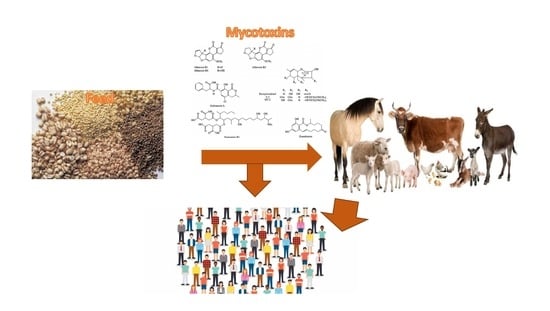

Prevalent Mycotoxins in Animal Feed: Occurrence and Analytical Methods

Abstract

:1. Introduction

- Forages—silage made from grass or cereal crops;

- Cereals and other home-grown crops—feeds with a high energy and/or protein content;

- Compound feeds—manufactured mixtures of single feed materials, minerals, and vitamins;

- Products and by-products of the human food and brewing industries—residues of vegetable processing, spent grains from brewing and malting and by-products of the baking, bread-making, and confectionery industries.

2. Mycotoxins Classes and Toxicity

2.1. Aflatoxins

2.2. Fumonisins

2.3. Ochratoxins

2.4. Trichothecenes

2.5. Zearalenone

3. Mycotoxins Economic and Commercial Implications

4. Mycotoxin Occurrence

Co-Occurrence

5. Mycotoxin Determination Methods

5.1. Sampling

5.2. Sample Preparation

5.3. Analytical Procedure

5.3.1. Sample Pretreatment

Extraction with Solvents—Classical Solid-Liquid Extraction

Instrumental Solvent Extraction—Microwave-Assisted Extraction

Instrumental Solvent Extraction—Ultrasonic Extraction

Cleanup Methods—Solid-Phase Extraction

Enhanced Solid-Phase Extraction—Immuno-Affinity Columns

Enhanced Solid-Phase Extraction—Multifunctional Columns

Enhanced Solid-Phase Extraction—Molecularly Imprinted Polymers

Combined Extraction/Clean-up/Concentration—QuEChERS

Combined Extraction/Clean-up/Concentration—Matrix Solid-Phase Dispersion

Combined Extraction/Clean-up/Concentration—Dispersive Liquid-Liquid Micro-Extraction

5.3.2. Detection

Screening Methods

Immunoassay-Based Methods

Enzyme-Linked Immunosorbent Assay

Lateral Flow Immunoassay

Fluorescence Polarization Immunoassay

Biosensors and Biosensor-Based Methods

Noninvasive Methods

Infrared Spectroscopy

Raman Spectroscopy

Chromatographic Methods

Thin Layer Chromatography

Gas Chromatography

Liquid Chromatography

6. Final Considerations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Sample | Country of Origin | Year of Collection | Mycotoxin/ Metabolite | Total Samples | Positive Samples | Year of Publication | Reference | ||

|---|---|---|---|---|---|---|---|---|---|

| % | Range (µg/kg) | Mean (µg/kg) | |||||||

| Corn | Argentine | NM | T-2 | 1 | 100 | NM | NM | 2016 | [63] |

| Corn | South Korea | 2014 | DON | 40 | 22.5 | ≥3.3–232.56 | 190.78 | 2016 | [143] |

| 3-AcDON | ND | ND | ND | ||||||

| Corn | China | 2013–2015 | AFB1 | 220 | 80 | ≥0.5–25.5 Φ | 3.9 | 2016 | [97] |

| ZEN | 96 | ≥10–1442.5 | 251.5 | ||||||

| DON | 98 | ≥100–4320.9 | 755.1 | ||||||

| Corn germ meal | AFB1 | 34 | 76 | ≥0.5–14.1 | 7.4 | ||||

| ZEN | 85 | ≥100–1518.2 | 495.7 | ||||||

| DON | 91 | ≥100–4402.7 | 1549.6 | ||||||

| Corn grain | Brazil | 2013 | FB1 | 15 | 80 | 16–1732 | 289 | 2016 | [156] |

| FB2 | 47 | 32–743 | 254 | ||||||

| Corn grits | FB1 | 15 | 100 | 88–2727 | 719 | ||||

| FB2 | 100 | 48–1454 | 386 | ||||||

| Corn hybrid 30V46 | Mexico | NM | FMs | NM | NM | NM | 370 | 2016 | [135] |

| AFs | NM | NM | 2.0 | ||||||

| Corn hybrid Oso | FMs | NM | NM | 250 | |||||

| AFs | NM | NM | 13.0 | ||||||

| Corn hybrid Leopardo | Mexico | NM | FMs | NM | NM | NM | 660 | 2016 | [135] |

| AFs | NM | NM | 7.5 | ||||||

| Corn meal | Brazil | 2013 | FB1 | 15 | 100 | 75–5439 | 1305 | 2016 | [156] |

| FB2 | 93 | 52–1481 | 651 | ||||||

| Corn hybrids 2B688RR and 30K73Hx—winter storage | Brazil | 2012 | AFs | 22 | 68 | 2.8–14.5 | 76.1 | 2016 | [157] |

| AFB1 | 9 | 0.49–6.5 | NM | ||||||

| AFB2 | 55 | 8.8–14.5 | NM | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | 23 | 2.9–4.1 | NM | ||||||

| Corn hybrids 2B688RR and 30K73Hx—summer storage | 2012/13 | AFs | 82 | 85 | 3.0–197.5 | 45.8 | |||

| AFB1 | 35 | 0.6–76.5 Φ | NM | ||||||

| AFB2 | 62 | 9–169.2 | NM | ||||||

| AFG1 | 28 | 2.1–17.7 | NM | ||||||

| AFG2 | 66 | 2.8–96.1 | NM | ||||||

| Crushed yellow corn | Iran | NM | AFB1 | 16 | 87.50 | NM–45.46 Φ | 9.94 | 2016 | [158] |

| Domestic DDGS | China | 2013–2015 | AFB1 | 24 | 100 | ≥0.5–13.6 | 10.4 | 2016 | [97] |

| ZEN | 100 | ≥100–529.6 | 351.9 | ||||||

| DON | 96 | ≥100–2146.8 | 1319.5 | ||||||

| Imported DDGS | AFB1 | 37 | 86 | ≥0.5–15.2 | 9.3 | ||||

| ZEN | 95 | ≥100–510.3 | 325.3 | ||||||

| DON | 97 | ≥100–3561.0 | 1483.6 | ||||||

| DDGS | NM | NM | DON | 5 | 40 | 435–724 | 579.5 | 2016 | [159] |

| 15-AcDON | ND | ND | ND | ||||||

| 3-AcDON | ND | ND | ND | ||||||

| AFB1 | ND | ND | ND | ||||||

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| FB1 | 20 | 80 | - | ||||||

| FB2 | ND | ND | ND | ||||||

| FB3 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| T-2 | ND | ND | ND | ||||||

| OTA | ND | ND | ND | ||||||

| ZEN | 20 | 1 | - | ||||||

| α-ZEL | ND | ND | ND | ||||||

| β-ZEL | ND | ND | ND | ||||||

| Ground maize | South Africa | NM | AFB1 | 3 | ND | ND | ND | 2018 | [160] |

| AFB2 | 100 | 0.474; 3.648 | 1.674 | ||||||

| AFG1 | 33 | 3.479 | - | ||||||

| AFG2 | 100 | 2.805; 98.486 | 34.892 | ||||||

| ZEN | 100 | <LOQ; 0.680 | 0.448 | ||||||

| α- ZEL | 100 | 1.329; 6.765 | 3.556 | ||||||

| β- ZEL | 100 | 2.159; 3.118 | 2.602 | ||||||

| FB1 | 100 | 26.036; 379.242 | 147.236 | ||||||

| DON | 100 | 4.339; 81.612 | 36.347 | ||||||

| 3-AcDON + 15-AcDON | 67 | 0.802; 2.177 | 1.489 | ||||||

| HT-2 | 100 | 8.576; 312.952 | 162.564 | ||||||

| OTA | ND | ND | ND | ||||||

| Maize | NM | NM | AFB1 | 6 | NM | NM | 18 | 2016 | [161] |

| Maize | Tanzania | 2012 | AFs | 120 | 45 | 0.1–269 | NM | 2016 | [73] |

| FB1 + FB2 | 85 | 49–18273 | |||||||

| Maize | Tanzania | 2010 | FB1 | 72 | 100 | 63.26–213.15 | 157.88 | 2016 | [162] |

| Maize | Kenya | 2014 | AFB1 | 497 | 76 | ≥1.0–1137.4 Φ | 16.0 | 2016 | [61] |

| Maize | China | 2012–2014 | AFB1 | 98 | 69 | ≥0.5–300.0 Φ | 47.9 | 2016 | [138] |

| ZEN | 72 | 85 | ≥10–1613.7 | 260.6 | |||||

| DON | 45 | 84 | ≥100–19811.0 Φ | 1394.4 | |||||

| Maize | Serbia | 2013 | DON | 600 | 2.5 | 260.1–1388 | 642.3 | 2017 | [163] |

| 2014 | 600 | 96.0 | 260.4–9050 Φ | 363.3 | |||||

| 2015 | 600 | 15.5 | 252.3–6280 | 921.1 | |||||

| Maize | Zambia | NM | AF | 250 | NM | 1.3–107.6 Φ | 25 | 2017 | [164] |

| Maize | Norway | NM | AFB1 | 13 | 46 | 0.13–100.4 Φ | 31.1 | 2016 | [165] |

| AFB2 | 15 | 7.3–17.4 | 12.4 | ||||||

| AFG1 | 46 | 0.10–0.10 | 0.10 | ||||||

| AFG2 | ND | ND | ND | ||||||

| AFs | 15 | 107.88–114.95 | 111.4 | ||||||

| FB1 | 100 | 31–8750 | 1001 | ||||||

| FB2 | 100 | 5–3540 | 354 | ||||||

| FB1 + FB2 | 100 | 36–12290 | 1355 | ||||||

| Maize | Poland | 2011–2014 | DON | 295 | 88 | ≥1.0–6688 | 766 | 2016 | [15] |

| T-2 | 67 | ≥0.2–550 Φ | 22.8 | ||||||

| HT-2 | 68 | ≥0.7–1583 Φ | 37.6 | ||||||

| ZEN | 92 | ≥0.07–521 | 75.3 | ||||||

| FMs | 83 | 58 | ≥1.6–1885 | 272 | |||||

| OTA | 113 | 11 | ≥0.13–86.0 | 13.9 | |||||

| AFs | 45 | 2 | 0.18 | - | |||||

| Maize | Qatar | NM | AFs | 10 | 70 | NM–120 | 33 | 2018 | [166] |

| OTA | 40 | NM–350 Φ | 181 | ||||||

| Maize | Serbia | 2015 | AFB1 | 180 | 57.2 | 1.3–88.8 Φ | 11.4 | 2017 | [167] |

| AFB2 | 13.9 | 0.60–2.8 | 1.3 | ||||||

| AFG1 | 5.6 | 1.8–28.5 | 8.6 | ||||||

| AFG2 | 2.8 | 2.2–7.5 | 3.8 | ||||||

| AFs | 57.2 | 1.3–91.4 | 12.7 | ||||||

| Maize | NM | NM | DON | 5 | 40 | 410–686 | 548.0 | 2016 | [159] |

| 15-AcDON | ND | ND | ND | ||||||

| 3-AcDON | 20 | 12 | - | ||||||

| AFB1 | ND | ND | ND | ||||||

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| FB1 | 20 | 43 | - | ||||||

| FB2 | ND | ND | ND | ||||||

| FB3 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| T-2 | ND | ND | ND | ||||||

| OTA | ND | ND | ND | ||||||

| ZEN | 20 | 2 | - | ||||||

| α-ZEL | ND | ND | ND | ||||||

| β-ZEL | ND | ND | ND | ||||||

| Maize | Egypt | 2014–2015 | AFB1 | 79 | 16 | 0.3–197.5 Φ | NM | 2017 | [168] |

| AFB2 | 5 | 0.42–9.8 | |||||||

| DON | 8 | 26–807 | |||||||

| FB1 | 51 | 1–2453 | |||||||

| FB2 | 18 | 1.3–386 | |||||||

| FB3 | 8 | 1.5–286 | |||||||

| OTA | 3 | 2.8–11 | |||||||

| ZEN | 13 | 0.46–184 | |||||||

| Maize | Pakistan | 2012–2013 | OTA | 120 | 69.7 | 5.18–198.68 | 118.23 | 2017 | [169] |

| Maize | Croatia | 2014–2015 | T-2/HT-2 | 38 | 57.9 | 31.2–336.2 Φ | 101 | 2017 | [170] |

| Bosnia and Herzegovina | 30 | 53.3 | 28.7–321.2 Φ | 125.2 | |||||

| Maize | China | NM | AFB1 | 41 | 39.0 | <0.03–>30 | 33.0 | 2018 | [171] |

| Maize | Egypt | 2014–2015 | AFB1 | 79 | 16 | 0.3–197.5 Φ | NM | 2017 | [168] |

| AFB2 | 5 | 0.42–9.8 | |||||||

| DON | 8 | 26–807 | |||||||

| FB1 | 51 | 1–2453 | |||||||

| FB2 | 18 | 1.3–386 | |||||||

| FB3 | 8 | 1.5–286 | |||||||

| OTA | 3 | 2.8–11 | |||||||

| ZEN | 13 | 0.46–184 | |||||||

| Maize | South Africa | 2006–2017 | AFs | 282 | 9.6 | >0.5–14 | NM | 2018 | [172] |

