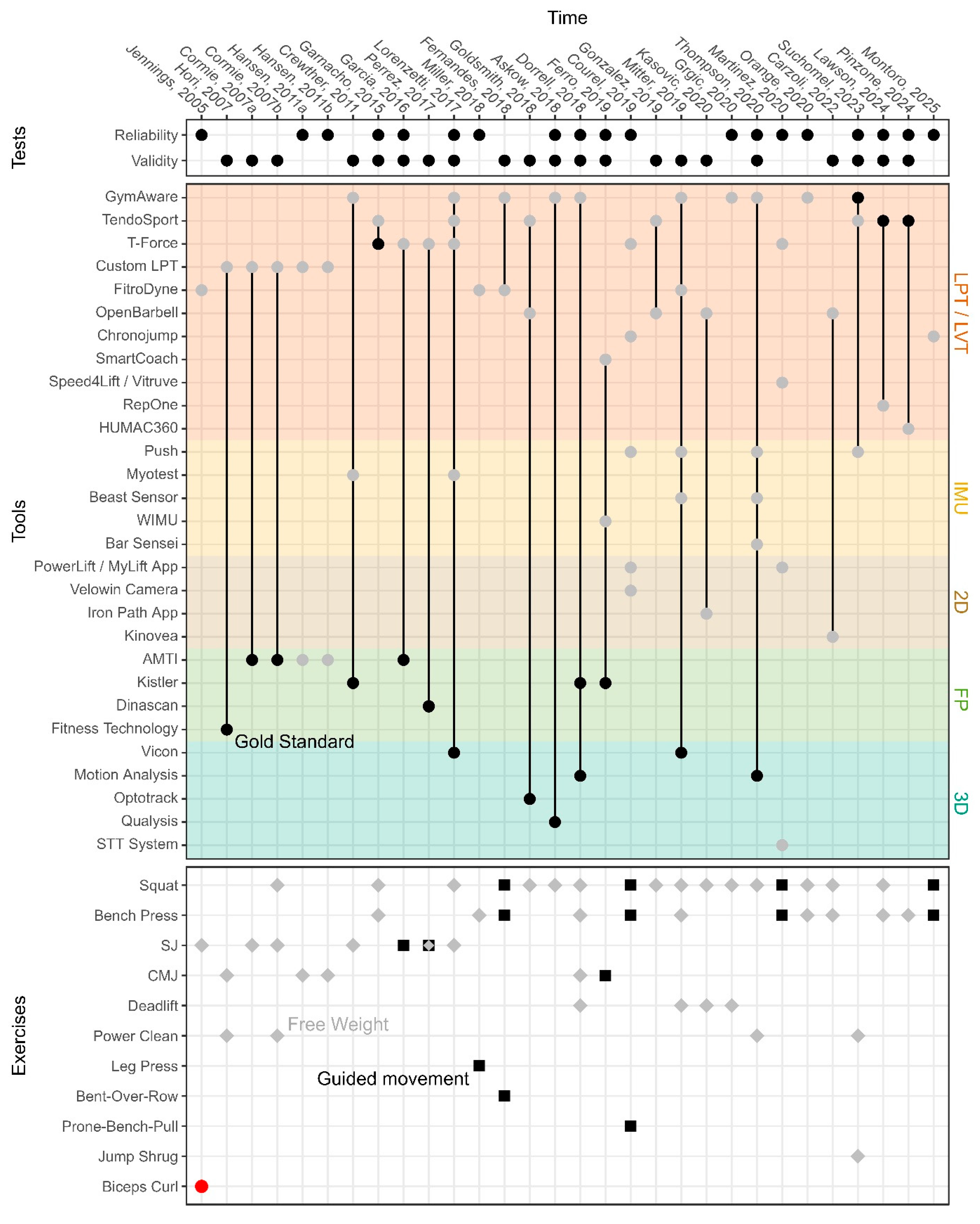

From Straight Lines to Curved Paths: Validity and Reliability of Linear Position Transducers to Assess Linear and Angular Motion

