Research and Prospects of Digital Twin-Based Fault Diagnosis of Electric Machines

Abstract

:1. Introduction

2. Current Status of Research on Digital Twins

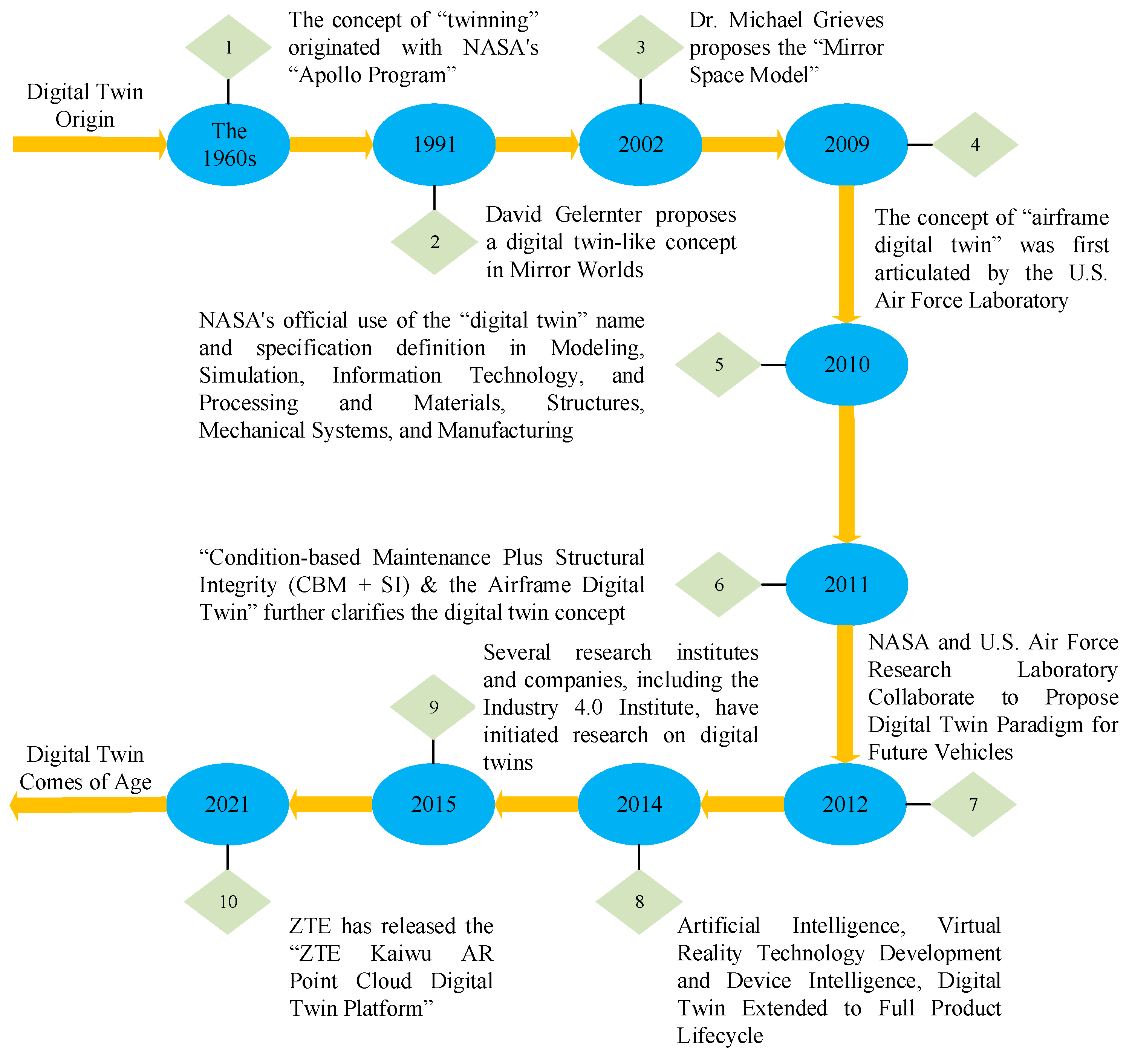

2.1. Origins and Development of Digital Twins

2.1.1. Origins of the Digital Twin

2.1.2. The Concept of a Digital Twin

- (1)

- Virtual–reality mapping. The digital twin collects and transmits real-time data of the physical entity to the virtual space through sensors and other technical means, and constructs a dynamic mapping relationship between the physical entity and the virtual model, which enables the virtual model to truly reflect the real-time situation of the physical entity [10].

- (2)

- Data-driven. The construction and operation of digital twins rely on massive amounts of real-time data. These data come from the physical entity’s sensors, historical operation records and the external environment. Through the analysis and processing of these data, the digital twin can continuously optimize its own model parameters, thus improving the simulation accuracy and prediction ability of the physical entity [11].

- (3)

- Model fusion. Digital twins usually consist of multiple models at different levels and in different domains, including geometric, physical, behavioral and rule models. These models are interrelated and fused together to form a complete digital twin system. Through model fusion, digital twins are able to comprehensively describe and analyze physical entities from multiple perspectives, providing powerful support for modeling and simulation of complex systems [12].

- (4)

- Real-time interaction. There is a real-time two-way interaction between the digital twin and the physical entity. On the one hand, the digital twin can be dynamically updated and optimized according to the real-time data of the physical entity; on the other hand, the simulation results and prediction information of the digital twin can be fed back to the physical entity to provide a basis for its operation control and decision-making [13].

- (5)

- Full lifecycle coverage. The digital twin runs through the entire lifecycle of a physical entity, from product design and manufacturing to operation and maintenance and end-of-life recycling. At different stages, digital twins can play different roles, such as virtual validation and optimization at the design stage, guidance of the production process at the manufacturing stage, and condition monitoring and fault prediction at the operation stage [14].

2.2. Key Technologies and Applications of Digital Twins

2.2.1. Digital Twin Key Technologies

- (1)

- Modeling technology. Digital twin modeling is the foundation of the technology, and the characteristics of multiple aspects of physical entities need to be considered to construct an accurate model. Multi-physics field modeling integrates the multi-physics field characteristics of physical entities; e.g., in the aerospace field, hydrodynamics, structural mechanics, and other multi-physics fields are coupled in the modeling of aircraft to accurately simulate flight states [10]. Multi-scale modeling covers different scale information from microscopic to macroscopic levels, and in the manufacturing industry, the atomic structure of microscopic parts and components is covered for overall performance modeling of the macroscopic product, which comprehensively reflects the product characteristics [11]. Data-driven modeling is based on a large number of historical data mining laws to establish models, such as in power equipment fault diagnosis, based on equipment operation data to establish fault prediction models to improve diagnostic accuracy [12].

- (2)

- Data processing technology. Data collection collects physical entity multi-source heterogeneous data through sensors, and collects equipment operation parameters, environmental data, etc., in industrial production [13]. Data cleaning removes erroneous and redundant data to improve data quality. Feature extraction refines key features from raw data to provide support for subsequent analysis and decision-making. Data fusion integrates multi-source data, such as the fusion of vehicle sensors, road conditions and other data in intelligent transportation systems to improve the reliability of system decision-making [14].

- (3)

- Communication technology. Communication technology realizes real-time interactions between physical entities and virtual model data. Fifth-generation technology has high speed, low latency and large connection characteristics, which meet the demand for real-time transmission of large amounts of data from digital twins and facilitate efficient communication between devices and models on the industrial Internet [15]. Industrial Ethernet is widely used in factory automation scenarios for its high reliability and real-time performance, guaranteeing stable transmission of equipment data [16]. Wireless sensor networks are suitable for data acquisition and transmission in complex environments, such as in building structural health monitoring, where wireless sensors are deployed to obtain structural status data [17].

- (4)

- Intelligent decision-making technology. Intelligent decision-making techniques are based on digital twin models and data to achieve optimal decision-making. Machine learning algorithms such as neural networks, support vector machines, etc., analyze and train on the digital twin data to achieve fault diagnosis, playing an important role in wind power equipment fault diagnosis [18]. Deep learning in image recognition, speech processing and other aspects performs remarkably and can help digital twins deal with complex data, improving the level of decision-making intelligence, such as in the field of intelligent security for image analysis to identify abnormal behavior [19]. Expert systems reason and make decisions based on the knowledge and experience of domain experts, providing professional decision support for digital twins—e.g., assisting doctors in judging medical conditions in medical diagnostic assistance systems [20].

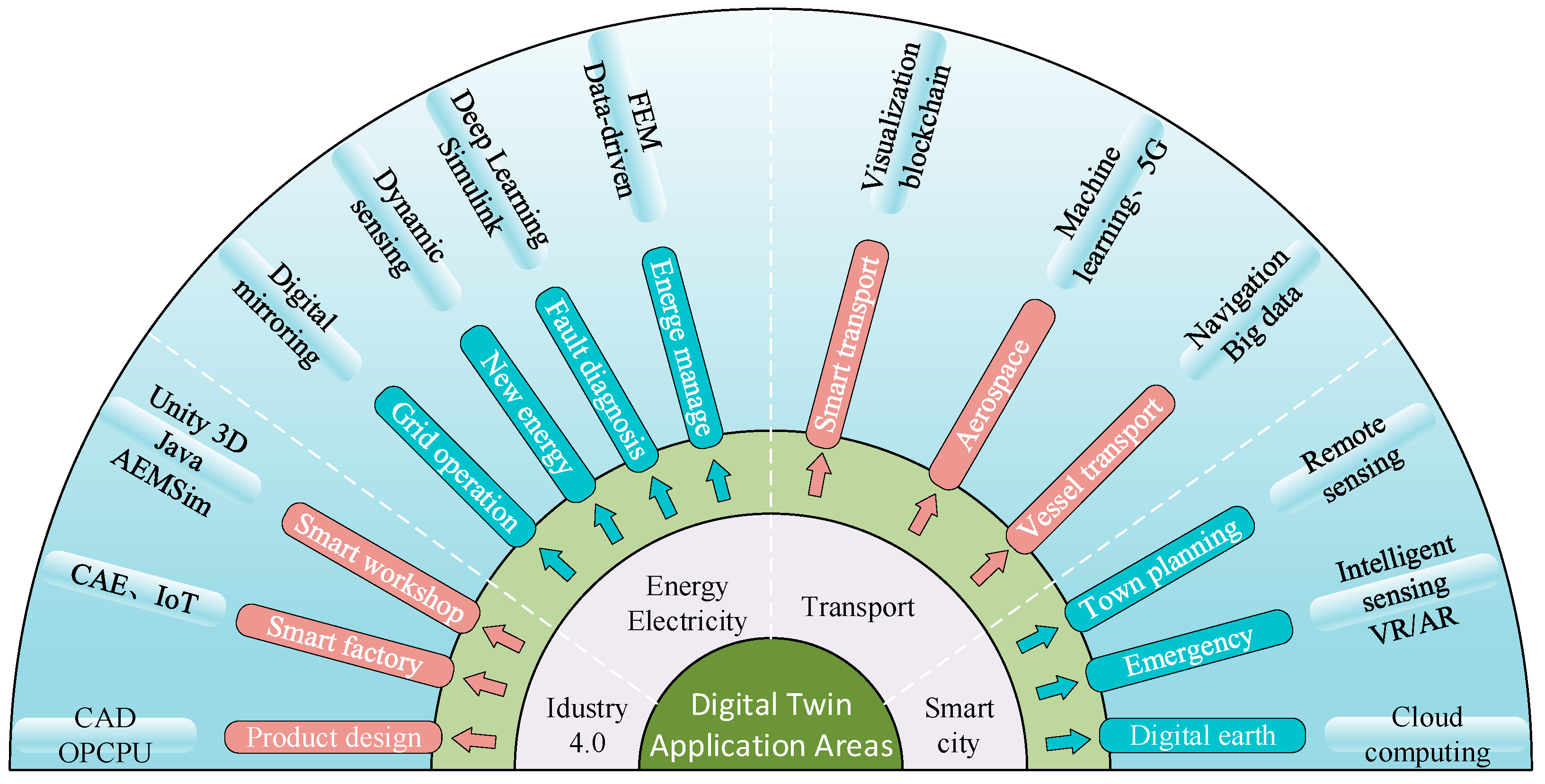

2.2.2. Digital Twin Application Areas

- (1)

- Smart manufacturing field. In the product design stage, virtual models are constructed for simulation and optimization. Design defects are found in advance, and the R&D cycle is shortened; e.g., digital twins are used to optimize the design of body structures in automobile manufacturing [21]. In the production process, digital twins enable real-time monitoring of equipment operating status and prediction of failures and timely maintenance to improve production efficiency and product quality; e.g., factories through digital twins can monitor the operating parameters of equipment to predict failures [22]. In the after-sales stage of products, product usage data can be analyzed based on digital twins to improve product performance and service; e.g., home appliance companies optimize product functionality by analyzing user usage data [23].

