Optimizing Sensor Placement for Event Detection: A Case Study in Gaseous Chemical Detection

Abstract

:1. Introduction

2. Background and Literature Review

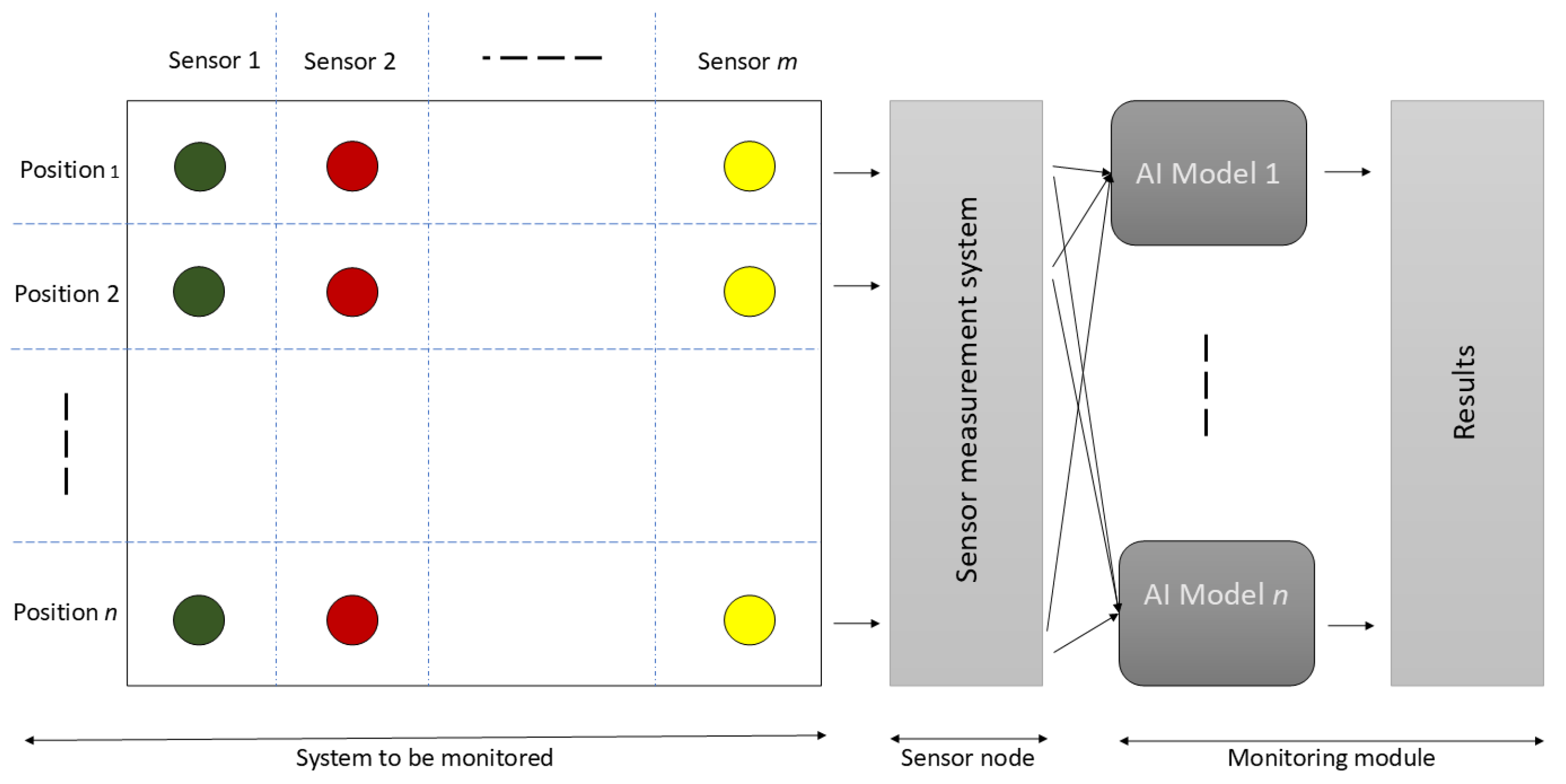

3. Context and Dataset

3.1. Context

3.2. Dataset

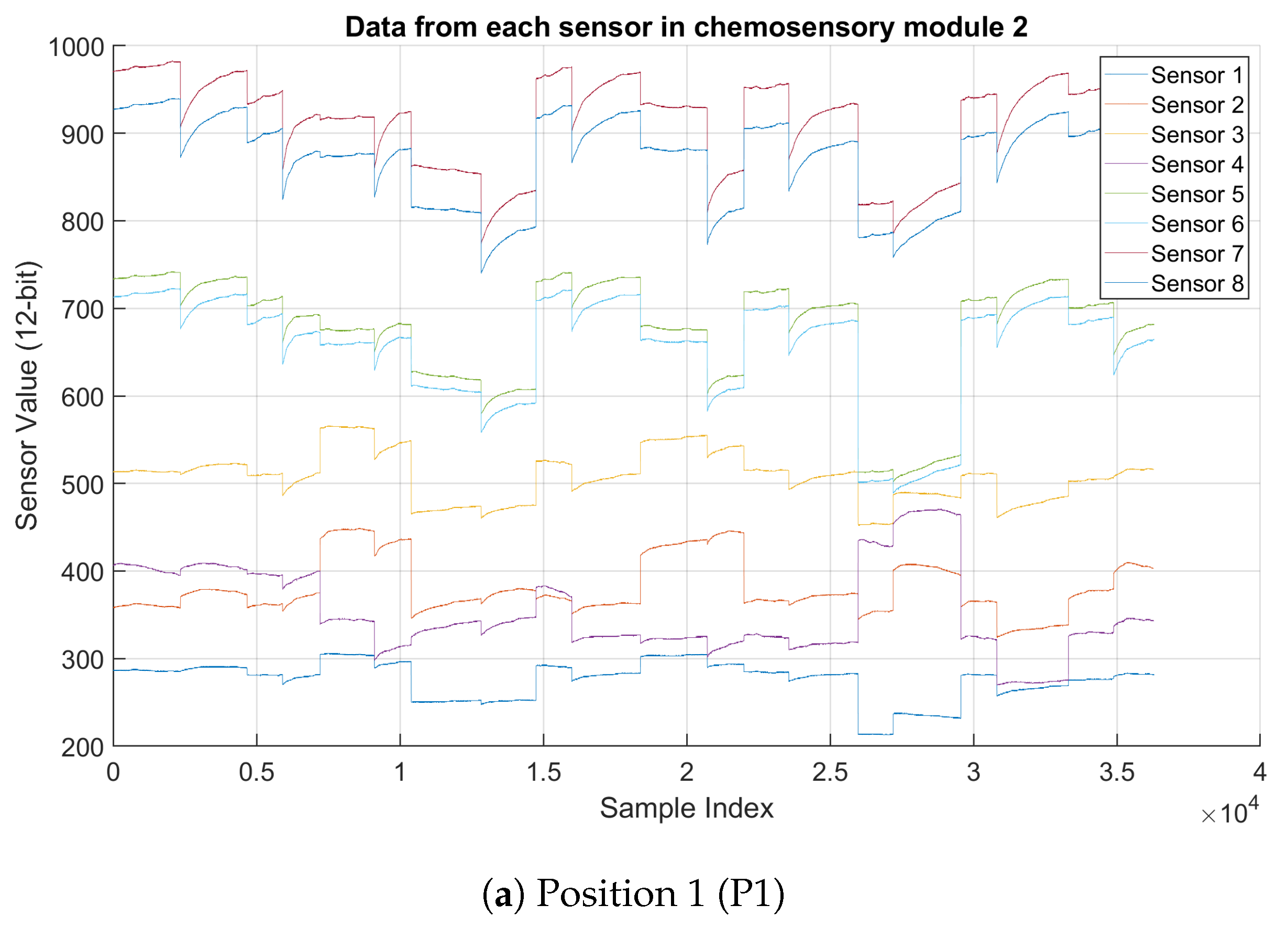

- Behavior Across All Sensors: Figure 2 shows data collected in the chemosensory module 2 at two different positions (P1 and P4) from eight sensors, each tracking a distinct signal. The general trends in both graphs are similar, suggesting that the gas exposure events at P1 and P4 follow a comparable sequence. The periodic increases and decreases in sensor values could indicate a reaction to varying gas concentrations. In P4, some sensors (e.g., Sensors 6 and 8) exhibit higher peak values than in P1. This suggests that gas concentrations at P4 might be slightly higher, or environmental factors (e.g., airflow) influence the readings. Looking at fluctuations in sensor values over time, the data at P4 have slightly more noise in some sensor signals, especially in the mid-range values (e.g., Sensor 5). P1 data, in contrast, looks smoother with fewer abrupt fluctuations.