| ZEN | 308 | 47.1 | >LOD–6276 | ||||||

| DON | 314 | 80.6 | >LOD–9176 | ||||||

| T-2 | 273 | 0.7 | >LOD–80 | ||||||

| FB1 + FB2 | 281 | 80.1 | >LOD–16932 | ||||||

| OTA | 269 | 7.4 | >LOD–95 | ||||||

| Maize and maize-based products | Tanzania | 2013/14 | AFs | 160 | 32 | 2.1–16.2 | 3.4 | 2016 | [173] |

| FMs | 39 | 0.4–62.0 | 5.6 | ||||||

| Maize kernel | China | 2012–2014 | FB1 | 225 | 74 | ≥4–28285 | 1878 | 2016 | [94] |

| FB2 | ≥3–11809 | 853 | |||||||

| FB1 + FB2 | ≥3–37653 | 2728 | |||||||

| Maize meal | NM | NM | DON | 5 | 40 | 412–787 | 599.5 | 2016 | [159] |

| 15-AcDON | ND | ND | ND | ||||||

| 3-AcDON | 20 | 13 | - | ||||||

| AFB1 | ND | ND | ND | ||||||

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| FB1 | 20 | 45 | - | ||||||

| FB2 | ND | ND | ND | ||||||

| FB3 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| T-2 | ND | ND | ND | ||||||

| OTA | ND | ND | ND | ||||||

| ZEN | 20 | 2 | ꟷ | ||||||

| α-ZEL | ND | ND | ND | ||||||

| β-ZEL | ND | ND | ND | ||||||

| Maize panel | NM | NM | AFB1 | 24 | 29.2 | ≥0.005–75.0 Φ | 22.1 | 2016 | [39] |

| Silage | Iran | NM | AFB1 | 103 | 94.17 | NM–71.57 Φ | 3.86 | 2016 | [158] |

| Silage | Brazil | NM | FM | 36 | ND | ND | ND | 2016 | [117] |

| DON | 2.7 | 300 | ꟷ | ||||||

| AF | 77.7 | <2.0–7.3 | NM | ||||||

| OTA | 33.3 | <2.0–6.9 | NM | ||||||

| ZEN | 22.2 | <25.0–91.3 | NM | ||||||

| T-2/HT-2 | ND | ND | ND | ||||||

| Silage | Iran | 2014 | AFB1 | 70 | 25.7 | 2.53–18.65 | 10.98 | 2016 | [174] |

| Silage | Spain | NM | DON | 148 | 10.8 | 143.1–6685.6 | 1685.4 | 2016 | [71] |

| FB1 | 9.5 | 10.4–994.1 | 212.4 | ||||||

| FB2 | 22.3 | 10.7–137.0 | 50.9 | ||||||

| ZEN | 21.6 | 63.5–820.2 | 221.1 | ||||||

| α-ZEL | 2.0 | 606.6–2889.4 | 1833.3 | ||||||

| β-ZEL | 2.7 | 326.1–1721.1 | 779.3 | ||||||

| 3-/15-AcDON | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| T-2 | ND | ND | ND | ||||||

| OTA | ND | ND | ND | ||||||

| AFB1 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| Silage | Italy | 2011–2013 | DON | NM | NM | NM | 49 | 2016 | [175] |

| Silage | England | 2014 | DON | 29 | 70 | ≥10.0–7111 | 603 | 2016 | [176] |

| ZEN | 55 | ≥10.0–3901 Φ | 209 | ||||||

| FB1 | 24 | ≥1.0–107 | 10.4 | ||||||

| FB2 | 24 | ≥1.0–24 | 2.50 | ||||||

| T-2 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| AFB1 | ND | ND | ND | ||||||

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| OTA | ND | ND | ND | ||||||

| Silage | Poland | 2011–2014 | DON | 143 | 86 | ≥1.0–7860 | 853 | 2016 | [15] |

| T-2 | 48 | ≥0.2–31.2 | 2.21 | ||||||

| HT-2 | 73 | ≥0.7–204 | 35.9 | ||||||

| ZEN | 87 | ≥0.07–1133 | 84.4 | ||||||

| FMs | 21 | 52 | ≥1.6–108 | 23.8 | |||||

| OTA | 61 | 36 | ≥0.13–10.2 | 2.16 | |||||

| AFs | 26 | 4 | 0.15 | - | |||||

| Fresh silage | Lithuania | NM | AFs | 20 | 15 | NM | 0.94 | 2016 | [72] |

| ZEN | 100 | 206.88 | |||||||

| DON | 100 | 1640.0 | |||||||

| T-2/HT-2 | 45 | 40.21 | |||||||

| OTA | ND | ND | |||||||

| Silage after 3 months of storage | AFs | 20 | 8 | NM | 16.86 | ||||

| ZEN | 100 | 880.04 | |||||||

| DON | 100 | 2600.0 | |||||||

| T-2/HT-2 | 100 | 141.48 | |||||||

| OTA | NM | 29.15 | |||||||

| Silage after 8 months of storage | AFs | 20 | 75 | NM | 20.05 | ||||

| ZEN | 100 | 380.42 | |||||||

| DON | 100 | 1118.3 | |||||||

| T-2/HT-2 | 100 | 147.25 | |||||||

| OTA | NM | 18.95 | |||||||

| Silage | Iran | NM | AFB1 | 40 | 40 | 0.3–8.24 | 4.47 | 2016 | [177] |

| AFB2 | 32 | 0.015–7.24 | 3.53 | ||||||

| AFG1 | 28 | 0.05–6.04 | 2.60 | ||||||

| AFG2 | 28 | 0.03–2.9 | 1.30 | ||||||

| WDG | NM | NM | DON | 5 | 40 | 218–276 | 247.0 | 2016 | [159] |

| 15-AcDON | ND | ND | ND | ||||||

| 3-AcDON | ND | ND | ND | ||||||

| AFB1 | ND | ND | ND | ||||||

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| FB1 | 20 | 35 | - | ||||||

| FB2 | ND | ND | ND | ||||||

| FB3 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| T-2 | ND | ND | ND | ||||||

| OTA | ND | ND | ND | ||||||

| ZEN | 20 | 1 | - | ||||||

| α-ZEL | ND | ND | ND | ||||||

| β-ZEL | ND | ND | ND | ||||||

| Sample | Country of Origin | Year of Collection | Mycotoxin/ Metabolite | Total Samples | Positive Samples | Year of Publication | Reference | ||

|---|---|---|---|---|---|---|---|---|---|

| % | Range (µg/kg) | Mean (µg/kg) | |||||||

| Silage | Iran | NM | FMs | 35 | 9 | NM–0.4 | 0.034 | 2016 | [178] |

| ZEN | 88 | NM–10.40 | 3.77 | ||||||

| Spring wheat | Lithuania | 2013/14 | DON | 114 | 99 | ≥100–10644.0 Φ | 798.77 | 2016 | [179] |

| Wheat | Pakistan | 2014 | AFB1 | 185 | 26.0 | 0.05–4.78 | 0.51 | 2016 | [180] |

| AFB2 | 7.0 | 0.02–0.48 | 0.02 | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| AFs | 26.0 | 0.02–5.26 | 0.53 | ||||||

| Wheat | Norway | NM | DON | 25 | 84 | 5–94 | 28.3 | 2016 | [165] |

| HT-2 | 36 | 10–23 | 15.0 | ||||||

| T-2 | 16 | 11–12 | 11.5 | ||||||

| HT-2 + T-2 | 24 | 20–34 | 19.38 | ||||||

| Wheat | China | 2012–2014 | AFB1 | 27 | 63 | ≥0.5–54.5 Φ | 11.0 | 2016 | [138] |

| ZEN | 36 | 83 | ≥10–1278.9 | 215.0 | |||||

| DON | 29 | 69 | ≥100–3536.2 | 1262.5 | |||||

| Wheat | China | 2013–2015 | AFB1 | 24 | 50 | ≥0.5–4.0 | 1.1 | 2016 | [97] |

| ZEN | 92 | ≥10–161.8 | 120.2 | ||||||

| DON | 100 | ≥100–1048.1 | 647.1 | ||||||

| Wheat | Belgium and Hungary | NM | DON | 16 | 100 | NM–1113 | 244 | 2016 | [181] |

| Wheat | Croatia | 2014–2015 | T-2/HT-2 | 24 | 33.3 | 32.5–123.4 | 55.8 | 2017 | [170] |

| Bosnia and Herzegovina | 28 | 21.4 | 31.5–105.0 | 59.0 | |||||

| Wheat | China | 2013 | DON | 1 | 100 | 1690 | - | 2016 | [140] |

| Wheat and wheat bran | Qatar | NM | AFs | 10 | 40 | NM–14 | 9 | 2018 | [166] |

| OTA | 60 | NM–45 | 3 | ||||||

| Wheat bran | Iran | NM | AFB1 | 41 | 97.56 | NM–56.13 Φ | 2.94 | 2016 | [158] |

| Wheat bran | NM | NM | AFB1 | 35 | NM | 9–31 Φ | 15 | 2016 | [161] |

| Wheat bran | China | 2013–2015 | AFB1 | 55 | 73 | ≥0.5–10.9 | 2.6 | 2016 | [97] |

| ZEN | 98 | ≥10–329.0 | 148.1 | ||||||

| DON | 98 | ≥100–3503.2 | 951.2 | ||||||

| Wheat bran | China | 2013 | DON | 1 | 100 | 2050 | - | 2016 | [140] |

| Wheat bran | China | NM | AFB1 | 30 | 10.0 | <0.03–19.9 | 9.8 | 2018 | [171] |

| Wheat dust | Belgium and Hungary | NM | DON | 16 | 100 | 607–14043 Φ | 5012 | 2016 | [181] |

| Wheat grains | Slovakia | 2013 | DON | 178 | 82.0 | NM–5100 | 740 | 2016 | [182] |

| Wheat shorts | China | 2013 | DON | 1 | 100 | 2940 | - | 2016 | [140] |

| Wheat shorts and red dog | China | 2013–2015 | AFB1 | 20 | 90 | ≥0.5–10.5 | 5.3 | 2016 | [97] |

| ZEN | 100 | ≥10–280.3 | 207.7 | ||||||

| DON | 100 | ≥100–1319.5 | 572.0 | ||||||

| Winter wheat | Lithuania | 2013/14 | DON | 30 | 67 | ≥100–1393.0 | 383.98 | 2016 | [179] |

| Sample | Country of Origin | Year of Collection | Mycotoxin/Metabolite | Total Samples | Positive Samples | Year of Publication | Reference | ||

|---|---|---|---|---|---|---|---|---|---|

| % | Range (µg/kg) | Mean (µg/kg) | |||||||

| Processed soya bean powder | Nigeria | NM | AFs | 20 | 45 | NM–813 Φ | NM | 2016 | [77] |

| FB1 | 100 | NM–4286 | NM | ||||||

| OTA | 40 | NM–125 | NM | ||||||

| Soy | Croatia | 2014–2015 | T-2/HT-2 | 7 | 28.6 | 32.3–33.8 | 33.1 | 2017 | [170] |

| Bosnia and Herzegovina | 5 | 40.0 | 30.6–42.5 | 36.6 | |||||

| Soya bean meal | USA | NM | FB1 | 1 | ND | ND | ND | 2016 | [63] |

| NM | AFB2 | 1 | ND | ND | ND | ||||

| Soya bean meal | Pakistan | 2012–2013 | OTA | 120 | 63.3 | 4.33–211.16 | 113.43 | 2017 | [169] |

| Soya bean seeds | Nigeria | NM | AFs | 21 | 100 | 111 Φ–3430 Φ | NM | 2016 | [77] |

| FB1 | 100 | 33–2270 | NM | ||||||

| OTA | 23.8 | NM–51 | NM | ||||||

| Soybean and soybean by-products | Brazil | 2010–2011 | AFB1 | 30 | 43.3 | LOQ–7.9 | 0.5 | 2018 | [183] |

| ZEN | 80 | LOQ–104 | 16.7 | ||||||

| Soybean meal | Pakistan | 2012/13 | AFB1 | 14 | 64 | 0.09–105.9 Φ | 4.90 | 2016 | [184] |

| AFs | LOQ–135.3 Φ | 5.20 | |||||||

| ZEN | 71 | 0.15–120.89 | 18.90 | ||||||

| Soybean meal | China | 2013–2015 | AFB1 | 29 | 90 | ≥0.5–9.8 | 3.9 | 2016 | [97] |

| ZEN | 97 | ≥10–332.5 | 189.5 | ||||||

| DON | 97 | ≥100–786.4 | 457.5 | ||||||

| Soybean meal | Iran | NM | AFB1 | 7 | 71.43 | NM–11.46 | 6.62 | 2016 | [158] |

| Soybean meal | China | NM | AFB1 | 34 | 29.4 | <0.03–9.9 | 1.7 | 2018 | [171] |

| Soybeans | Qatar | NM | AFs | 6 | 100 | 5–150 | 55 | 2018 | [166] |

| OTA | ND | ND | ND | ||||||

| Sample | Country of Origin | Year of Collection | Mycotoxin/ Metabolite | Total Samples | Positive Samples | Year of Publication | Reference | ||

|---|---|---|---|---|---|---|---|---|---|

| % | Range (µg/kg) | Mean (µg/kg) | |||||||

| Broiler feed | India | NM | OTA | 50 | 42 | 10.13–14.23 | 11.69 | 2016 | [139] |

| Broiler feeds | Thailand | NM | AFB1 | 100 | 93 | 0.47–8.52 | 2.02 | 2016 | [79] |

| AFB2 | 20 | 0.79–3.30 | 1.87 | ||||||

| AFG1 | 7 | 0.66–1.89 | 1.30 | ||||||

| AFG2 | ND | ND | ND | ||||||

| T-2 | 1 | 1.15 | - | ||||||

| OTA | ND | ND | ND | ||||||

| ZEN | 63 | 2.22–263.51 | 84.27 | ||||||

| DON | 9 | 33.58–60.81 | 45.05 | ||||||

| Broiler finisher feed | Egypt | NM | FB1 | 2 | 50 | NM | NM | 2016 | [63] |

| Broiler starter feed | AFB1 | 1 | ND | ND | ND | ||||

| AFB2 | |||||||||

| Calves feed | Croatia | 2014–2015 | T-2/HT-2 | 17 | 47.1 | 26.3–129.3 | 65.1 | 2017 | [170] |

| Bosnia and Herzegovina | 12 | 58.3 | 25.7–70.5 | 42.7 | |||||

| Cattle complete feed | China | 2013–2015 | AFB1 | 6 | 100 | ≥0.5–8.3 | 4.5 | 2016 | [97] |

| ZEN | ND | ND | ND | ||||||

| DON | ND | ND | ND | ||||||

| Cattle compound feed | Spain | 2012–2014 | AFB1 | 6 | 33 | <2 | - | 2018 | [185] |

