workplaces of the Future by Integrating Smart and Adaptive Exoskeletons. Procedia CIRP 2018, 67, 268–273. [Google Scholar] [CrossRef]

- Li, G. Development and Application of Exoskeleton Robot in Coal mine. Smart Mine Magazine, 27 May 2024. (In Chinese) [Google Scholar]

- Nivedhithaa, L.; Mohamed Akram, A.S. Safety Backpack for the Gas Industry and Mining Industry Workers. 2023. Available online: https://easychair.org/publications/preprint/3Pbr (accessed on 28 October 2024).

- Rajan, S.; Kumar, N.S.; Chandrasekaran, G.; Sowmiya, K.; Varalakshmi, K.; Priyadarshi, N.; Bhaskar, M.S.; Kumar, N. Atmospheric Monitoring and Fire Prevention Electronic System for Mining Workers. In Proceedings of the 2022 IEEE 9th Uttar Pradesh Section International Conference on Electrical, Electronics and Computer Engineering (UPCON), Prayagraj, India, 2–4 December 2022. [Google Scholar]

- Oura. A Really Smart Ring. Available online: https://ouraring.com/product/rings (accessed on 28 October 2024).

- Wilson, M. Samsung Galaxy Ring: The Smart Ring is Now Official, Heres Everything We Know. Available online: https://www.techradar.com/health-fitness/fitness-trackers/samsung-galaxy-ring-rumors-suggest-its-another-small-step-towards-reality (accessed on 28 October 2024).

- Wang, G.; Pan, B.; Li, Q. Video Analysis based Production safety monitoring system for Open pit Mine. Coal Technol. 2023, 42, 162–166. (In Chinese) [Google Scholar]

- Li, Y.; Wang, H.; Bai, S. Application of Safety Centralized Monitoring System in Intelligent mine. Ind. Mine Autom. 2023, 49, 47–51. (In Chinese) [Google Scholar]

- Myway. Mine Video Surveillance System. Available online: https://www.maiwe.com.cn/view/1304.html (accessed on 28 October 2024). (In Chinese).

- Yang, M. “How Does Electronic Fence” Protect Coal Mine Safety. Available online: http://paper.people.com.cn/zgnyb/html/2024-04/22/node_2321.htm (accessed on 28 October 2024). (In Chinese).

- Fu, Q.; Meng, Z.; He, J. Application of virtual electronic fence in 5G+ smart mine field. Autom. Appl. 2023, 64, 235–237+240. (In Chinese) [Google Scholar]

- Tian, Y.; Guo, X.; Zhao, R.; Tong, X. Safety early warning system of crushing station of surface production System of South Open Pit Coal Mine of Tianchi Energy, Xinjiang. Open Pit Min. Technol. 2024, 39, 106–109. (In Chinese) [Google Scholar]

- Pei, L. Application and Operation Research of Mine ventilation Safety Monitoring System. Min. Equip. 2024, 89–91. (In Chinese) [Google Scholar]

- Liu, T.; Wang, C.; Wei, Y.; Zhao, Y.; Huo, D.; Shang, Y.; Wang, Z.; Ning, Y. Fibre optic sensors for mine hazard detection. J. Phys. Conf. Series 2009, 178, 012004. [Google Scholar] [CrossRef]

- Du, W.; Chai, J.; Zhang, D.; Lei, W. Application of Optical Fiber Sensing Technology in Mine Safety Monitoring. China Equip. Eng. 2024, 173–175. (In Chinese) [Google Scholar]

- Chen, J. Exploration and Application of intelligent inspection robot for mining belt Transportation. Electron. Prod. 2022, 30, 95–97. (In Chinese) [Google Scholar]

- Shi, Y.; Huang, W.; Liu, Z. Analysis of Video Monitoring and Automatic Identification Technology for Intelligent Inspection Devices for Mining. Manuf. Upgrad. Today 2023, 39–41. (In Chinese) [Google Scholar]