Abstract

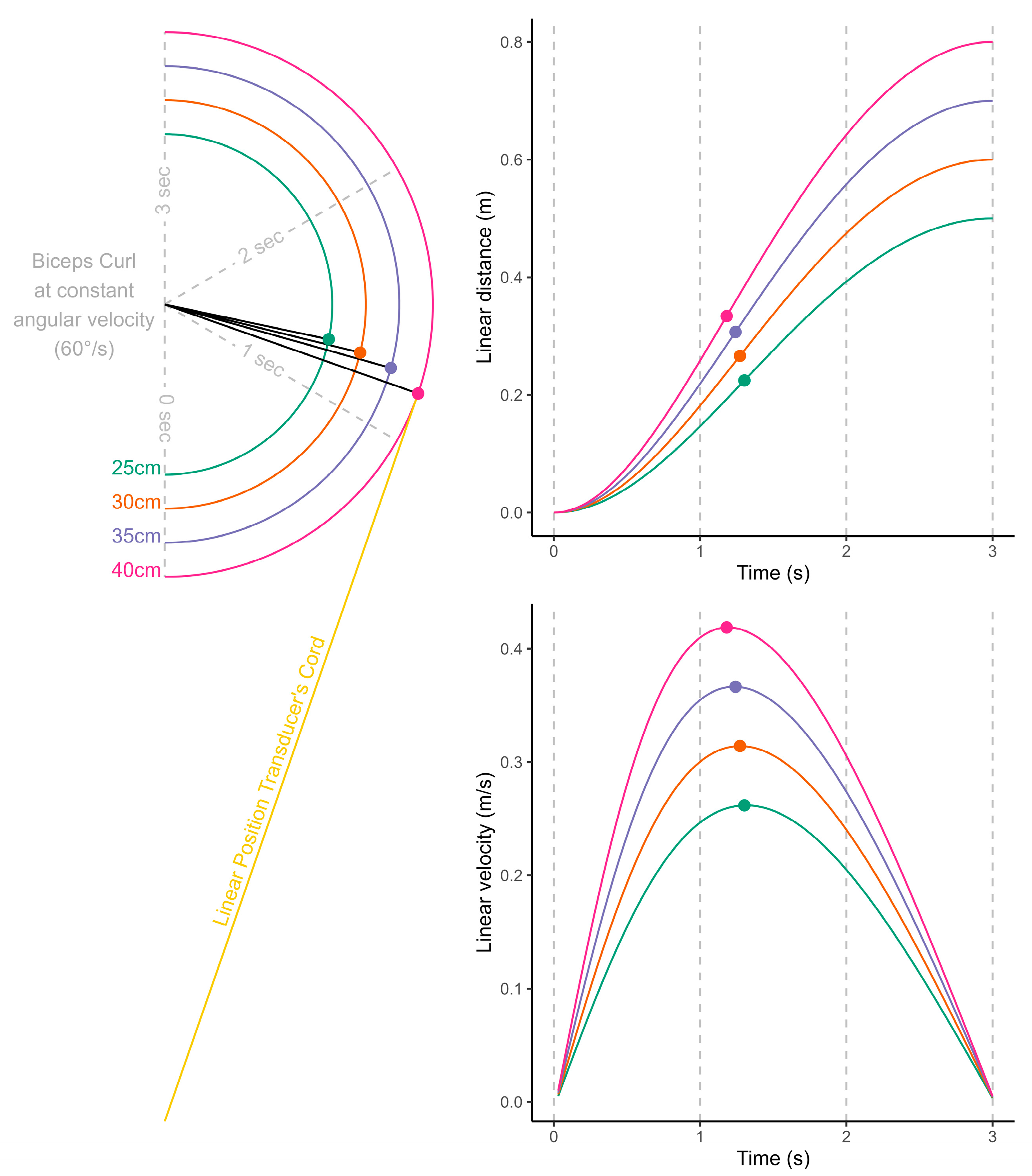

1. Introduction

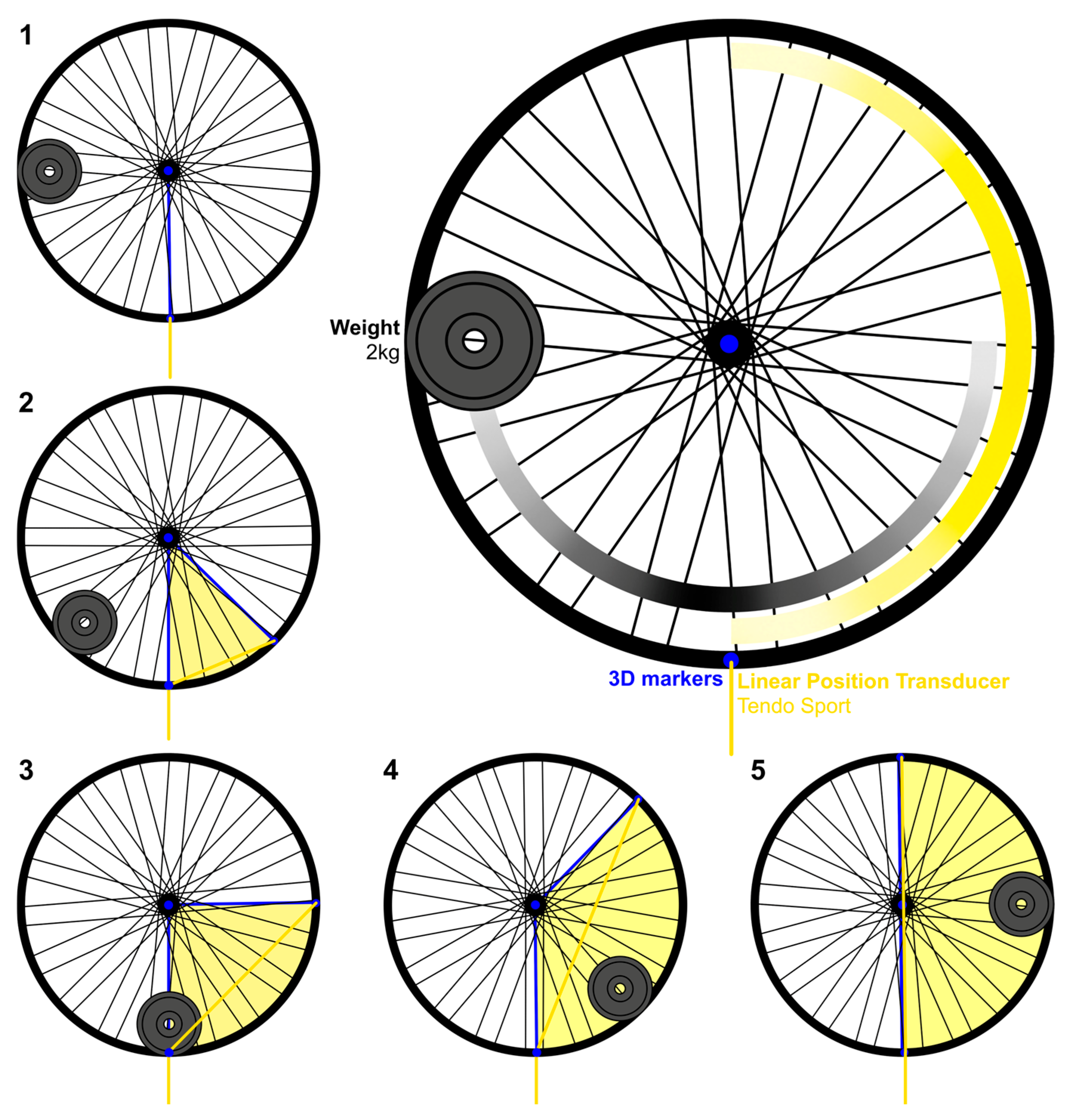

2. Materials and Methods

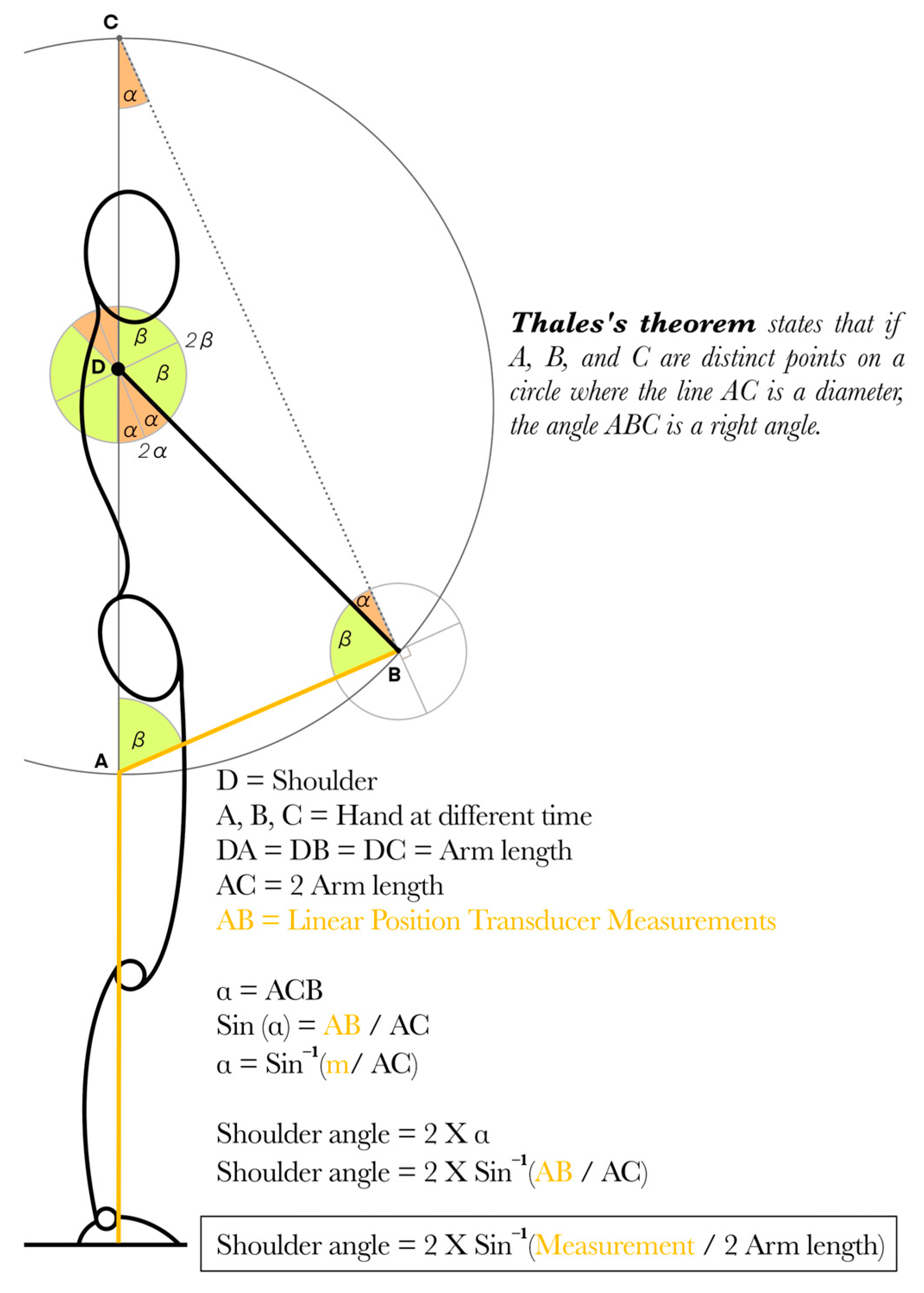

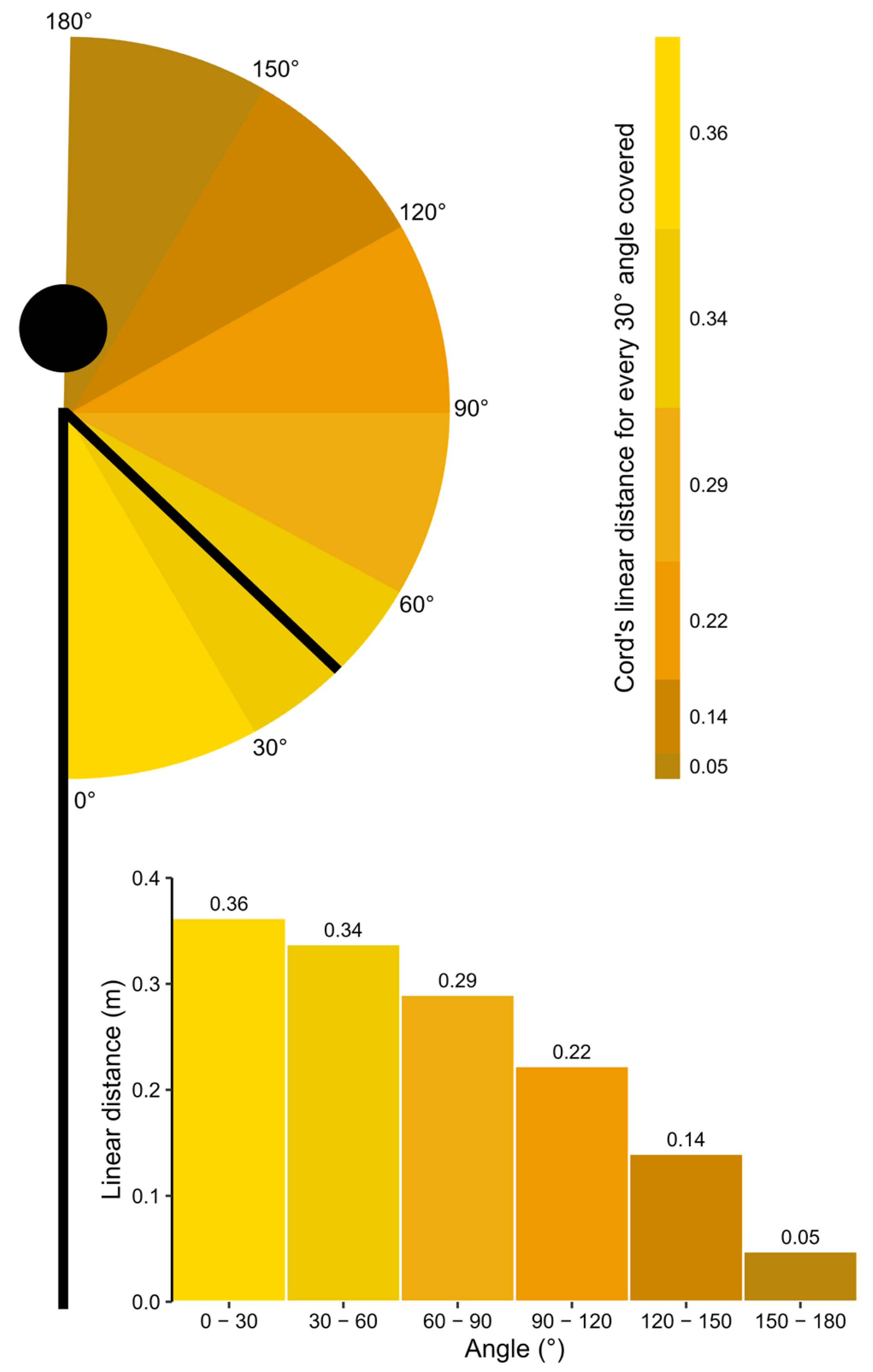

2.1. Mathematical Foundations

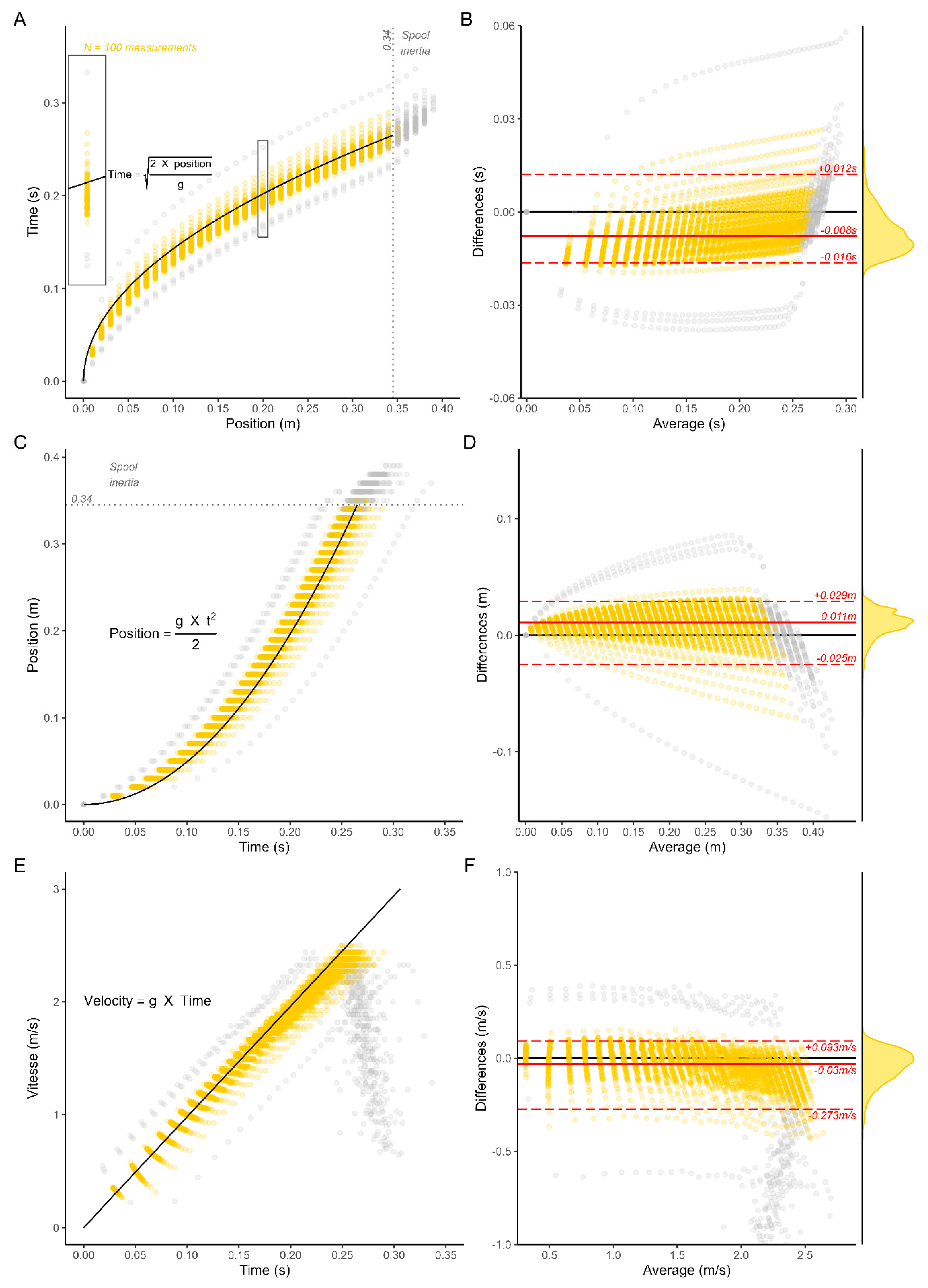

2.2. Part I—Free Fall Testing

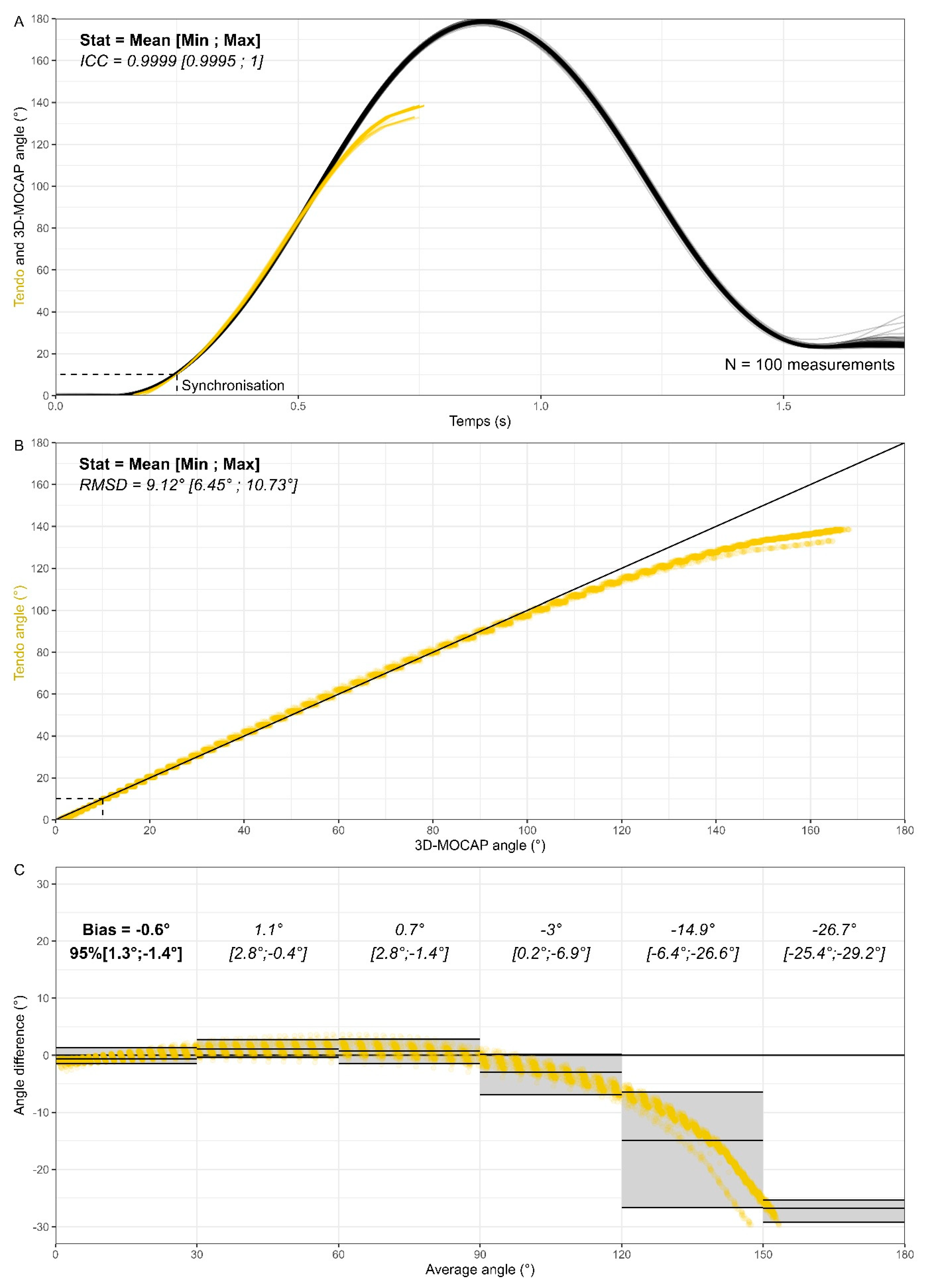

2.3. Part II—Ex Vivo Testing with a Wheel

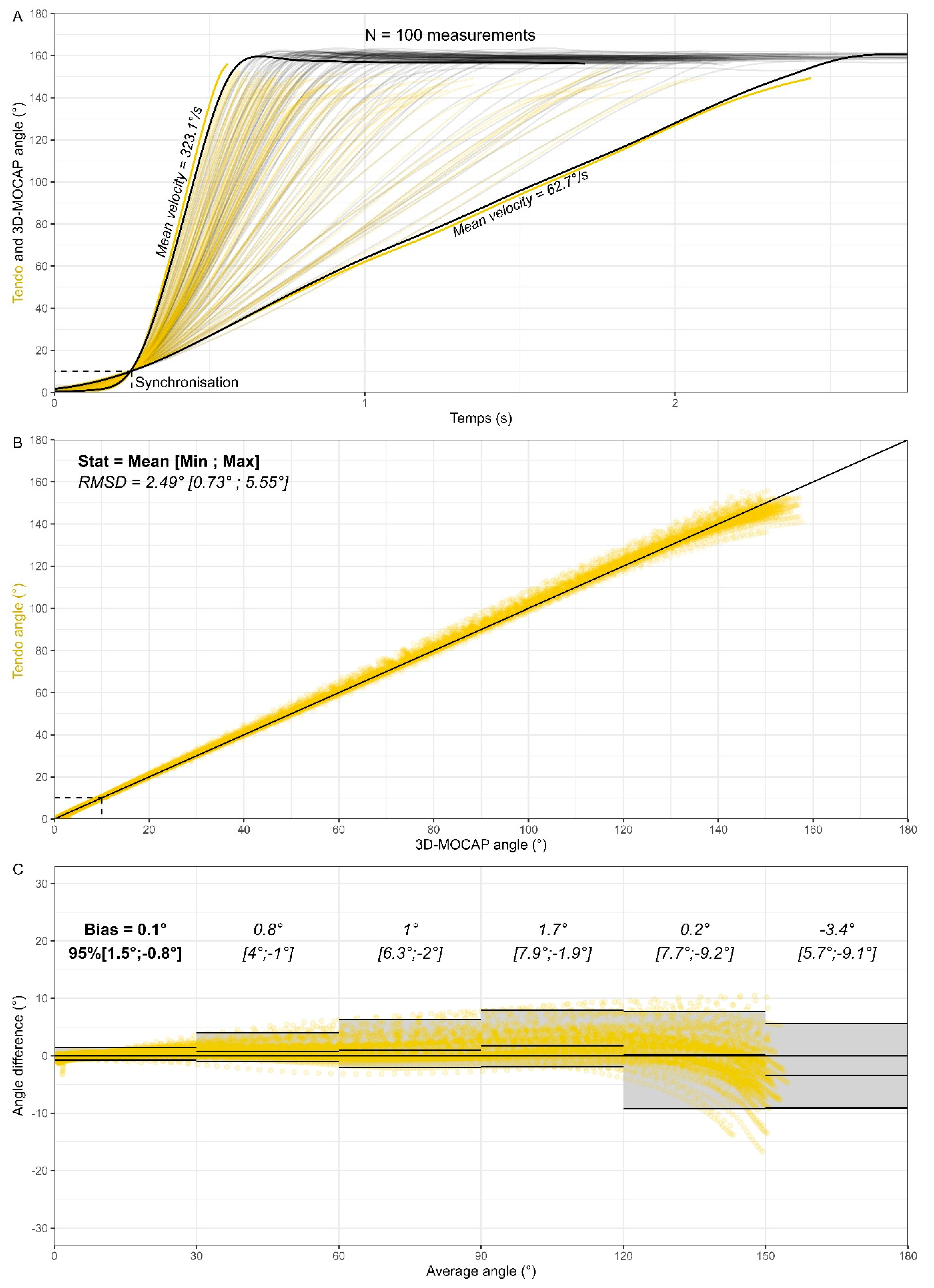

2.4. Part III—In Vivo Tests During Shoulder Flexion

2.5. Data Analysis and Statistics

3. Results

4. Discussion

4.1. Part I

4.2. Part II and Part III

4.3. Limits

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 1RM | One repetition with maximal amount of weight |

| ICC | Intraclass correlation coefficient |

