Artificial Tongue Embedded with Conceptual Receptor for Rubber Gustatory Sensor by Electrolytic Polymerization Technique with Utilizing Hybrid Fluid (HF)

Abstract

:1. Introduction

2. Material

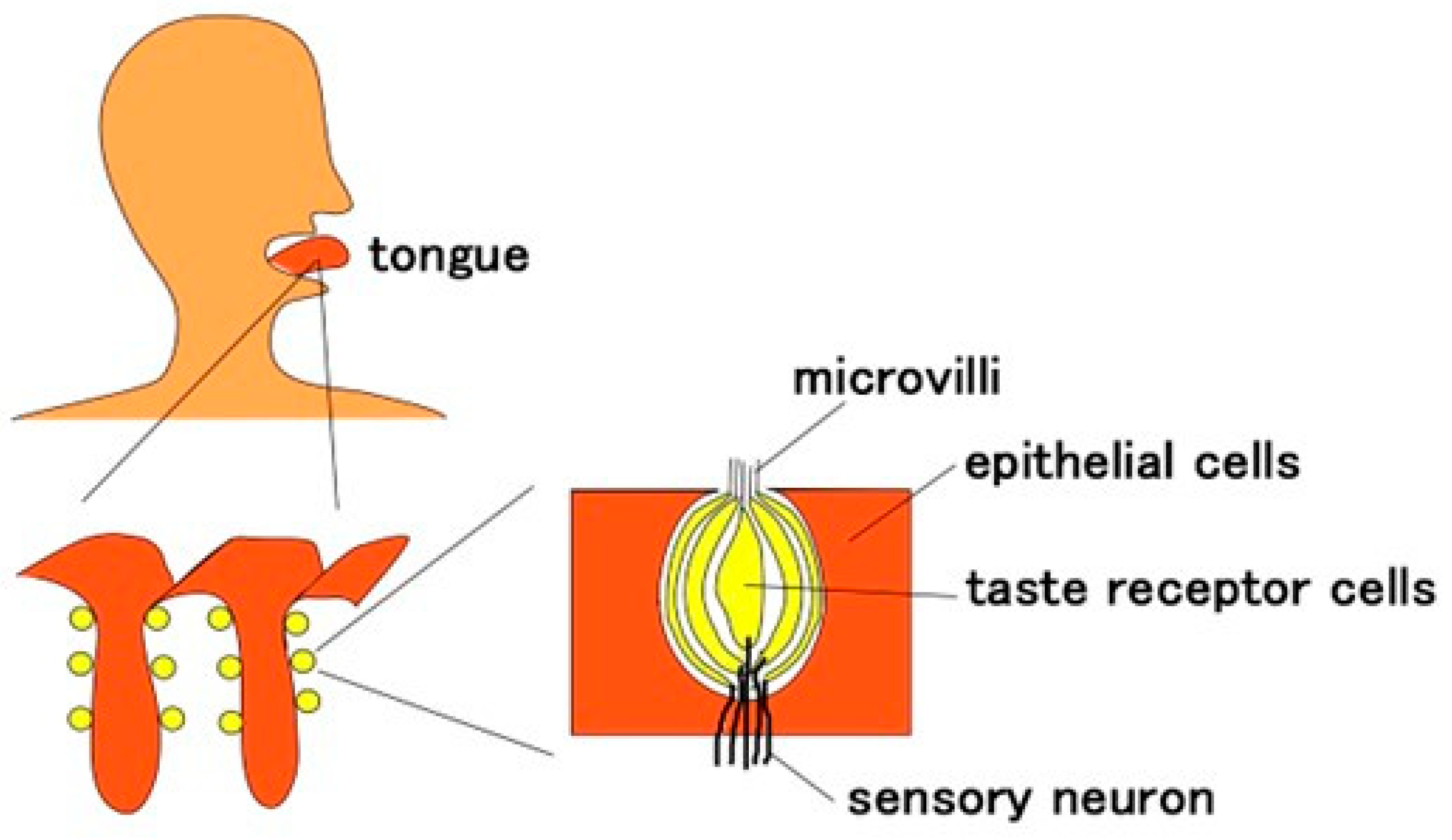

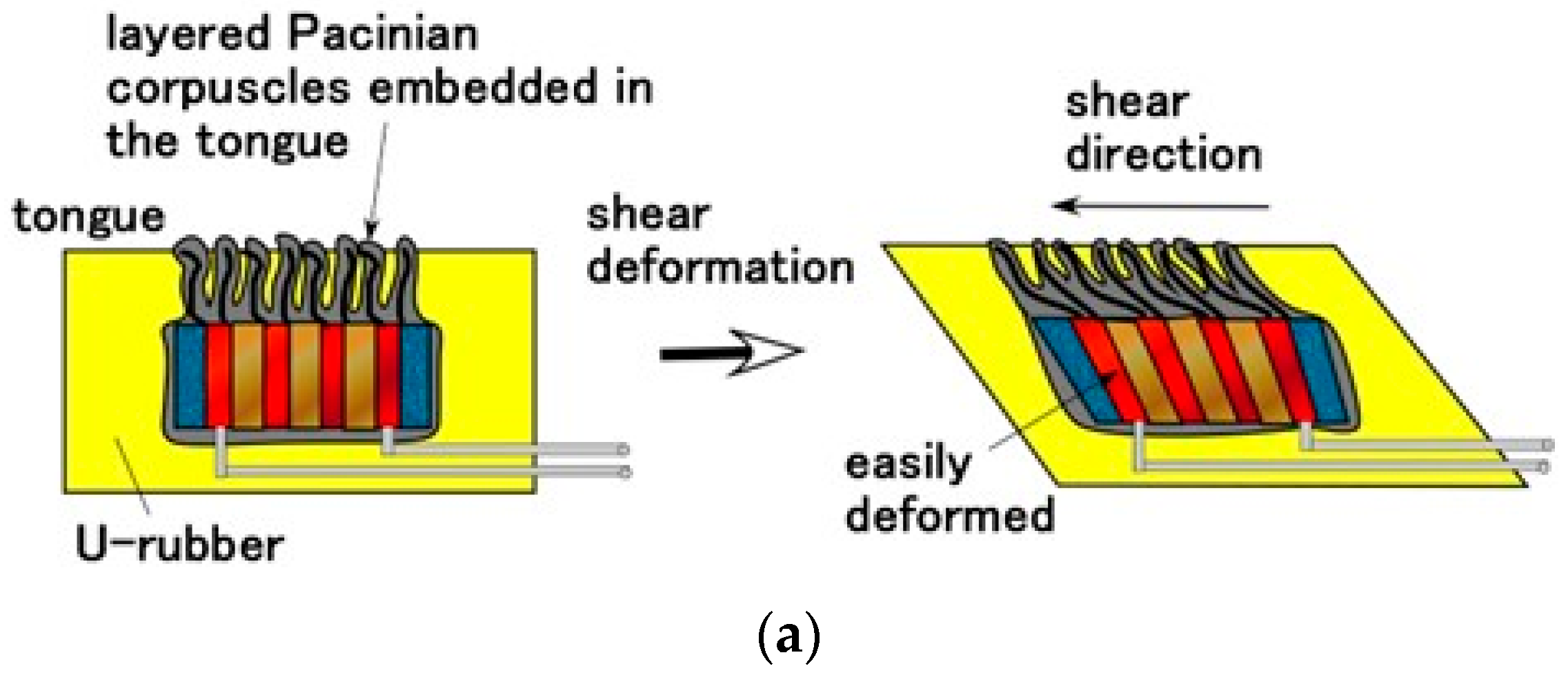

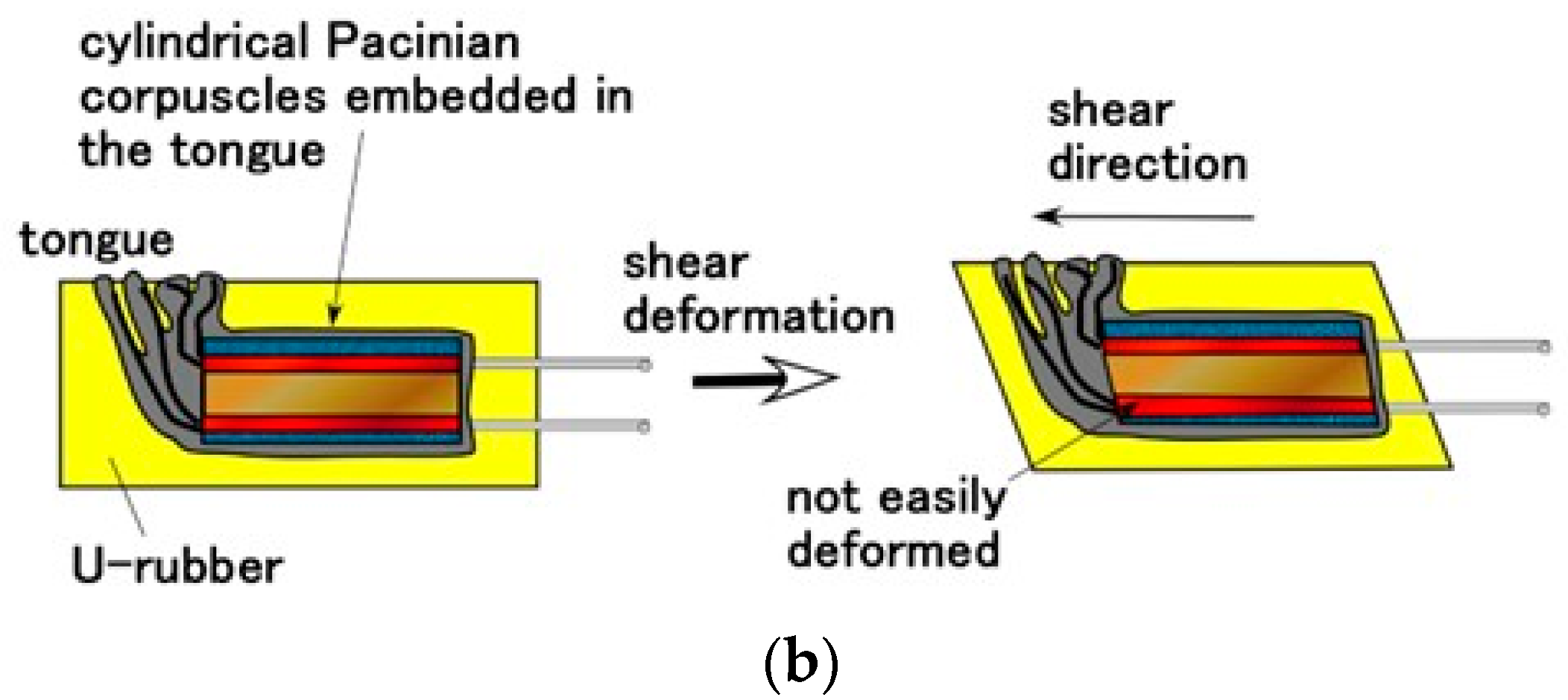

2.1. Conceptual Receptor

2.2. HF Rubber

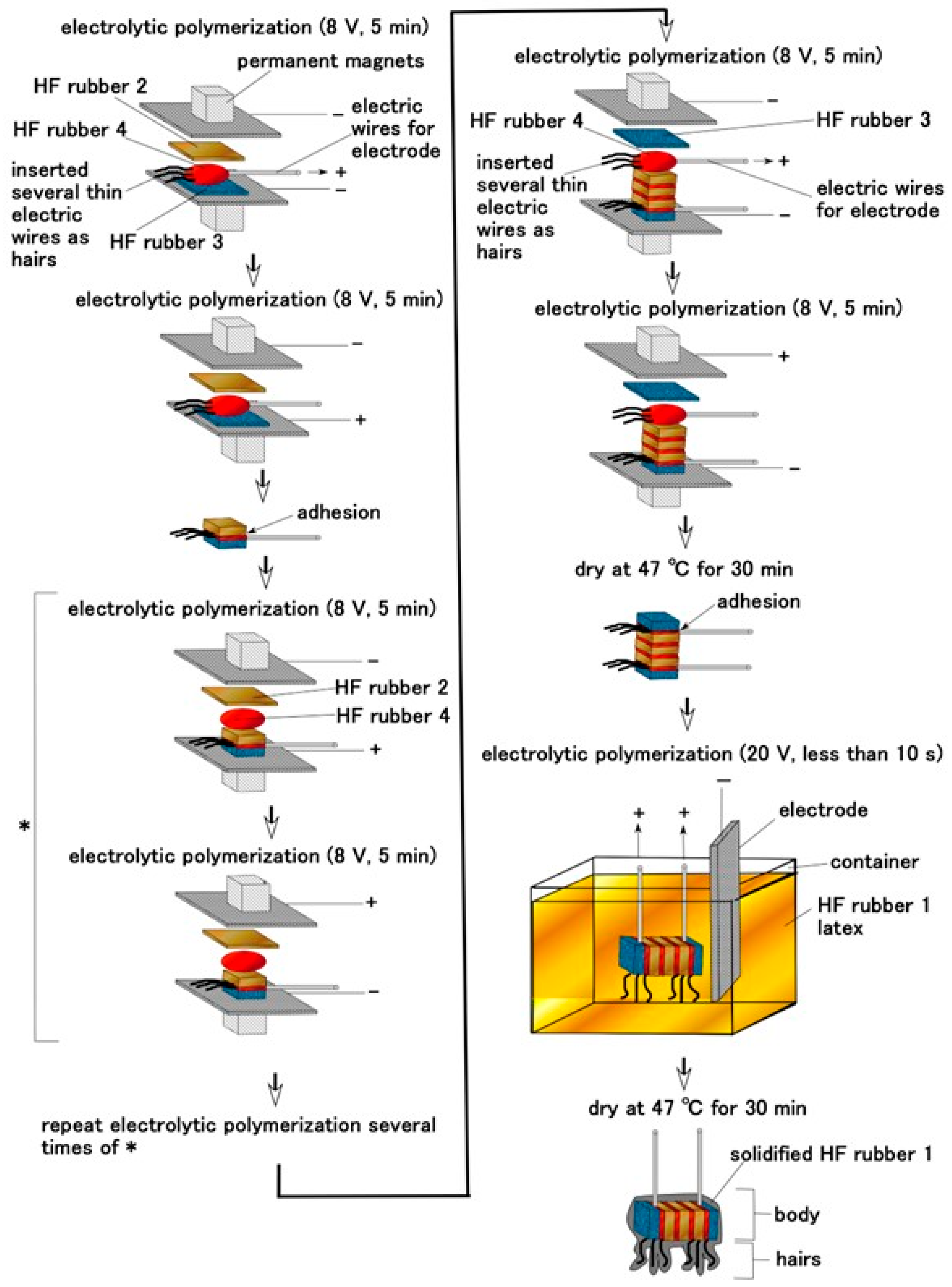

2.3. Artificial Receptor and Tongue

2.4. Equivalent Electric Circuit

