Samarium (III) Selective Membrane Sensor Based on Tin (IV) Boratophosphate

Abstract

:Introduction

Experimental

Reagents

Preparation of exchanger

Preparation of membranes

Preparation of epoxy resin-based membranes

Preparation of PVC membranes

Preparation of PS membranes

EMF measurements

Results and Discussions

Optimization of membrane composition

Calibration curve and statistical data

Effect of internal solution concentration

Effect of pH

Selectivity coefficients and analytical properties of Sm (III) selective electrode

Effect of partially non-aqueous medium on the working of Sm (III) electrode

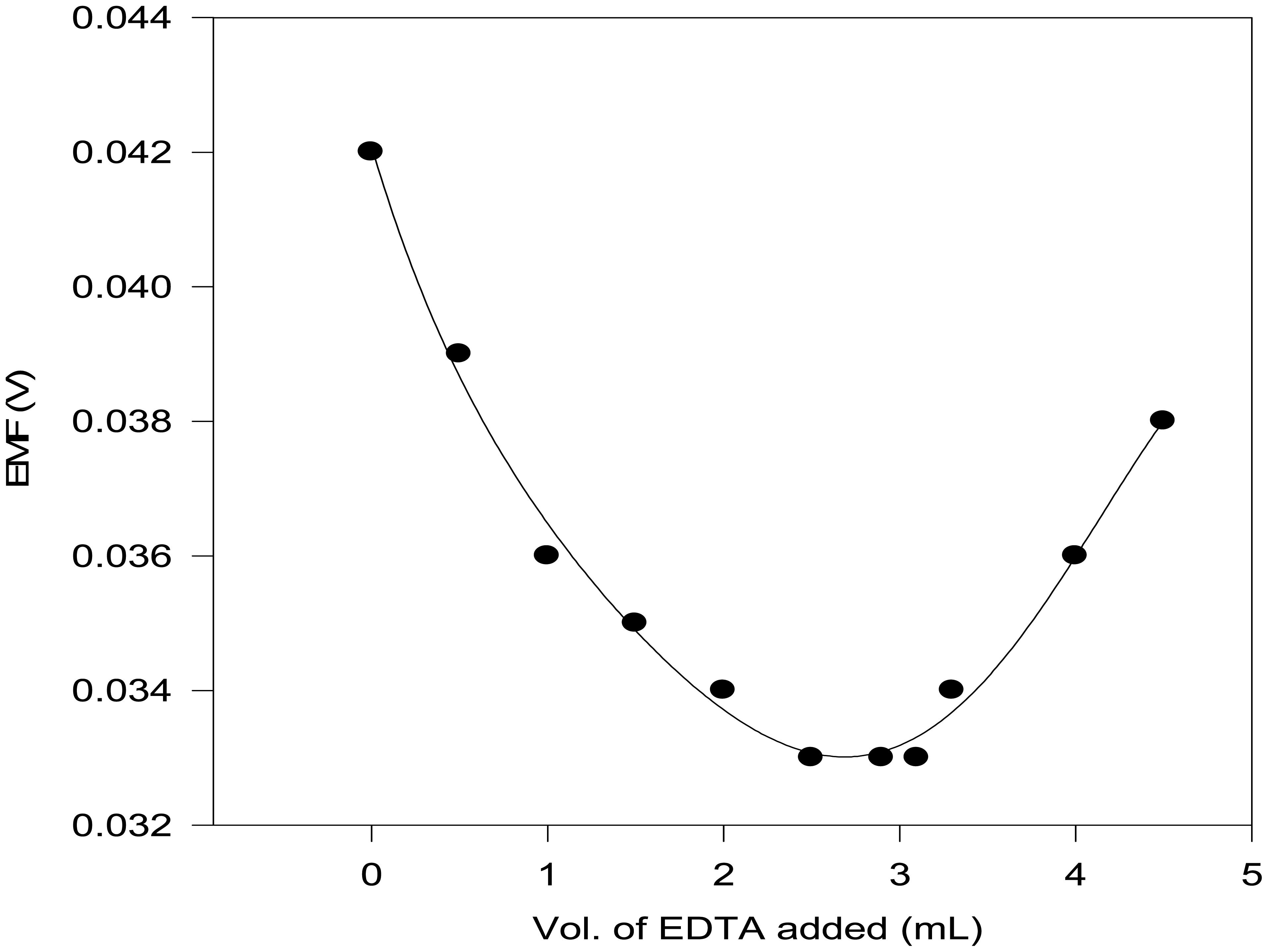

Potentiometric titration

Acknowledgments

References

- Hopkins, B.S. Chemistry of the Rarer Elements; D.C. Heath and Company: Boston, 1923; p. 93. [Google Scholar]