| IMU | Inertial measurement unit |

| LoA | Limits of agreement |

| LPT | Linear position transducer |

| RMSD | Root mean square differences |

References

- Jennings, C.L.; Viljoen, W.; Durandt, J.; Lambert, M.I. The Reliability of the Fitrodyne as a Measure of Muscle Power. J. Strength Cond. Res. 2005, 19, 859–863. [Google Scholar] [CrossRef]

- González-Badillo, J.J.; Sánchez-Medina, L. Movement Velocity as a Measure of Loading Intensity in Resistance Training. Int. J. Sports Med. 2010, 31, 347–352. [Google Scholar] [CrossRef]

- Garnacho-Castaño, M.V.; López-Lastra, S.; Maté-Muñoz, J.L. Type of the Paper. J. Sports Sci. Med. 2015, 14, 128–136. [Google Scholar] [PubMed]

- García-Ramos, A.; Stirn, I.; Strojnik, V.; Padial, P.; De La Fuente, B.; Argüelles-Cienfuegos, J.; Feriche, B. Comparison of the Force-, Velocity-, and Power-Time Curves Recorded with a Force Plate and a Linear Velocity Transducer. Sports Biomech. 2016, 15, 329–341. [Google Scholar] [CrossRef] [PubMed]

- Askow, A.T.; Stone, J.D.; Arndts, D.J.; King, A.C.; Goto, S.; Hannon, J.P.; Garrison, J.C.; Bothwell, J.M.; Esposito, P.E.; Jagim, A.R.; et al. Validity and Reliability of a Commercially-Available Velocity and Power Testing Device. Sports 2018, 6, 170. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez, A.M.; Mangine, G.T.; Spitz, R.W.; Ghigiarelli, J.J.; Sell, K.M. Agreement Between the Open Barbell and Tendo Linear Position Transducers for Monitoring Barbell Velocity during Resistance Exercise. Sports 2019, 7, 125. [Google Scholar] [CrossRef]

