Artificial Intelligence for Quality Defects in the Automotive Industry: A Systemic Review

Abstract

1. Introduction

2. Materials and Methods

3. Taxonomy

3.1. AI Taxonomy Based on Quality Management (QM)

3.1.1. AI Taxonomy Based on Quality Planning

3.1.2. AI Taxonomy Based on Quality Control

3.1.3. AI Taxonomy Based on Quality Assurance

3.1.4. AI Taxonomy Based on Quality Improvement

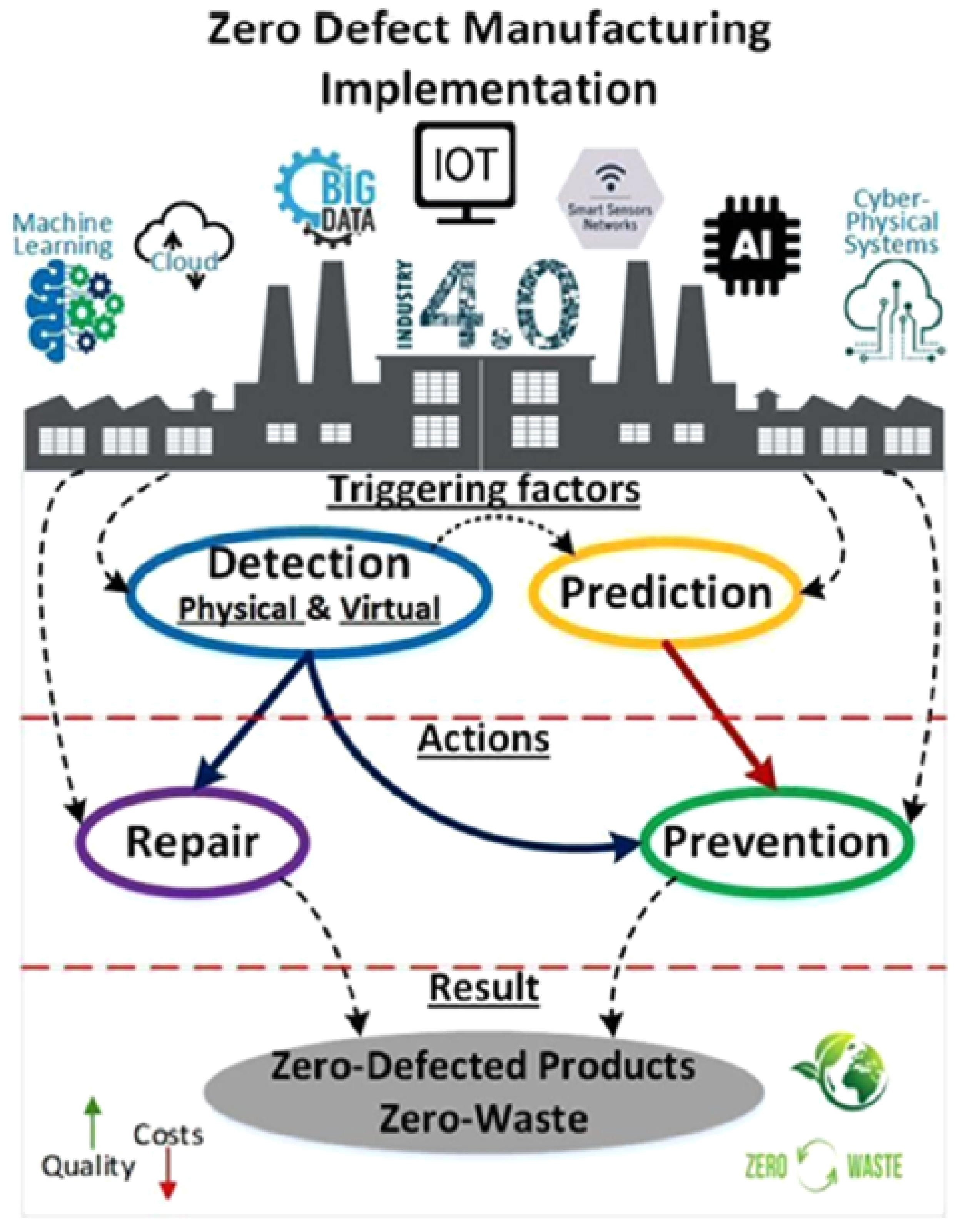

3.2. AI Taxonomy Following Zero-Defect Manufacturing (ZDM)

3.2.1. AI Techniques for Detection (Physical and Virtual) Level

- The first document is “Toward Zero-Defect Manufacturing with the support of Artificial Intelligence—Insights from an industrial application” [23]. Its purpose is to implement artificial intelligence (AI) in an industrial application to achieve zero-defect manufacturing (ZDM). The article explains that AI can be used as an enabler of ZDM, to support quality management and complex quality issues. Poor data quality and incorrect classification of approved products complicated the modeling and reduced its precision. The preparation time to establish a ZDM-focused architecture was identified as an important obstacle to implementing the ZDM model. Data science initiatives should be initiated immediately to confirm the accuracy of the data, the results of which should be used to continuously improve the application.

- The subsequent document is an approach based on artificial intelligence of things for the detection of anomalies in rotating machines [24]. The framework developed, based on artificial intelligence of things (AIoT), is validated on three rotating machines. The results confirm the strength of the proposed procedure and its capability for remote real-time monitoring and control of the machines. Integrating AI with IoT is highly positive for timely follow-up, deliberation, and preventive maintenance of rotating machines. Four classification models were tested, and good results were achieved for three rotating machines with 100% accuracy.

- The following study of this category is “Numerical simulation of gears for fault detection using artificial intelligence models” [25]. The article presents a method for activating AI models by constructing a model of grouped parameters in gears. Samples are generated by inserting types of failures into the model. A sample matrix is used for AI training and the classification is selected to classify failure samples. Parameters such as gear stiffness and damping are adjusted to improve classification accuracy, which ranges from 80% to 100%. It is demonstrated that AI trained with simulation data can classify measured data, compensating for the lack of real data. The proposed method overcomes the issue of inaccurate classification due to insufficient training data, showing its effectiveness in fault detection in gear systems.

- The next investigation is “Development and comparative evaluation of various fault detection algorithms for a drum brake using artificial neural networks and a physics-based model” [26]. The study presents an AI-based fault detection framework and a system failure model to identify the most common faults in automobile drum brakes. In summary, the study presents effective methods for detecting drum brake faults using AI, with promising results in terms of accuracy and robustness.

- We also included the paper “Predicting Operators Fatigue in a Human in the AI Loop for Defect Detection in Manufacturing” [27]. It studied how defect inspection can be improved using machine learning models to identify and predict operator fatigue. The results were conceptual approaches for integrating operators into AI-based inspection and a fatigue monitoring system to improve working conditions. Based on experiments with defect labeling data, most of the labeling quality decreased over time, which is linked to increased operator fatigue.

- The subsequent study is “Semi-supervised learning for industrial fault detection and diagnosis: A systemic review” [28]. The article addresses automation of fault detection and diagnosis (FDD) through machine learning (ML) methods. A comprehensive review of the literature on semi-supervised learning (SSL) for FDD is conducted, noting difficulties in comparing results due to variations in experiments and implementations. The review highlights key journals and methods used, with an emphasis on intrinsically semi-supervised methods. The article concludes by highlighting the importance of future research to demonstrate the unique advantages of SSL in industrial data.

- We add the investigation “A bi-level data-driven framework for fault-detection and diagnosis of HVAC systems” [29]. The article addresses the application of machine learning methods for fault analysis in HVAC (heating, ventilation, and air conditioning) systems, highlighting their high accuracy in detection. A novel data-based framework is proposed to improve diagnostic procedures. This framework consists of a two-level machine learning model that uses principal component analysis (PCA) to reduce the dimensionality of the dataset. A correlation analysis is conducted to identify the most influential variables. The proposed model successfully identified eight types of issues, using PCA to reduce the dimensionality of the data set and the RF algorithm to improve the detection accuracy.

- We also include the article “Application of sensing techniques and AI-based methods to laser welding real-time monitoring: A critical review of the recent literature” [30]. The article reviews research from the past 10 years on real-time monitoring of laser welding, focusing on detection techniques and advanced technologies based on AI. Techniques such as PCA for data processing and seam tracking with CCD cameras (charge-coupled devices) for analyzing seam characteristics in real time are mentioned. The potential of AI, especially deep learning, for processing and analyzing data in welding monitoring is highlighted. The conclusion emphasizes the importance of developing intelligent quality assessment systems as an interesting and challenging field in this area.

- The investigation “Real-time arc-welding defect detection and classification with principal component analysis and artificial neural networks” [31] presents an innovative system for the automatic detection and classification of arc welds. It proposes the combined use of principal components analysis (PCA) and artificial neural networks (ANN) for this purpose. The ANN enables automatic detection of welding defects. Once properly trained, the ANN can discriminate between different welding defects, such as lack of penetration or reduced gas flow. Ultimately, the combined application of PCA and ANN offers an effective solution for the automatic detection and classification of defects in arc welds.

