Bioinspired Spinosum Capacitive Pressure Sensor Based on CNT/PDMS Nanocomposites for Broad Range and High Sensitivity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Spinosum Microstructure CNT/PDMS Films as the Dielectric Layer

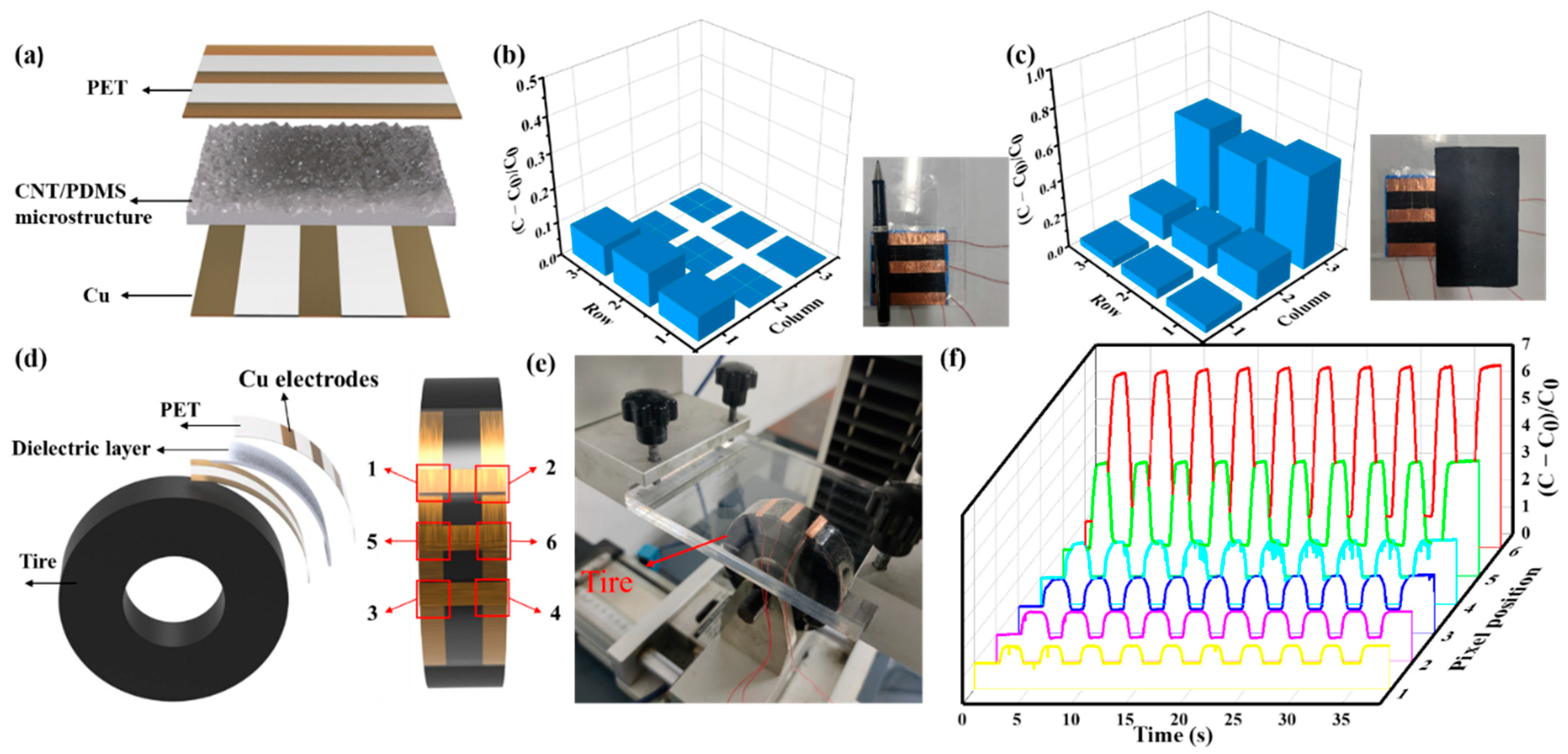

2.2. Preparation of the Sensor Array