- Ganjali, M.R.; Pourjavid, M.R.; Rezapour, M.; Haghgoo, S. Novel samarium (III) selective membrane sensor based on glipizid. Sensors and Actuators B 2003, 89, 21. [Google Scholar]

- Kirk, O.R.; Othmer, D.F. Encyclopedia of Chemical Technology; Wiley: New York, 1982; Volume 19, p. 851. [Google Scholar]

- Si, Z.; Wang, L.; Hu, J.; Jiang, W. Enhanced luminescence of terbium-1-cyclopropyl-6-fluoro-1,4-dihydro-4-oxo-7-(1-piperazinyl)-3-quinolinecarboxylic acid with lanthanum and its applications. J. Microchem. 2001, 70, 19. [Google Scholar]

- Hrdlicka, A.; Havei, J.; Moreno, C.; Valiente, M. Micellar-enhanced highly sensitive reaction of rare earths with xylenol orange and surfactants. Study of reaction conditions and optimization of spectrophotometric method. Anal. Sci. 1991, 7, 925. [Google Scholar]

- Mazzucotelli, A.; Depaz, F.; Magi, E.; Frache, B. Interferences of major elements in the determinations of rare earth elements by inductively coupled plasma atomic emission spectroscopy. Anal. Sci. 1992, 8, 189. [Google Scholar]

- Masuda, A.; Nakamura, N.; Tanaka, T. Fines structures of mutually normalized rare earth patterns of chondrites. Geochim. Cosmochim. Acta 1973, 37, 239. [Google Scholar]

- Marsh, S.F. Separation of lanthanide fission products from nuclear fuels by extraction chromatography and cation exchange for isotope dilution mass spectrometric analysis. Anal. Chem. 1967, 39, 641. [Google Scholar]

- Chowdhury, D.A.; Ogata, T.; Kamata, S. Samarium (III)-selective electrode using neutral bis(thialkylxanthato)alkanes. Anal. Chem. 1996, 68, 366. [Google Scholar]

- Ogata, T.; Chowdhury, D.A.; Kamata, S.; Usui, Y.; Ohashi, K. Neutral 1,4-bis(3-thiapentylxanthato)butane as sensing material for samarium(III) ion. Chem. Lett. 1995, 24, 1041. [Google Scholar]

- Jammal, A.E.; Bouklouze, A.A.; Patriarche, G.J.; Christian, G.D. Use of ethylene-vinyl-acetate as new membrane matrix for calcium ion-selective electrode preparation. Talanta 1991, 38, 929. [Google Scholar]

- Arnold, M.A.; Solsky, R.L. Ion-selective electrode. Anal. Chem. 1986, 58, 84R. [Google Scholar]

- Buck, R.P.; Lindner, E. Recommendations for nomenclature of ion-selective electrodes (IUPAC recommendations 1994). Pure Appl. Chem. 1994, 66, 2527. [Google Scholar]

- Kraus, K.A.; Phillips, H.O. Adsorption on inorganic materials - I. Cation exchange properties of zirconium phosphate. J. Am. Chem. Soc. 1956, 78, 694. [Google Scholar]

- Kraus, K.A.; Phillips, H.O.; Carlson, T.A.; Johnson, J.S. Basic chemistry in nuclear energy. 2nd UN Conf. Peaceful Uses At. Energy, Geneva 1958, 28, 3. [Google Scholar]

- Amphlett, C.B. 2nd UN Conf. Peaceful Uses At Energy, Geneva 1958, 28, 17.

- Amphlett, C.B. Inorganic Ion Exchangers; Elsevier: Amsterdam, 1964. [Google Scholar]

- Bakker, E. Selectivity of liquid membrane ion selective electrodes. Electroanalysis 1997, 9, 7. [Google Scholar]

- Umezawa, Y.; Umezawa, K.; Sato, H. Selectivity coefficients for ion-selective electrodes: recommended methods for reporting KPot.A,B values (technical report). Pure Appl. Chem. 1995, 67, 507. [Google Scholar]

- Jain, A.K.; Singh, R.P. Srivastava, S.K.; Agrawal, S. Studies with inorganic ion-exchange membranes. Talanta 1978, 25, 157. [Google Scholar]

- Malik, W.U.; Srivastava, S.K.; Bansal, A. Potentiometric estimation of molybdate ion with a solid membrane electrode. Anal. Chem. 1982, 54, 1399. [Google Scholar]

