Tool Condition Monitoring for High-Performance Machining Systems—A Review

Abstract

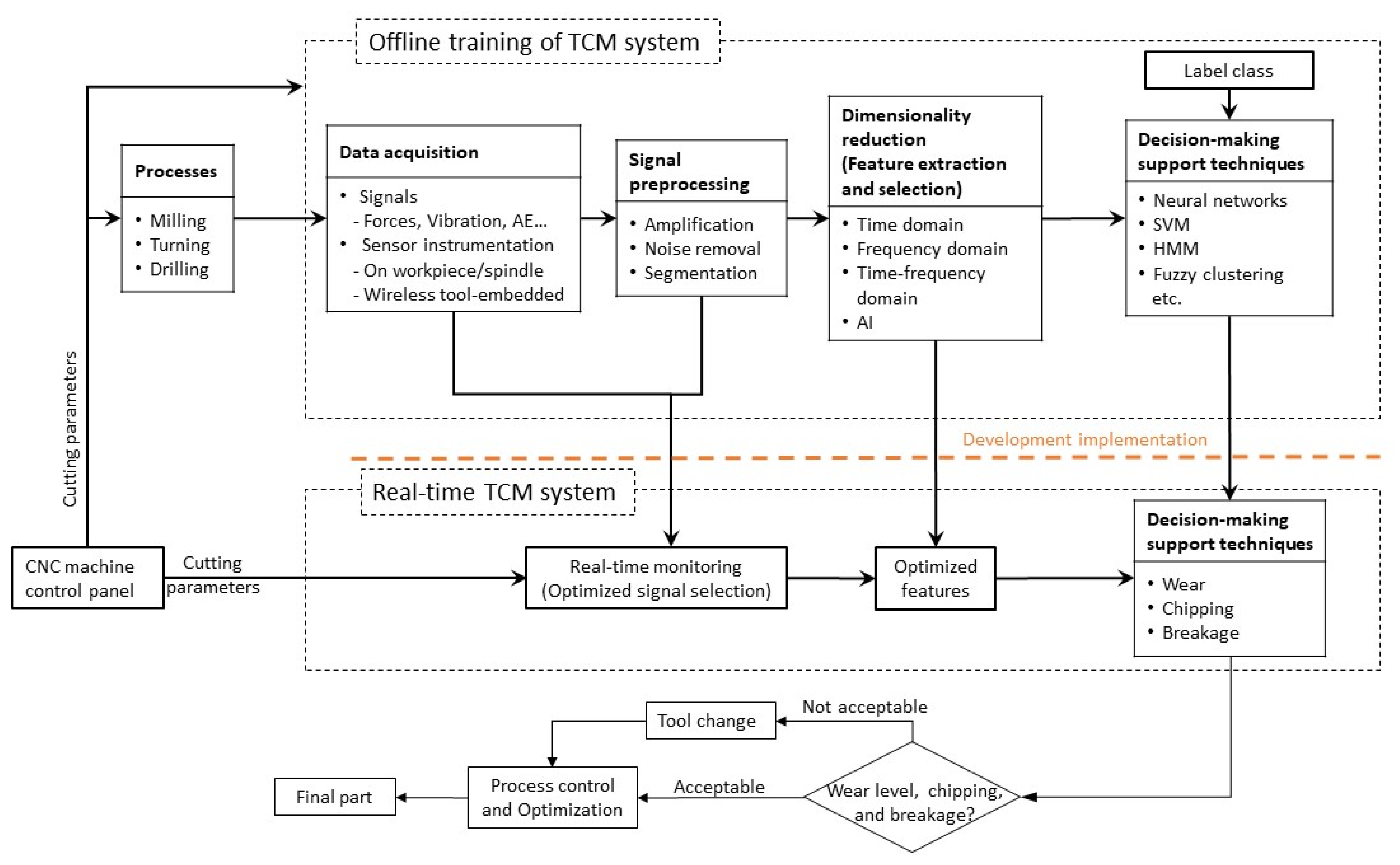

:1. Introduction

2. Sensing and Data Acquisition

2.1. Conventional Means of Sensing

2.1.1. Cutting Force Signal

2.1.2. Vibration Signal

2.1.3. Acoustic Emission Signal

2.1.4. Motor Current Signal

2.1.5. Temperature Signal

2.1.6. Spindle Rotational Speed Signal

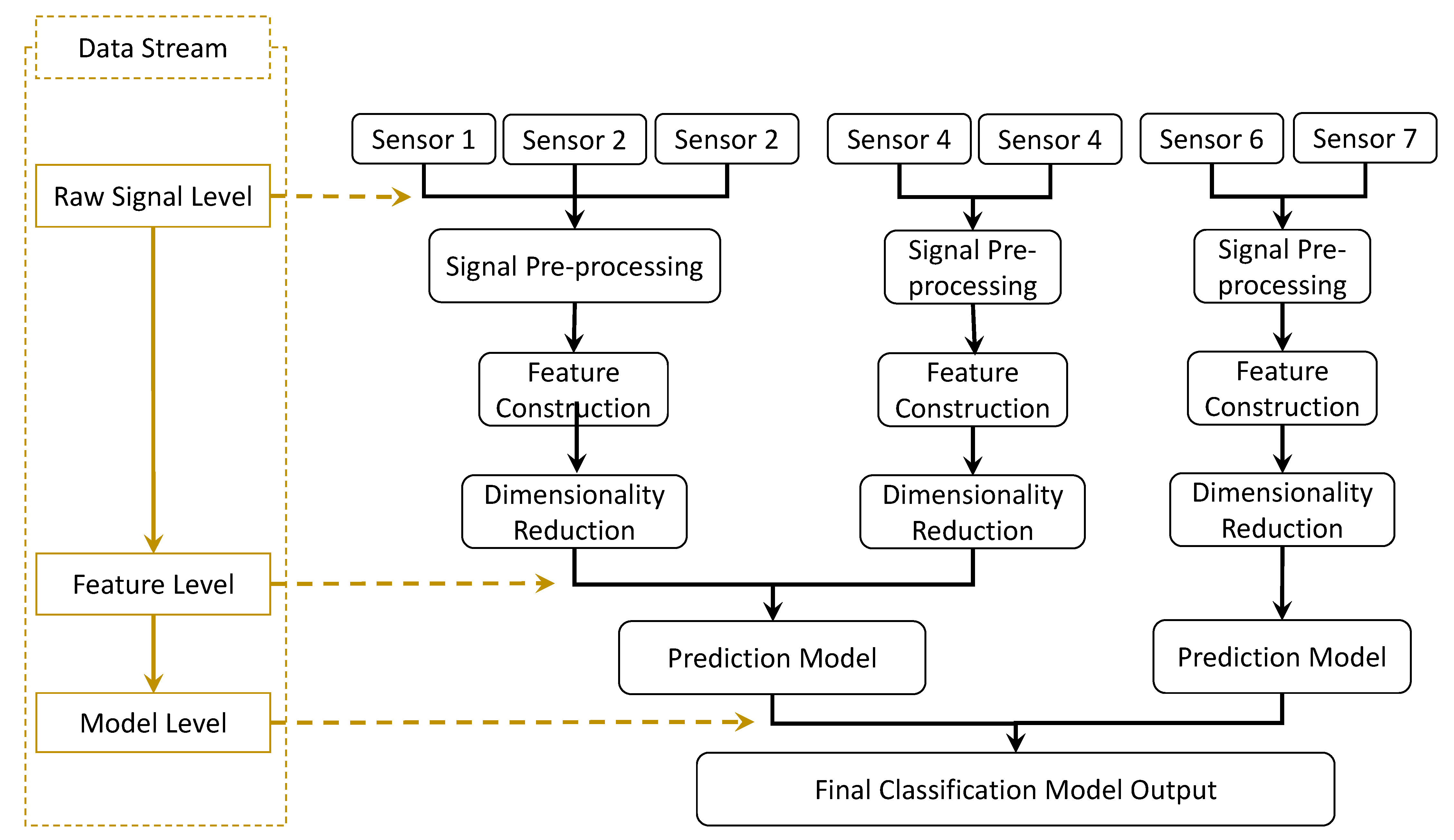

2.1.7. Multi-Signal Approach

2.2. Universal Sensor Node Approach

2.2.1. Sensory Integration

2.2.2. Data Transmission and Power Management

3. Signal Pre-Processing

- Amplification: At an early step, the signal is typically amplified due to the low-level output signal of the used sensor, which increases the signal-to-noise ratio and reduces the unwanted interference. The maximum voltage range of the signal should meet the maximum input range condition of the analog–digital converter to achieve the best level of accuracy [17].

- Sampling: After amplifying the signal, the acquired signal should be sampled at a sampling rate more than two times the highest frequency of interest seen in the signal according to the Nyquist–Shannon sampling theorem [88]. In practice, the sampling rate should be 5–10 times the highest frequency of interest for better representation of process variables [20].

- Filtering: Digital or analog filtering is used to exclude the undesired signal frequencies while preserving the correlation between sensor data and process variables, such as studying the cutting force signals at the tool-pass frequency [84]. Filtering is also commonly used to avoid aliasing from high frequency signals, which can be accomplished by attenuating signals above the Nyquist frequency with an anti-aliasing filter. Anti-aliasing filters are appropriate for vibration signals since accelerometer readings are typically evaluated in the frequency domain [88]. In general, the obtained signal can be filtered using high-pass, low-pass, or band-pass to exclude undesired signal frequency components.

- Segmentation: As an optional technique for pre-processing sensor data, segments of the signal are extracted when the tool is engaged with the workpiece material as only these segments include information about the tool condition [8,131]. The most basic and widely used technique of signal segmentation is the detection of a signal value surpassing a predefined threshold in a user-defined time window [8,132,133]. An experimental definition of the threshold value is required because it is determined as part of the maximum signal value. Another segmentation approach can be implemented per tool rotation to produce repeating patterns of the extracted segments [22], where an overlapping time moving frame was applied to avoid disruption of data continuity.

