Content/Potency Assessment of Botulinum Neurotoxin Type-A by Validated Liquid Chromatography Methods and Bioassays

Abstract

:1. Introduction

2. Results and Discussion

2.1. In Vitro Cell Culture Assay

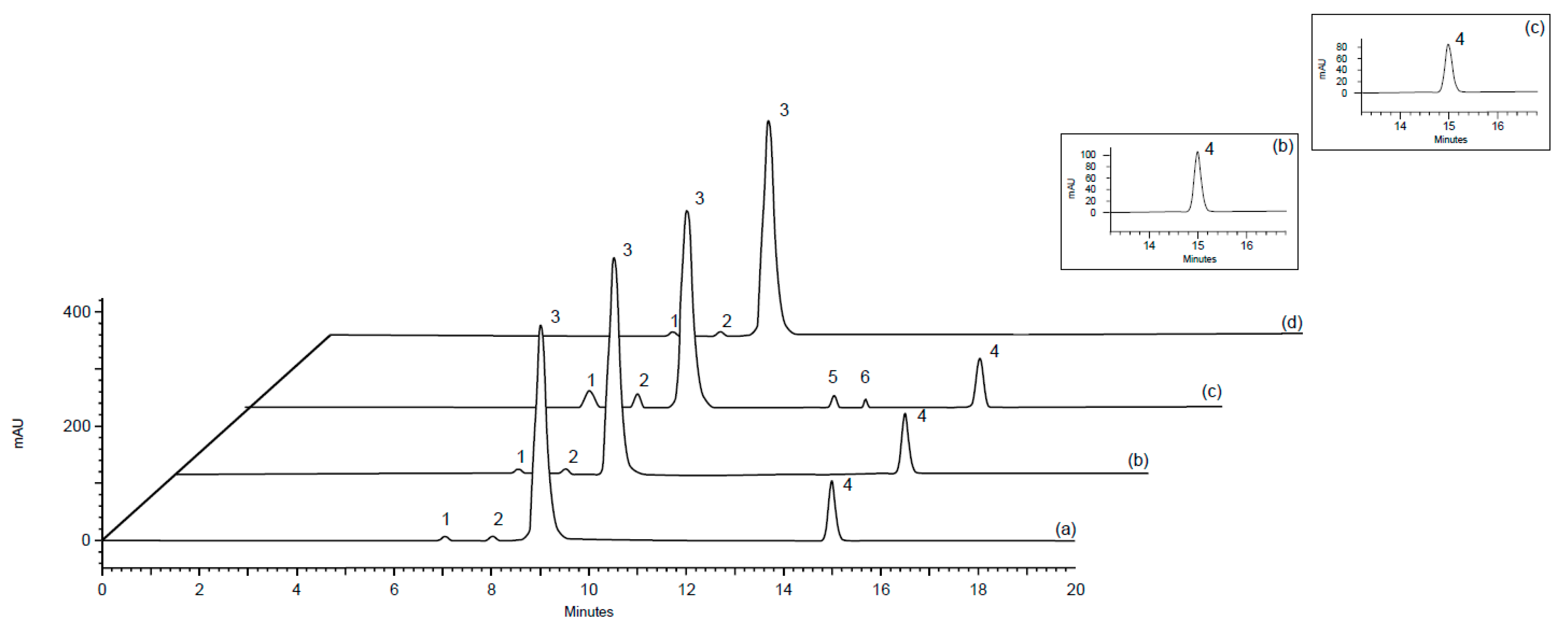

2.2. Development of the SEC Method

2.3. Validation of the SEC Method

2.4. Application of the LC Methods and Bioassays

2.5. Cytotoxicity Evaluation

3. Conclusions

4. Materials and Methods

4.1. Reagents and Chemicals

4.2. Equipments

4.3. Standard and Sample Preparations

4.4. Chromatographic Procedures

4.5. Bioassays

4.6. Validation of the SEC Method

4.7. Analysis of BoNTA in Biopharmaceutical Products

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Schantz, E.J.; Johnson, E.A. Properties and use of botulinum toxin and other microbial neurotoxins in medicine. Microbiol. Rev. 1992, 56, 80–99. [Google Scholar] [PubMed]

