Wall Insulation Materials in Different Climate Zones: A Review on Challenges and Opportunities of Available Alternatives

Abstract

:1. Introduction

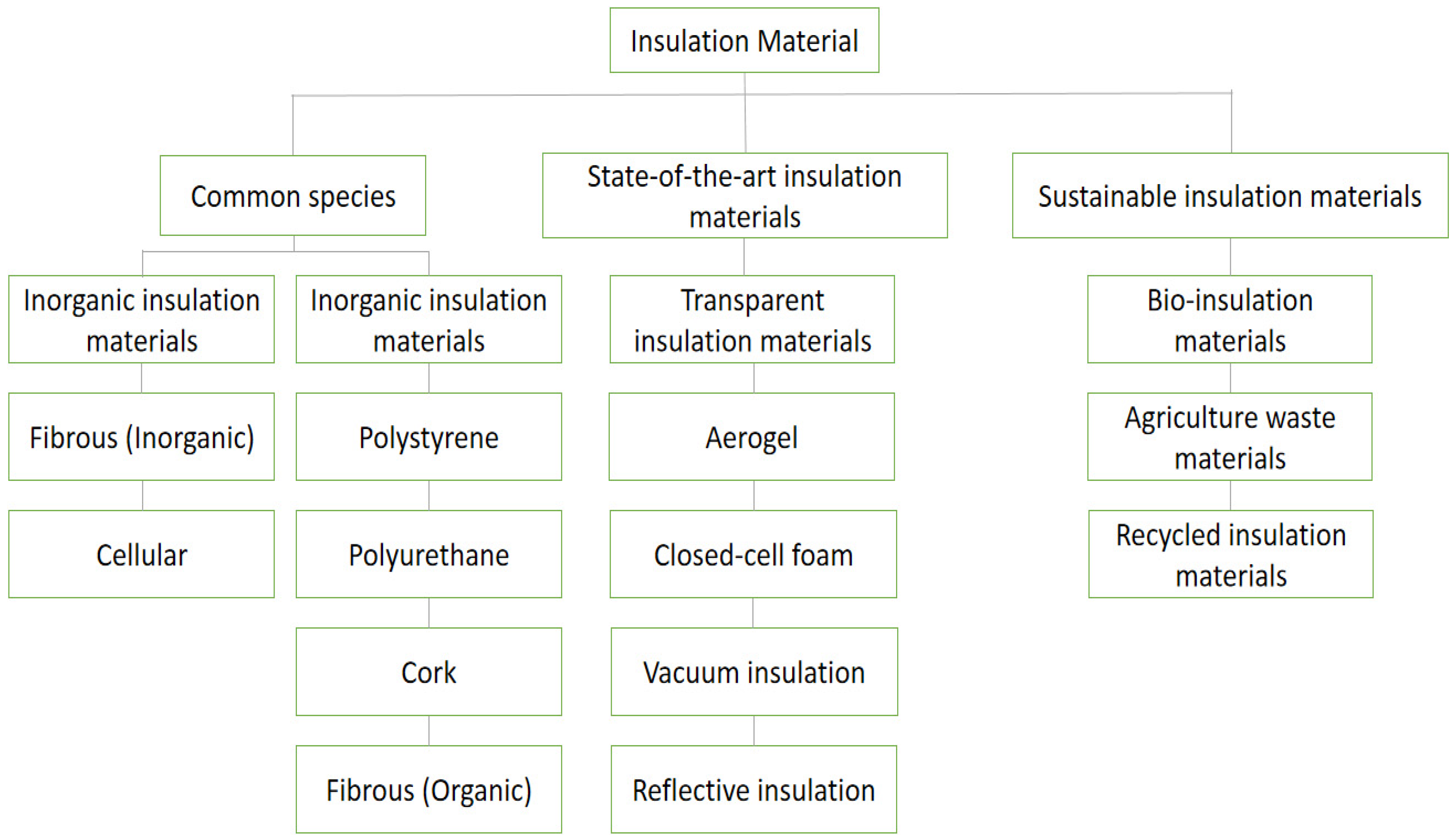

2. Types of Insulation Materials

2.1. Inorganic Insulation Materials

2.1.1. Inorganic Fibrous

2.1.2. Cellular

2.2. Organic Insulation Materials

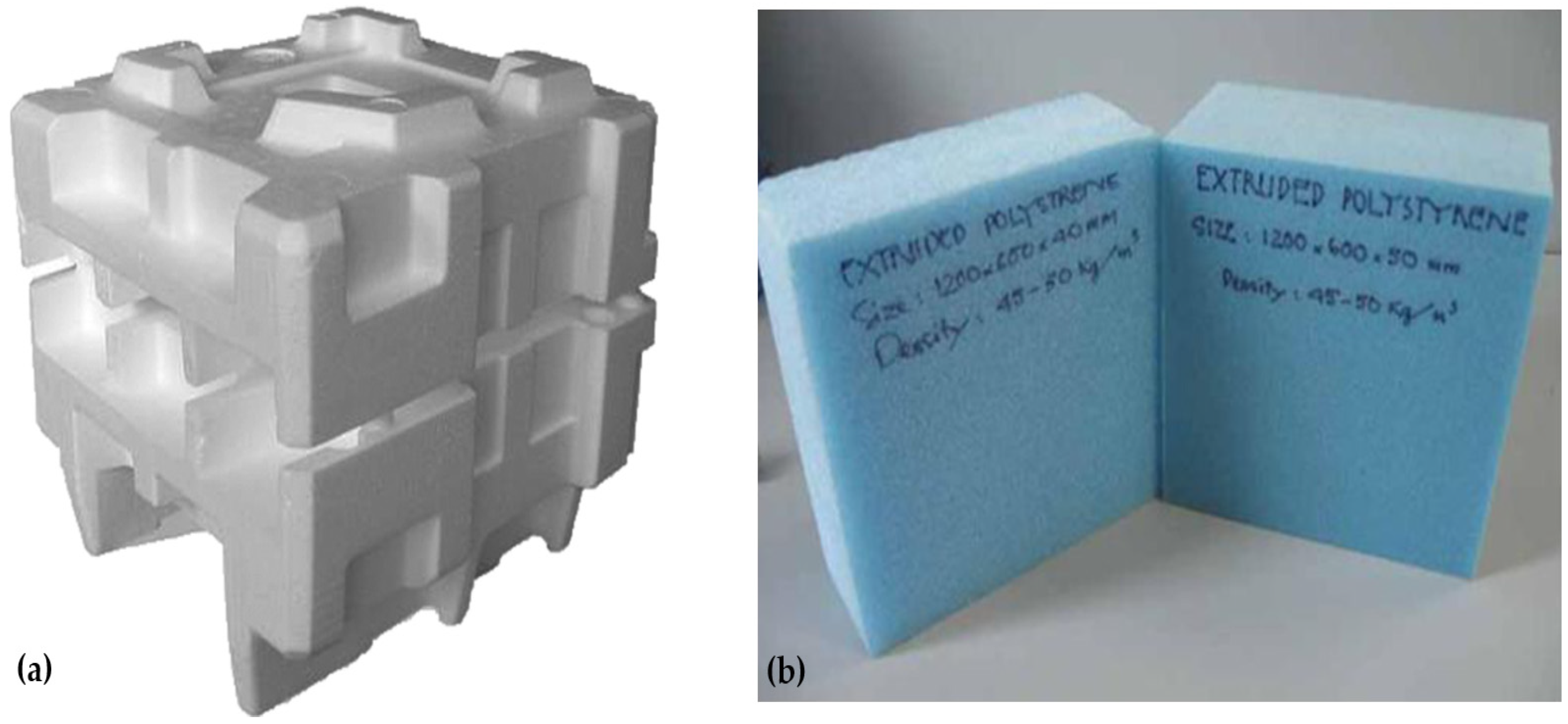

2.2.1. Polystyrene

- Expanded polystyrene (EPS)