4. Signal Processing Techniques

4.1. Features Construction

4.2. Dimensionality Reduction

4.2.1. Feature Selection

- Filter techniques are open-loop computational methods that only consider the relationship between features and class label without involving the subsequent tool wear classification model, as shown in Figure 6. They evaluate the usefulness of features subsets based on their intrinsic properties using evaluation measures, such as dependency, consistency, or information, to eliminate low-ranking features [171,174,175]. The ranking measure is determined using statistical measures, such as Pearson’s correlation coefficient, the coefficient of determination, minimum redundancy maximum relevance (mRMR), or analysis of variance ANOVA [171,174,176,177,178]. A detailed discussion on various performance measures is available in [179]. Filter techniques have relatively low computational cost and high scalability to large feature datasets. Their major drawback is the non-involvement of the decision-making algorithm, which makes its accuracy data-dependent.

- Wrapper techniques are closed-loop techniques, in which the tool wear model is used for selecting the most discriminative features by minimizing the misclassification error of the model, as shown in Figure 7 [180]. Several models have been developed by training the classification algorithm using different subsets of features in order to define the optimum subset with minimum classification error. In terms of classification accuracy, wrapper techniques outperform filter techniques. Additionally, they consider the dependencies among selected features [137]. However, the primary downsides of this technique are the expensive computational effort to achieve convergence, and being more prone to overfitting, compared to filter techniques. Feature subsets are usually generated using heuristic or random search strategies [181,182]. Forward and backward sequential selection methods are used by sequentially adding or removing one feature at a time, respectively, until a local maximum accuracy is achieved [183]. Because both methods ignore the inter-dependency of features, sequential floating forward selection (SFFS) and sequential floating backward selection (SFBS) were developed [184]. The genetic algorithm (GA) [185] and the ant colony algorithm [186] are among the most representative methods of random search strategies that have been used to optimize the constructed features and to select features with a high correlation with the tool health state [187].

- Hybrid techniques are the result of merging a wrapper technique and a filter technique to inherit the complementary strengths of both models, as shown in Figure 8 [137]. For model-independent techniques (wrapper and embedded techniques), the size of the candidate feature dataset should be kept modest; otherwise, a significant amount of training data will be required [188]. Therefore, the filter technique using the mRMR is applied to remove irrelevant features and to alleviate redundancy among features. It has been successfully applied to reduce the feature dataset size by 1000-fold in grinding operations [177]. This preselection stage is followed by applying the wrapper technique through assessing the model performance using the coefficient of determination and root-mean-square error (RMSE).

- Embedded techniques are built-in feature selection techniques, in which the feature selection and the model training processes are merged [181]. During the model training, a scaling factor is assigned to each candidate feature, and it is optimized to reflect its relative relevance [189]. Embedded techniques have the merits of the filter and wrapper techniques. They are computationally efficient while maintaining a classification accuracy comparable to wrapper techniques owing to omitting the repeated execution and evaluation of each feature subset by the learning algorithm. However, they are classifier dependent, and their performance might degrade if the initially constructed dataset has several irrelevant features [137]. A gradient boosting decision tree (GBDT) is an example of embedded techniques in TCM systems that were used to optimize the size of the initially constructed feature dataset from 198 features to 40 discriminative features in tool wear monitoring application [190]. Abubakr et al. used a random forest (RF) classifier, in which out-of-bag (OOB) samples are utilized to reduce the constructed feature pool from 152 to 15 features while maintaining a high level of classification accuracy [139].

4.2.2. Feature Transformation

5. Decision Making for Tool Wear Monitoring

6. Integrated Tool Breakage/Chipping Monitoring and Decision Making

7. Conclusions and Future Research Avenues

- Data acquisition: Until recently, previous TCM research has adopted a conventional approach, in which the sensors are mounted on the machine spindle or the workpiece. In this approach, vibration and acoustic emission AE sensors were preferred in industrial TCM applications, since monitoring cutting forces using a table dynamometer is impractical due to the high intrusiveness and investment cost. Although the cutting tool temperature is correlated to tool wear in the milling operations of difficult-to-cut materials, such as Ti6Al4V alloy, it is not widely monitored and used as an indicator of tool wear. The quality of the vibration and AE signals are impacted by the long signal transmission path and multiple reflective surfaces, particularly when they are mounted on the machine spindle. This problem can be alleviated by using a universal wireless tool-embedded sensor node in the TCM system. The application of this approach is still limited. Recently, some researchers were able to integrate force, vibration, and temperature sensors into the tool holder to increase the universality of the TCM system. To date, AE has not been integrated yet on a rotating tool for milling operations, due to the complex signal conditioning electronics needed to fit in a confined space on the tool holder. For the conventional multi-sensor approach, optimizing the sensors’ selection and location need to be further investigated, based on the availability and ease of integration of the sensors, as well as the TCM system performance and economics. In the reported commercial and academic designs of TCM tool-embedded sensor nodes, no optimization has been attempted for the selection of the sensors type, proximity, and orientation. Additionally, none of the reported designs have been tailored for machining difficult-to-cut materials, where high cutting forces and concentrated heat can be encountered, causing sensor drift. The sampling rate and the reduced structural stiffness are still the main obstacles for developing a reliable universal wireless sensor node. Furthermore, a comprehensive solution for the power management of the senor node has not been realized yet to reduce the interruptions and/or the intrusiveness to the machining process.

- Feature construction and dimensionality reduction: The TCM research to date has focused on using conventional features constructed from the time, frequency, and time–frequency domains, rather than discovering novel features that correlate to the tool health state, while being independent of the cutting parameters. The compatibility of such features with the most up-to-date tool wear modeling algorithms should be investigated. The time–frequency domain has attracted attention of many researchers in TCM applications, particularly the EMD technique and its variants due to its ability to handle nonlinear nonstationary signals. This technique is, however, susceptible to mode mixing and mode splitting. The fast iterative filtering technique can tackle these issues but its application is still limited in TCM. The generality, adaptability, and computational cost of AI algorithms can be improved by monitoring new variables or discovering new features. Based on the reviewed literature, there has been no detailed investigation of the tool wear impact on the chip segmentation and its consequences on the acquired signals, rubbing force, tooth-pass frequency, and the direction of the resultant cutting force. Such investigation may help to explore a robust feature or variable that decreases the learning effort and increases the generality of the developed model. Due to the great impact of dimensionality reduction on the performance and accuracy of machine learning algorithms, a wide variety of dimensionality reduction strategies have been proposed in recent decades to address the problem of high-dimensional data in TCM applications. The two main adopted techniques are feature selection and feature transformation. However, there is currently no universal strategy for dimensionality reduction that can be applied to all scenarios. Future TCM research should consider developing techniques that are tailored for the nature of acquired sensory data in machining operations to improve the accuracy and robustness of the TCM system.

- Decision making for tool health state monitoring: A remarkable interest has been given to tool wear monitoring with the anticipated increase in utilizing more advanced artificial intelligence AI techniques. Conventional algorithms such as ANNs became more popular for tool wear modeling. Choosing the appropriate algorithm is impacted by the information content and quality of the processed signal. This necessitates extensive research into the efficacy of various signal features and signal processing techniques before implementing the monitoring AI algorithms needed to reduce the learning effort and improve the TCM system generalization. The complex nonlinear and nonstationary nature of machining processes has led to utilizing advanced deep learning algorithms. To overcome their main limitation, few studies have recently been conducted to propose a practical deep learning algorithms with low training efforts to increase the possibility of adopting them for industrial TCM systems. The vast majority of the previous research has focused on exploiting process-feedback signals to identify changes in cutting parameters following tool chipping and/or breakage in machining operations. However, it is crucial to predict and prevent sudden tool failures by chipping and/or breakage before it happens. Only one research work has been found that can monitor the unstable crack propagation stage in stationary tools before the occurrence of chipping and/or breakage in intermittent machining operations using an AE sensor by pre-setting a threshold based on experimental results. A fully automated and comprehensive solution for milling operations still needs to be developed. There is also a need for establishing a correlation between the AE bursts and the chipped material, as well as optimizing the location of mounting the AE in the milling machine to reduce the signal transmission path and multiple acoustic wave reflections.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Kene, A.P.; Choudhury, S.K. Analytical modeling of tool health monitoring system using multiple sensor data fusion approach in hard machining. Measurement 2019, 145, 118–129. [Google Scholar] [CrossRef]

- Wong, S.Y.; Chuah, J.H.; Yap, H.J. Technical data-driven tool condition monitoring challenges for CNC milling: A review. Int. J. Adv. Manuf. Technol. 2020, 107, 4837–4857. [Google Scholar] [CrossRef]

- Mia, M.; Królczyk, G.; Maruda, R.; Wojciechowski, S. Intelligent optimization of hard-turning parameters using evolutionary algorithms for smart manufacturing. Materials 2019, 12, 879. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hassan, M.; Sadek, A.; Attia, M.H.; Thomson, V. Intelligent Machining: Real-Time Tool Condition Monitoring and Intelligent Adaptive Control Systems. J. Mach. Eng. 2018, 18, 5–18. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, J. On-line tool wear measurement for ball-end milling cutter based on machine vision. Comput. Ind. 2013, 64, 708–719. [Google Scholar] [CrossRef]

- Tiwari, K.; Shaik, A.; Nara, A. Tool wear prediction in end milling of Ti-6Al-4V through Kalman filter based fusion of texture features and cutting forces. Procedia Manuf. 2018, 26, 1459–1470. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Bustillo, A.; Mikolajczyk, T. Artificial intelligence for automatic prediction of required surface roughness by monitoring wear on face mill teeth. J. Intell. Manuf. 2017, 29, 1045–1061. [Google Scholar] [CrossRef] [Green Version]

- Bhattacharyya, P.; Sengupta, D.; Mukhopadhyay, S. Cutting force-based real-time estimation of tool wear in face milling using a combination of signal processing techniques. Mech. Syst. Signal Processing 2007, 21, 2665–2683. [Google Scholar] [CrossRef]

- Hanachi, H.; Yu, W.; Kim, I.Y.; Liu, J.; Mechefske, C.K. Hybrid data-driven physics-based model fusion framework for tool wear prediction. Int. J. Adv. Manuf. Technol. 2018, 101, 2861–2872. [Google Scholar] [CrossRef]

- Taylor, F.W. On the Art of Cutting Metals; American Society of Mechanical Engineers: New York, NY, USA, 1906; Volume 23. [Google Scholar]