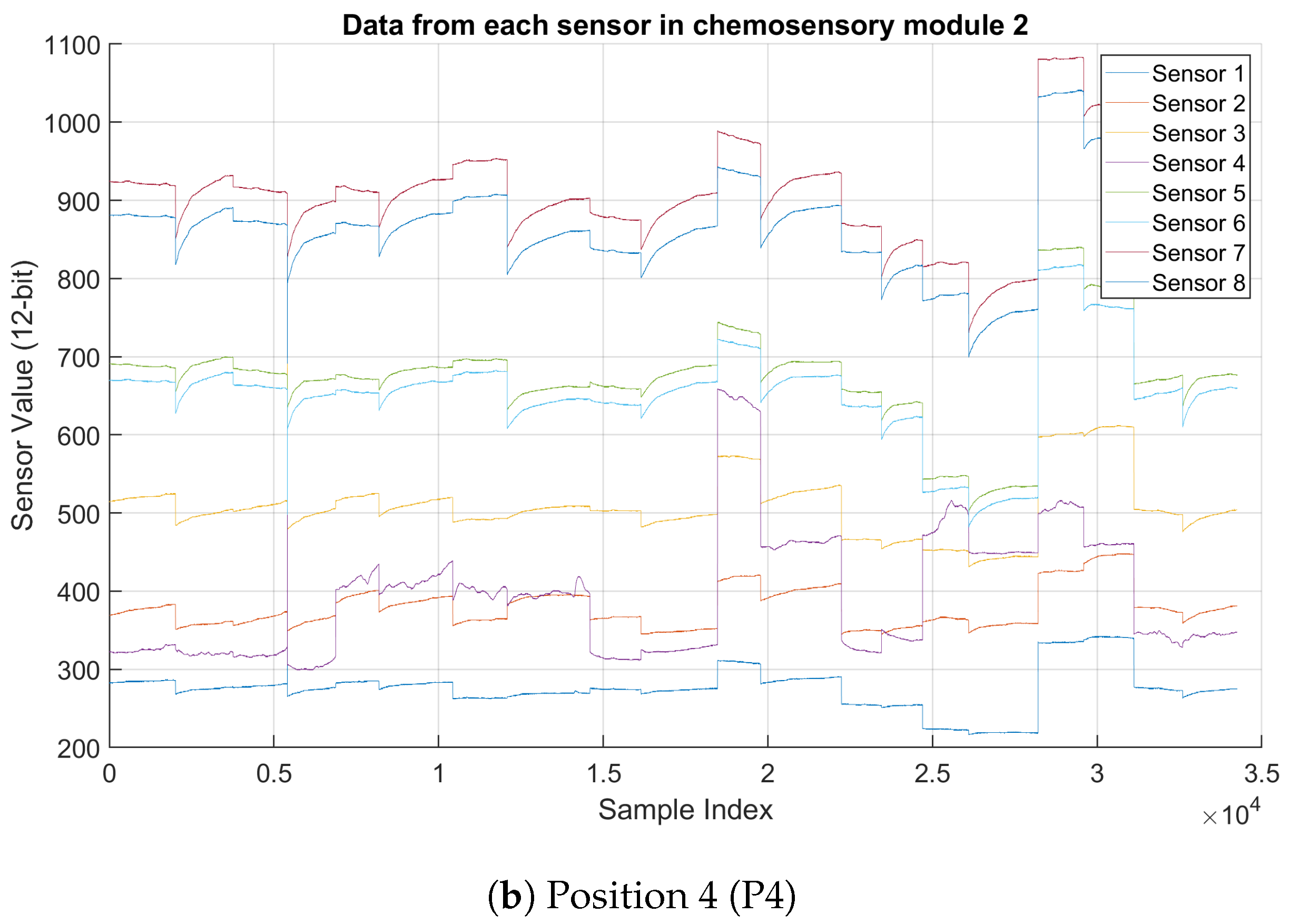

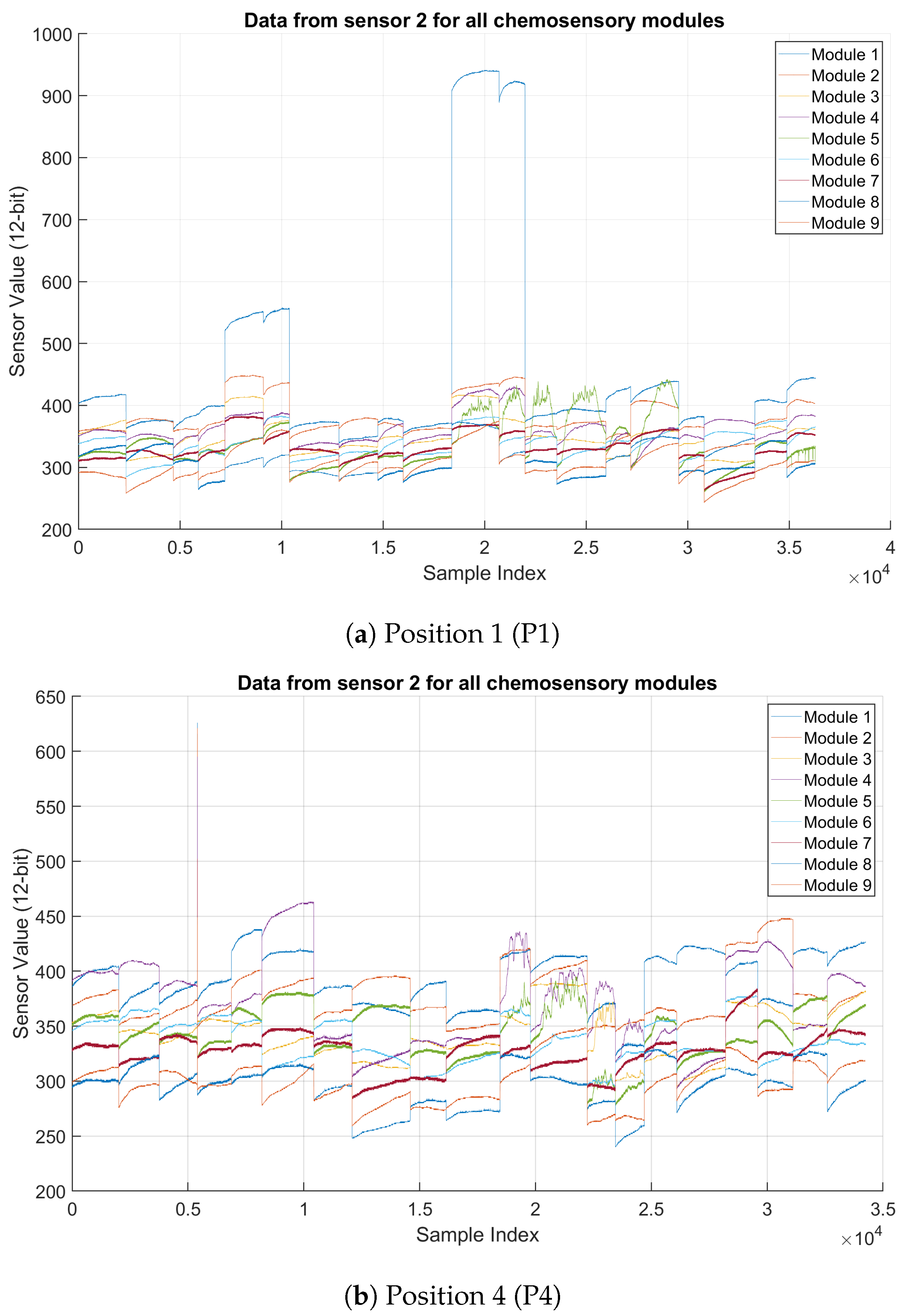

- Consistency Among the different modules: The graphs in Figure 3 represent data from Sensor 2 recorded across nine chemosensory modules (Module 1 to Module 9) at two positions, P1 and P4. Both locations exhibit distinct step-like changes in sensor readings over time, indicating abrupt shifts in gas concentrations. P4 displays higher variability and noise in sensor signals than P1, particularly in the mid-range values. Most modules have similar trends, responding similarly to gas concentration changes. This suggests that the sensor is generally reliable across different modules. Some modules (e.g., Module 8 in P4) show higher fluctuations, which may indicate sensitivity differences or noise issues. P4 appears to have more noise than P1, possibly due to environmental factors (e.g., turbulence or gas diffusion patterns).