2.3. Characterization of the Morphology and Performance of the CNT/PDMS-Based Spinosum Pressure Sensors

2.4. Finite Element Analysis

3. Results and Discussion

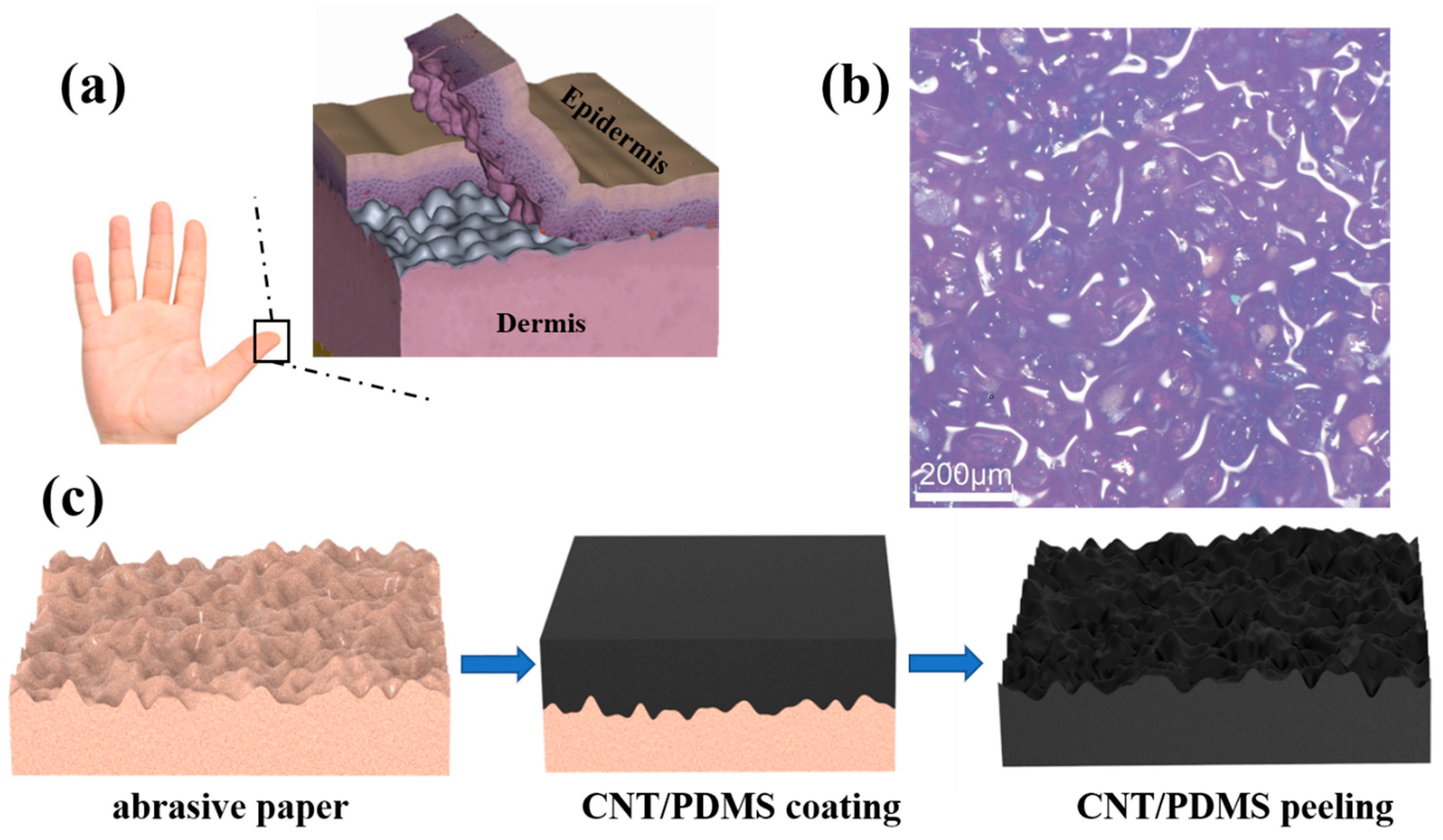

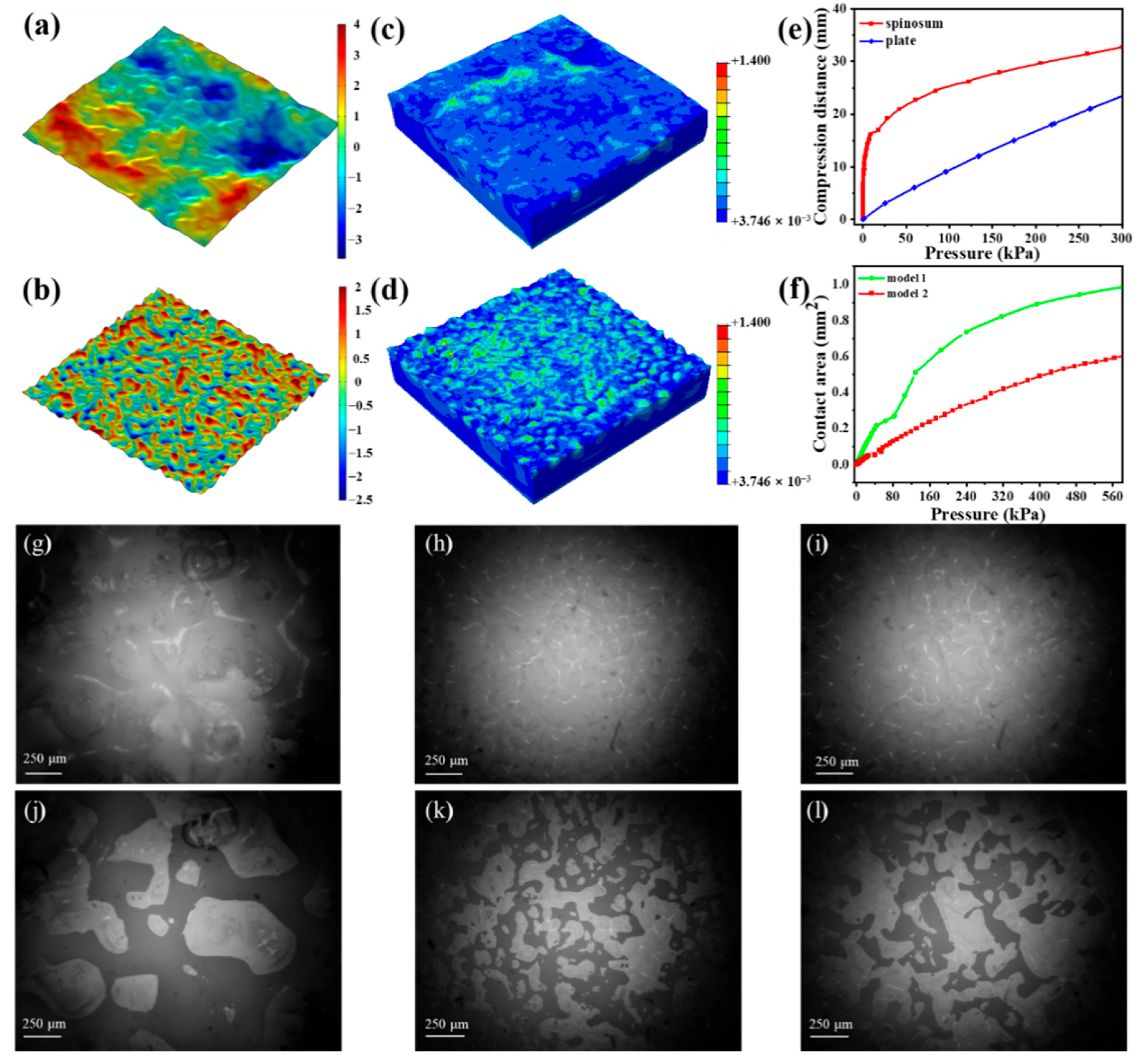

3.1. Designs for Spinosum Capacitive Pressure Sensors

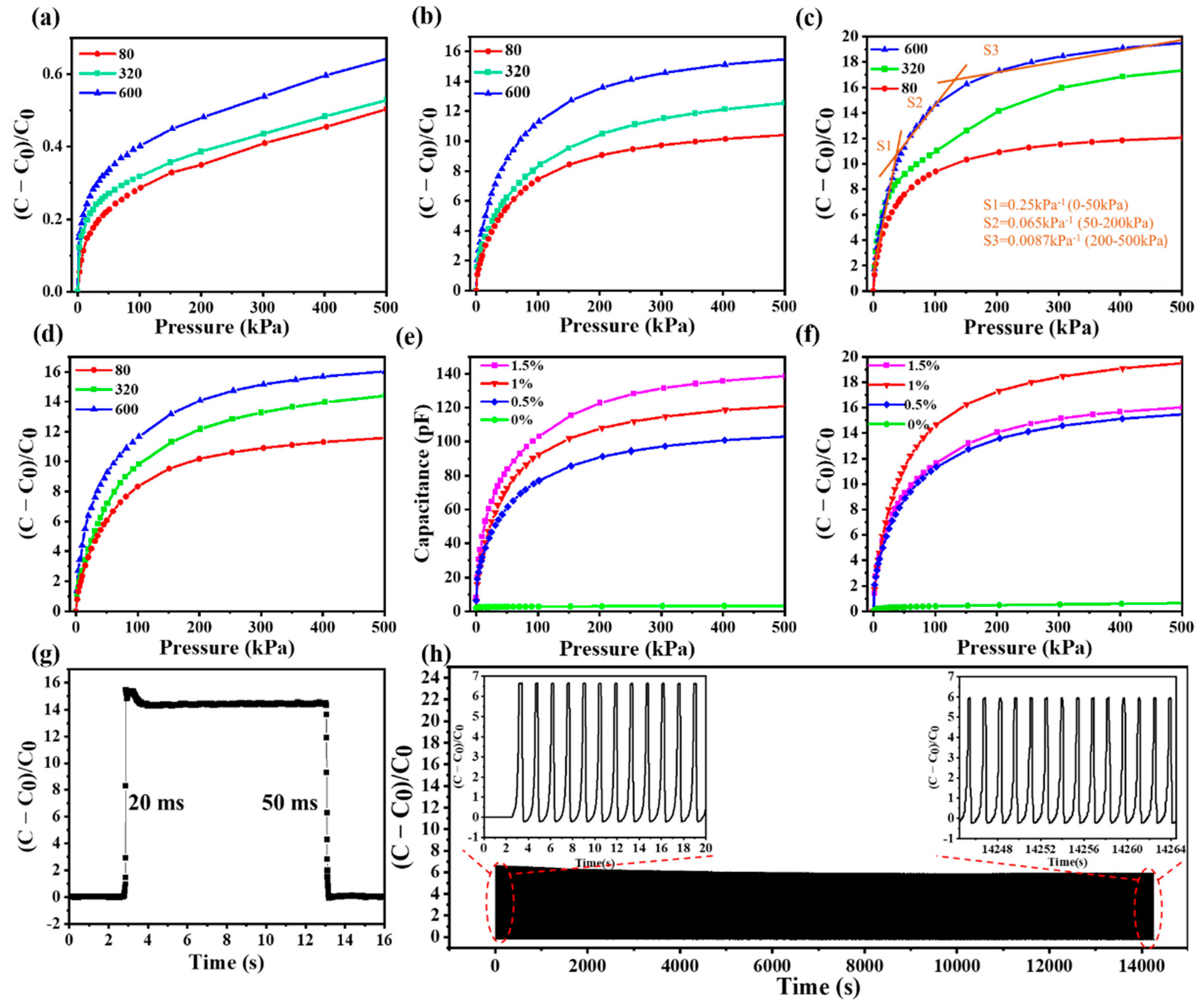

3.2. The Performance of Spinosum Capacitive Pressure Sensors