- Zhu, K.; Zhang, Y. A generic tool wear model and its application to force modeling and wear monitoring in high speed milling. Mech. Syst. Signal Processing 2019, 115, 147–161. [Google Scholar] [CrossRef]

- Pálmai, Z. Proposal for a new theoretical model of the cutting tool’s flank wear. Wear 2013, 303, 437–445. [Google Scholar] [CrossRef]

- Hou, Y.; Zhang, D.; Wu, B.; Luo, M. Milling Force Modeling of Worn Tool and Tool Flank Wear Recognition in End Milling. IEEE/ASME Trans. Mechatron. 2015, 20, 1024–1035. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Salur, E.; Gupta, M.K.; Sarıkaya, M.; Pimenov, D.Y. A state-of-the-art review on sensors and signal processing systems in mechanical machining processes. Int. J. Adv. Manuf. Technol. 2021, 116, 2711–2735. [Google Scholar] [CrossRef]

- Nath, C. Integrated Tool Condition Monitoring Systems and Their Applications: A Comprehensive Review. Procedia Manuf. 2020, 48, 852–863. [Google Scholar] [CrossRef]

- Kuntoglu, M.; Aslan, A.; Pimenov, D.Y.; Usca, U.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kaplonek, W.; Sharma, S. A Review of Indirect Tool Condition Monitoring Systems and Decision-Making Methods in Turning: Critical Analysis and Trends. Sensors 2020, 21, 108. [Google Scholar] [CrossRef] [PubMed]

- Teti, R.; Jemielniak, K.; O’Donnell, G.; Dornfeld, D. Advanced monitoring of machining operations. CIRP Ann. 2010, 59, 717–739. [Google Scholar] [CrossRef] [Green Version]

- Mohanraj, T.; Shankar, S.; Rajasekar, R.; Sakthivel, N.R.; Pramanik, A. Tool condition monitoring techniques in milling process—A review. J. Mater. Res. Technol. 2020, 9, 1032–1042. [Google Scholar] [CrossRef]

- Tao, Z.; An, Q.; Liu, G.; Chen, M. A novel method for tool condition monitoring based on long short-term memory and hidden Markov model hybrid framework in high-speed milling Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 105, 3165–3182. [Google Scholar] [CrossRef]

- Zhou, C.a.; Guo, K.; Sun, J. An integrated wireless vibration sensing tool holder for milling tool condition monitoring with singularity analysis. Measurement 2021, 174, 109038. [Google Scholar] [CrossRef]

- Krishnakumar, P.; Rameshkumar, K.; Ramachandran, K.I. Acoustic Emission-Based Tool Condition Classification in a Precision High-Speed Machining of Titanium Alloy: A Machine Learning Approach. Int. J. Comput. Intell. Appl. 2018, 17, 1850017. [Google Scholar] [CrossRef]

- Hassan, M.; Sadek, A.; Attia, M.H.; Thomson, V. A Novel Generalized Approach for Real-Time Tool Condition Monitoring. J. Manuf. Sci. Eng. 2018, 140, 021010. [Google Scholar] [CrossRef]

- Li, T.; Shi, T.; Tang, Z.; Liao, G.; Duan, J.; Han, J.; He, Z. Real-time tool wear monitoring using thin-film thermocouple. J. Mater. Processing Technol. 2021, 288, 116901. [Google Scholar] [CrossRef]

- Wang, M.; Wang, J. CHMM for tool condition monitoring and remaining useful life prediction. Int. J. Adv. Manuf. Technol. 2012, 59, 463–471. [Google Scholar] [CrossRef]

- Zhou, Y.; Xue, W. Review of tool condition monitoring methods in milling processes. Int. J. Adv. Manuf. Technol. 2018, 96, 2509–2523. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoğlu, M.; Güneş, A.; Şahin, Ö.S. Optimization of Cutting Forces During Turning of Composite Materials. Acad. Platf. J. Eng. Sci. 2020, 8, 423–431. [Google Scholar] [CrossRef]

- Sick, B. On-Line and Indirect Tool Wear Monitoring in Turning with Artificial Neural Networks: A Review of More Than a Decade of Research. Mech. Syst. Signal Processing 2002, 16, 487–546. [Google Scholar] [CrossRef]

- Huang, P.; Li, J.; Sun, J.; Zhou, J. Vibration analysis in milling titanium alloy based on signal processing of cutting force. Int. J. Adv. Manuf. Technol. 2012, 64, 613–621. [Google Scholar] [CrossRef]

- Cabrera, C.G.; Araujo, A.C.; Castello, D.A. On the wavelet analysis of cutting forces for chatter identification in milling. Adv. Manuf. 2017, 5, 130–142. [Google Scholar] [CrossRef]

- Chen, J.C.; Chen, W.-L. A tool breakage detection system using an accelerometer sensor. J. Intell. Manuf. 1999, 10, 187–197. [Google Scholar] [CrossRef]

- Koike, R.; Ohnishi, K.; Aoyama, T. A sensorless approach for tool fracture detection in milling by integrating multi-axial servo information. CIRP Ann. 2016, 65, 385–388. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Vasiliadis, E.; Chryssolouris, G. Tool wear predictability estimation in milling based on multi-sensorial data. Int. J. Adv. Manuf. Technol. 2015, 82, 509–521. [Google Scholar] [CrossRef] [Green Version]

- Xu, H.; Zhang, C.; Hong, G.S.; Zhou, J.; Hong, J.; Woon, K.S. Gated Recurrent Units Based Neural Network for Tool Condition Monitoring. In Proceedings of the 2018 International Joint Conference on Neural Networks (IJCNN), Rio de Janeiro, Brazil, 8–13 July 2018; pp. 1–7. [Google Scholar]

- Zhou, C.a.; Yang, B.; Guo, K.; Liu, J.; Sun, J.; Song, G.; Zhu, S.; Sun, C.; Jiang, Z. Vibration singularity analysis for milling tool condition monitoring. Int. J. Mech. Sci. 2020, 166, 105254. [Google Scholar] [CrossRef]

- Rao, K.V.; Kumar, Y.P.; Singh, V.K.; Raju, L.S.; Ranganayakulu, J. Vibration-based tool condition monitoring in milling of Ti-6Al-4V using an optimization model of GM(1,N) and SVM. Int. J. Adv. Manuf. Technol. 2021, 115, 1931–1941. [Google Scholar] [CrossRef]

- Cuka, B.; Kim, D.-W. Fuzzy logic based tool condition monitoring for end-milling. Robot. Comput.-Integr. Manuf. 2017, 47, 22–36. [Google Scholar] [CrossRef]

- Sahu, N.K.; Andhare, A.B.; Andhale, S.; Abraham, R.R. Prediction of surface roughness in turning of Ti-6Al-4V using cutting parameters, forces and tool vibration. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Novi Sad, Serbia, 6–8 June 2018; p. 012037. [Google Scholar]

- Abellan-Nebot, J.V.; Romero Subirón, F. A review of machining monitoring systems based on artificial intelligence process models. Int. J. Adv. Manuf. Technol. 2010, 47, 237–257. [Google Scholar] [CrossRef]

- Kral, Z.; Horn, W.; Steck, J. Crack propagation analysis using acoustic emission sensors for structural health monitoring systems. Sci. World J. 2013, 2013, 823603. [Google Scholar] [CrossRef] [Green Version]

- Dornfeld, D.A.; Diei, E.N. A Model of Tool Fracture Generated Acoustic Emission During Machining. J. Eng. Ind. 1987, 109, 227–233. [Google Scholar] [CrossRef]

- Hassan, M.; Sadek, A.; Damir, A.; Attia, M.H.; Thomson, V. A novel approach for real-time prediction and prevention of tool chipping in intermittent turning machining. CIRP Ann. 2018, 67, 41–44. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Umer, U.; Mohany, A. Application of acoustic emissions in machining processes: Analysis and critical review. Int. J. Adv. Manuf. Technol. 2018, 98, 1391–1407. [Google Scholar] [CrossRef]

- Haber, R.E.; Jiménez, J.E.; Peres, C.R.; Alique, J.R. An investigation of tool-wear monitoring in a high-speed machining process. Sens. Actuators A Phys. 2004, 116, 539–545. [Google Scholar] [CrossRef]

- Vallejo, A.J.; Morales-Menendez, R. Cost-effective supervisory control system in peripheral milling using HSM. Annu. Rev. Control. 2010, 34, 155–162. [Google Scholar] [CrossRef]

- Ammouri, A.H.; Hamade, R.F. Current rise criterion: A process-independent method for tool-condition monitoring and prognostics. Int. J. Adv. Manuf. Technol. 2014, 72, 509–519. [Google Scholar] [CrossRef]

- Dey, S.; Stori, J.A. A Bayesian network approach to root cause diagnosis of process variations. Int. J. Mach. Tools Manuf. 2005, 45, 75–91. [Google Scholar] [CrossRef]

- Hassan, M. Generalized Sensor-Based Tool Failure Detection and Prevention System for Intermittent Cutting Operations. Ph.D. Thesis, McGill University, Montreal, QC, Canada, 2019. [Google Scholar]

- Hassan, M.; Sadek, A.; Attia, M.H. A Generalized Multisensor Real-Time Tool Condition–Monitoring Approach Using Deep Recurrent Neural Network. Smart Sustain. Manuf. Syst. 2019, 3, 41–52. [Google Scholar] [CrossRef]

- Montronix Monitoring Solutions. Available online: http://www.montronix.com/ (accessed on 15 December 2021).