- (2)

- Energy and power field. In power generation, generator sets are modeled to monitor the operating status in real time, predict failures and performance degradation and optimize power generation efficiency—e.g., monitoring boiler operating parameters to predict failures in thermal power generation [24]. In transmission, digital twin models of transmission lines are constructed to monitor line status, assess fault risk and improve transmission reliability; e.g., digital twins are used to monitor transmission line ice cover [25]. Distribution links, as supported by digital twins, help realize digital management of distribution networks and optimize power distribution—e.g., analyzing distribution network load distribution to optimize power supply schemes through digital twins [26].

- (3)

- Transportation field. In intelligent transportation systems, data on vehicles, roads and traffic flow are fused to optimize traffic signal control and route planning to alleviate traffic congestion [27]. In the field of aerospace, the modeling of aircraft and engines to monitor performance and health and to ensure flight safety uses digital twins—e.g., the use of digital twins by aircraft manufacturers to monitor engine operation status [28]. In ship transportation, real-time monitoring of ship navigation status uses digital twins, optimizing route planning and improving transportation efficiency and safety—e.g., analyzing ship navigation data to optimize routes through digital twins [29].

- (4)

- Smart city field. In urban planning, the construction of urban digital models to simulate the development of a city provides a basis for planning decisions—e.g., simulating the development of the city to assess the feasibility of planned programs [30]. In urban management, digital twins help realize real-time monitoring and intelligent management of urban infrastructure, environment, transportation, etc. One example of an application is monitoring urban environmental data to realize intelligent environmental protection [31]. In emergency management, digital twins are used to simulate disaster scenarios, develop emergency plans and improve emergency response capabilities [32].

3. Current Research Status of Motor Fault Diagnosis Technology

3.1. Types and Causes of Common Motor Faults

3.1.1. Electrical Faults

- (1)

- Stator winding faults: Stator winding faults are the more common types of electrical faults in motors, including phase-to-phase short circuits, turn-to-turn short circuits and grounded short circuits. Reference [33] states that about 32% of the damage to induction motors is caused by short circuit faults due to insulation failure. Insulation aging is one of the main causes of stator winding short circuits. During long-term operation, the electromagnetic stress, thermal stress and environmental factors inside the motor will gradually degrade the performance of the insulating material, ultimately reducing the insulating ability. In addition, mechanical damage, moisture, etc., may also trigger stator winding short circuiting. During the manufacturing, installation or operation of a motor, if it is impacted by external forces, the winding insulation may be damaged; and when motors are operated in a humid environment, moisture intrusion will reduce the insulation performance and increase the probability of short circuit failure [34]. Reference [35] states that 80% of stator electrical faults are caused by weak turn-to-turn insulation. After an ITSC fault occurs in a nine-phase PMSM, the stator windings will form a short circuit loop, which generates a large short circuit current under the action of the magnetic field, causing severe damage to the motor. Reference [36] points out that the insulation aging caused by long-term operation of asynchronous motors, overload caused by abnormal loads and poor contact caused by wear and tear of components will make direct contact between the windings and cause short circuiting of the rotor windings.

- (2)

- Rotor failure: Rotor failure mainly includes rotor broken bars and rotor imbalance. The broken rotor strip will cause motor output torque reduction, abnormal vibration and noise during operation. As described in [37], when the motor is frequently started, braked or overloaded, the rotor guide bar will be subjected to significant mechanical stress and electromagnetic forces, which can easily lead to the fracture of the guide bar in the long term. In addition, the poor quality of rotor materials and the presence of internal defects also increase the risk of rotor bar breakage. Rotor imbalance is usually caused by rotor manufacturing process errors, improper installation or localized wear during operation. An unbalanced rotor generates centrifugal force when rotating, resulting in increased vibration of the motor, which not only affects the service life of the motor, but also may cause damage to the surrounding equipment [38].

- (3)

- Demagnetization failure: When the PMSM operates at high speeds or high loads, the temperature rises significantly, causing irreversible demagnetization of the permanent magnets. The demagnetization fault will degrade the performance of the motor, as evidenced by the change in the output characteristics of the motor under different load and speed conditions. Reference [39] investigated three demagnetization fault states of PMSM—normal, mild demagnetization (10% demagnetization) and severe demagnetization (25% demagnetization)—and pointed out that the temperature of the PMSM increases significantly during high-speed or high-load operation, which may result in irreversible demagnetization of the permanent magnets, and then degrade the performance of the motor. Reference [40] points out that the operating conditions of PMSM are complex, and factors such as inrush currents generated by armature reactions, severe mechanical vibrations and excessive temperatures may lead to irreversible demagnetization of the permanent magnets.

3.1.2. Mechanical Faults

- (1)

- Bearing failure: Bearing failure occupies a high proportion of motor failures and is mainly manifested as bearing wear, fatigue spalling, poor lubrication and so on. According to [41], mechanical friction during long-term operation is an important cause of bearing wear, while insufficient lubrication, impurity intrusion and other factors will further aggravate the degree of wear. According to [42], when the bearing is poorly lubricated, the friction coefficient increases, which accelerates the wear of the bearing; if impurities enter into the bearing interior, it will destroy the normal operation of the bearing and trigger fatigue spalling. According to [43], inner ring failure is a common type of motor bearing failure, and during the operation of the motor, when the bore size of the inner ring is different, there will be defects such as breakage and holes in the inner ring. Reference [44] states that factors covering load variations, insufficient cooling, manufacturing defects, current problems, shaft clearance, transient voltage events and voltage imbalance can put additional stress on the internal components of the motor, accelerating the wear and aging of components and ultimately leading to the occurrence of bearing failures.

- (2)

- Other mechanical failures: The motor may also experience mechanical problems such as brush wear and collector ring failure. During the operation of the motor, the brushes and the collector ring are in constant contact and friction, and if the contact pressure is uneven or the current density distribution is abnormal, it will lead to increased localized wear of the brushes [45]. Collector ring failures are usually manifested as surface oxidation, burns, etc., which are closely related to the electrical performance and environmental factors during motor operation [46]. In an environment of high humidity or the presence of corrosive gases, the surface of the collector ring is easy to oxidize, which affects its electrical conductivity; and when the motor is overloaded or short-circuited and suffers other abnormalities, the excessive current will cause the surface of the collector ring to be burned [47].

3.2. Motor Fault Diagnosis Methods and Applications

3.2.1. Sensor-Based Diagnostic Methods

3.2.2. Diagnostic Methods Based on Data Analysis

- (1)

- Time-domain analysis method: Time-domain analysis is to directly analyze the collected motor operation data in the time domain, such as observing the waveform changes of current and voltage signals. However, ref. [51] points out that time-domain analysis has limitations when facing complex faults, which makes it difficult to accurately extract fault characteristics, and for some minor faults, thee changes in the time-domain signals may not be obvious and can be easily ignored.

- (2)

- Frequency-domain analysis method: Frequency-domain analysis involves converting the time-domain signal to the frequency domain by means of Fourier transform and other means to analyze the frequency components of the signal, so as to find out the fault characteristic frequency [52]. Through the frequency-domain analysis of the motor vibration signal, if it is found that the amplitude at a specific frequency increases abnormally, it can be judged that there may be rotor imbalance, a bearing failure and other problems. Reference [53] proposes a generalized diagnostic method based on stator current spectral features and motor speed using an SVM algorithm. The time-domain waveform of load current is obtained through an experiment, and the spectrum is obtained by fast Fourier transform, and the 30 Hz and 90 Hz frequency components are extracted as the SVM features, while the motor speed is used as an additional feature to improve the accuracy of rotor broken bar fault diagnosis [54].

- (3)

- Data mining and machine learning methods: Reference [55] used a particle swarm optimization algorithm-optimized least squares support vector machine (PSO—LSSVM) approach to diagnose motor faults, which significantly improves the accuracy and efficiency of fault diagnosis by learning and training on a large amount of fault data. Literature [56] proposed an edge intelligence-based application deployment method for motor fault diagnosis, which achieves efficient and accurate fault diagnosis on resource-constrained edge devices by integrating multi-scale convolutional neural networks, long- and short-term memory networks and attention mechanisms, combined with knowledge distillation and model quantization techniques. Reference [57] constructs a CNN-based fault diagnosis system for induction motors. The CNN model analyzes the input data and then determines whether the motor is in a normal state, a rotor fault state or a bearing fault state. In view of the strong RF classification capability and CNN feature extraction capability, ref. [58] proposed to combine the two to form a CNN-RF model. The model first utilizes CNN to extract features from the fault data, and then RF diagnoses the fault type based on the extracted features. Experiments show that compared with other models, the CNN-RF model has a higher accuracy in motor fault diagnosis.

3.2.3. Model-Based Diagnostic Methods

- (1)