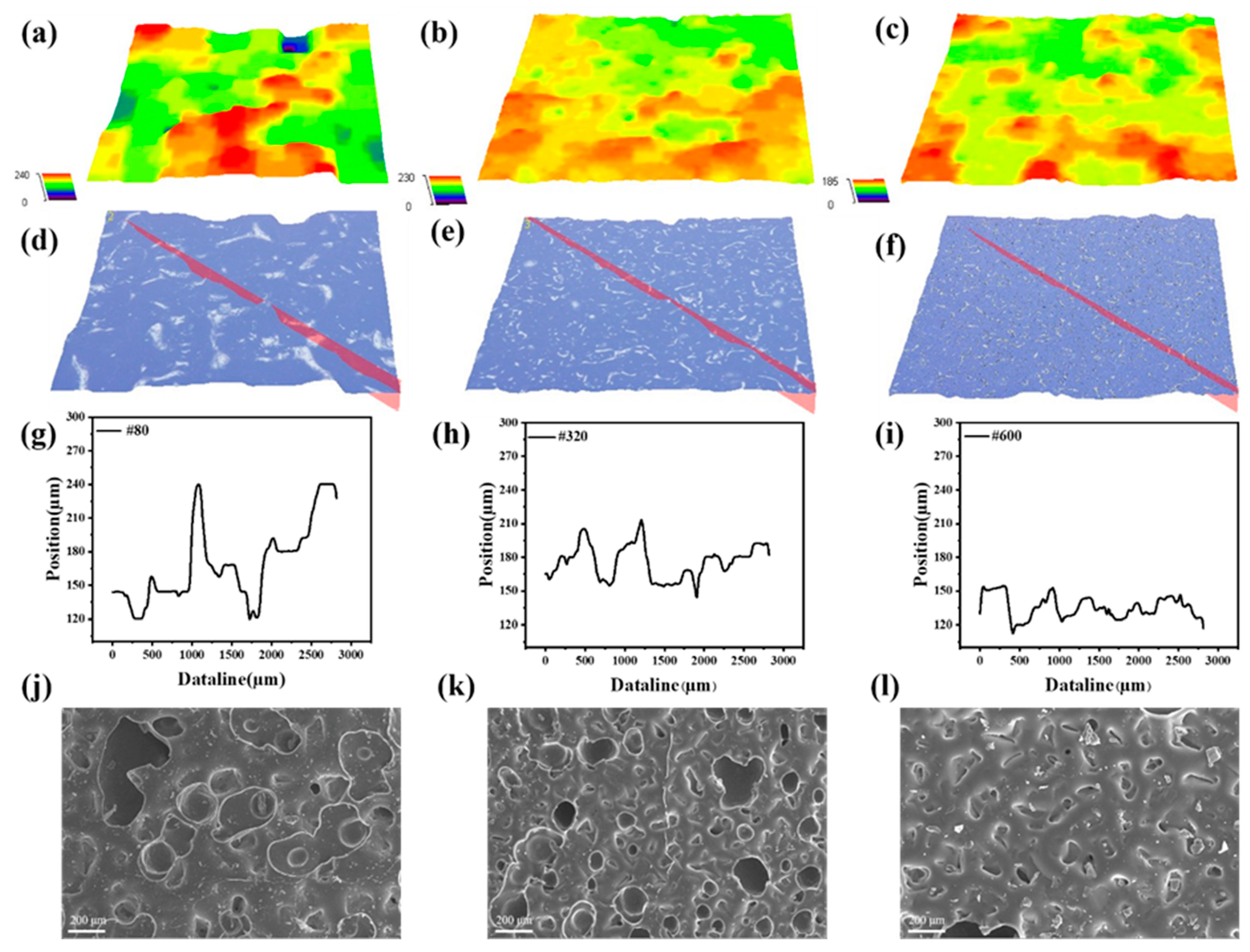

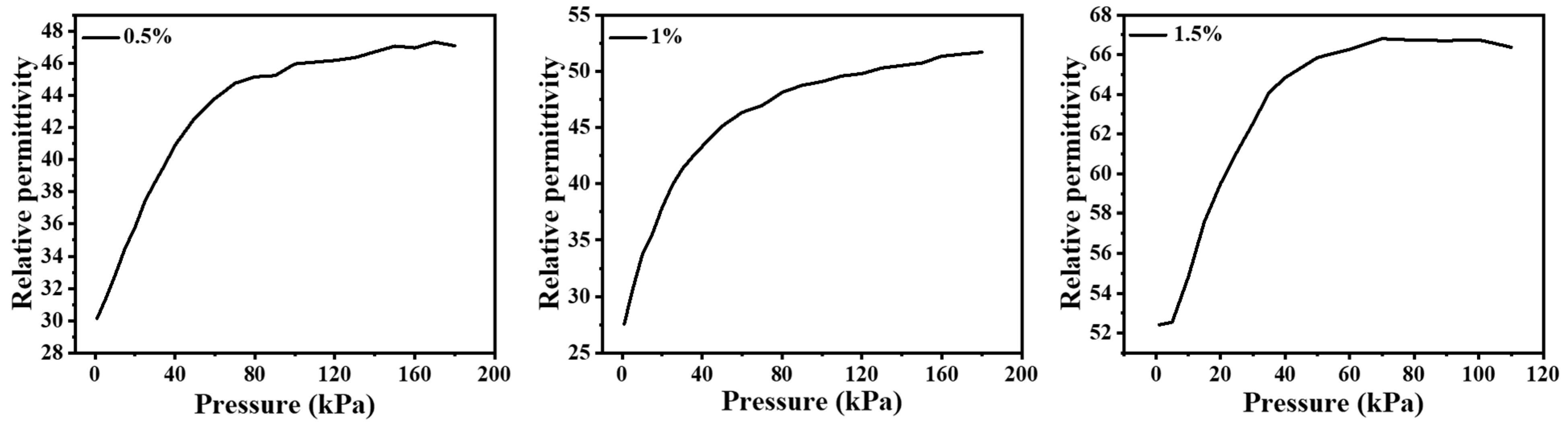

3.3. The Effect of the Mesh Number of Abrasive Papers and CNT Doping Content on the Sensing Property

3.4. Application of Spinosum Capacitive Pressure Sensor

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Bao, R.; Tao, J.; Li, J.; Dong, M.; Pan, C. Recent progress in tactile sensors and their applications in intelligent systems. Sci. Bull. 2020, 65, 70–88. [Google Scholar] [CrossRef]

- Tao, J.; Dong, M.; Li, L.; Wang, C.; Li, J.; Liu, Y.; Bao, R.; Pan, C. Real-time pressure mapping smart insole system based on a controllable vertical pore dielectric layer. Microsyst. Nanoeng. 2020, 6, 62. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wang, Z.; Zhou, H.; Guo, X.; Zhang, Y.; Wang, Y.; Liu, P.; Liu, C.; Ma, Y.; Zhang, Y. Highly sensitive pressure sensor based on structurally modified tissue paper for human physiological activity monitoring. J. Appl. Polym. Sci. 2020, 137, 48973. [Google Scholar] [CrossRef]