- The next article is “Quantitative detection of defects based on Markov–PCA–BP algorithm using pulsed infrared thermography technology” [32], in which a Markov-PCA-BP algorithm with a predictive system was developed, combining PCA with neural network theory. A network model was used to forecast the depth and diameter of the defects. The depth and diameter of the defect were correctly identified by the Markov-PCA-BP system. The proposed method was effective, considering that the prediction fault for diameter and depth was approximately 4% to 10%.

- Next, we included the document “Study on PCA-SAFT imaging using leaky Rayleigh waves” [33]. This article highlights the rebuilding of high-quality images of internal or surface issues through a picture identification method that combines Rayleigh wave testing and the synthetic aperture focusing technique (SAFT). The findings reveal that the PCA-SAFT image model can decrease mechanical vibrations and image artifacts. Lateral resolution of defects is optimized, and the average defect sizing error is reduced by 48.81%. Correlation studies demonstrate that as the spread distance increases, the acoustic energy of the wave surface is reduced. The PCA algorithm can efficiently reduce system noise in Rayleigh waves with leaks.

- The next document is “Early and extremely early multilabel fault diagnosis in induction motors” [34], which presents an intelligent multifault diagnosis method to evaluate various fault conditions in induction motors. Using PCA and decision trees, it enables accurate diagnostics. The results show that the method is effective with complete data and capable of handling data from motors operating at different frequencies and detecting faults with precision. The combination of PCA and decision trees facilitates the identification of simultaneous faults. In summary, this intelligent fault diagnosis method is proven to be effective, robust, and capable of detecting early faults with high performance in induction motor systems.

- Afterwards, we considered the paper “Hydrogen leakage fault classification diagnosis based on data driven in the hydrogen supply system of fuel cell trucks” [35]. The article presents a diagnostic method for classifying hydrogen leaks on the basis of data, using a K-means algorithm. PCA is used to reduce the dimensionality of the information, and SVM (support vector machine) is carried out for diagnosis. Hydrogen leaks are simulated using a fuel cell truck model, generating 1200 failure scenarios that are classified into three levels. PCA-SVM is used to improve diagnostic accuracy, achieving 91.2%, 91.2%, and 90.3% accuracy. The SSA-PCA-SVM (sparrow search algorithm) method shows higher diagnostic accuracy compared to standard SVM and PCA-SVM. The results also indicate relationships between hydrogen leak mass, ambient temperature, and pressure.

- The next study is “Fault detection and classification in kinematic chains by means of PCA extraction-reduction of features from thermographic images” [36]. This work presents a methodology for correctly identifying and categorizing a broad range of defective conditions in kinematic chains. It focuses on developing non-invasive methods to diagnose these fault conditions. The reduction of the matrix by PCA enables a three-dimensional representation that facilitates the visualization of defective conditions. The suggested plan is confirmed with an organizer based on ANN, achieving an accuracy of 96.8%. The extraction and reduction of statistical features through PCA allows for clear detection and visualization of fault conditions.

- The article “Fuel cell diagnosis methods for embedded automotive applications” [37] focuses on the importance of ensuring the durability of fuel cells in the industrialization of technologies. The methods for each stage are detailed, including the use of temperature and pressure sensors, as well as dimension reduction algorithms such as PCA. Classifiers, divided into supervised, unsupervised, and mixed categories, are crucial for determining whether samples indicate a defective state. Three main steps are outlined for the implementation of a diagnostic algorithm in vehicles, from creating a prototype to validating it on a test bench.

- The research “Path Planning Optimization for Driverless Vehicle in Parallel Parking Integrating Radial Basis Function Neural Network” [38] describes a novel method for optimizing parallel parking paths for autonomous vehicles using a radial basis function neural network (RBFNN) to train Bézier curve control points. The method is validated through MATLAB (R2021a) simulations and experiments using a smart mini-car with an ultrasonic sensor. The results indicate that the optimized Bézier route meets the requirements for continuity of curvature, safety, and constraint, improving parking capabilities in tight spaces. The trained RBFNN provides accurate control points for the Bézier curve, resulting in a path with gradual curvature changes that ease steering adjustments and enhance safety. The study demonstrates that the proposed method offers better curvature continuity and optimization efficiency compared to traditional paths.

- The next article is “Data-driven monitoring and validation of experiments on automotive engine test beds” [39]. The article focuses on the implementation of data-based issue analysis procedures to identify variations and determine root causes with the aim of reducing costs and design time. A fault isolation technique using Fisher discriminant analysis (FDA) and contribution plot (CP) is proposed. The application of these techniques is demonstrated with results for detecting a fault in a pressure sensor. In summary, the study explores the application of data-based fault diagnosis methods, highlighting the effectiveness of the multi-modal dynamic approach and the usefulness of contribution analysis in identifying root causes.

- The next paper is “Application of Hidden Markov Models for Fault Detection in Automotive Engines” [40], which proposes the use of Markov models to enhance the engine design process, with the aim of reducing costs and time. During development, clear fault detection is achieved after 600 samples, with a 4.33% false alarm rate and a 24.83% missed detection rate. The study points out that traditional statistical approaches are not suitable for complex systems like engines, which is why the hidden Markov model is adopted for fault detection. The application of this model in an engine test bench demonstrates its effectiveness in fault detection.

- The next study is “Recent Progress and Prospective Evaluation of Fault Diagnosis Strategies for Electrified Drive Powertrains: A comprehensive review” [41], which describes a systematic review of failure types and diagnostic techniques for electrified drive powertrain systems (EPDS). It addresses different failures, along with their corresponding diagnostic methods. The need to develop new methods to address unknown failures and enhance the integration of new failure modes is emphasized, underscoring the potential of artificial intelligence and big data analysis to identify early signs of failures and improve the safety and reliability of EPDS.

- The last publication is “Fault diagnostics in air intake system of combustion engine using virtual sensors” [42]. This article presents a method for diagnosing faults in a gasoline engine’s air intake system that are not detected by onboard diagnostic systems. The method involves generating residuals by comparing real sensor readings (MAP and MAF) with virtual sensor outputs based on models. This technique was tested in conventional port fuel injection (PFI) and gasoline direct injection (GDI) engines. Residuals were used to detect these faults, revealing that some issues were not captured by onboard diagnostics. Future research will involve developing a hybrid engine model and creating virtual sensors based on transient states.

3.2.2. AI Techniques for the Prediction Level

- The first study is “How can artificial intelligence enhance car manufacturing? A Delphi study-based identification and assessment of general use cases” [43]. It highlights the enormous potential of AI to reduce operational costs in automobile manufacturing and describes general use cases of AI application in this sector. It points out the lack of a comprehensive overview on the use of AI in automobile manufacturing, with most articles focusing on details of specific use cases. The availability and quality of data are identified as important factors in the application of AI in the automotive industry, and it is acknowledged that the Delphi method has limitations in producing quantitative results that meet scientific requirements.

- The next article is “Online quality inspection of ultrasonic composite welding by combining AI technologies with welding process signatures” [44]. The study proposes an AI method for quality inspection in composite welding. Using artificial neural networks (ANN) and random forest (RF) models, the method predicts the failure load and the quality of the weld. The results show high levels of accuracy for both models, with an average relative error of 7.1% for ANN and 99% accuracy for RF. It is suggested that the ANN model could further improve accuracy, as well as AI’s ability to explore new functions and establish correlations between inputs and outputs.

- The next publication of this classification is “AI-based decision model for a quality-oriented production ramp-up” [45]. The work presents an AI-based decision model designed to configure process parameters and improve production quality using a digital shadow. The results provide tools to enhance quality by employing neural networks trained with Bayesian regularization and solving minimization problems using the SQP (sequential quadratic programming) algorithm. The quality of the regression is evaluated, and the production increases are simulated to assess the performance of the adaptive model. In conclusion, an AI-based adaptive decision model is developed that improves process quality and can simulate physical manufacturing processes.

- The next article is “Strength and manufacturability enhancement of a composite automotive component via an integrated finite element/artificial neural network multi-objective optimization approach” [8]. This paper addresses the upgrade of a hybrid automotive structure molded by injection, using plastic over the combination of finite element method, AI, and evolutionary investigation methods. The procedure demonstrated a reduction in product deformation and manufacturing time by 10% and 62%, respectively.

- The next journal article is “Intelligent systems in the automotive industry: applications and trends” [46]. This article explores the extensive use of AI, technology, and intelligent systems in the automotive industry in manufacturing, diagnostics, onboard systems, warranty analysis, and design. It highlights the integration of computational intelligence methodologies, including fuzzy logic, neural networks, and machine learning, into various automotive processes. The article also discusses the potential of AI in improving corporate knowledge management and reducing warranty costs through data mining. In addition, it identifies opportunities to apply advanced technologies in different functional areas of the automotive industry, with the aim of enhancing customer satisfaction and product quality.