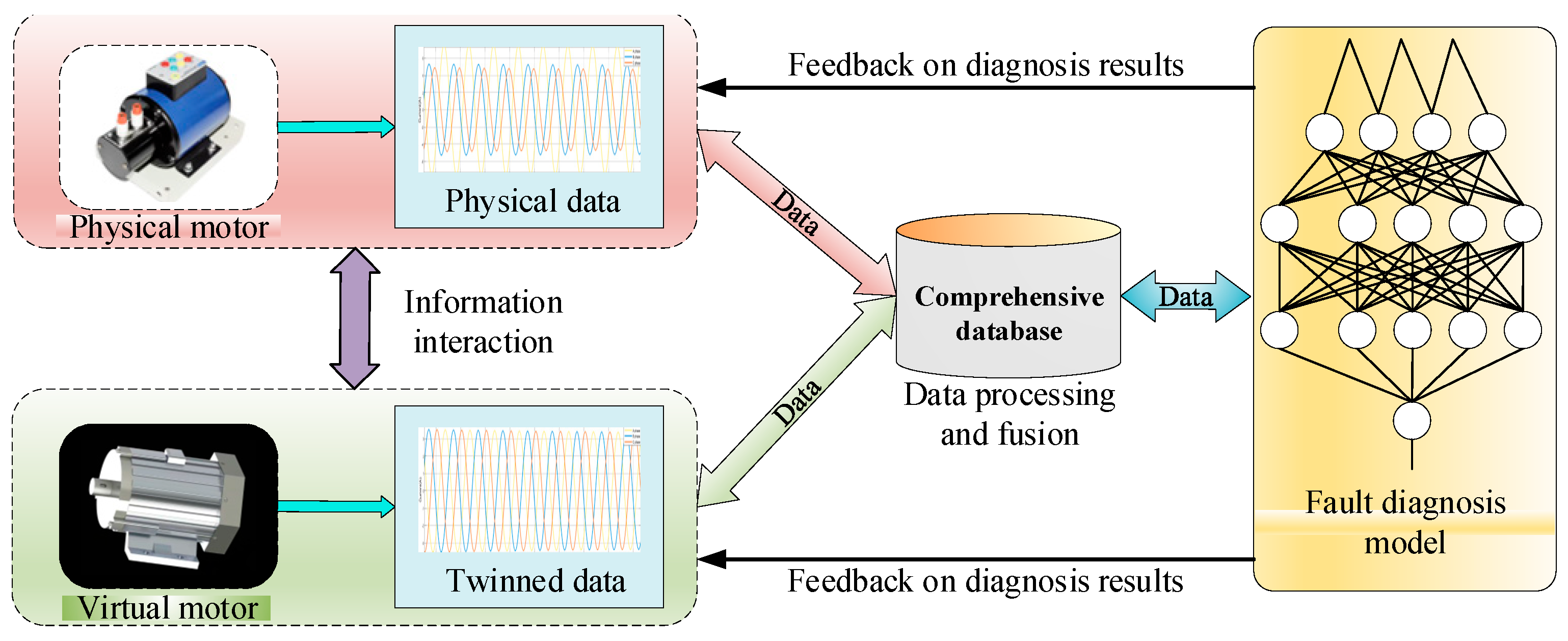

- Digital twin model: A digital twin model can comprehensively reflect the physical characteristics and operating state of a motor, providing a more accurate basis for fault diagnosis and having broad application prospects in the fields of wind power, aerospace and others requiring high reliability of the motor. Reference [59] proposed a wind turbine drive train fault diagnosis method based on a digital twin, through the establishment of a digital twin model of the motor, real-time simulation of the motor’s operating state and comparison and analysis with the actual operating data, so as to realize the diagnosis and prediction of motor faults. Reference [60] states that in wind farms, the use of digital twin models allows real-time monitoring and fault prediction of wind turbine motors, scheduling maintenance in advance, reducing operation and maintenance costs and improving power generation efficiency.

- (2)

- Deep learning model: Deep learning models have powerful learning and adaptive capabilities, and can accurately recognize complex motor fault patterns [61,62]. The deep learning network-based asynchronous motor fault identification method proposed in the [63] first utilizes SAE to reduce noise and dimensionality of the fault dataset, and then uses CNN to automatically learn the deep features of the fault data. The method has strong adaptability and generalization ability to non-linear fault data, and comprehensively improves the accuracy, robustness and efficiency of asynchronous motor multi-fault diagnosis. Reference [64] proposes a prototype refinement method based on Deep Reinforcement Learning (DRL) for semi-supervised few-sample motor fault diagnosis to solve the problem of data scarcity in industrial scenarios, and experimentally verifies the effectiveness of the method in cross-category and cross-condition diagnosis tasks. In motor fault diagnosis, the neural network constructs a fault diagnosis model by learning the feature data of the motor under normal operation and various fault states. Literature [65] combines tools such as continuous wavelet transform, DFT, STFT, etc., and realizes automated diagnosis with the help of an adaptive neural network fuzzy inference system (ANFIS), which is able to detect the number of faulty turns and faulty phases.

3.2.4. Comparative Analysis of Different Diagnostic Methods

3.2.5. Areas of Application of Diagnostic Methods

- (1)

- Industrial field: In industrial production, the normal operation of a motor, as a core component of mechanical equipment, is directly related to production efficiency and product quality. The various diagnostic methods mentioned above have been widely used in industrial motor fault diagnosis. Reference [66] points out that in the automated production line of a factory, through real-time monitoring of the motor’s operating data and the use of diagnostic methods based on sensors and data analysis, it is possible to discover hidden motor faults in a timely manner to ensure the stable operation of the production line. Reference [67] takes an elevator as an example, where the elevator had a permanent magnet synchronous motor as a key component; the reliability of its operating state is crucial. Using the fault diagnosis method for data analysis, combined with Kalman filtering, it is possible to discover minor faults in the motor over time and avoid further deterioration of the faults. In industrial scenarios using motors, ref. [68] constructs a network structure containing feature extractors, classifiers and unseen fault detectors, utilizing online samples and samples of each known category for adversarial training, for monitoring the operating status of motors, and for timely detection of faults and diagnosis.

- (2)

- Energy field: In the energy industry, such as wind power and thermal power generation, the reliability of motors directly affects the production and supply of energy. Fault diagnosis of wind turbines based on digital twin and machine learning methods in [69] effectively guarantees the stable operation of wind power systems. Through real-time monitoring and fault diagnosis of motors, maintenance plans can be formulated in advance to reduce downtime and improve the reliability and economy of energy production [70]. In smart power plants, ref. [71] uses multi-sensor data acquisition and SDP image conversion to collect multi-source signals such as data on the current, electromagnetism and vibration of the motor in real time, having installed Hall current sensors, vibration sensors and high-frequency AC magnetic field probes on the motor. These signals are converted into SDP images and input into the MSF-SACapsNet model for analysis, which can accurately identify whether the motor is in a state of rotor imbalance, rotor misalignment, bearing failure, etc.

- (3)

- Transportation: In the field of transportation, motors are widely used in electric vehicles, electric trains and other equipment. Accurate fault diagnosis is crucial to ensure the safety and smoothness of transportation. Diagnostic methods based on sensors and data analysis can monitor the running status of motors in real time, detect faults over time, avoid accidents during operation, and guarantee the safety of passengers and normal transportation [72]. In the CRH2 high-speed train traction system, in view of the non-linearity of the induction motor, ref. [73] proposes constructing a T-S fuzzy model to represent the operating state of the motor at different speeds with multiple linear submodels, and then combine these submodels into a global system model through the fuzzy affiliation function, so as to effectively deal with the non-linear problem of the motor.

- (4)

- Other fields: Motor troubleshooting techniques are also used in smart homes and medical devices. In smart home systems, motors are used to drive various types of equipment. By monitoring and diagnosing the operating status of motors, faults can be detected in a timely manner, improving the reliability of home equipment and user experience [74]. In the field of medical devices, the use of advanced fault diagnosis methods can monitor the status of motors in some life-support equipment in real time to ensure the normal operation of the equipment, providing reliable protection for medical work [75]. In some high-end medical equipment, such as magnetic resonance imaging machines and intensive care monitors, the use of fault diagnosis technology for real-time monitoring of the motors in these devices can detect potential problems in real-time and avoid equipment failures that can cause harm to patients [76].

| Reference Signal | Diagnosis Method | Advantages | Limitations | Reference |

|---|---|---|---|---|

| Vibration | Bayesian algorithms, SVM, KNN | high diagnostic efficiency and generalization capability | Insufficient diagnostic capability for complex conditions | [44] |

| Vibration | CNN, GUI | High accuracy | \ | [49] |

| Vibration | CNN, LSTM | High diagnostic accuracy and speed | Limited application scenarios | [56] |

| Vibration | DRL | Good small sample fault diagnosis | Large computational and experimental costs | [62] |

| Current | FFT, KNN, SVM | Effective extraction of key features for high diagnostic accuracy | Feature extraction relies on expert knowledge | [43] |

| Current | Cubic Fractional Order Model, Traceless Kalman Filter | High diagnostic accuracy for minor faults considering | \ | [65] |

| Current | T-S fuzzy model, fault observer | Robust and sensitive, high accuracy | \ | [70] |

| Flux | Search coils, harmonic magnetic fields | Low cost and fast | Simulation-based, not practical enough | [35] |

| Power Torque | Autoencoder and K-means | High accuracy without sensors | \ | [39] |

| Magnetic Flux Density | FEM | Non-invasive diagnostics to reduce testing costs | \ | [40] |

| Current RPM | FFT, SVM | High diagnostic accuracy for minor faults | No mention of simultaneous occurrence of multiple failures | [53] |

| Vibration Current | Model-based, signal processing, data-driven | Automatic fault recognition and extraction | Insufficient precision, low resolution | [57] |

| Vibration Current | CNN, LeakyRelu Function | High robustness and generalization | \ | [61] |

| Current Torque | LabVIEW Motor Model, CNN-RF Model | High accuracy | \ | [58] |

| Torque | FT, DWT | Utilization of mathematical tools, wide range of diagnostics | Poor low-speed diagnostics and high hardware costs | [63] |

| Acceleration | Knowledge distillation strategies for predicting score ordering | Automatic fault detection with high diagnostic accuracy | \ | [66] |

| Vibration Current | Capsule network with self-attention mechanism | High diagnostic accuracy and robustness | High consumption of computing resources | [69] |