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| ZEN | 11 | 88.2 | - | ||||||

| OTA | 33 | <25 | - | ||||||

| DON | 11 | 289.9 | - | ||||||

| 3-AcDON + 15-AcDON | ND | ND | ND | ||||||

| FB1 | 67 | <375–863.9 | 697.6 | ||||||

| FB2 | 67 | <125–276.1 | 215.2 | ||||||

| T-2 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| Cattle feed | China | NM | AFB1 | 20 | 30 | NM–28.27 Φ | 3.96 | 2016 | [78] |

| AFB2 | 25 | NM–22.43 | 2.98 | ||||||

| AFG1 | 15 | NM–12.37 | 1.24 | ||||||

| AFG2 | 5 | NM–1.84 | 0.09 | ||||||

| OTA | 25 | NM–15.64 | 1.53 | ||||||

| ZEN | 20 | NM–14.43 | 1.45 | ||||||

| T-2 | 30 | NM–8.23 | 2.07 | ||||||

| Cattle feed | Egypt | NM | AFB1 | 60 | 18.3 | 1.5–72.4 Φ | 24.15 | 2016 | [136] |

| Cattle feed | South Korea | 2014 | DON | 60 | 100.0 | 91.65–950.25 | 602.51 | 2016 | [143] |

| 3-AcDON | 3.3 | ≥8.3–52.10 | 32.75 | ||||||

| Cattle feed | NM | NM | ZEN | 14 | NM | <1.1 | - | 2018 | [186] |

| α-ZEL | ND | ND | ND | ||||||

| β-ZEL | ND | ND | ND | ||||||

| Cattle feeds | Korea | 2009–2016 | ZEN | 174 | 97.7 | NM | 134.23 | 2017 | [187] |

| Chicken complete feed | China | 2012–2014 | AFB1 | 290 | 57 | ≥0.5–187.5 Φ | 25.4 | 2016 | [138] |

| Chicken feed | China | NM | AFB1 | 20 | 30 | NM–21.27 Φ | 2.68 | 2016 | [78] |

| AFB2 | 25 | NM–15.33 | 1.56 | ||||||

| AFG1 | 10 | NM–8.36 | 0.43 | ||||||

| AFG2 | 5 | NM–1.64 | 0.08 | ||||||

| OTA | 25 | NM–10.55 | 1.09 | ||||||

| ZEN | 25 | NM–61.59 | 4.84 | ||||||

| T-2 | 15 | NM–5.28 | 0.32 | ||||||

| Chicken feed | NM | NM | ZEN | 13 | ND | ND | ND | 2018 | [186] |

| α-ZEL | ND | ND | ND | ||||||

| β-ZEL | NM | <0.6 | - | ||||||

| Chicken feeds | Korea | NM | AFs | 20 | 100 | 0.10–1.86 | 0.56 | 2016 | [141] |

| AFB1 | NM | 0.09–1.70 | 0.38 | ||||||

| OTA | 100 | 0.14–2.24 | 0.77 | ||||||

| ZEN | 85 | 5.17–147.53 | 35.02 | ||||||

| Chicken feed | South Korea | 2014 | DON | 50 | 94.0 | ≥3.3–603.10 | 258.36 | 2016 | [143] |

| 3-AcDON | 2.0 | ≥8.3–29.70 | - | ||||||

| Complementary dairy cow feed | NM | NM | AFB1 | 31 | 71.0 | ≥0.005–51.4 Φ | 10.1 | 2016 | [39] |

| Complete farm-mixed wet feed for pigs | Norway | NM | DON | 15 | 27 | 10–34 | 354 | 2016 | [165] |

| HT-2 | 7 | 10 | - | ||||||

| T-2 | ND | ND | ND | ||||||

| T-2 + HT-2 | ND | ND | ND | ||||||

| Complete feed for pigs | DON | 13 | 100 | 20–289 | 117.0 | ||||

| HT-2 | 100 | 10–94 | 47.0 | ||||||

| T-2 | 73 | 10–60 | 23.4 | ||||||

| T-2 + HT-2 | 97 | 22–140 | 66.7 | ||||||

| ZEN | 97 | 1.5–217.2 | 37.8 | ||||||

| OTA | 80 | 0.1–1.44 | 0.32 | ||||||

| Complete feed samples for swine, poultry and cattle | Poland | 2011–2014 | DON | 480 | 99 | ≥1.0–5478 Φ | 4689 | 2016 | [15] |

| T-2 | 97 | ≥0.2–185 | 8.19 | ||||||

| ZEN | 99 | ≥0.07–349 | 35.6 | ||||||

| HT-2 | 479 | 97 | ≥0.7–276 Φ | 16.7 | |||||

| FMs | 14 | 86 | ≥1.6–1063 | 209 | |||||

| OTA | 412 | 69 | ≥0.13–88.0 Φ | 3.14 | |||||

| AFs | 241 | 12 | NM–1.31 | 0.47 | |||||

| Complete feed | China | 2012–2014 | ZEN | 147 | 95 | ≥10–3261.2 Φ | 221.0 | 2016 | [138] |

| DON | 116 | 77 | ≥100–2611.4 | 626.8 | |||||

| Compound feeds | South Africa | NM | AFB1 | 5 | 40 | <0.06 | - | 2018 | [160] |

| AFB2 | 100 | 0.551; 1.365 | 0.871 | ||||||

| AFG1 | 20 | <0.15 | - | ||||||

| AFG2 | 100 | 7.848; 31.748 | 17.589 | ||||||

| ZEN | 80 | 0.562; 1.853 | 1.127 | ||||||

| α-ZEL | 100 | 0.975; 3.391 | 2.711 | ||||||

| β-ZEL | 100 | 1.776; 3.801 | 2.875 | ||||||

| FB1 | 100 | 494.409; 1389.624 | 805.677 | ||||||

| DON | 100 | 3.225; 56.520 | 33.154 | ||||||

| 3-AcDON + 15-AcDON | 20 | >0.27 | - | ||||||

| HT-2 | 80 | >0.21; 5.061 | 2.972 | ||||||

| OTA | ND | ND | ND | ||||||

| Concentrate cow feed | Iran | 2014 | AFB1 | 70 | 44.3 | 2.08–19.41 | 9.77 | 2016 | [174] |

| Concentrated feed | China | NM | DON | 8 | 75 | 11.6–277.6 | NM | 2016 | [93] |

| 3-AcDON | 63 | 5.6–56.4 | |||||||

| 15-AcDON | 63 | 5.7–160.2 | |||||||

| Dairy cattle CFM | Egypt | NM | AFB1 | 1 | 100 | NM | NM | 2016 | [63] |

| AFB2 | |||||||||

| Dairy cattle feed | Brazil | 2011–2014 | AFB1 | 160 | 100 | 0.2–50.0 Φ | NM | 2016 | [84] |

| Dairy concentrate feed | Kenya | NM | AFB1 | NM | NM | 21.33–147.86 Φ | 47.84 | 2016 | [188] |

| DON | ≥18.53–179.89 | 86.95 | |||||||

| Dairy feed | Kenya | 2014 | AFB1 | 277 | 73 | ≥1–9661 Φ | 154.5 | 2016 | [189] |

| Dairy feeds | NM | NM | AFB1 | 156 | 100 | 7–419 Φ | 97 | 2016 | [161] |

| Duck complete feed | China | 2012–2014 | AFB1 | 282 | 52 | ≥0.5–150.0 Φ | 22.6 | 2016 | [138] |

| Duck complete feed | China | 2013–2015 | AFB1 | 6 | 100 | ≥0.5–8.84 | 6.4 | 2016 | [97] |

| ZEN | 86 | ≥10–357.9 | 307.0 | ||||||

| DON | 100 | ≥100–2613.7 | 1718.3 | ||||||

| Duck feed | NM | NM | ZEN | 15 | 7 | 39.08~47.61 | - | 2018 | [186] |

| α-ZEL | 7 | 4.19 | - | ||||||

| β-ZEL | ND | ND | ND | ||||||

| Feed and raw materials | Italy | 2010–2014 | AFB1 | 919 | 68 | ≥1–18.37 | NM | 2016 | [190] |

| Finished feed | South Africa | 2006–2017 | AFs | 310 | 5.8 | >LOD–232 | NM | 2018 | [172] |

| ZEN | 301 | 57.5 | >LOD–386 | ||||||

| DON | 311 | 67.2 | >LOD–9805 | ||||||

| T2 | 301 | 1.3 | >LOD–4.5 | ||||||

| FB1 + FB2 | 306 | 83.3 | >LOD–7578 | ||||||

| OTA | 259 | 3.1 | >LOD–6.0 | ||||||

| Feed materials | Spain | 2012–2014 | AFB1 | 3 | ND | ND | ND | 2018 | [185] |

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| ZEN | ND | ND | ND | ||||||

| OTA | 33 | <25 | - | ||||||

| DON | ND | ND | ND | ||||||

| 3-AcDON + 15-AcDON | ND | ND | ND | ||||||

| FB1 | 67 | <375 | - | ||||||

| FB2 | 67 | <125 | - | ||||||

| T-2 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| Formula feed | China | NM | DON | 11 | 82 | 47.1–864.5 | NM | 2016 | [93] |

| 3-AcDON | 73 | 5.1–221.8 | |||||||

| 15-AcDON | 55 | 5.0–350.4 | |||||||

| Finished feed for poultry, swine and ruminant, maize and maize silage | 44 countries | 2012–2015 | AFB1 | 1113 | 4.9 | ≥1.5–1077 Φ | NM | 2016 | [43] |

| AFB2 | 1.4 | ≥1.5–112 | |||||||

| AFG1 | 1.9 | ≥1.5–95 | |||||||

| AFG2 | 0.80 | ≥1.5–12 | |||||||

| ZEN | 88 | ≥1–11192 Φ | |||||||

| DON | 79 | ≥1.5–13488 | |||||||

| 3-AcDON | 7.1 | ≥15–527 | |||||||

| 15-AcDON | 13 | ≥15–2177 | |||||||

| T-2 | 10 | ≥10–852 Φ | |||||||

| T-2 Tetraol | 1.3 | ≥15–290 | |||||||

| T-2 Triol | 0.10 | ≥15–93 | |||||||

| HT-2 | 19 | ≥10–2328 Φ | |||||||

| FB1 | 67 | ≥4.0–31784 | |||||||

| FB2 | 58 | ≥4.0–12968 | |||||||

| FB3 | 40 | ≥4.0–3345 | |||||||

| FB4 | 28 | ≥4.0–4341 | |||||||

| FB6 | 0.10 | ≥4.0–30 | |||||||

| OTA | 4.5 | ≥1.5–67 | |||||||

| Full ration pellet for dairy cow | Iran | NM | AFB1 | 64 | 100.00 | 0.02–36.07 Φ | 3.64 | 2016 | [158] |

| Feed | Egypt | 2014–2015 | AFB1 | 77 | 4 | NM–11 | NM | 2017 | [168] |

| DON | 71 | NM–1516 | |||||||

| FB1 | 77 | NM–2409 | |||||||

| FB2 | 69 | NM–260 | |||||||

| FB3 | 55 | NM–310 | |||||||

| HT-2 | 13 | NM–32.3 | |||||||

| T-2 | 25 | NM–39.5 | |||||||

| ZEN | 92 | NM–791 | |||||||

| α-ZEL | 6 | NM–8 | |||||||

| β-ZEL | 36 | NM–60 | |||||||

| Layer feed | India | NM | OTA | 50 | 46 | 12.33–15.20 | 13.22 | 2016 | [139] |

| Layer poultry feed | Egypt | NM | AFB1 | 1 | ND | ND | ND | 2016 | [63] |

| AFB2 | |||||||||

| Mixed dairy cow feeds | Turkey | 2012–2015 | AFB1 | 76 | 26.3 | 0.278–6.89 Φ | 2.25 | 2016 | [191] |