- Lu, S. Application of intelligent Algorithm based on Machine vision in Mine safety monitoring system. Mod. Min. 2024, 40, 10–12+16. (In Chinese) [Google Scholar]

- Tang, Y.; Wang, S. Application research of intelligent Safety monitoring and inspection robot in Coal mine. Mech. Manag. Dev. 2023, 38, 185–186+189. (In Chinese) [Google Scholar]

- Zhu, S. Research and Application of UWB Technology based precise Personnel positioning System in Yaoqiao Coal Mine. Energy Technol. Manag. 2023, 48, 159–161+170. (In Chinese) [Google Scholar]

- Pan, X.; Chen, X. Research on Key Technologies of intelligent inspection robot for mining. Ind. Min. Autom. 2020, 10, 43–48. (In Chinese) [Google Scholar]

- Weihai Crystal Digital Mine. Underground Safety and Avoid Six Systems Personnel Positioning System. Available online: http://www.minestar.cn/page252 (accessed on 29 October 2024). (In Chinese).

- Dian, F.J.; Vahidnia, R.; Rahmati, A. Wearables and the Internet of Things (IoT), Applications, Opportunities, and Challenges: A Survey. IEEE Access 2020, 8, 69200–69211. [Google Scholar] [CrossRef]

- Bing, Z.; Wang, X.; Dong, Z.; Dong, L.; He, T. A novel edge computing architecture for intelligent coal mining system. Wirel. Netw. 2023, 29, 1545–1554. [Google Scholar] [CrossRef]

- Sammarco, J.J.; Paddock, R.; Fries, E.F.; Karra, V.K. A Technology Review of Smart Sensors with Wireless Networks for Applications in Hazardous Work Environments. 2007. Available online: https://stacks.cdc.gov/view/cdc/8472/cdc_8472_DS1.pdf (accessed on 29 October 2024).

- Nguyen, H.C.; Dam, T.H.; Le, M.T.; Nguyen, Q.C.; Nguyen, D.D. Internet of Things-Based Telehealth Monitoring System in Mines: Architectural Concept and Wearable Device Prototype. In Proceedings of the 2023 IEEE 9th International Conference on Smart Instrumentation, Measurement and Applications (ICSIMA), Kuala Lumpur, Malaysia, 17–18 October 2023. [Google Scholar]

- Muduli, L.; Mishra, D.P.; Jana, P.K. Application of wireless sensor network for environmental monitoring in underground coal mines: A systematic review. J. Netw. Comput. Appl. 2018, 106, 48–67. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, L.; Shi, J.; Peng, S.; Guan, Y.; Shang, J. A Review of Routing Protocols for Wireless Body Area Networks for Miner Safety. In Proceedings of the 2020 IEEE Intl Conf on Parallel & Distributed Processing with Applications, Big Data & Cloud Computing, Sustainable Computing & Communications, Social Computing & Networking (ISPA/BDCloud/SocialCom/SustainCom), Exeter, UK, 17–19 December 2020. [Google Scholar]

- Sun, Y.; Zuo, H.; Qian, J.; Zhao, F. Internet of Things application model and key Technologies for Coal mine Safety Production. Coal Sci. Technol. 2013, 41, 84–88. (In Chinese) [Google Scholar]

- Sun, J. Research on Wired broadband Information Transmission in underground Coal Mines. Ind. Mine Autom. 2013, 39, 1–5. (In Chinese) [Google Scholar]

- Ibhaze, A.E.; Akinola, D.O.; Imoize, A.L.; Orukpe, P.E.; Edeko, F.O. A review of downhole communication technologies. J. Telecommun. Electron. Comput. Eng. (JTEC) 2022, 14, 1–10. [Google Scholar] [CrossRef]

- Moskovitch, R. Multivariate temporal data analysis—A review. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2022, 12, e1430. [Google Scholar] [CrossRef]