- Frevert, J. Pharmaceutical, biological, and clinical properties of botulinum neurotoxin type A products. Drugs R&D 2015, 15, 1–9. [Google Scholar] [CrossRef]

- Chen, S. Clinical uses of botulinum neurotoxins: Current indications, limitations and future developments. Toxins 2012, 4, 913–939. [Google Scholar] [CrossRef] [PubMed]

- Pirazzini, M.; Rossetto, O.; Eleopra, R.; Montecucco, C. Botulinum neurotoxins: Biology, pharmacology, and toxicology. Pharmacol. Rev. 2017, 69, 200–235. [Google Scholar] [CrossRef] [PubMed]

- Binz, T.; Kurazono, H.; Wille, M.; Frevert, J.; Wernars, K.; Niemann, H. The complete sequence of botulinum neurotoxin type A and comparison with other clostridial neurotoxins. J. Biol. Chem. 1990, 265, 9153–9158. [Google Scholar] [PubMed]

- Jankovic, J. Botulinum toxin: State of the art. Mov. Disord. 2017, 32, 1131–1138. [Google Scholar] [CrossRef] [PubMed]

- Rossetto, O.; Pirazzini, M.; Montecucco, C. Botulinum neurotoxins: Genetic, structural and mechanistic insights. Nat. Rev. Microbiol. 2014, 12, 535–549. [Google Scholar] [CrossRef]

- Sesardic, D.; Das Gaines, R. Botulinum toxin: Applying the 3Rs to product potency testing. NC3Rs 2009, 1–8. [Google Scholar]

- Sesardic, T. Bioassays for evaluation of medical products derived from bacterial toxins. Curr. Opin. Microbiol. 2012, 15, 310–316. [Google Scholar] [CrossRef]

- EUROPEAN Pharmacopoeia, 9th ed.; Council of Europe: Strasbourg, France, 2017; pp. 1860–1861.

- Adler, S.; Bicker, G.; Bigalke, H.; Bishop, C.; Blumel, J.; Dressler, D.; Fitzgerald, J.; Gessler, F.; Heuschen, H.; Kegel, B.; et al. The current scientific and legal status of alternative methods to the LD50 test for botulinum neurotoxin potency testing. The report and recommendations of a ZEBET Expert Meeting. Altern. Lab. Anim. 2010, 38, 315–330. [Google Scholar]

- Basavanna, U.; Muruvanda, T.; Brown, E.W.; Sharma, S.K. Development of a Cell-Based Functional Assay for the Detection of Clostridium botulinum Neurotoxin Types A and E. Int. J. Microbiol. 2013, 2013, 593219. [Google Scholar] [CrossRef] [PubMed]

- Pellett, S. Progress in Cell Based Assays for Botulinum Neurotoxin Detection. Curr. Top. Microbiol. Immunol. 2013, 364, 257–285. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.K.; Cai, S.; Singh, B. Here a method, there a method, everywhere many methods. What should a laboratory do to validate an assay for the detection of botulinum neurotoxins? Botulinum J. 2008, 1, 183–198. [Google Scholar] [CrossRef]

- Lévêque, C.; Ferracci, G.; Maulet, Y.; Grand-Masson, C.; Seagar, M.; El Far, O. A chip-based assay for botulinum neurotoxin A activity in pharmaceutical preparations. Appl. Microbiol. Biotechnol. 2015, 99, 4355–4360. [Google Scholar] [CrossRef] [PubMed]