| AFB2 | 23.7 | 0.081–0.752 | 0.231 | ||||||

| AFG1 | 22.4 | 0.207–0.788 | 0.334 | ||||||

| AFG2 | ND | ND | ND | ||||||

| Mixed ruminant feed | Turkey | 2012/13 | AFs | 88 | 81.81 | NM–33.90 | 5.22 | 2016 | [192] |

| AFB1 | 81.81 | NM–19.24 Φ | 2.85 | ||||||

| OTA | 95.45 | NM–79.10 | 30.45 | ||||||

| FMs | 94.31 | NM–1600 | 307.5 | ||||||

| Pig complete feed | China | 2012–2014 | AFB1 | 802 | 30 | ≥0.5–111.0 Φ | 12.6 | 2016 | [138] |

| Pig complete feed (powder) | China | 2013–2015 | AFB1 | 25 | 96 | ≥0.5–9.1 | 13.7 | 2016 | [97] |

| ZEN | 96 | ≥10–835.4 Φ | 290.4 | ||||||

| DON | 96 | ≥100–2767.6 Φ | 999.2 | ||||||

| Pig complete feed (pellet) | AFB1 | 90 | 78 | ≥0.5–18.1 | 5.8 | ||||

| ZEN | 82 | ≥10–329.0 Φ | 291.4 | ||||||

| DON | 81 | ≥100–3346.0 Φ | 642.5 | ||||||

| Pig feed | China | NM | AFB1 | 20 | 40 | NM–32.12 Φ | 4.29 | 2016 | [78] |

| AFB2 | 25 | NM–21.53 | 2.34 | ||||||

| AFG1 | 20 | NM–7.35 | 1.01 | ||||||

| AFG2 | 10 | NM–5.08 | 0.31 | ||||||

| OTA | 20 | NM–13.22 | 1.23 | ||||||

| ZEN | 30 | NM–18.78 | 1.87 | ||||||

| T-2 | 35 | NM–1.55 | 35 | ||||||

| Pigs feed | Croatia | 2014–2015 | T-2/HT-2 | 24 | 53.3 | 24.7–93.4 | 39.9 | 2017 | [170] |

| Bosnia and Herzegovina | 16 | 50 | 25.6–118.1 | 45.9 | |||||

| Pig feeds | Korea | 2009–2016 | ZEN | 160 | 95.0 | NM | 31.70 | 2017 | [187] |

| Pig feed | NM | NM | ZEN | 17 | 6 | 124.78 | - | 2018 | [186] |

| α-ZEL | NM | <0.6 | - | ||||||

| β-ZEL | ND | ND | ND | ||||||

| Pig feed | South Korea | 2014 | DON | 50 | 100.0 | 32.38–932.48 Φ | 164.74 | 2016 | [143] |

| 3-AcDON | ND | ND | ND | ||||||

| Poultry compound feed | Spain | 2012–2014 | AFB1 | 9 | 11 | <2 | - | 2018 | [185] |

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| ZEN | 11 | <50 | - | ||||||

| OTA | 11 | <25 | - | ||||||

| DON | 11 | <250 | - | ||||||

| 3-AcDON + 15-AcDON | ND | ND | ND | ||||||

| FB1 | 11 | <375 | - | ||||||

| FB2 | 11 | 139.2 | - | ||||||

| T-2 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| Poultry feed 1 | Pakistan | 2012/13 | AFB1 | 11 | 82 | 0.09–145.7 Φ | 6.20 | 2016 | [184] |

| AFs | LOQ–165.5 | 9.30 | |||||||

| ZEN | 82 | 0.15–125.20 | 15.80 | ||||||

| Poultry feed 2 | AFB1 | 13 | 54 | 0.09–98.3 Φ | 4.97 | ||||

| AFs | LOQ–103.1 | 7.89 | |||||||

| ZEN | 77 | 0.15–118.42 | 19.45 | ||||||

| Poultry feed | Pakistan | 2012–2013 | OTA | 120 | 68.6 | 2.88–178.78 | 93.03 | 2017 | [169] |

| Poultry feed | Croatia | 2014–2015 | T-2/HT-2 | 13 | 53.9 | 30.0–63.7 | 44.6 | 2017 | [170] |

| Bosnia and Herzegovina | 9 | 66.7 | 32.6–52.3 | 42.6 | |||||

| Poultry feeds | Morocco | 2013/14 | OTA | 62 | 30.6 | 0.24–26.8 | 7.1 | 2016 | [90] |

| Poultry feeds | Korea | 2009–2016 | ZEN | 160 | 96.3 | NM | 37.93 | 2017 | [187] |

| Poultry, swine, cattle, horse and lamb feed | Spain | NM | DON | 32 | NM | NM | NM | 2016 | [104] |

| AFG2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFB2 | ND | ND | ND | ||||||

| AFB1 | ND | ND | ND | ||||||

| T-2 | ND | ND | ND | ||||||

| ZEN | 6 | 13.8–14.8 | 14.3 | ||||||

| OTA | ND | ND | ND | ||||||

| FB1 | NM | NM | NM | ||||||

| FB2 | NM | NM | NM | ||||||

| Premixed feed | China | NM | DON | 12 | 67 | 97.4–776.3 | NM | 2016 | [93] |

| 3-AcDON | 42 | 26.5–135.1 | |||||||

| 15-AcDON | 17 | 99.5–332.8 | |||||||

| Rabbit feed | China | NM | AFB1 | 20 | 30 | NM–12.22 Φ | 1.56 | 2016 | [78] |

| AFB2 | 25 | NM–9.31 | 1.28 | ||||||

| AFG1 | 10 | NM–6.37 | 0.51 | ||||||

| AFG2 | 5 | NM–1.46 | 0.07 | ||||||

| OTA | 25 | NM–15.21 | 1.44 | ||||||

| ZEN | 40 | NM–10.46 | 2.25 | ||||||

| T-2 | 25 | NM–7.49 | 0.86 | ||||||

| Sheep compound feed | Spain | 2012–2014 | AFB1 | 17 | 6 | <2 | - | 2018 | [185] |

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| ZEN | 18 | <50–104,4 | 79,5 | ||||||

| OTA | 29 | <25 | - | ||||||

| DON | 12 | <250 | - | ||||||

| 3-AcDON +15-AcDON | ND | ND | ND | ||||||

| FB1 | 53 | <375 | - | ||||||

| FB2 | 53 | <125 | - | ||||||

| T-2 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| Starter feed | India | NM | OTA | 50 | 32 | 5.13–6.73 | 5.78 | 2016 | [139] |

| Silage, corn dust, commercial concentrate | Thailand | 2011 | AFB1 | 125 | NM | 3.95–114.9 | NM | 2017 | [193] |

| Swine compound feed | Spain | 2012–2014 | AFB1 | 20 | 15 | <2 | - | 2018 | [185] |

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| ZEN | 10 | <50 | - | ||||||

| OTA | 40 | <25 | - | ||||||

| DON | 5 | 254,9 | - | ||||||

| 3-AcDON + 15-AcDON | ND | ND | ND | ||||||

| FB1 | 45 | <375 | - | ||||||

| FB2 | 45 | <125 | - | ||||||

| T-2 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| Swine feed | Hungary | NM | DON | 45 | NM | 137–997 Φ | 261 | 2016 | [194] |

| ZEN | 18–192 | 39 | |||||||

| T-2 | 18–55 | 40 | |||||||

| Total mixed ration for dairy | England | 2014 | DON | 38 | 66 | ≥10.0–1654 | 154 | 2016 | [176] |

| ZEN | 39 | ≥10.0–1431 Φ | 84.2 | ||||||

| FB1 | NM | ≥1.0–119 | 11.5 | ||||||

| FB2 | NM | ≥1.0–48.0 | 3.95 | ||||||

| T-2 | ND | ND | ND | ||||||

| HT-2 | ND | ND | ND | ||||||

| AFB1 | ND | ND | ND | ||||||

| AFB2 | ND | ND | ND | ||||||

| AFG1 | ND | ND | ND | ||||||

| AFG2 | ND | ND | ND | ||||||

| OTA | ND | ND | ND | ||||||

| Total mixed rations | South Africa | NM | AFB1 | 5 | 100 | <0.06; 0.463 | 0.299 | 2018 | [160] |

| AFB2 | 100 | 0.903; 5.339 | 3.070 | ||||||

| AFG1 | 80 | <0.15; 2.655 | 1.049 | ||||||

| AFG2 | 100 | 31.307; 50.199 | 40.708 | ||||||

| ZEN | 100 | 0.325; 28.040 | 7.191 | ||||||

| α-ZEL | 100 | 2.913; 5.637 | 3.723 | ||||||

| β-ZEL | 100 | 1.445; 3.356 | 2.708 | ||||||

| FB1 | 100 | 134.231; 1067.822 | 542.589 | ||||||

| DON | 100 | <1.62; 18.038 | 10.255 | ||||||

| 3-AcDON + 15-AcDON | 80 | 0.507; 2.634 | 1.281 | ||||||

| HT-2 | 100 | 0.834; 48.268 | 22.970 | ||||||

| OTA | ND | ND | ND | ||||||

Appendix B

| Mycotoxin/ Metabolite | Matrix | Sample Pre-Treatment | ELISA | Year of Publication | Reference | ||

|---|---|---|---|---|---|---|---|

| Extraction | Format | Detection Method | LOD; LOQ (µg/kg) or (µg/L) | ||||

| AFB1 | Maize; wheat bran and dairy feeds | MeCN 80% | Direct competitive | Optical density | NM | 2016 | [161] |

| AFB1 | Corn silage; crushed yellow corn; wheat bran; soybean meal and full ration pellet for dairy cow | MeOH 70% | Competitive | Absorbance | 1; NM | 2016 | [158] |

| AFB1 | Dairy concentrate feed | MeOH 70% | Competitive | Absorbance | 1.75; 3.61 | 2016 | [188] |

| AFB1 | Feed and raw materials | 1 g of NaCl and MeOH 70% | Competitive | Absorbance | 1; NM | 2016 | [190] |

| AFs | Distiller’s dried grains with solubles | MeOH 80% | Direct competitive | Absorbance | NM | 2016 | [195] |

| AFB1 | Commercial concentrate | Methyl alcohol 70% | Direct competitive | Absorbance | NM; 3.43 | 2018 | [193] |

| Corn dust | NM; 3.12 | ||||||

| Silage | NM; 6.93 | ||||||

| DON | Dairy concentrate feed | Distilled water | Competitive | Absorbance | 18.5; 21.68 | 2016 | [188] |

| DON | Wheat | Water | Direct competitive | Absorbance | 233; NM | 2016 | [181] |

| Wheat dust | 458; NM | ||||||

| DON | Maize | Distilled water | Direct competitive | Optical density | 100; 250 | 2017 | [163] |

| DON | Swine feed | NM | Competitive | Absorbance | 13; 200 | 2016 | [194] |

| DON | Cereals and feedstuff | Double-distilled water | Direct competitive | Absorbance | 300; NM | 2017 | [196] |

| Wheat and feedstuff | 480; NM | ||||||

| FMs | Wheat silage | MeOH 80% | Competitive | Absorbance | NM | 2016 | [178] |

| OTA | Poultry feed and poultry feed ingredients | MeOH 70% | Direct Competitive | Absorbance | 1.9; 2.0 | 2017 | [169] |

| T-2 | Swine feed | NM | Competitive | Absorbance | 13; 200 | 2016 | [194] |

| T-2/HT-2 | Maize | MeOH 70% | Competitive | Absorbance | 9.1; 14.6 | 2017 | [170] |

| Wheat | 14.6; 20.1 | ||||||

| Pig feed | 14.8; 21.5 | ||||||

| ZEN | Swine feed | NM | Competitive | Absorbance | 13; 200 | 2016 | [194] |

| ZEN | Wheat silage | MeOH 60% | Competitive | Absorbance | 12.5; NM | 2016 | [178] |

| Mycotoxin/ Metabolite | Matrix | Sample Pre-Treatment | GC-MS | Year of Publication | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| Extraction | Clean-Up | Derivatization | Ionization/ Ion Selection | Scan Mode | LOD; LOQ (µg/kg) or (µg/L) | ||||

| DON | Wheat; complete feed for pigs; complete farm-mixed wet feed for pigs | NM | NM | NM | NM | NM | NM; 10 | 2016 | [165] |

| DON | Durum wheat | MeCN 82% | Charcoal/Alumina/Celite column | TMSIM-TMCS (100/1 v/v) | NM | SIM | 0.01; NM | 2016 | [197] |

| 3-AcDON | |||||||||

| 15-AcDON | |||||||||

| T-2 | Wheat; complete feed for pigs; complete farm-mixed wet feed for pigs | NM | NM | NM | NM | NM | NM; 10 | 2016 | [165] |

| HT-2 | NM; 10 | ||||||||

| T-2 + HT-2 | NM; 10 | ||||||||

| Mycotoxin/ Metabolite | Matrix | Sample Pre-Treatment | HPLC | Year of Publication | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| Extraction | Clean-Up | Derivatization | Detection Method | Column | LOD; LOQ (µg/kg) or (µg/L) | ||||