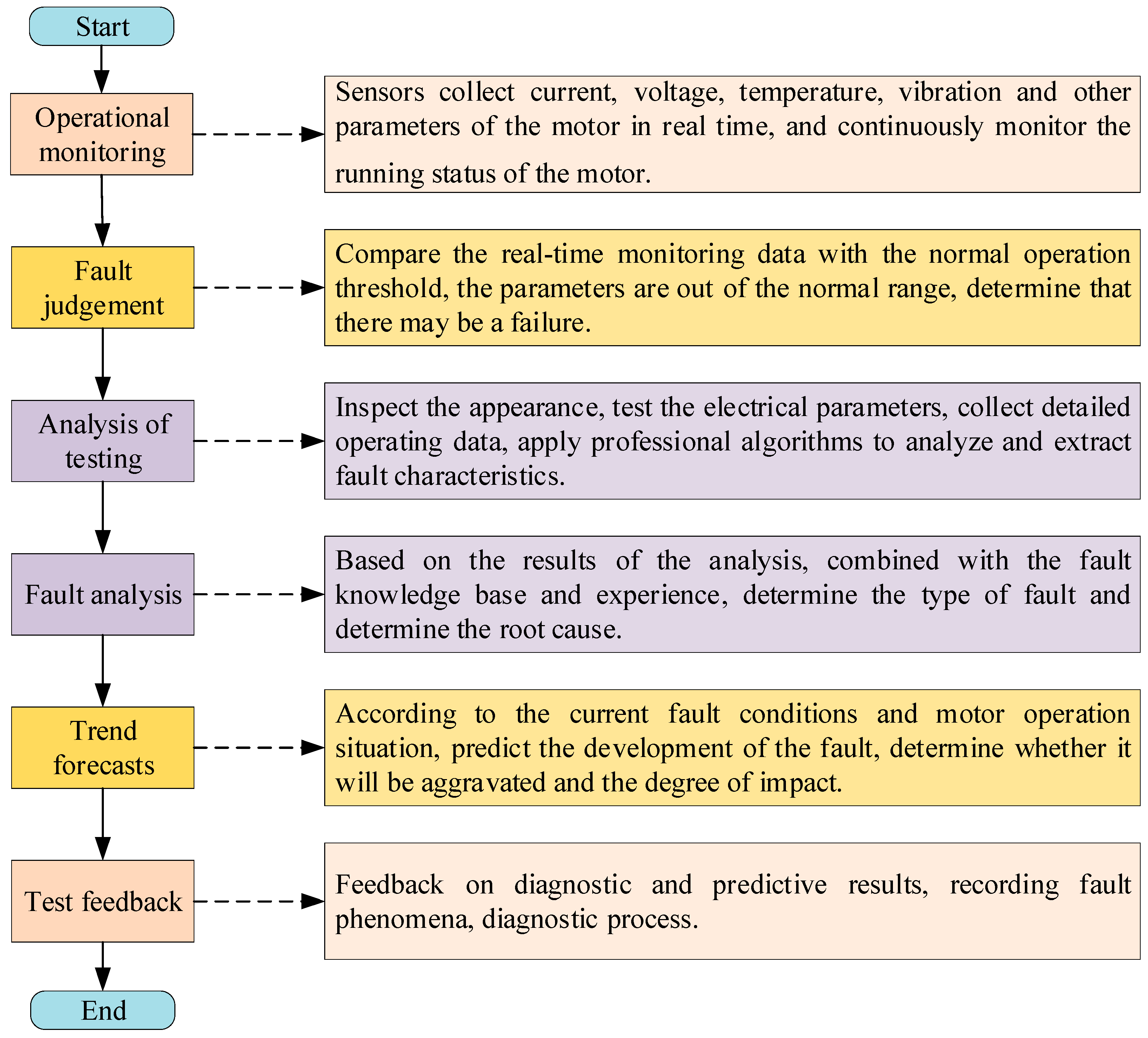

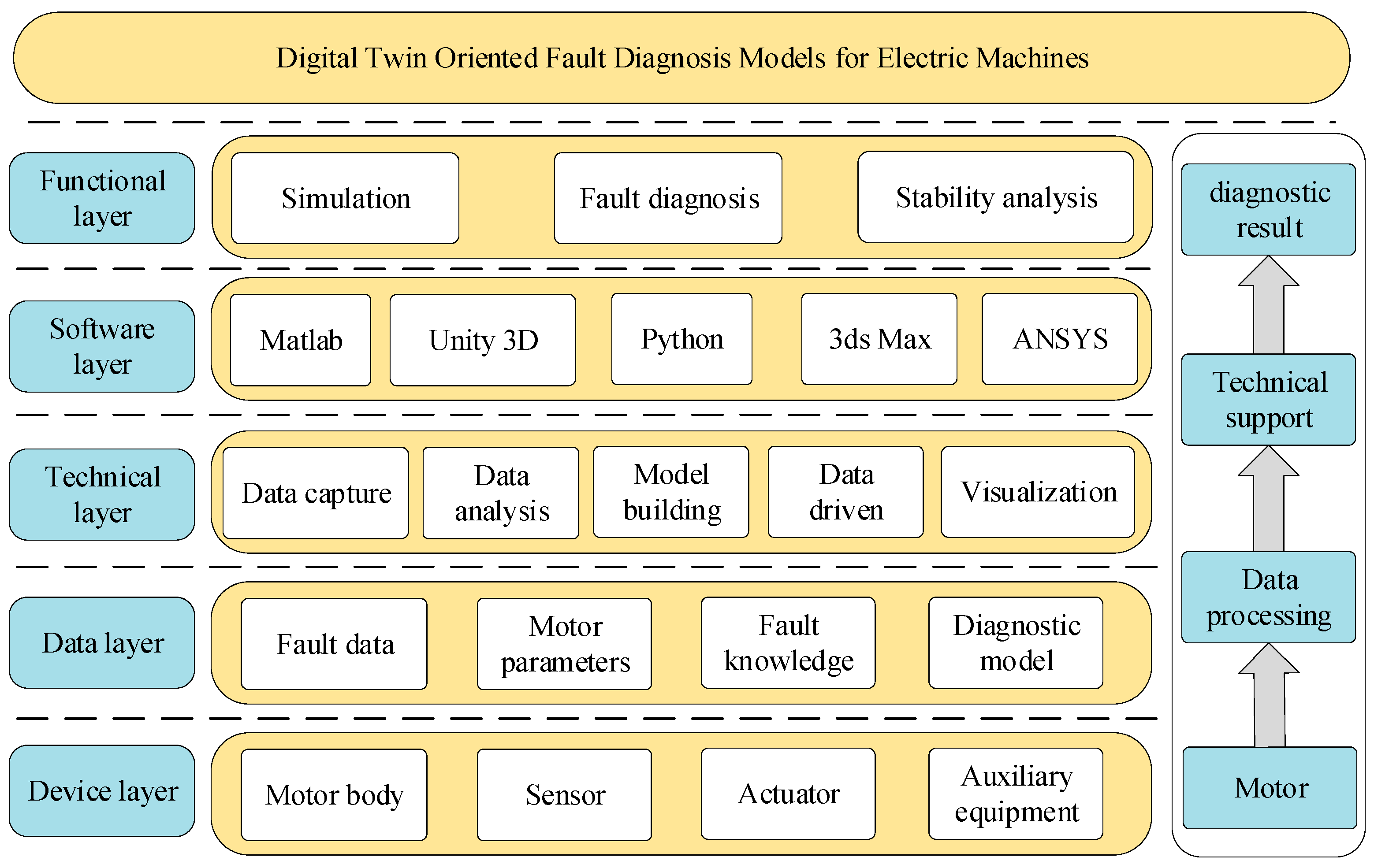

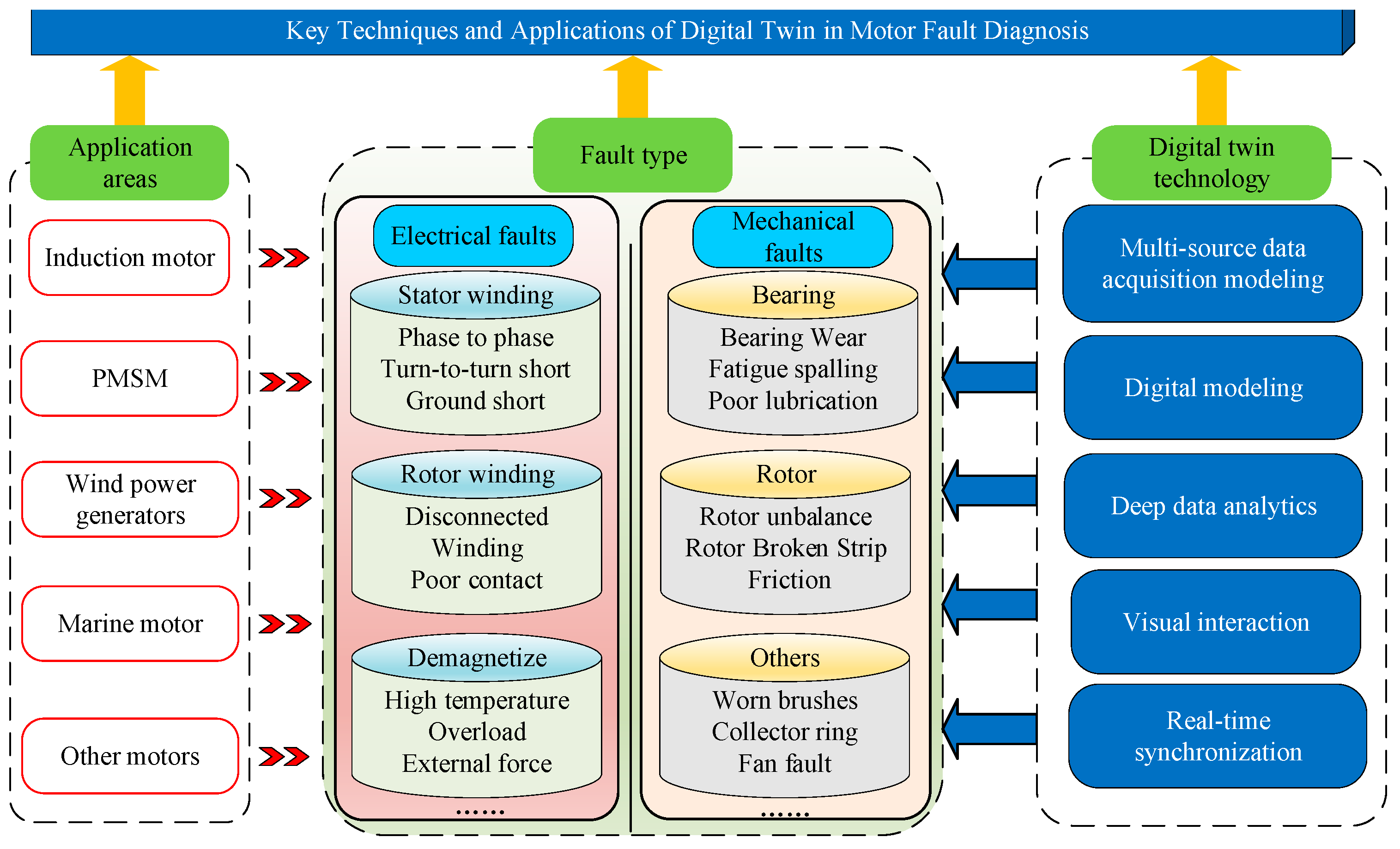

4. Research on Key Technologies and Applications of Digital Twins in Motor Fault Diagnosis

4.1. Key Techniques for Fault Diagnosis of Digital Twin Motors

4.1.1. Modeling Techniques for Multi-Source Data Acquisition

4.1.2. Digital Modeling Techniques

4.1.3. Deep Data Analysis Mining Techniques

4.1.4. Multimodal Visual Interaction Technology

4.1.5. Real-Time Update Synchronization Technology

4.2. Application of Digital Twins in Motor Fault Diagnosis

4.2.1. Induction Motor Troubleshooting

4.2.2. Troubleshooting Permanent Magnet Synchronous Motor

4.2.3. Troubleshooting Wind Turbines

4.2.4. Troubleshooting in Other Motor Fields

4.2.5. Comparative Analysis of Different Application Areas

5. Conceptualization of Digital Twin Applications in Fault Diagnosis of Three-Phase Synchronous Generators

5.1. Data-Driven Digital Twin-Based Model Construction

5.1.1. Defining the Model Architecture

5.1.2. Data Acquisition

5.1.3. Model Training

5.2. Sample Generation Method Based on Semi-Supervised Learning Framework

5.2.1. Background on the Selection of Semi-Supervised Clustering Algorithms

5.2.2. Initial Classifier Training

5.2.3. Unlabeled Data Forecasting

5.2.4. High-Confidence Sample Screening and Addition

5.2.5. Model Retraining and Iteration

6. Conclusions

6.1. Technological Advantages and Application Achievements

- (1)

- Realization of real-time accurate monitoring and diagnosis: Digital twin technology, with the help of multi-source data acquisition modeling, digital modeling, in-depth data analysis and mining, as well as multi-modal visual interaction, real-time updating and synchronization and other key technologies, enables building virtual models that can provide highly accurate simulations of physical entities. Motor operation data are collected in real time through sensors, processed and analyzed to drive virtual models, realizing real-time mapping and accurate simulation of the motor operation state. This makes it possible to capture subtle changes in motor operation over time, accurately determine the type, location and severity of faults, and also predict the development trends in faults based on historical data and models, providing a basis for early intervention and maintenance.

- (2)

- Multi-field application with outstanding results: In the field of induction motor fault diagnosis, the digital twin model is based on multi-physical field simulation, which can expand relevant datasets and provide a strong basis for diagnosis by simulating the changes in the electromagnetic characteristics of motors during faults. In the field of permanent magnet synchronous motors, an accurate digital twin model can monitor and simulate and analyze the running status of the motor in real time, discover early faults in an appropriate amount of time, and ensure efficient and stable operation. Wind turbines work in harsh environments; digital twin technology combined with related algorithms can increase diagnosis accuracy up to 99.1%, effectively solving the many problems of traditional diagnostic methods. In other motor applications, digital twins provide a new way to diagnose faults in complex power systems and motor equipment, and provide effective support for fault diagnosis and preventive maintenance of related equipment.