- The next research report for this category is “Application of artificial intelligence technology in the manufacturing process and purchasing and supply management” [47]. The text highlights the growing role of AI and big data in transforming supply chains and manufacturing, focusing on how these technologies are driving concepts such as smart factories and manufacturing. The ability of AI to identify defects and issues more quickly and accurately, thereby optimizing processes, is emphasized. In summary, AI is being successfully applied in various aspects of manufacturing and supply chain management, offering significant benefits in terms of quality, efficiency, and resource management.

- The next investigation is “Predictive maintenance enabled by machine learning: Use cases and challenges in the automotive industry” [48]. In the automotive sector, ensuring functional safety while maintaining maintenance costs has become a challenge. A way to accomplish this is through predictive maintenance (PdM). Machine learning (ML) is potentially a PdM tool, delivering cost savings and better prediction capabilities. Among the auto parts studied in the article, the drivetrain emerged as a key user of PdM.

- Afterwards, we considered the research called “A parallel strategy for predicting the quality of welded joints in automotive bodies based on machine learning” [49]. This research proposes a procedure to estimate the quality of weld points using ML. PCA was also used to determine the quantity of main elements to decrease the dimensionality of the data set and ease the classification of the subsets of data. There is a strong correlation between the variables; they are autonomous and can be reviewed by the PCA algorithm.

- We considered the text “Systematic review on machine learning methods for manufacturing processes–Identifying artificial intelligence methods for field application” [50]. The study provides a systematic review of the applications of ML in several factory environments. In production process planning, Q-learning is used to manage large volumes of data in Internet of things environments. For quality control, decision trees and convolutional neural networks (CNNs) are used for defect classification. In predictive maintenance, both supervised and unsupervised methods are combined for fault detection and estimation of industrial equipment lifespan. In summary, the study highlights the broad spectrum of ML applications in plant processes and emphasizes the importance of its integration to improve efficiency and quality in manufacturing.

- We also found the study “Speech Recognition Using Deep Neural Networks: A Systematic Review” [51]. In recent decades, extensive research has been conducted related to the use of machine learning in speech processing applications, specifically speech recognition. Recently, the focus has shifted towards utilizing deep learning for these applications, yielding significantly better results. This paper reviews studies on the use of deep learning in speech processing, analyzing 174 publications from 2006 to 2018. Most of these works focus on speech recognition, with 79% of the studies concentrated in this area. The study suggests exploring new feature extraction methods and using hybrid models and recurrent neural networks (RNNs) in future research, as they offer great potential in speech recognition.

- In the publication “Optimal feature selection on Serial Cascaded deep learning for predictive maintenance system in automotive industry with fused optimization algorithm” [52], some data-driven predictive maintenance techniques were selected. To prevent production manufacturing shutdown, it is key to implement an efficient predictive maintenance model. Those parameters that were specified are subjected to hybrid deep learning based on Python (v. 3.8) to predict the occurrence of defects. This system´s precision and accuracy outperform other approaches.

- The article “Deep Learning based Predictive Testing Strategy in the Automotive Industry” [53] explains an abstract structure following deep neural networks to forecast the result of a quality control test using automobile arrangement and data processing. By applying the testing framework, the efficiency can be increased by 15%. The indications of a great method are that it achieves a comparatively high NPR (negative prediction rate) while maintaining the FOR (false emission rate) at a minimum value.

- The research “Adaptive-neural-network-based robust lateral motion control for autonomous vehicle at driving limits” [54] introduces a new lateral motion control method designed to enhance the stability and tracking accuracy of the trajectory of autonomous vehicles under challenging driving conditions. The proposed control system integrates a strong steering controller with an adaptive neural network (ANN) approximator. The robust steering controller aims to suppress lateral deviation, handle external disturbances, and maintain vehicle stability. The method was tested through simulations and real-world experiments, showing that it effectively maintains vehicle stability and improves trajectory tracking performance compared to traditional methods. The control scheme demonstrated superior robustness against unknown disturbances, with significant improvements in dynamic performance and trajectory tracking accuracy.

- Then, we looked at “Optimization of green sand process for quality improvement in castings by using combination of Taguchi Techniques-GRA-PCA” [55]. Here, components produced through sand casting have many quality features. The perspective of the publication is based on optimizing the key process specifications to reduce the presence of issues, applying Taguchi’s design of experiments (DoE) combined with gray relational analysis (GRA) and principal component analysis (PCA). According to variance analysis, the main process parameter that affects the result is the carbon equivalent (CE), with a contribution of approximately 86%.

- The following paper is “Life prediction of copper wire bonds in commercial devices using principal component analysis” [56], which develops a data-driven predictive model using PCA to estimate the failure time of cable joints for plastic components, which is necessary to predict the reliability of the system or module. PCA is used to detect trends and affinities within a big list of features affecting a component, reducing the number of parameters from 14 to 9. In this method, the higher the volume of data, the higher the precision that can be expected.

- The investigation “Prediction of Thermal Aspects for Brass Material-Based Natural Convection Heat Transfer System by Using Adaptive Neuro-fuzzy Inference System” [57] presents an adaptive neuro-fuzzy inference system (ANFIS) model created to forecast the performance of a natural thermal transfer system. The ANFIS approach effectively simulates how variations in input parameters such as current and voltage affect temperature responses at different locations in the system. Comparison with experimental data shows that the ANFIS model accurately predicts temperatures, especially at lower temperature points, such as the fourth sensor location.

3.2.3. AI Techniques for the Repair Level

- The first publication is “Component design optimization based on artificial intelligence in support of additive manufacturing repair and restoration: Status and future outlook for remanufacturing” [58]. The study addresses automating repair and restoration in the context of the increasing popularity of metal additive manufacturing (AM), which is still considered limited. It provides a comprehensive overview of the application of AI to optimize repair design through additive manufacturing. The study emphasizes the need to develop a systematic approach to optimize the design of components that facilitates repair through AM from the early stages of the design.

- The next publication of this classification is “Digital Management Systems in Manufacturing Using Industry 5.0 Technologies” [59], in which the industrial revolutions up to Industry 5.0 are discussed. The first four industrial revolutions introduced significant technological advancements. Industry 5.0 is emerging as a new era in which humans and machines will work collaboratively, using technologies such as cobots, digital twins, exoskeletons, smart materials, advanced AI, and IoT. This revolution aims to improve efficiency, customization, and environmental sustainability in manufacturing. Industry 5.0 emphasizes human–machine collaboration and the integration of advanced technologies to improve manufacturing processes and reduce environmental impacts.

- The subsequent article is “Artificial Intelligence and Advanced Materials in Automotive Industry: Potential applications and perspectives” [7]. A literature review of AI applications in the automotive sector is provided. It offers solutions to make automotive design, manufacturing, aftersales, and the vehicle itself more intelligent. The techniques explained make vehicles smarter, safer, and more reliable. In addition, it seeks to automate processes, reduce manual labor, improve efficiency, and eliminate repetitive tasks. AI is highly versatile and has numerous applications in the automotive sector.

3.2.4. AI Techniques for the Prevention Level

- The article considered within this category is called “Hierarchical decision making for proactive quality control: system development for defect reduction in automotive coating operations” [60]. This article describes that automotive coating is an example of product quality control that needs the combination of quality prediction and inspection. Furthermore, it shares a novel approach to a quality control method to handle complex issues in manufacturing systems. A case study is developed for the quality control of a vehicle topcoat application that implemented an intelligent decision-making system. This model can evaluate the execution of the process and helps prevent defects at several phases of the coating application. The effectiveness of this method relies on a tool named DRACO (Defect Reduction in Automotive Coating Operations). In conclusion, the authors share that the described methodology has relevance in many manufacturing applications.

3.2.5. Others

- The initial paper is “An Artificial-Intelligence-Based Method to Automatically Create Interpretable Models from Data Targeting Embedded Control Applications” [61]. The study presents an automated approach to model creation, simplifying engineering in control and calibration functions. Various potential implementations of the system are mentioned, such as method development, system recognition, organizational enhancement, and model decline. The feasibility of the method is demonstrated with two examples, highlighting its efficiency in achieving accurate results with fewer calibration parameters. Additional potential applications of the method are mentioned, including model compression, runtime optimization, system identification, and data analysis.

- The next document is “Artificial Intelligence (AI) and Its Applications in Indian Manufacturing: A Review” [62]. This text addresses the adoption of AI in the manufacturing industry, within the context of India. It highlights how AI is revolutionizing the industry through automation and intelligent robots, especially within the framework of Industry 4.0. In India, the manufacturing sector is controlled by small and medium enterprises (SMEs), which have difficulties in adopting advanced technologies such as AI due to lack of adequate infrastructure and specific government policies. In addition, the text addresses other topics, such as unemployment and its contributors, such as lack of relevant skills and preference for traditional manufacturing methods. The text also emphasizes the need to update the educational system so that the benefits of new technologies can be widely accessible.