| AFB1 | Wheat | MeOH 80% | Easi-Extract® AF IAC | Post-column derivatization | Fluorescence | LiChroCART 100Å RP-18 (5 mm, 250 × 4.0 mm) | 0.031; 0.093 | 2016 | [180] |

| AFB2 | 0.022; 0.066 | ||||||||

| AFG1 | 0.032; 0.096 | ||||||||

| AFG2 | 0.028; 0.084 | ||||||||

| AFs | 0.091; 0.273 | ||||||||

| AFB1 | Maize | NM | IAC | Post-column derivatization | Fluorescence | NM | NM; 0.1 | 2016 | [165] |

| AFB2 | NM; 0.1 | ||||||||

| AFG1 | NM; 0.1 | ||||||||

| AFG2 | NM; 0.1 | ||||||||

| AFs | NM; 0.1 | ||||||||

| AFB1 | Corn silage | MeOH 80% | C18 SPE column | Electrochemical post-column derivatization | Fluorescence | NM | 0.12; 0.4 | 2016 | [177] |

| AFB2 | 0.015; 0.05 | ||||||||

| AFG1 | 0.05; 0.16 | ||||||||

| AFG2 | 0.03; 0.1 | ||||||||

| AFB1 | Maize; wheat; pig, chicken and duck complete feed | MeOH 80% | CF AFLA IAC | - | Fluorescence | C18 (250 × 4.6 mm, 5 μm) | 0.5; 1.5 | 2016 | [138] |

| AFB1 | Soybean kernels | MeCN 75% | IAC AlfaStarTM Fit | Post-column photochemical derivatization | Fluorescence | X-Terra RP18 (4.6 × 150 mm, 5 µm) | 0.13; 0.37 | 2018 | [183] |

| AFB1 | Maize panel and complementary dairy cow feed | NM | AflaPrep® IAC SPE | Electrochemical post-column derivatization with potassium bromide | Fluorescence | NM | 0.005; 0.014 | 2016 | [39] |

| AFB1 | Maize; maize silage and complete feed samples for swine, poultry, and cattle | MeOH 80% | AflaTest® IAC | Post-column derivatization | Fluorescence | Shimadzu Nexera with Gemini-NX-C18 (150 × 4.6 mm, 3 μm) | 0.05; 0.15 | 2016 | [15] |

| AFB2 | 0.02; 0.06 | ||||||||

| AFG1 | 0.25; 0.75 | ||||||||

| AFG2 | 0.08; 0.24 | ||||||||

| AFB1 | Dehulled yellow corn | MeOH 70% with 1% NaCl | AflaTest® WB IAC | Pre-column derivatization with trifluoroacetic acid | Fluorescence | Synergi Hydro-RP (250 mm × 4.6 mm, 4 μm) | 0.08; 0.25 | 2016 | [142] |

| AFB2 | 0.03; 0.11 | ||||||||

| AFG1 | 0.13; 0.39 | ||||||||

| AFG2 | 0.09; 0.27 | ||||||||

| AFB1 | Post-column photochemical derivatization (PHRED cell) | C18 (150 mm × 4.6 mm, 3.5 μm) | 0.02; 0.06 | ||||||

| AFB2 | 0.01; 0.02 | ||||||||

| AFG1 | 0.02; 0.05 | ||||||||

| AFG2 | 0.01; 0.02 | ||||||||

| AFB1 | Electrochemical post-column bromination derivatization (Kobra cell) | C18 (150 mm × 4.6 mm, 3.5 μm) | 0.04; 0.11 | ||||||

| AFB2 | 0.02; 0.05 | ||||||||

| AFG1 | 0.05; 0.14 | ||||||||

| AFG2 | 0.01; 0.04 | ||||||||

| AFB1 | Mixed dairy cow feeds | MeOH 80% with 5 g NaCl | AflaTest® IAC | - | Fluorescence | Reversed phase inertsil® ODS-3 (5 μm, 250 × 4.6 mm i. d.) | 0.054; 0.181 | 2016 | [191] |

| AFB2 | 0.046; 0.153 | ||||||||

| AFG1 | 0.059; 0.197 | ||||||||

| AFG2 | 0.050; 0.168 | ||||||||

| AFB1 | Dairy cattle feed | 1 g NaCl | AflaTest® IAC | - | Fluorescence | NM | NM | 2016 | [84] |

| AFB1 | Corn; domestic and imported distiller’s dried grains with solubles; corn germ meal; wheat; bran; wheat shorts and red dog; soybean meal; pig complete feed (powder and pellet); duck and cattle complete feed | MeOH 80% | MycoSep® 226 column | Post-column photochemical derivatization | Fluorescence | C18 (4.6 mm × 150 mm, 5 μm) | 0.5; 1.5 | 2016 | [97] |

| AFB1 | Animal feedstuffs | IL-DLLME coupled to magnetic SPE | - | - | Fluorescence | RP C18 analytical (150 × 4.6 mm, 5 μm) | 0.632; NM | 2016 | [106] |

| AFB2 | 0.087; NM | ||||||||

| AFG1 | 0.422; NM | ||||||||

| AFG2 | 0.146; NM | ||||||||

| AFB1 | Maize | MeCN 84% | MycoSep® 224 AflaZon SPE column | Post-column derivatization with iodine | Fluorescence | ZORBAX Eclipse Plus C18 (4.6 × 100 mm, i.d. 3.5 µm) | 0.4; 1.3 | 2017 | [167] |

| AFB2 | 0.20; 0.60 | ||||||||

| AFG1 | 0.40; 1.4 | ||||||||

| AFG2 | 0.60; 1.8 | ||||||||

| DON | Maize; wheat and complete feed | MeOH 60% | CF DON IAC | - | UV | mm × 4.6 mm × C18 5 μm reverse-phase | 100; 260 | 2016 | [138] |

| DON | Milled wheat; bran | Water | DON-Test IAC | - | DAD | C18 reversed-phase (250 × 4.6 mm, 4 μ) | 22; 77 | 2016 | [144] |

| DON | Corn; domestic and imported distiller’s dried grains with solubles; corn germ meal; wheat; bran; wheat shorts and red dog; soybean meal; pig complete feed (powder and pellet); duck and cattle complete feed | MeOH 60% | CF AFLA IAC | - | UV | C18 (4.6 mm × 150 mm, 5 μm) | 0.02; 0.06 | 2016 | [97] |

| DON | Wheat; wheat shorts; wheat bran | MeCN 84% | MycoSep® 227 column | - | UV | C18-HL (250 mm × 4.6 mm, 5 μm) | NM | 2016 | [140] |

| FB1 | Maize kernel | Ultrapure water and MeCN | SAX column | Post-column derivatization with o-phthaldialdehyde | Fluorescence | ZORBAX SB-C18 reversed-phase (250 mm × 4.6 mm, 5 μm) | 4; 13 | 2016 | [94] |

| FB2 | 3; 10 | ||||||||

| FB1 | Corn grain; corn grits; corn meal | MeOH 80% | SPE cartridge | - | Fluorescence | C18 reversed-phase (150 × 4.6 mm, 5 µm) | 2.5; 12.5 | 2016 | [156] |

| FB2 | 6; 31.3 | ||||||||

| OTA | Complete feed for pigs | NM | IAC | - | Fluorescence | NM | NM; 0.1 | 2016 | [165] |

| OTA | Maize; maize silage and complete feed samples for swine, poultry, and cattle | MeCN 60% | OCHRAPREP® IAC | - | Fluorescence | Shimadzu Nexera with Gemini-NX-C18 (150 × 4.6 mm, 3 μm) | 0.13; 0.40 | 2016 | [15] |

| ZEN | Complete feed for pigs | NM | IAC | - | Fluorescence | NM | NM; 3.0 | 2016 | [165] |

| ZEN | Maize; wheat and complete feed | MeCN 84% | ZearaStar IAC | - | UV | 150-mm × 4.6-mm × C18 5-μm reverse-phase | 10; 24 | 2016 | [138] |

| ZEN | Soybean kernels | MeCN 75% | IAC NeoColumnTM 8140 | - | Fluorescence | ODS Purospher (4.0 × 250 mm × 5 μm) | 2.0; 6.0 | 2018 | [76] |

| ZEN | Corn; domestic and imported distiller’s dried grains with solubles; corn germ meal; wheat; bran; wheat shorts and red dog; soybean meal; pig complete feed (powder and pellet); duck and cattle complete feed | MeOH 60% | CF AFLA IAC | - | Fluorescence | C18 (4.6 mm × 150 mm, 5 μm) | 1.5; 4 | 2016 | [97] |

| Mycotoxin/ Metabolite | Matrix | Sample Pre-Treatment | LC-MS | Year of Publication | Reference | |||

|---|---|---|---|---|---|---|---|---|

| Extraction | Clean-Up | Ionization/ Ion Selection | Scan Mode | LOD; LOQ (µg/kg) or (µg/L) | ||||

| AFB1 | Distiller’s dried grains with solubles | QuEChERS-like approach | UHPLC ESI (±) QTRAP | MRM | NM; 1 | 2016 | [159] | |

| AFB2 | NM; 1 | |||||||

| AFG1 | NM; 1 | |||||||

| AFG2 | NM; 1 | |||||||

| AFB1 | Pig, cattle, chicken and rabbit feed | MeCN/water/acetic acid (80:18:2) | mIAC | ESI (±) QqQ | SRM | 0.02; 0.06 | 2016 | [78] |

| AFB2 | 0.02; 0.06 | |||||||

| AFG1 | 0.04; 0.12 | |||||||

| AFG2 | 0.03; 0.09 | |||||||

| AFB1 | Animal feed | MeCN/water/acetic acid (79:20:1) | AflaTest® IAC | UPLC ESI (±) QqQ | MRM | 0.50; 1.0 | 2016 | [198] |

| AFB2 | 0.50; 1.0 | |||||||

| AFG1 | 0.50; 1.0 | |||||||

| AFG2 | 0.50; 1.0 | |||||||

| AFB1 | Finished feed for poultry, swine and ruminant, maize and maize silage | MeCN/water/acetic acid (79:20:1) | - | ESI IT | NM | NM | 2016 | [43] |

| AFB2 | ||||||||

| AFG1 | ||||||||

| AFG2 | ||||||||

| AFB1 | Poultry, swine, cattle, horse and lamb feed | QuEChERS-based approach | UHPLC HESI (±) Orbitrap | Full scan | NM; 2.5 | 2016 | [104] | |

| AFB2 | NM; 2.5 | |||||||

| AFG1 | NM; 2.5 | |||||||

| AFG2 | NM; 2.5 | |||||||

| AFB1 | Maize silage | MeCN 84% with 1% of acetic acid | - | HESI (±) QqQ | SRM | 0.05; 0.17 | 2016 | [71] |

| AFG1 | 0.05; 0.17 | |||||||

| AFB1 | Feed | MeCN/water/acetic acid (79:20:1) | - | HPLC ESI (±) | MRM | 0.72; 2.4 | 2017 | [168] |

| Maize | 0.3; 0.98 | |||||||

| AFB2 | 0.42; 1.4 | |||||||

| AFB1 | Compound feed for swine, sheep, poultry, cattle, equine and feed materials | MeCN/water/formic acid (80:19:1) | - | UPLC ESI (+) | MRM | 1; 2 | 2018 | [185] |

| AFB2 | 2; 4 | |||||||

| AFG1 | 2; 4 | |||||||

| AFG2 | 2; 4 | |||||||

| AFB1 | Corn and feed | MeOH and sodium chloride | AOF-MS-PREP and DZT-MS-PREP multiantibody IAC in tandem | ESI (+) QTRAP | MRM | 0.2; 0.7 | 2018 | [199] |

| AFB2 | 0.2; 0.5 | |||||||

| AFG1 | 0.4; 1.1 | |||||||

| AFG2 | 0.1; 0.3 | |||||||

| AFB1 | Ground maize, compound feeds, total mixed rations | MeCN/water/acetic acid (79:20:1) | - | UHPLC ESI (+) QTOF | NM | 0.02; 0.06 | 2018 | [160] |

| AFB2 | 0.05; 0.16 | |||||||

| AFG1 | 0.05; 0.15 | |||||||

| AFG2 | 0.06; 0.19 | |||||||

| DON | Maize | MeCN/water/acetic acid (79:20:1) | C18 SPE column | ESI (+) QqQ | SRM | 7; 14 | 2016 | [70] |

| 15-AcDON | 5; 10 | |||||||

| DON | Distiller’s dried grains with solubles | QuEChERS-like approach | UHPLC ESI (±) QTRAP | MRM | NM; 100 | 2016 | [159] | |

| 15-AcDON | NM; 50 | |||||||

| 3-AcDON | NM; 25 | |||||||

| DON | Formula feed | MeCN 50% | GPD HLB SPE cartridge | UHPLC ESI (±) QqQ | MRM | 0.08; 0.10 | 2016 | [93] |

| 3-AcDON | 2.09; 4.17 | |||||||

| 15-AcDON | 0.57; 1.21 | |||||||

| DON | Concentrated feed | 0.23; 0.52 | ||||||

| 3-AcDON | 2.31; 4.85 | |||||||

| 15-AcDON | 0.98; 1.86 | |||||||

| DON | Premixed feed | 0.12; 0.24 | ||||||

| 3-AcDON | 1.32; 2.98 | |||||||

| 15-AcDON | 0.74; 1.86 | |||||||

| DON | Corn silage | MeCN with 1% of acetic acid and deionized water with sodium acetate trihydrate | - | ESI (+) QqQ | SRM | NM; NM | 2016 | [175] |