- Jaen-Cuellar, A.Y.; Osornio-Ríos, R.A.; Trejo-Hernández, M.; Zamudio-Ramírez, I.; Díaz-Saldaña, G.; Pacheco-Guerrero, J.P.; Antonino-Daviu, J.A. System for Tool-Wear Condition Monitoring in CNC Machines under Variations of Cutting Parameter Based on Fusion Stray Flux-Current Processing. Sensors 2021, 21, 8431. [Google Scholar] [CrossRef]

- Rizal, M.; Ghani, J.A.; Zaki Nuawi, M.; Hassan Che Haron, C. A Review of Sensor System and Application in Milling Process for Tool Condition Monitoring. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 2083–2097. [Google Scholar] [CrossRef]

- Lee, B.Y.; Tarng, Y.S. Application of the Discrete Wavelet Transform to the Monitoring of Tool Failure in End Milling Using the Spindle Motor Current. Int. J. Adv. Manuf. Technol. 1999, 15, 238–243. [Google Scholar] [CrossRef]

- He, Z.; Shi, T.; Xuan, J.; Li, T. Research on tool wear prediction based on temperature signals and deep learning. Wear 2021, 478–479, 1580–1597. [Google Scholar] [CrossRef]

- Venugopal, K.A.; Paul, S.; Chattopadhyay, A.B. Growth of tool wear in turning of Ti-6Al-4V alloy under cryogenic cooling. Wear 2007, 262, 1071–1078. [Google Scholar] [CrossRef]

- Lamraoui, M.; Thomas, M.; El Badaoui, M.; Girardin, F. Indicators for monitoring chatter in milling based on instantaneous angular speeds. Mech. Syst. Signal Processing 2014, 44, 72–85. [Google Scholar] [CrossRef]

- Takata, S.; Nakajima, T.; Ahn, J.H.; Sata, T. Tool Breakage Monitoring by Means of Fluctuations in Spindle Rotational Speed. CIRP Ann. 1987, 36, 49–52. [Google Scholar] [CrossRef]

- Girardin, F.; Rémond, D.; Rigal, J.-F. Tool wear detection in milling—An original approach with a non-dedicated sensor. Mech. Syst. Signal Processing 2010, 24, 1907–1920. [Google Scholar] [CrossRef]

- ADXRS649. Available online: https://www.analog.com/en/products/adxrs649.html (accessed on 15 December 2021).

- Prickett, P.W.; Johns, C. An overview of approaches to end milling tool monitoring. Int. J. Mach. Tools Manuf. 1999, 39, 105–122. [Google Scholar] [CrossRef]

- Jauregui, J.C.; Resendiz, J.R.; Thenozhi, S.; Szalay, T.; Jacso, A.; Takacs, M. Frequency and Time-Frequency Analysis of Cutting Force and Vibration Signals for Tool Condition Monitoring. IEEE Access 2018, 6, 6400–6410. [Google Scholar] [CrossRef]

- Caggiano, A. Tool Wear Prediction in Ti-6Al-4V Machining through Multiple Sensor Monitoring and PCA Features Pattern Recognition. Sensors 2018, 18, 823. [Google Scholar] [CrossRef] [Green Version]

- Hu, M.; Ming, W.; An, Q.; Chen, M. Tool wear monitoring in milling of titanium alloy Ti–6Al–4 V under MQL conditions based on a new tool wear categorization method. Int. J. Adv. Manuf. Technol. 2019, 104, 4117–4128. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of signal behaviors for sensor fusion with tool condition monitoring system in turning. Measurement 2021, 173, 108582. [Google Scholar] [CrossRef]

- Niu, B.; Sun, J.; Yang, B. Multisensory based tool wear monitoring for practical applications in milling of titanium alloy. Mater. Today Proc. 2020, 22, 1209–1217. [Google Scholar] [CrossRef]

- Duo, A.; Basagoiti, R.; Arrazola, P.J.; Cuesta, M. Sensor signal selection for tool wear curve estimation and subsequent tool breakage prediction in a drilling operation. Int. J. Comput. Integr. Manuf. 2022, 35, 203–227. [Google Scholar] [CrossRef]

- Duo, A.; Basagoiti, R.; Arrazola, P.J.; Aperribay, J.; Cuesta, M. The capacity of statistical features extracted from multiple signals to predict tool wear in the drilling process. Int. J. Adv. Manuf. Technol. 2019, 102, 2133–2146. [Google Scholar] [CrossRef]

- Mehta, P.; Werner, A.; Mears, L. Condition based maintenance-systems integration and intelligence using Bayesian classification and sensor fusion. J. Intell. Manuf. 2013, 26, 331–346. [Google Scholar] [CrossRef]

- Zhang, C.; Yao, X.; Zhang, J.; Jin, H. Tool Condition Monitoring and Remaining Useful Life Prognostic Based on a Wireless Sensor in Dry Milling Operations. Sensors 2016, 16, 795. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, N.; Ravi, Y.B.; Patra, A.; Mukhopadhyay, S.; Paul, S.; Mohanty, A.R.; Chattopadhyay, A.B. Estimation of tool wear during CNC milling using neural network-based sensor fusion. Mech. Syst. Signal Processing 2007, 21, 466–479. [Google Scholar] [CrossRef]

- Worden, K.; Staszewski, W.J.; Hensman, J.J. Natural computing for mechanical systems research: A tutorial overview. Mech. Syst. Signal Processing 2011, 25, 4–111. [Google Scholar] [CrossRef]

- Kannatey-Asibu, E.; Yum, J.; Kim, T.H. Monitoring tool wear using classifier fusion. Mech. Syst. Signal Processing 2017, 85, 651–661. [Google Scholar] [CrossRef] [Green Version]

- Kuljanic, E.; Sortino, M. TWEM, a method based on cutting forces—monitoring tool wear in face milling. Int. J. Mach. Tools Manuf. 2005, 45, 29–34. [Google Scholar] [CrossRef]

- Çakir, M.; Güvenç, M.A.; Mistikoğlu, S. IoT based Condition Monitoring System Design for Investigation of Non-Oil Ball Bearing in terms of Vibration, Temperature, Acoustic Emission, Current and Revolution Parameters. In Proceedings of the 10th International Symposium on Intelligent Manufacturing and Service Systems, Sakarya, Turkey, 9–11 September 2019; pp. 1059–1068. [Google Scholar]

- Bouzid, O.M.; Tian, G.Y.; Cumanan, K.; Moore, D. Structural Health Monitoring of Wind Turbine Blades: Acoustic Source Localization Using Wireless Sensor Networks. J. Sens. 2015, 2015, 139695. [Google Scholar] [CrossRef]

- Hodge, V.J.; O’Keefe, S.; Weeks, M.; Moulds, A. Wireless Sensor Networks for Condition Monitoring in the Railway Industry: A Survey. IEEE Trans. Intell. Transp. Syst. 2015, 16, 1088–1106. [Google Scholar] [CrossRef]

- Ostasevicius, V.; Karpavicius, P.; Jurenas, V.; Cepenas, M.; Cesnavicius, R.; Eidukynas, D. Development of universal wireless sensor node for tool condition monitoring in milling. Int. J. Adv. Manuf. Technol. 2020, 110, 1015–1025. [Google Scholar] [CrossRef]

- Sarrafzadeh, M.; Dabiri, F.; Jafari, R.; Massey, T.; Nahapetian, A. Low power light-weight embedded systems. In Proceedings of the 2006 International Symposium on Low Power Electronics and Design, Tegernsee, Germany, 4–6 October 2006; pp. 207–212. [Google Scholar]

- Xie, Z.; Li, J.; Lu, Y. An integrated wireless vibration sensing tool holder for milling tool condition monitoring. Int. J. Adv. Manuf. Technol. 2017, 95, 2885–2896. [Google Scholar] [CrossRef]

- Xie, Z.; Lu, Y.; Chen, X. A multi-sensor integrated smart tool holder for cutting process monitoring. Int. J. Adv. Manuf. Technol. 2020, 110, 853–864. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, M.; Dai, W. Machined Surface Quality Monitoring Using a Wireless Sensory Tool Holder in the Machining Process. Sensors 2019, 19, 1847. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramsauer, C.; Bleicher, F. New method for determining single cutting edge breakage of a multi-tooth milling tool based on acceleration measurements by an instrumented tool holder. J. Mach. Eng. 2021, 21, 67–77. [Google Scholar] [CrossRef]

- Suprock, C.A.; Fussell, B.K.; Hassan, R.Z.; Jerard, R.B. A low cost wireless tool tip vibration sensor for milling. In Proceedings of the International Manufacturing Science and Engineering Conference, Evanston, IL, USA, 7–10 October 2008; pp. 465–474. [Google Scholar]

- O’Donnell, G.; Young, P.; Kelly, K.; Byrne, G. Towards the improvement of tool condition monitoring systems in the manufacturing environment. J. Mater. Processing Technol. 2001, 119, 133–139. [Google Scholar] [CrossRef]

- Rizal, M.; Ghani, J.A.; Nuawi, M.Z.; Haron, C.H.C. An embedded multi-sensor system on the rotating dynamometer for real-time condition monitoring in milling. Int. J. Adv. Manuf. Technol. 2017, 95, 811–823. [Google Scholar] [CrossRef]

- Murphy, C. Choosing the Most Suitable Predictive Maintenance Sensor. 2020. Available online: https://www.analog.com/ru/technical-articles/choosing-the-most-suitable-predictive-maintenance-sensor.html (accessed on 15 December 2021).

- Zhou, L.; Duan, F.; Mba, D. Wireless Acoustic Emission Transmission System Designed for Fault Detection of Rotating Machine. In Advanced Technologies for Sustainable Systems; Lecture Notes in Networks and Systems; Springer: Berlin/Heidelberg, Germany, 2017; pp. 201–207. [Google Scholar]

- Li, X. A brief review: Acoustic emission method for tool wear monitoring during turning. Int. J. Mach. Tools Manuf. 2002, 42, 157–165. [Google Scholar] [CrossRef] [Green Version]

- Marwala, T. Data processing techniques for condition monitoring. In Condition Monitoring Using Computational Intelligence Methods; Springer: Berlin/Heidelberg, Germany, 2012; pp. 27–51. [Google Scholar] [CrossRef]

- Ledeczi, A.; Hay, T.; Volgyesi, P.; Hay, D.R.; Nadas, A.; Jayaraman, S. Wireless Acoustic Emission Sensor Network for Structural Monitoring. IEEE Sens. J. 2009, 9, 1370–1377. [Google Scholar] [CrossRef]

- MICRO-SHM. Available online: https://www.mistrasgroup.com/ (accessed on 15 December 2021).