- Thompson, S.W.; Rogerson, D.; Dorrell, H.F.; Ruddock, A.; Barnes, A. The Reliability and Validity of Current Technologies for Measuring Barbell Velocity in the Free-Weight Back Squat and Power Clean. Sports 2020, 8, 94. [Google Scholar] [CrossRef]

- Courel-Ibáñez, J.; Martínez-Cava, A.; Morán-Navarro, R.; Escribano-Peñas, P.; Chavarren-Cabrero, J.; González-Badillo, J.J.; Pallarés, J.G. Reproducibility and Repeatability of Five Different Technologies for Bar Velocity Measurement in Resistance Training. Ann. Biomed. Eng. 2019, 47, 1523–1538. [Google Scholar] [CrossRef]

- Hori, N.; Newton, R.U.; Andrews, W.A.; Kawamori, N.; Mcguigan, M.R.; Nosaka, K. Comparison of Four Different Methods to Measure Power Output During the Hang Power Clean and the Weighted Jump Squat. J. Strength Cond. Res. 2007, 21, 314–320. [Google Scholar] [CrossRef]

- Crewther, B.T.; Kilduff, L.P.; Cunningham, D.J.; Cook, C.; Owen, N.; Yang, G.-Z. Validating Two Systems for Estimating Force and Power. Int. J. Sports Med. 2011, 32, 254–258. [Google Scholar] [CrossRef]

- Ferro, A.; Floría, P.; Villacieros, J.; Muñoz-López, A. Maximum Velocity during Loaded Countermovement Jumps Obtained with an Accelerometer, Linear Encoder and Force Platform: A Comparison of Technologies. J. Biomech. 2019, 95, 109281. [Google Scholar] [CrossRef]

- Mitter, B.; Hölbling, D.; Bauer, P.; Stöckl, M.; Baca, A.; Tschan, H. Concurrent Validity of Field-Based Diagnostic Technology Monitoring Movement Velocity in Powerlifting Exercises. J. Strength Cond. Res. 2021, 35, 2170–2178. [Google Scholar] [CrossRef] [PubMed]