- Xiong, W.; Guo, D.; Yang, Z.; Zhu, C.; Huang, Y. Conformable, programmable and step-linear sensor array for large-range wind pressure measurement on curved surface. Sci. China Technol. Sci. 2020, 63, 2073–2081. [Google Scholar] [CrossRef]

- Liu, W.; Gong, L.; Yang, H. Integrated conductive rubber composites for contact deformation detection of tubular seals. Polym. Test. 2021, 96, 107089. [Google Scholar] [CrossRef]

- Xiang, X.; Li, H.; Zhu, Y.; Xia, S.; He, Q. The composite hydrogel with “ 2D flexible crosslinking point” of reduced graphene oxide for strain sensor. J. Appl. Polym. Sci. 2021, 138, 50801. [Google Scholar] [CrossRef]

- Zeng, Q.; Lai, D.; Ma, P.; Lai, X.; Zeng, X.; Li, H. Fabrication of conductive and superhydrophobic poly(lactic acid) nonwoven fabric for human motion detection. J. Appl. Polym. Sci. 2022, 139, e52453. [Google Scholar] [CrossRef]

- Lee, H.; Taheri, S. Intelligent tires? A review of tire characterization literature. IEEE Intell. Transp. Syst. Mag. 2017, 9, 114–135. [Google Scholar] [CrossRef]

- Zhu, B.; Han, J.; Zhao, J. Tire-pressure identification using intelligent tire with three-axis accelerometer. Sensors 2019, 19, 2560. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Taheri, S. A novel approach to tire parameter identification. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 233, 55–72. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Keating, T.; Todoroki, A.; Hiraoka, N. Rubber-based strain sensor fabricated using photolithography for intelligent tires. Sens. Actuators A 2008, 148, 1–9. [Google Scholar] [CrossRef]

- Son, J.-h.; Heo, D.; Song, Y.; Chung, J.; Kim, B.; Nam, W.; Hwang, P.T.J.; Kim, D.; Koo, B.; Hong, J.; et al. Highly reliable triboelectric bicycle tire as self-powered bicycle safety light and pressure sensor. Nano Energy 2022, 93, 106797. [Google Scholar] [CrossRef]

- Luo, C.L.; Jiao, J.Y.; Su, X.J.; Zheng, L.X.; Yan, W.G.; Zhong, D.Z. Interlinked microcone resistive sensors based on self-assembly carbon nanotubes film for monitoring of signals. Nanomaterials 2022, 12, 2325. [Google Scholar] [CrossRef]

- Xue, B.; Xie, H.; Zhao, J.; Zheng, J.; Xu, C. Flexible piezoresistive pressure sensor based on electrospun rough polyurethane nanofibers film for human motion monitoring. Nanomaterials 2022, 12, 723. [Google Scholar] [CrossRef]

- Su, M.; Li, P.; Liu, X.; Wei, D.; Yang, J. Textile-based flexible capacitive pressure sensors: A review. Nanomaterials 2022, 12, 1495. [Google Scholar] [CrossRef]

- Choi, J.; Kwon, D.; Kim, K.; Park, J.; Orbe, D.D.; Gu, J.; Ahn, J.; Cho, I.; Jeong, Y.; Oh, Y.; et al. Synergetic effect of porous elastomer and percolation of carbon nanotube filler toward high performance capacitive pressure sensors. ACS Appl. Mater. Interfaces 2020, 12, 1698–1706. [Google Scholar] [CrossRef]

- Mu, J.; Xian, S.; Yu, J.; Zhao, J.; Song, J.; Li, Z.; Hou, X.; Chou, X.; He, J. Synergistic enhancement properties of a flexible integrated pan/pvdf piezoelectric sensor for human posture recognition. Nanomaterials 2022, 12, 1155. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Song, J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Goh, Q.L.; Chee, P.S.; Lim, E.H.; Ng, D.W.-K. An AI-assisted and self-powered smart robotic gripper based on eco-egain nanocomposite for pick-and-place operation. Nanomaterials 2022, 12, 1317. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.-R.; Tian, Z.-Q.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Mishra, R.B.; El-Atab, N.; Hussain, A.M.; Hussain, M.M. Recent progress on flexible capacitive pressure sensors: From design and materials to applications. Adv. Mater. Technol. 2021, 6, 2001023. [Google Scholar] [CrossRef]

- Liu, S.-Y.; Lu, J.-G.; Shieh, H.-P.D. Influence of permittivity on the sensitivity of porous elastomer-based capacitive pressure sensors. IEEE Sens. J. 2018, 18, 1870–1876. [Google Scholar] [CrossRef]