- Extruded polystyrene (XPS)

2.2.2. Polyurethane (PUR)

2.2.3. Cork

2.2.4. Organic Fibrous

- Cellulose

- Sheep Wool Insulation Materials

2.3. State-of-the-Art Insulation Materials

2.3.1. Transparent Insulation Materials (TIMs)

2.3.2. Aerogel

2.3.3. Closed-Cell Foam

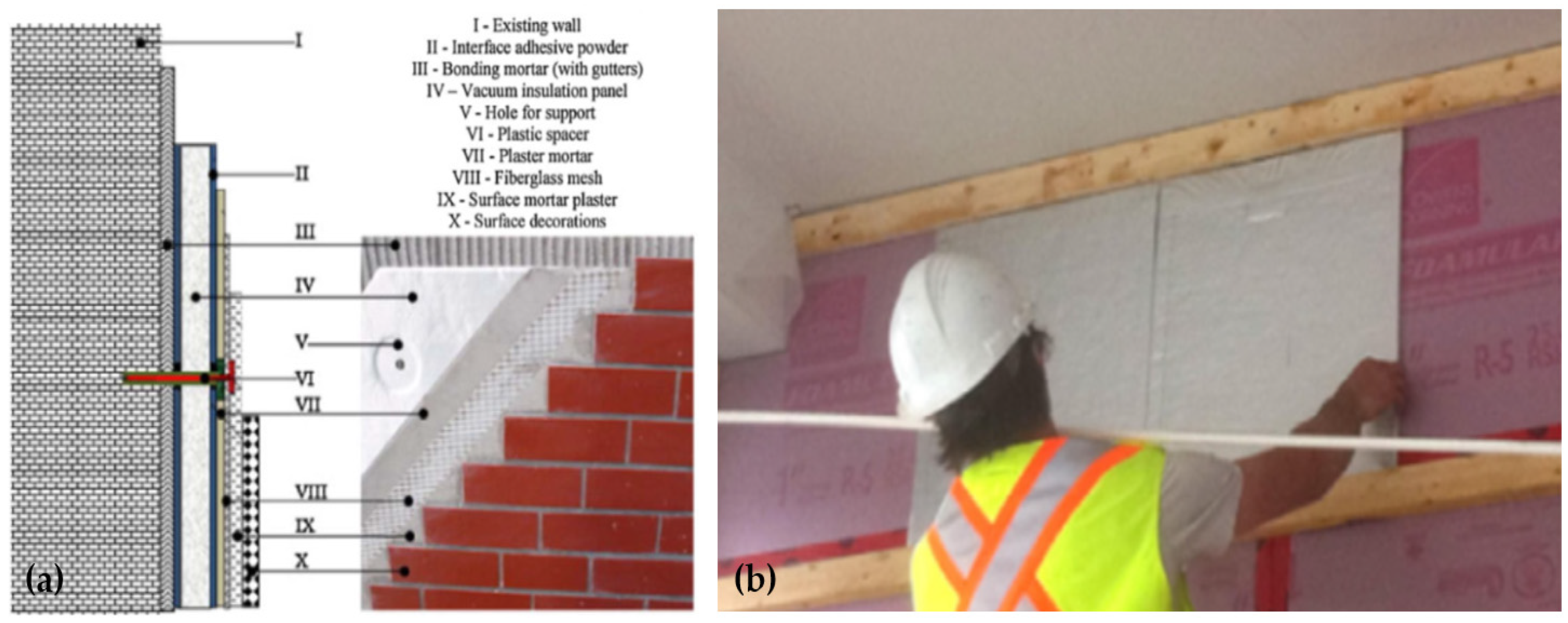

2.3.4. Vacuum Insulation

2.3.5. Reflective Insulation

2.4. Sustainable Insulation Materials

2.4.1. Bio-Insulation Materials

2.4.2. Agriculture Waste Materials

2.4.3. Recycled Insulation Materials

3. Suitable Insulation Materials for Different Climates

3.1. East Asia

3.1.1. Japan

3.1.2. China

3.2. The Middle East

3.2.1. Iran

3.2.2. Turkey

3.3. North America

3.3.1. Canada

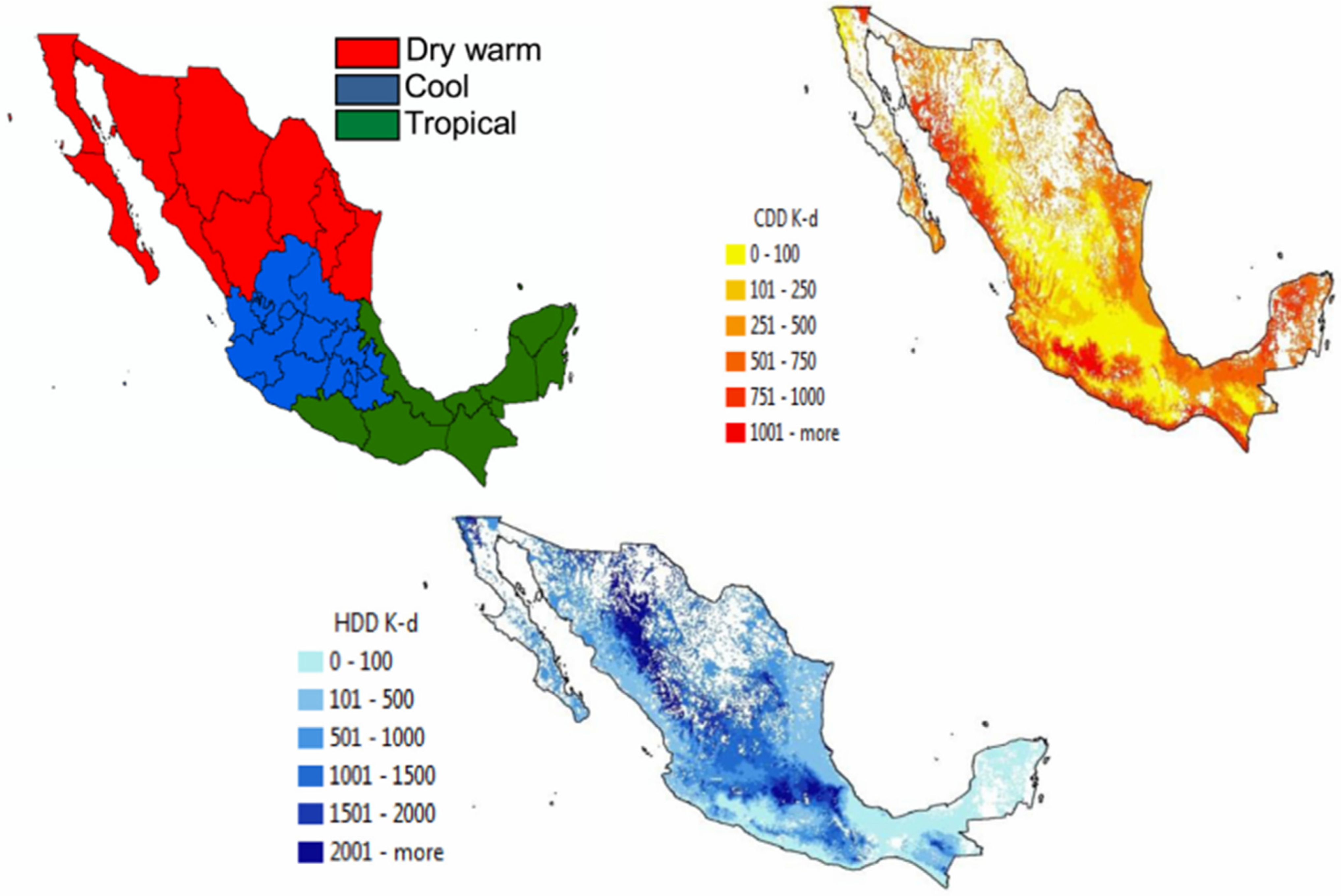

3.3.2. Mexico

3.4. South America

Brazil

3.5. Europe

3.6. Australia

3.7. Summary

- The OTR of thermal insulating materials drops substantially in climates where the temperature range between summer and winter is higher, but their payback period will be shorter. The effect of saving energy will be more noticeable as the thermal insulation layer thickness rises.

- Reflective insulation can be utilised in hot, sunny climates to further reduce energy use, as is already the case in Iran and the Middle East. Additionally, roof insulation is frequently used in hotter, more arid climates.

- Researchers have frequently examined the optimum insulation material thickness for the commonly used insulation materials in various climatic zones within a specific country or region. Chinese scientists, for instance, tested the optimum EPS of representative cities in temperate continental climate (Urumqi), temperate monsoon climate (Beijing), and subtropical monsoon climate (Shanghai), and found that the best EPS thickness in these areas is 216 mm, 205 mm, and 175 mm, respectively. The average annual cost can be significantly decreased while also enhancing the economy and environmental protection by designing the optimal thickness for various climatic types.

- In temperate areas, wood-fibre multifunctional panels can be utilised for south-facing external walls for enhanced heat resistance, whereas north-facing exterior walls in cold climates can use XPS multifunctional panels.

- Due to the wide temperature range between climate zones, it is essential to consider the linear relationship between temperature and thermal conductivity when designing external wall insulation materials. Low temperatures will decrease the thermal conductivity of inorganic and petrochemical insulation materials.

- In savannah climate regions, such as the central and western parts of Brazil, rock wool and glass wool insulation materials are typically used. This increases individual thermal comfort and satisfaction. Additionally, the service life of these two types of insulation materials is generally higher than that of EPS in these climate regions.

- Some European countries prefer to use recycled plastic, foam board, and other insulating materials that have superior hydrophilicity, fire resistance, and stability due to the Mediterranean climate, which is typically hot and dry in the summer and mild and rainy in the winter.

- Aerogel and PCMS are being used as exterior wall insulation materials in countries with predominantly temperate marine climates to save energy and improve indoor comfort levels. These countries also use wall plants as insulation, keeping the interior cool in the summer and warm in the winter.

- Different types and thicknesses of insulation materials are normally not selected in areas that experience slight climatic variations. Instead, these countries frequently focus on past design practices and the cost-effectiveness of insulation when designing insulated facades.

4. Current Challenges and Opportunities

- Studies have revealed that conventional lightweight building envelopes often disregard the characteristics of heat capacity, which can increase the risk of interior overheating in mild and warm climates. In such cases, specific ventilation techniques as well as high thermal resistance façades are recommended to manage indoor air temperature [102,103].

- Following the relevant building energy conservation design standards, finding the proper thermal insulation materials in various climate zones and promoting the innovation of external wall thermal insulation structure technology can ensure the realisation of building energy conservation goals. This is because the requirements for building energy conservation around the world are rising.

- As the thermo-physical characteristics of dynamic insulations will vary with environmental circumstances, they should be developed and used in building envelopes in the future to prevent the adverse impacts of diurnal and seasonal variations.

