Improvement of Regasification Process Efficiency for Floating Storage Regasification Unit

Abstract

:1. Introduction

2. Research Methodology

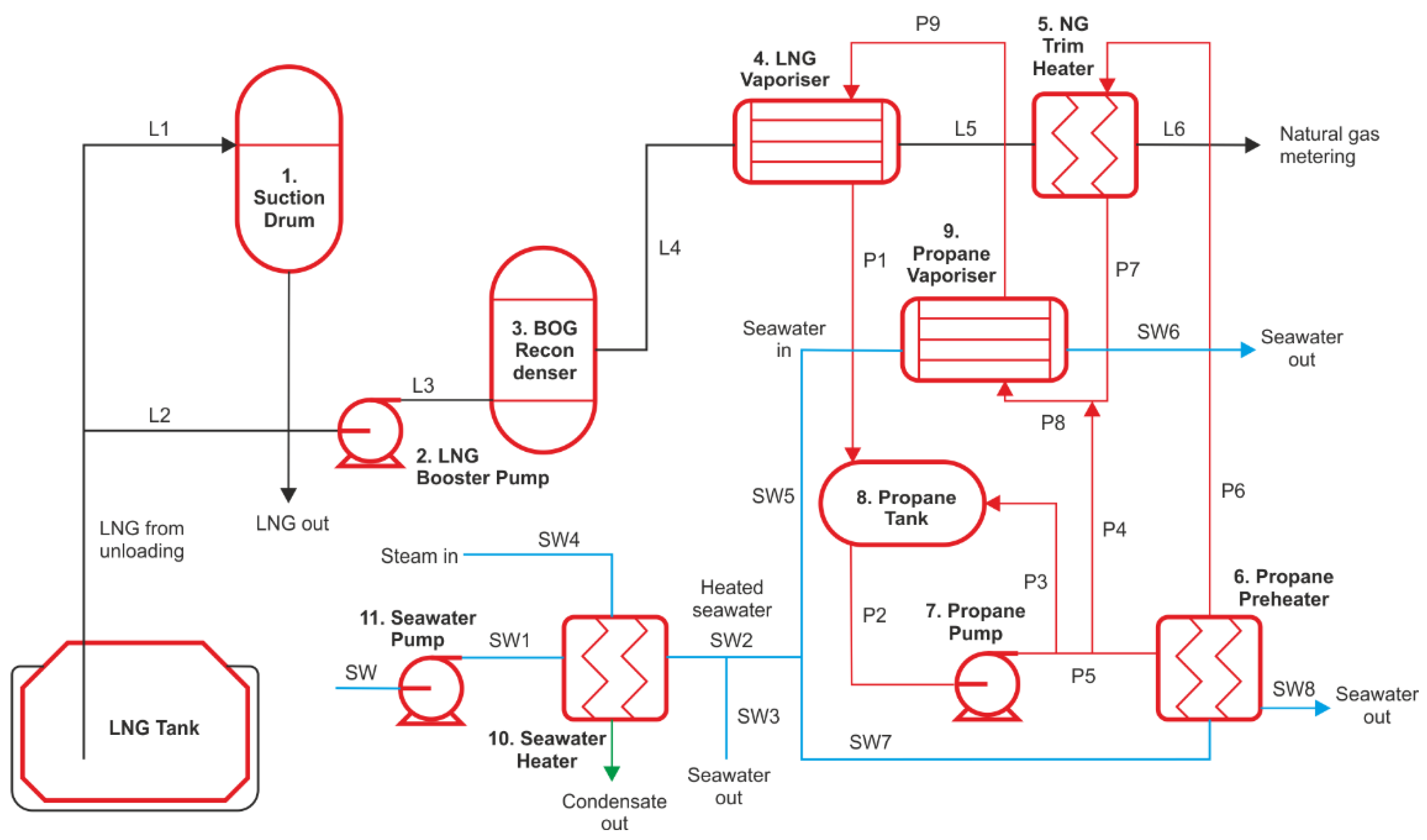

2.1. Description of Regasification Process on the FSRU

2.2. Mathematical Modelling of LNG Regasification Process

- -

- The heat transfer between the environment and the system is not feasible;

- -

- Heat exchangers are the counter-flow type and adiabatic;

- -

- The isentropic efficiency of pumps, turbines, and compressors is equal to 0.9.