- The study “Comparison of FDA-based and PCA-based features in fault diagnosis of automobile gearboxes” [63] presents a method to assess a multi-speed automotive gearbox. In the mentioned document, the gears analyzed are positioned on the main shaft, which is backed by a tachometer sensor. Fisher discriminant analysis (FDA) was applied to address a dimensionality issue. Failure analysis was compared with PCA, and it was found that the FDA-based diagnostic method has higher accuracy and lower monitoring costs. The failures studied were classified into three categories: problems in gear 2, problems in gear 3, and combined problems. Compared to PCA, FDA provides more acceptable results in classifying single or more complex gear failure conditions, improving average recognition by approximately 14%.

- The subsequent document is “Multi-criteria decision making with PCA in EDM of A2 tool steel” [64]. The effect of the process parameters lp (current), Ton (on-time), Tau (duty cycle), and V (discharge voltage) was studied using a complete factorial design methodology in the Electro Design Machine (EDM) for A2 steel, and significant effects on the selected responses MRR (material removal rate) and EWR (electrode wear rate) were considered from both qualitative (main effect plots) and quantitative (ANOVA) perspectives. The ANOVA results indicated that lp and Ton are the main process parameters. PCA was performed to find the balance between the MRR and EWR responses. Furthermore, it was found that Lp is directly aligned to MRR and EWR and has the highest input to the MRR, while Ton has the main impact on the EWR.

- The following journal article is “Compact Base Station Antenna Based on Image Theory for UWB/5G RTLS Embraced Smart Parking of Driverless Cars” [65]. This paper introduces a compact base station antenna designed for real-time location systems (RTLS) using ultra-wideband (UWB) and 5G technologies, aimed at enhancing smart parking solutions for autonomous vehicles. The design improves the precision of RTLS systems for autonomous vehicle parking by maintaining stable radiation patterns throughout the frequency range. Future work will involve real-world tests with autonomous vehicles.

- The next publication is “Hierarchical k-nearest neighbors classification and binary differential evolution for fault diagnostics of automotive bearings operating under variable conditions” [66]. This work focuses on developing a diagnostic system to detect early degradation, isolate faulty bearings, and classify the types of defects. This framework is developed according to a layered organization of K-nearest neighbors (KNN) classifiers. The overall performance of the model has been validated with validation data, demonstrating a correct classification rate of 79.78%. The C2 classifier is identified to have the least satisfactory performance, attributed to different ways of inducing defects. It is concluded that the deployment and validation of the proposed approach requires further testing that reproduces bearing degradation in automobiles.

3.3. AI Taxonomy Based on the Perceived Quality Framework (PQF)

3.3.1. AI Taxonomy Based on Visual Quality

- We found a document called “An Artificial Intelligence Platform Proposal for Paint Structure Quality Prediction within the Industry 4.0 Concept”. In this journal article, an artificial intelligence (AI) framework is proposed to create a quality forecast using big data. Car painting activities are complex. They require a large quantity of data, and the process is heterogeneous. The developed AI platform confirms the accuracy and validity of the initial phases. This works integrates an architecture to collect data with the big data solution, an analysis based on principal component analysis to reduce dimensionality. The quality of the painting process is assessed using specific spectrometers and measuring features. The proposed solution to the AI platform checks the availability of operating the neural network to foresee the quality of the procedure configurations [68].

- The next manuscript is called “A Case Study on First Time Quality Feature Investigation for an Automotive Paint Shop”. Considering automated vehicle body shops, manufacturing devices are typically implemented to coat automotive bodies in white. During the painting process, data is tracked, collected from sensors that control the painting in a consolidated process called the painted surface performance management (PSPM) method.In this research, machine learning (ML) approaches choose the main characteristics that could affect the result of the painting process, which needs further validation and research. The chosen configurations are used to set first time quality (FTQ) targets to forecast FTQ results. The study combined additional information to understand the relationship between the characteristics of machine learning and FTQ. ML was found to be a helpful tool for identifying the main characteristics that impact the target variables [69].

- The next investigation is “A perspective on the artificial intelligence’s transformative role in advancing diffractive optics”. AI methods such as machine learning and generative models enable the analysis of vast data sets to improve the accuracy of diffractive optical elements (DOEs), which are designed for certain tasks and requirements. The use of artificial intelligence approaches triggers the development of optical structures that handle light with high accuracy. In addition, AI improves production processes that result in better quality and productivity. In addition, AI methods speed up design iterations and prototyping. This consolidation of AI into several optics enables a great opportunity to change the functions of optical technology among different industries [70].

3.3.2. AI Taxonomy Based on Tactile Quality

- The next document is “Minimization of defects generation in laser welding process of steel alloy for automotive application” [71]. The text describes machine learning (ML) implementation to reduce and predict issue generation in laser welding processes for automotive uses. The result was a predictive quality control model with a prediction capacity precision of 61.4%. The principal results in terms of probability were that the generation of a welding depth defect is irrelevant, the probability of causing an internal problem is 15%, and, within optimized conditions, the probability of defects coming from false negative prediction is 15%.

- The next research is “Recent advances in artificial intelligence boosting materials design for electrochemical energy storage”. In the context of electrochemical energy storage (EES), artificial intelligence has a key role in innovation as the lead designer and inventor of batteries, fuel cells, and other materials. This study reviews machine learning tools in the developments of materials science, focusing on energy retention of battery technologies and fuel cell performance. In this paper, a comprehensive review is shared on AIs that have improved the study of advanced materials for EES, and therefore offer opportunities to discover new frameworks in materials science. Machine learning and deep learning can analyze high-volume data sets to identify trends and relationships. Furthermore, AI can improve synthesis and processing features, increasing the efficiency of the material development cycle. We found that the quality of the data is key and has an effect on the results of the models [72].

3.3.3. AI Taxonomy Based on Auditory Quality

- The initial article of this category is “Faulty voice diagnosis of automotive gearbox based on acoustic feature extraction and classification technique” [73]. The paper addresses the establishment of a systemic approach to diagnosing defects in automobile gearboxes through the analysis of defective sounds and ML techniques. The stages of continuous learning algorithms are described, including feature extraction, selection, and categorization. Five classification algorithms are used to model the gearbox fault diagnosis problem as an ML challenge. The main objective is to extract useful information from the sound signals to detect any issues in the gearbox component.

- The second article is “Auditory experience in vehicles: A systematic review and future research directions”. The purpose of this article is to investigate manuscripts on auditory experiences within a vehicle context and to share opinions about future opportunities to investigate this topic. The information collected was categorized according to the type of engine, and a contrastive analysis of the investigation tendency followed. The study demonstrated the existence of research topics in internal combustion vehicle (ICVs) not addressed in electric vehicles (EVs) and other growing research topics in the EV sector. Auditory sensations in vehicles are one of the elements of emerging driving experiences that can significantly improve customer satisfaction. As automated driving technology increases steadily, the continuous interconnection between people and vehicles is estimated to increase; therefore, investigation of auditory customer interfaces is the key to improving the quality of the driving experience [74].

3.3.4. AI Taxonomy Based on Olfactory Quality

- The first article of this subcategory is “Self-validating sensor technology and its application in artificial olfaction: A review”. A sensor is equipment that detects changes in concrete quantities and transforms them into electrical energy. Automated detection equipment depends on precise and correct sensor measurements. The trustworthiness and maintainability of the system can be improved with an intelligent functional structure to track sensor status delivered by self-validating sensor technology. The consistency and robustness of gas chemical sensors for artificial olfaction have limited the mass production of the electronic nose system. In this paper, self-validating sensor technology applications were systematically reviewed, with briefings on the deployment procedures, demonstrating its capability in artificial olfaction [75].

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- World Economic Forum. The Future of Autonomous and Urban Mobility, n.d. Available online: https://www.weforum.org/communities/the-future-of-autonomous-and-urban-mobility/ (accessed on 15 May 2024).

- The Logistics World. Características de la Industria Automotriz: Un Sector en Evolución Constante, n.d. Available online: https://thelogisticsworld.com/manufactura/caracteristicas-de-la-industria-automotriz-un-sector-en-evolucion-constante/ (accessed on 10 June 2024).

- Fernando, Y.; Tseng, M.L.; Sroufe, R.; Abideen, A.Z.; Shaharudin, M.S.; Jose, R. Eco-innovation impacts on recycled product performance and competitiveness: Malaysian automotive industry. Sustain. Prod. Consum. 2021, 28, 1677–1686. [Google Scholar] [CrossRef]

- Hwang, Y.K.; Venter, A. The impact of the digital economy and institutional quality in promoting low-carbon energy transition. Renew. Energy 2024, 238, 121884. [Google Scholar] [CrossRef]

- Josephinshermila, P.; Malarvizhi, K.; Pran, S.G.; Veerasamy, B. Accident detection using automotive smart black-box based monitoring system. Meas. Sensors 2023, 27, 100721. [Google Scholar] [CrossRef]

- Fan, J.; Meng, X.; Tian, J.; Xing, C.; Wang, C.; Wood, J. A review of transportation carbon emissions research using bibliometric analyses. J. Traffic Transp. Eng. (Engl. Ed.) 2023, 10, 878–899. [Google Scholar] [CrossRef]

- Kamran, S.S.; Haleem, A.; Bahl, S.; Javaid, M.; Prakash, C.; Budhhi, D. Artificial intelligence and advanced materials in automotive industry: Potential applications and perspectives. Mater. Today Proc. 2022, 62, 4207–4214. [Google Scholar] [CrossRef]

- Fonseca, J.H.; Jang, W.; Han, D.; Kim, N.; Lee, H. Strength and manufacturability enhancement of a composite automotive component via an integrated finite element/artificial neural network multi-objective optimization approach. Compos. Struct. 2024, 327, 117694. [Google Scholar] [CrossRef]

- ISO 9000:2015; Quality Management Systems—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2015. Available online: https://www.iso.org/standard/45481.html (accessed on 23 January 2025).