- Phase change material (PCM) exterior wall insulations are excellent for usage in mild and warm regions because they absorb and store heat in large quantities, preventing overheating [104,105]. The prior studies indicate that, however, there is still a lack of applicable research on how to introduce PCM into exterior wall insulation materials and ensure their rigidity and durability.

- Although previous studies have conducted lots of research on exterior wall insulation materials in various climate zones, it should go through the whole process of the planning layout as well as the design of buildings’ components. In order to obtain the best outcomes from the architectural envelope design, it is still required to test and refine the current approaches.

- Future research should prioritise the volume heat capacity of wall insulation materials in addition to their durability, thermal resistance, thermal conductivity, as well as sustainability-related concerns.

- In addition to providing superior insulating performance, insulation materials also need to focus on other qualities like affordability and environmental issues, especially carbon emissions. To replace non-renewable energy sources in various climate zones, it is also possible to introduce solar energy as a renewable energy source; for instance, building envelopes in building integrated photovoltaics (BIPV) [106,107,108].

- More new advanced technologies can be offered by the developed countries for the development of thermal insulation materials due to the better economic status of these industrialised countries. Developing countries are also encouraged to focus on thermal insulation materials are encouraged to assist in updating the relevant policies to facilitate the promotion of energy conservation and emission reduction targets in the building and construction sector.

5. Conclusions

- Thermal conductivity is the most crucial factor since it influences the thermal insulation effect of materials. Using materials with lower thermal conductivity can help reduce the thickness of the external wall insulation layer while still providing the same energy saving. At the end of the life cycle, recycling rates should also be improved.

- The second key factor is the durability of the material. Bio-insulations and recycled insulating materials have varying degrees of durability; In high-humidity climates, mildew and insects may harm biomass materials used as insulation. The review has shown that traditional thermal insulation materials, such as EPS and XPS, typically are of acceptable durability. However, new sustainable materials, such as recycled materials, wool, bio-mass materials, etc., contain organic components, which are prone to mildew, corrosion and insects. Vacuum insulation panels also need improved materials to prevent air leakage. Future research on durability aspects is required as a result.

- The service life and the thermal insulation effects can also make users unsatisfied. For arid environments, the fire resistance property cannot be ignored. Some traditional thermal insulation materials, like EPS, glass wool, rock wool, and polyurethane, offer much better fire resistance than sustainable materials. Sustainable insulations, however, can be used in combination with other materials to improve refractory performance, although they may lose their economic advantage.

- Temperature, humidity, and sunlight intensity are three factors affecting the suitability of insulation materials in various climates. When the temperature fluctuates, the thermal conductivity of some compounds changes. Foam insulation materials like polyisocyanurate, for instance, have a particular conductivity; they are not recommended to be used if the temperature difference between day and night is high, or the temperature variation between seasons is large. Insulation materials, like bio-insulations and recycled materials, are also more sensitive to humidity. In high-humidity conditions, mildew is easily formed, affecting the material’s performance. Such sensitive materials are not recommended for external wall insulation in high-humidity environments. It is also suggested that in severe sunlight and high-temperature areas, reflective materials should be employed on buildings’ roofs and walls to isolate the radiant heat transfer to the interior space.

- A new form of phase-change thermal insulation material has recently emerged. PCM thermal insulation materials are used to self-adapt to the indoor temperature in order to achieve a more comfortable indoor ambient temperature due to the indoor overheating problem caused by traditional building materials with low heat transfer coefficients.