2.3. Thermodynamic Calculation of LNG Regasification System

3. Results and Discussions

3.1. Results of Energy Analysis and Yield of Cold Energy

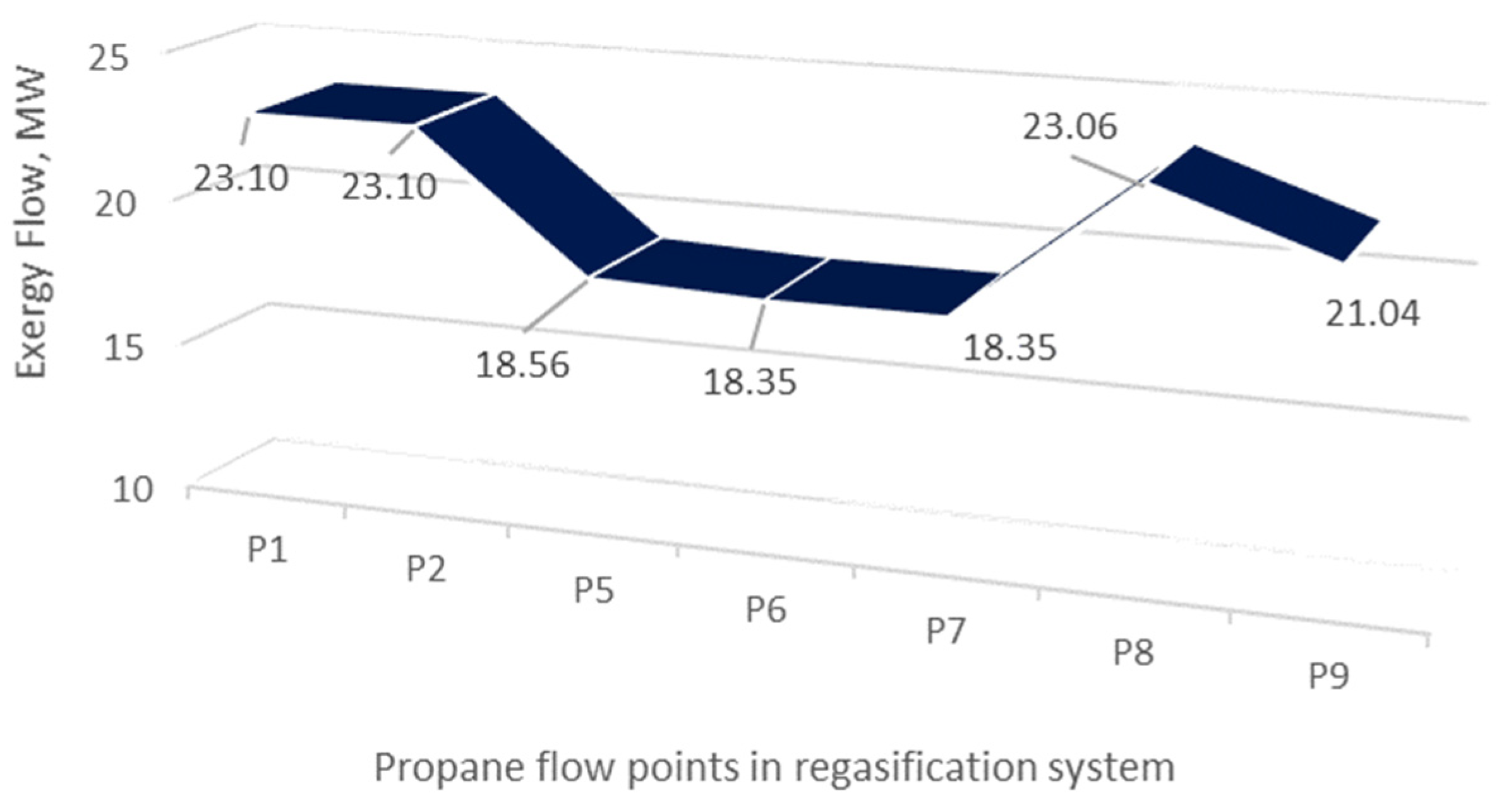

3.2. Results of Exergy Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IGU 2020. World LNG Report. International Gas Union. Available online: https://www.igu.org/app/uploads-wp/2020/04/2020-World-LNG-Report.pdf (accessed on 1 October 2020).