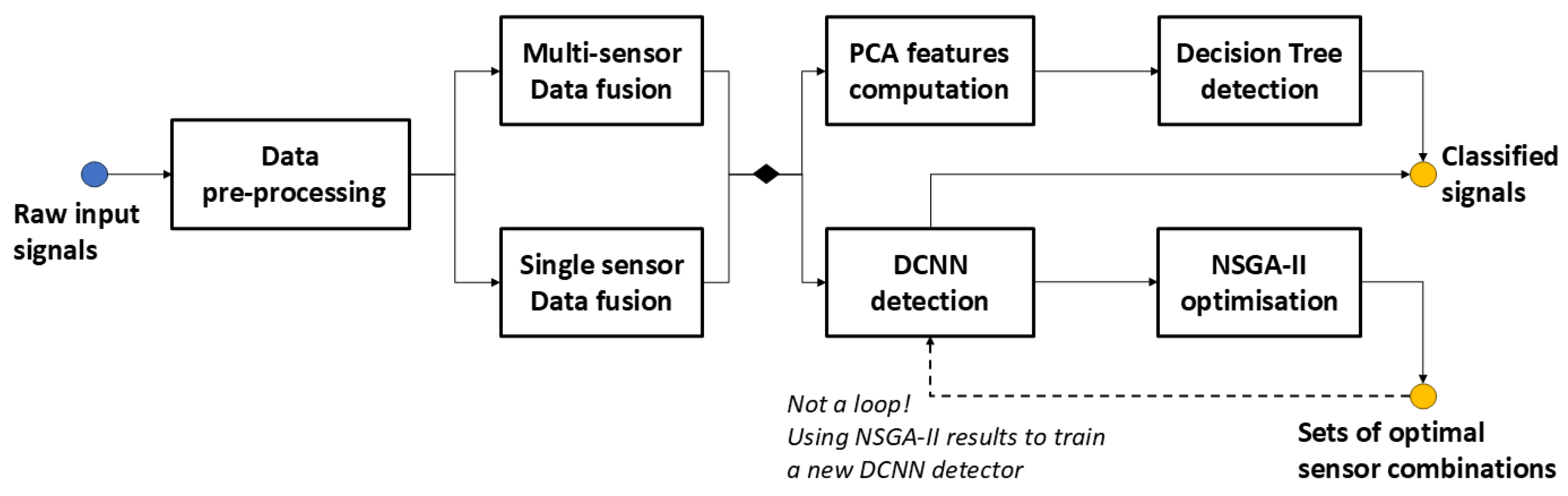

4. Methodology

4.1. Pre-Processing and Data Fusion

4.2. Principal Component Analysis

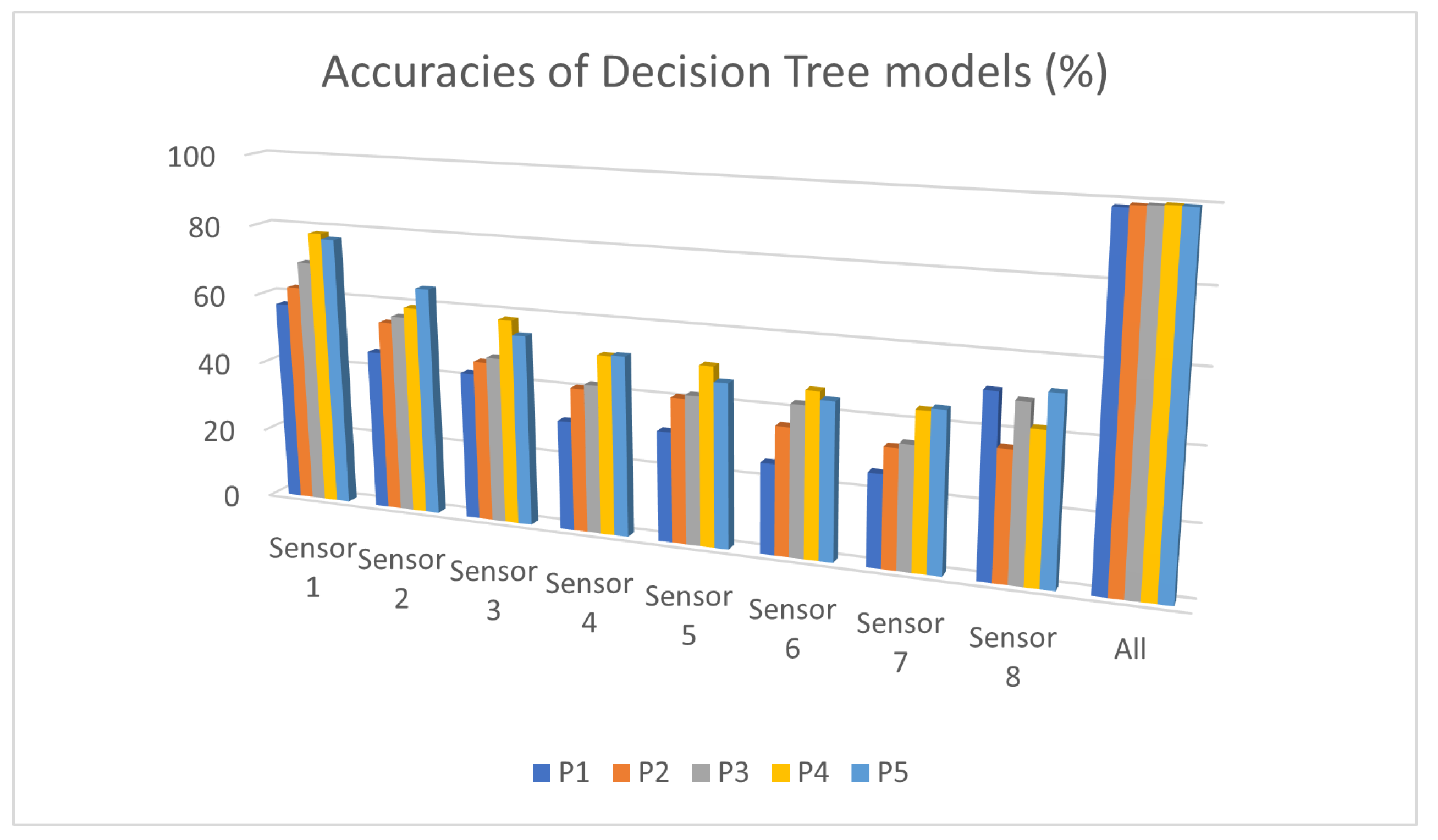

4.3. Decision Tree

- Model type: Fine tree, which is a decision tree with many leaves that makes many fine distinctions between classes.

- Maximum number of splits: 500, which defines the maximum number of splits or branch points to control the depth of the tree.