- Qin, Y.; Wang, D.; Yang, Y. Integrated cutting force measurement system based on MEMS sensor for monitoring milling process. Microsyst. Technol. 2020, 26, 2095–2104. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Ma, L.; Melkote, S.N.; Castle, J.B. PVDF sensor-based monitoring of milling torque. Int. J. Adv. Manuf. Technol. 2013, 70, 1603–1614. [Google Scholar] [CrossRef]

- Ma, L.; Melkote, S.N.; Morehouse, J.B.; Castle, J.B.; Fonda, J.W.; Johnson, M.A. Thin-Film PVDF Sensor-Based Monitoring of Cutting Forces in Peripheral End Milling. J. Dyn. Syst. Meas. Control. 2012, 134, 051014. [Google Scholar] [CrossRef]

- Nguyen, V.; Melkote, S.; Deshamudre, A.; Khanna, M.; Walker, D. PVDF sensor based monitoring of single-point cutting. J. Manuf. Processes 2016, 24, 328–337. [Google Scholar] [CrossRef]

- Liang, Q.; Zhang, D.; Coppola, G.; Mao, J.; Sun, W.; Wang, Y.; Ge, Y. Design and Analysis of a Sensor System for Cutting Force Measurement in Machining Processes. Sensors 2016, 16, 70. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Y.; Fei, J.; Zhao, Y.; Li, X.; Gao, Y. Development of a Tri-Axial Cutting Force Sensor for the Milling Process. Sensors 2016, 16, 405. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Bing, J.; Xiao, L.; Yun, K.; Wan, L. Development and Testing of an Integrated Rotating Dynamometer Based on Fiber Bragg Grating for Four-Component Cutting Force Measurement. Sensors 2018, 18, 1254. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, C.; Cheng, K.; Chen, X.; Minton, T.; Rakowski, R. Design of an instrumented smart cutting tool and its implementation and application perspectives. Smart Mater. Struct. 2014, 23, 035019. [Google Scholar] [CrossRef] [Green Version]

- Albrecht, A.; Park, S.S.; Altintas, Y.; Pritschow, G. High frequency bandwidth cutting force measurement in milling using capacitance displacement sensors. Int. J. Mach. Tools Manuf. 2005, 45, 993–1008. [Google Scholar] [CrossRef]

- Qin, Y.; Zhao, Y.; Li, Y.; Zhao, Y.; Wang, P. A novel dynamometer for monitoring milling process. Int. J. Adv. Manuf. Technol. 2017, 92, 2535–2543. [Google Scholar] [CrossRef]

- Luo, M.; Luo, H.; Axinte, D.; Liu, D.; Mei, J.; Liao, Z. A wireless instrumented milling cutter system with embedded PVDF sensors. Mech. Syst. Signal Processing 2018, 110, 556–568. [Google Scholar] [CrossRef] [Green Version]

- Rao, B.C.; Gao, R.X.; Friedrich, C.R. Integrated force measurement for on-line cutting geometry inspection. IEEE Trans. Instrum. Meas. 1995, 44, 977–980. [Google Scholar] [CrossRef]

- Shin, B.-C.; Ha, S.-J.; Cho, M.-W.; Seo, T.-I.; Yoon, G.-S.; Heo, Y.-M. Indirect cutting force measurement in the micro end-milling process based on frequency analysis of sensor signals. J. Mech. Sci. Technol. 2010, 24, 165–168. [Google Scholar] [CrossRef]

- Auchet, S.; Chevrier, P.; Lacour, M.; Lipinski, P. A new method of cutting force measurement based on command voltages of active electro-magnetic bearings. Int. J. Mach. Tools Manuf. 2004, 44, 1441–1449. [Google Scholar] [CrossRef]

- Wu, F.; Li, Y.; Guo, B.; Zhang, P. The Design of Force Measuring Tool Holder System Based on Wireless Transmission. IEEE Access 2018, 6, 38556–38566. [Google Scholar] [CrossRef]

- Rizal, M.; Ghani, J.A.; Nuawi, M.Z.; Che Haron, C.H. Development and testing of an integrated rotating dynamometer on tool holder for milling process. Mech. Syst. Signal Processing 2015, 52–53, 559–576. [Google Scholar] [CrossRef]

- Pro-Micron Spike. Available online: https://www.pro-micron.de/spike/?lang=en (accessed on 15 December 2021).

- Li, Y.; Liu, C.; Hua, J.; Gao, J.; Maropoulos, P. A novel method for accurately monitoring and predicting tool wear under varying cutting conditions based on meta-learning. CIRP Ann. 2019, 68, 487–490. [Google Scholar] [CrossRef]

- Wang, R.; Song, Q.; Liu, Z.; Ma, H.; Gupta, M.K.; Liu, Z. A Novel Unsupervised Machine Learning-Based Method for Chatter Detection in the Milling of Thin-Walled Parts. Sensors 2021, 21, 5779. [Google Scholar] [CrossRef]

- Shunk iTENDO. Available online: https://schunk.com/us_en/homepage/itendo/ (accessed on 15 December 2021).

- Bleicher, F.; Ramsauer, C.M.; Oswald, R.; Leder, N.; Schoerghofer, P. Method for determining edge chipping in milling based on tool holder vibration measurements. CIRP Ann. 2020, 69, 101–104. [Google Scholar] [CrossRef]

- Xie, Z.; Lu, Y.; Li, J. Development and testing of an integrated smart tool holder for four-component cutting force measurement. Mech. Syst. Signal Processing 2017, 93, 225–240. [Google Scholar] [CrossRef]

- Reinink, J.; Van De Kruijs, R.W.E.; Bijkerk, F. Self-contained in-vacuum in situ thin film stress measurement tool. Rev. Sci. Instrum. 2018, 89, 053904. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, X.Y.; Lu, X.; Wang, S.; Wang, W.; Li, W.D. A multi-sensor based online tool condition monitoring system for milling process. Procedia CIRP 2018, 72, 1136–1141. [Google Scholar] [CrossRef]

- Zhou, C.a.; Guo, K.; Zhao, Y.; Zan, Z.; Sun, J. Development and testing of a wireless rotating triaxial vibration measuring tool holder system for milling process. Measurement 2020, 163, 108034. [Google Scholar] [CrossRef]

- Guha, A.; Li, H.; Sun, Z.; Ma, C.; Werschmoeller, D.; Li, X. Wireless acquisition of temperature data from embedded thin film sensors in cutting insert. J. Manuf. Processes 2012, 14, 360–365. [Google Scholar] [CrossRef]

- Campidelli, A.F.; Lima, H.V.; Abrão, A.M.; Maia, A.A. Development of a wireless system for milling temperature monitoring. Int. J. Adv. Manuf. Technol. 2019, 104, 1551–1560. [Google Scholar] [CrossRef]

- Cen, L.; Melkote, S.N.; Castle, J.; Appelman, H. A Wireless Force-Sensing and Model-Based Approach for Enhancement of Machining Accuracy in Robotic Milling. IEEE/ASME Trans. Mechatron. 2016, 21, 2227–2235. [Google Scholar] [CrossRef]

- Chung, T.K.; Yeh, P.C.; Lee, H.; Lin, C.M.; Tseng, C.Y.; Lo, W.T.; Wang, C.M.; Wang, W.C.; Tu, C.J.; Tasi, P.Y.; et al. An Attachable Electromagnetic Energy Harvester Driven Wireless Sensing System Demonstrating Milling-Processes and Cutter-Wear/Breakage-Condition Monitoring. Sensors 2016, 16, 269. [Google Scholar] [CrossRef] [Green Version]

- Alvi, S.A.; Afzal, B.; Shah, G.A.; Atzori, L.; Mahmood, W. Internet of multimedia things: Vision and challenges. Ad Hoc Netw. 2015, 33, 87–111. [Google Scholar] [CrossRef]

- Kazeem, O.O.; Akintade, O.O.; Kehinde, L.O. Comparative study of communication interfaces for sensors and actuators in the cloud of internet of things. Int. J. Internet Things 2017, 6, 9–13. [Google Scholar] [CrossRef]

- Wi-Fi Alliance. Available online: https://www.wi-fi.org/ (accessed on 15 December 2021).

- Bluetooth Technology. Available online: https://www.bluetooth.com/ (accessed on 15 December 2021).

- Caroff, T.; Brulais, S.; Faucon, A.; Boness, A.; Arrizabalaga, A.S.; Ellinger, J. Ultra low power wireless multi-sensor platform dedicated to machine tool condition monitoring. Procedia Manuf. 2020, 51, 296–301. [Google Scholar] [CrossRef]

- Tang, X.; Wang, X.; Cattley, R.; Gu, F.; Ball, A.D. Energy Harvesting Technologies for Achieving Self-Powered Wireless Sensor Networks in Machine Condition Monitoring: A Review. Sensors 2018, 18, 4113. [Google Scholar] [CrossRef] [Green Version]

- Dell, R. Batteries fifty years of materials development. Solid State Ion. 2000, 134, 139–158. [Google Scholar] [CrossRef]

- Ostasevicius, V.; Markevicius, V.; Jurenas, V.; Zilys, M.; Cepenas, M.; Kizauskiene, L.; Gyliene, V. Cutting tool vibration energy harvesting for wireless sensors applications. Sens. Actuators A Phys. 2015, 233, 310–318. [Google Scholar] [CrossRef] [Green Version]

- Ostasevicius, V.; Jurenas, V.; Augutis, V.; Gaidys, R.; Cesnavicius, R.; Kizauskiene, L.; Dundulis, R. Monitoring the condition of the cutting tool using self-powering wireless sensor technologies. Int. J. Adv. Manuf. Technol. 2016, 88, 2803–2817. [Google Scholar] [CrossRef] [Green Version]

- Ostasevicius, V.; Karpavicius, P.; Paulauskaite-Taraseviciene, A.; Jurenas, V.; Mystkowski, A.; Cesnavicius, R.; Kizauskiene, L. A Machine Learning Approach for Wear Monitoring of End Mill by Self-Powering Wireless Sensor Nodes. Sensors 2021, 21, 3137. [Google Scholar] [CrossRef]

- Bombiński, S.; Błażejak, K.; Nejman, M.; Jemielniak, K. Sensor Signal Segmentation for Tool Condition Monitoring. Procedia CIRP 2016, 46, 155–160. [Google Scholar] [CrossRef] [Green Version]

- Nordmann Tool Monitoring. Available online: http://www.toolmonitoring.com/ (accessed on 15 December 2021).