- Zoelle, A.; Keairns, D.; Pinkerton, L.L.; Turner, M.J.; Woods, M.; Kuehn, N.; Shah, V.; Chou, V. Cost and Performance Baseline for Fossil Energy Plants Volume 1a: Bituminous Coal (PC) and Natural Gas to Electricity Revision 3; U.S. Department of Energy, Office of Scientific and Technical Information: Washington, DC, USA, 2015. [CrossRef] [Green Version]

- IEA, The Role of Gas in Today’s Energy Transitions. World Energy Outlook Special Report 2019. Available online: https://www.iea.org/reports/the-role-of-gas-in-todays-energy-transitions (accessed on 1 October 2020).

- Thinkstep, Life Cycle GHG Emission Study on the Use of LNG as Marine Fuel. Final Report 2020. Available online: https://sphera.com/de/reports/life-cycle-ghg-emission-study-on-the-use-of-lng-as-marine-fuel/ (accessed on 1 October 2020).

- Abergel, T.; Delmastro, C. IEA, Tracking Buildings 2020—Heat Pumps. 2020. Available online: https://www.iea.org/reports/tracking-buildings-2020/heat-pumps#abstract (accessed on 1 October 2020).

- He, T.; Chong, Z.R.; Zheng, J.; Ju, Y.; Linga, P. LNG Cold Energy Utilization: Prospects and Challenges. Energy 2018, 170, 557–568. [Google Scholar] [CrossRef]

- Choi, I.-H.; Lee, S.; Seo, Y.; Chang, D. Analysis and optimization of cascade Rankine cycle for liquefied natural gas cold energy recovery. Energy 2013, 61, 179–195. [Google Scholar] [CrossRef]

- Franco, A.; Casarosa, C. Thermodynamic analysis of direct expansion configurations for electricity production by LNG cold energy recovery. Appl. Therm. Eng. 2015, 78, 649–657. [Google Scholar] [CrossRef]

- Bao, J.; Yuan, T.; Zhang, L.; Zhang, N.; Zhang, X.; He, G. Comparative study of liquefied natural gas (LNG) cold energy power generation systems in series and parallel. Energy Convers. Manag. 2019, 184, 107–126. [Google Scholar] [CrossRef]

- Pospíšil, J.; Charvát, P.; Arsenyeva, O.; Klimes, L.; Špiláček, M.; Klemeš, J.J. Energy demand of liquefaction and regasification of natural gas and the potential of LNG for operative thermal energy storage. Renew. Sustain. Energy Rev. 2019, 99, 1–15. [Google Scholar] [CrossRef]

- Messineo, A.; Panno, D. Potential applications using LNG cold energy in Sicily. Int. J. Energy Res. 2008, 32, 1058–1064. [Google Scholar] [CrossRef] [Green Version]

- Dhameliya, H.; Agrawal, P. LNG Cryogenic Energy Utilization. Energy Procedia 2016, 90, 660–665. [Google Scholar] [CrossRef]

- Lin, W.; Huang, M.; Gu, A. A seawater freeze desalination prototype system utilizing LNG cold energy. Int. J. Hydrogen Energy 2017, 42, 18691–18698. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Sharifzadeh, M.M.M.; Zonouz, M.J.; Rosen, M.A. Cost and economic potential analysis of a cascading power cycle with liquefied natural gas regasification. Energy Convers. Manag. 2018, 156, 68–83. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Ziabasharhagh, M. Optimal design and integration of a cryogenic Air Separation Unit (ASU) with Liquefied Natural Gas (LNG) as heat sink, thermodynamic and economic analyses. Energy 2017, 126, 868–885. [Google Scholar] [CrossRef]

- Lian, J.; Xia, B.; Yin, Y.; Yang, G.; Gou, X. Research on High Efficient Utilization on LNG Cold Energy. In Proceedings of the 4th International Conference on Computer, Mechatronics, Control and Electronics Engineering, Hangzhou, China, 28–29 September 2015. [Google Scholar] [CrossRef] [Green Version]

- Angelino, G.; Invernizzi, C.M. Carbon dioxide power cycles using liquid natural gas as heat sink. Appl. Therm. Eng. 2009, 29, 2935–2941. [Google Scholar] [CrossRef] [Green Version]

- Atienza-Márquez, A.; Bruno, J.C.; Coronas, A. Cold recovery from LNG-regasification for polygeneration applications. Appl. Therm. Eng. 2019, 132, 463–478. [Google Scholar] [CrossRef]

- Shi, X.; Che, D. A combined power cycle utilizing low-temperature waste heat and LNG cold energy. Energy Convers. Manag. 2009, 50, 567–575. [Google Scholar] [CrossRef]