6.2. Challenges to Be Urgently Addressed

- (1)

- The existing literature refers to the following insufficient aspects: Firstly, the lack of standardization and specification limits development. There is a lack of unified technical standards and specifications, and different studies and applications differ greatly in data formats, interface standards, modeling methods, diagnostic processes, etc., which makes it difficult for systems to be compatible and work together. This not only increases the cost and difficulty of technology promotion, but also hinders cross-domain cooperation and technological innovation, limiting the wide application and in-depth development of digital twin technology in the field of motor fault diagnosis. Secondly, the elaboration of cross-domain application is not in-depth. For the cross-domain application of motor fault diagnosis methods in different fields, the literature is not deep enough. Although applications in industrial manufacturing, energy, aerospace and other fields are mentioned, there is a lack of detailed description on how to make targeted adjustments and optimizations according to the characteristics and needs of different fields.

- (2)

- Limitations of existing methods: First, there are data-related problems. There are problems with data acquisition and quality, and it is more difficult to acquire accurate, complete and high-quality data in complex environments. The problem of data imbalance is prominent, with more normal state data and less fault state data, leading to a decrease in the diagnostic ability of models for faults. The second is the problem of model accuracy and real-time performance. Model accuracy is constrained by the quality and quantity of data as well as the model design and training process. In practical applications, complex working conditions and variable environments make it difficult for the model to accurately reflect the real state of the motor. Third, there is the problem of sustainable diagnosis and generalization ability. Existing diagnostic models have difficulty maintaining accuracy and reliability in the face of equipment aging, maintenance activities and emerging failure modes.

- (3)

- The main challenges of integrating DTs for fault diagnosis are the following: Firstly, there is the challenge of data processing and transmission. Data processing capabilities are highly required to deal with large-scale, multi-source, heterogeneous data, and motor fault diagnosis requires the integration of sensor data, historical data, maintenance records and other data in various formats and sources, which makes all these data difficult to process. Second, modeling challenges deserve mention. Especially for complex electromechanical equipment, it is difficult to accurately model the interactions between components, which affects the accuracy and reliability of the model. Third, there are security and privacy challenges. Data security and privacy protection are crucial. DT systems involve a large amount of sensitive data and, the openness and interconnectivity of these systems increase security risks. The question of how to realize data sharing and effective utilization under the premise of data security is a major challenge.

6.3. Clear Direction for Future Development

- (1)

- Efforts are being made to solve existing problems: In data processing and transmission, advanced algorithms are being developed to remove noise, fill in missing values and improve data quality; the integration of big data elements related to data transmission with AI technology is significant, and needs to be analyzed and reviewed in terms of the reliability of data transmission, the adaptability of AI algorithms, the validity of the fusion of data and algorithms, and the security and privacy protection of relevant methods. AS for model optimization, new model structures and algorithms are being explored, such as lightweight neural networks and distributed computing models, to improve computational efficiency and model interaction in real time while ensuring accuracy. These optimizations should be based on existing digitalization and information technology and other related industry standards, such as GB/T 23011—2022 “Informationization and Industrialization Convergence Digital Transformation Value Benefit Reference Model” [113] and GB/T 28827.1—2022 “Information Technology Services Operation and Maintenance” [114], to strengthen the cooperation between industry, academia and research institutes, to conduct in-depth research on the theory of digital twins, to provide feedback from industry about practical application problems, and to integrate resources in research institutes. It is important to overcome key issues such as data formats, interface standards and modeling methods, among other issues, as well as to meet the requirements of practical applications and help create digital twin industry standards. It is also important to deepen the integration of multiple disciplines, promote the intersection of computer science, mathematics, physics and other disciplines, introduce cutting-edge theories and methods to optimize digital twin models, improve their performance, and provide technical support for motor fault diagnosis.

- (2)

- Strengthening multidisciplinary integration and innovation: We should continue to deepen the cross-integration of computer science, mathematics, physics and other multidisciplinary disciplines, and draw on the cutting-edge theories and methods of each discipline. We must also combine new advances in artificial intelligence to develop smarter and more efficient digital twin models; use mathematical optimization algorithms to improve the processes of model training and parameter adjustment; establish more accurate physical models of electric motors based on the principles of physics, so as to improve the performance and adaptability of the digital twin models; reduce human intervention and direct contact; and carry out risk assessments to ensure the safety of personnel and reduce material losses.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SVM | Support Vector Machine |

| KNN | K-Nearest Neighbor |

| CNN | Convolutional Neural Network |

| FFT | Fast Fourier Transform |

| GUI | Graphical User Interface |

| LSTM | Long Short-Term Memory |

| DRL | Deep Reinforcement Learning |

| ASO | Atomic Search Optimization |

| FEM | Finite Element Method |

| FT | Fourier Transform |

| DWT | Discrete Wavelet Transform |

| VMD | Variational Mode Decomposition |

| PCCDP | Percentage Contrast Current Dot Pattern |

| NARX | Nonlinear Autoregressive with Exogenous Inputs |

| MCSA | Motor Current Signature Analysis |

| STFT | Short-Time Fourier Transform |

| GCN | Graph Convolutional Network |

References

- Mizes, K.G.C.; Lindsey, J.; Escola, G.S.; Ölveczky, B.P. The role of motor cortex in motor sequence execution depends on demands for flexibility. Nat. Neurosci. 2024, 27, 2466–2475. [Google Scholar] [CrossRef] [PubMed]

- Karanlik, O.; Acar, G.; Ayta, S. Investigation of the relationship between gross motor maturation from 1 to 18 months and preschool gross motor performance in at-risk infants. J. Eval. Clin. Pract. 2025, 31, e14115. [Google Scholar] [CrossRef] [PubMed]

- Lv, X.M.; Lu, Z.B.; Huang, Z.H.; Wei, Z.H. Improving fault diagnosis in elevator systems with GAN-based synthetic data. Int. J. Sens. Netw. 2025, 47, 26–35. [Google Scholar] [CrossRef]

- Wu, W.C. Automotive Motor Fault Diagnosis Model Integrating Machine Learning Algorithm and Fuzzy Control Theory. Int. J. Fuzzy Syst. 2025. [Google Scholar] [CrossRef]

- Li, W.G.; Fan, N.Y.; Peng, X.; Zhang, C.H.; Li, M.Y.; Yang, X.; Ma, L.J. Fault Diagnosis for Motor Bearings via an Intelligent Strategy Combined with Signal Reconstruction and Deep Learning. Energies 2024, 17, 4773. [Google Scholar] [CrossRef]

- Chen, Q.; Han, X.; Liu, G.H.; Zhao, W.X.; Shi, H. Inter-Turn Fault Diagnosis and Control for Five-Phase PMSMs by Disturbance Observer. IEEE Trans. Ind. Electron. 2024, 71, 13901–13909. [Google Scholar] [CrossRef]

- Shao, G.D. Manufacturing Digital Twin Standards. In Proceedings of the ACM/IEEE 27th International Conference on Model Driven Engineering Languages and Systems: Companion Proceedings (MODELS), Linz, Austria, 22–27 September 2024; pp. 370–377. [Google Scholar]

- Grieves, M. Digital Twin Certified: Employing Virtual Testing of Digital Twins in Manufacturing to Ensure Quality Products. Machines 2023, 11, 808. [Google Scholar] [CrossRef]

- Le Moigne, J. NASA’S Advanced Information Systems Technology (AIST): Combining New Observing Strategies and Analytics Frameworks to Build Earth System Digital Twins. In Proceedings of the IEEE International Geoscience and Remote Sensing Symposium (IGARSS), Kuala Lumpur, Malaysia, 17–22 July 2022; pp. 4724–4727. [Google Scholar]

- Xiao, B.; Zhong, J.S.; Bao, X.Y.; Chen, L.; Bao, J.S.; Zheng, Y. Digital twin-driven prognostics and health management for industrial assets. Sci. Rep. 2024, 14, 13443. [Google Scholar] [CrossRef]

- Zhuang, C.; Liu, J.; Xiong, H.; Ding, X.; Liu, S.; Weng, G. Connotation, architecture and trends of product digital twin. Comput. Integr. Manuf. Syst. 2017, 23, 753–768. [Google Scholar]

- Chen, K.K.; Zhao, B.; Zhou, H.Y.; Zhou, L.M.; Niu, K.; Jin, X.; Li, R.S.; Yuan, Y.W.; Zheng, Y.J. Digital Twins in Plant Factory: A Five-Dimensional Modeling Method for Plant Factory Transplanter Digital Twins. Agriculture 2023, 13, 1336. [Google Scholar] [CrossRef]

- Wang, S.; Lai, X.N.; He, X.W.; Qiu, Y.M.; Song, X.G. Building a Trustworthy Product-Level Shape-Performance Integrated Digital Twin With Multifidelity Surrogate Model. J. Mech. Des. 2022, 144, 031703. [Google Scholar] [CrossRef]

- Zhao, L.; Jiang, X.; Hong, Y.; Sun, M.; Wang, Y.; Kang, L.; Cao, L. Smart ocean digital twin technology and its application. Sci. Technol. Rev. 2024, 42, 91–101. [Google Scholar]

- Dehlaghi Ghadim, A. Identification of Cyberattacks in Industrial Control Systems. Ph.D. Thesis, RISE Research Institute of Sweden, Gothenburg, Sweden, 2023. [Google Scholar]

- Tao, F.; Zhang, H.; Zhang, C.Y. Advancements and challenges of digital twins in industry. Nat. Comput. Sci. 2024, 4, 169–177. [Google Scholar] [CrossRef] [PubMed]

- Adeagbo, M.O.; Wang, S.M.; Ni, Y.Q. Revamping structural health monitoring of advanced rail transit systems: A paradigmatic shift from digital shadows to digital twins. Adv. Eng. Inform. 2024, 61, 102450. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Wang, D.M.; Teng, W.; Liu, Y.B. Improved criticality analysis method of equipment failures in wind turbines. IET Renew. Power Gener. 2019, 13, 1205–1213. [Google Scholar] [CrossRef]

- Chen, H.T.; Jing, S.X.; Wang, X.H.; Wang, Z.Y. Fault diagnosis of wind turbine gearbox based on wavelet neural network. J. Low Freq. Noise Vib. Act. Control 2018, 37, 977–986. [Google Scholar] [CrossRef]

- Xie, F.Y.; Li, G.; Liu, H.; Sun, E.G.; Wang, Y. Advancing Early Fault Diagnosis for Multi-Domain Agricultural Machinery Rolling Bearings through Data Enhancement. Agriculture 2024, 14, 112. [Google Scholar] [CrossRef]

- Wang, C.; Bie, Z.; Pan, C.; Wang, X.; Yan, C. Contingency Intelligent Screening and Ranking Approach for Integrated Energy System Considering Expected Loss. Autom. Electr. Power Syst. 2019, 43, 44–53. [Google Scholar]

- Bourdeau, M.; Zhai, X.Q.; Nefzaoui, E.; Guo, X.F.; Chatellier, P. Modeling and forecasting building energy consumption: A review of data-driven techniques. Sustain. Cities Soc. 2019, 48, 101533. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, G.; Li, G.; Cui, Q. Intelligent Full-Digital Technology and Its Applications in Power Plant. Electr. Power 2020, 53, 202–211. [Google Scholar]

- Diz, S.D.; Lopez, R.M.; Sanchez, F.J.R.; Pena, E.J.B. A Digital Twin Approach for Online Impedance-Based Stability Analysis of Three-Phase AC Systems. IEEE Trans. Ind. Electron. 2024, 71, 16845–16856. [Google Scholar] [CrossRef]

- Yu, P.; Wang, Z.Y.; Guo, Y.F.; Tai, N.L.; Jun, W. Application prospect and key technologies of digital twin technology in the integrated port energy system. Front. Energy Res. 2023, 10, 1044978. [Google Scholar] [CrossRef]