- Tool and Process Monitoring. Available online: http://www.artis.de/ (accessed on 15 December 2021).

- Iliyas Ahmad, M.; Yusof, Y.; Daud, M.E.; Latiff, K.; Abdul Kadir, A.Z.; Saif, Y. Machine monitoring system: A decade in review. Int. J. Adv. Manuf. Technol. 2020, 108, 3645–3659. [Google Scholar] [CrossRef]

- Anowar, F.; Sadaoui, S.; Selim, B. Conceptual and empirical comparison of dimensionality reduction algorithms (PCA, KPCA, LDA, MDS, SVD, LLE, ISOMAP, LE, ICA, t-SNE). Comput. Sci. Rev. 2021, 40, 100378. [Google Scholar] [CrossRef]

- Guyon, I.; Gunn, S.; Nikravesh, M.; Zadeh, L.A. Feature Extraction: Foundations and Applications; Springer: Berlin/Heidelberg, Germany, 2008; Volume 207. [Google Scholar]

- Zebari, R.; Abdulazeez, A.; Zeebaree, D.; Zebari, D.; Saeed, J. A Comprehensive Review of Dimensionality Reduction Techniques for Feature Selection and Feature Extraction. J. Appl. Sci. Technol. Trends 2020, 1, 56–70. [Google Scholar] [CrossRef]

- Lauro, C.H.; Brandão, L.C.; Baldo, D.; Reis, R.A.; Davim, J.P. Monitoring and processing signal applied in machining processes—A review. Measurement 2014, 58, 73–86. [Google Scholar] [CrossRef]

- Abubakr, M.; Hassan, M.A.; Krolczyk, G.M.; Khanna, N.; Hegab, H. Sensors selection for tool failure detection during machining processes: A simple accurate classification model. CIRP J. Manuf. Sci. Technol. 2021, 32, 108–119. [Google Scholar] [CrossRef]

- Bektas, O.; Jones, J.A.; Sankararaman, S.; Roychoudhury, I.; Goebel, K. A neural network filtering approach for similarity-based remaining useful life estimation. Int. J. Adv. Manuf. Technol. 2018, 101, 87–103. [Google Scholar] [CrossRef] [Green Version]

- Proteau, A.; Tahan, A.; Thomas, M. Specific cutting energy: A physical measurement for representing tool wear. Int. J. Adv. Manuf. Technol. 2019, 103, 101–110. [Google Scholar] [CrossRef]

- Warren Liao, T.; Ting, C.-F.; Qu, J.; Blau, P.J. A wavelet-based methodology for grinding wheel condition monitoring. Int. J. Mach. Tools Manuf. 2007, 47, 580–592. [Google Scholar] [CrossRef]

- Lee, W.K.; Ratnam, M.M.; Ahmad, Z.A. Detection of chipping in ceramic cutting inserts from workpiece profile during turning using fast Fourier transform (FFT) and continuous wavelet transform (CWT). Precis. Eng. 2017, 47, 406–423. [Google Scholar] [CrossRef]

- Huang, Z.; Zhu, J.; Lei, J.; Li, X.; Tian, F. Tool wear predicting based on multi-domain feature fusion by deep convolutional neural network in milling operations. J. Intell. Manuf. 2019, 31, 953–966. [Google Scholar] [CrossRef]

- Ferrando Chacón, J.L.; Fernández de Barrena, T.; García, A.; Sáez de Buruaga, M.; Badiola, X.; Vicente, J. A Novel Machine Learning-Based Methodology for Tool Wear Prediction Using Acoustic Emission Signals. Sensors 2021, 21, 5984. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Sun, W. Tool Wear Condition Monitoring in Milling Process Based on Current Sensors. IEEE Access 2020, 8, 95491–95502. [Google Scholar] [CrossRef]

- Fang, N.; Pai, P.S.; Mosquea, S. Effect of tool edge wear on the cutting forces and vibrations in high-speed finish machining of Inconel 718: An experimental study and wavelet transform analysis. Int. J. Adv. Manuf. Technol. 2010, 52, 65–77. [Google Scholar] [CrossRef]

- Mori, K.; Kasashima, N.; Yoshioka, T.; Ueno, Y. Prediction of spalling on a ball bearing by applying the discrete wavelet transform to vibration signals. Wear 1996, 195, 162–168. [Google Scholar] [CrossRef]

- Selesnick, I.W. Wavelet Transform With Tunable Q-Factor. IEEE Trans. Signal Processing 2011, 59, 3560–3575. [Google Scholar] [CrossRef]

- Wang, C.; Gan, M.; Zhu, C.A. Intelligent fault diagnosis of rolling element bearings using sparse wavelet energy based on overcomplete DWT and basis pursuit. J. Intell. Manuf. 2017, 28, 1377–1391. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. London. Ser. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Zahra, A.; Kanwal, N.; ur Rehman, N.; Ehsan, S.; McDonald-Maier, K.D. Seizure detection from EEG signals using Multivariate Empirical Mode Decomposition. Comput. Biol. Med. 2017, 88, 132–141. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rehman, N.; Mandic, D.P. Multivariate empirical mode decomposition. Proc. R. Soc. A Math. Phys. Eng. Sci. 2009, 466, 1291–1302. [Google Scholar] [CrossRef]

- Huang, N.E. Introduction to the Hilbert–Huang Transform and Its Related Mathematical Problems. In Hilbert–Huang Transform and Its Applications; Interdisciplinary Mathematical Sciences Series; World Scientific: Singapore, 2014; pp. 1–26. [Google Scholar]

- Mandic, D.P.; Rehman, N.U.; Wu, Z.; Huang, N.E. Empirical Mode Decomposition-Based Time-Frequency Analysis of Multivariate Signals: The Power of Adaptive Data Analysis. IEEE Signal Processing Mag. 2013, 30, 74–86. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, N.E. Ensemble Empirical Mode Decomposition: A Noise-Assisted Data Analysis Method. Adv. Adapt. Data Anal. 2011, 1, 1–41. [Google Scholar] [CrossRef]

- Yeh, J.-R.; Shieh, J.-S.; Huang, N.E. Complementary Ensemble Empirical Mode Decomposition: A Novel Noise Enhanced Data Analysis Method. Adv. Adapt. Data Anal. 2011, 2, 135–156. [Google Scholar] [CrossRef]

- Ur Rehman, N.; Mandic, D.P. Filter Bank Property of Multivariate Empirical Mode Decomposition. IEEE Trans. Signal Processing 2011, 59, 2421–2426. [Google Scholar] [CrossRef]

- Torres, M.E.; Colominas, M.A.; Schlotthauer, G.; Flandrin, P. A complete ensemble empirical mode decomposition with adaptive noise. In Proceedings of the 2011 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Prague, Czech Republic, 22–27 May 2011; pp. 4144–4147. [Google Scholar]

- Zheng, J.; Cheng, J.; Yang, Y. Partly ensemble empirical mode decomposition: An improved noise-assisted method for eliminating mode mixing. Signal Processing 2014, 96, 362–374. [Google Scholar] [CrossRef]

- Lang, X.; Zheng, Q.; Zhang, Z.; Lu, S.; Xie, L.; Horch, A.; Su, H. Fast Multivariate Empirical Mode Decomposition. IEEE Access 2018, 6, 65521–65538. [Google Scholar] [CrossRef]

- Cicone, A. Iterative filtering as a direct method for the decomposition of nonstationary signals. Numer. Algorithms 2020, 85, 811–827. [Google Scholar] [CrossRef] [Green Version]

- Stallone, A.; Cicone, A.; Materassi, M. New insights and best practices for the successful use of Empirical Mode Decomposition, Iterative Filtering and derived algorithms. Sci. Rep. 2020, 10, 15161. [Google Scholar] [CrossRef] [PubMed]

- Cicone, A.; Zhou, H. Numerical analysis for iterative filtering with new efficient implementations based on FFT. Numer. Math. 2021, 147, 1–28. [Google Scholar] [CrossRef]

- Cicone, A.; Liu, J.; Zhou, H. Adaptive local iterative filtering for signal decomposition and instantaneous frequency analysis. Appl. Comput. Harmon. Anal. 2016, 41, 384–411. [Google Scholar] [CrossRef] [Green Version]

- Lei, Z.; Zhou, Y.; Sun, B.; Sun, W. An intrinsic timescale decomposition-based kernel extreme learning machine method to detect tool wear conditions in the milling process. Int. J. Adv. Manuf. Technol. 2020, 106, 1203–1212. [Google Scholar] [CrossRef]

- Zhang, B.; Katinas, C.; Shin, Y.C. Robust Tool Wear Monitoring Using Systematic Feature Selection in Turning Processes With Consideration of Uncertainties. J. Manuf. Sci. Eng. 2018, 140, 081010. [Google Scholar] [CrossRef]

- Vallejo, A.J.; Morales-Menéndez, R.; Alique, J. On-line cutting tool condition monitoring in machining processes using artificial intelligence. Robot. Autom. Control. 2008, 1, 494–518. [Google Scholar] [CrossRef]

- Chungchoo, C.; Saini, D. On-line tool wear estimation in CNC turning operations using fuzzy neural network model. Int. J. Mach. Tools Manuf. 2002, 42, 29–40. [Google Scholar] [CrossRef]

- Penedo, F.; Haber, R.E.; Gajate, A.; del Toro, R.M. Hybrid Incremental Modeling Based on Least Squares and Fuzzy K-NN for Monitoring Tool Wear in Turning Processes. IEEE Trans. Ind. Inform. 2012, 8, 811–818. [Google Scholar] [CrossRef]

- Li, N.; Chen, Y.; Kong, D.; Tan, S. Force-based tool condition monitoring for turning process using v-support vector regression. Int. J. Adv. Manuf. Technol. 2017, 91, 351–361. [Google Scholar] [CrossRef]

- Hawkins, D.M. The problem of overfitting. J. Chem. Inf. Comput. Sci. 2004, 44, 170–178. [Google Scholar] [CrossRef]

- Cai, J.; Luo, J.; Wang, S.; Yang, S. Feature selection in machine learning: A new perspective. Neurocomputing 2018, 300, 70–79. [Google Scholar] [CrossRef]