| DON | Maize; maize silage and complete feed samples for swine, poultry, and cattle | MeCN 80% | Bond Elut® Mycotoxin column | API | NM | 1.0; 3.0 | 2016 | [15] |

| DON | Maize silage | MeCN 84% with 1% of acetic acid | - | HESI (±) QqQ | SRM | 34.2; 113.9 | 2016 | [71] |

| 3-/15-AcDON | 1.6; 5.2 | |||||||

| DON | Animal feed | QuEChERS | UPLC ESI (±) QqQ | MRM | 50; 100 | 2016 | [198] | |

| 3-AcDON | 10; 50 | |||||||

| DON | Finished feed for poultry, swine and ruminant, maize and maize silage | MeCN/water/acetic acid (79:20:1) | - | ESI IT | NM | NM | 2016 | [43] |

| 3-AcDON | ||||||||

| 15-AcDON | ||||||||

| DON | Poultry, swine, cattle, horse and lamb feed | QuEChERS-based approach | UHPLC HESI (±) Orbitrap | Full scan | NM; 450 | 2016 | [104] | |

| DON | Feed | MeCN/water/acetic acid (79:20:1) | - | HPLC ESI (±) | MRM | 9.5; 31 | 2017 | [168] |

| Maize | 26; 86 | |||||||

| DON | Compound feed for swine, sheep, poultry, cattle, equine and feed materials | MeCN/water/formic acid (80:19:1) | - | UPLC ESI (+) | MRM | 125; 250 | 2018 | [185] |

| DON | Corn and feed | MeOH and sodium chloride | AOF-MS-PREP and DZT-MS-PREP multiantibody IAC in tandem | ESI (+) QTRAP | MRM | 12.1; 36.8 | 2018 | [199] |

| 3-/15-AcDON | Ground maize, compound feeds, total mixed rations | MeCN/water/acetic acid (79:20:1) | - | UHPLC ESI (+) QTOF | NM | 0.08; 0.27 | 2018 | [160] |

| DON | 0.49; 1.62 | |||||||

| FB1 | Maize | 0.4 M phosphate buffer | - | ESI (+) QqQ | NM | 10; 30 | 2016 | [200] |

| FB2 | 10; 30 | |||||||

| FB1 + FB2 | 10; 30 | |||||||

| FB1 | Maize | MeCN/water/acetic acid (79:20:1) | C18 SPE column | ESI (+) QqQ | SRM | 8.2; 16.4 | 2016 | [70] |

| FB2 | 11.5; 23 | |||||||

| FB3 | 14; 28 | |||||||

| FB1 | Maize silage | MeCN 84% with 1% of acetic acid | - | HESI (±) QqQ | SRM | 1.7; 5.8 | 2016 | [71] |

| FB2 | 3.9; 12.9 | |||||||

| FB1 | Distiller’s dried grains with solubles | QuEChERS-like approach | UHPLC ESI (±) QTRAP | MRM | NM; 25 | 2016 | [159] | |

| FB2 | NM; 25 | |||||||

| FB3 | NM; 25 | |||||||

| FB1 | Animal feed | QuEChERS | UPLC ESI (±) QqQ | MRM | 10; 50 | 2016 | [198] | |

| FB2 | 10; 50 | |||||||

| FB1 | Maize; maize silage and complete feed samples for swine, poultry, and cattle | MeCN 80% | MultiSep® 211 SPE column | API | NM | 1.6; 5.0 | 2016 | [15] |

| FB2 | 1.6; 5.0 | |||||||

| FB3 | 1.6; 5.0 | |||||||

| FB1 | Poultry, swine, cattle, horse and lamb feed | QuEChERS-based approach | UHPLC HESI (±) Orbitrap | Full scan | NM; 2500 | 2016 | [104] | |

| FB2 | NM; 2500 | |||||||

| FB1 | Finished feed for poultry, swine and ruminant, maize and maize silage | MeCN/water/acetic acid (79:20:1) | - | ESI IT | NM | NM | 2016 | [43] |

| FB2 | ||||||||

| FB3 | ||||||||

| FB4 | ||||||||

| FB6 | ||||||||

| FB1 | Feed | MeCN/water/acetic acid (79:20:1) | - | HPLC ESI (±) | MRM | 2.6; 8.5 | 2017 | [168] |

| FB2 | 1; 3.3 | |||||||

| FB3 | 3.8; 11 | |||||||

| FB1 | Maize | 1; 3.3 | ||||||

| FB2 | 1.3; 4.3 | |||||||

| FB3 | 1.5; 4.9 | |||||||

| FB1 | Compound feed for swine, sheep, poultry, cattle, equine and feed materials | MeCN/water/formic acid (80:19:1) | - | UPLC ESI (+) | MRM | 187.5; 375 | 2018 | [185] |

| FB2 | 62.5; 125 | |||||||

| FB1 | Corn and feed | MeOH and sodium chloride | AOF-MS-PREP and DZT-MS-PREP multiantibody IAC in tandem | ESI (+) QTRAP | MRM | 39.2; 118.7 | 2018 | [199] |

| FB2 | 28.0; 84.9 | |||||||

| FB1 | Ground maize, compound feeds, total mixed rations | MeCN/water/acetic acid (79:20:1) | - | UHPLC ESI (+) QTOF | NM | 3.46; 11.52 | 2018 | [160] |

| OTA | Maize silage | MeCN 84% with 1% of acetic acid | - | HESI (±) QqQ | SRM | 0.29; 0.97 | 2016 | [71] |

| OTA | Distiller’s dried grains with solubles | QuEChERS-like approach | UHPLC ESI (±) QTRAP | MRM | NM; 1 | 2016 | [159] | |

| OTA | Pig, cattle, chicken and rabbit feed | MeCN/water/acetic acid (80:18:2) | mIAC | ESI (±) QqQ | SRM | 0.12; 0.36 | 2016 | [78] |

| OTA | Animal feed | QuEChERS | UPLC ESI (±) QqQ | MRM | 1.0; 5.0 | 2016 | [198] | |

| OTA | Finished feed for poultry, swine and ruminant, maize and maize silage | MeCN/water/acetic acid (79:20:1) | - | ESI IT | NM | NM | 2016 | [43] |

| OTA | Poultry, swine, cattle, horse and lamb feed | QuEChERS-based approach | UHPLC HESI (±) Orbitrap | Full scan | NM; 25 | 2016 | [104] | |

| OTA | Maize | MeCN/water/acetic acid (79:20:1) | - | HPLC ESI (±) | MRM | 2.8; 9.4 | 2017 | [168] |

| OTA | Ground maize, compound feeds, total mixed rations | MeCN/water/acetic acid (79:20:1) | - | UHPLC ESI (+) QTOF | NM | 0.08; 0.26 | 2018 | [160] |

| OTA | Corn and feed | MeOH and sodium chloride | AOF-MS-PREP and DZT-MS-PREP multiantibody IAC in tandem | ESI (+) QTRAP | MRM | 0.7; 2.0 | 2018 | [199] |

| OTA | Compound feed for swine, sheep, poultry, cattle, equine and feed materials | MeCN/water/formic acid (80:19:1) | - | UPLC ESI (+) | MRM | 12.5; 25 | 2018 | [185] |

| T-2 | Layer feed | MeCN 84% | MycoSep® 227 column | ESI (+) QqQ | MRM | 0.9; 2.9 | 2016 | [201] |

| HT-2 | 7.1; 23.8 | |||||||

| T-2 triol | 1.0; 3.4 | |||||||

| T-2 tetraol | 7.5; 25 | |||||||

| HT-2 | Maize silage | MeCN 84% with 1% of acetic acid | - | HESI (±) QqQ | SRM | 4.9; 16.2 | 2016 | [71] |

| T-2 | 0.29; 0.96 | |||||||

| T-2 | Distiller’s dried grains with solubles | QuEChERS-like approach | UHPLC ESI (±) QTRAP | MRM | NM; 2.5 | 2016 | [159] | |

| HT-2 | NM; 25 | |||||||

| T-2 | Pig, cattle, chicken and rabbit feed | MeCN/water/acetic acid (80:18:2) | mIAC | ESI (±) QqQ | SRM | 0.12; 0.36 | 2016 | [78] |

| T-2 | Maize; maize silage and complete feed samples for swine, poultry, and cattle | MeCN 80% | Bond Elut® Mycotoxin column | API | NM | 0.2; 0.6 | 2016 | [15] |

| HT-2 | 0.7; 2.0 | |||||||

| T-2 | Animal feed | QuEChERS | UPLC ESI (±) QqQ | MRM | 6.0; 25 | 2016 | [198] | |

| HT-2 | 10; 25 | |||||||

| HT-2 | Maize | MeCN/water/acetic acid (79:20:1) | C18 SPE column | ESI (+) QqQ | SRM | 6.5; 13 | 2016 | [70] |

| T-2 | Finished feed for poultry, swine and ruminant, maize and maize silage | MeCN/water/acetic acid (79:20:1) | - | ESI IT | NM | NM | 2016 | [43] |

| T-2 Tetraol | ||||||||

| T-2 Triol | ||||||||

| HT-2 | ||||||||

| T-2 | Poultry, swine, cattle, horse and lamb feed | QuEChERS-based approach | UHPLC HESI (±) Orbitrap | Full scan | NM; 500 | 2016 | [104] | |

| HT-2 | Feed | MeCN/water/acetic acid (79:20:1) | - | HPLC ESI (±) | MRM | 1.7; 5.7 | 2017 | [168] |

| T-2 | 1.05; 3.5 | |||||||

| T-2 | Compound feed for swine, sheep, poultry, cattle, equine and feed materials | MeCN/water/formic acid (80:19:1) | - | UPLC ESI (+) | MRM | 12.5; 25 | 2018 | [185] |

| HT-2 | 12.5; 25 | |||||||

| T-2 | Corn and feed | MeOH and sodium chloride | AOF-MS-PREP and DZT-MS-PREP multiantibody IAC in tandem | ESI (+) QTRAP | MRM | 1.0; 2.9 | 2018 | [199] |

| HT-2 | 2.2; 6.6 | |||||||

| HT-2 | Ground maize, compound feeds, total mixed rations | MeCN/water/acetic acid (79:20:1) | - | UHPLC ESI (+) QTOF | NM | 0.06; 0.21 | 2018 | [160] |

| ZEN | Animal feed | QuEChERS | UPLC ESI (±) QqQ | MRM | 5.0; 10 | 2016 | [198] | |

| ZEN | Pig, cattle, chicken and rabbit feed | MeCN/water/acetic acid (80:18:2) | mIAC | ESI (±) QqQ | SRM | 0.25; 0.75 | 2016 | [78] |

| ZEN | Maize | MeCN/water/acetic acid (79:20:1) | C18 SPE column | ESI (+) QqQ | SRM | 3.25; 6.5 | 2016 | [70] |

| α-ZEL | 4.6; 9.2 | |||||||

| β-ZEL | 5; 10 | |||||||

| ZEN | Maize silage | MeCN 84% with 1% of acetic acid | - | HESI (±) QqQ | SRM | 3.4; 11.2 | 2016 | [71] |

| α-ZEL | 17.3; 57.7 | |||||||

| β-ZEL | 10.4; 34.6 | |||||||

| ZEN | Distiller’s dried grains with solubles | QuEChERS-like approach | UHPLC ESI (±) QTRAP | MRM | NM; 0.5 | 2016 | [159] | |

| α-ZEL | NM; 2.5 | |||||||

| β-ZEL | NM; 2.5 | |||||||

| ZEN | Maize; maize silage and complete feed samples for swine, poultry, and cattle | MeCN 80% | Bond Elut® Mycotoxin column | API | NM | 0.07; 0.20 | 2016 | [15] |

| ZEN | Finished feed for poultry, swine and ruminant, maize and maize silage | MeCN/water/acetic acid (79:20:1) | - | ESI IT | NM | NM | 2016 | [43] |

| ZEN | Maize | MeCN 75% | Magnetic SPE with magnetic nanoparticles | API (+) UV-Vis DAD coupled with a MS detector | SIM | 0.8; 2.5 | 2016 | [202] |

| α- ZEL | 1.0; 3.3 | |||||||

| β- ZEL | 0.6; 1.9 | |||||||

| ZEN | Poultry, swine, cattle, horse and lamb feed | QuEChERS-based approach | UHPLC HESI (±) Orbitrap | Full scan | NM; 10 | 2016 | [104] | |

| ZEN | Feed | MeCN 75%, sodium chloride, Tween 20 | IAC | HPLC ESI (±) | MRM | 0.1-3; 0.3-8 | 2017 | [187] |

| ZEN | Feed | MeCN/water/acetic acid (79:20:1) | - | HPLC ESI (±) | MRM | 0.64; 2.1 | 2017 | [168] |

| α- ZEL | 1.3; 4.5 | |||||||

| β- ZEL | 1.2; 3.5 | |||||||

| ZEN | Maize | 0.46; 1.5 | ||||||

| ZEN | Feed | MeCN 80% | IAC-ZER | HPLC ESI (+) | MRM | 1.1; 3.1 | 2018 | [186] |

| α- ZEL | 0.6; 2.2 | |||||||

| β- ZEL | 0.6; 2.1 | |||||||

| ZEN | Compound feed for swine, sheep, poultry, cattle, equine and feed materials | MeCN/water/formic acid (80:19:1) | - | UPLC ESI (+) | MRM | 25; 50 | 2018 | [185] |

| ZEN | Corn and feed | MeOH and sodium chloride | AOF-MS-PREP and DZT-MS-PREP multiantibody IAC in tandem | ESI (+) QTRAP | MRM | 14.7; 44.5 | 2018 | [199] |

| ZEN | Ground maize, compound feeds, total mixed rations | MeCN/water/acetic acid (79:20:1) | - | UHPLC ESI (+) QTOF | NM | 0.04; 0.12 | 2018 | [160] |

| α- ZEL | 0.19; 0.63 | |||||||

| β- ZEL | 0.19; 0.64 | |||||||

References

- European Commission. Comission recomendation of 14 January 2011 establishing guidelines for the distinction between feed materials, feed additives, biocidal products and veterinary medicinal products. Off. J. Eur. Union 2011, 2011, 75–79. [Google Scholar]

- Food Standards Agency Food.gov.uk. Available online: https://www.food.gov.uk/business-industry/farmingfood/animalfeed/what-farm-animals-eat (accessed on 4 December 2016).