- Future developments should be directed towards sustainable and high-performance insulation materials. At this stage, recycled materials still have a lot of issues, like unstable performance, insufficient strength, and short life, that must be addressed. The overall cost of high-performance materials needs to be reduced while their service life is extended. The utilization of phase change exterior thermal insulation materials will also be the future development trend. Besides, efforts should be continued to develop materials with lower thermal conductivity while also focusing on sustainability aspects. From the literature, it has been found that some sustainable materials have the same thermal insulation effect as traditional thermal insulation materials, indicating that it is essential to investigate how to improve the durability and suitability of sustainable insulation materials so that they can be widely used in buildings.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASTM | American society for testing and materials |

| BIPV | Building integrated photovoltaics |

| CED | Cumulative energy demand |

| ECS | Energy cost saving |

| EP | Eutrophication |

| EPS | Expanded polystyrene |

| EU | European Union |

| GSA | Granular silica aerogel |

| GWP | Global warming potential |

| HCN | Hydrogen cyanide |

| ISO | International organisation for standardisation |

| LCA | Life cycle assessment |

| LNG | Liquefied natural gas |

| OTR | Optimal thermal resistance |

| PCM | Phase change material |

| POCP | Photochemical oxidant formation |

| PP | Payback period |

| PSi | Polyimide-silica |

| PUR | Polyurethane |

| TIM | Transparent insulation material |

| UNFCCC | United Nations framework convention on climate change |

| XPS | Extruded polystyrene |

References

- Abu-Jdayil, B.; Mourad, A.H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Mousavi, S.; Rismanchi, B.; Brey, S.; Aye, L. Lessons learned from PCM embedded radiant chilled ceiling experiments in Melbourne. Energy Rep. 2022, 8, 54–61. [Google Scholar] [CrossRef]

- Vivek, A.; Chandan Swaroop, M.; Ashok, K.; Tabish, A.; Anuj, K.; Arijit, G.; Aritra, G. Potential and future prospects of geothermal energy in space conditioning of buildings: India and worldwide review. Sustainability 2020, 12, 8428. [Google Scholar]

- Rahimpour, Z.; Verbic, G.; Chapman, A.C. Can phase change materials in building insulation improve self-consumption of residential rooftop solar? An Australian case study. Renew. Energy 2022, 192, 24–32. [Google Scholar] [CrossRef]

- Schiavoni, S.; D׳Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Fragkos, P.; Tasios, N.; Paroussos, L.; Capros, P.; Tsani, S.J.E.P. Energy system impacts and policy implications of the European intended Nationally Determined Contribution and low-carbon pathway to 2050. Energy Policy 2017, 100, 216–226. [Google Scholar] [CrossRef]

- Mousavi, S.; Rismanchi, B.; Brey, S.; Aye, L. PCM embedded radiant chilled ceiling: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 151, 111601. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Jin, L.W.; Wang, Z.N.; Zhang, J.Y.; Liu, X.; Zhang, L.H. Effects of wall configuration on building energy performance subject to different climatic zones of China. Appl. Energy 2017, 185, 1565–1573. [Google Scholar] [CrossRef]

- Wati, E.; Meukam, P.; Nematchoua, M.K. Influence of external shading on optimum insulation thickness of building walls in a tropical region. Appl. Therm. Eng. 2015, 90, 754–762. [Google Scholar] [CrossRef] [Green Version]

- Pisello, A.L.; Castaldo, V.L.; Pignatta, G.; Cotana, F.; Santamouris, M. Experimental in-lab and in-field analysis of waterproof membranes for cool roof application and urban heat island mitigation. Energy Build. 2016, 114, 180–190. [Google Scholar] [CrossRef]

- Huang, H.; Zhou, Y.; Huang, R.; Wu, H.; Sun, Y.; Huang, G.; Xu, T. Optimum insulation thicknesses and energy conservation of building thermal insulation materials in Chinese zone of humid subtropical climate. Sustain. Cities Soc. 2020, 52, 101840. [Google Scholar] [CrossRef]

- Yuan, J.; Farnham, C.; Emura, K. Optimal combination of thermal resistance of insulation materials and primary fuel sources for six climate zones of Japan. Energy Build. 2017, 153, 403–411. [Google Scholar] [CrossRef]

- Zhu, P.; Huckemann, V.; Fisch, M.N. The optimum thickness and energy saving potential of external wall insulation in different climate zones of China. Procedia Eng. 2011, 21, 608–616. [Google Scholar] [CrossRef] [Green Version]

- Rosas-Flores, J.A.; Rosas-Flores, D. Potential energy savings and mitigation of emissions by insulation for residential buildings in Mexico. Energy Build. 2020, 209, 109698. [Google Scholar] [CrossRef]

- Berardi, U. The impact of temperature dependency of the building insulation thermal conductivity in the Canadian climate. Energy Procedia 2017, 132, 237–242. [Google Scholar] [CrossRef]

- Emeli Lalesca Aparecida da, G.; Elaise, G.; Renata Mansuelo Alves, D.; Luciane Cleonice, D.; Ivan Julio Apolonio, C.; João Carlos Machado, S.; Karyna de Andrade Carvalho, R. Adaptive comfort assessment for different thermal insulations for building envelope against the effects of global warming in the mid-western Brazil. IOP Conf. Ser. Earth Environ. Sci. 2019, 329, 012057. [Google Scholar] [CrossRef]

- Mueller, A. Recycling mineral wool waste-technologies for the conservation of fiber structure. InterCeram Int. Ceram. Rev. 2009, 58, 378–381. [Google Scholar]

- Kumar, D.; Alam, M.; Zou, P.X.; Sanjayan, J.G.; Memon, R.A. Comparative analysis of building insulation material properties and performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Fangueiro, R. Fibrous Composite Materials for Civil Engineering Applications; Woodhead Publishing Limited: Philadelphia, PA, USA, 2011. [Google Scholar]

- Villasmil, W.; Fischer, L.J.; Worlitschek, J. A review and evaluation of thermal insulation materials and methods for thermal energy storage systems. Renew. Sustain. Energy Rev. 2019, 103, 71–84. [Google Scholar] [CrossRef]

- Tatematsu, K.; Hirota, T.; Suzuki, H.; Taniguchi, M.; Nunoi, Y.; Uzawa, T. Influence of temperature and moisture on aging of glass wool. J. Environ. Eng. 2014, 79, 753–762. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Liu, T. Development and application status of glass wool, rock wool, and ceramic wool. In Thermal Insulation and Radiation Control Technologies for Buildings; Springer: Berlin/Heidelberg, Germany, 2022; pp. 129–161. [Google Scholar]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Toward aerogel based thermal superinsulation in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Zukowski, M.; Haese, G. Experimental and numerical investigation of a hollow brick filled with perlite insulation. Energy Build. 2010, 42, 1402–1408. [Google Scholar] [CrossRef]

- Gao, H.; Liu, H.; Liao, L.; Mei, L.; Shuai, P.; Xi, Z.; Lv, G. A novel inorganic thermal insulation material utilizing perlite tailings. Energy Build. 2019, 190, 25–33. [Google Scholar] [CrossRef]

- Lakatos, A.; Kalmár, F. Analysis of water sorption and thermal conductivity of expanded polystyrene insulation materials. Build. Serv. Eng. Res. Technol. 2013, 34, 407–416. [Google Scholar] [CrossRef]

- Demirel, B. Optimization of the composite brick composed of expanded polystyrene and pumice blocks. Constr. Build. Mater. 2013, 40, 306–313. [Google Scholar] [CrossRef]