3. Experimental Procedure

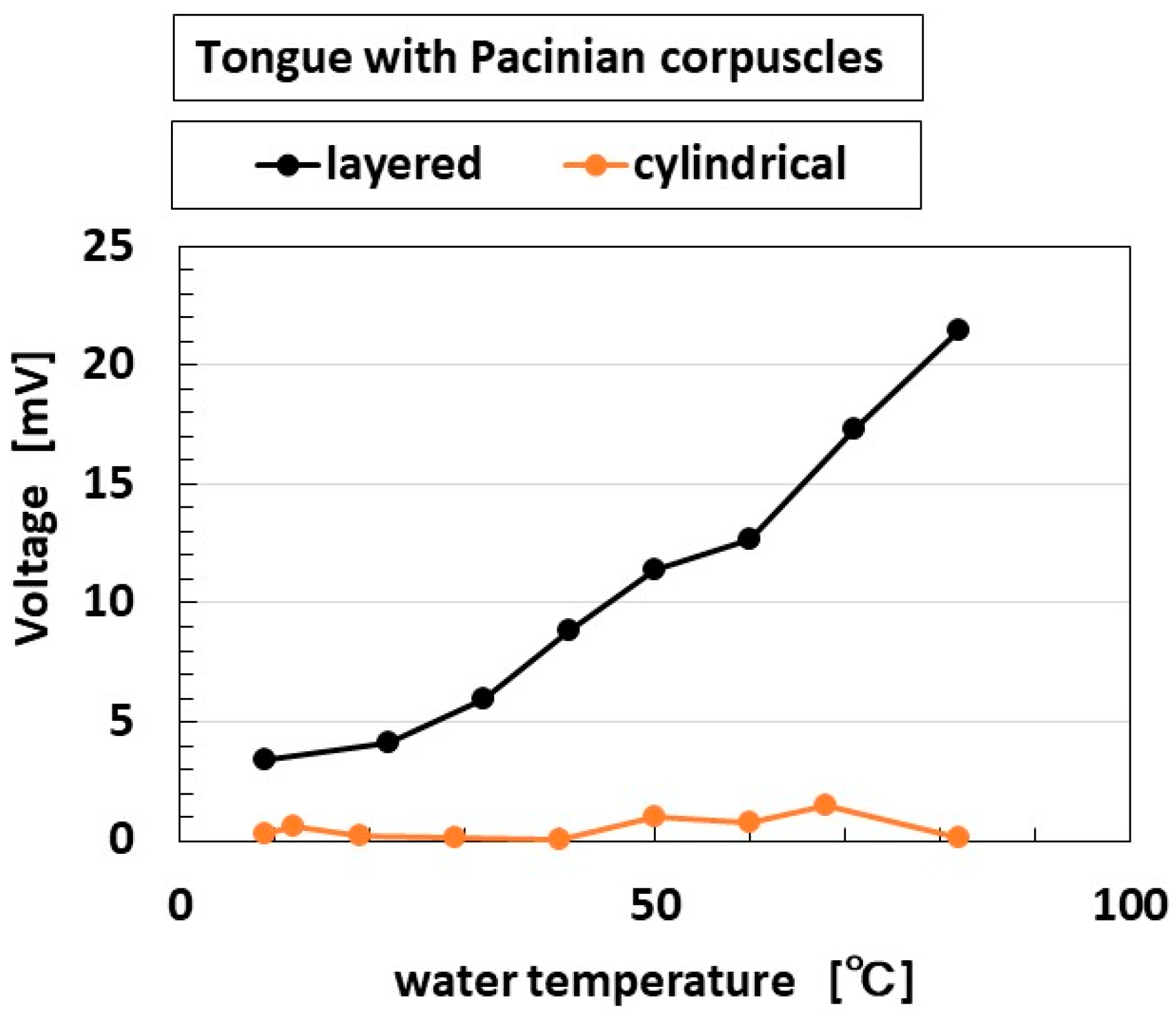

3.1. Mechanical and Thermal Response

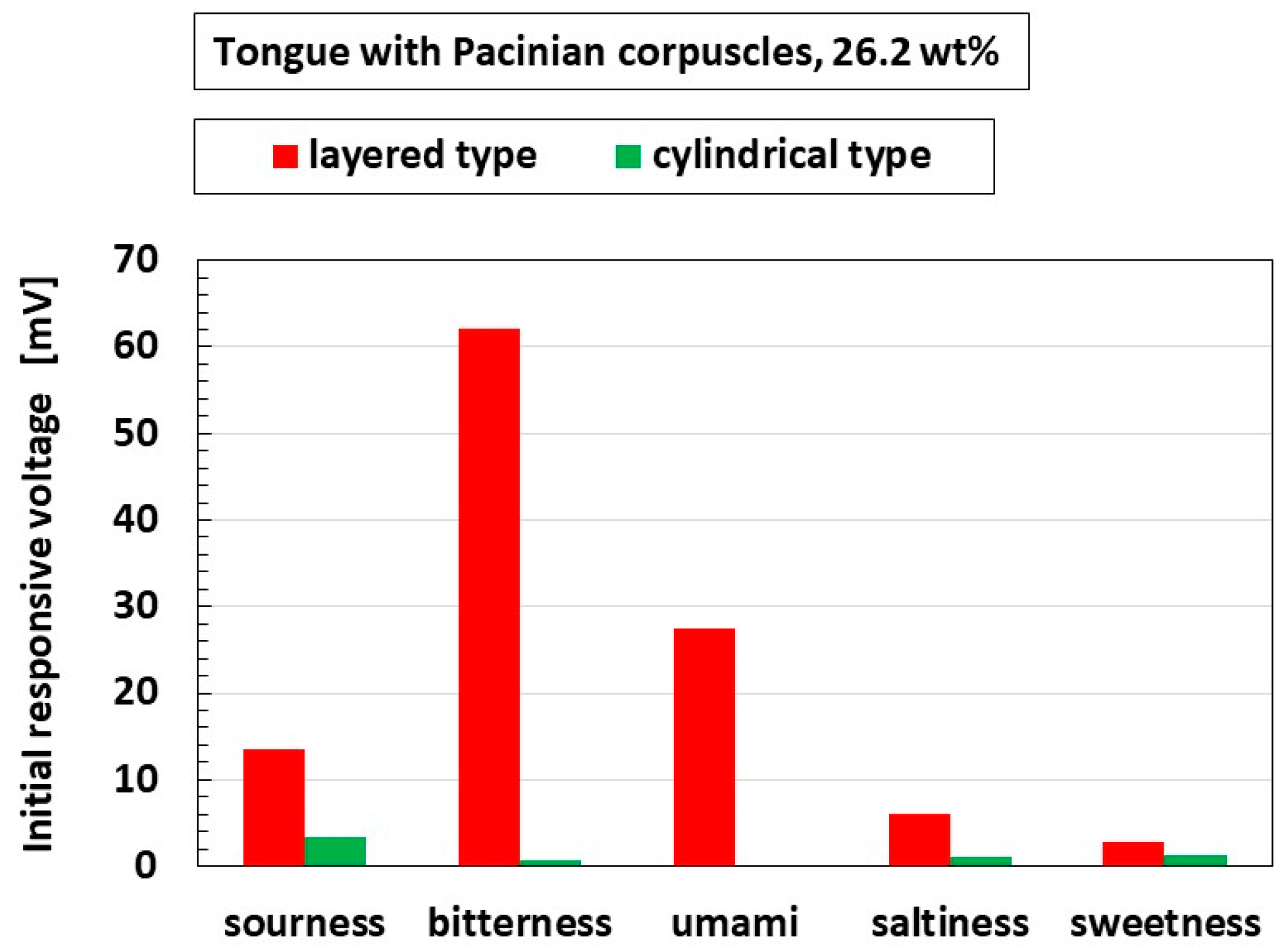

3.2. Gustatory Response

4. Results and Discussion

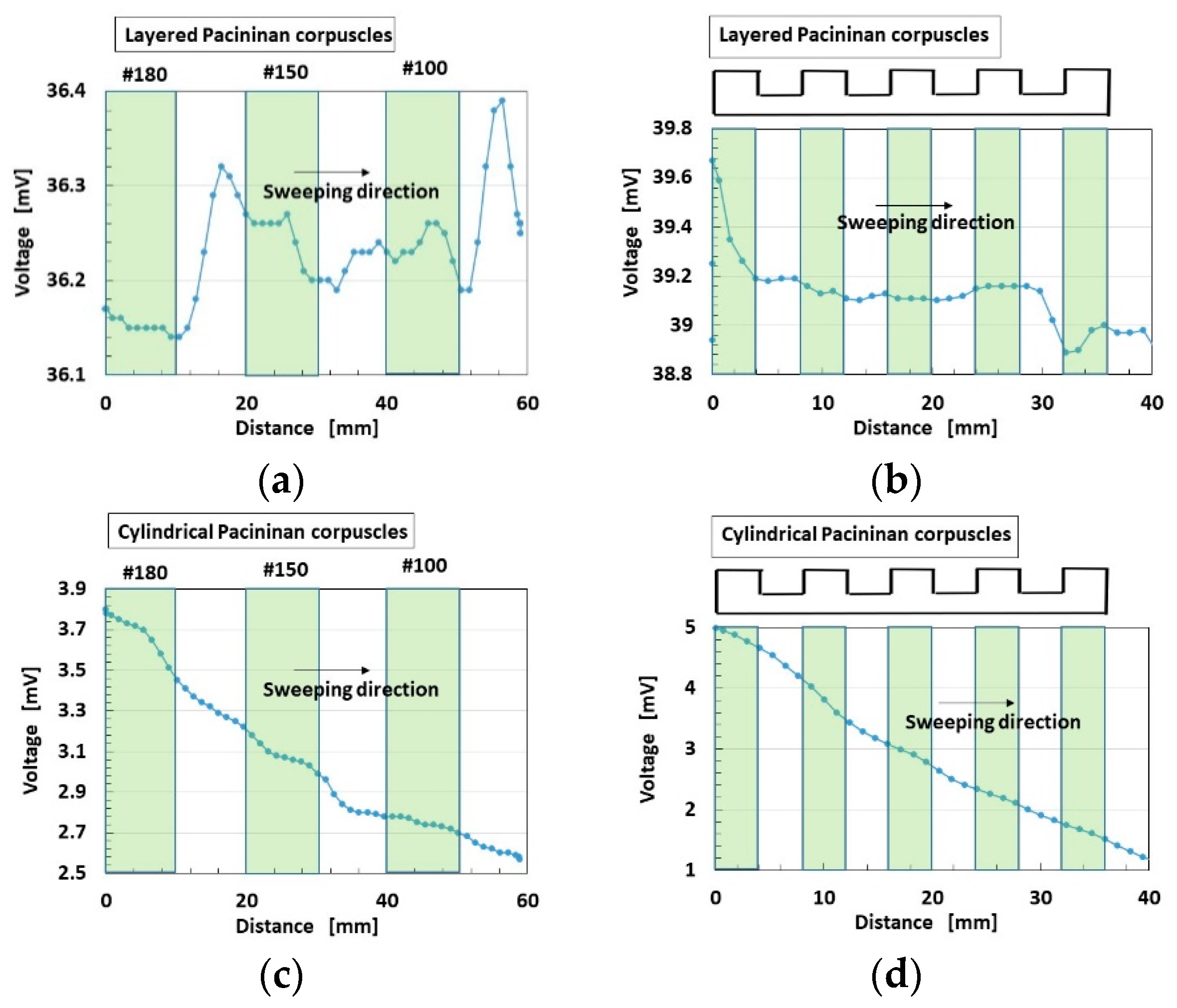

4.1. Mechanical and Thermal Response

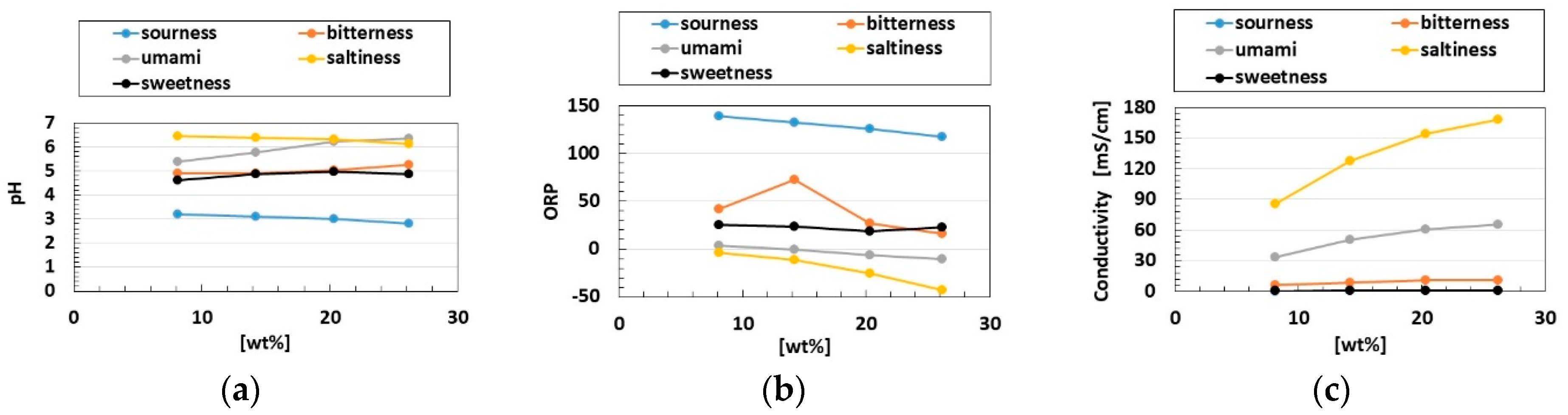

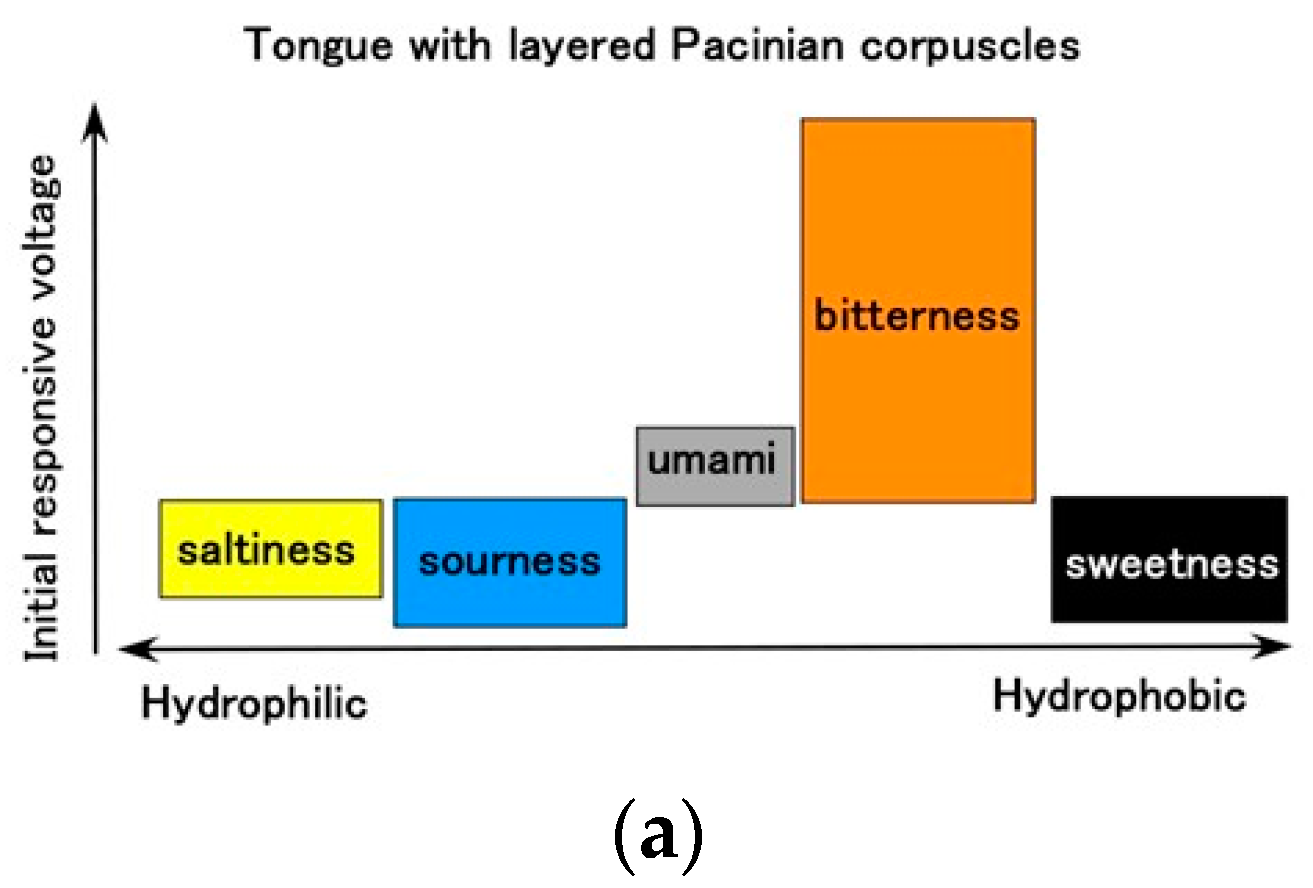

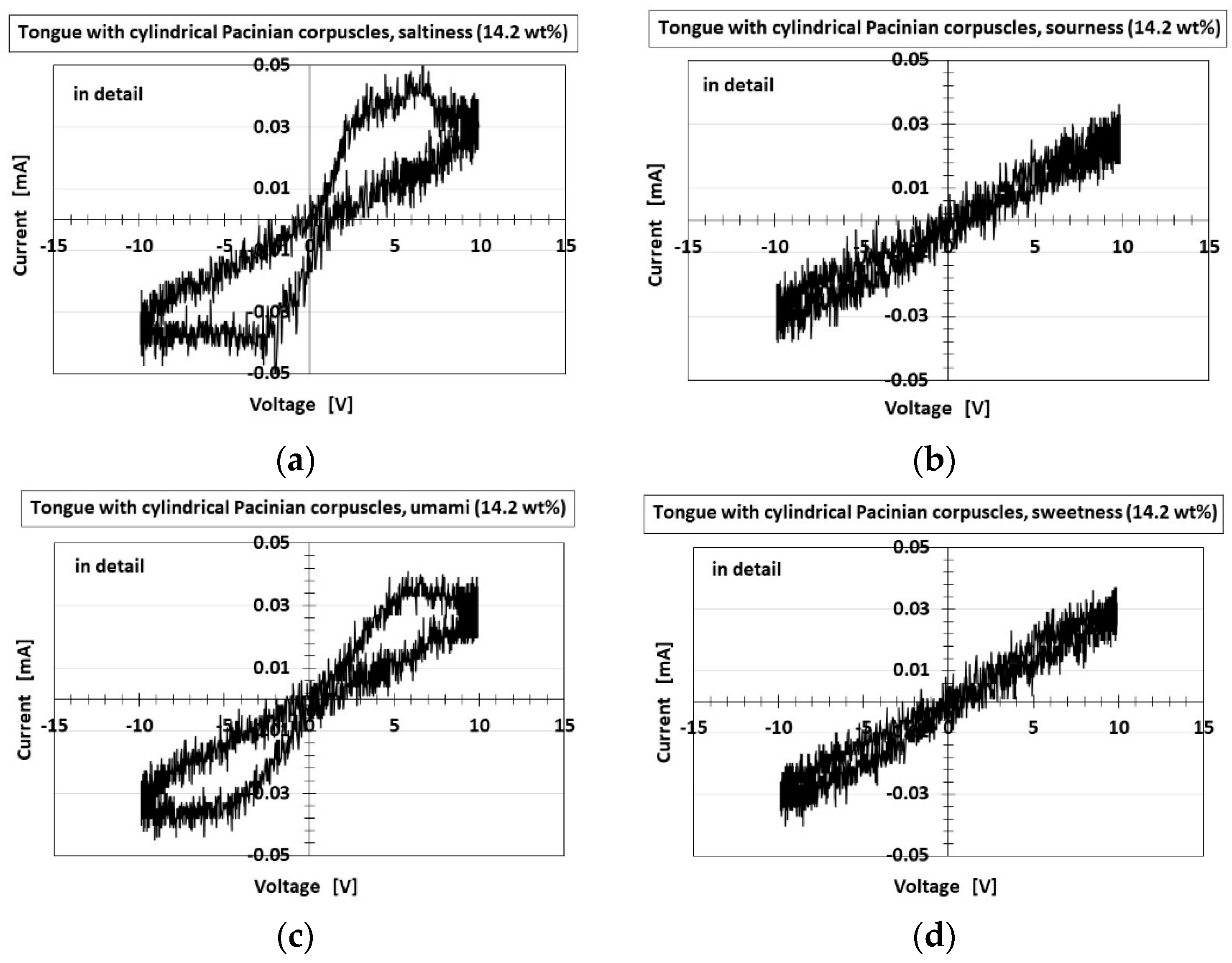

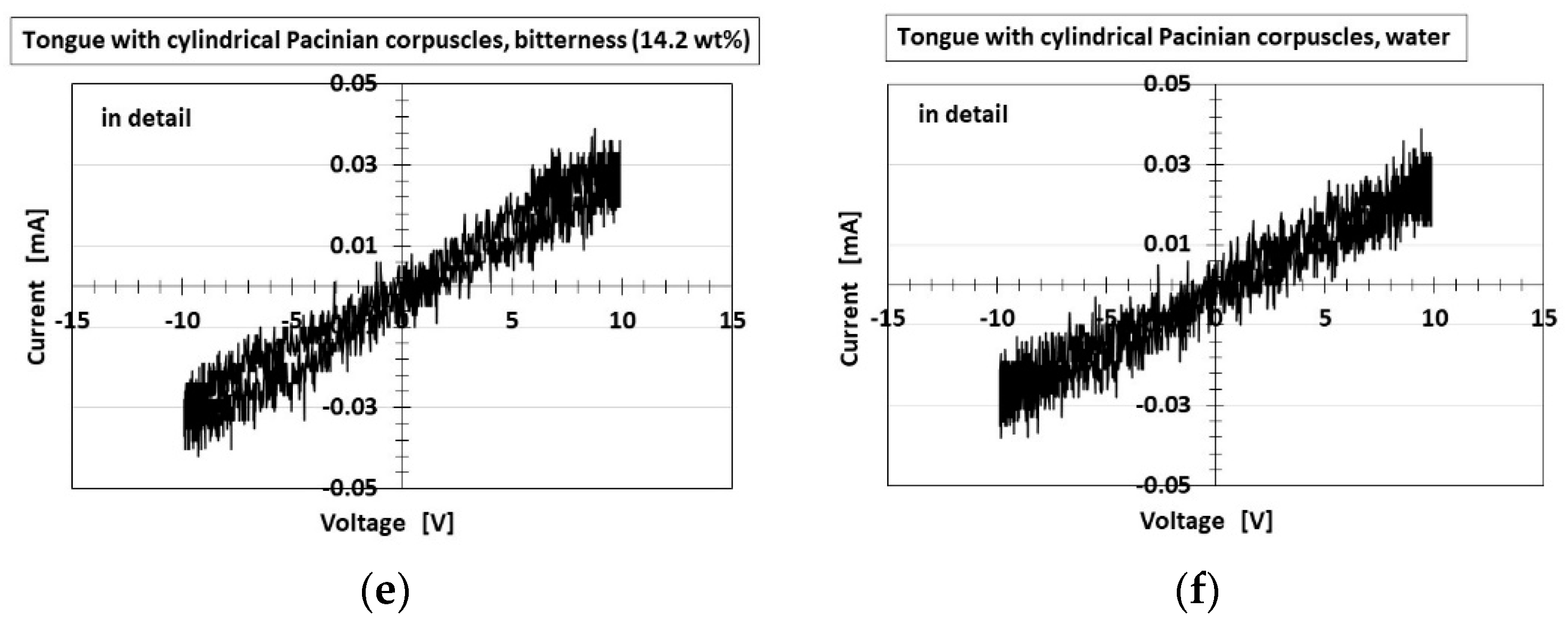

4.2. Gustatory Response