- Lévêque, C.; Ferracci, G.; Maulet, Y.; Grand-Masson, C.; Blanchard, M.P.; Seagar, M. A substrate sensor chip to assay the enzymatic activity of Botulinum neurotoxin A. Biosens. Bioelectron. 2013, 49, 276–281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gaines, R.D.; Heath, A.B.; Martin, H.; Sesardic, D. Validation of in vitro assays for botulinum toxin: A case study. Dev. Biol. Stand. 1999, 101, 267–276. [Google Scholar]

- Bandala, C.; Perez-Santos, J.L.M.; Lara-Padilla, E.; Delgado, L.; Anaya-Ruiz, M. Effect of botulinum toxin A on proliferation and apoptosis in the T47D breast cancer cell line. Asian Pac. J. Cancer Prev. 2013, 14, 891–894. [Google Scholar] [CrossRef]

- Pathe-Neuschäfer-Rube, A.; Neuschäfer-Rube, F.; Haas, G.; Langoth-Fehringer, N.; Püschel, G. Cell-Based Reporter Release Assay to Determine the Potency of Proteolytic Bacterial Neurotoxins. Toxins 2018, 10, 360. [Google Scholar] [CrossRef]

- Grenda, T.; Kukier, E.; Kwiatek, K. Methods and difficulties in detection of Clostridium botulinum and its toxins. J. Vet. Sci. 2014, 17, 195–205. [Google Scholar] [CrossRef]

- Fonfria, E.; Maignel, J.; Lezmi, S.; Martin, V.; Splevins, A.; Shubber, S.; Kalinichev, M.; Foster, K.; Picaut, P.; Krupp, J. The expanding therapeutic utility of botulinum neurotoxins. Toxins 2018, 10, 208. [Google Scholar] [CrossRef]

- Chirino, A.J.; Mire-Sluis, A. Characterizing biological products and assessing comparability following manufacturing changes. Nat. Biotechnol. 2004, 22, 1383–1391. [Google Scholar] [CrossRef] [PubMed]

- Skrlin, A.; Krnic, E.K.; Gosak, D.; Prester, B.; Mrsa, V.; Vuletic, M.; Runac, D. Correlation of liquid chromatographic and biological assay for potency assessment of filgrastim and related impurities. J. Pharm. Biomed. Anal. 2010, 53, 262–268. [Google Scholar] [CrossRef]

- Perobelli, R.F.; Xavier, B.; da Silveira, A.R.; Remuzzi, G.L.; Motta, L.G.J.; Dalmora, S.L. Quantitation of the monoclonal antibody Denosumab by bioassay and validated LC methods. Int. J. Biol. Macromol. 2018, 119, 96–104. [Google Scholar] [CrossRef] [PubMed]

- UNITED STATES Pharmacopeia, 39th ed.; The United States Pharmacopeia Convention: Rockville, MD, USA, 2016; Volume 1045, pp. 917–931.

- Hong, P.; Koza, S.; Bouvier, E.S.P. A review size-exclusion chromatography for the analysis of protein biotherapeutics and their aggregates. J. Liq. Chromatogr. Relat. Technol. 2012, 35, 2923–2950. [Google Scholar] [CrossRef]

- Orphanou, C.; Gervais, D. Higher-order structure and conformational change in biopharmaceuticals. J. Chem. Technol. Biotechnol. 2018, 93, 2477–2485. [Google Scholar] [CrossRef]

- Freitas, G.W.; Perobelli, R.F.; Maldaner, F.P.S.; Xavier, B.; Dalmora, D.A.; Schramm, V.G.; Dalmora, S.L. Evaluation of botulinum toxin type A by bioassays and a validated reversed-phase liquid chromatography method. Anal. Methods 2016, 8, 587–592. [Google Scholar] [CrossRef]

- Boyer, A.E.; Gallegos-Candela, M.; Lins, R.C.; Kuklenyik, Z.; Woolfitt, A.; Moura, H.; Kalb, S.; Quinn, C.P.; Barr, J.R. Quantitative mass spectrometry for bacterial protein toxins—A sensitive, specific, high-throughput tool for detection and diagnosis. Molecules 2011, 16, 2391–2413. [Google Scholar] [CrossRef] [PubMed]