- Vo, C.V.; Bunge, F.; Duffy, J.; Hood, L. Advances in thermal insulation of extruded polystyrene foams. Cell. Polym. 2011, 30, 137–156. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.-W.; Sung, W.-F.; Chu, H.-S. Thermal conductivity of polyurethane foams. Int. J. Heat Mass Transf. 1999, 42, 2211–2217. [Google Scholar] [CrossRef]

- Asdrubali, F.; Schiavoni, S.; Horoshenkov, K.V. A review of sustainable materials for acoustic applications. Build. Acoust. 2012, 19, 283–312. [Google Scholar] [CrossRef]

- Hurtado, P.L.; Rouilly, A.; Vandenbossche, V.; Raynaud, C. A review on the properties of cellulose fibre insulation. Build. Environ. 2016, 96, 170–177. [Google Scholar] [CrossRef] [Green Version]

- Kwon, Y.C.; Yarbrough, D.W. A comparison of Korean cellulose insulation with cellulose insulation manufactured in the United States of America. J. Build. Phys. 2004, 27, 185–197. [Google Scholar] [CrossRef]

- Semitekolos, D.; Pardou, K.; Georgiou, P.; Koutsouli, P.; Bizelis, I.; Zoumpoulakis, L. Investigation of mechanical and thermal insulating properties of wool fibres in epoxy composites. Polym. Polym. Compos. 2021, 29, 1412–1421. [Google Scholar] [CrossRef]

- Florea, I.; Manea, D.L. Analysis of thermal insulation building materials based on natural fibers. Procedia Manuf. 2019, 32, 230–235. [Google Scholar] [CrossRef]

- Korjenic, A.; Klaric, S.; Hadžic, A.; Korjenic, S. Sheep wool as a construction material for energy efficiency improvement. Energies 2015, 8, 5765–5781. [Google Scholar] [CrossRef] [Green Version]

- Paneri, A.; Wong, I.L.; Burek, S. Transparent insulation materials: An overview on past, present and future developments. Sol. Energy 2019, 184, 59–83. [Google Scholar] [CrossRef] [Green Version]

- Wong, I.L.; Eames, P.C.; Perera, R.S. A review of transparent insulation systems and the evaluation of payback period for building applications. Sol. Energy 2007, 81, 1058–1071. [Google Scholar] [CrossRef]

- Gao, T.; Jelle, B.P.; Ihara, T.; Gustavsen, A. Insulating glazing units with silica aerogel granules: The impact of particle size. Appl. Energy 2014, 128, 27–34. [Google Scholar] [CrossRef]

- Zhuang, J.; Ghaffar, S.H.; Fan, M.; Corker, J. Restructure of expanded cork with fumed silica as novel core materials for vacuum insulation panels. Compos. Part B Eng. 2017, 127, 215–221. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Belloni, E.; Agosti, F. Development of innovative aerogel based plasters: Preliminary thermal and acoustic performance evaluation. Sustainability 2014, 6, 5839–5852. [Google Scholar] [CrossRef] [Green Version]

- Murphy, J. Long-term aging of closed-celled foam insulation. Cell. Polym. 2010, 29, 313–326. [Google Scholar] [CrossRef]

- Fujimoto, H. High Thermal Insulation Technology Contributing to Residential Energy Saving; NISTEP Science & Technology Foresight Center: Tokyo, Japan, 2009. [Google Scholar]

- Fricke, J.; Heinemann, U.; Ebert, H.P. Vacuum insulation panels—From research to market. Vacuum 2008, 82, 680–690. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Chen, Z.; Yang, Z.; Hu, J.; Yang, Y.; Chang, L.; Lee, L.J.; Xu, T. Preparation and characterization of vacuum insulation panels with super-stratified glass fiber core material. Energy 2015, 93, 945–954. [Google Scholar] [CrossRef]

- Katsura, T.; Memon, S.; Radwan, A.; Nakamura, M.; Nagano, K. Thermal performance analysis of a new structured-core translucent vacuum insulation panel in comparison to vacuum glazing: Experimental and theoretically validated analyses. Sol. Energy 2020, 199, 326–346. [Google Scholar] [CrossRef]

- Di, X.; Xie, Z.G.; Chen, J.; Zheng, S. Residual gas analysis in vacuum insulation panel (VIP) with glass fiber core and investigation of getter for VIP. Build. Environ. 2020, 186, 107337. [Google Scholar] [CrossRef]

- Mao, S.; Kan, A.; Zhu, W.; Yuan, Y. The impact of vacuum degree and barrier envelope on thermal property and service life of vacuum insulation panels. Energy Build. 2020, 209, 109699. [Google Scholar] [CrossRef]

- Liang, Y.; Wu, H.; Huang, G.; Yang, J.; Wang, H. Thermal performance and service life of vacuum insulation panels with aerogel composite cores. Energy Build. 2017, 154, 606–617. [Google Scholar] [CrossRef]

- Aditya, L.; Mahlia, T.; Rismanchi, B.; Ng, H.; Hasan, M.; Metselaar, H.; Muraza, O.; Aditiya, H. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Mukhopadhyaya, P.; MacLean, D.; Korn, J.; Van Reenen, D.; Molleti, S. Building application and thermal performance of vacuum insulation panels (VIPs) in Canadian subarctic climate. Energy Build. 2014, 85, 672–680. [Google Scholar] [CrossRef] [Green Version]

- Reflective Insulation Manufacturers Association. Understanding and Using Reflective Insulation, Radiant Barriers and Radiation Control Coatings; Reflective Insulation Manufacturers Association: Phoenix, AZ, USA, 2002. [Google Scholar]

- Lee, S.W.; Lim, C.H.; Salleh, E.I.B. Reflective thermal insulation systems in building: A review on radiant barrier and reflective insulation. Renew. Sustain. Energy Rev. 2016, 65, 643–661. [Google Scholar] [CrossRef]

- Pourghorban, A.; Kari, B.M.; Asoodeh, H. Holistic survey of reflective insulation systems (RISs) in vertical applications in building envelopes under various climatic conditions. Energy 2022, 242, 122959. [Google Scholar] [CrossRef]

- Malz, S.; Steininger, P.; Dawoud, B.; Krenkel, W.; Steffens, O. On the development of a building insulation using air layers with highly reflective interfaces. Energy Build. 2021, 236, 110779. [Google Scholar] [CrossRef]

- Baharetha, S.M.; Al-Hammad, A.A.; Alshuwaikhat, H.M. Towards a unified set of sustainable building materials criteria. In ICSDEC 2012: Developing the Frontier of Sustainable Design, Engineering, and Construction, Proceedings of the 2012 International Conference on Sustainable Design and Construction; American Society of Civil Engineers (ASCE): Reston, Virginia, 14 November 2012; pp. 732–740. [Google Scholar]

- Li, Z.; Gong, X.Z.; Wang, Z.H.; Liu, Y. Life cycle assessment of external thermal insulation composite system based on rock wool board. Key Eng. Mater. 2014, 599, 315–318. [Google Scholar]

- Hidalgo, J.P.; Welch, S.; Torero, J.L. Performance criteria for the fire safe use of thermal insulation in buildings. Constr. Build. Mater. 2015, 100, 285–297. [Google Scholar] [CrossRef]

- Tye, R. Heat transmission in cellulosic fiber insulation materials. J. Test. Eval. 1974, 2, 176–179. [Google Scholar]