- Ha, K.H.; Zhang, W.; Jang, H.; Kang, S.; Wang, L.; Tan, P.; Hwang, H.; Lu, N. Highly sensitive capacitive pressure sensors over a wide pressure range enabled by the hybrid responses of a highly porous nanocomposite. Adv. Mater. 2021, 33, e2103320. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Chen, W.; Liang, B.; Liu, C.; Yang, L.; Lu, D.; Mo, Z.; Zhu, H.; Tang, Z.; Gui, X. Capacitive pressure sensor with high sensitivity and fast response to dynamic interaction based on graphene and porous nylon networks. ACS Appl. Mater. Interfaces 2018, 10, 12816–12823. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Zhang, J.; Li, Y.; Huang, L. Flexible and high sensitive capacitive pressure sensor with microstructured electrode inspired by ginkgo leaf. J. Phys. D Appl. Phys. 2021, 54, 465401. [Google Scholar] [CrossRef]

- Wan, S.; Bi, H.; Zhou, Y.; Xie, X.; Su, S.; Yin, K.; Sun, L. Graphene oxide as high-performance dielectric materials for capacitive pressure sensors. Carbon 2017, 114, 209–216. [Google Scholar] [CrossRef]

- Yang, J.; Luo, S.; Zhou, X.; Li, J.; Fu, J.; Yang, W.; Wei, D. Flexible, tunable, and ultrasensitive capacitive pressure sensor with microconformal graphene electrodes. ACS Appl. Mater. Interfaces 2019, 11, 14997–15006. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.; Shen, Y.; Tian, L.; Hu, Y.; Zhu, P.; Sun, R.; Wong, C.-P. A flexible, ultra-highly sensitive and stable capacitive pressure sensor with convex microarrays for motion and health monitoring. Nano Energy 2020, 70, 104436. [Google Scholar] [CrossRef]

- Mannsfeld, S.C.; Tee, B.C.; Stoltenberg, R.M.; Chen, C.V.; Barman, S.; Muir, B.V.; Sokolov, A.N.; Reese, C.; Bao, Z. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, S.; Yue, W.; Zhang, C.; Li, Y. Anodized aluminum oxide-assisted low-cost flexible capacitive pressure sensors based on double-sided nanopillars by a facile fabrication method. ACS Appl. Mater. Interfaces 2019, 11, 48594–48603. [Google Scholar] [CrossRef] [PubMed]

- Pang, C.; Koo, J.H.; Nguyen, A.; Caves, J.M.; Kim, M.G.; Chortos, A.; Kim, K.; Wang, P.J.; Tok, J.B.-H.; Bao, Z. Highly skin-conformal microhairy sensor for pulse signal amplification. Adv. Mater. 2015, 27, 634–640. [Google Scholar] [CrossRef] [PubMed]

- Miller, S.; Bao, Z. Fabrication of flexible pressure sensors with microstructured polydimethylsiloxane dielectrics using the breath figures method. J. Mater. Res. 2015, 30, 3584–3594. [Google Scholar] [CrossRef]

- Lee, Y.; Park, J.; Cho, S.; Shin, Y.-E.; Lee, H.; Kim, J.; Myoung, J.; Cho, S.; Kang, S.; Baig, C.; et al. Flexible ferroelectric sensors with ultrahigh pressure sensitivity and linear response over exceptionally broad pressure range. ACS Nano 2018, 12, 4045–4054. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.; Wang, Z.; Zhang, H.; Yang, W.; Xiang, L.; Zhao, Z.; Peng, L.-M.; Hu, Y. Tunable, ultrasensitive, and flexible pressure sensors based on wrinkled microstructures for electronic skins. ACS Appl. Mater. Interfaces 2019, 11, 21218–21226. [Google Scholar] [CrossRef]

- Hwang, J.; Kim, Y.; Yang, H.; Oh, J.H. Fabrication of hierarchically porous structured PDMS composites and their application as a flexible capacitive pressure sensor. Composites Part B Eng. 2021, 211, 108607. [Google Scholar] [CrossRef]

- Yang, L.; Liu, Y.; Filipe, C.D.M.; Ljubic, D.; Luo, Y.; Zhu, H.; Yan, J.; Zhu, S. Development of a highly sensitive, broad-range hierarchically structured reduced graphene oxide/polyhipe foam for pressure sensing. ACS Appl. Mater. Interfaces 2019, 11, 4318–4327. [Google Scholar] [CrossRef]