- Splitting criterion: Gini diversity index, which specifies the measure of the splitting criterion for deciding when to split nodes. It determines the purity of a specific class after it has been split according to a particular attribute. The best split increases the purity of the sets resulting from the split [38].

- Validation: Fivefold cross-validation is used to obtain a better insight into the prediction accuracy for the new data. It divides the training data into five random parts. It forms 05 new trees and then examines the predictive accuracy of each new tree on the data not included in the formation of that tree. This method gives a good estimate of the predictive accuracy of the resulting tree since it tests the new trees on new data.

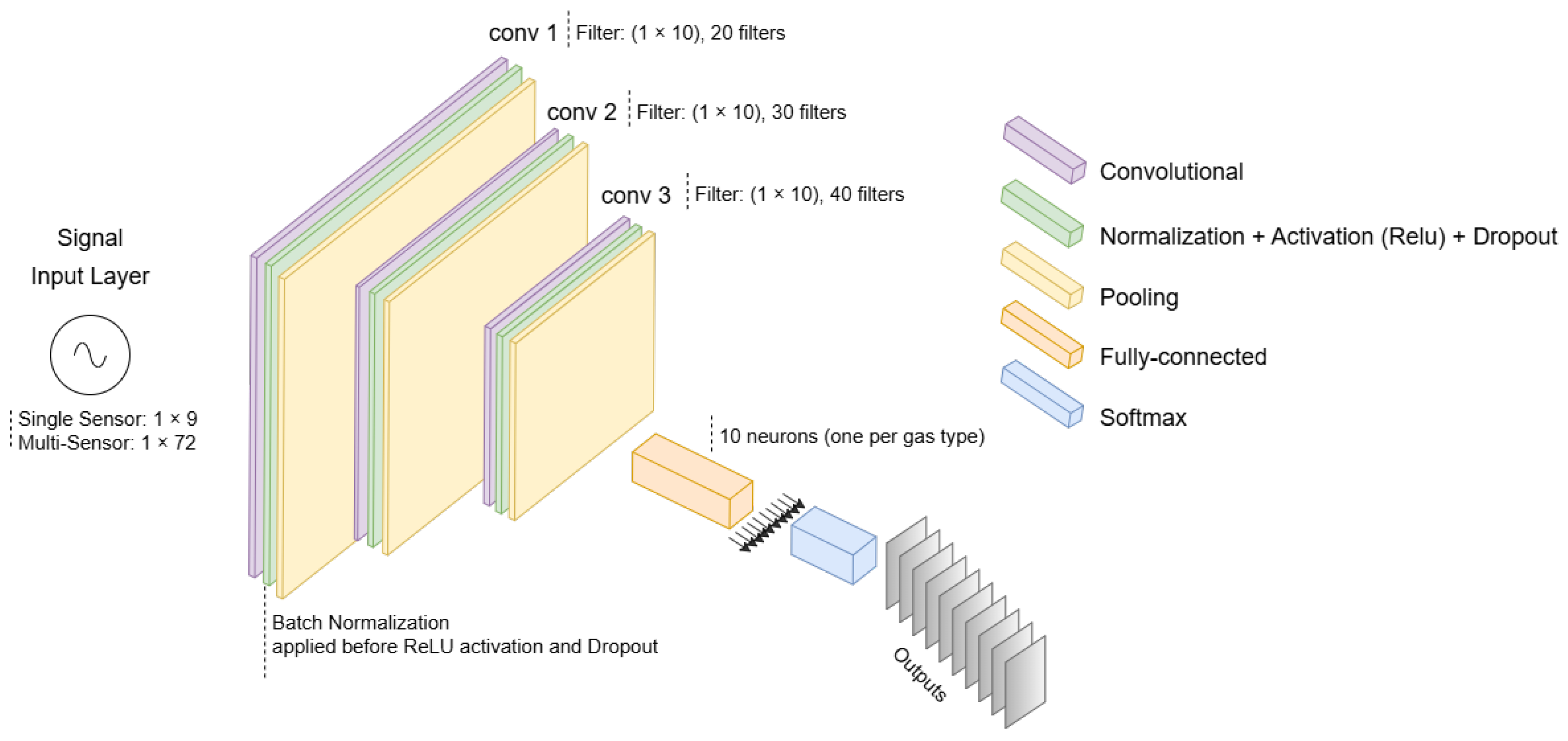

4.4. DCNN

4.5. NSGA-II Optimization

- Non-dominated sorting: NSGA-II sorts candidate solutions into several Pareto fronts. A Pareto front contains so-called ‘non-dominated’ solutions, meaning no other solution on this front simultaneously outperforms a given solution for all objectives. NSGA-II categorizes solutions into Pareto fronts based on dominance relationships. A solution dominates another solution if , where represents the ith objective function. The first Pareto front contains non-dominated solutions (no solution is strictly better in all objectives). The second front contains solutions dominated only by those in the first front, and so on.

- Crowding distance: The computation of the crowding distance involves arranging the population of solutions based on the values of each objective function in ascending order. After this sorting, the boundary solutions with the smallest and largest function values are given an infinite distance value. To maintain solution diversity, NSGA-II computes the crowding distance metric, which estimates how close a solution is to its neighbors. The crowding distance of a solution is given bywhere and are the function values of adjacent solutions in the sorted list of objective m, and are the maximum and minimum values in that front. Larger crowding distances ensure better distribution across the Pareto front. Solutions in sparse regions are favored during selection.

- Genetic operators: NSGA-II uses genetic algorithm operators, namely selection, crossover, and mutation, to evolve the population over generations. Selection uses a binary sorting process based on Pareto dominance and crowding distance. Simulation binary crossover (SBX) is generally used to generate offspring solutions, and polynomial mutation is used to introduce small variations and maintain genetic diversity.

| Algorithm 1 NSGA-II algorithm overview. |

|

- Concerning the first objective, we minimize the number of active sensors to reduce deployment and maintenance costs:The aim is to minimize this sum, which represents the total number of sensors activated in the network. This number inherently accounts for both deployment and maintenance costs, as each additional sensor contributes to the overall expenses of installation, operation, and upkeep. Deployment costs include purchasing, calibration, and installation, while maintenance costs cover servicing, recalibration, power consumption, and replacements. Since these costs scale with the number of sensors, minimizing the total number of sensors effectively minimizes all associated costs.