- Mokhtar, A.; Hassan, K.; Aziz, A.A.; Wahid, M. Plywood from oil palm trunks. J. Oil Palm Res. 2011, 23, 1159–1165. [Google Scholar]

- Abdullah, C.K.; Jawaid, M.; Khalil, H.A.; Zaidon, A.; Hadiyane, A. Oil palm trunk polymer composite: Morphology, water absorption, and thickness swelling behaviours. BioResources 2012, 7, 2948–2959. [Google Scholar]

- Aizat, A.; Zaidon, A.; Nabil, F.; Bakar, E.; Rasmina, H. Effects of diffusion process and compression on polymer loading of laminated compreg oil palm (elaeis guineensis) wood and its relation to properties. J. Biobased Mater. Bioenergy 2014, 8, 519–525. [Google Scholar] [CrossRef]

- Baskaran, M.; Azmi, N.A.C.H.; Hashim, R.; Sulaiman, O. Properties of binderless particleboard and particleboard with addition of urea formaldehyde made from oil palm trunk waste. J. Phys. Sci. 2017, 28, 151–159. [Google Scholar] [CrossRef] [Green Version]

- Nuryawan, A.; Abdullah, C.; Hazwan, C.M.; Olaiya, N.; Yahya, E.B.; Risnasari, I.; Masruchin, N.; Baharudin, M.; Khalid, H.; Abdul Khalil, H. Enhancement of oil palm waste nanoparticles on the properties and characterization of hybrid plywood biocomposites. Polymers 2020, 12, 1007. [Google Scholar] [CrossRef]

- Chin, K. Mechanical and physical properties of oil palm trunk core particleboard bonded with different UF resins. J. Oil Palm Res. 2014, 26, 163–169. [Google Scholar]

- Liu, L.; Zou, S.; Li, H.; Deng, L.; Bai, C.; Zhang, X.; Wang, S.; Li, N. Experimental physical properties of an eco-friendly bio-insulation material based on wheat straw for buildings. Energy Build. 2019, 201, 19–36. [Google Scholar] [CrossRef]

- Mawardi, I.; Aprilia, S.; Faisal, M.; Ikramullah; Rizal, S. An investigation of thermal conductivity and sound absorption from binderless panels made of oil palm wood as bio-insulation materials. Results Eng. 2022, 13, 100319. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, B.; Riaz Ahmad, M. Characterization of a novel bio-insulation material for multilayer wall and research on hysteresis effect. Constr. Build. Mater. 2021, 290, 123162. [Google Scholar] [CrossRef]

- Wang, S.; Li, H.; Zou, S.; Zhang, G. Experimental research on a feasible rice husk/geopolymer foam building insulation material. Energy Build. 2020, 226, 110358. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Grillet, A.C.; Diep, T.M.H.; Do, T.V.V.; Thuc, C.N.H.; Woloszyn, M. Hygric and thermal insulation properties of building materials based on bamboo fibers. In Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2018; Volume 8, pp. 508–522. [Google Scholar]

- Ramos, A.; Briga-Sá, A.; Pereira, S.; Correia, M.; Pinto, J.; Bentes, I.; Teixeira, C.A. Thermal performance and life cycle assessment of corn cob particleboards. J. Build. Eng. 2021, 44, 102998. [Google Scholar] [CrossRef]

- Do, N.H.N.; Tran, V.T.; Tran, Q.B.M.; Le, K.A.; Thai, Q.B.; Nguyen, P.T.T.; Duong, H.M.; Le, P.K. Recycling of pineapple leaf and cotton waste fibers into heat-insulating and flexible cellulose aerogel composites. J. Polym. Environ. 2021, 29, 1112–1121. [Google Scholar] [CrossRef]

- Gaujena, B.; Agapovs, V.; Borodinecs, A.; Strelets, K. Analysis of thermal parameters of hemp fiber insulation. Energies 2020, 13, 6385. [Google Scholar] [CrossRef]

- Do, N.H.N.; Le, T.M.; Tran, H.Q.; Pham, N.Q.; Le, K.A.; Nguyen, P.T.T.; Duong, H.M.; Le, T.A.; Le, P.K. Green recycling of fly ash into heat and sound insulation composite aerogels reinforced by recycled polyethylene terephthalate fibers. J. Clean. Prod. 2021, 322, 129138. [Google Scholar] [CrossRef]

- Moghaddam Fard, P.; Alkhansari, M.G. Innovative fire and water insulation foam using recycled plastic bags and expanded polystyrene (eps). Constr. Build. Mater. 2021, 305, 124785. [Google Scholar] [CrossRef]

- Reynoso, L.E.; Carrizo Romero, Á.B.; Viegas, G.M.; San Juan, G.A. Characterization of an alternative thermal insulation material using recycled expanded polystyrene. Constr. Build. Mater. 2021, 301, 124058. [Google Scholar] [CrossRef]

- Jensen, M.S.; Alfieri, P.V. Design and manufacture of insulation panels based on recycled lignocellulosic waste. Clean. Eng. Technol. 2021, 3, 100111. [Google Scholar] [CrossRef]

- Owoeye, S.S.; Matthew, G.O.; Ovienmhanda, F.O.; Tunmilayo, S.O. Preparation and characterization of foam glass from waste container glasses and water glass for application in thermal insulations. Ceram. Int. 2020, 46, 11770–11775. [Google Scholar] [CrossRef]

- König, J.; Nemanič, V.; Žumer, M.; Petersen, R.R.; Østergaard, M.B.; Yue, Y.; Suvorov, D. Evaluation of the contributions to the effective thermal conductivity of an open-porous-type foamed glass. Constr. Build. Mater. 2019, 214, 337–343. [Google Scholar] [CrossRef]

- Samar, M.; Saxena, S. Study of chemical and physical properties of perlite and its application in India. Int. J. Sci. Technol. Manag. 2016, 5, 70–80. [Google Scholar]

- Caiyou, Z.; Ping, W.; Li, W.; Dan, L. Reducing railway noise with porous sound-absorbing concrete slabs. Adv. Mater. Sci. Eng. 2014, 2014, 206549. [Google Scholar]

- Schmitz, A.; Meier, A.; Raabe, G. Inter-laboratory test of sound insulation measurements on heavy walls: Part I—Preliminary test. Build. Acoust. 1999, 6, 159–169. [Google Scholar] [CrossRef]

- Peletskii, V.é.; Shur, B.A. Experimental study of the thermal conductivity of heat insulation materials based on expanded vermiculite. Refract. Ind. Ceram. 2007, 48, 356–358. [Google Scholar] [CrossRef]

- Carbajo, J.; Esquerdo-Lloret, T.V.; Ramis, J.; Nadal-Gisbert, A.V.; Denia, F.D. Acoustic properties of porous concrete made from arlite and vermiculite lightweight aggregates. Mater. Constr. 2015, 65, e072. [Google Scholar] [CrossRef] [Green Version]

- Kaushika, N.D.; Sumathy, K. Solar transparent insulation materials: A review. Renew. Sustain. Energy Rev. 2003, 7, 317–351. [Google Scholar] [CrossRef]

- Alotaibi, S.S.; Riffat, S. Vacuum insulated panels for sustainable buildings: A review of research and applications. Int. J. Energy Res. 2014, 38, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Koru, M. Determination of thermal conductivity of closed-cell insulation materials that depend on temperature and density. Arab. J. Sci. Eng. 2016, 41, 4337–4346. [Google Scholar] [CrossRef]

- Japan Weather Agency. Expanded AMeDAS Weather Data. 2015. Available online: http://www.jma.go.jp/amedas/ (accessed on 15 November 2022).