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Rosolia, U.; Zhang, X.; Borrelli, F. Data-driven predictive control for autonomous systems. Annu. Rev. Control. Robot. Auton. Syst. 2018, 1, 259–286. [Google Scholar] [CrossRef]

- Ji, X.; Zhao, X.; Tan, M.C.; Zhao, R. Artificial perception built on memristive system: Visual, auditory, and tactile sensations. Adv. Intell. Syst. 2019, 2, 1900118. [Google Scholar] [CrossRef]

- Gibney, E. The inside story on wearable electronics. Nature 2015, 528, 26–28. [Google Scholar] [CrossRef]

- Baldwin, E.A.; Bai, J.; Plotto, A.; Dea, S. Electronic noses and tongues: Applications for the food and pharmaceutical industries. Sensors 2011, 11, 4744–4766. [Google Scholar] [CrossRef]

- Svechtarova, M.I.; Buzzacchera, I.; Tobes, B.J.; Lauko, J.; Anton, N.; Wilson, C.J. Sensor devices inspired by the five senses: A review. Electroanalysis 2016, 28, 1201–1241. [Google Scholar] [CrossRef]

- Yang, G.-Z.; Bellingham, J.; Dupont, P.E.; Fischer, P.; Floridi, L.; Full, R.; Jacobstein, N.; Kumar, V.; McNutt, M.; Merrifield, R.; et al. The grand challenges of science robotics. Sci. Robot. 2018, 3, eaar7650. [Google Scholar] [CrossRef]

- Guo, H.; Pu, X.; Chen, J.; Meng, Y.; Yeh, M.-H.; Liu, G.; Tang, Q.; Chen, B.; Liu, D.; Qi, S.; et al. A highly sensitive, self-powered triboelectric auditory sensor for social robotics and hearing aids. Sci. Robot. 2018, 3, eaat2516. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.C.; Mun, J.; Kwon, S.Y.; Park, S.; Bao, Z.; Park, S. Electronic skin: Recent progress and future prospects for skin-attachable devices for health monitoring, robotics, and prosthetics. Adv. Mater. 2019, 31, 1904765. [Google Scholar] [CrossRef]

- Hou, C.; Tai, G.; Liu, Y.; Liu, R.; Liang, X.; Wu, Z.; Wu, Z. Borophene pressure sensing for electronic skin and human-machine interface. Nano Ener. 2022, 97, 107189. [Google Scholar] [CrossRef]

- Heng, W.; Solomon, S.; Gao, W. Flexible electronics and devices as human-machine interfaces for medical robotics. Adv. Mater. 2021, 34, 2107902. [Google Scholar] [CrossRef]

- Chortos, A.; Liu, J.; Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 2016, 15, 937–950. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Qi, P.; Fan, W.; Wang, H.; Sui, K. Bioinspired multifunctional self-powered ionic receptors derived by gradient polyelectrolyte hydrogels. Chem. Eng. J. 2022, 438, 135610. [Google Scholar] [CrossRef]