- Maximize the overall accuracy of gas detection to ensure effective environmental monitoring:where is the accuracy of sensor j at position i. The overall accuracy is the average of the detection accuracies at each position, weighted by the sensor activity at each position. The negative sign in front of the function represents the need to maximize accuracy, as multi-objective optimization algorithms seek to minimize objective functions.

- Constraint: at least one sensor must be active in each critical monitoring zone to guarantee minimum detection throughout the monitored zone:

- Optimization process [9]:

- –

- Initialization: An initial population of solutions is randomly generated. Each solution represents a set of sensors activated or deactivated at different positions.

- –

- Pareto sorting: The solutions are ranked according to their performance on the two objectives. Non-dominated solutions are identified and ranked on the first Pareto front.

- –

- Crossover and mutation: At each iteration, the solutions are combined (crossover) and modified (mutation) to generate new sensor configurations while respecting the defined objectives.

- –

- Selection of optimal solutions: At the end of each generation, solutions are selected based on Pareto sorting and crowding distance, ensuring a good compromise between objectives and a diversity of proposed solutions.

The algorithm is run over several generations until convergence is reached, resulting in optimal solutions representing trade-offs between the number of sensors and detection accuracy. These solutions recommend sensor combinations that optimize the detection system’s cost and performance. - The Matlab 2023a implementation of the NSGA-II algorithm was used with a population size of 50, 100 generations, a crossover rate of 0.9, and a mutation rate of 0.05.

5. Results and Discussion

5.1. Performance of the DCNN and Decision Tree Detection Algorithms

5.2. Results of the NSGA-II Multi-Objective Optimization

5.3. Performance of the DCNN Using the Optimal Sets of Sensor

- The results confirm that the combination of multiple sensors can yield outstanding performance. In particular, at Position P3, the combination of Sensors (2, 3, 4) achieves the maximum accuracy of 100%, demonstrating the strength of this configuration for gas detection. At Position P2, the combination of Sensors (2, 4) achieves a very high accuracy of 99.9%, reinforcing the utility of using selected sensor subsets for specific positions.

- Interestingly, a single sensor (Sensor 2) alone achieves a remarkable 99.9% accuracy at Position P4, suggesting that in some cases, a single sensor can suffice without the need for fusion with other sensors. This reinforces the possibility of cost-effective configurations where single sensors perform optimally.

- The table highlights the variability of optimal sensor combinations across positions. For example, at Position P3, a multi-sensor configuration (2, 3, 4) leads to the best result. In contrast, at Position P4, a single sensor (Sensor 2) achieves nearly perfect accuracy. This underscores the importance of tailoring sensor combinations to the specific requirements of each position.

- Our previous analyses of DCNN performance (Section 5.1) noted that Sensor 2 was a critical contributor across different combinations, particularly when combined with Sensors 3 and 4, which may have a strong potential for optimal performance. The current results further support this observation by demonstrating that the (2, 3, 4) combination is indeed effective, achieving 100% accuracy at P3.

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ali, M.I.; Patel, P.; Breslin, J.G. Middleware for Real-Time Event Detection and Predictive Analytics in Smart Manufacturing. In Proceedings of the 2019 15th International Conference on Distributed Computing in Sensor Systems (DCOSS), Santorini Island, Greece, 29–31 May 2019; pp. 370–376. [Google Scholar] [CrossRef]

- Janjua, Z.H.; Vecchio, M.; Antonini, M.; Antonelli, F. IRESE: An intelligent rare-event detection system using unsupervised learning on the IoT edge. Eng. Appl. Artif. Intell. 2019, 84, 41–50. [Google Scholar] [CrossRef]

- Kumar, M.; Singh, P.K.; Maurya, M.K.; Shivhare, A. A survey on event detection approaches for sensor-based IoT. Internet Things 2023, 22, 100720. [Google Scholar] [CrossRef]

- Vergara, A.; Fonollosa, J.; Mahiques, J.; Trincavelli, M.; Rulkov, N.; Huerta, R. On the performance of gas sensor arrays in open sampling systems using Inhibitory Support Vector Machines. Sens. Actuators B Chem. 2013, 185, 462–477. [Google Scholar] [CrossRef]

- Imam, N.; Cleland, T. Rapid online learning and robust recall in a neuromorphic olfactory circuit. Nat. Mach. Intell. 2020, 2, 181–191. [Google Scholar] [CrossRef] [PubMed]

- Gamboa, J.C.R.; da Silva, A.J.; Araujo, I.C.S.; Albarracin, E.S.; Duran, A.C.M. Validation of the rapid detection approach for enhancing the electronic nose systems performance, using different deep learning models and support vector machines. Sens. Actuators B Chem. 2021, 327, 128921. [Google Scholar] [CrossRef]

- Rüffer, D.; Hoehne, F.; Bühler, J. New Digital Metal-Oxide (MOx) Sensor Platform. Sensors 2018, 18, 1052. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Abdel-Fatah, L.; Sangaiah, A.K. Metaheuristic Algorithms: A Comprehensive Review. In Intelligent Data-Centric Systems, Computational Intelligence for Multimedia Big Data on the Cloud with Engineering Applications; Academic Press: Cambridge, MA, USA, 2018; pp. 185–231. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Morgado, G.; Postolache, O.; Pereira, J.D. Smart City Air Quality Monitoring supported IoT ecosystem. In Proceedings of the 2023 16th International Conference on Sensing Technology (ICST), Hyderabad, India, 17–20 December 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Rath, R.J.; Farajikhah, S.; Oveissi, F.; Dehghani, F.; Naficy, S. Chemiresistive Sensor Arrays for Gas/Volatile Organic Compounds Monitoring: A Review. Adv. Eng. Mater. 2023, 25, 2200830. [Google Scholar] [CrossRef]

- Sinclair, I.; Dunton, J. Sensors and Transducers; Newnes: Oxford, UK, 2001. [Google Scholar]