- Liang, H.; Kong, L.; Liu, G.; Dong, W.; Liu, X. ASL-CatBoost Method for Wind Turbine Fault Detection Integrated with Digital Twin. J. Syst. Simul. 2024, 36, 873–887. [Google Scholar]

- Wang, J.; Xiang, Y.; He, Z. Models and implementation of digital twin based spacecraft system engineering. Comput. Integr. Manuf. Syst. 2019, 25, 1348–1360. [Google Scholar]

- Yin, Y.; Zheng, P.; Li, C.X.; Wang, L.H. A state-of-the-art survey on Augmented Reality-assisted Digital Twin for futuristic human-centric industry transformation. Robot. Comput. Integr. Manuf. 2023, 81, 102515. [Google Scholar] [CrossRef]

- Tao, F.; Xiao, B.; Qi, Q.L.; Cheng, J.F.; Ji, P. Digital twin modeling. J. Manuf. Syst. 2022, 64, 372–389. [Google Scholar] [CrossRef]

- Han, C.; Guo, M.; Wu, X.; Liu, H.; Hu, B.; Li, C.; Li, H.; Luo, X. System for Controlling Cotton Topping Machine Group Based on Digital Twin, Has Digital Twin Model for Performing Data Processing on Wireless Transmission of Each Topping Machine Operation Parameter and Unmanned Machine Locating Information. CN117784696-A, 29 March 2024. [Google Scholar]

- Li, J.Q.; Liu, G.H. Data-Centric Workshop Digital Twin Conceptual Modeling Method and Application. In Proceedings of the IEEE 18th International Conference on Automation Science and Engineering (IEEE CASE), Mexico City, Mexico, 20–24 August 2022; pp. 92–99. [Google Scholar]

- Wang, W.; Yong, M.; Huang, J.; Zhou, S.; Ni, C.; Pang, J.; Lu, G.; Huang, H. Research on Construction of Condition Analysis Technology of Digital Twin for High Voltage Equipment. High Volt. Appar. 2023, 59, 119–128. [Google Scholar]

- Lin, S. Study on Digital Architecture of Transportation Infrastructure for Multi-source Data Fusion. J. Highw. Transp. Res. Dev. 2018, 35, 122. [Google Scholar]

- Li, M.; Nie, M.; He, J.; Chen, K.a.; Wang, X.; Xu, Y. Pilot Protection of Flexible DC Grid Based on Digital Twin. Proc. Chin. Soc. Electr. Eng. 2022, 42, 1773–1782. [Google Scholar]

- Lv, X.Y.; Zheng, X.Q. A Diagnosis Method for Inter-turn Short-circuit Fault of A Nine-phase Permanent Magnet Synchronous Motor Based on Search Coil. In Proceedings of the 25th International Conference on Electrical Machines and Systems (ICEMS), Rajamangala Univ Technol Lanna, Chiang Mai, Thailand, 29 November–2 December 2022. [Google Scholar]

- Wang, C.A.; Li, J.M.; Zhu, X.L.; Xu, C.N.; Cheng, X.Z. Adaptive Neural Fuzzy Petri Net Algorithm for Motor Fault Diagnosis. In Proceedings of the 5th International Conference on Advances in Energy Resources and Environment Engineering (ICAESEE), Chongqing, China, 6–8 December 2019. [Google Scholar]

- Lam, H.K.; Lam, P.D.; Ok, S.Y.; Lee, S.H. Digital Twin Smart City Visualization with MoE-Based Personal Thermal Comfort Analysis. Sensors 2025, 25, 705. [Google Scholar] [CrossRef]

- Wu, D.H.; Tao, W.; Duan, X.Y.; Luan, Y. Applications and Analysis of Digital Twin in Prognostic and Health Management. In Proceedings of 2021 IEEE 11th International Conference on Electronics Information and Emergency Communication, Beijing, China, 18–20 June 2021; Wenzheng, L., Jixing, Y., Eds.; IEEE: Piscataway, NJ, USA, 2021; pp. 200–203. [Google Scholar]

- Chang, L.K.; Wang, S.H.; Tsai, M.C. Demagnetization Fault Diagnosis of a PMSM Using Auto-Encoder and K-Means Clustering. Energies 2020, 13, 4467. [Google Scholar] [CrossRef]

- Huang, F.Q.; Zhang, X.F.; Qin, G.J.; Xie, J.P.; Peng, J.; Huang, S.D.; Long, Z.; Tang, Y. Demagnetization Fault Diagnosis of Permanent Magnet Synchronous Motors Using Magnetic Leakage Signals. IEEE Trans. Ind. Inform. 2023, 19, 6105–6116. [Google Scholar] [CrossRef]

- Dong, L.; Wen, X.J.; Sheng, S.S.; Yan, Z.H.; Liu, J.F. Research on the Modeling Method of Mould Bed Twin for Ship Segment Construction. In Proceedings of the 14th International Conference on Communication Software and Networks (ICCSN), Electr Network, Chongqing, China, 10–12 June 2022; pp. 152–156. [Google Scholar]

- Fera, F.; Spandonidis, C. A Fault Diagnosis Approach Utilizing Artificial Intelligence for Maritime Power Systems within an Integrated Digital Twin Framework. Appl. Sci. 2024, 14, 8107. [Google Scholar] [CrossRef]

- Lee, C.Y.; Le, T.A.; Chu, T.H.; Hsu, S.C. A motor fault diagnosis using hybrid binary differential evolution algorithm and whale optimization algorithm with storage space. IET Control. Theory Appl. 2025, 19, e12783. [Google Scholar] [CrossRef]

- Jigyasu, R.; Shrivastava, V.; Singh, S. Deep optimal feature extraction and selection-based motor fault diagnosis using vibration. Electr. Eng. 2024, 106, 6339–6358. [Google Scholar] [CrossRef]

- Liu, B.; Tan, Z.K.; Lan, C.F. Key Concepts and Framework of Power Distribution and Utilization of Transparent Power Grids. Front. Energy Res. 2022, 10, 900890. [Google Scholar] [CrossRef]

- Minchev, D.; Varbanets, R.; Shumylo, O.; Zalozh, V.; Aleksandrovska, N.; Bratchenko, P.; Truong, T.H. Digital Twin Test-Bench Performance for Marine Diesel Engine Applications. Pol. Marit. Res. 2023, 30, 81–91. [Google Scholar] [CrossRef]

- Al Duhayyim, M.; Mohamed, H.G.; Alzahrani, J.S.; Alabdan, R.; Aziz, A.S.A.; Zamani, A.; Yaseen, I.; Alsaid, M.I. Sandpiper Optimization with a Deep Learning Enabled Fault Diagnosis Model for Complex Industrial Systems. Electronics 2022, 11, 4190. [Google Scholar] [CrossRef]

- Rassolkin, A.; Orosz, T.; Demidova, G.L.; Kuts, V.; Rjabtsikov, V.; Vaimann, T.; Kallaste, A. Implementation of Digital Twins for electrical energy conversion systems in selected case studies. Proc. Est. Acad. Sci. 2021, 70, 19–39. [Google Scholar] [CrossRef]

- Li, S.; Shi, J. Research on Deep Learning Method for Induction Motor Fault Diagnosis. Comput. Eng. Appl. 2024, 60, 329–336. [Google Scholar]

- Dibaj, A.; Gao, Z.; Nejad, A.R. Fault detection of offshore wind turbine drivetrains in different environmental conditions through optimal selection of vibration measurements. Renew. Energy 2023, 203, 161–176. [Google Scholar] [CrossRef]

- Rjabtsikov, V.; Ibrahim, M.; Asad, B.; Rassolkin, A.; Vaimann, T.; Kallaste, A.; Kuts, V.; Stepien, M.; Krawczyk, M. Digital Twin Service Unit Development for an EV Induction Motor Fault Detection. In Proceedings of the IEEE International Electric Machines and Drives Conference (IEMDC), San Francisco, CA, USA, 15–18 May 2023. [Google Scholar]

- Muhammad, W.; Khan, H.; Kamal, T.; Ahn, D.; Oh, K.Y. Intelligent Troubleshooting of Vertical Bandsaws, Leveraging Ensemble Learning on Low-Level Data. IEEE Access 2024, 12, 171280–171294. [Google Scholar] [CrossRef]

- Rodriguez-Blanco, M.A.; Golikov, V.; Vazquez-Avila, J.L.; Samovarov, O.; Sanchez-Lara, R.; Osorio-Sánchez, R.; Pérez-Ramírez, A. Comprehensive and Simplified Fault Diagnosis for Three-Phase Induction Motor Using Parity Equation Approach in Stator Current Reference Frame. Machines 2022, 10, 379. [Google Scholar] [CrossRef]

- Sun, C.F.; Duan, Z.S.; Yang, Y.; Wang, M.; Hu, L.J. The Motor Fault Diagnosis Based on Neural Network and The Theory of D-S Evidence. In Proceedings of the 2nd International Conference on Advanced Materials and Engineering Materials (ICAMEM 2012), Beijing, China, 29–30 December 2012; p. 881. [Google Scholar]

- Li, Z.H.; Mao, H.F.; Cui, J.G.; Zhang, Y. Motor Bearing Fault Diagnosis Based on MSICA-LSSVM. In Proceedings of the International Conference on Recent Trends in Materials and Mechanical Engineering (ICRTMME 2011), Shenzhen, China, 27–28 January 2011; pp. 747–752. [Google Scholar]

- Zhou, Z.; Qiao, Y.S.; Lin, X.S.; Li, P.R.; Wu, N.; Yu, D. A Deployment Method for Motor Fault Diagnosis Application Based on Edge Intelligence. Sensors 2025, 25, 9. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, S.Y.; Li, W.F.; Liang, H.; Wang, C.D. Faults and Diagnosis Methods of Permanent Magnet Synchronous Motors: A Review. Appl. Sci. 2019, 9, 2116. [Google Scholar] [CrossRef]

- Sunal, C.E.; Dyo, V.; Velisavljevic, V. Review of Machine Learning Based Fault Detection for Centrifugal Pump Induction Motors. IEEE Access 2022, 10, 71344–71355. [Google Scholar] [CrossRef]

- Li, H.; Ma, X.; Dong, K.; Li, J.; Shen, W.; Zhao, Y.; Li, Z. Research on Fault Ride Through for Wind Power System in the Terminal of the Power Grid System. High Volt. Appar. 2017, 53, 192–196. [Google Scholar]

- Liu, Z.S.; Wang, X.F.; Feng, X. Optimum Design and Control of Marine Permanent Magnet Synchronous Motor. In Proceedings of the 5th International Conference on Precision Machinery and Manufacturing Technology (ICPMMT), Auckland, New Zealand, 3–7 February 2020. [Google Scholar]

- Shi, J.; Li, J.N.; Wang, T. A Convolutional Neural Network Model-Based Approach for Multi-Fault Diagnosis of Asynchronous Motors. In Proceedings of the IEEE/IAS Industrial and Commercial Power System Asia (IEEE I and CPS Asia), Chongqing, China, 7–9 July 2023; pp. 883–888. [Google Scholar]

- Xia, P.C.; Huang, Y.X.; Liu, C.L.; Liu, J. Learn to Supervise: Deep Reinforcement Learning-Based Prototype Refinement for Few-Shot Motor Fault Diagnosis. IEEE Trans. Neural Netw. Learn. Syst. 2024; early access. [Google Scholar] [CrossRef]

- Faiz, J.; Jafari, A. Interturn Fault Diagnosis in Brushless Direct Current Motors—A Review. In Proceedings of the 19th IEEE International Conference on Industrial Technologies (ICIT), Lyon, France, 19–22 February 2018; pp. 437–444. [Google Scholar]