- Qi, M.; Park, J.; Kim, J.; Lee, I.; Moon, I. Advanced integration of LNG regasification power plant with liquid air energy storage: Enhancements in flexibility, safety, and power generation. Appl. Energy 2020, 269, 115049. [Google Scholar] [CrossRef]

- Wang, G.-B.; Zhang, X.-R. Thermodynamic analysis of a novel pumped thermal energy storage system utilizing ambient thermal energy and LNG cold energy. Energy Convers. Manag. 2017, 148, 1248–1264. [Google Scholar] [CrossRef]

- Klaipeda Terminal—Characteristics of the Terminal. Available online: https://www.kn.lt/en/our-activities/lng-terminals/klaipeda-lng-terminal/559 (accessed on 1 October 2020).

- Egashira, S. LNG Vaporizer for LNG Re-gasification Terminal. KOBELCO Technol. Rev. 2013, 32, 64–69. Available online: https://www.kobelco.co.jp/english/ktr/pdf/ktr_32/064-069.pdf (accessed on 1 October 2020).

- Klaipeda LNG Reloading Station. Available online: https://www.kn.lt/en/our-activities/lng-terminals/lng-reloading-station/2761 (accessed on 1 October 2020).

- Wheatcroft, E.; Wynn, H.; Lygnerud, K.; Bonvicini, G.; Leonte, D. The Role of Low Temperature Waste Heat Recovery in Achieving 2050 Goals: A Policy Positioning Paper. Energies 2020, 13, 2107. [Google Scholar] [CrossRef] [Green Version]

- Lygnerud, K.; Wheatcroft, E.; Wynn, H. Contracts, Business Models and Barriers to Investing in Low Temperature District Heating Projects. Appl. Sci. 2019, 9, 3142. [Google Scholar] [CrossRef] [Green Version]

- Tahmasebi, S.; Abbasabadi, A.B.; Ghasemi, N.; Javadian, H.; Mashhadi, S.; Fattahi, M.; Arian, Y.R.; Maddah, H. Investigation of various feed conditions on NGL recovery plant energy and exergy performance: A case study. J. Nat. Gas Sci. Eng. 2015, 22, 83–89. [Google Scholar] [CrossRef]

- Chang, H.-M.; Kim, B.H.; Choi, B. Hydrogen liquefaction process with Brayton refrigeration cycle to utilize the cold energy of LNG. Cryogenics 2020, 108, 103093. [Google Scholar] [CrossRef]

- He, T.; Nair, S.K.; Babu, P.; Linga, P.; Karimi, I. A novel conceptual design of hydrate based desalination (HyDesal) process by utilizing LNG cold energy. Appl. Energy 2018, 222, 13–24. [Google Scholar] [CrossRef]

- Kanbur, B.B.; Xiang, L.; Dubey, S.; Choo, F.H.; Duan, F. Cold utilization systems of LNG: A review. Renew. Sustain. Energy Rev. 2017, 79, 1171–1188. [Google Scholar] [CrossRef]

- Agarwal, R.; Rainey, T.J.; Rahman, S.M.A.; Steinberg, T.; Perrons, R.K.; Brown, R.J. LNG Regasification Terminals: The Role of Geography and Meteorology on Technology Choices. Energies 2017, 10, 2152. [Google Scholar] [CrossRef] [Green Version]

- Migliore, C.; Tubilleja, C.; Vesovic, V. Weathering prediction model for stored liquefied natural gas (LNG). J. Nat. Gas Sci. Eng. 2015, 26, 570–580. [Google Scholar] [CrossRef] [Green Version]

- GIIGNL. Custody Transfer Handbook, 5th ed.; International Group of Liquefied Natural Gas Importers; 2017; pp. 1–179. Available online: https://giignl.org/system/files/giignl_cthb_5.0.web_.pdf (accessed on 1 October 2020).

- Dong, H.; Zhao, L.; Zhang, S.; Wang, A.; Cai, J. Using cryogenic exergy of liquefied natural gas for electricity production with the Stirling cycle. Energy 2013, 63, 10–18. [Google Scholar] [CrossRef]

- Li, S.; Wang, B.; Dong, J.; Jiang, Y. Thermodynamic analysis on the process of regasification of LNG and its application in the cold warehouse. Therm. Sci. Eng. Prog. 2017, 4, 1–10. [Google Scholar] [CrossRef]

- Noh, Y.; Kim, J.; Kim, J.; Chang, D. Economic evaluation of BOG management systems with LNG cold energy recovery in LNG import terminals considering quantitative assessment of equipment failures. Appl. Therm. Eng. 2018, 143, 1034–1045. [Google Scholar] [CrossRef]