- Psarommatis, F.; Azamfirei, V. Zero Defect Manufacturing: A complete guide for advanced and sustainable quality management. J. Manuf. Syst. 2024, 77, 764–779. [Google Scholar] [CrossRef]

- Hörbe, R.; Erol, S. Artificial Intelligence in planning and control tasks: A study of potential use cases and perceived challenges in Austrian make-to-order companies. Procedia CIRP 2024, 130, 232–237. [Google Scholar] [CrossRef]

- İfraz, M.; Aktepe, A.; Ersöz, S.; Çetinyokuş, T. Demand forecasting of spare parts with regression and machine learning methods: Application in a bus fleet. J. Eng. Res. 2023, 11, 100057. [Google Scholar] [CrossRef]

- Mayr, A.; Weigelt, M.; Masuch, M.; Meiners, M.; Hüttel, F.; Franke, J. Application scenarios of artificial intelligence in electric drives production. Procedia Manuf. 2018, 24, 40–47. [Google Scholar] [CrossRef]

- Saadallah, A.; Abdulaaty, O.; Büscher, J.; Panusch, T.; Morik, K.; Deuse, J. Early quality prediction using deep learning on time series sensor data. Procedia CIRP 2022, 107, 611–616. [Google Scholar] [CrossRef]

- Büscher, J.; Zajackowski, J.; Rademacher, H.G.; Tillmann, W.; Deuse, J. Trustworthiness of Artificial Intelligence Applications for Quality Optimisation in Metal Additive Manufacturing. Procedia CIRP 2024, 122, 497–502. [Google Scholar] [CrossRef]

- Saadallah, A.; Büscher, J.; Abdulaaty, O.; Panusch, T.; Deuse, J.; Morik, K. Explainable predictive quality inspection using deep learning in electronics manufacturing. Procedia CIRP 2022, 107, 594–599. [Google Scholar] [CrossRef]

- Schmitt, J.; Bönig, J.; Borggräfe, T.; Beitinger, G.; Deuse, J. Predictive model-based quality inspection using Machine Learning and Edge Cloud Computing. Adv. Eng. Inform. 2020, 45, 101101. [Google Scholar] [CrossRef]

- Gao, R.X.; Krüger, J.; Merklein, M.; Möhring, H.C.; Váncza, J. Artificial Intelligence in manufacturing: State of the art, perspectives, and future directions. CIRP Ann. 2024, 73, 723–749. [Google Scholar] [CrossRef]

- Cavaliere, G.; Borgianni, Y.; Savio, E. Performances of an in-line deep learning-based inspection system for surface defects of die-cast components for hybrid vehicles. Procedia CIRP 2024, 126, 999–1004. [Google Scholar] [CrossRef]

- Moreira, L.C.; Li, W.; Lu, X.; Fitzpatrick, M.E. Supervision controller for real-time surface quality assurance in CNC machining using artificial intelligence. Comput. Ind. Eng. 2019, 127, 158–168. [Google Scholar] [CrossRef]

- Molina, L.M.; Teti, R.; Alvir, E.M.R. Quality, efficiency and sustainability improvement in machining processes using artificial intelligence. Procedia CIRP 2023, 118, 501–506. [Google Scholar] [CrossRef]

- Singh, J.; Ahuja, I.; Singh, H.; Singh, A. Development and implementation of Autonomous Quality Management System (AQMS) in an automotive manufacturing using Quality 4.0 concept—A case study. Comput. Ind. Eng. 2022, 168, 108121. [Google Scholar] [CrossRef]

- Leberruyer, N.; Bruch, J.; Ahlskog, M.; Afshar, S. Toward Zero Defect Manufacturing with the support of Artificial Intelligence—Insights from an industrial application. Comput. Ind. 2023, 147, 103877. [Google Scholar] [CrossRef]

- Mian, T.; Choudhary, A.; Fatima, S.; Panigrahi, B.K. Artificial intelligence of things based approach for anomaly detection in rotating machines. Comput. Electr. Eng. 2023, 109, 108760. [Google Scholar] [CrossRef]

- Wang, H.; Yang, R.; Xiang, J. Numerical simulation of gears for fault detection using artificial intelligence models. Measurement 2022, 203, 111898. [Google Scholar] [CrossRef]

- Yella, A.; Chaudhary, A.; Sundar, S. Development and comparative evaluation of various fault detection algorithms for a drum brake using artificial neural networks and a physics-based model. Eng. Appl. Artif. Intell. 2023, 124, 106565. [Google Scholar] [CrossRef]

- Rožanec, J.M.; Križnar, K.; Montini, E.; Cutrona, V.; Koehorst, E.; Fortuna, B.; Mladenić, D.; Emmanouilidis, C. Predicting operators’ fatigue in a human in the artificial intelligence loop for defect detection in manufacturing. IFAC-PapersOnLine 2023, 56, 7609–7614. [Google Scholar] [CrossRef]

- Ramírez-Sanz, J.M.; Maestro-Prieto, J.A.; Arnaiz-González, Á.; Bustillo, A. Semi-supervised learning for industrial fault detection and diagnosis: A systemic review. ISA Trans. 2023, 143, 255–270. [Google Scholar] [CrossRef] [PubMed]

- Movahed, P.; Taheri, S.; Razban, A. A bi-level data-driven framework for fault-detection and diagnosis of HVAC systems. Appl. Energy 2023, 339, 120948. [Google Scholar] [CrossRef]

- Cai, W.; Wang, J.; Jiang, P.; Cao, L.; Mi, G.; Zhou, Q. Application of sensing techniques and artificial intelligence-based methods to laser welding real-time monitoring: A critical review of recent literature. J. Manuf. Syst. 2020, 57, 1–18. [Google Scholar] [CrossRef]

- Mirapeix, J.; García-Allende, P.; Cobo, A.; Conde, O.; López-Higuera, J. Real-time arc-welding defect detection and classification with principal component analysis and artificial neural networks. NDT Int. 2007, 40, 315–323. [Google Scholar] [CrossRef]

- Tang, Q.; Dai, J.; Liu, J.; Liu, C.; Liu, Y.; Ren, C. Quantitative detection of defects based on Markov–PCA–BP algorithm using pulsed infrared thermography technology. Infrared Phys. Technol. 2016, 77, 144–148. [Google Scholar] [CrossRef]

- Shen, X.; Hu, H.; Li, X.; Li, S. Study on PCA-SAFT imaging using leaky Rayleigh waves. Measurement 2021, 170, 108708. [Google Scholar] [CrossRef]

- Juez-Gil, M.; Saucedo-Dorantes, J.J.; Arnaiz-González, Á.; López-Nozal, C.; García-Osorio, C.; Lowe, D. Early and extremely early multi-label fault diagnosis in induction motors. ISA Trans. 2020, 106, 367–381. [Google Scholar] [CrossRef]

- Cui, Y.; He, R.; Liu, S. Hydrogen leakage faults classification diagnosis based on data-driven in hydrogen supply system of fuel cell trucks. Int. J. Hydrog. Energy 2024, 49, 1473–1482. [Google Scholar] [CrossRef]

- Osornio-Rios, R.A.; Jaen-Cuellar, A.Y.; Alvarado-Hernandez, A.I.; Zamudio-Ramirez, I.; Cruz-Albarran, I.A.; Antonino-Daviu, J.A. Fault detection and classification in kinematic chains by means of PCA extraction-reduction of features from thermographic images. Measurement 2022, 197, 111340. [Google Scholar] [CrossRef]

- Aubry, J.; Steiner, N.Y.; Morando, S.; Zerhouni, N.; Hissel, D. Fuel cell diagnosis methods for embedded automotive applications. Energy Rep. 2022, 8, 6687–6706. [Google Scholar] [CrossRef]

- Yu, L.; Wang, X.; Hou, Z.; Du, Z.; Zeng, Y.; Mu, Z. Path planning optimization for driverless vehicle in parallel parking integrating radial basis function neural network. Appl. Sci. 2021, 11, 8178. [Google Scholar] [CrossRef]

- Haghani, A.; Jeinsch, T.; Roepke, M.; Ding, S.X.; Weinhold, N. Data-driven monitoring and validation of experiments on automotive engine test beds. Control. Eng. Pract. 2016, 54, 27–33. [Google Scholar] [CrossRef]

