Comparison of Guide to Expression of Uncertainty in Measurement and Monte Carlo Method for Evaluating Gauge Factor Calibration Test Uncertainty of High-Temperature Wire Strain Gauge

Abstract

:1. Introduction

2. Mathematical Model

3. Evaluation Principle

3.1. GUM Evaluation Principle

3.1.1. Calculate the Standard Uncertainty

3.1.2. Calculate the Combined Standard Uncertainty

3.2. MCM Evaluation and Verification Principle

3.2.1. MCM Evaluation Principle

3.2.2. Verifying GUM by MCM

4. Calibration Test and the Evaluation Results

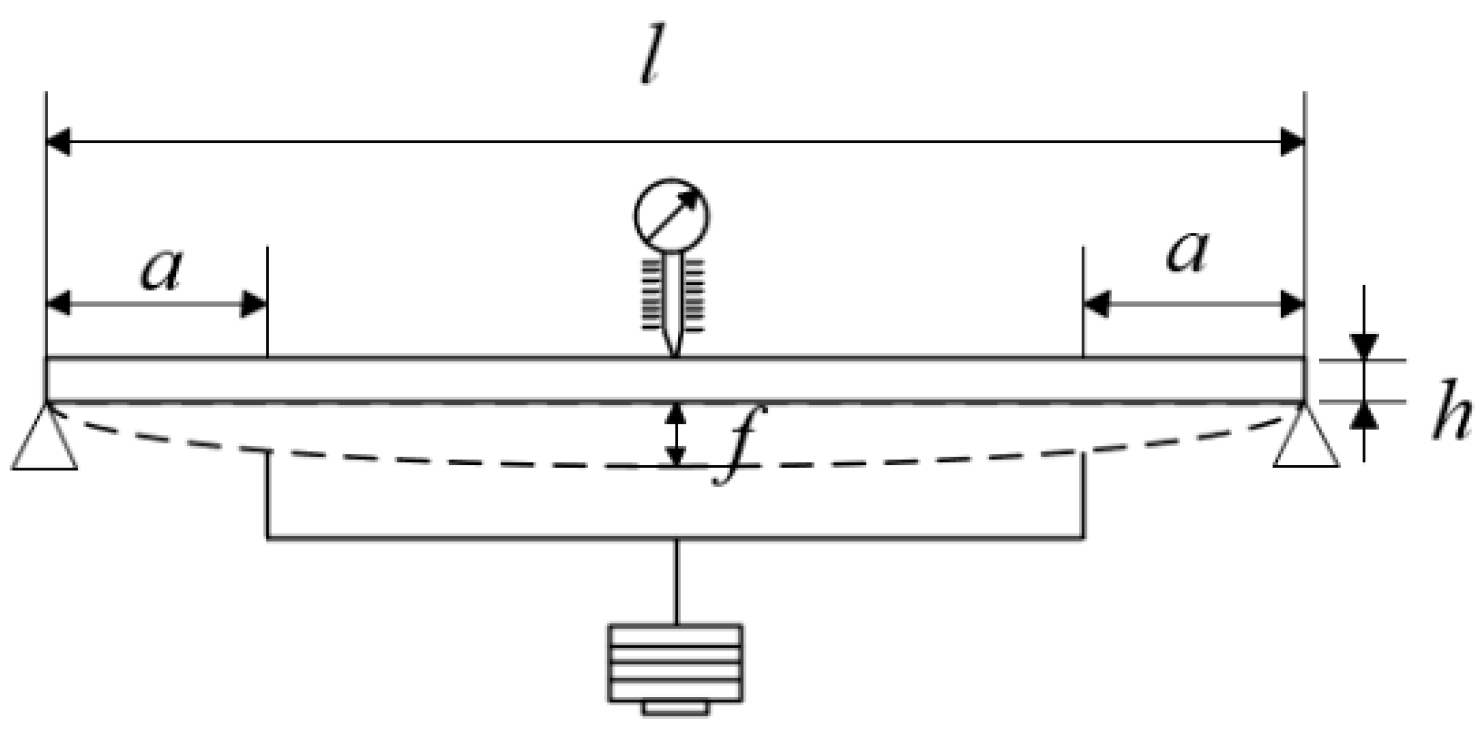

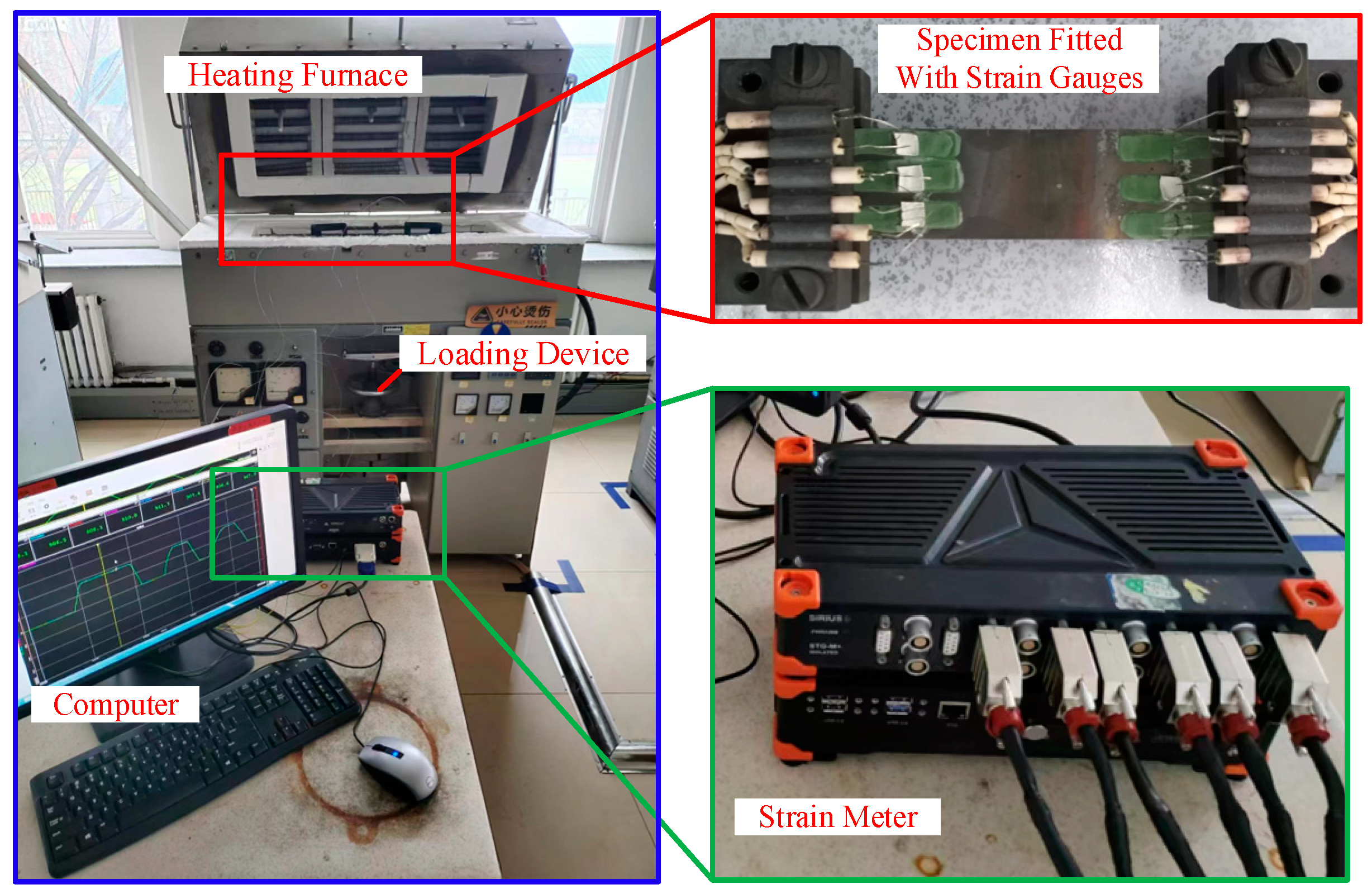

4.1. Calibration Test System

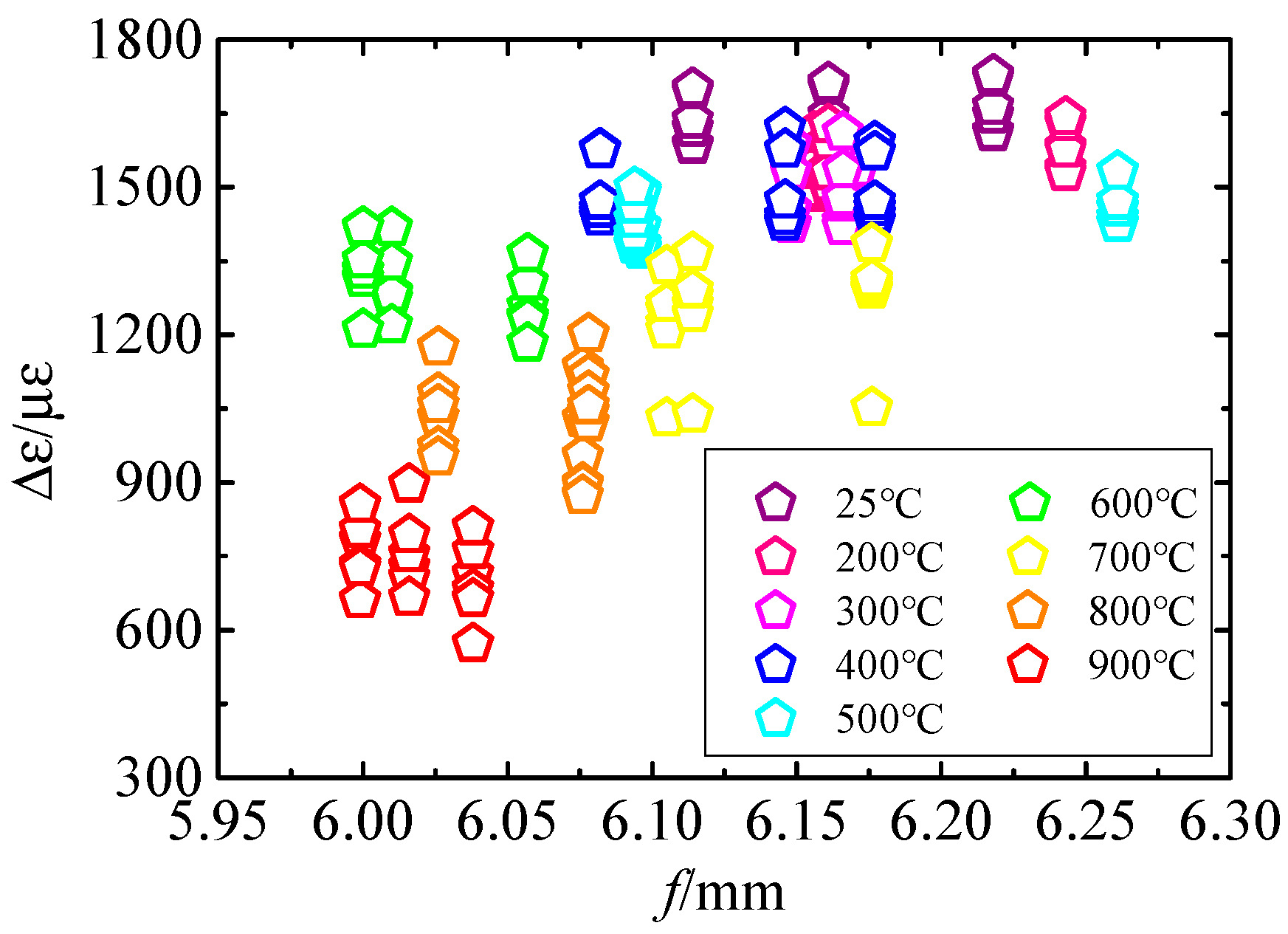