- Tabella, G.; Ciuonzo, D.; Paltrinieri, N.; Rossi, P.S. Bayesian Fault Detection and Localization Through Wireless Sensor Networks in Industrial Plants. IEEE Internet Things J. 2024, 11, 13231–13246. [Google Scholar] [CrossRef]

- Shaheen, K.; Chawla, A.; Uilhoorn, F.E.; Rossi, P.S. Partial-Distributed Architecture for Multisensor Fault Detection, Isolation, and Accommodation in Hydrogen-Blended Natural Gas Pipelines. IEEE Internet Things J. 2024, 11, 35420–35431. [Google Scholar] [CrossRef]

- Boujnah, A.; Boubaker, A.; Pecqueur, S.; Lmimouni, K.; Kalboussi, A. An electronic nose using conductometric gas sensors based on P3HT doped with triflates for gas detection using computational techniques (PCA, LDA, and kNN). J. Mater. Sci. Mater. Electron. 2022, 33, 27132–27146. [Google Scholar] [CrossRef]

- González, E.; Casanova-Chafer, J.; Romero, A.; Vilanova, X.; Mitrovics, J.; Llobet, E. LoRa Sensor Network Development for Air Quality Monitoring or Detecting Gas Leakage Events. Sensors 2020, 20, 6225. [Google Scholar] [CrossRef] [PubMed]

- Augustin, A.; Yi, J.; Clausen, T.; Townsley, W.M. A Study of LoRa: Long Range & Low Power Networks for the Internet of Things. Sensors 2016, 16, 1466. [Google Scholar] [CrossRef] [PubMed]

- Shaheen, K.; Chawla, A.; Uilhoorn, F.E.; Rossi, P.S. Model-Based Architecture for Multisensor Fault Detection, Isolation, and Accommodation in Natural-Gas Pipelines. IEEE Sens. J. 2024, 24, 3554–3567. [Google Scholar] [CrossRef]

- Iwaszenko, S.; Kalisz, P.; Słota, M.; Rudzki, A. Detection of Natural Gas Leakages Using a Laser-Based Methane Sensor and UAV. Remote Sens. 2021, 13, 510. [Google Scholar] [CrossRef]

- Zacharakis, I.; Giagopoulos, D. Optimal Sensor Placement for Vibration-Based Damage Localization Using the Transmittance Function. Sensors 2024, 24, 1608. [Google Scholar] [CrossRef]

- Suryanarayana, G.; Arroyo, J.; Helsen, L.; Lago, J. A data driven method for optimal sensor placement in multi-zone buildings. Energy Build. 2021, 243, 110956. [Google Scholar] [CrossRef]

- Staszewski, W.J.; Worden, K. Overview of optimal sensor location methods for damage detection. In Smart Structures and Materials 2001: Modeling, Signal Processing, and Control in Smart Structures, Proceedings of the SPIE’s 8th Annual International Symposium on Smart Structures and Materials, Newport Beach, CA, USA, 21 August 2001; SPIE: Bellingham, WA, USA, 2001. [Google Scholar] [CrossRef]

- Bellegoni, M.; Ovidi, F.; Tempesti, L.; Mariotti, A.; Tognotti, L.; Landucci, G.; Galletti, C. Optimization of gas detectors placement in complex industrial layouts based on CFD simulations. J. Loss Prev. Process. Ind. 2022, 80, 104859. [Google Scholar] [CrossRef]

- Sun, L.; Chen, X.; Zhang, B.; Mu, C.; Zhou, C. Optimization of gas detector placement considering scenario probability and detector reliability in oil refinery installation. J. Loss Prev. Process. Ind. 2020, 65, 104131. [Google Scholar] [CrossRef]

- Klise, K.A.; Nicholson, B.L.; Laird, C.D. Sensor Placement Optimization Using Chama; Technical Report; Sandia National Lab.: Albuquerque, NM, USA, 2017. [Google Scholar] [CrossRef]

- Zi, Y.; Fan, L.; Wu, X.; Chen, J.; Han, Z. Microseismic sensor placement optimization for rapid leakage alarm of geologic carbon storage. Presented at the SEG/AAPG International Meeting for Applied Geoscience & Energy, Houston, TX, USA, 27 August–1 September 2023; pp. 426–429. [Google Scholar] [CrossRef]

- Gad, A. Particle Swarm Optimization Algorithm and Its Applications: A Systematic Review. Arch. Comput. Methods Eng. 2022, 29, 2531–2561. [Google Scholar] [CrossRef]

- Guilmeau, T.; Chouzenoux, E.; Elvira, V. Simulated Annealing: A Review and a New Scheme. In Proceedings of the SSP 2021—IEEE Statistical Signal Processing Workshop, Rio de Janeiro, Brazil, 11–14 July 2021. [Google Scholar]

- Ahmed, W.; Shah, N.; Muntean, G.M. An Innovative NSGA-II-Based Byzantine Fault Tolerant Solution for Software Defined Network Environments. Comput. Netw. 2024, 254, 110819. [Google Scholar] [CrossRef]

- Luan, C.; Liu, R.; Zhang, Q.; Sun, J.; Liu, J. Multi-Objective Land Use Optimization Based on Integrated NSGA–II–PLUS Model: Comprehensive Consideration of Economic Development and Ecosystem Services Value Enhancement. J. Clean. Prod. 2024, 434, 140306. [Google Scholar] [CrossRef]

- ElMeyer zu Westerhausen, S.; Kyriazis, A.; Hühne, C.; Lachmayer, R. Design Methodology for Optimal Sensor Placement for Cure Monitoring and Load Detection of Sensor-Integrated, Gentelligent Composite Parts. Proc. Des. Soc. 2024, 4, 673–682. [Google Scholar] [CrossRef]

- Fonollosa, J.; Rodríguez-Luján, I.; Trincavelli, M.; Huerta, R. Dataset from chemical gas sensor array in turbulent wind tunnel. Data Brief 2015, 3, 169–174. [Google Scholar] [CrossRef]