- Li, T.; Li, Y.; Zhang, T. Materials, structures, and functions for flexible and stretchable biomimetic sensors. Acc. Chem. Res. 2019, 52, 288–296. [Google Scholar] [CrossRef]

- Menon, G.K. New insights into skin structure: Scratching the surface. Adv. Drug Deliv. Rev. 2002, 54, S3–S17. [Google Scholar] [CrossRef]

- Pang, Y.; Zhang, K.; Yang, Z.; Jiang, S.; Ju, Z.; Li, Y.; Wang, X.; Wang, D.; Jian, M.; Zhang, Y.; et al. Epidermis microstructure inspired graphene pressure sensor with random distributed spinosum for high sensitivity and large linearity. ACS Nano 2018, 12, 2346–2354. [Google Scholar] [CrossRef]

- Duan, Y.; He, S.; Wu, J.; Su, B.; Wang, Y. Recent progress in flexible pressure sensor arrays. Nanomaterials 2022, 12, 2495. [Google Scholar] [CrossRef]

- Pyo, S.; Choi, J.; Kim, J. Flexible, transparent, sensitive, and crosstalk-free capacitive tactile sensor array based on graphene electrodes and air dielectric. Adv. Electron. Mater. 2018, 4, 1700427. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, X.; Chu, R.; Wang, S.; Zeng, W.; Qu, L.; Zhao, Y.; Yan, F.; Xing, G. Rapid-response, low detection limit, and high-sensitivity capacitive flexible tactile sensor based on three-dimensional porous dielectric layer for wearable electronic skin. ACS Appl. Mater. Interfaces 2019, 11, 40716–40725. [Google Scholar] [CrossRef] [PubMed]

- Mahata, C.; Algadi, H.; Lee, J.; Kim, S.; Lee, T. Biomimetic-inspired micro-nano hierarchical structures for capacitive pressure sensor applications. Measurement 2020, 151, 107095. [Google Scholar] [CrossRef]

- Pignanelli, J.; Schlingman, K.; Carmichael, T.B.; Rondeau-Gagné, S.; Ahamed, M.J. A comparative analysis of capacitive-based flexible PDMS pressure sensors. Sens. Actuators A 2019, 285, 427–436. [Google Scholar] [CrossRef]

- Kim, J.; Chou, E.F.; Le, J.; Wong, S.; Chu, M.; Khine, M. Soft wearable pressure sensors for beat-to-beat blood pressure monitoring. Adv. Healthc Mater. 2019, 8, e1900109. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.; Wang, H.; Yang, W. Variable percolation threshold of composites with fiber fillers under compression. J. Appl. Phys. 2010, 108, 013509. [Google Scholar] [CrossRef]

| Dielectric Layer | Materials | Sensing Range (kPa) | Sensitivity (kPa−1) | Response Time (ms) | Ref |

|---|---|---|---|---|---|

| pillars | SU8 | 0–30 | 0.0065 | 70 | [41] |

| porous | PS/graphene/MWCNTs | 0–4.5 | 0.062 | 45 | [42] |

| microdome | PDMS | 0.5–10 | 0.055 | 200 | [43] |

| pyramid | PDMS | 0.5–6 | 0.185 | - | [44] |

| microridge | PDMS | 0–10 | 0.148 | 20 | [45] |

| spinosum | CNT/PDMS | 0–500 | 0.25 | 20 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Y.; Wu, J.; He, S.; Su, B.; Li, Z.; Wang, Y. Bioinspired Spinosum Capacitive Pressure Sensor Based on CNT/PDMS Nanocomposites for Broad Range and High Sensitivity. Nanomaterials 2022, 12, 3265. https://doi.org/10.3390/nano12193265

Duan Y, Wu J, He S, Su B, Li Z, Wang Y. Bioinspired Spinosum Capacitive Pressure Sensor Based on CNT/PDMS Nanocomposites for Broad Range and High Sensitivity. Nanomaterials. 2022; 12(19):3265. https://doi.org/10.3390/nano12193265

Chicago/Turabian StyleDuan, Yanhao, Jian Wu, Shixue He, Benlong Su, Zhe Li, and Youshan Wang. 2022. "Bioinspired Spinosum Capacitive Pressure Sensor Based on CNT/PDMS Nanocomposites for Broad Range and High Sensitivity" Nanomaterials 12, no. 19: 3265. https://doi.org/10.3390/nano12193265

APA StyleDuan, Y., Wu, J., He, S., Su, B., Li, Z., & Wang, Y. (2022). Bioinspired Spinosum Capacitive Pressure Sensor Based on CNT/PDMS Nanocomposites for Broad Range and High Sensitivity. Nanomaterials, 12(19), 3265. https://doi.org/10.3390/nano12193265