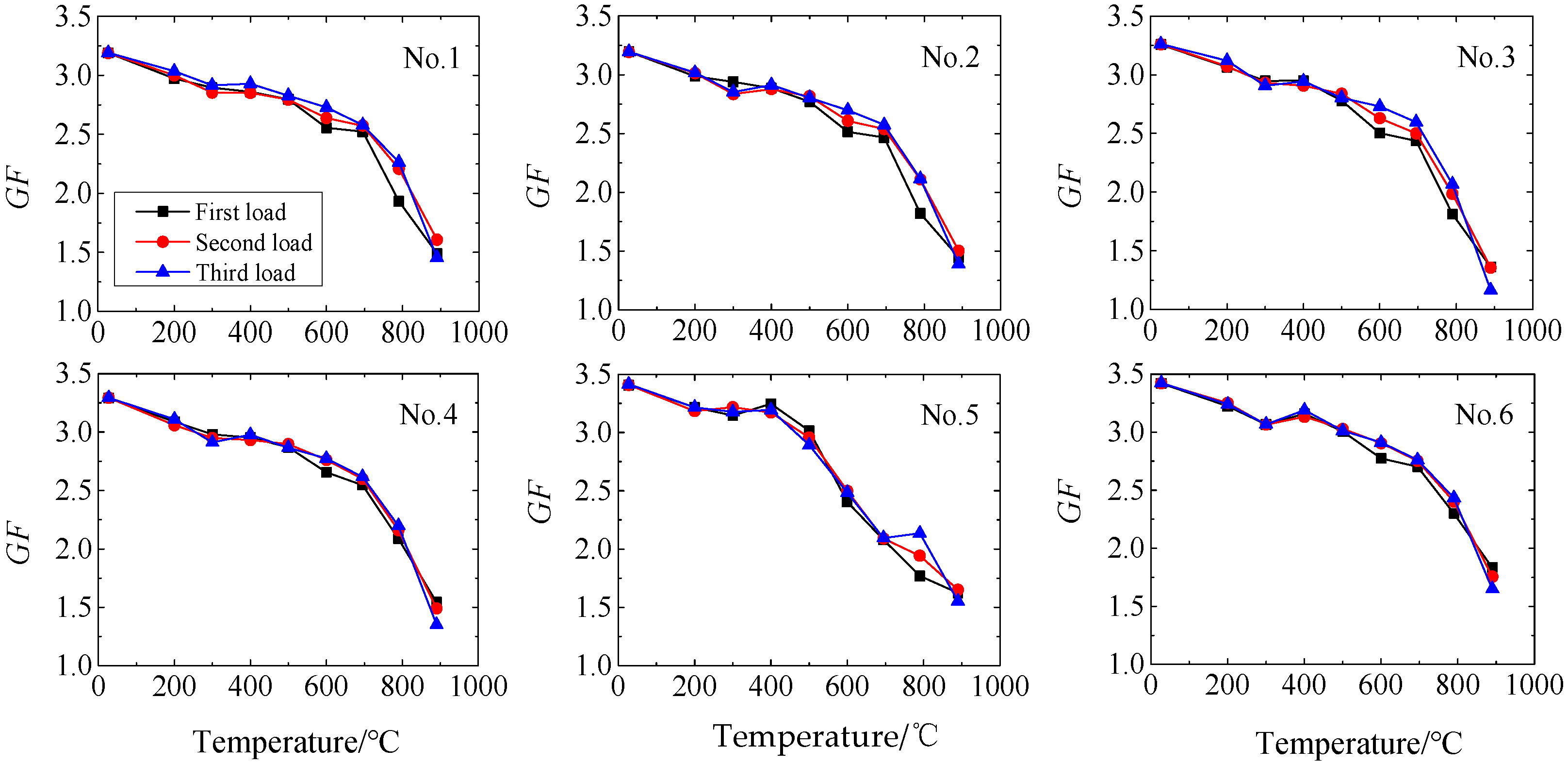

4.2. Test Results

4.3. Evaluation Results of GUM

4.4. Evaluation Results of MCM

4.5. Comparison Between GUM and MCM

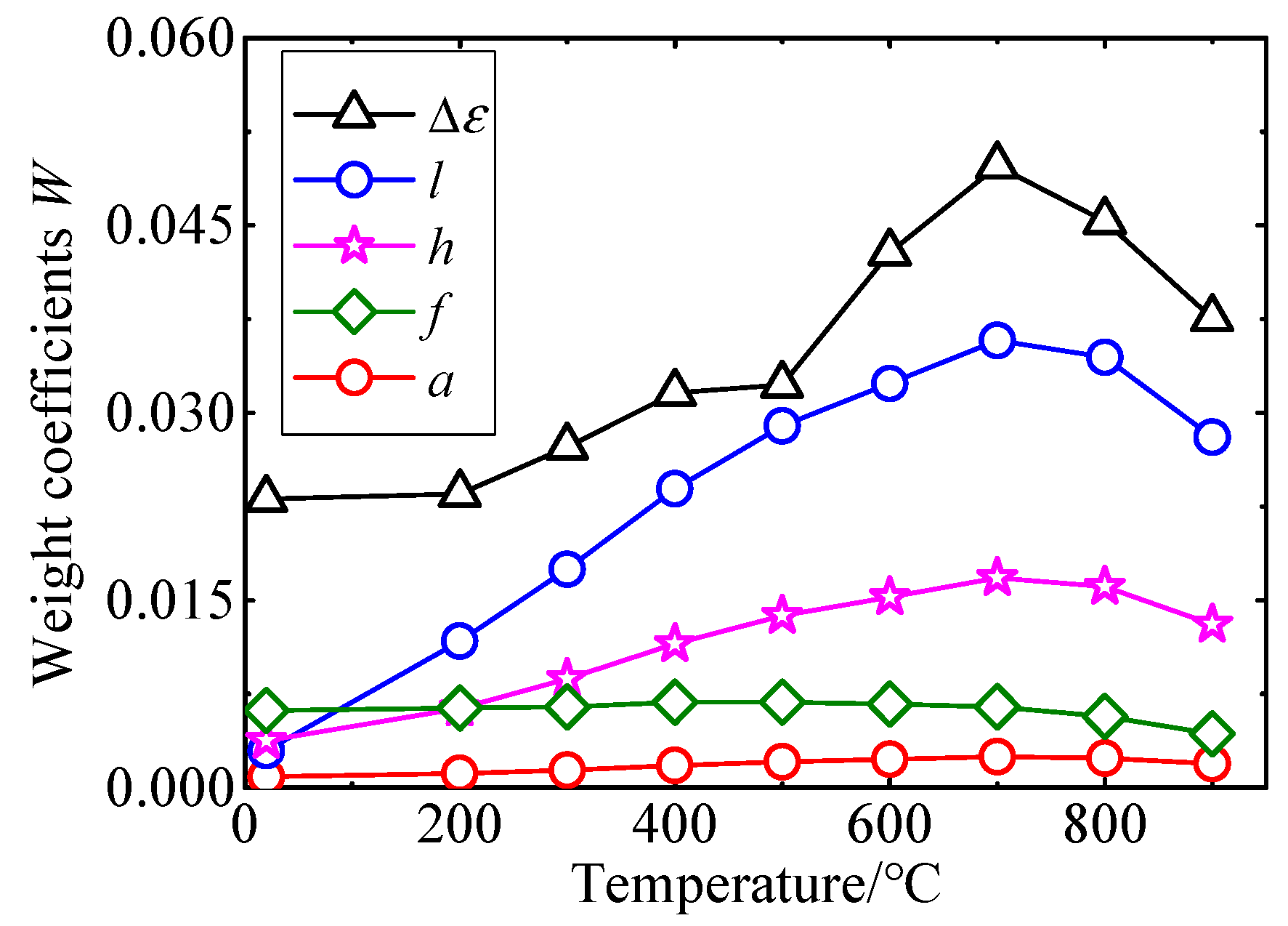