- Hoang, D.T.; Kang, H.J. A Motor Current Signal-Based Bearing Fault Diagnosis Using Deep Learning and Information Fusion. IEEE Trans. Instrum. Meas. 2020, 69, 3325–3333. [Google Scholar] [CrossRef]

- Yu, W.; Wen, C.L.; Chen, Y. Minor Fault Diagnosis Based on Fractional-order Model of Permanent Magnet Synchronous Motor. In Proceedings of the 43rd Annual Conference of the IEEE-Industrial-Electronics-Society (IECON), Beijing, China, 29 October–1 November 2017; pp. 8082–8086. [Google Scholar]

- Ding, A.; Yi, X.J.; Qin, Y.; Wang, B. Self-driven continual learning for class-added motor fault diagnosis based on unseen fault detector and propensity distillation. Eng. Appl. Artif. Intell. 2024, 127, 107382. [Google Scholar] [CrossRef]

- Song, X.W.; Liao, Z.Q.; Jia, B.Z.; Kong, D.F.; Niu, J.Z. Rolling Bearing Fault Diagnosis Under Different Severity Based on Statistics Detection Index and Canonical Discriminant Analysis. IEEE Access 2023, 11, 86686–86696. [Google Scholar] [CrossRef]

- Qiao, X.Y.; Luo, H.; Zhang, K.; Li, K.; Jiang, Y.C.; Huo, M.Y. Subspace Frequency Estimation Under Colored Noise With Application to Fault Diagnosis of Motor Rolling Bearings. IEEE Trans. Ind. Inform. 2024, 20, 11014–11023. [Google Scholar] [CrossRef]

- Long, Z.; Guo, J.Y.; Ma, X.G.; Wu, G.P.; Rao, Z.M.; Zhang, X.F.; Xu, Z.Y. Motor fault diagnosis based on multisensor-driven visual information fusion. ISA Trans. 2024, 155, 524–535. [Google Scholar] [CrossRef]

- Adamczyk, M.; Orlowska-Kowalska, T. Current sensor fault-tolerant control based on modified Luenberger observers for safety-critical vector-controlled induction motor drives. Bull. Pol. Acad. Sci. Tech. Sci. 2024, 72, 151041. [Google Scholar] [CrossRef]

- Lv, H.; Su, Y.; Liang, Y.; Xu, F. Method for Training Fault Diagnosis Model of Motor Applied to Fields of Aerospace, Involves Constructing Initial Fault Diagnosis Model, and Training Initial Fault Diagnosis Model Based on Sample Space to Obtain Fault Diagnosis Model Of Motor. CN118964997-A, 15 November 2024. [Google Scholar]

- Niu, T.Y.; Wang, J.Y.; Miao, Q. Fault diagnosis of induction motor in the cooling water supply system using a multi-channel data fusion transformer with limited sample conditions. Meas. Sci. Technol. 2024, 35, 106103. [Google Scholar] [CrossRef]

- Aguayo-Tapia, S.; Avalos-Almazan, G.; Rangel-Magdaleno, J.D. Entropy-Based Methods for Motor Fault Detection: A Review. Entropy 2024, 26, 299. [Google Scholar] [CrossRef]

- Fan, H.W.; Ren, Z.F.; Cao, X.G.; Zhang, X.H.; Huang, J.X. A GTI & Ada-Act LMCNN Method for Intelligent Fault Diagnosis of Motor Rotor-Bearing Unit Under Variable Conditions. IEEE Trans. Instrum. Meas. 2024, 73, 3508314. [Google Scholar] [CrossRef]

- Wei, X.X.; Zhang, Z.H.; Huang, H.J.; Zhou, Y.Q. An overview on deep clustering. Neurocomputing 2024, 590, 127761. [Google Scholar] [CrossRef]

- Tang, F. Short-term wind power prediction based on improved sparrow search algorithm optimized long short-term memory with peephole connections. Wind. Eng. 2025, 49, 71–90. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, H.Y.; Wang, Y.; Mao, Y.F. Inverse physics-informed neural networks for digital twin-based bearing fault diagnosis under imbalanced samples. Knowl. Based Syst. 2024, 292, 111641. [Google Scholar] [CrossRef]

- Xia, J.Y.; Chen, Z.Y.; Chen, J.X.; He, G.L.; Huang, R.Y.; Li, W.H. A digital twin-driven approach for partial domain fault diagnosis of rotating machinery. Eng. Appl. Artif. Intell. 2024, 131, 107848. [Google Scholar] [CrossRef]

- Xu, Y.D.; Jiang, Q.B.; Li, S.; Zhao, Z.H.; Sun, B.B.; Huang, G.Q. Digital twin-driven discriminative graph learning networks for cross-domain bearing fault recognition. Comput. Ind. Eng. 2024, 193, 110292. [Google Scholar] [CrossRef]

- Zhou, Y.D.; Zhou, J.X.; Cui, Q.W.; Wen, J.M.; Fei, X. Digital twin-driven online intelligent assessment of wind turbine gearbox. Wind Energy 2024, 27, 797–815. [Google Scholar] [CrossRef]

- You, K.S.; Lian, Z.W.; Chen, R.H.; Gu, Y.K. A novel rolling bearing fault diagnosis method based on time-series fusion transformer with interpretability analysis. Nondestruct. Test. Eval. 2024; early access. [Google Scholar] [CrossRef]

- Herbus, K.; Dymarek, A.; Ociepka, P.; Dzitkowski, T.; Grabowik, C.; Szewerda, K.; Bialas, K.; Monica, Z. Development and Validation of Concept of Innovative Method of Computer-Aided Monitoring and Diagnostics of Machine Components. Appl. Sci. 2024, 14, 10056. [Google Scholar] [CrossRef]

- Yu, X.L.; Yang, Y.; Du, M.G.; He, Q.B.; Peng, Z.K. Dynamic Model-Embedded Intelligent Machine Fault Diagnosis Without Fault Data. IEEE Trans. Ind. Inform. 2023, 19, 11466–11476. [Google Scholar] [CrossRef]

- Kang, T.Y.; Kim, T.-S. Signal-Based Fault Detection and Diagnosis on Electronic Packaging and Applications of Artificial Intelligence Techniques. J. Microelectron. Packag. Soc. 2023, 30, 30–41. [Google Scholar]

- Mousavi, Z.; Varahram, S.; Ettefagh, M.M.; Sadeghi, M.H.; Feng, W.Q.; Bayat, M. A digital twin-based framework for damage detection of a floating wind turbine structure under various loading conditions based on deep learning approach. Ocean. Eng. 2024, 292, 116563. [Google Scholar] [CrossRef]

- De Kooning, J.D.M.; Stockman, K.; De Maeyer, J.; Jarquin-Laguna, A.; Vandevelde, L. Digital Twins for Wind Energy Conversion Systems: A Literature Review of Potential Modelling Techniques Focused on Model Fidelity and Computational Load. Processes 2021, 9, 116563. [Google Scholar] [CrossRef]

- Liu, Z.C.; Fang, L.L.; Jiang, D.; Qu, R.H. A Machine-Learning-Based Fault Diagnosis Method With Adaptive Secondary Sampling for Multiphase Drive Systems. IEEE Trans. Power Electron. 2022, 37, 8767–8772. [Google Scholar] [CrossRef]

- Peng, D.D.; Yazdanianasr, M.; Mauricio, A.; Verwimp, T.; Desmet, W.; Gryllias, K. Physics-driven cross domain digital twin framework for bearing fault diagnosis in non-stationary conditions. Mech. Syst. Signal Process. 2025, 228, 112266. [Google Scholar] [CrossRef]

- Du, B.C.; Huang, W.; Li, T.Y.; Hu, R.G.; Cheng, Y.; Cui, S.M. A Digital Twin System for Two-Stage PMSM Rotor and Bearing Faults Identification Based on Deep Learning and Improved-RGB Acoustic Image. IEEE Trans. Power Electron. 2025, 40, 2184–2195. [Google Scholar] [CrossRef]

- Lee, H.; Son, S.; Jeong, D.; Sun, K.H.; Jeon, B.C.; Oh, K.Y. High-fidelity multiphysics model of a permanent magnet synchronous motor for fault data generation. J. Sound Vib. 2024, 589, 118573. [Google Scholar] [CrossRef]

- Hu, W.F.; Fang, J.H.; Zhang, Y.X.; Liu, Z.Y.; Verma, A.S.; Liu, H.W.; Cong, F.Y.; Tan, J.R. Digital twin of wind turbine surface damage detection based on deep learning-aided drone inspection. Renew. Energy 2025, 241, 122332. [Google Scholar] [CrossRef]

- Dos Santos, J.F.; Tshoombe, B.K.; Santos, L.H.B.; Araujo, R.C.F.; Manito, A.R.A.; Fonseca, W.S.; Silva, M.O. Digital Twin-Based Monitoring System of Induction Motors Using IoT Sensors and Thermo-Magnetic Finite Element Analysis. IEEE Access 2023, 11, 1682–1693. [Google Scholar] [CrossRef]

- Huang, Y.R.; Yuan, B.; Xu, S.Y.; Han, T. Fault Diagnosis of Permanent Magnet Synchronous Motor of Coal Mine Belt Conveyor Based on Digital Twin and ISSA-RF. Processes 2022, 10, 1679. [Google Scholar] [CrossRef]

- Adamou, A.A.; Alaoui, C.; Diop, M.M.; Skorek, A. Squirrel Cage Induction Motors Accurate Modelling for Digital Twin Applications. Modelling 2024, 5, 1582–1600. [Google Scholar] [CrossRef]

- Adamou, A.A.; Alaoui, C. Efficiency-Centered Fault Diagnosis of In-Service Induction Motors for Digital Twin Applications: A Case Study on Broken Rotor Bars. Machines 2024, 12, 604. [Google Scholar] [CrossRef]

- Chen, Z.C.; Liang, D.L.; Jia, S.F.; Yang, L.; Yang, S.Z. Incipient Interturn Short-Circuit Fault Diagnosis of Permanent Magnet Synchronous Motors Based on the Data-Driven Digital Twin Model. IEEE J. Emerg. Sel. Top. Power Electron. 2023, 11, 3514–3524. [Google Scholar] [CrossRef]

- Xia, P.C.; Huang, Y.X.; Tao, Z.Y.; Liu, C.L.; Liu, J. A digital twin-enhanced semi-supervised framework for motor fault diagnosis based on phase-contrastive current dot pattern. Reliab. Eng. Syst. Saf. 2023, 235, 109256. [Google Scholar] [CrossRef]

- Martinez-Roman, J.; Puche-Panadero, R.; Sapena-Bano, A.; Terron-Santiago, C.; Burriel-Valencia, J.; Pineda-Sanchez, M. Analytical Model of Induction Machines with Multiple Cage Faults Using the Winding Tensor Approach. Sensors 2021, 21, 5076. [Google Scholar] [CrossRef] [PubMed]

- Li, H.J.; Shi, T.N. Diagnosis of Inter-Turn Short-Circuit Incipient Fault in Permanent Magnet Synchronous Motors Using Input Current on the Power Side. IEEE Trans. Ind. Inform. 2024, 20, 13741–13752. [Google Scholar] [CrossRef]

- Bouzid, S.; Viarouge, P.; Cros, J. Real-Time Digital Twin of a Wound Rotor Induction Machine Based on Finite Element Method. Energies 2020, 13, 5413. [Google Scholar] [CrossRef]

- Hu, W.Y.; Wang, T.Y.; Chu, F.L. Novel Ramanujan Digital Twin for Motor Periodic Fault Monitoring and Detection. IEEE Trans. Ind. Inform. 2023, 19, 11564–11572. [Google Scholar] [CrossRef]