- Rehman, H.U. Experimental performance evaluation of solid concrete and dry insulation materials for passive buildings in hot and humid climatic conditions. Appl. Energy 2017, 185, 1585–1594. [Google Scholar] [CrossRef] [Green Version]

- Synnefa, A.; Santamouris, M.; Akbari, H. Estimating the effect of using cool coatings on energy loads and thermal comfort in residential buildings in various climatic conditions. Energy Build. 2007, 39, 1167–1174. [Google Scholar] [CrossRef]

- Sahebzadeh, S.; Dalvand, Z.; Sadeghfar, M.; Heidari, A. Vernacular architecture of Iran’s hot regions; elements and strategies for a comfortable living environment. Smart Sustain. Built Environ. 2020, 9, 573–593. [Google Scholar] [CrossRef]

- Alijani, B.; Ghohroudi, M.; Arabi, N. Developing a climate model for Iran using GIS. Theor. Appl. Climatol. 2008, 92, 103–112. [Google Scholar] [CrossRef]

- Yigit, S.; Caglayan, S.; Ozorhon, B. Evaluation of optimum building envelope materials in different climate regions of Turkey. In IOP Conference Series: Materials Science and Engineering; Iop Publishing: Bristol, UK, 2019. [Google Scholar]

- Awad, H.; Secchi, L.; Gül, M.; Ge, H.; Knudson, R.; Al-Hussein, M. Thermal resistance of multi-functional panels in cold-climate regions. J. Build. Eng. 2021, 33, 101838. [Google Scholar] [CrossRef]

- Reyes-Barajas, K.D.; Romero-Moreno, R.A.; Luna-León, A.; Olvera-García, D.; Sotelo-Salas, C.; Bojórquez-Morales, G. Economic feasibility of passive strategies for energy efficient envelopes of mass-built housing in hot-dry climate. Int. J. Energy Prod. Manag. 2021, 6, 129–142. [Google Scholar]

- Nguyen, D.M.; Grillet, A.-C.; Diep, T.M.H.; Bui, Q.-B.; Woloszyn, M. Characterization of hygrothermal insulating biomaterials modified by inorganic adsorbents. Heat Mass Transf. 2020, 56, 2473–2485. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Grillet, A.-C.; Diep, T.M.H.; Ha Thuc, C.N.; Woloszyn, M. Hygrothermal properties of bio-insulation building materials based on bamboo fibers and bio-glues. Constr. Build. Mater. 2017, 155, 852–866. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal properties of clayey plasters with olive fibers. Constr. Build. Mater. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Urbikain, M.K. Energy efficient solutions for retrofitting a residential multi-storey building with vacuum insulation panels and low-E windows in two European climates. J. Clean. Prod. 2020, 269, 121459. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Sanjayan, J.G. Retrofitting building envelope using phase change materials and aerogel render for adaptation to extreme heatwave: A multi-objective analysis considering heat stress, energy, environment, and cost. Sustainability 2021, 13, 10716. [Google Scholar] [CrossRef]

- Razzaghmanesh, M.; Razzaghmanesh, M. Thermal performance investigation of a living wall in a dry climate of australia. Build. Environ. 2017, 112, 45–62. [Google Scholar] [CrossRef]

- Stazi, F.; Tomassoni, E.; Di Perna, C. Super-insulated wooden envelopes in Mediterranean climate: Summer overheating, thermal comfort optimization, environmental impact on an Italian case study. Energy Build. 2017, 138, 716–732. [Google Scholar] [CrossRef]

- Karanafti, A.C.; Theodosiou, T.G. Investigation of the envelope’s thermal transmittance influence on the energy efficiency of residential buildings under various Mediterranean region climates. IOP Conf. Ser. Earth Environ. Sci. 2021, 899, 012009. [Google Scholar] [CrossRef]

- Tao, J.; Luan, J.; Liu, Y.; Qu, D.; Yan, Z.; Ke, X. Technology development and application prospects of organic-based phase change materials: An overview. Renew. Sustain. Energy Rev. 2022, 159, 112175. [Google Scholar] [CrossRef]

- Iffa, E.; Hun, D.; Salonvaara, M.; Shrestha, S.; Lapsa, M. Performance evaluation of a dynamic wall integrated with active insulation and thermal energy storage systems. J. Energy Storage 2022, 46, 103815. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, M.; Xu, J.; Li, C.; Yan, J.; Zhou, G.; Zhong, W.; Hao, T.; Song, J.; Xue, X. Single-junction organic solar cells with over 19% efficiency enabled by a refined double-fibril network morphology. Nat. Mater. 2022, 21, 656–663. [Google Scholar] [CrossRef]

- Wang, D.; Li, Y.; Zhou, G.; Gu, E.; Xia, R.; Yan, B.; Yao, J.; Zhu, H.; Lu, X.; Yip, H.-L.; et al. High-performance see-through power windows. Energy Environ. Sci. 2022, 15, 2629–2637. [Google Scholar] [CrossRef]

- Ma, R.; Yan, C.; Yu, J.; Liu, T.; Liu, H.; Li, Y.; Chen, J.; Luo, Z.; Tang, B.; Lu, X.; et al. High-efficiency ternary organic solar cells with a good figure-of-merit enabled by two low-cost donor polymers. ACS Energy Lett. 2022, 7, 2547–2556. [Google Scholar] [CrossRef]

| Category | Thermal Insulation Material | Thermal Conductivity (W/m·K) | Density (kg/m3) | Specific Heat (kJ/kg·K) | Installation Position in Wall Structures | Production Method | Refs. |

|---|---|---|---|---|---|---|---|

| Inorganic insulation material | Fibrous (Glass wool) | 0.030–0.046 | 10–100 | 0.9–1.0 | Interior and exterior | Glass wool is made by mixing natural sand and typically recycled glass at temperatures ranging from 1300 to 1450 °C. Centrifugation and blowing procedures are used to convert fibres, which are subsequently linked together via resin. | [5,19] |

| Fibrous (Rock wool) | 0.033–0.046 | 40–200 | 0.8–1.0 | Interior and exterior | Rock wool is made by melting stone (diabase, dolerite) at around 1500 °C and hurling the molten material out of a wheel or disc, resulting in fibres. | [18,33] | |

| Cellular (Foamed glass) | 0.038–0.055 | 100–200 | 0.21 | Exterior | Porous foam glass is a porous glass material filled with bubbles after softening, foaming, and annealing by adding a foaming agent, modifier, accelerator, and other ingredients based on ordinary glass. | [78,79] | |

| Cellular (Perlite) | 0.040–0.060 | 32–176 | 0.2 | Interior and exterior | Polystyrene foam is turned into polystyrene emulsion with water, then heated and combined with expanded perlite in a rotary drum. | [80,81] | |

| Cellular (Calcium Silicate) | 0.059–0.065 | 200–240 | 1.3 | Usually for interior | Calcium silicate slurry is made by breaking calcium silicate and mixing it with water. The hard calcium silicate slurry is synthesised and prepared by adding fibre-reinforced raw materials and sodium silicate at 190–250 °C and 1.3–4.0 MPa. | [82] | |

| Cellular (Vermiculite) | 0.040–0.064 | 64–130 | 0.84–1.08 | Exterior | Vermiculite with a diameter greater than 2 mm is screened and put into the crucible. The expanded vermiculite is then made by calcining the crucible containing vermiculite at high temperatures in a muffle furnace. | [83,84] | |