5. Analysis of Uncertain Sources

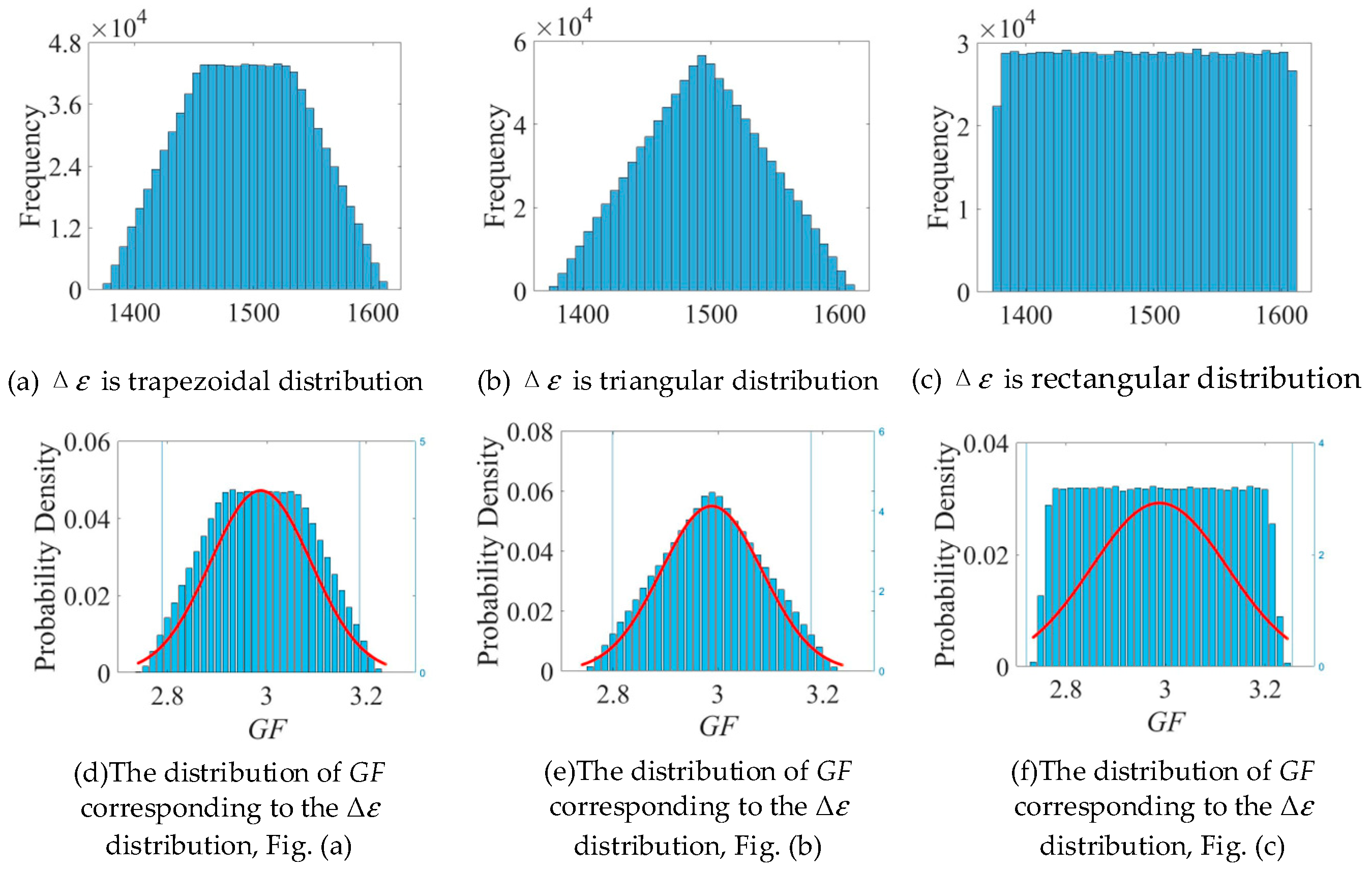

5.1. The Influence of on the

5.2. The Influence of the Uncertainty of the Input on

5.3. The Influence of the PDF of Each Factor on

6. Conclusions

- (1)