- Ngatchou, P.; Zarei, A.; El-Sharkawi, A. Pareto Multi Objective Optimization. In Proceedings of the 13th International Conference on Intelligent Systems Application to Power Systems, Arlington, VA, USA, 6–10 November 2005; pp. 84–91. [Google Scholar] [CrossRef]

- Suawa, P.; Meisel, T.; Jongmanns, M.; Huebner, M.; Reichenbach, M. Modeling and Fault Detection of Brushless Direct Current Motor by Deep Learning Sensor Data Fusion. Sensors 2022, 22, 3516. [Google Scholar] [CrossRef]

- Thudumu, S.; Branch, P.; Jin, J.; Singh, J. A comprehensive survey of anomaly detection techniques for high dimensional big data. J. Big Data 2020, 7, 42. [Google Scholar] [CrossRef]

- Xia, Z.; Chen, Y.; Xu, C. Multiview PCA: A Methodology of Feature Extraction and Dimension Reduction for High-Order Data. IEEE Trans. Cybern. 2022, 52, 11068–11080. [Google Scholar] [CrossRef]

- Mienye, I.D.; Jere, N. A Survey of Decision Trees: Concepts, Algorithms, and Applications. IEEE Access 2024, 12, 86716–86727. [Google Scholar] [CrossRef]

- Suryakanthi, T. Evaluating the Impact of GINI Index and Information Gain on Classification using Decision Tree Classifier Algorithm. Int. J. Adv. Comput. Sci. Appl. 2020, 11, 612–619. [Google Scholar] [CrossRef]

- Suawa, P.F.; Hübner, M. Health Monitoring of Milling Tools under Distinct Operating Conditions by a Deep Convolutional Neural Network model. In Proceedings of the 2022 Design, Automation & Test in Europe Conference & Exhibition (DATE), Antwerp, Belgium, 14–23 March 2022; pp. 1107–1110. [Google Scholar] [CrossRef]

- Li, P.; Huang, L.; Peng, J. Sensor Distribution Optimization for Structural Impact Monitoring Based on NSGA-II and Wavelet Decomposition. Sensors 2018, 18, 4264. [Google Scholar] [CrossRef]

- Souri, A.; Ghafour, M.Y.; Ahmed, A.M.; Safara, F.; Yamini, A.; Hoseyninezhad, M. A New Machine Learning-Based Healthcare Monitoring Model for Student’s Condition Diagnosis in Internet of Things Environment. Soft Comput. 2020, 24, 17111–17121. [Google Scholar] [CrossRef]

- SGX. SGX Datasheet MiCS-6814. Available online: https://www.sgxsensortech.com/uploads/f_note/1143_Datasheet-MiCS-6814-rev-8.pdf (accessed on 31 March 2025).

- Sensirion. Sensirion Datasheet SGP41. Available online: https://sensirion.com/media/documents/5FE8673C/61E96F50/Sensirion_Gas_Sensors_Datasheet_SGP41.pdf (accessed on 31 March 2025).

| Positions (Pi)/ Solutions (S_t) | P1 | P2 | P3 | P4 | P5 | Total Number of Sensors | Overall Accuracy (%) |

|---|---|---|---|---|---|---|---|

| S_1 | 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 11 | 94.56 |

| S_2 | 1; 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 12 | 94.61 |

| S_3 | 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 11 | 94.57 |

| S_4 | 1; 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 12 | 94.60 |

| S_5 | 1; 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 12 | 94.58 |

| S_6 | 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 11 | 94.56 |

| S_7 | 1; 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 12 | 94.60 |

| S_8 | 2; 4 | 2 | 2; 3; 4 | 2 | 2; 4; 7 | 10 | 94.51 |

| S_9 | 1; 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 12 | 94.60 |

| S_10 | 2; 4 | 2 | 2; 3; 4 | 2 | 2; 4; 7 | 10 | 94.51 |

| S_11 | 1; 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 12 | 94.57 |

| S_12 | 2; 4 | 2; 4 | 2; 4 | 2 | 2; 4; 7 | 10 | 94.55 |

| S_13 | 2; 4 | 2 | 2; 3; 4 | 2 | 2; 4; 7 | 10 | 94.53 |

| S_14 | 1; 2; 4 | 2; 4 | 2; 4 | 2 | 2; 4; 7 | 11 | 94.57 |

| S_15 | 2; 4 | 2 | 2; 3; 4 | 2 | 2; 4; 7 | 10 | 94.46 |

| S_16 | 1; 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 12 | 94.55 |

| S_17 | 1; 2; 4 | 2; 4 | 2; 3; 4 | 2 | 2; 4; 7 | 12 | 94.59 |

| Sensors/Positions (Pi) | Sensor 2 | Sensors (2; 4) | Sensors (2; 3; 4) | Sensors (2; 4; 7) | Sensors (1; 2; 4) |

|---|---|---|---|---|---|

| P1 | - | 98.6% | - | - | 97.8% |

| P2 | 97.8% | 99.9% | - | - | - |

| P3 | - | 99.7% | 100% | - | - |

| P4 | 99.9% | - | - | - | - |

| P5 | - | - | - | 99.1% | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suawa, P.F.; Herglotz, C. Optimizing Sensor Placement for Event Detection: A Case Study in Gaseous Chemical Detection. Sensors 2025, 25, 2397. https://doi.org/10.3390/s25082397

Suawa PF, Herglotz C. Optimizing Sensor Placement for Event Detection: A Case Study in Gaseous Chemical Detection. Sensors. 2025; 25(8):2397. https://doi.org/10.3390/s25082397

Chicago/Turabian StyleSuawa, Priscile Fogou, and Christian Herglotz. 2025. "Optimizing Sensor Placement for Event Detection: A Case Study in Gaseous Chemical Detection" Sensors 25, no. 8: 2397. https://doi.org/10.3390/s25082397

APA StyleSuawa, P. F., & Herglotz, C. (2025). Optimizing Sensor Placement for Event Detection: A Case Study in Gaseous Chemical Detection. Sensors, 25(8), 2397. https://doi.org/10.3390/s25082397