- Salehian, M.; Haghani, A.; Jeinsch, T. Application of Hidden Markov Models for Fault Detection in Automotive Engines. IFAC-PapersOnLine 2022, 55, 767–771. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, R.; Xu, X.; Yang, L.; Ran, M. Recent progress and prospective evaluation of fault diagnosis strategies for electrified drive powertrains: A comprehensive review. Measurement 2023, 222, 113711. [Google Scholar] [CrossRef]

- Komorska, I.; Wołczyński, Z.; Borczuch, A. Fault diagnostics in air intake system of combustion engine using virtual sensors. Diagnostyka 2018, 19, 80972. [Google Scholar] [CrossRef]

- Demlehner, Q.; Schoemer, D.; Laumer, S. How can artificial intelligence enhance car manufacturing? A Delphi study-based identification and assessment of general use cases. Int. J. Inf. Manag. 2021, 58, 102317. [Google Scholar] [CrossRef]

- Li, Y.; Yu, B.; Wang, B.; Lee, T.H.; Banu, M. Online quality inspection of ultrasonic composite welding by combining artificial intelligence technologies with welding process signatures. Mater. Des. 2020, 194, 108912. [Google Scholar] [CrossRef]

- Ngo, Q.H.; Schmitt, S.; Ellerich, M.; Schmitt, R.H. Artificial intelligence based decision model for a quality oriented production ramp-up. Procedia CIRP 2020, 88, 521–526. [Google Scholar] [CrossRef]

- Gusikhin, O.; Rychtyckyj, N.; Filev, D. Intelligent systems in the automotive industry: Applications and trends. Knowl. Inf. Syst. 2007, 12, 147–168. [Google Scholar] [CrossRef]

- Kehayov, M.; Holder, L.; Koch, V. Application of artificial intelligence technology in the manufacturing process and purchasing and supply management. Procedia Comput. Sci. 2022, 200, 1209–1217. [Google Scholar] [CrossRef]

- Theissler, A.; Pérez-Velázquez, J.; Kettelgerdes, M.; Elger, G. Predictive maintenance enabled by machine learning: Use cases and challenges in the automotive industry. Reliab. Eng. Syst. Saf. 2021, 215, 107864. [Google Scholar] [CrossRef]

- Chen, G.; Sheng, B.; Luo, R.; Jia, P. A parallel strategy for predicting the quality of welded joints in automotive bodies based on machine learning. J. Manuf. Syst. 2022, 62, 636–649. [Google Scholar] [CrossRef]

- Fahle, S.; Prinz, C.; Kuhlenkötter, B. Systematic review on machine learning (ML) methods for manufacturing processes–Identifying artificial intelligence (AI) methods for field application. Procedia CIRP 2020, 93, 413–418. [Google Scholar] [CrossRef]

- Nassif, A.B.; Shahin, I.; Attili, I.; Azzeh, M.; Shaalan, K. Speech recognition using deep neural networks: A systematic review. IEEE Access 2019, 7, 19143–19165. [Google Scholar] [CrossRef]

- Chinta, V.S.; Reddi, S.K.; Yarramsetty, N. Optimal feature selection on Serial Cascaded deep learning for predictive maintenance system in automotive industry with fused optimization algorithm. Adv. Eng. Inform. 2023, 57, 102105. [Google Scholar] [CrossRef]

- Schoch, A.; Refflinghaus, R.; Zivkovic, P. Deep Learning based Predictive Testing Strategy in the Automotive Industry. Procedia CIRP 2023, 118, 1108–1113. [Google Scholar] [CrossRef]

- Ji, X.; He, X.; Lv, C.; Liu, Y.; Wu, J. Adaptive-neural-network-based robust lateral motion control for autonomous vehicle at driving limits. Control. Eng. Pract. 2018, 76, 41–53. [Google Scholar] [CrossRef]

- Chaudhari, S.; Aloni, S. Optimization of green sand process for quality improvement in castings by using combination of Taguchi Techniques-GRA-PCA. Mater. Today Proc. 2022, 62, 1115–1121. [Google Scholar] [CrossRef]

- Manoharan, S.; Patel, C.; Dunford, S.; Beshears, J.; McCluskey, P. Life prediction of copper wire bonds in commercial devices using principal component analysis (PCA). Microelectron. Reliab. 2019, 99, 137–151. [Google Scholar] [CrossRef]

- Singh, S.; Bahl, S.; Trehan, S.; Goyal, D.; Bagha, A.K. Prediction of Thermal Aspects for Brass Material-Based Natural Convection Heat Transfer System by Using Adaptive Neuro-fuzzy Inference System. In Proceedings of the Current Advances in Mechanical Engineering: Select Proceedings of ICRAMERD 2020; Springer: Berlin/Heidelberg, Germany, 2021; pp. 807–815. [Google Scholar]

- Abd Aziz, N.; Adnan, N.A.A.; Abd Wahab, D.; Azman, A.H. Component design optimisation based on artificial intelligence in support of additive manufacturing repair and restoration: Current status and future outlook for remanufacturing. J. Clean. Prod. 2021, 296, 126401. [Google Scholar] [CrossRef]

- Fazal, N.; Haleem, A.; Bahl, S.; Javaid, M.; Nandan, D. Digital management systems in manufacturing using industry 5.0 technologies. In Advancement in Materials, Manufacturing and Energy Engineering, Vol. II: Select Proceedings of ICAMME 2021; Springer: Berlin/Heidelberg, Germany, 2022; pp. 221–234. [Google Scholar]

- Lou, H.H.; Huang, Y.L. Hierarchical decision making for proactive quality control: System development for defect reduction in automotive coating operations. Eng. Appl. Artif. Intell. 2003, 16, 237–250. [Google Scholar] [CrossRef]

- Buchner, J.S.; Boblest, S.; Engel, P.; Junginger, A.; Ulmer, H. An Artificial-Intelligence-Based Method to Automatically Create Interpretable Models from Data Targeting Embedded Control Applications. IFAC-PapersOnLine 2020, 53, 13789–13796. [Google Scholar] [CrossRef]

- Rizvi, A.T.; Haleem, A.; Bahl, S.; Javaid, M. Artificial intelligence (AI) and its applications in Indian manufacturing: A review. In Current Advances in Mechanical Engineering: Select Proceedings of ICRAMERD 2020; Springer: Berlin/Heidelberg, Germany, 2021; pp. 825–835. [Google Scholar]

- Gharavian, M.H.; Ganj, F.A.; Ohadi, A.; Bafroui, H.H. Comparison of FDA-based and PCA-based features in fault diagnosis of automobile gearboxes. Neurocomputing 2013, 121, 150–159. [Google Scholar] [CrossRef]

- Sahu, S.N.; Nayak, N.C. Multi-criteria decision making with PCA in EDM of A2 tool steel. Mater. Today: Proc. 2018, 5, 18641–18648. [Google Scholar] [CrossRef]

- Sharif, A.; Guo, J.; Ouyang, J.; Sun, S.; Arshad, K.; Imran, M.A.; Abbasi, Q.H. Compact base station antenna based on image theory for UWB/5G RTLS embraced smart parking of driverless cars. IEEE Access 2019, 7, 180898–180909. [Google Scholar] [CrossRef]

- Baraldi, P.; Cannarile, F.; Di Maio, F.; Zio, E. Hierarchical k-nearest neighbours classification and binary differential evolution for fault diagnostics of automotive bearings operating under variable conditions. Eng. Appl. Artif. Intell. 2016, 56, 1–13. [Google Scholar] [CrossRef]

- Braun, A.; Stylidis, K.; Söderberg, R. Cognitive quality: An unexplored perceived quality dimension in the automotive industry. Procedia CIRP 2020, 91, 869–874. [Google Scholar] [CrossRef]

- Kebisek, M.; Tanuska, P.; Spendla, L.; Kotianova, J.; Strelec, P. Artificial intelligence platform proposal for paint structure quality prediction within the industry 4.0 concept. IFAC-PapersOnLine 2020, 53, 11168–11174. [Google Scholar] [CrossRef]

- Fan, H.T.; Xiao, G.; Arinez, J.; Coulthard, M. A case study on first time quality feature investigation for an automotive paint shop. Manuf. Lett. 2022, 33, 919–926. [Google Scholar] [CrossRef]

- Khonina, S.; Kazanskiy, N.; Efimov, A.; Nikonorov, A.; Oseledets, I.; Skidanov, R.; Butt, M. A perspective on the artificial intelligence’s transformative role in advancing diffractive optics. Iscience 2024, 27, 110270. [Google Scholar] [CrossRef] [PubMed]

- Maculotti, G.; Genta, G.; Verna, E.; Bonù, S.; Bonù, L.; Cagliero, R.; Galetto, M. Minimization of defects generation in laser welding process of steel alloy for automotive application. Procedia CIRP 2022, 115, 48–53. [Google Scholar] [CrossRef]