- Adams, C.A. Nutrition-based health in animal production. Nutr. Res. Rev. 2006, 19, 79–89. [Google Scholar] [CrossRef] [Green Version]

- GRACE Foundation GRACE Communications Foundation. Available online: http://www.sustainabletable.org/260/animal-feed (accessed on 2 December 2016).

- Pinotti, L.; Ottoboni, M.; Giromini, C.; Dell’Orto, V.; Cheli, F. Mycotoxin Contamination in the EU Feed Supply Chain: A Focus on Cereal Byproducts. Toxins 2016, 8, 45. [Google Scholar] [CrossRef]

- Wilkinson, J.M. Re-defining efficiency of feed use by livestock. Animal 2011, 5, 1014–1022. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Awika, J.M. Major Cereal Grains Production and Use around the World. In Advances in Cereal Science: Implications to Food Processing and Health Promotion; Awika, J.M., Piironen, V., Bean, S., Eds.; American Chemical Society: Washington, DC, USA, 2011; pp. 1–13. ISBN 9780841226364. [Google Scholar]

- Oliveira, P.M.; Zannini, E.; Arendt, E.K. Cereal fungal infection, mycotoxins, and lactic acid bacteria mediated bioprotection: From crop farming to cereal products. Food Microbiol. 2014, 37, 78–95. [Google Scholar] [CrossRef]

- Capper, J.L.; Berger, L.; Brashears, M.M.; Jensen, H.H. Animal Feed vs. Human Food: Challenges and Opportunities in Sustaining Animal Agriculture Toward 2050; Council for Agricultural Science and Technology: Ames, IA, USA, 2013. [Google Scholar]

- FAO. Protein Sources for the Animal Feed Industry; FAO’s Animal Production and Health: Rome, Italy, 2002. [Google Scholar]

- Ray, D.K.; Mueller, N.D.; West, P.C.; Foley, J.A. Yield Trends Are Insufficient to Double Global Crop Production by 2050. PLoS ONE 2013, 8, e66428. [Google Scholar]

- Streit, E.; Naehrer, K.; Rodrigues, I.; Schatzmayr, G. Mycotoxin occurrence in feed and feed raw materials worldwide: Long-term analysis with special focus on Europe and Asia. J. Sci. Food Agric. 2013, 93, 2892–2899. [Google Scholar] [CrossRef]

- Perry, T.W. Animal life-Cycle Feeding and Nutrition; Cunha, T.J., Ed.; Academic Press, Inc.: London, UK, 1984; ISBN 0125520603. [Google Scholar]

- Heuzé, V.; Tran, G. Maize Grain. Available online: http://www.feedipedia.org/node/556 (accessed on 6 December 2016).

- Kosicki, R.; Błajet-Kosicka, A.; Grajewski, J.; Twaruzek, M. Multiannual mycotoxin survey in feed materials and feedingstuffs. Anim. Feed Sci. Technol. 2016, 215, 165–180. [Google Scholar] [CrossRef]

- Cowieson, A.J. Factors that affect the nutritional value of maize for broilers. Anim. Feed Sci. Technol. 2005, 119, 293–305. [Google Scholar] [CrossRef]

- FAO. Food Outlook—Biannual Report on Global Food Markets; FAO: Rome, Italy, 2016. [Google Scholar]

- Heuzé, V.; Tran, G.; Renaudeau, D.; Lessire, M.; Lebas, F. Wheat Grain. Available online: http://www.feedipedia.org/node/223 (accessed on 6 December 2016).

- Heuzé, V.; Tran, G. Wheat (General). Available online: http://www.feedipedia.org/node/6435 (accessed on 6 December 2016).

- Heuzé, V.; Tran, G. Soybean (General). Available online: http://www.feedipedia.org/node/753 (accessed on 6 December 2016).

- Martín-Pedrosa, M.; Varela, A.; Guillamon, E.; Cabellos, B.; Burbano, C.; Gomez-Fernandez, J.; De Mercado, E.; Gomez-Izquierdo, E.; Cuadrado, C.; Muzquiz, M. Biochemical characterization of legume seeds as ingredients in animal feed. Span. J. Agric. Res. 2016, 14, 0901. [Google Scholar] [CrossRef]

- Newkirk, R. SOYBEAN Feed Industry Guide; Canadian International Grains Institute: Winnipeg, MB, Canada, 2010. [Google Scholar]

- Tilman, D.; Balzer, C.; Hill, J.; Befort, B.L. Global food demand and the sustainable intensification of agriculture. Proc. Natl. Acad. Sci. USA 2011, 108, 20260–20264. [Google Scholar] [CrossRef] [Green Version]

- Kruse, J. Estimating Demand for Agricultural Commodities to 2050; Global Harvest Initiative: Washington, DC, USA, 2010; pp. 1–26. [Google Scholar]

- FAO. The State of Food and Agriculture; FAO: Rome, Italy, 2009; ISBN 9789251062159. [Google Scholar]

- Krska, R.; Richard, J.L.; Schuhmacher, R.; Slate, A.B.; Whitaker, T.B. Romer Labs Guide to Mycotoxins, 4th ed.; Binder, E.M., Krska, R., Eds.; Romer Labs Inc.: Leicestershire, England, 2012; ISBN 9780957372115. [Google Scholar]

- FAO & WHO. Animal Feed Impact on Food Safety; FAO: Rome, Itlay, 2007. [Google Scholar]

- EU Commission. The European Parliament and The Council of the European Union Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed. Off. J. Eur. Union 2015, L 32, 1–30. [Google Scholar]

- Tima, H.; Brückner, A.; Mohácsi-Farkas, C.; Kiskó, G. Fusarium mycotoxins in cereals harvested from Hungarian fields. Food Addit. Contam. Part B 2016, 9, 127–131. [Google Scholar] [CrossRef]

- Binder, E.M.; Tan, L.M.; Chin, L.J.; Handl, J.; Richard, J. Worldwide occurrence of mycotoxins in commodities, feeds and feed ingredients. Anim. Feed Sci. Technol. 2007, 137, 265–282. [Google Scholar] [CrossRef]

- Dzuman, Z.; Zachariasova, M.; Veprikova, Z.; Godula, M.; Hajslova, J. Multi-analyte high performance liquid chromatography coupled to high resolution tandem mass spectrometry method for control of pesticide residues, mycotoxins, and pyrrolizidine alkaloids. Anal. Chim. Acta 2015, 863, 29–40. [Google Scholar] [CrossRef]

- CAST. Mycotoxins: Risks in Plant, Animal, and Human Systems; CAST: Ames, IA, USA, 2003. [Google Scholar]

- Smith, M.C.; Madec, S.; Coton, E.; Hymery, N. Natural Co-occurrence of mycotoxins in foods and feeds and their in vitro combined toxicological effects. Toxins 2016, 8, 94. [Google Scholar] [CrossRef]

- Bordin, K.; Sawada, M.M.; da Costa Rodrigues, C.E.; da Fonseca, C.R.; Oliveira, C.A.F. Incidence of Aflatoxins in Oil Seeds and Possible Transfer to Oil: A Review. Food Eng. Rev. 2014, 6, 20–28. [Google Scholar]

- Sirhan, A.Y.; Tan, G.H.; Wong, R.C.S. Determination of aflatoxins in food using liquid chromatography coupled with electrospray ionization quadrupole time of flight mass spectrometry (LC-ESI-QTOF-MS/MS). Food Control 2013, 31, 35–44. [Google Scholar] [CrossRef]

- da Rocha, M.E.B.; da Freire, F.C.O.; Maia, F.E.F.; Guedes, M.I.F.; Rondina, D. Mycotoxins and their effects on human and animal health. Food Control 2014, 36, 159–165. [Google Scholar] [CrossRef]

- Piotrowska, M.; Śliżewska, K.; Biernasiak, J. Soybean—Pest Resistance; El-Shemy, H.A., Ed.; InTech: Rijeka, Croatia, 2013; ISBN 9789535109785. [Google Scholar]

- IARC. Agents Classified by the IARC Monographs, Volumes 1–117; IARC: Lyon, France, 2016. [Google Scholar]

- Dimitrieska-Stojković, E.; Stojanovska-Dimzoska, B.; Ilievska, G.; Uzunov, R.; Stojković, G.; Hajrulai-Musliu, Z.; Jankuloski, D. Assessment of aflatoxin contamination in raw milk and feed in Macedonia during 2013. Food Control 2016, 59, 201–206. [Google Scholar] [CrossRef]

- Groopman, J.D.; Kensler, T.W.; Wu, F. Mycotoxins—Occurrence and Toxic Effects. Encycl. Hum. Nutr. 2013, 2, 337–341. [Google Scholar]

- Marin, S.; Ramos, A.J.; Cano-Sancho, G.; Sanchis, V. Mycotoxins: Occurrence, toxicology, and exposure assessment. Food Chem. Toxicol. 2013, 60, 218–237. [Google Scholar] [CrossRef]

- Streit, E.; Schatzmayr, G.; Tassis, P.; Tzika, E.; Marin, D.; Taranu, I.; Tabuc, C.; Nicolau, A.; Aprodu, I.; Puel, O.; et al. Current Situation of Mycotoxin Contamination and Co-occurrence in Animal Feed—Focus on Europe. Toxins 2012, 4, 788–809. [Google Scholar] [CrossRef]

- Kovalsky, P.; Kos, G.; Nährer, K.; Schwab, C.; Jenkins, T.; Schatzmayr, G.; Sulyok, M.; Krska, R. Co-Occurrence of Regulated, Masked and Emerging Mycotoxins and Secondary Metabolites in Finished Feed and Maize—An Extensive Survey. Toxins 2016, 8, 363. [Google Scholar] [CrossRef]

- Pitt, J.I.; Taniwaki, M.H.; Cole, M.B. Mycotoxin production in major crops as influenced by growing, harvesting, storage and processing, with emphasis on the achievement of Food Safety Objectives. Food Control 2013, 32, 205–215. [Google Scholar] [CrossRef]

- Anukul, N.; Maneeboon, T.; Roopkham, C.; Chuaysrinule, C.; Mahakarnchanakul, W. Fumonisin and T-2 toxin production of Fusarium spp. isolated from complete feed and individual agricultural commodities used in shrimp farming. Mycotoxin Res. 2014, 30, 9–16. [Google Scholar] [CrossRef]

- Marroquín-Cardona, A.G.; Johnson, N.M.; Phillips, T.D.; Hayes, A.W. Mycotoxins in a changing global environment—A review. Food Chem. Toxicol. 2014, 69, 220–230. [Google Scholar] [CrossRef]

- Murugesan, G.R.; Ledoux, D.R.; Naehrer, K.; Berthiller, F.; Applegate, T.J.; Grenier, B.; Phillips, T.D.; Schatzmayr, G. Prevalence and effects of mycotoxins on poultry health and performance, and recent development in mycotoxin counteracting strategies. Poult. Sci. 2015, 94, 1298–1315. [Google Scholar] [CrossRef]

- Milani, J.M. Ecological conditions affecting mycotoxin production in cereals: A review. Vet. Med. 2013, 58, 405–411. [Google Scholar] [CrossRef]

- Juan, C.; Ritieni, A.; Mañes, J. Occurrence of Fusarium mycotoxins in Italian cereal and cereal products from organic farming. Food Chem. 2013, 141, 1747–1755. [Google Scholar] [CrossRef]

- Rodríguez-Carrasco, Y.; Ruiz, M.J.; Font, G.; Berrada, H. Exposure estimates to Fusarium mycotoxins through cereals intake. Chemosphere 2013, 93, 2297–2303. [Google Scholar] [CrossRef]

- Ran, R.; Wang, C.; Han, Z.; Wu, A.; Zhang, D.; Shi, J. Determination of deoxynivalenol (DON) and its derivatives: Current status of analytical methods. Food Control 2013, 34, 138–148. [Google Scholar] [CrossRef]

- González Peyera, M.L.; Sulyok, M.; Baralla, V.; Dalcero, A.M.; Krska, R.; Chulze, S.; Cavaglieri, L.R. Evaluation of zearalenone, α-zearalenol, β-zearalenol, zearalenone 4-sulfate and β-zearalenol 4-glucoside levels during the ensiling process. World Mycotoxin J. 2014, 7, 291–295. [Google Scholar] [CrossRef]