- Moody, G.J.; Thomas, J.D.R. Development and publication of work with selective ion-sensitive electrodes. Talanta 1972, 19, 623. [Google Scholar]

- Harsanyi, E.G.; Toth, K.; Polos, L.; Pungor, E. Adsorption phenomenon of silver-iodide based ionselective electrode. Anal. Chem. 1982, 54, 1094. [Google Scholar]

- Harsanyi, E.G.; Toth, K.; Pungor, E. The behavior of the silver sulphide precipitate based ion-selective electrode in the low concentration range. Anal. Chim. Acta 1984, 161, 333. [Google Scholar]

- .

| Electrode No. | SnBP(%) | Binder | Medium | Slope (mV/decade) | Measuring Range (M) | Response Time (s) |

|---|---|---|---|---|---|---|

| 1 | 30 | PVC | THF | 40 | 2.0×10-5-10-1 | 20 |

| 2 | 40 | PVC | THF | 42 | 2.0×10-5-10-1 | 20 |

| 3 | 10 | Araldite | - | 40 | 1.0×10-5-10-1 | 15 |

| 4 | 20 | Araldite | - | 40 | 2.5×10-5-10-1 | 15 |

| 5 | 30 | Araldite | - | 42 | 1.0×10-5-10-1 | 15 |

| 6 | 40 | Araldite | - | 40 | 1.0×10-5-10-1 | 10 |

| 7 | 40 | Polystyrene | - | 42 | 2.0×10-5-10-1 | 15 |

| Interfering ion (B) | Selectivity Coefficient values (KpotA,B) | |

|---|---|---|

| Interfering ion concentration | ||

| 10-3 M | 10-4 M | |

| La(III) | 0.31 | 0.40 |

| Ce(III) | 0.25 | 0.31 |

| Nd(III) | 0.40 | 0.50 |

| Eu(III) | 0.40 | 0.50 |

| Pr(III) | 0.50 | 0.63 |

| Tb(III) | 0.32 | 0.40 |

| Dy(III) | 0.40 | 0.40 |

| Y(III) | 0.31 | 0.40 |

| Fe(III) | 0.25 | 0.25 |

| Al(III) | 0.10 | 0.31 |

| Ca(II) | 0.50 | 0.50 |

| Na(I) | 0.50 | 0.63 |

| Solvent | Percentage(v/v) | Slope (mV/decade) | Measuring range(M) |

|---|---|---|---|

| Acetone | 5 | 40.0 | 1.0×10-5 to 10-1 |

| 10 | 40.0 | 3.2×10-5 to 10-1 | |

| 15 | 40.0 | 3.2×10-5 to 10-1 | |

| 20 | 40.0 | 1.0×10-5 to 10-1 | |

| Ethanol | 5 | 40.2 | 1.0×10-5 to 10-1 |

| 10 | 40.1 | 2.0×10-5 to 10-1 | |

| 15 | 40.0 | 1.0×10-5 to 10-1 | |

| 20 | 40.2 | 4.3×10-5 to 10-1 | |

| Acetonitrile | 5 | 40.0 | 1.0×10-5 to 10-1 |

| 10 | 40.1 | 1.0×10-5 to 10-1 | |

| 15 | 40.0 | 2.3×10-5 to 10-1 | |

| 20 | 40.0 | 1.0×10-5 to 10-1 |

© 2004 by MDPI ( http://www.mdpi.org). Reproduction is permitted for non-commercial purposes.

Share and Cite

Mittal, S.K.; Sharma, H.K.; Kumar, A.S.K. Samarium (III) Selective Membrane Sensor Based on Tin (IV) Boratophosphate. Sensors 2004, 4, 125-135. https://doi.org/10.3390/s40800125

Mittal SK, Sharma HK, Kumar ASK. Samarium (III) Selective Membrane Sensor Based on Tin (IV) Boratophosphate. Sensors. 2004; 4(8):125-135. https://doi.org/10.3390/s40800125

Chicago/Turabian StyleMittal, Susheel K., Harish Kumar Sharma, and Ashok S. K. Kumar. 2004. "Samarium (III) Selective Membrane Sensor Based on Tin (IV) Boratophosphate" Sensors 4, no. 8: 125-135. https://doi.org/10.3390/s40800125

APA StyleMittal, S. K., Sharma, H. K., & Kumar, A. S. K. (2004). Samarium (III) Selective Membrane Sensor Based on Tin (IV) Boratophosphate. Sensors, 4(8), 125-135. https://doi.org/10.3390/s40800125