- Ali, D.; Frimpong, S. Artificial intelligence, machine learning and process automation: Existing knowledge frontier and way forward for mining sector. Artif. Intell. Rev. 2020, 53, 6025–6042. [Google Scholar] [CrossRef]

- Pan, H.; Tong, S.; Wei, X.; Teng, B. Fatigue state recognition system for miners based on a multi-modal feature extraction and fusion framework. IEEE Trans. Cogn. Dev. Syst. 2024, 1–10. [Google Scholar] [CrossRef]

- Imam, M.; Baïna, K.; Tabii, Y.; Ressami, E.M.; Adlaoui, Y.; Benzakour, I.; Abdelwahed, E.H. The Future of Mine Safety: A Comprehensive Review of Anti-Collision Systems Based on Computer Vision in Underground Mines. Sensors 2023, 9, 4294. [Google Scholar] [CrossRef]

- Mansouri, S.S.; Karvelis, P.; Kanellakis, C.; Kominiak, D.; Nikolakopoulos, G. Vision-based MAV navigation in underground mine using convolutional neural network. In Proceedings of the IECON 2019 45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019. [Google Scholar]

- Zhai, G.; Zhang, W.; Hu, W.; Ji, Z. Coal Mine Rescue Robots Based on Binocular Vision: A Review of the State of the Art. IEEE Access 2020, 8, 130561–130575. [Google Scholar] [CrossRef]

- Yi, C. Research on Key technologies of Human motion intention perception for lower limb exoskeleton Robot. Harbin Inst. Technol. 2022. (In Chinese) [Google Scholar]

- Dong, Q.; Wu, Y. Research on Risk Assessment of Multitarget Wireless Sensing Detection Auxiliary Engineering in Mine Geological Environment. J. Sens. 2021, 2021, 9915430. (In Chinese) [Google Scholar] [CrossRef]

- Wang, X. Coal Mine Safety Risk Intelligent control and information decision analysis system. Appl. Intell. Syst. Multi Modal Inf. Anal. 2022, 45–52. [Google Scholar]

- Smirnov, A.; Pashkin, M.; Levashova, T.; Shilov, N.; Kashevnik, A. Role-based decision mining for multiagent emergency response management. Auton. Intell. Syst. Multi Agents Data Min. 2007, 4476, 178–191. [Google Scholar]

- Syed Faiz Ul Huda, C.K. Muhammad Ali Noman, Syed Yasir Shah, Muhammad Mubashir Iqbal: Iot Based Smart Kit for Coal Miners Safety Purpose. Int. J. Adv. Trends Comput. Sci. Eng. 2021, 10, 2469–2472. [Google Scholar]

- Wang, K.; Xie, S.; Rodrigues, J. Medical data security of wearable tele-rehabilitation under internet of things. Internet Things Cyber Phys. Syst. 2022, 2, 1–11. [Google Scholar] [CrossRef]

| Author | Domain | Innovation |

|---|---|---|

| Yeanjae Kim et al. [20] | Mining industry | Add an approach warning system for those wearing smart helmets to prevent collisions between equipment and pedestrians in mines. |

| Yiyang Zhuang et al. [21] | Mining industry | Embedded fiber-optic sensors directly into the thin surface layer of the helmet housing to enable the device to sense and analyze blunt force impact events that could provide a direct way to assess the helmet’s head protection capabilities and assess the potential physiological effects of blunt force impact events in real time. |

| Lalitha K et al. [22] | Mining industry | A convolutional neural network algorithm was used to train an AI model to recognize workers’ gestures to help operators communicate. Gestures are labeled “good”, “bad”, “doing well”, and “emergency evacuation”. |

| Lei Wang et al. [23] | Mining industry | Integration of wireless communication technology, positioning technology, and a sound and light alarm module. The ZigBee terminal node is used to upload the data to the gateway, and the location information of the staff is determined according to RSS positioning technology to provide the corresponding emergency treatment. |