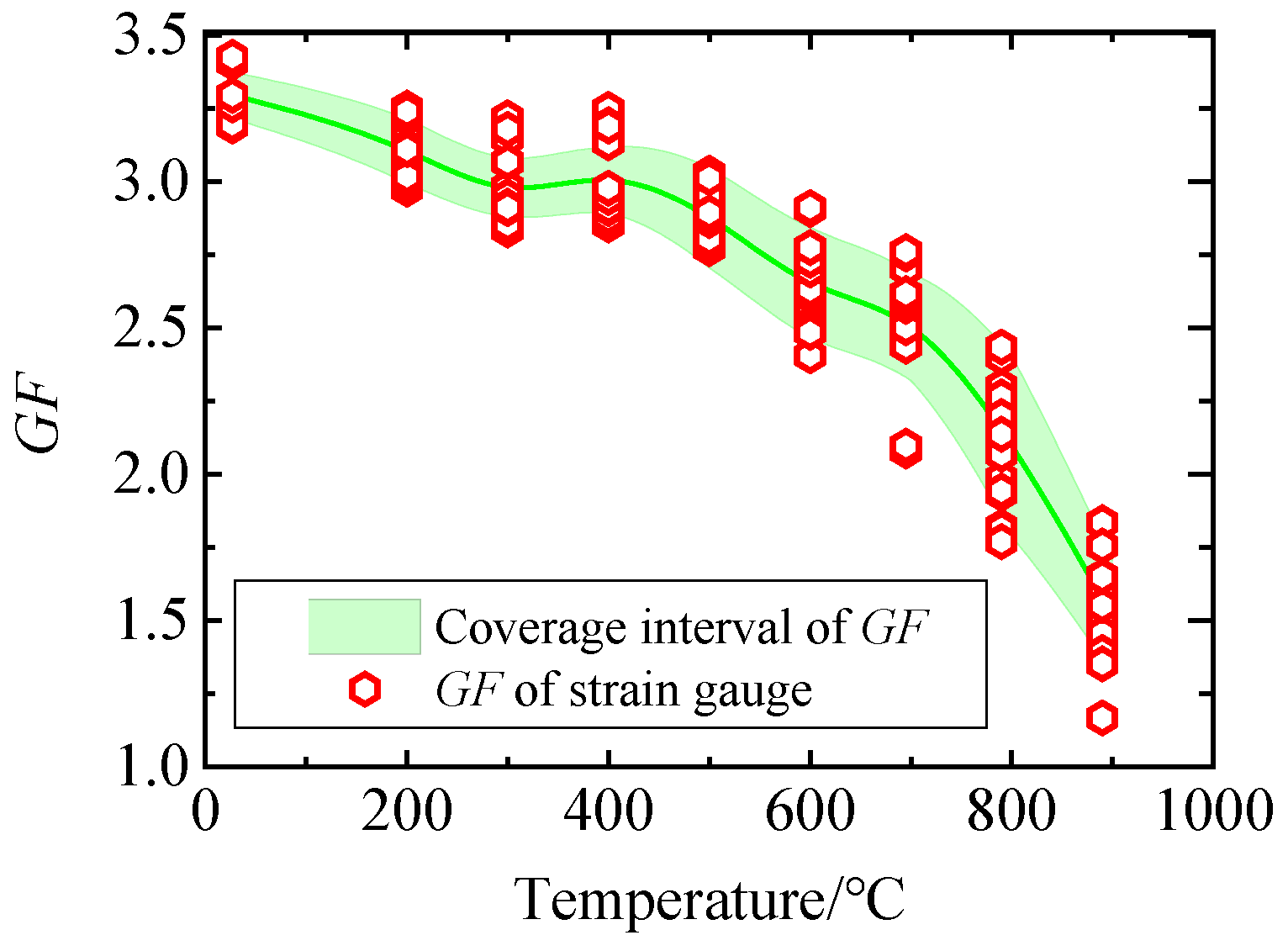

- The calibration test results of the high-temperature strain gauge show that the decreases with the increase in temperature nonlinearly. At 25 °C, is about 3.29, and when the temperature reaches 900 °C, decreases to 1.6.

- (2)

- GUM and MCM are used to evaluate the uncertainty of the calibration test, and the results are compared and analyzed. The uncertainty obtained by GUM is too small, but it cannot cover all the test results and cannot accurately characterize the true dispersion of . The endpoint deviation values are all greater than the numerical tolerance, that is, GUM has not passed the verification and is not suitable for the uncertainty evaluation of the strain gauge .

- (3)

- MCM can obtain more samples through large-scale stochastic numerical simulation. The evaluation results can be better matched with the test results, and the evaluation results are more accurate and effective. The dispersion is 6.1% at 25 °C, and it reaches 21.8% when the temperature rises to 900 °C.

- (4)

- The concept of weight coefficient is proposed, which includes the sensitivity of the mathematical model to each input, the uncertainty of each input, and the PDF of each input. The analysis proves the influence of the three aspects on , which can be an effective supplement to MCM, and the major uncertain source in the mathematical model can be quantitatively analyzed. The uncertainty evaluation can be applied to other fields and provides important information for improving the stability of the installation process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| T/°C | First Load: Deflection/Strain (mm/με) | Second Load: Deflection/Strain (mm/με) | Third Load: Deflection/Strain (mm/με) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 6.161 | 6.218 | 6.114 | |||||||||||||||

| 1596 | 1599 | 1630 | 1647 | 1705 | 1712 | 1611 | 1613 | 1647 | 1664 | 1722 | 1728 | 1585 | 1587 | 1620 | 1636 | 1696 | 1701 | |

| 200 | 6.156 | 6.161 | 6.243 | |||||||||||||||

| 1487 | 1494 | 1533 | 1544 | 1608 | 1612 | 1502 | 1508 | 1537 | 1531 | 1594 | 1627 | 1539 | 1530 | 1582 | 1577 | 1631 | 1643 | |

| 300 | 6.171 | 6.166 | 6.148 | |||||||||||||||

| 1451 | 1473 | 1478 | 1494 | 1577 | 1537 | 1430 | 1420 | 1468 | 1477 | 1612 | 1535 | 1456 | 1425 | 1452 | 1454 | 1587 | 1532 | |

| 400 | 6.146 | 6.177 | 6.082 | |||||||||||||||

| 1428 | 1441 | 1473 | 1474 | 1621 | 1577 | 1431 | 1444 | 1459 | 1471 | 1592 | 1572 | 1447 | 1439 | 1455 | 1471 | 1578 | 1576 | |

| 500 | 6.096 | 6.094 | 6.261 | |||||||||||||||

| 1385 | 1372 | 1377 | 1421 | 1493 | 1488 | 1383 | 1394 | 1405 | 1434 | 1464 | 1499 | 1438 | 1426 | 1426 | 1458 | 1471 | 1532 | |

| 600 | 6.057 | 6.010 | 6.000 | |||||||||||||||

| 1258 | 1237 | 1232 | 1307 | 1183 | 1365 | 1288 | 1273 | 1284 | 1348 | 1220 | 1418 | 1330 | 1315 | 1331 | 1352 | 1211 | 1419 | |