- Liu, X.; Fan, K.; Huang, X.; Ge, J.; Liu, Y.; Kang, H. Recent advances in artificial intelligence boosting materials design for electrochemical energy storage. Chem. Eng. J. 2024, 490, 151625. [Google Scholar] [CrossRef]

- Singh, M.K.; Kumar, S.; Nandan, D. Faulty voice diagnosis of automotive gearbox based on acoustic feature extraction and classification technique. J. Eng. Res. 2023, 11, 100051. [Google Scholar] [CrossRef]

- Song, Y.; Kim, W.; Yun, M.H. Auditory experience in vehicles: A systematic review and future research directions. Heliyon 2024, 10, e34838. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, M.; Chen, Z.; Zhao, W.; Shi, Y. Self-validating sensor technology and its application in artificial olfaction: A review. Measurement 2024, 242, 116025. [Google Scholar] [CrossRef]

- Cholewinski, P.; Kellner, M.; Richter, W.; Roggendorf, M.; Tschiesner, A.; Venus, A. Automotive R&D Transformation: Optimizing Gen AI’s Potential Value; McKinsey & Company: New York, NY, USA, 2024. [Google Scholar]

- Ragani, A.F.; Stein, J.P. Unveiling the Next Frontier of Engineering Simulation; McKinsey & Company: New York, NY, USA, 2023. [Google Scholar]

- Gen AI in High Gear: Mercedes-Benz Leverages the Power of ChatGPT; McKinsey & Company: New York, NY, USA, 2023.

- Chui, M.; Hall, B.; Mayhew, H.; Singla, A.; Sukharevsky, A. The State of AI in 2022—And a Half Decade in Review; McKinsey & Company: New York, NY, USA, 2022. [Google Scholar]

- Catlin, T.; Kelkar, A.; McElhaney, D.; Paterakis, D. Navigating Unknowns: Auto Insurance Questions in a New Mobility Era; McKinsey & Company: New York, NY, USA, 2024. [Google Scholar]

- Al Issa, A.; Boehm, J.; Nayfeh, M. Boards of Directors: The Final Cybersecurity Defense for Industrials; McKinsey & Company: New York, NY, USA, 2024. [Google Scholar]

| Article | Taxonomy: Category/Subcategory | AI Application or Technique | Solution/Support | Limitations (Discussions and Conclusions) |

|---|---|---|---|---|

| [7] | ZDM/Repair | Artificial intelligence (AI) and related tools | Review of AI’s benefits for automotive industry, i.e., vehicles are more intelligent, safer, reliable, automated with increased efficiency. | Lack of real scenarios for AI implementations to enhance the understanding of the applications. |

| [8] | ZDM/Prediction | Artificial neural networks (ANN), evolutionary algorithms | Reduction of production deterioration by 10% and manufacturing time by 62%. | The method relies on specific raw materials and production activities, making it difficult to apply to other sectors. |

| [10] | QM | Industry 4.0/Quality 4.0 technologies, robotics, IoT | The document indicates the importance of QM deployment using technologies within Industry 4.0 and Quality 4.0 frameworks, considering the operational and finance impacts. | The article does not provide specific case studies or examples of Quality 4.0 deployments in real scenarios. |

| [11] | QM/QP | Machine learning (ML), deep-reinforcement learning | AI improves forecasting, capacity planning, and order release. ML enhances prediction accuracy. | Problems arise from difficulties in handling orders, control of supply and demand, and ineffective order approval processes. |

| [12] | QM/QP | Regression models, artificial neural networks (ANN) | AI techniques like regression and ANN improve demand forecasting accuracy for spare parts. | No limitations are specified; only obstacles related to spare part existence and cost are included. |

| [13] | QM/QP | Knowledge-based systems (KBS), machine learning (ML) | KBS and ML help optimize scheduling and maximize production efficiency in electric drive manufacturing. | No specific limitations mentioned. |

| [14] | QM/QP | Convolutional neural networks (CNN), machine learning (ML) | CNN and ML are utilized to forecast early quality within the manufacturing process using sensor data, improving the categorization accuracy. | While no explicit limitations were identified, potential issues include real-time data processing and a potential increase in the complexity of sensor data. |

| [15] | QM/QC | Random forest (RF), gradient boosting trees (GBT), fully connected neural networks (FCNN) | Usage of preventive models to improve reliability and quality of metallic additive manufacturing (MAM). | Machine learning models lack transparency, making their decision-making processes difficult to understand. |

| [16] | QM/QC | Convolutional neural networks (CNN), machine learning (ML) | Projection of product quality through sensor data and corrective action implementation. | No explicit limitations are stated; however, potential challenges may include sensor data inconsistencies and real-time adjustment difficulties. |

| [17] | QM/QC | Supervised machine learning (ML) | Projection of final product quality, enhancing inspection efficiency, and making cost savings. | No explicit limitations are mentioned, though difficulties might arise in data integration and infrastructure deployment. |

| [18] | QM/QA | Artificial intelligence (AI) and related tools | Automation of monitoring, which positively impacts on delay decrease and human workforce dependency. | No specific constraints are identified, but AI integration and the complexity of new technologies could present challenges. |

| [19] | QM/QA | Deep learning (DL) for defect detection | Identification of physical issues with a high rate of precision. | The model’s effectiveness is limited to surface defect detection and may not be generalizable to other product types. |

| [20] | QM/QA | AI-based supervision controller | Reduction of deviations among the required and actual surface roughness, increasing product quality. | No explicit limitations are highlighted, but obstacles in execution and machine compatibility may occur. |

| [21] | QM/QI | AI techniques (Bayesian networks, fuzzy logic, ANFIS) | Strengthening of machining process and enhancement of quality, efficiency, and sustainability. | Availability of raw material availability and cost increase as part of AI integration. |

| [22] | QM/QI | IoT, AI, Quality 4.0 concepts | Enrichment of productivity, product design, and customer experience. | No explicit restrictions are mentioned; however, scaling and integrating these technologies across diverse manufacturing environments could be difficult. |

| [23] | ZDM/Detection | Artificial intelligence (AI), machine learning (ML) | Increase of quality management and handling of complex quality defects. | Inappropriate data and wrong organization of released products decrease model precision. Additionally, the time required to establish ZDM architecture was a significant barrier. |

| [24] | ZDM/Detection | Artificial intelligence of things (AIoT) | Fulfillment of 100% accuracy in error identification of rotating machines. | No specific limitations or challenges are addressed, though additional testing could be beneficial. |

| [25] | ZDM/Detection | Artificial intelligence (AI) | Fault identification with a precision ranging from 80% to 100%,. | A potential constraint is the reliance on simulated data, which may not represent real-world scenarios. |

| [26] | ZDM/Detection | Artificial neural networks (ANN) | Effective identification of typical claims in automobile drum brakes with high precision. | Limitations may involve further validation in practical scenarios. |

| [27] | ZDM/Detection | Machine learning (ML) models | Integration of operators, and forecasting of worker fatigue fostering better working conditions. | Fatigue estimation accuracy could be impacted by various uncontrolled factors. |

| [28] | ZDM/Detection | Semi-supervised learning (SSL) | Literature review that covers error identification and diagnosis in industrial environments, highlighting future investigation needs. | Difficulties in results comparison among setting and deployments of SSL. |

| [29] | ZDM/Detection | Machine learning, PCA, random forest (RF) | Dimensionality reduction and enhancement of detection precision in automobile HVAC system fault diagnosis. | The study does not detail limitations, but additional testing could assess how the model reacts across different HVAC systems or contexts. |

| [30] | ZDM/Detection | Deep learning, PCA | A revision of AI techniques and CCD camera-based systems used in on-time laser welding tracking and quality evaluation. | There is limited discussion of the practical challenges of applying these AI techniques in industrial contexts, along with the need for continued development in smart quality evaluation systems. |

| [31] | ZDM/Detection | PCA, artificial neural networks (ANN) | Creation of an approach for the automatic identification and categorization of welding incidents. | The article lacks a thorough discussion of real-world situations and issues such as data quality, expandability, and the consolidation of this approach into actual industrial workflows. |

| [32] | ZDM/Detection | PCA, backpropagation neural network (BP) | Model used to estimate the sizes of issues in materials with prediction error of 4% to 10%. | The study does not extensively explore difficulties related to the transferability of the model or its results under changing material conditions and real-world adoptions. |

| [33] | ZDM/Detection | Principal component analysis (PCA) | Production of top-quality images of mistakes that enhances lateral resolution and reduces the average defect sizing error by 48.81%. | It remains unclear how well the method performs in non-ideal conditions or in manufacturing environments with fluctuating noise and interference levels. |

| [34] | ZDM/Detection | Principal component analysis (PCA), decision trees | Diagnosing multiple early faults in induction motors at several frequencies | Performance may be affected due to noise or incomplete data, particularly in real-world applications with changing operating conditions. |

| [35] | ZDM/Detection | PCA, K-means, support vector machine (SVM), SSA-PCA-SVM | Dimensionality reduction and improvement of diagnostic precision to approximately 90%. | Real-world applications may have limitations where environmental variables or unexpected leak patterns affect precision. |