- Swartz, M. HPLC detectors: A brief review. J. Liq. Chromatogr. Relat. Technol. 2010, 33, 1130–1150. [Google Scholar] [CrossRef]

- Shabir, G.A.; John Lough, W.; Arain, S.A.; Bradshaw, T.K. Evaluation and application of best practice in analytical method validation. J. Liq. Chromatogr. Relat. Technol. 2007, 30, 311–333. [Google Scholar] [CrossRef]

- Shabir, G.A. Validation of high-performance liquid chromatography methods for pharmaceutical analysis understanding the differences and similarities between validation requirements of the US Food and Drug Administration, the US Pharmacopeia and the International Conference on Harmonization. J. Chromatogr. A 2003, 987, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Matak, I.; Lacković, Z. Botulinum toxin A, brain and pain. Prog. Neurobiol. 2014, 119, 39–59. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pineda, C.; Hernández, G.C.; Jacobs, I.A.; Alvarez, D.F.; Carini, C. Assessing the immunogenicity of biopharmaceuticals. BioDrugs 2016, 30, 195–206. [Google Scholar] [CrossRef] [PubMed]

- Rampersad, S.N. Multiple applications of Alamar Blue as an indicator of metabolic function and cellular health in cell viability bioassays. Sensors 2012, 12, 12347–12360. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, C.D.A., Jr.; Perobelli, R.F.; Xavier, B.; Maldaner, F.P.S.; da Silva, F.S.; Dalmora, S.L. Analysis of streptokinase by validated liquid chromatography methods and correlation with an in vitro bioassay. J. Sep. Sci. 2017, 40, 407–414. [Google Scholar] [CrossRef] [PubMed]

- ICH—International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use: Guideline on Validation of Analytical Procedure: Text and Methodology Q2 (R1); International Conference on Harmonization: Geneva, Switzerland, 2005.

- FDA—Food and Drug Administration. Guidance for industry: Analytical Procedures and Methods Validation for Drugs and Biologics; Food and Drug Administration: Washington, DC, USA, 2015. [Google Scholar]

| Nominal Concentration (U mL−1) | Mean Concentration Measured a (U mL−1) | RSD b (%) | Accuracy a (%) | Bias c (%) |

|---|---|---|---|---|

| 40 | 40.02 | 0.73 | 100.04 | 0.05 |

| 50 | 50.13 | 0.14 | 100.26 | 0.26 |

| 60 | 60.56 | 0.22 | 100.93 | 0.93 |

| Variable | Range Investigated | BoNTA a (%) | RSD b (%) | Optimized Value |

|---|---|---|---|---|

| Mobile phase pH | 6.5 | 99.56 | 0.57 | 7.0 |

| 7.0 | 101.12 | 0.17 | ||

| 7.5 | 100.13 | 0.86 | ||

| Potassium phosphateconcentration (mM) | 30 | 99.86 | 0.54 | 50 |

| 50 | 100.19 | 0.29 | ||

| 70 | 102.40 | 0.43 | ||

| Flow rate (mL min−1) | 0.8 | 99.90 | 0.69 | 1.0 |

| 1.0 | 100.16 | 0.19 | ||

| 1.2 | 98.72 | 0.98 | ||

| Wavelength (nm) | 210–320 | − | − | 220 |

| Sample | Theoretical Amount | LD50 mouse bioassay a | T-47D bioassay a | SEC a | RPC a | ||||

|---|---|---|---|---|---|---|---|---|---|

| Potency | Confidence Intervals | Potency | Confidence Intervals | Monomer | HMW Proteins | Main Peak | Related Proteins | ||

| (U mL−1) | (%) | (p = 0.95) | (%) | (p = 0.95) | (%) | (%) | (%) | (%) | |

| 1 | 100 | 88.70 | 79.70–98.20 | 90.50 | 84.20–97.30 | 89.10 | 0.52 | 87.90 | 0.41 |