- Kohtz, S.; Zhao, J.H.; Renteria, A.; Lalwani, A.; Xu, Y.W.; Zhang, X.L.; Haran, K.S.; Senesky, D.; Wang, P.F. Optimal sensor placement for permanent magnet synchronous motor condition monitoring using a digital twin-assisted fault diagnosis approach. Reliab. Eng. Syst. Saf. 2024, 242, 109714. [Google Scholar] [CrossRef]

- Lopes, T.D.; Raizer, A.; Junior, W.V. The Use of Digital Twins in Finite Element for the Study of Induction Motors Faults. Sensors 2021, 21, 7833. [Google Scholar] [CrossRef]

- Lei, Z.C.; Zhou, H.; Hu, W.S.; Liu, G.P.; Guan, S.Q.; Feng, X.L. Toward a Web-Based Digital Twin Thermal Power Plant. IEEE Trans. Ind. Inform. 2022, 18, 1716–1725. [Google Scholar] [CrossRef]

- Liu, H.; Sun, W.L.; Bao, S.H.; Xiao, L.F.; Jiang, L. Research on Key Technology of Wind Turbine Drive Train Fault Diagnosis System Based on Digital Twin. Appl. Sci. 2024, 14, 5991. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, W.L.; Liu, L.Q.; Wang, B.K.; Bao, S.H.; Jiang, R.B. Fault Diagnosis of Wind Turbine Planetary Gear Based on a Digital Twin. Appl. Sci. 2023, 13, 4776. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, X.G.; Su, L.; Sun, R.H.; Yu, M.D.; Huang, W.T. A Digital Twin Approach for Fault Diagnosis in Unmanned Ships Integrated Power System. In Proceedings of the 4th IEEE Sustainable Power and Energy Conference (ISPEC), Curtin University, Electr Network, Perth, Australia, 4–7 December 2022. [Google Scholar]

- Hasan, A.; Asfihani, T.; Osen, O.; Bye, R.T. Leveraging digital twins for fault diagnosis in autonomous ships. Ocean. Eng. 2024, 292, 116546. [Google Scholar] [CrossRef]

- Dimitrova, M.; Aminzadeh, A.; Meiabadi, M.S.; Karganroudi, S.S.; Taheri, H.; Ibrahim, H. A Survey on Non-Destructive Smart Inspection of Wind Turbine Blades Based on Industry 4.0 Strategy. Appl. Mech. 2022, 3, 1299–1326. [Google Scholar] [CrossRef]

- Cui, L.L.; Xiao, Y.C.; Liu, D.D.; Han, H.G. Digital twin-driven graph domain adaptation neural network for remaining useful life prediction of rolling bearing. Reliab. Eng. Syst. Saf. 2024, 245, 109991. [Google Scholar] [CrossRef]

- Xu, J.Q.; Jin, W.B.; Guo, H.; Yu, T.; Jiao, Z.X. Design and Analysis of a High-Speed Wet-Type Fault-Tolerant Permanent Magnet Motor Considering Oil Frictional Loss for Aerospace Electrohydrostatic Actuator Application. IEEE Trans. Transp. Electrif. 2024, 10, 4667–4677. [Google Scholar] [CrossRef]

- Pham, V.N.; Do Ba, Q.H.; Le, D.A.T.; Nguyen, M.; Bui, L.; Coboi, A.E. Using Artificial Intelligence (AI) for Monitoring and Diagnosing Electric Motor Faults Based on Vibration Signals. In Proceedings of the 38th International Conference on Information Networking (ICOIN), Ho Chi Minh City, Vietnam, 17–19 January 2024; pp. 720–725. [Google Scholar]

- GB/T 23011-2022; Informationization and Industrialization Convergence Digital Transformation Value Benefit Reference Model. State Administration for Market Regulation: Beijing, China, 2022.

- GB/T 28827.1-2022; Information Technology Service—Operations and Maintenance—Part 1: General Requirements. State Administration for Market Regulation: Beijing, China, 2022.

| Type of Motor | Diagnosis Method | Inadequacy of Traditional Methods | Digital Twin Improvements | Reference |

|---|---|---|---|---|

| PMSM | Based on search coils | Complex hardware Poor generalizability High interference impact | Highly adaptable and versatile Intelligent calibration and self-updating High fault extraction capability | [35,96] |

| Induction motor | Based on data-driven and physical models | Relies on large amounts of failure history data Rely on accurate physical models Rely on human guarding | Digital twin system simulates normal operating values Enables intelligent monitoring and optimization | [41,97] |

| Wind turbine | Model-based and data acquisition monitoring system | Reliance on expert experience High cost of data acquisition Insufficient precision | Analyze failure warning using historical operating condition information Early detection of potential faults using residual values as fault characterization variables | [59,109] |

| Marine propulsion motor | Based on stacked self-encoders and convolutional neural networks | Effectively detects early failures and determines when they occur | Digital twin model expansion for scarce datasets Strong adaptability and generalization to non-linear fault data | [61,107] |

| Other motors | Fault frequency-based approach | Susceptible to noise interference Difficult to acquire data | Good data quality, accuracy and reliability Strong model generalization ability | [62,95] |

| Type of Fault | Diagnosis Method | Monitoring Indicators | Data Supports | Strengths and Limitations | Reference |

|---|---|---|---|---|---|

| Gear contact fatigue damage | VBDM-DT model | Model input torque | The model error is 8.34% | Intelligent calibration for high model fidelity; Model functionality and applicability need to be expanded | [80] |

| Motor inner ring failure, outer ring failure | Model based on time series fusion Transformer | Diagnostic Precision, Accuracy, Recall, F1 | Accuracy 99.99%, Recall 99.98%, F1 Score 0.99 | Excellent performance in overall performance indicators; Generalization ability in real scenarios needs to be strengthened | [81] |

| Bearing failures | Parameterized CNN | Vibration response characteristic for frequency and amplitude | Diagnostic accuracy 94.0741% | Diagnosis without fault data, high diagnostic accuracy; Need to improve the digital twin model | [83] |

| Demagnetization faults, dynamic eccentricity faults | SFT, CNN | Fault state | Accuracy 99.72%, 10 times more efficient | High fault recognition accuracy and stability; Unexpanded fault diagnosis types | [89] |

| Motor surface damage | RDSS-YOLO neural network | Average Precision, Recall | Average Precision of 95.7%, Recall rate 96.8% | Higher detection accuracy; Unable to detect internal component damage | [91] |

| Bearing wear, corrosion | Multi-objective particle swarm optimization algorithm | Mean absolute error | RMSE is 0.051 | Reduced dependence on actual data, high diagnostic accuracy; More modes under actual working conditions are not considered | [110] |

| PMSM turn-to-turn short circuit faults | NARX Network | Three-phase current residuals, relative mean square error | \ | Reduced dependence on actual data, high diagnostic accuracy; More modes under actual working conditions are not considered | [96] |

| Rotor broken bars, stator winding failure, rotor misalignment | PCCDP, clustering-based metric learning | Diagnostic accuracy | High diagnostic accuracy in case of label scarcity | No need for fault data and precise motor parameters; Separate digital twins are required for different motor models | [97] |

| Failure of rotor bar breakage | MCSA | Low-sideband harmonic components | Experimental LSH amplitude increased by 3.62 dB when the bar was broken, and by 3.34 dB in the simulation | Simple model construction, good agreement between simulation and experimental data; Variation in motor parameters with temperature, frequency and saturation are not considered | [98] |

| Axis misalignment | ResNet-50 deep learning | Model testing accuracy, validation accuracy | Diagnostic accuracy of 98.6% | AI applications to improve diagnostic accuracy and efficiency; Difficult and costly to obtain sufficient high-quality learning data | [112] |

| Motor inner ring failure, outer ring failure | Inverse PINN | Vibration signal spectrum | Diagnostic accuracy of 98% on average | Effectively addressing sample imbalances; Need to further improve the quality and diversity of generated data | [77] |

| Short circuit failure | Artificial intelligence-based methods, signal processing and feature extraction techniques | Current, signal reflection parameters | Diagnostic accuracy of 98.6% | Artificial intelligence applications to improve diagnostic accuracy and efficiency; Difficult and costly to obtain sufficient high-quality learning data | [84] |

| Motor bearing outer ring spalling | High-fidelity multi-physics field finite element modeling | Vibration response, torque | Tolerance of about 3% | Solves the problem of data scarcity; Models bias in predicting certain vibrations | [90] |

| Collector ring oxidation | FEM, thermomagnetic intensity coupling simulation and analysis | Motor phase current, case temperature | Current measurement error 4.4%, temperature measurement error 10% | Non-intrusive monitoring with low errors; No mention of the stability of the system operating under complex conditions | [92] |

| Turn-to-turn short circuit | Digital twin-based and improved Sparrow Search Algorithm | Current, voltage, speed | Diagnostic accuracy 98.2143% | High diagnostic accuracy due to 3D visualization and monitoring; Aability to apply theory to practice needs to be improved | [93] |

| Rotor breaks | FEA, Fuzzy Logic Control | Motor losses, temperature, efficiency | Rapidity varies across models | Circuit modeling is simple and efficient; Limited accuracy when dealing with complex situations | [94] |

| Rotor breaks | Digital shadowing system based on efficiency modeling | Machine loss, efficiency | Diagnostic accuracy 99.99%, F1 Score 0.99 | Good adaptability to different fault severities; Range of applications to be expanded | [95] |

| Rotor broken strip, broken end ring | Multi-cage fault analysis model of electric machine based on winding tensor method | Characteristic fault harmonic components | Good agreement between simulated and experimental data | Fast calculation speed and simple calculation of model parameters; Variation in motor parameters with temperature is not considered | [99] |

| Rotor imbalance, broken bars | FEM | Stator and rotor current, coil voltage, electromagnetic torque | Measured stator current at 60 Hz 5.780 A, modeled value 5.865 A | Accurate and efficient modeling of difficult-to-measure electromagnetic quantities; Does not take into account magnetic saturation | [100] |

| Broken bar failure, winding failure | RPT, Bayesian updating | Fault characteristic frequency | BRB faults can be effectively diagnosed at −10 dB noise level | Strong robustness to noise interference; Lacks context awareness | [101] |

| Rotor breaks | MCSA, FEM | Time–frequency-domain current signal characteristics | Average error 1.55% | Non-invasive testing with low diagnostic error; Three-dimensional FEM models are computationally complex | [103] |

| Inner ring, outer ring failure | IVMD combined with PSO-LSSVM | Time–frequency-domain characterization of vibration signals | Diagnostic accuracy 99.1% | High visualization and diagnostic accuracy; Experimentally unstudied more types of faults | [105] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Xiao, H.; Ye, Z.; Luo, N.; Zhou, M. Research and Prospects of Digital Twin-Based Fault Diagnosis of Electric Machines. Sensors 2025, 25, 2625. https://doi.org/10.3390/s25082625

Hu J, Xiao H, Ye Z, Luo N, Zhou M. Research and Prospects of Digital Twin-Based Fault Diagnosis of Electric Machines. Sensors. 2025; 25(8):2625. https://doi.org/10.3390/s25082625

Chicago/Turabian StyleHu, Jiaqi, Han Xiao, Zhihao Ye, Ningzhao Luo, and Minhao Zhou. 2025. "Research and Prospects of Digital Twin-Based Fault Diagnosis of Electric Machines" Sensors 25, no. 8: 2625. https://doi.org/10.3390/s25082625

APA StyleHu, J., Xiao, H., Ye, Z., Luo, N., & Zhou, M. (2025). Research and Prospects of Digital Twin-Based Fault Diagnosis of Electric Machines. Sensors, 25(8), 2625. https://doi.org/10.3390/s25082625