- Li, J.; Lu, J.; Chen, C.; Ma, J.; Liao, X. Tool wear state prediction based on feature-based transfer learning. Int. J. Adv. Manuf. Technol. 2021, 113, 3283–3301. [Google Scholar] [CrossRef]

- Dash, M.; Liu, H. Feature selection for classification. Intell. Data Anal. 1997, 1, 131–156. [Google Scholar] [CrossRef]

- Jemielniak, K.; Kwiatkowski, L.; Wrzosek, P. Diagnosis of tool wear based on cutting forces and acoustic emission measures as inputs to a neural network. J. Intell. Manuf. 1998, 9, 447–455. [Google Scholar] [CrossRef]

- Guo, W.; Li, B.; Zhou, Q. An intelligent monitoring system of grinding wheel wear based on two-stage feature selection and Long Short-Term Memory network. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 2436–2446. [Google Scholar] [CrossRef]

- Aralikatti, S.S.; Ravikumar, K.N.; Kumar, H. Fault diagnosis of single-point cutting tool using vibration signal by rotation forest algorithm. SN Appl. Sci. 2019, 1, 1017. [Google Scholar] [CrossRef] [Green Version]

- Ghojogh, B.; Samad, M.N.; Mashhadi, S.A.; Kapoor, T.; Ali, W.; Karray, F.; Crowley, M. Feature selection and feature extraction in pattern analysis: A literature review. arXiv 2019, arXiv:1905.02845. [Google Scholar]

- Kohavi, R.; John, G.H. Wrappers for feature subset selection. Artif. Intell. 1997, 97, 273–324. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Wu, L.; Ye, Y. A Review on Dimensionality Reduction Techniques. Int. J. Pattern Recognit. Artif. Intell. 2019, 33, 1950017. [Google Scholar] [CrossRef]

- Khalid, S.; Khalil, T.; Nasreen, S. A survey of feature selection and feature extraction techniques in machine learning. In Proceedings of the 2014 Science and Information Conference, London, UK, 27–29 August 2014; pp. 372–378. [Google Scholar]

- Aha, D.W.; Bankert, R.L. A Comparative Evaluation of Sequential Feature Selection Algorithms. In Learning from Data; Lecture Notes in Statistics; Springer: Berlin/Heidelberg, Germany, 1996; pp. 199–206. [Google Scholar]

- Pudil, P.; Novovičová, J.; Kittler, J. Floating search methods in feature selection. Pattern Recognit. Lett. 1994, 15, 1119–1125. [Google Scholar] [CrossRef]

- Liao, X.; Zhou, G.; Zhang, Z.; Lu, J.; Ma, J. Tool wear state recognition based on GWO–SVM with feature selection of genetic algorithm. Int. J. Adv. Manuf. Technol. 2019, 104, 1051–1063. [Google Scholar] [CrossRef]

- Warren Liao, T. Feature extraction and selection from acoustic emission signals with an application in grinding wheel condition monitoring. Eng. Appl. Artif. Intell. 2010, 23, 74–84. [Google Scholar] [CrossRef]

- Jović, A.; Brkić, K.; Bogunović, N. A review of feature selection methods with applications. In Proceedings of the 2015 38th International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 25–29 May 2015; pp. 1200–1205. [Google Scholar]

- Shi, D.; Gindy, N.N. Tool wear predictive model based on least squares support vector machines. Mech. Syst. Signal Processing 2007, 21, 1799–1814. [Google Scholar] [CrossRef]

- Subrahmanya, N.; Shin, Y.C. Automated sensor selection and fusion for monitoring and diagnostics of plunge grinding. J. Manuf. Sci. Eng. 2008, 130, 031014. [Google Scholar] [CrossRef]

- Li, G.; Wang, Y.; He, J.; Hao, Q.; Yang, H.; Wei, J. Tool wear state recognition based on gradient boosting decision tree and hybrid classification RBM. Int. J. Adv. Manuf. Technol. 2020, 110, 511–522. [Google Scholar] [CrossRef]

- Gracia, A.; González, S.; Robles, V.; Menasalvas, E. A methodology to compare Dimensionality Reduction algorithms in terms of loss of quality. Inf. Sci. 2014, 270, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Ayesha, S.; Hanif, M.K.; Talib, R. Overview and comparative study of dimensionality reduction techniques for high dimensional data. Inf. Fusion 2020, 59, 44–58. [Google Scholar] [CrossRef]

- Janecek, A.; Gansterer, W.; Demel, M.; Ecker, G. On the Relationship Between Feature Selection and Classification Accuracy. In Proceedings of the Workshop on New Challenges for Feature Selection in Data Mining and Knowledge Discovery at ECML/PKDD 2008, Antwerp, Belgium, 15 September 2008; pp. 90–105. [Google Scholar]

- Yang, Y.; Hao, B.; Hao, X.; Li, L.; Chen, N.; Xu, T.; Aqib, K.M.; He, N. A Novel Tool (Single-Flute) Condition Monitoring Method for End Milling Process Based on Intelligent Processing of Milling Force Data by Machine Learning Algorithms. Int. J. Precis. Eng. Manuf. 2020, 21, 2159–2171. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, Y.; Liu, C.; Xie, Q.; Xu, Y. A new tool wear monitoring method based on multi-scale PCA. J. Intell. Manuf. 2019, 30, 113–122. [Google Scholar] [CrossRef]

- Wu, X.; Li, J.; Jin, Y.; Zheng, S. Modeling and analysis of tool wear prediction based on SVD and BiLSTM. Int. J. Adv. Manuf. Technol. 2020, 106, 4391–4399. [Google Scholar] [CrossRef]

- Jin, X.; Zhao, M.; Chow, T.W.S.; Pecht, M. Motor Bearing Fault Diagnosis Using Trace Ratio Linear Discriminant Analysis. IEEE Trans. Ind. Electron. 2014, 61, 2441–2451. [Google Scholar] [CrossRef]

- Zhu, K.P.; Hong, G.S.; Wong, Y.S. A Comparative Study of Feature Selection For Hidden Markov Model-Based Micro-Milling Tool Wear Monitoring. Mach. Sci. Technol. 2008, 12, 348–369. [Google Scholar] [CrossRef]

- Xie, Z.; Li, J.; Lu, Y. Feature selection and a method to improve the performance of tool condition monitoring. Int. J. Adv. Manuf. Technol. 2019, 100, 3197–3206. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Zhao, R.; Mao, K.; Zhang, L. A New Probabilistic Kernel Factor Analysis for Multisensory Data Fusion: Application to Tool Condition Monitoring. IEEE Trans. Instrum. Meas. 2016, 65, 2527–2537. [Google Scholar] [CrossRef]

- Shi, X.; Wang, R.; Chen, Q.; Shao, H. Cutting sound signal processing for tool breakage detection in face milling based on empirical mode decomposition and independent component analysis. J. Vib. Control. 2015, 21, 3348–3358. [Google Scholar] [CrossRef]

- Kong, D.; Chen, Y.; Li, N.; Tan, S. Tool wear monitoring based on kernel principal component analysis and v-support vector regression. Int. J. Adv. Manuf. Technol. 2017, 89, 175–190. [Google Scholar] [CrossRef]

- Lee, W.J.; Mendis, G.P.; Triebe, M.J.; Sutherland, J.W. Monitoring of a machining process using kernel principal component analysis and kernel density estimation. J. Intell. Manuf. 2020, 31, 1175–1189. [Google Scholar] [CrossRef]

- Nor, N.M.; Hussain, M.A.; Hassan, C.R.C. Process Monitoring and Fault Detection in Non-Linear Chemical Process Based On Multi-Scale Kernel Fisher Discriminant Analysis. In 12th International Symposium on Process Systems Engineering and 25th European Symposium on Computer Aided Process Engineering; Computer Aided Chemical Engineering Series; Elsevier: Amsterdam, The Netherlands, 2015; pp. 1823–1828. [Google Scholar]

- Benkedjouh, T.; Medjaher, K.; Zerhouni, N.; Rechak, S. Health assessment and life prediction of cutting tools based on support vector regression. J. Intell. Manuf. 2015, 26, 213–223. [Google Scholar] [CrossRef] [Green Version]

- Caggiano, A.; Angelone, R.; Napolitano, F.; Nele, L.; Teti, R. Dimensionality Reduction of Sensorial Features by Principal Component Analysis for ANN Machine Learning in Tool Condition Monitoring of CFRP Drilling. Procedia CIRP 2018, 78, 307–312. [Google Scholar] [CrossRef]

- Zhu, M.; Martinez, A.M. Subclass discriminant analysis. IEEE Trans Pattern Anal Mach Intell 2006, 28, 1274–1286. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gkalelis, N.; Mezaris, V.; Kompatsiaris, I. Mixture Subclass Discriminant Analysis. IEEE Signal Processing Lett. 2011, 18, 319–322. [Google Scholar] [CrossRef]

- Chang, W.-Y.; Wu, S.-J.; Hsu, J.-W. Investigated iterative convergences of neural network for prediction turning tool wear. Int. J. Adv. Manuf. Technol. 2020, 106, 2939–2948. [Google Scholar] [CrossRef]

- Zhou, C.a.; Guo, K.; Yang, B.; Wang, H.; Sun, J.; Lu, L. Singularity Analysis of Cutting Force and Vibration for Tool Condition Monitoring in Milling. IEEE Access 2019, 7, 134113–134124. [Google Scholar] [CrossRef]

- Tobon-Mejia, D.A.; Medjaher, K.; Zerhouni, N. CNC machine tool’s wear diagnostic and prognostic by using dynamic Bayesian networks. Mech. Syst. Signal Processing 2012, 28, 167–182. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.; Liang, S.; Tang, D.; Liu, H. A weighted hidden Markov model approach for continuous-state tool wear monitoring and tool life prediction. Int. J. Adv. Manuf. Technol. 2016, 91, 201–211. [Google Scholar] [CrossRef]

- Kong, D.; Chen, Y.; Li, N. Gaussian process regression for tool wear prediction. Mech. Syst. Signal Processing 2018, 104, 556–574. [Google Scholar] [CrossRef]