| 2 | 100 | 94.70 | 86.60–103.50 | 95.10 | 88.80–101.80 | 95.50 | 0.50 | 94.20 | 0.12 |

| 3 | 100 | 113.10 | 102.80–124.90 | 114.30 | 108.80–124.50 | 115.10 | 0.15 | 113.56 | 0.08 |

| 4 | 200 | 98.70 | 87.40–111.30 | 99.90 | 90.20–110.70 | 99.02 | 0.21 | 100.10 | 0.05 |

| 5 | 100 | 94.60 | 84.50–105.40 | 95.30 | 87.70–103.40 | 94.25 | 0.72 | 93.40 | 0.52 |

| 6 | 100 | 101.50 | 90.19–114.65 | 102.30 | 92.10–113.70 | 101.92 | 0.16 | 100.66 | 0.18 |

| 7 | 100 | 98.40 | 88.30–109.60 | 99.30 | 90.80–108.60 | 99.31 | 0.13 | 98.30 | 0.07 |

| Mean a | − | 98.46 | − | 99.53 | − | 99.17 | 0.34 | 98.30 | 0.23 |

| SD b | − | 7.72 | − | 7.58 | − | 8.17 | 0.24 | 8.07 | 0.18 |

| ANOVA | F calculated | ||||||||

| Between-methods | 0.02976 | ||||||||

| Sample | Theoretical Amount | LD50 Mouse Bioassay a | T–47D Bioassay a | SEC a | RPC a | ||||

|---|---|---|---|---|---|---|---|---|---|

| Potency | Confidence Intervals | Potency | Confidence Intervals | Monomer | HMW Proteins | Main Peak | Related Proteins | ||

| (U mL−1) | (%) | (p = 0.95) | (%) | (p = 0.95) | (%) | (%) | (%) | (%) | |

| 4 b | 200 | 98.70 | 87.40–111.30 | 99.90 | 90.20–110.70 | 99.02 | 0.21 | 100.10 | 0.05 |

| 4 c | − | 50.90 | 42.60–61.20 | 52.30 | 43.20–60.80 | 53.40 | 14.19 | 50.70 | 19.45 |

| 4 d | − | 151.20 | 143.70–159.10 | 153.80 | 145.90–160.20 | 0152.10 | 0.12 | 149.80 | 0.10 |

| 4 e | − | Inactive | − | 29.10 | 22.10–36.90 | 77.90 | 8.62 | − | − |

| 4 f | − | 95.20 | 87.00–103.00 | 97.40 | 89.40–105.30 | − | − | 80.53 | 10.26 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xavier, B.; Perobelli, R.F.; Walter, M.E.; da Silva, F.S.; Dalmora, S.L. Content/Potency Assessment of Botulinum Neurotoxin Type-A by Validated Liquid Chromatography Methods and Bioassays. Toxins 2019, 11, 35. https://doi.org/10.3390/toxins11010035

Xavier B, Perobelli RF, Walter ME, da Silva FS, Dalmora SL. Content/Potency Assessment of Botulinum Neurotoxin Type-A by Validated Liquid Chromatography Methods and Bioassays. Toxins. 2019; 11(1):35. https://doi.org/10.3390/toxins11010035

Chicago/Turabian StyleXavier, Bruna, Rafaela Ferreira Perobelli, Maurício Elesbão Walter, Francielle Santos da Silva, and Sérgio Luiz Dalmora. 2019. "Content/Potency Assessment of Botulinum Neurotoxin Type-A by Validated Liquid Chromatography Methods and Bioassays" Toxins 11, no. 1: 35. https://doi.org/10.3390/toxins11010035

APA StyleXavier, B., Perobelli, R. F., Walter, M. E., da Silva, F. S., & Dalmora, S. L. (2019). Content/Potency Assessment of Botulinum Neurotoxin Type-A by Validated Liquid Chromatography Methods and Bioassays. Toxins, 11(1), 35. https://doi.org/10.3390/toxins11010035