- Zeng, H.; He, H.; Fu, Y.; Zhao, T.; Han, W.; Xing, L.; Zhang, Y.; Zhan, Y.; Xue, X. A self-powered brain-linked biosensing electronic-skin for actively tasting beverage and its potential application in artificial gustation. Nanoscale 2018, 10, 19987–19994. [Google Scholar] [CrossRef] [PubMed]

- Ciosek, P.; Wróblewski, W. Sensor arrays for liquid sensing—electronic tongue systems. Analyst 2007, 132, 963–978. [Google Scholar] [CrossRef]

- Kaczmarek, K. The tongue display unit (TDU) for electrotactile spatiotemporal pattern presentation. Sci. Iran. 2011, 18, 1476–1485. [Google Scholar] [CrossRef]

- Zhang, N.; Wei, X.; Fan, Y.; Zhou, X.; Liu, Y. Recent advances in development of biosensors for taste-related analyses. TrAC Trend Analyt. Chem. 2020, 129, 115925. [Google Scholar] [CrossRef]

- Ye, Z.; Ai, T.; Wu, X.; Onodera, T.; Ikezaki, H.; Toko, K. Elucidation of response mechanism of a potentiometric sweetness sensor with a lipid/polymer membrane for uncharged sweeteners. Chemosensors 2022, 10, 166. [Google Scholar] [CrossRef]

- Zhao, T.; Wang, Q.; Du, A. Self-powered flexible sour sensor for detecting ascorbic acid concentration based on triboelectrification/enzymatic-reaction coupling effect. Sensors 2021, 21, 373. [Google Scholar] [CrossRef]

- Li, M.; Zhang, N.; Cui, Z.; Wang, W.; Wang, C.; Wang, D.; Li, M.; Lu, W.; Qing, G.; Liu, Y. Biomimetic ion nanochannels for sensing umami substances. Biomaterials 2022, 282, 121418. [Google Scholar] [CrossRef]

- Cheng, L.; Meng, Q.-H.; Lilienthal, A.J.; Qi, P.F. Development of compact electronic noses: A review. Meas. Sci. Technol. 2021, 32, 062002. [Google Scholar] [CrossRef]

- Covington, J.A.; Marco, S.; Persaud, K.C.; Schiffman, S.S.; Nagle, H.T. Artificial olfaction in the 21st century. IEEE Sens. J. 2021, 21, 12969–12990. [Google Scholar] [CrossRef]

- Shimada, K.; Ikeda, R.; Kikura, H.; Takahashi, H. Morphological fabrication of rubber cutaneous receptors embedded in a stretchable skin-mimicking human tissue by the utilization of hybrid fluid. Sensors 2021, 21, 6834. [Google Scholar] [CrossRef]

- Shimada, K. Morphological fabrication of equilibrium and auditory sensors through electrolytic polymerization on hybrid fluid rubber (HF rubber) for smart materials of robotics. Sensors 2022, 22, 5447. [Google Scholar] [CrossRef] [PubMed]

- Shimada, K. Elastic MCF rubber with photovoltaics and sensing for use as artificial or hybrid skin (H-Skin): 1st report on dry-type solar cell rubber with piezoelectricity for compressive sensing. Sensors 2018, 18, 1841. [Google Scholar] [CrossRef]

- Shimada, K.; Ikeda, R.; Kikura, H.; Takahashi, H. Development of novel magnetic responsive intelligent fluid, hybrid fluid (HF), for production of soft and tactile rubber. World J. Mech. 2021, 11, 187–203. [Google Scholar] [CrossRef]

- Gao, Z.; Ishihara, S.; Nakano, S.; Hayakawa, F.; Funami, T.; Kohyama, K. Texture evaluation of soft gels with different fracture strains using an artificial tongue. J. Tex. Stud. 2016, 47, 496–503. [Google Scholar] [CrossRef]

- Toko, K.; Hara, D.; Tahara, Y.; Yasuura, M.; Ikezaki, H. relationship between the amount of bitter substances adsorbed onto lipid/polymer membrane and the electric response of taste sensors. Sensors 2014, 14, 16274–16286. [Google Scholar] [CrossRef]

- Wu, X.; Tahara, Y.; Yatabe, R.; Toko, K. Taste sensor: Electronic tongue with lipid membranes. Anal. Sci. 2020, 36, 147–159. [Google Scholar] [CrossRef] [Green Version]

| HF Rubber 1 | HF Rubber 2 | HF Rubber 3 | HF Rubber 4 | ||

|---|---|---|---|---|---|

| Ingredients | water | 3 g | 3 g | 1 g | 1 g |

| Sodium tungstate (VI) dehydrate (Na2WO4 2H2O, Fujifilm Wako Chemical Co., Ltd., Osaka, Japan) | 0.5 g | 0.5 g | - | 0.5 g | |

| TiO2 (Anataze type, Fujifilm Wako Chemical Co., Ltd., Osaka, Japan) | 0.5 g | 0.5 g | 0.5 g | 0.5 g | |

| HF | 1 g | 1 g | 1 g | 1 g | |

| NR-latex (Ulacol; Rejitex Co., Ltd., Atsugi, Japan) | 3 g | 3 g | 3 g | 3 g | |

| CR-latex (671A; Showa Denko Co., Ltd., Tokyo, Japan) | 3 g | 3 g | 3 g | 3 g | |

| Carbonyl Ni powder (No. 123, Yamaishi Co., Ltd., Noda, Japan) | 3 g | 3 g | 3 g | 3 g | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shimada, K. Artificial Tongue Embedded with Conceptual Receptor for Rubber Gustatory Sensor by Electrolytic Polymerization Technique with Utilizing Hybrid Fluid (HF). Sensors 2022, 22, 6979. https://doi.org/10.3390/s22186979

Shimada K. Artificial Tongue Embedded with Conceptual Receptor for Rubber Gustatory Sensor by Electrolytic Polymerization Technique with Utilizing Hybrid Fluid (HF). Sensors. 2022; 22(18):6979. https://doi.org/10.3390/s22186979

Chicago/Turabian StyleShimada, Kunio. 2022. "Artificial Tongue Embedded with Conceptual Receptor for Rubber Gustatory Sensor by Electrolytic Polymerization Technique with Utilizing Hybrid Fluid (HF)" Sensors 22, no. 18: 6979. https://doi.org/10.3390/s22186979