- Suchomel, T.J.; Techmanski, B.S.; Kissick, C.R.; Comfort, P. Reliability, Validity, and Comparison of Barbell Velocity Measurement Devices during the Jump Shrug and Hang High Pull. J. Funct. Morphol. Kinesiol. 2023, 8, 35. [Google Scholar] [CrossRef] [PubMed]

- Harris, N.K.; Cronin, J.; Taylor, K.-L.; Boris, J.; Sheppard, J. Understanding Position Transducer Technology for Strength and Conditioning Practitioners. Strength Cond. J. 2010, 32, 66–79. [Google Scholar] [CrossRef]

- Cormie, P.; Deane, R.; Mcbride, J.M. Methodological Concerns for Determining Power Output in the Jump Squat. J. Strength Cond. Res. 2007, 21, 424–430. [Google Scholar] [CrossRef]

- Carzoli, J.; Sousa, C.; Helms, E.; Zourdos, M. Agreement Between Kinovea Video Analysis and the Open Barbell System for Resistance Training Movement Outcomes. J. Hum. Kinet. 2022, 81, 27–39. [Google Scholar] [CrossRef]

- Martínez-Cava, A.; Morán-Navarro, R.; Sánchez-Medina, L.; González-Badillo, J.J.; Pallarés, J.G. Velocity- and Power-Load Relationships in the Half, Parallel and Full Back Squat. J. Sports Sci. 2019, 37, 1088–1096. [Google Scholar] [CrossRef]

- Sánchez-Medina, L.; González-Badillo, J.; Pérez, C.; Pallarés, J. Velocity- and Power-Load Relationships of the Bench Pull vs. Bench Press Exercises. Int. J. Sports Med. 2013, 35, 209–216. [Google Scholar] [CrossRef]

- Sánchez-Medina, L.; Pallarés, J.; Pérez, C.; Morán-Navarro, R.; González-Badillo, J. Estimation of Relative Load from Bar Velocity in the Full Back Squat Exercise. Sports Med. Int. Open 2017, 1, E80–E88. [Google Scholar] [CrossRef]

- Cunanan, A.J.; Hornsby, W.G.; South, M.A.; Ushakova, K.P.; Mizuguchi, S.; Sato, K.; Pierce, K.C.; Stone, M.H. Survey of Barbell Trajectory and Kinematics of the Snatch Lift from the 2015 World and 2017 Pan-American Weightlifting Championships. Sports 2020, 8, 118. [Google Scholar] [CrossRef]

- Sandau, I.; Langen, G.; Nitzsche, N. Variability of Time Series Barbell Kinematics in Elite Male Weightlifters. Front. Sports Act. Living 2023, 5, 1264280. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro Neto, F.; Dorneles, J.R.; Luna, R.M.; Spina, M.A.; Gonçalves, C.W.; Gomes Costa, R.R. Performance Differences Between the Arched and Flat Bench Press in Beginner and Experienced Paralympic Powerlifters. J. Strength Cond. Res. 2022, 36, 1936–1943. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Cava, A.; Hernández-Belmonte, A.; Courel-Ibáñez, J.; Morán-Navarro, R.; González-Badillo, J.J.; Pallarés, J.G. Reliability of Technologies to Measure the Barbell Velocity: Implications for Monitoring Resistance Training. PLoS ONE 2020, 15, e0232465. [Google Scholar] [CrossRef]

- Montoro-Bombú, R.; Costa, A.; Sousa, P.M.; Pinheiro, V.; Forte, P.; Monteiro, L.; Ribeiro, A.S.; Rama, L. Reliability and Accuracy of Linear Position Transducers during the Bench Press and Back Squat: Implications for Velocity-Based Training. J. Funct. Morphol. Kinesiol. 2025, 10, 109. [Google Scholar] [CrossRef]

- Pérez-Castilla, A.; Feriche, B.; Jaric, S.; Padial, P.; García-Ramos, A. Validity of a Linear Velocity Transducer for Testing Maximum Vertical Jumps. J. Appl. Biomech. 2017, 33, 388–392. [Google Scholar] [CrossRef]

- Miller, R.M.; Freitas, E.D.S.; Heishman, A.D.; Koziol, K.J.; Galletti, B.A.R.; Kaur, J.; Bemben, M.G. Test-Retest Reliability Between Free Weight and Machine-Based Movement Velocities. J. Strength Cond. Res. 2020, 34, 440–444. [Google Scholar] [CrossRef]

- Cormie, P.; McBride, J.M.; McCaulley, G.O. Validation of Power Measurement Techniques in Dynamic Lower Body Resistance Exercises. J. Appl. Biomech. 2007, 23, 103–118. [Google Scholar] [CrossRef]

- Moreno-Villanueva, A.; Pino-Ortega, J.; Rico-González, M. Validity and Reliability of Linear Position Transducers and Linear Velocity Transducers: A Systematic Review. Sports Biomech. 2024, 23, 1340–1369. [Google Scholar] [CrossRef]

- Fernandes, J.F.T.; Lamb, K.L.; Clark, C.C.T.; Moran, J.; Drury, B.; Garcia-Ramos, A.; Twist, C. Comparison of the FitroDyne and GymAware Rotary Encoders for Quantifying Peak and Mean Velocity During Traditional Multijointed Exercises. J. Strength Cond. Res. 2021, 35, 1760–1765. [Google Scholar] [CrossRef]

- Kasovic, J.; Martin, B.; Carzoli, J.P.; Zourdos, M.C.; Fahs, C.A. Agreement Between the Iron Path App and a Linear Position Transducer for Measuring Average Concentric Velocity and Range of Motion of Barbell Exercises. J. Strength Cond. Res. 2021, 35, S95–S101. [Google Scholar] [CrossRef]

- Weakley, J.; Morrison, M.; García-Ramos, A.; Johnston, R.; James, L.; Cole, M.H. The Validity and Reliability of Commercially Available Resistance Training Monitoring Devices: A Systematic Review. Sports Med. 2021, 51, 443–502. [Google Scholar] [CrossRef]