| Lili Kong et al. [24] | Mining industry | The traditional helmet is equipped with toxic gas monitoring, temperature and humidity and other environmental information collection sensors, and pressure monitoring is used for early warning of abnormal situations, and the mine working environment information is actually monitored. |

| A. Jesudoss et al. [25] | Transportation field | Equipped with infrared sensors to check if the person is wearing a helmet and a gas sensor that identifies alcohol in the rider’s breath. |

| Yanseng Li et al. [26] | Transportation field | By using modules such as WTGPS+BD Beidou positioning and bone conduction Bluetooth technology in the smart helmet, navigation and positioning, Bluetooth broadcasting, LCD display, pulse heartbeat monitoring, automatic alarm and other functions are realized. |

| Author | Domain | Innovation |

|---|---|---|

| Sayan Sarkar et al. [34] | Mining industry | Smartwatch designed to monitor and analyze different cardiorespiratory and humoral based parameters of downhole operators, recording performance indicators and stress of operators. |

| W. Pratt Rogers et al. [35] | Mining industry | With existing smartwatches, it is possible to assess different fatigue conditions for downhole operators by combining the ability to evaluate performance measures in real time with subjective measures. |

| Yufeng Jiang et al. [36] | Mining industry | On the basis of non-invasive measurement to avoid environmental interference and ensure the explosion-proof requirements, a bracelet with high integration and lightweight structure was designed for monitoring the blood oxygen saturation, body temperature and pulse wave data of the human body. |

| Alessandro Leone et al. [37] | Industry | Using a combination of wristbands and EOGs, a framework was designed to analyze heart rate, electrodermal response, and EOG signals to extract features that could monitor excessive stress or cognitive load. |

| SA Khowaja et al. [38] | Industry | For the purpose of a low cost and low sampling rate, a smartwatch was designed, and the monitoring performance was improved by the method of machine learning, and the stress can be detected in the real environment. |

| W Sanchez et al. [39] | Industry | Compare multiple machine learning algorithms to identify work stress in its initial stages through the behavior and physical activity of employees as monitored by Fitbit® wrist-worn sensors. |

| Víctor González et al. [40] | Industry | Applied a variety of metal oxide sensors to achieve the use of watches for toluene, xylene, and ethylbenzene gas detection. |

| Abhinav Parate et al. [41] | Daily | Methods of detecting gesture behavior with a watch were designed to judge the eating and smoking situation of watch wearers from their usual gestures. |

| ANDUN et al. [42] | Medical | Through long-term monitoring of human health, sleep health, psychological pressure, blood pressure, blood sugar, blood lipids and other data, the self-developed algorithm is used to predict the occurrence probability of more than 10 diseases and chronic diseases in the next 30 days. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Y.; Liu, Y.; Lu, C.; Cui, D.; Yang, J.; Zhou, R. Research on Intelligent Monitoring and Protection Equipment of Vital Signs of Underground Personnel in Coal Mines: Review. Sensors 2025, 25, 63. https://doi.org/10.3390/s25010063

Liang Y, Liu Y, Lu C, Cui D, Yang J, Zhou R. Research on Intelligent Monitoring and Protection Equipment of Vital Signs of Underground Personnel in Coal Mines: Review. Sensors. 2025; 25(1):63. https://doi.org/10.3390/s25010063

Chicago/Turabian StyleLiang, Yuntao, Yingjie Liu, Changjia Lu, Dawei Cui, Jinghu Yang, and Rui Zhou. 2025. "Research on Intelligent Monitoring and Protection Equipment of Vital Signs of Underground Personnel in Coal Mines: Review" Sensors 25, no. 1: 63. https://doi.org/10.3390/s25010063

APA StyleLiang, Y., Liu, Y., Lu, C., Cui, D., Yang, J., & Zhou, R. (2025). Research on Intelligent Monitoring and Protection Equipment of Vital Signs of Underground Personnel in Coal Mines: Review. Sensors, 25(1), 63. https://doi.org/10.3390/s25010063