- Grenier, B.; Applegate, T.J. Modulation of intestinal functions following mycotoxin ingestion: Meta-analysis of published experiments in animals. Toxins 2013, 5, 396–430. [Google Scholar] [CrossRef]

- The Commission of the European Communities. The Commission of the European Communities Comission recomendation of 17 August 2006 on the presence of deoxynivalenol, zearalenone, ochratoxin A, T-2 and HT-2 and fumonisins in products intended for animal feeding. Off. J. Eur. Union 2006, L 229, 7–9. [Google Scholar]

- FAO. On-Farm Mycotoxin Control in Food and Feed Grain; FAO: Rome, Italy, 2007. [Google Scholar]

- Alkadri, D.; Rubert, J.; Prodi, A.; Pisi, A.; Mañes, J.; Soler, C. Natural co-occurrence of mycotoxins in wheat grains from Italy and Syria. Food Chem. 2014, 157, 111–118. [Google Scholar] [CrossRef]

- Pereira, V.L.; Fernandes, J.O.; Cunha, S.C. Mycotoxins in cereals and related foodstuffs: A review on occurrence and recent methods of analysis. Trends Food Sci. Technol. 2014, 36, 96–136. [Google Scholar] [CrossRef]

- Guerre, P. Worldwide Mycotoxins Exposure in Pig and Poultry Feed Formulations. Toxins 2016, 8, 350. [Google Scholar] [CrossRef]

- Garcia, L.P.; Savi, G.D.; Santos, K.; Scussel, V.M. Fumonisins and fungi in dry soybeans (Glycine Max L.) for human consumption. Food Addit. Contam. Part B 2016, 9, 79–84. [Google Scholar] [CrossRef]

- Krnjaja, V.; Lević, J.; Stanković, S.; Petrović, T.; Tomić, Z.; Mandić, V.; Bijelić, Z. Moulds and mycotoxins in stored maize grains. Biotechnol. Anim. Husb. 2013, 29, 527–536. [Google Scholar] [CrossRef]

- Sirma, A.; Senerwa, D.; Grace, D.; Makita, K.; Mtimet, N.; Kang’ethe, E.; Lindahl, J. Aflatoxin B1 occurrence in millet, sorghum and maize from four agro-ecological zones in Kenya. Afr. J. Food Agric. Nutr. Dev. 2016, 16, 10991–11003. [Google Scholar] [CrossRef]

- Li, X.; Zhao, L.; Fan, Y.; Jia, Y.; Sun, L.; Ma, S.; Ji, C.; Ma, Q.; Zhang, J. Occurrence of mycotoxins in feed ingredients and complete feeds obtained from the Beijing region of China. J. Anim. Sci. Biotechnol. 2014, 5, 37. [Google Scholar] [CrossRef]

- Abdou, D.A.M.; Othman, R.M.; El-Bordeny, N.E.; Ibrahim, N.A.; Abouzeid, M.A. Monitoring imported grain-based ingredients used in feed processing for toxigenic moulds and naturally occurring mycotoxins. Egypt. J. Exp. Biol. 2016, 15, 145–154. [Google Scholar] [CrossRef]

- Stoev, S.D. Foodborne mycotoxicoses, risk assessment and underestimated hazard of masked mycotoxins and joint mycotoxin effects or interaction. Environ. Toxicol. Pharmacol. 2015, 39, 794–809. [Google Scholar] [CrossRef]

- Greco, M.V.; Franchi, M.L.; Golba, S.L.R.; Pardo, A.G.; Pose, G.N. Mycotoxins and Mycotoxigenic Fungi in Poultry Feed for Food-Producing Animals. Sci. World J. 2014, 2014, 968215. [Google Scholar] [CrossRef] [PubMed]

- Aiko, V.; Mehta, A. Occurrence, detection and detoxification of mycotoxins. J. Biosci. 2015, 40, 943–954. [Google Scholar] [CrossRef]

- The commission of the European Communities. The Commission of the European Communities Commission Regulation (EC) No 386/2009 of 12 May 2009 amending Regulation (EC) No 1831/2003 of the European Parliament and of the Council as regards the establishment of a new functional group of feed additives. Off. J. Eur. Union 2009, L 188, 66. [Google Scholar]

- Food Standards Agency Food.gov.uk. Available online: https://www.food.gov.uk/business-industry/farmingfood/crops/mycotoxinsguidance/animalfeed (accessed on 3 August 2017).

- Chen, Y.; Chen, Q.; Han, M.; Zhou, J.; Gong, L.; Niu, Y.; Zhang, Y.; He, L.; Zhang, L. Development and optimization of a multiplex lateral flow immunoassay for the simultaneous determination of three mycotoxins in corn, rice and peanut. Food Chem. 2016, 213, 478–484. [Google Scholar] [CrossRef]

- Chilaka, C.A.; De Boevre, M.; Atanda, O.O.; De Saeger, S. Occurrence of Fusarium mycotoxins in cereal crops and processed products (Ogi) from Nigeria. Toxins 2016, 8, 342. [Google Scholar] [CrossRef]

- Dagnac, T.; Latorre, A.; Fernández Lorenzo, B.; Llompart, M. Validation and application of a liquid chromatography-tandem mass spectrometry based method for the assessment of the co-occurrence of mycotoxins in maize silages from dairy farms in NW Spain. Food Addit. Contam. Part A 2016, 33, 1850–1863. [Google Scholar] [CrossRef]

- Jovaišienė, J.; Bakutis, B.; Baliukonienė, V.; Matusevičius, P.; Lipiński, K.; Antoszkiewicz, Z.; Fijałkowska, M. Mycotoxins and Biogenic Amines Content and Their Changes During Storages in Produced in Lithuania in Maize Silages. Vet. Med. Zoot. 2016, 73, 58–63. [Google Scholar]

- Kamala, A.; Kimanya, M.; Haesaert, G.; Tiisekwa, B.; Madege, R.; Degraeve, S.; Cyprian, C.; Meulenaer, B. De Local post-harvest practices associated with aflatoxin and fumonisin contamination of maize in three agro ecological zones of Tanzania. Food Addit. Contam. Part A 2016, 33, 551–559. [Google Scholar] [CrossRef]

- Mngqawa, P.; Shephard, G.S.; Green, I.R.; Ngobeni, S.H.; de Rijk, T.C.; Katerere, D.R. Mycotoxin contamination of home-grown maize in rural northern South Africa (Limpopo and Mpumalanga Provinces). Food Addit. Contam. Part B 2016, 9, 38–45. [Google Scholar] [CrossRef]

- Murugesan, R. Mycotoxin Survey in the 2015 US Corn; BIOMIN: Herzogenburg, Austria, 2016. [Google Scholar]

- Calori-Domingues, M.A.; Bernardi, C.M.G.; Nardin, M.S.; de Souza, G.V.; Dos Santos, F.G.R.; Stein, M.D.A.; Gloria, E.M.D.; Dias, C.T.D.S.; de Camargo, A.C. Co-occurrence and distribution of deoxynivalenol, nivalenol and zearalenone in wheat from Brazil. Food Addit. Contam. Part B 2016, 9, 142–151. [Google Scholar] [CrossRef]

- Egbuta, M.A.; Mwanza, M.; Phoku, J.Z.; Chilaka, C.A.; Dutton, M.F. Comparative Analysis of Mycotoxigenic Fungi and Mycotoxins Contaminating Soya Bean Seeds and Processed Soya Bean from Nigerian Markets. Adv. Microbiol. 2016, 6, 1130–1139. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Hu, R.; Zhang, Z.; Li, P.; Zhang, Q.; Wang, M. Development of a multiple immunoaffinity column for simultaneous determination of multiple mycotoxins in feeds using UPLC-MS/MS. Anal. Bioanal. Chem. 2016, 408, 6027–6036. [Google Scholar] [CrossRef]

- Kongkapan, J.; Poapolathep, S.; Isariyodom, S.; Kumagai, S. Simultaneous detection of multiple mycotoxins in broiler feeds using a liquid chromatography tandem-mass spectrometry. J. Vet. Med. Sci. 2016, 78, 259–264. [Google Scholar] [CrossRef] [Green Version]

- Zachariasova, M.; Dzuman, Z.; Veprikova, Z.; Hajkova, K.; Jiru, M. Occurrence of multiple mycotoxins in European feedingstuffs, assessment of dietary intake by farm animals. Anim. Feed Sci. Technol. 2014, 193, 124–140. [Google Scholar] [CrossRef]

- Gutleb, A.C.; Caloni, F.; Giraud, F.; Cortinovis, C.; Pizzo, F.; Hoffmann, L.; Bohn, T.; Pasquali, M. Detection of multiple mycotoxin occurrences in soy animal feed by traditional mycological identification combined with molecular species identification. Toxicol. Rep. 2015, 2, 275–279. [Google Scholar] [CrossRef] [Green Version]

- Xie, L.; Chen, M.; Ying, Y. Development of Methods for Determination of Aflatoxins. Crit. Rev. Food Sci. Nutr. 2016, 56, 2642–2664. [Google Scholar] [CrossRef]

- Cheli, F.; Battaglia, D.; Gallo, R.; Dell’Orto, V. EU legislation on cereal safety: An update with a focus on mycotoxins. Food Control 2014, 37, 315–325. [Google Scholar] [CrossRef]

- Keller, L.A.M.; Aronovich, M.; Keller, K.M.; Castagna, A.A.; Cavaglieri, L.R.; da Rocha Rosa, C.A. Incidence of Mycotoxins (AFB1 and AFM1) in Feeds and Dairy Farms from Rio de Janeiro State, Brazil. Vet. Med. 2016, 1, 29–35. [Google Scholar] [CrossRef]

- Bryden, W.L. Mycotoxin contamination of the feed supply chain: Implications for animal productivity and feed security. Anim. Feed Sci. Technol. 2012, 173, 134–158. [Google Scholar] [CrossRef]

- Wagner, C. Critical Practicalities in Sampling for Mycotoxins in Feed. J. AOAC Int. 2015, 98, 301–308. [Google Scholar] [CrossRef]

- Turner, N.W.; Bramhmbhatt, H.; Szabo-vezse, M.; Poma, A.; Coker, R.; Piletsky, S.A. Analytical methods for determination of mycotoxins: An update (2009–2014). Anal. Chim. Acta 2015, 901, 12–33. [Google Scholar] [CrossRef]

- The European Commission. The European Commission Commission Regulation (EC) No 691/2013 of 19 July 2013 amending Regulation (EC) No 152/2009 as regards methods of sampling and analysis. Off. J. Eur. Union 2013, L 197, 1–12. [Google Scholar]

- The European Commission. The Commission of the European Communities Comission regulation (EC) No 401/2006 of 23 February 2006 laying down the methods of sampling and analysis for the official control of the levels of mycotoxins in foodstuffs. Off. J. Eur. Union 2006, L 70, 12–34. [Google Scholar]

- Sifou, A.; Mahnine, N.; Manyes, L.; El Adlouni, C.; El Azzouzi, M.; Zinedine, A. Determination of Ochratoxin A in Poultry Feeds Available in Rabat area (Morocco) by High Performance Liquid Chromatography. J. Mater. Environ. Sci. 2016, 7, 2229–2234. [Google Scholar]

- Chen, S.; Zhang, H. Development of a microwave-assisted-extraction-based method for the determination of aflatoxins B1, G1, B2, and G2 in grains and grain products. Anal. Bioanal. Chem. 2013, 405, 1623–1630. [Google Scholar] [CrossRef]

- Li, C.; Wu, Y.-L.; Yang, T.; Huang-Fu, W.-G. Rapid Determination of Fumonisins B1 and B2 in Corn by Liquid Chromatography-Tandem Mass Spectrometry with Ultrasonic Extraction. J. Chromatogr. Sci. 2012, 50, 57–63. [Google Scholar] [CrossRef]

- Fan, Z.; Bai, B.; Jin, P.; Fan, K.; Guo, W.; Zhao, Z.; Han, Z. Development and Validation of an Ultra-High Performance Liquid Chromatography-Tandem Mass Spectrometry Method for Simultaneous Determination of Four Type B Trichothecenes and Masked Deoxynivalenol in Various Feed Products. Molecules 2016, 21, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Liu, Y.; Jiang, Y.; Li, R.; Pang, M.; Liu, Y.; Dong, J. Fusarium species identification and fumonisin production in maize kernels from Shandong Province, China, from 2012 to 2014. Food Addit. Contam. Part B 2016, 9, 203–209. [Google Scholar] [CrossRef] [PubMed]

- Binder, E.M. Managing the risk of mycotoxins in modern feed production. Anim. Feed Sci. Technol. 2007, 133, 149–166. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, X.; Zhang, Q.; Li, P. Determination for multiple mycotoxins in agricultural products using HPLC-MS/MS via a multiple antibody immunoaffinity column. J. Chromatogr. B 2016, 1021, 145–152. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Li, J.; Li, Y.; Li, T.; He, Q.; Tang, Y.; Liu, H.; Su, Y.; Yin, Y.; Liao, P. Aflatoxin B1, zearalenone and deoxynivalenol in feed ingredients and complete feed from different Province in China. J. Anim. Sci. Biotechnol. 2016, 7, 1–10. [Google Scholar] [CrossRef] [Green Version]