| [36] | ZDM/Detection | PCA, atificial neural networks (ANN) | Kinematic chains organization with a 90.8% reliability | As the approach fulfills high precision, effectiveness may change according the several fault types or operating conditions. |

| [37] | ZDM/Detection | PCA, supervised and unsupervised classifiers | Innovative diagnosis for automobile fuel cell issues, reducing dimensionality with PCA. | Consistency and reliability across diverse processes remains a challenge. Additional validation is required. |

| [38] | ZDM/Detection | Radial basis function neural network (RBFNN) | Progress in curvature smoothness, security, and parking efficiency are shown. | Real-world verification and further validation in multiple parking situations are needed for broader applicability. |

| [39] | ZDM/Detection | Fisher discriminant analysis (FDA) | Model for detecting issues in automotive engine test beds. | Deeper research is key to checking the adaptability to more complex systems and a broader range of error types. |

| [40] | ZDM/Detection | Hidden Markov model (HMM) | Incident identification in automotive engines, reaching a 4.33% false alarm rate and a 24.83% missed detection rate. | Conventional statistical models are not suitable for engines, even though the proposed method still has a potentially high missed detection rate. |

| [41] | ZDM/Detection | Artificial intelligence and related tools | Systematic review of defect types and diagnostic strategies for electrified drive powertrain systems (EPDS). | Due to unknown failure modes, it is essential to foster innovative assessment models. |

| [42] | ZDM/Detection | Model-based fault diagnosis | Development of a model to detect undiagnosed problems of automotive air intake system of combustion motors. | Future investigation will emphasize the expansion of a hybrid engine model and designing virtual sensors. |

| [43] | ZDM/Prediction | Artificial intelligence and its related tools | Identification of AI in automotive production, emphasizing its potential to minimize functional costs and boost efficiency. | Limitations in generating quantitative results that achieve scientific standards. |

| [44] | ZDM/Prediction | Artificial neural networks (ANN), random forest (RF) | AI model for online quality inspection to estimate load failure and weld quality, fulfilling superior precision. | Limitations are not described, though improvements in ANN method accuracy are suggested. |

| [45] | ZDM/Prediction | Neural networks (Bayesian regularization) | Robust manufacturing quality through simulation. | The research does not explicitly discuss relevance and adaptability limitations, but simulation results indicate potential outcomes. |

| [46] | ZDM/Prediction | Fuzzy logic, neural networks, machine learning | Automotive AI deployment to enhance corporate knowledge management and decrease warranty costs. | Limitations are not discussed, but recommendations that broader AI applications could enhance customer satisfaction and product quality across various automotive domains are shared. |

| [47] | ZDM/Prediction | Artificial intelligence and related tools | Fast precision issue recognition, optimizing tasks in smart factories. | No limitations are discussed, but AI impacts are highlighted. |

| [48] | ZDM/Prediction | Machine learning (ML) | Machine learning’s role in predictive maintenance (RdM) for the automotive industry is emphasized, specifically in drivetrain systems, indicating cost savings and enhanced prediction capability. | Challenges in implementing predictive maintenance (RdM) are identified, basically related to functional safety while keeping cost efficiency. |

| [49] | ZDM/Prediction | Machine learning (ML), principal component analysis (PCA) | Projection of automotive´s welded joints quality using machine learning and PCA. | The manuscript does not thoroughly examine the practical difficulties of adapting this approach to large-scale manufacturing facilities. |

| [50] | ZDM/Prediction | Machine learning (ML), Q-learning, decision trees, CNNs | AI defect categorization, and supervised/unsupervised approaches for predictive maintenance. | The research does not assess flexibility or adaptability issues across industries. |

| [51] | ZDM/Prediction | Deep learning, recurrent neural networks (RNNs) | Review of speech recognition publications to discuss updates in feature extraction and hybrid approaches for improved identification precision. | More research about new feature extraction is recommended. |

| [52] | ZDM/Prediction | Hybrid deep learning, feature selection | Projection of errors in automotive manufacturing. with high conformance. | No constraints are expressed, but future advancements could enable wider industrial solutions and on-time data incorporation. |

| [53] | ZDM/Prediction | Deep learning | Forecast of automotive production quality control tests, enhancing efficiency by 15%. | Fulfilling a balance between the negative prediction rate (NPR) and the false emission rate (FOR) remains a key condition. |

| [54] | ZDM/Prediction | Adaptive neural network (ANN) | Elevating the balance and trajectory tracking precision, especially under difficult driving scenarios. | Further refinement in different environmental and operational contexts is necessary. |

| [55] | ZDM/Prediction | Principal component analysis (PCA) | Increment casting quality by targeting issue reduction. | Additional investigation is needed to optimize other process characteristics. |

| [56] | ZDM/Prediction | Principal component analysis (PCA) | Projection of failure time of copper wire bonds, which is key for forecasting the reliability of parts. | Improvement of accuracy depends on data volume, yet dependence on data quality remains an issue. Additional studies are needed to confirm transferability across several products and environments. |

| [57] | ZDM/Prediction | Adaptive neuro-fuzzy inference system (ANFIS) | A model is made to estimate the thermal performance of a natural convection heat transfer system by sharing accurate results. | The developed model demonstrated high forecasting accuracy, but adaptability to more complex methods or different product types remains unexplored, and its resilience for real-time adaptations or diverse sustainable conditions has not been assessed. |

| [58] | ZDM/Repair | Artificial intelligence for optimization in AM (additive manufacturing) | Systemic review of AI applications for improving repair and restoration in metal additive manufacturing (AM). It facilitates repair processes through AM methods to enhance part design. | AI practices in AM are limited, requiring systematic approaches for further development. In addition, it does not review challenges such as material constraints and industrial adaptability. |

| [59] | ZDM/Repair | Advanced AI, IoT, digital twins | Analysis of the progression of industrial revolutions, highlighting Industry 5.0, which emphasizes human–machine partnership. | Lack of detailed examples or real-world adoptions of these technologies. Moreover, it does not thoroughly review the consolidation of challenges within actual production methods or workforce adaptability requirements. |

| [60] | ZDM/Prevention | Artificial intelligence and its related applications | Consolidation of prediction and inspection of automotive coating quality control evaluation and decreasing defects of the vehicle topcoat application. | Absence of specific challenges encountered during the method adoption or sharing of benchmarks with other industry practices. |

| [61] | ZDM/Others | Automated model creation, interpretable AI models | Demonstrating the model’s efficiency in automatically creating interpretable approaches for embedded control applications while fulfilling expected results. | Omission of detailed discussion of its limitations or potential challenges in applying automation to more complicated or large-volume control systems. Further research on adaptability and robustness is suggested. |

| [62] | ZDM/Others | AI, intelligent robots | Systemic review of AI consolidation in Indian production, highlighting the need for better infrastructure and policies to facilitate AI adoption. The importance of updating educational models to align with technological advancements is also remarked upon. | Limitations are noted in terms of lack of infrastructure, government policies, unemployment concerns, and skills gaps, without proposing specific solutions. |

| [63] | ZDM/Others | Fisher discriminant analysis (FDA), principal component analysis (PCA) | Defect diagnosis in vehicle gearboxes with FDA/PCA approaches, with resulting FDA showing higher precision and less monitoring costs compared to PCA. Average recognition is enhanced by approximately 14%. | The study is focused on the gearbox only; therefore, it does not explore adaptability to other components. |

| [64] | ZDM/Others | Principal component analysis (PCA) | The article identified the key process parameters of the studied electrical discharging machining (EDM) process, so-called Lp and Ton parameters, which are typically related to quality. | Lack of detection of interaction impact with other features of Lp and Ton, as critical parameters. |

| [65] | ZDM/Others | IoT | Enhancement of precision and reliability of autonomous vehicle parking. It maintains stable radiation patterns across frequencies, which is crucial for RTLS systems. | There is a gap for further validation and testing needed for real-world scenarios in autonomous vehicles. |

| [66] | ZDM/Others | K-nearest neighbors (KNN), binary differential evolution | Early degradation identification and error categorizations of automotive bearings with an effective rate of 79.78%. | More testing with bearing degradation simulations in automotive applications is necessary for verification and adoption. |

| [68] | PQF/Visual Quality | AI, big data, principal component analysis (PCA), neural networks | Projection of paint quality in the automotive sector, which is evaluated through specific measuring features. | The complexity of the painting process and the high data volume may delay or make harder the AI platform’s adaptability and real-time implementation. Additionally, consolidating diverse data and ensuring neural network estimation precision under variable conditions needs further validation. |

| [69] | PQF/Visual Quality | Machine learning (ML) | Detection of critical characteristics negatively impacting automotive painting; support for FTQ target setting and forecast results. | Needs more validation and investigation to confirm the chosen features. Relationship between ML and FTQ requires further research. |

| [70] | PQF/Visual Quality | Machine learning (ML) and generative models | Improving the design and precision of DOEs, optical structures, their quality and productivity. | Needs more validation and investigation to confirm the chosen features. Relationship between ML and FTQ requires further research. |