| 700 | 6.105 | 6.114 | 6.176 | |||||||||||||||

| 1251 | 1223 | 1209 | 1263 | 1031 | 1340 | 1278 | 1261 | 1242 | 1291 | 1038 | 1367 | 1294 | 1291 | 1303 | 1313 | 1051 | 1385 | |

| 800 | 6.076 | 6.026 | 6.078 | |||||||||||||||

| 954 | 898 | 895 | 1030 | 873 | 1135 | 1081 | 1033 | 972 | 1057 | 951 | 1175 | 1118 | 1044 | 1021 | 1085 | 1055 | 1202 | |

| 900 | 6.016 | 5.999 | 6.038 | |||||||||||||||

| 728 | 707 | 666 | 754 | 793 | 896 | 783 | 732 | 661 | 726 | 804 | 855 | 714 | 682 | 572 | 663 | 761 | 809 | |

References

- Staab, G.H. Mechanical Test Methods for Lamina. In Laminar Composites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 99–138. [Google Scholar]

- Wrbanek, J.; Fralick, G.; Martin, L.; Blaha, C. A Thin Film Multifunction Sensor for Harsh Environments. In Proceedings of the 37th Joint Propulsion Conference and Exhibit, Salt Lake City, UT, USA, 8–11 July 2001. [Google Scholar]

- Otto, J.; Gregory, Q.L. A self-compensated ceramic strain gage for use at elevated temperatures. Sens. Actuators A Phys. 2001, 88, 234–240. [Google Scholar]

- Hao, Z.; Chen, G. Characterization of out-of-plane tensile stress–strain behavior for GFRP composite materials at elevated temperatures. Compos. Struct. 2022, 290, 115477. [Google Scholar] [CrossRef]

- Teppernegg, T.; Klünsner, T. High temperature mechanical properties of WC–Co hard metals. Int. J. Refract. Met. Hard Mater. 2016, 56, 139–144. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, F.; Ai, Y.; Tian, J.; Wang, Z. Structural uncertainty analysis of high-temperature strain gauge based on Monte Carlo stochastic finite element method. Sensors 2023, 23, 8647. [Google Scholar] [CrossRef]

- Yang, S.; Li, H. Effect of Al2O3/Al bilayer protective coatings on the high-temperature stability of PdCr thin film strain gages. J. Alloys Compd. 2018, 759, 1–7. [Google Scholar] [CrossRef]

- Schmid, P.; Zarfl, C.; Balogh, G.; Schmid, U. Gauge Factor of Titanium/Platinum Thin Films up to 350 °C. Procedia Eng. 2014, 87, 172–175. [Google Scholar] [CrossRef]

- ISO/IEC 98-3; Uncertainty of Measurement—Part 3: Guide to the Expression of Uncertainty in Measurement. ISO: Geneva, Switzerland, 2010.

- Zhang, F.; Zhang, X.; Ai, Y. Sensitive grid structure optimization of high temperature strain gauge based on response surface methodology. Chin. J. Sci. Instrum. 2023, 44, 144–155. [Google Scholar]

- El Fazani, H.; Coil, J.; Chamberland, O.; Laliberte, J. Determination of experimental uncertainties in tensile properties of additively manufactured polymers using the GUM method. Measurement 2022, 202, 111726. [Google Scholar] [CrossRef]

- Chen, Y.; Li, X.; Huang, L.; Wang, X.; Liu, C.; Zhao, F.; Hua, Y.; Feng, P. GUM method for evaluation of measurement uncertainty: BPL long wave time service monitoring. Measurement 2022, 189, 110459. [Google Scholar] [CrossRef]

- Song, M.S.; Fang, X.H.; Huang, J. Research on the measurement uncertainty evaluation method of infinitesimal sample in calibration and testing. Chin. J. Sci. Instrum. 2014, 35, 419–426. [Google Scholar]

- JCGM 101:2008; Evaluation of Measurement Data—Supplement 1 to the Guide to the Expression of Uncertainty in Measurement—Propagation of Distributions Using a Monte Carlo Methodt. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:guide:98:-3:ed-1:v2:suppl:1:v1:en (accessed on 23 January 2025).

- González, C.; Vilaplana, J.M.; Parra-Rojas, F.C.; Serrano, A. Validation of the GUM uncertainty framework and the Unscented transformation for Brewer UV irradiance measurements using the Monte Carlo method. Measurement 2025, 239, 115466. [Google Scholar] [CrossRef]

- Jiang, W.S.; Li, X.; Luo, Z. Uncertainty evaluation of calibration model of six DOF robot arm. Chin. J. Sci. Instrum. 2022, 43, 26–34. [Google Scholar]

- Huang, M.F.; Jing, H.; Kuang, B. Measurement uncertainty evaluation based on quasi MonteCarlo method. Chin. J. Sci. Instrum. 2009, 30, 120–125. [Google Scholar]

- Singh, J.; Kumaraswamidhas, L.A.; Bura, N.; Sharma, N.D. A Monte Carlo simulation investigation on the effect of the probability distribution of input quantities on the effective area of a pressure balance and its uncertainty. Measurement 2021, 172, 108853. [Google Scholar] [CrossRef]