- Miana, M.; del Hoyo, R.; Rodrigálvarez, V. Comparison of evaporation rate and heat flow models for prediction of Liquefied Natural Gas (LNG) ageing during ship transportation. Fuel 2016, 177, 87–106. [Google Scholar] [CrossRef]

- Sun, X.; Yao, S.; Xu, J.; Feng, G.; Yan, L. Design and Optimization of a Full-Generation System for Marine LNG Cold Energy Cascade Utilization. J. Therm. Sci. 2020, 29, 587–596. [Google Scholar] [CrossRef]

- Zhao, L.; Dong, H.; Tang, J.; Cai, J. Cold energy utilization of liquefied natural gas for capturing carbon dioxide in the flue gas from the magnesite processing industry. Energy 2016, 105, 45–56. [Google Scholar] [CrossRef]

- Brown, J.S.; Brignoli, R.; Daubman, S. Methodology for estimating thermodynamic parameters and performance of working fluids for organic Rankine cycles. Energy 2014, 73, 818–828. [Google Scholar] [CrossRef]

- Fahmy, M.; Nabih, H.; El-Rasoul, T. Optimization and comparative analysis of LNG regasification processes. Energy 2015, 91, 371–385. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Mehrpooya, M.; Pourfayaz, F. Thermodynamic and exergy analysis and optimization of a transcritical CO2 power cycle driven by geothermal energy with liquefied natural gas as its heat sink. Appl. Therm. Eng. 2016, 109, 640–652. [Google Scholar] [CrossRef]

- Lee, D.-H.; Ha, M.-K.; Kim, S.-Y.; Shin, S.-C. Research of design challenges and new technologies for floating LNG. Int. J. Nav. Arch. Ocean Eng. 2014, 6, 307–322. [Google Scholar] [CrossRef] [Green Version]

- Terehovics, E.; Veidenbergs, I.; Blumberga, D. Energy and exergy balance methodology. Wood chip dryer. Energy Procedia 2017, 128, 551–557. [Google Scholar] [CrossRef]

- Labidi, J.; Boulet, E.; Paris, J. On Intrinsic Exergy Efficiency and Heat Pumps. Chem. Eng. Res. Des. 2000, 78, 180–183. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Energy, environment and sustainable development. Appl. Energy 1999, 64, 427–440. [Google Scholar] [CrossRef] [Green Version]

- Winterbone, D.E.; Turan, A. Chapter 15—Combustion and Flames. In Advanced Thermodynamics for Engineers, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Akpinar, E.K.; Bicer, Y. Investigation of heat transfer and exergy loss in a concentric double pipe exchanger equipped with swirl generators. Int. J. Therm. Sci. 2005, 44, 598–607. [Google Scholar] [CrossRef]

- Paniagua, I.L.; Martín, J.R.; Fernández, C.G.; Alvaro, Á.J.; Carlier, R.N. A New Simple Method for Estimating Exergy Destruction in Heat Exchangers. Entropy 2013, 15, 474–489. [Google Scholar] [CrossRef]

- Galovic, A.; Zivic, M.; Kokanovic, M. Analysis of Exergy Destruction of an Evaporator or/an a Condenser. Strojarstvo 2009, 51, 73–78. [Google Scholar]

| Case | Composition of LNG, % | Flow Rate of LNG, kg·h−1 | Pressure, MPa (g) | BOG Recondensation |

|---|---|---|---|---|

| Case 1 | Methane—86; ethane—8; propane—4; i-butane—1; n-butane—1 | 120,000 | 3.5 | No recondensation |

| Case 2 | Methane—99.6; nitrogen—0.4 | 102,666 | 6.5 | With BOG circulation |

| Case 3 | Methane—96; nitrogen—4 | 105,666 | 6.5 | No recondensation |

| Case 4 | Methane—86; ethane—8; propane—4; i-butane—1; n-butane—1 | 50,000 | 6.5 | Partly recondensation |

| Case 5 | Methane—86; ethane—8; propane—4; i-butane—1; n-butane—1 | 120,000 | 5.5 | Partly recondensation |

| Regasification Case | M | V (Without Correction) | Vmix | K1 | K2 | ρLNG | Rg |

|---|---|---|---|---|---|---|---|

| Units | kg·kmol−1 | L·mol−1 | L·mol−1 | L·mol−1 | L·mol−1 | kg·m−3 | kJ·(kmol·K)−1 |