| Organic insulation material | Polystyrene (EPS) | 0.031–0.037 | 15–75 | 1.25 | Interior and exterior | EPS is typically made by evaporating pentane into polystyrene particles. This method may produce closed-cell foam that is white and stiff. | [5,20] |

| Polystyrene (XPS) | 0.025–0.035 | 32–40 | 1.3–1.7 | Interior and exterior | XPS is made by feeding molten polystyrene (like hydrofluorocarbons (HFC)), CO2, or C6H6 through a nozzle, relieving pressure, expanding, and adding a foaming ingredient. | [18,20,28] | |

| Polyurethane (PUR) | 0.020–0.030 | 30–160 | 1.3–1.45 | Interior and exterior | Polyurethane (PUR) and polyisocyanurates are made when isocyanates and polyols react. During expansion, the closed pores are filled with expanding gases, CO2, or C6H6. | [1,18,29] | |

| Cork | 0.037–0.050 | 100–120 | 1.5–1.7 | Exterior | Cork thermal insulation is primarily made from cork oak. | [18,29] | |

| Fibrous (Cellulose) | 0.037–0.042 | 30–80 | 1.3–1.6 | Interior and exterior | Cellulose is made using recycled paper, wood fibre and boric acid to improve thermal characteristics. | [5,18,32,33] | |

| Fibrous (Sheep wool fibre-epoxy composites) | 0.32–0.3 | - | - | Exterior | The epoxy resin and hardener are mixed at a ratio of 100 and 58 parts/weight, respectively. The wool samples are taken from two different Greek sheep breeds, i.e., Kalarritiko and Katsika. The composite is finally made using a hydraulic heat press. | [34] | |

| Fibrous (Sheep wool and gypsum composites) | 0.046 | 415 | - | Exterior | After equally mixing the gypsum and water, it is poured on the sheep wool and dried to form the composite. Composites containing 35 g sheep wool, 250 g gypsum, and 160 g water are in high demand. | [35] | |

| Fibrous (Sheep wool inner wall insulation layer) | 0.04 | - | - | Interior | Sheep wool is directly used inside the wall. To achieve the insulating function, using gypsum cement is also utilised as a binder to form a 0.08 m thick inner wall insulation layer. | [36] | |

| State-of-the-art insulation material | TIM (without aerogel) | 0.22 × 10−3–1.3 × 10−3 | - | - | Interior | TIMs are assembled using a transparent cover and double-pane glazing unit with an air cavity. | [18,38,85] |

| Aerogel | 0.013–0.021 | 70–150 | 1.0 | Exterior | Aerogel is synthesised using the sol-gel process to remove liquid from the gel. | [18,86] | |

| Closed-cell foam | 0.025–0.048 | 16–55 | - | Exterior | Closed-cell foam is spray insulation in which the cells are entirely enclosed and pushed together to avoid air and moisture traps within the foam. | [87] | |

| Sustainable insulation material | Bio-insulation (Oil palm wood) | 0.050–0.143 | 0.58–0.70 | - | Interior and exterior | Using heat, the oil palm wood is pelletised, boiled, dried, and pressed into insulation boards. | [67] |

| Bio-insulation (Magnesium phosphate cement and large corn stalk) | 0.087–0.165 | 0.060–0.131 | 0.101 | Interior and exterior | MgO, fly ash, and NH4H2PO4 are combined in a 3:1:2 weight ratio to prepare the MPC binder. Corn stover thermal insulation concrete, in which corn stover makes up a third of the total weight of all solid materials, is obtained after stirring and curing. | [68] | |

| Bio-insulation (Rice husk/geopolymer foam composite) | 0.082–0.184 | 174–813 | - | Interior and exterior | The rice husk is combined with a stabiliser, a foaming agent, and a mixture of alkaline activator and metakaolin before being moulded. | [69] | |

| Bio-insulation (Wheat straw) | 0.092–0.186 | 235–894.1 | - | Interior and exterior | After the wheat straw has been pre-wetted, the mixed water and NaOH solid particles are added to the sodium silicate solution to make the alkali activator. The mineral binder, metakaolin and the alkali activator are mixed, followed by the surfactant and the H2O2 solution. The pre-wetted wheat straw is finally added to the foam geopolymer slurry. | [66] | |

| Bio-insulation (Bamboo fibres) | 0.077–0.088 | 311–538 | - | Interior and exterior | Bamboo fibres and glue are manually mixed and dried in an oven at 100 °C for 24 h. Fibreboards are then prepared after pressing via a hydraulic press. | [70] | |

| Agriculture waste (Corncob particleboards) | 0.052–1.33 | - | - | Interior and exterior | After the corncob is punched into a board, the surface is coated with 15% (w/v) polystyrene to fill the voids between the fibres and strengthen the bond between the particles, resulting in particleboard. | [71] | |

| Agriculture waste (Pineapple leaf and cotton waste fibres) | 0.039–0.043 | 19–46 | - | Interior and exterior | Fibres were cut into smaller sample sizes and blended with sonication dilute polyvinyl alcohol solution. They are then baked in an oven at 70 °C for 2 h. The samples are eventually vacuumed and freeze-dried after being pre-cooled at −5 °C for 24 h to form cellulose aerogels. | [72] | |

| Agriculture waste (Hemp fibre) | 0.054–0.059 | 200–300 | - | Interior and exterior | After final grinding with a disc mill, drying at 150 °C, and adding binder moulding, insulation panels are stabilised by mixing the pre-moistened stem fibre mixture with chopped stems of dried hemp. | [73] |

| Climate Zones | Representative Cities | HDD18 (°C-day) | CDD28 (°C-Day) | Location (Lat., Long.) |

|---|---|---|---|---|

| I | Sapporo | 3530.1 | 0.0 | 43.1° N, 141.3° E |

| II | Akita | 2746.3 | 0.0 | 39.2° N, 140.1° E |

| III | Fukushima | 2362.2 | 0.0 | 37.8° N, 140.5° E |

| IV | Osaka | 1485.5 | 28.6 | 34.7° N, 135.5° E |

| V | Kagoshima | 1024.3 | 25.4 | 31.6° N, 130.6° E |

| VI | Naha | 60.0 | 52.8 | 26.2° N, 127.7° E |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Kong, J.; Mousavi, S.; Rismanchi, B.; Yap, P.-S. Wall Insulation Materials in Different Climate Zones: A Review on Challenges and Opportunities of Available Alternatives. Thermo 2023, 3, 38-65. https://doi.org/10.3390/thermo3010003

Dong Y, Kong J, Mousavi S, Rismanchi B, Yap P-S. Wall Insulation Materials in Different Climate Zones: A Review on Challenges and Opportunities of Available Alternatives. Thermo. 2023; 3(1):38-65. https://doi.org/10.3390/thermo3010003

Chicago/Turabian StyleDong, Yitong, Jiashu Kong, Seyedmostafa Mousavi, Behzad Rismanchi, and Pow-Seng Yap. 2023. "Wall Insulation Materials in Different Climate Zones: A Review on Challenges and Opportunities of Available Alternatives" Thermo 3, no. 1: 38-65. https://doi.org/10.3390/thermo3010003

APA StyleDong, Y., Kong, J., Mousavi, S., Rismanchi, B., & Yap, P.-S. (2023). Wall Insulation Materials in Different Climate Zones: A Review on Challenges and Opportunities of Available Alternatives. Thermo, 3(1), 38-65. https://doi.org/10.3390/thermo3010003