- Forster, M.; Seibold, F.; Krille, T.; Waidmann, C.; Weigand, B.; Poser, R. A Monte Carlo approach to evaluate the local measurement uncertainty in transient heat transfer experiments using liquid crystal thermography. Measurement 2022, 190, 110648. [Google Scholar] [CrossRef]

- Rost, K.; Wendt, K.; Härtig, F. Evaluating a task-specific measurement uncertainty for gear measuring instruments via Monte Carlo simulation. Precis. Eng. 2016, 44, 220–230. [Google Scholar] [CrossRef]

- Motra, H.B.; Hildebrand, J.; Wuttke, F. The Monte Carlo Method for evaluating measurement uncertainty: Application for determining the properties of materials. Probabilistic Eng. Mech. 2016, 45, 220–228. [Google Scholar] [CrossRef]

- Sepahi-Boroujeni, S.; Mayer, J.R.; Khameneifar, F. Prompt uncertainty estimation with GUM framework for on-machine tool coordinate metrology. Procedia CIRP 2022, 112, 117–121. [Google Scholar] [CrossRef]

- Wang, W.; Song, M.S.; Chen, Y.H. Application of Monte-Carlo method in measurement uncertainty evaluation of complicated model. Chin. J. Sci. Instrum. 2008, 29, 1446–1449. [Google Scholar]

- Castro, H.F. Validation of the GUM using the Monte Carlo method when applied in the calculation of the measurement uncertainty of a compact prover calibration. Flow Meas. Instrum. 2021, 77, 101877. [Google Scholar] [CrossRef]

- Chen, A.; Chen, C. Comparison of GUM and Monte Carlo methods for evaluating measurement uncertainty of perspiration measurement systems. Measurement 2016, 87, 27–37. [Google Scholar] [CrossRef]

- Reis, M.L.; Castro, R.M.; Mello, O.A. Calibration uncertainty estimation of a strain-gage external balance. Measurement 2013, 46, 24–33. [Google Scholar] [CrossRef]

- Teomete, E. Measurement of crack length sensitivity and strain gage factor of carbon fiber reinforced cement matrix composites. Measurement 2015, 74, 21–30. [Google Scholar] [CrossRef]

- GB/T 13992-2010; Metallic Bonded Resistance Strain Gauges. China Testing Technology Research Institute: Shanghai, China, 2010.

- E0251-20A; Standard Test Methods for Performance Characteristics of Metallic Bonded Resistance Strain Gages. iTeh Standards: Newark, DE, USA, 2014.

- Ai, Y.; Liu, M.; Zhang, F. Research on the structural optimization method to improve the service life and accuracy of high temperature strain gauge. Chin. J. Sci. Instrum. 2022, 43, 28–38. [Google Scholar]

- Gregory, O.J.; Chen, X. Strain and temperature effects in indium–tin-oxide sensors. Thin Solid Film. 2010, 518, 5622–5625. [Google Scholar] [CrossRef]

| T/°C | 25 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Uncertainty | ||||||||||

| /mm | 0.01 | 0.02 | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | |

| /mm | 0.29 | 1.21 | 1.88 | 2.55 | 3.23 | 3.91 | 4.59 | 5.26 | 5.94 | |

| /mm | 0.29 | 0.39 | 0.51 | 0.64 | 0.78 | 0.92 | 1.07 | 1.22 | 1.37 | |

| /mm | 0.052 | 0.049 | 0.012 | 0.048 | 0.096 | 0.030 | 0.039 | 0.029 | 0.020 | |

| /με | 3.23 | 27.22 | 54.58 | 30.88 | 28.33 | 38.32 | 13.35 | 31.54 | 28.82 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhang, F.; Ai, Y.; Tian, J.; Wang, Z. Comparison of Guide to Expression of Uncertainty in Measurement and Monte Carlo Method for Evaluating Gauge Factor Calibration Test Uncertainty of High-Temperature Wire Strain Gauge. Sensors 2025, 25, 1633. https://doi.org/10.3390/s25051633

Zhao Y, Zhang F, Ai Y, Tian J, Wang Z. Comparison of Guide to Expression of Uncertainty in Measurement and Monte Carlo Method for Evaluating Gauge Factor Calibration Test Uncertainty of High-Temperature Wire Strain Gauge. Sensors. 2025; 25(5):1633. https://doi.org/10.3390/s25051633

Chicago/Turabian StyleZhao, Yazhi, Fengling Zhang, Yanting Ai, Jing Tian, and Zhi Wang. 2025. "Comparison of Guide to Expression of Uncertainty in Measurement and Monte Carlo Method for Evaluating Gauge Factor Calibration Test Uncertainty of High-Temperature Wire Strain Gauge" Sensors 25, no. 5: 1633. https://doi.org/10.3390/s25051633

APA StyleZhao, Y., Zhang, F., Ai, Y., Tian, J., & Wang, Z. (2025). Comparison of Guide to Expression of Uncertainty in Measurement and Monte Carlo Method for Evaluating Gauge Factor Calibration Test Uncertainty of High-Temperature Wire Strain Gauge. Sensors, 25(5), 1633. https://doi.org/10.3390/s25051633