- Spörri, J.; Schiefermüller, C.; Müller, E. Collecting Kinematic Data on a Ski Track with Optoelectronic Stereophotogrammetry: A Methodological Study Assessing the Feasibility of Bringing the Biomechanics Lab to the Field. PLoS ONE 2016, 11, e0161757. [Google Scholar] [CrossRef] [PubMed]

- Song, K.; Hullfish, T.J.; Scattone Silva, R.; Silbernagel, K.G.; Baxter, J.R. Markerless Motion Capture Estimates of Lower Extremity Kinematics and Kinetics are Comparable to Marker-Based across 8 Movements. J. Biomech. 2023, 157, 111751. [Google Scholar] [CrossRef] [PubMed]

- De Leva, P. Joint Center Longitudinal Positions Computed from a Selected Subset of Chandler’s Data. J. Biomech. 1996, 29, 1231–1233. [Google Scholar] [CrossRef] [PubMed]

- Wickham, H.; Averick, M.; Bryan, J.; Chang, W.; McGowan, L.; François, R.; Grolemund, G.; Hayes, A.; Henry, L.; Hester, J.; et al. Welcome to the Tidyverse. J. Open Source Softw. 2019, 4, 1686. [Google Scholar] [CrossRef]

- Koo, T.K.; Li, M.Y. A Guideline of Selecting and Reporting Intraclass Correlation Coefficients for Reliability Research. J. Chiropr. Med. 2016, 15, 155–163, Erratum in J. Chiropr. Med. 2017, 16, 346. [Google Scholar] [CrossRef]

- Parker, R.A.; Scott, C.; Inácio, V.; Stevens, N.T. Using Multiple Agreement Methods for Continuous Repeated Measures Data: A Tutorial for Practitioners. BMC Med. Res. Methodol. 2020, 20, 154. [Google Scholar] [CrossRef]

- Giavarina, D. Understanding Bland Altman Analysis. Biochem. Med. 2015, 25, 141–151. [Google Scholar] [CrossRef]

- Gerke, O. Nonparametric Limits of Agreement in Method Comparison Studies: A Simulation Study on Extreme Quantile Estimation. Int. J. Environ. Res. Public Health 2020, 17, 8330. [Google Scholar] [CrossRef]

- Kiatkulanusorn, S.; Luangpon, N.; Srijunto, W.; Watechagit, S.; Pitchayadejanant, K.; Kuharat, S.; Bég, O.A.; Suato, B.P. Analysis of the concurrent validity and reliability of five common clinical goniometric devices. Sci. Rep. 2023, 13, 20931. [Google Scholar] [CrossRef]

- Hancock, G.E.; Hepworth, T.; Wembridge, K. Accuracy and Reliability of Knee Goniometry Methods. J. Exp. Orthop. 2018, 5, 46. [Google Scholar] [CrossRef]

- Chapleau, J.; Canet, F.; Petit, Y.; Laflamme, G.Y.; Rouleau, D.M. Validity of Goniometric Elbow Measurements: Comparative Study with a Radiographic Method. Clin. Orthop. Relat. Res. 2011, 469, 3134–3140. [Google Scholar] [CrossRef]

| Markers | Positions | |

|---|---|---|

| Torso | C7 Vertebra | On the spinous process of the 7th cervical vertebra |

| T10 Vertebra | On the spinous process of the 10th thoracic vertebra | |

| Clavicle | On the jugular notch where the clavicles meet the sternum | |

| Sternum | On the xiphoid process of the sternum | |

| Right scapula | Anywhere over the right scapula (Not included in the Plug-in Gait model calculations. No equivalent on the left side. Asymmetry helps distinguish right from left during labeling) | |

| Upper limb | Shoulder (X2) | On the acromioclavicular joint |

| Upper arm (X2) | On the upper lateral 1/3 surface of the arm | |

| Lateral elbow (X2) | On the lateral epicondyle approximating the elbow joint axis | |

| Medial elbow (X2) | On the medial epicondyle approximating the elbow joint axis | |

| Forearm (X2) | On the lower lateral 1/3 surface of the forearm | |

| Lateral wrist (X2) | On the lateral side of the wrist (Thumbs) as close to the wrist joint center as possible. | |

| Medial wrist (X2) | On the medial side of the wrist (pinky finger), as close to the wrist joint center as possible. | |

| Finger (X2) | On the proximal portion of the first phalanges of the index finger | |

| Pelvis | Anterior (X2) | Anterior superior iliac spine |

| Posterior (X2) | Posterior superior iliac spine (immediately below the sacroiliac joints, where the spine joins the pelvis) |

| Variable | Error | |

|---|---|---|

| Measure of time (T) | ||

| Measure of distance (D) | ||

| Measure of mass (M) | ||

| Velocity computation (V) First differentiation | ||

| Acceleration computation (A) Second differentiation | ||

| Force computation (F) | ||

| Power computation (P) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lecocq, T.; Truchon, M.; Tordi, N.; Gouelle, A. From Straight Lines to Curved Paths: Validity and Reliability of Linear Position Transducers to Assess Linear and Angular Motion. Sensors 2025, 25, 5987. https://doi.org/10.3390/s25195987

Lecocq T, Truchon M, Tordi N, Gouelle A. From Straight Lines to Curved Paths: Validity and Reliability of Linear Position Transducers to Assess Linear and Angular Motion. Sensors. 2025; 25(19):5987. https://doi.org/10.3390/s25195987

Chicago/Turabian StyleLecocq, Tom, Maxime Truchon, Nicolas Tordi, and Arnaud Gouelle. 2025. "From Straight Lines to Curved Paths: Validity and Reliability of Linear Position Transducers to Assess Linear and Angular Motion" Sensors 25, no. 19: 5987. https://doi.org/10.3390/s25195987

APA StyleLecocq, T., Truchon, M., Tordi, N., & Gouelle, A. (2025). From Straight Lines to Curved Paths: Validity and Reliability of Linear Position Transducers to Assess Linear and Angular Motion. Sensors, 25(19), 5987. https://doi.org/10.3390/s25195987