- Serin, G.; Sener, B.; Ozbayoglu, A.M.; Unver, H.O. Review of tool condition monitoring in machining and opportunities for deep learning. Int. J. Adv. Manuf. Technol. 2020, 109, 953–974. [Google Scholar] [CrossRef]

- Lee, J.; Choi, H.J.; Nam, J.; Jo, S.B.; Kim, M.; Lee, S.W. Development and analysis of an online tool condition monitoring and diagnosis system for a milling process and its real-time implementation. J. Mech. Sci. Technol. 2017, 31, 5695–5703. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, Y.; Huang, Z.; Chen, N.; Li, L.; Jiang, Y.; He, N. Research on the milling tool wear and life prediction by establishing an integrated predictive model. Measurement 2019, 145, 178–189. [Google Scholar] [CrossRef]

- Wu, D.; Jennings, C.; Terpenny, J.; Gao, R.X.; Kumara, S. A Comparative Study on Machine Learning Algorithms for Smart Manufacturing: Tool Wear Prediction Using Random Forests. J. Manuf. Sci. Eng. 2017, 139, 071018. [Google Scholar] [CrossRef]

- Lei, Y.; Jia, F.; Lin, J.; Xing, S.; Ding, S.X. An Intelligent Fault Diagnosis Method Using Unsupervised Feature Learning Towards Mechanical Big Data. IEEE Trans. Ind. Electron. 2016, 63, 3137–3147. [Google Scholar] [CrossRef]

- Wang, J.; Wang, P.; Gao, R.X. Enhanced particle filter for tool wear prediction. J. Manuf. Syst. 2015, 36, 35–45. [Google Scholar] [CrossRef]

- Ma, J.; Luo, D.; Liao, X.; Zhang, Z.; Huang, Y.; Lu, J. Tool wear mechanism and prediction in milling TC18 titanium alloy using deep learning. Measurement 2021, 173, 108554. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, D.; Yan, R.; Mao, K.; Shen, F.; Wang, J. Machine Health Monitoring Using Local Feature-Based Gated Recurrent Unit Networks. IEEE Trans. Ind. Electron. 2018, 65, 1539–1548. [Google Scholar] [CrossRef]

- Chen, Y.; Jin, Y.; Jiri, G. Predicting tool wear with multi-sensor data using deep belief networks. Int. J. Adv. Manuf. Technol. 2018, 99, 1917–1926. [Google Scholar] [CrossRef]

- Shi, C.; Panoutsos, G.; Luo, B.; Liu, H.; Li, B.; Lin, X. Using Multiple-Feature-Spaces-Based Deep Learning for Tool Condition Monitoring in Ultraprecision Manufacturing. IEEE Trans. Ind. Electron. 2019, 66, 3794–3803. [Google Scholar] [CrossRef] [Green Version]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Processing 2016, 72–73, 303–315. [Google Scholar] [CrossRef]

- Sun, C.; Ma, M.; Zhao, Z.; Tian, S.; Yan, R.; Chen, X. Deep Transfer Learning Based on Sparse Autoencoder for Remaining Useful Life Prediction of Tool in Manufacturing. IEEE Trans. Ind. Inform. 2019, 15, 2416–2425. [Google Scholar] [CrossRef]

- Dou, J.; Jiao, S.; Xu, C.; Luo, F.; Tang, L.; Xu, X. Unsupervised online prediction of tool wear values using force model coefficients in milling. Int. J. Adv. Manuf. Technol. 2020, 109, 1153–1166. [Google Scholar] [CrossRef]

- Hassan, M.; Sadek, A.; Attia, M.H. Novel sensor-based tool wear monitoring approach for seamless implementation in high speed milling applications. CIRP Ann. 2021, 70, 87–90. [Google Scholar] [CrossRef]

- Liao, Y.; Ragai, I.; Huang, Z.; Kerner, S. Manufacturing process monitoring using time-frequency representation and transfer learning of deep neural networks. J. Manuf. Processes 2021, 68, 231–248. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, Y.; Guo, L.; Gao, H.; Tan, Y. Automatically Designing Network-based Deep Transfer Learning Architectures based on Genetic Algorithm for In-situ Tool Condition Monitoring. IEEE Trans. Ind. Electron. 2021, 1. [Google Scholar] [CrossRef]

- Mamledesai, H.; Soriano, M.A.; Ahmad, R. A Qualitative Tool Condition Monitoring Framework Using Convolution Neural Network and Transfer Learning. Appl. Sci. 2020, 10, 7298. [Google Scholar] [CrossRef]

- Hassan, M.; Damir, A.; Attia, H.; Thomson, V. Benchmarking of Pattern Recognition Techniques for Online Tool Wear Detection. Procedia CIRP 2018, 72, 1451–1456. [Google Scholar] [CrossRef]

- Snr, D.E.D. Correlation of cutting force features with tool wear in a metal turning operation. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2001, 215, 435–440. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhu, H.; Hu, K.; Wu, J.; Shao, X.; Wang, Y. Multisensory Data-Driven Health Degradation Monitoring of Machining Tools by Generalized Multiclass Support Vector Machine. IEEE Access 2019, 7, 47102–47113. [Google Scholar] [CrossRef]

- Mou, W.; Jiang, Z.; Zhu, S. A study of tool tipping monitoring for titanium milling based on cutting vibration. Int. J. Adv. Manuf. Technol. 2019, 104, 3457–3471. [Google Scholar] [CrossRef]

- Kang, G.-S.; Kim, S.-G.; Yang, G.-D.; Park, K.-H.; Lee, D.Y. Tool Chipping Detection Using Peak Period of Spindle Vibration During End-Milling of Inconel 718. Int. J. Precis. Eng. Manuf. 2019, 20, 1851–1859. [Google Scholar] [CrossRef]

- Ritou, M.; Garnier, S.; Furet, B.; Hascoet, J.Y. Angular approach combined to mechanical model for tool breakage detection by eddy current sensors. Mech. Syst. Signal Processing 2014, 44, 211–220. [Google Scholar] [CrossRef] [Green Version]

- Hassan, M.; Sadek, A.; Damir, A.; Attia, M.H.; Thomson, V. Tool Pre-Failure Monitoring in Intermittent Cutting Operations. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar] [CrossRef]

- Krampikowska, A.; Pala, R.; Dzioba, I.; Swit, G. The Use of the Acoustic Emission Method to Identify Crack Growth in 40CrMo Steel. Materials 2019, 12, 2140. [Google Scholar] [CrossRef] [Green Version]

- Tandon, N.; Nakra, B.C. Comparison of vibration and acoustic measurement techniques for the condition monitoring of rolling element bearings. Tribol. Int. 1992, 25, 205–212. [Google Scholar] [CrossRef]

| Author | Forces | Vibrations | Temperature | Wireless Protocol | ||

|---|---|---|---|---|---|---|

| Axis 1 | Design | Sensors | Axis | (Data Rate) | ||

| Zhou et al. [20] | - | - | - | x, y, z | - | Wi-Fi (40,000 S/channel) |

| Luo et al. [102] | Fx, Fy, Fz | Under inserts | PVDF | - | - | Wi-Fi (20,000 S/channel) |

| Xie et al. [79] | Fx, Fy, Fz, Mz | Modified tool holder | Capacitive | x | - | Wi-Fi (5000 S/channel) |

| SPIKE [80,108] | Mx, My, Mz | Unknown | Unknown | - | - | Wi-Fi (2500 S/channel) |

| Wu et al. [106] | Fz, Mz | Modified tool holder | Strain gauge | - | - | Wi-Fi (1000 S/channel) |

| Nguyen et al. [95] | Mz | On the tool holder | PVDF | - | - | Bluetooth (13,000 S/channel) |

| iTENDO [81,111] | - | - | - | x | - | Bluetooth (9500 S/channel) |

| Qin et al. [91] | Fz, Mz | Flexible element | MEMS | x | - | Zigbee (250 Kbps) |

| Rizal et al. [84] | Fx, Fy, Fz, Mz | Flexible element | Strain gauge | z | √ | Telemetry (5000 S/channel) |

| Technology | Data Speed Theoretical (Mb/s) | Data Speed Typical (Mb/s) | Latency (ms) | Range Indoor (m) | Trans. Power (mW) | Sleep Power (mW) | Author |

|---|---|---|---|---|---|---|---|

| Wi-Fi n/g | 75 | 54 | 1.5 | 50 | 350 | 300 | [20,78,114] |

| Bluetooth | 1–3 | 0.7–2.1 | 6 | 30 | - | - | [81] |

| Bluetooth LE | 0.125–2 | 0.27–1.37 | 2.5 | 10 | 60 | 8 | [125] |

| Zigbee | 0.25 | 0.15 | 140 | 30 | 72 | 4 | [119,120] |

| Technology | Lead Acid | Nickel–Cadmium | Nickel–Metal Hydride | Lithium-Ion |

|---|---|---|---|---|

| Energy density (Wh/kg) | 35–50 | 30–60 | 60–80 | 80–180 |

| Self-discharge/month | 2–8% | 5–15% | 15–25% | 2–10% |

| Fast-charge time (hour) | 8–16 | 1 | 2–4 | 1–4 |

| Charge/discharge cycles | 250–1000 | 1000–50,000 | 300–600 | 3000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, A.; Hassan, M.; M’Saoubi, R.; Attia, H. Tool Condition Monitoring for High-Performance Machining Systems—A Review. Sensors 2022, 22, 2206. https://doi.org/10.3390/s22062206

Mohamed A, Hassan M, M’Saoubi R, Attia H. Tool Condition Monitoring for High-Performance Machining Systems—A Review. Sensors. 2022; 22(6):2206. https://doi.org/10.3390/s22062206

Chicago/Turabian StyleMohamed, Ayman, Mahmoud Hassan, Rachid M’Saoubi, and Helmi Attia. 2022. "Tool Condition Monitoring for High-Performance Machining Systems—A Review" Sensors 22, no. 6: 2206. https://doi.org/10.3390/s22062206

APA StyleMohamed, A., Hassan, M., M’Saoubi, R., & Attia, H. (2022). Tool Condition Monitoring for High-Performance Machining Systems—A Review. Sensors, 22(6), 2206. https://doi.org/10.3390/s22062206