| Case 1 * | 19.1290 | 0.0400 | 0.0398 | 0.00718 | 0.00129 | 480.26 | 0.435 |

| Case 2 | 16.0000 | 0.0400 | 0.0380 | 0.00001 | 0.00032 | 423.42 | 0.520 |

| Case 3 | 16.4220 | 0.0360 | 0.0352 | −2.66·10−6 | 1.07·10−5 | 432.40 | 0.506 |

| Case | Energy Input, MW | Energy Output, MW |

|---|---|---|

| 1 | 224.98 | 201.21 |

| 2 | 183.78 | 164.36 |

| 3 | 198.51 | 177.53 |

| 4 | 79.96 | 71.58 |

| 5 | 214.78 | 192.09 |

| Equipment | Exergy Input, MW | Exergy Output, MW | Losses, % |

|---|---|---|---|

| Booster pump | 47.40 | 47.11 | 1 |

| BOG recondenser | 47.11 | 46.65 | 1 |

| LNG vaporiser | 68.51 | 58.90 | 14 |

| NG trim heater | 53.66 | 53.15 | 1 |

| Propane preheater | 51.95 | 51.82 | >1 |

| Propane vaporiser | 142.43 | 140.73 | 1 |

| Cases | LNG Subsystem | Propane Closed Loop | Total Amount of LNG Cold Energy Verifying Initial and Final Conditions, kW | |||||

|---|---|---|---|---|---|---|---|---|

| Power Consumption by Booster Pump, kW | Absorbed Heat by BOG Recondenser, kW | Absorbed Heat by LNG Vaporiser, kW | Absorbed Heat by NG Trim Heater, kW | Power Consumption by Propane Pump, kW | Released Heat by Propane Preheater, kW | Released Heat by Propane Vaporiser, kW | ||

| Case 1: LNG flow—120,000 kg·h−1, regasification pressure 3.5 MPa(g), no BOG recondensation, methane content of LNG—86% | 160 | 0 | 23,804 | 1343 | 160 | 4021 | 20,504 | 22,630 |

| Case 2: LNG flow—102,666 kg·h−1, regasification pressure 6.5 MPa(g), with BOG recondensation, methane content of LNG—99.6% | 130 | 342 | 19,450 | 941 | 130 | 3285 | 16,879 | 21,360 |

| Case 3: LNG flow—105,666 kg·h−1, regasification pressure 6.5 MPa(g), no BOG recondensation, methane content of LNG—96% | 141 | 0 | 20,419 | 799 | 141 | 3548 | 18,091 | 22,513 |

| Case 4: LNG flow—50,000 kg·h−1, regasification pressure 6.5 MPa(g), partly BOG recondensation, methane content of LNG—86% | 114 | 236 | 8389 | 472 | 114 | 1563 | 7161 | 20,429 |

| Case 5: LNG flow—120,000 kg·h−1, regasification pressure 5.5 MPa(g), partly BOG recondensation, methane content of LNG—86% | 152 | 34 | 22,696 | 1309 | 152 | 3839 | 19,955 | 24,777 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Semaskaite, V.; Bogdevicius, M.; Paulauskiene, T.; Uebe, J.; Filina-Dawidowicz, L. Improvement of Regasification Process Efficiency for Floating Storage Regasification Unit. J. Mar. Sci. Eng. 2022, 10, 897. https://doi.org/10.3390/jmse10070897

Semaskaite V, Bogdevicius M, Paulauskiene T, Uebe J, Filina-Dawidowicz L. Improvement of Regasification Process Efficiency for Floating Storage Regasification Unit. Journal of Marine Science and Engineering. 2022; 10(7):897. https://doi.org/10.3390/jmse10070897

Chicago/Turabian StyleSemaskaite, Vigaile, Marijonas Bogdevicius, Tatjana Paulauskiene, Jochen Uebe, and Ludmila Filina-Dawidowicz. 2022. "Improvement of Regasification Process Efficiency for Floating Storage Regasification Unit" Journal of Marine Science and Engineering 10, no. 7: 897. https://doi.org/10.3390/jmse10070897

APA StyleSemaskaite, V., Bogdevicius, M., Paulauskiene, T., Uebe, J., & Filina-Dawidowicz, L. (2022). Improvement of Regasification Process Efficiency for Floating Storage Regasification Unit. Journal of Marine Science and Engineering, 10(7), 897. https://doi.org/10.3390/jmse10070897