Optimization and Validation of Dispersive Liquid–Liquid Microextraction for Simultaneous Determination of Aflatoxins B1, B2, G1, and G2 in Senna Leaves and Pods Using HPLC-FLD with Pre-Column Derivatization

Abstract

1. Introduction

2. Results and Discussion

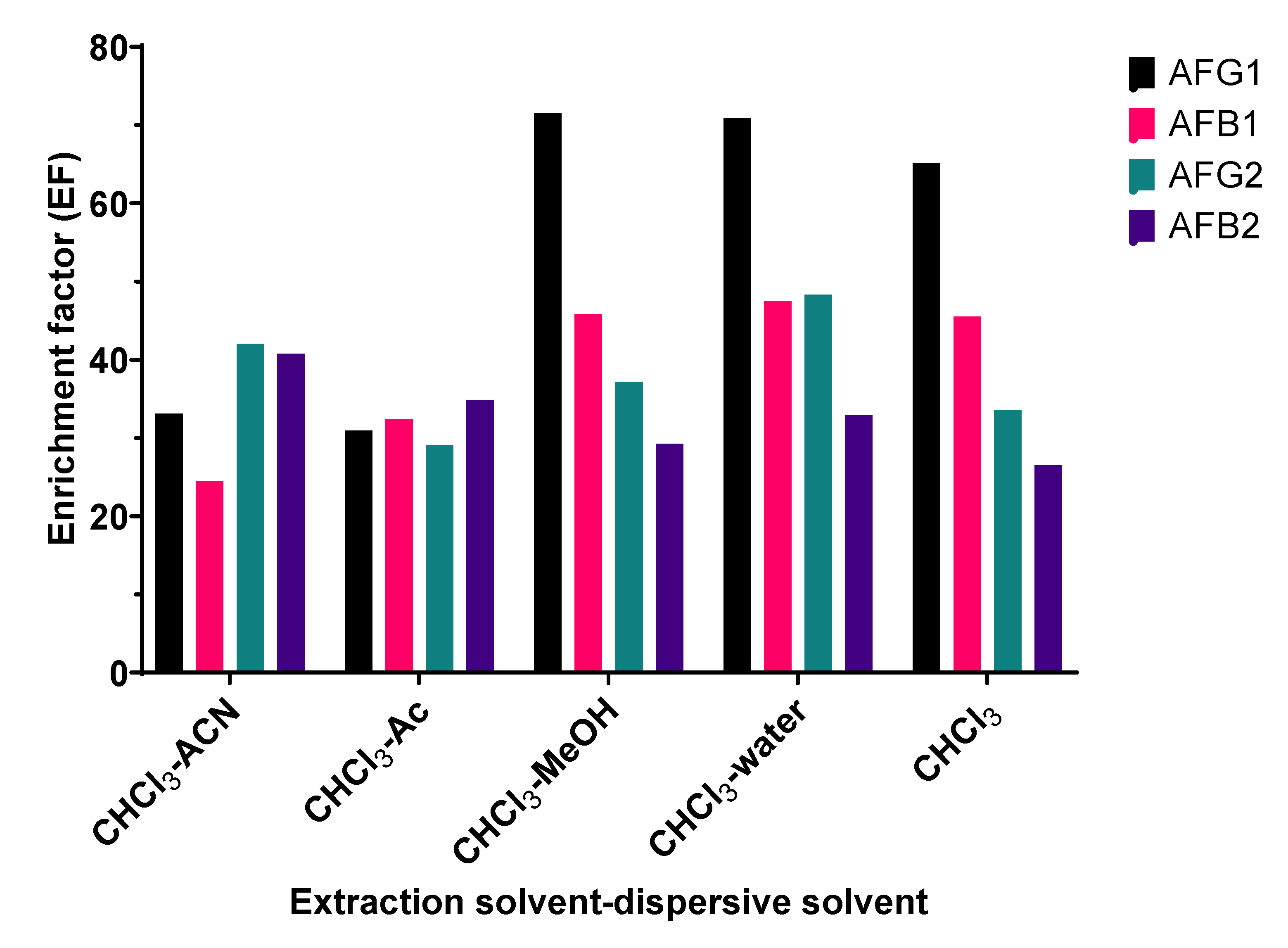

2.1. Selection of Dispersive Solvent

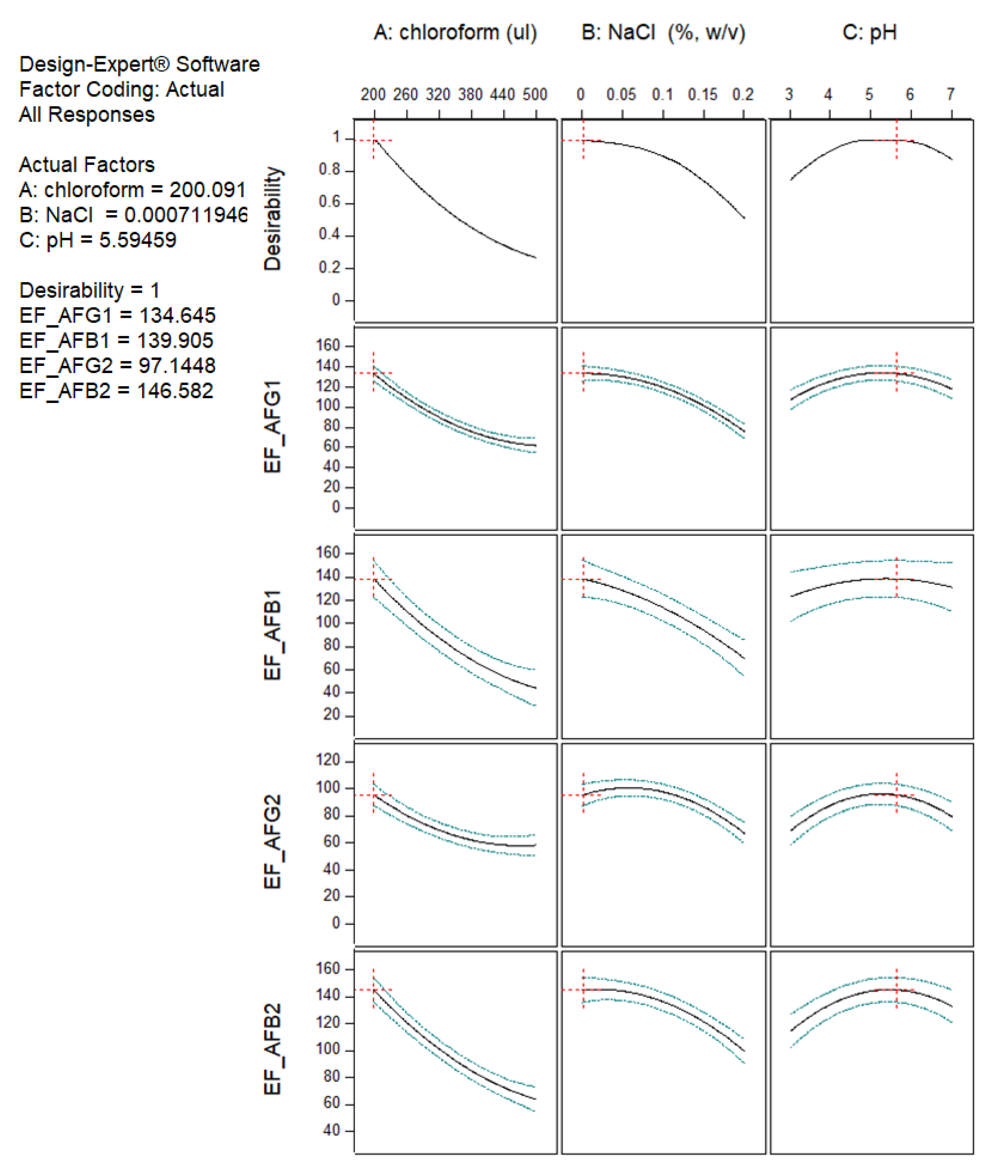

2.2. Optimization of DLLME Parameters

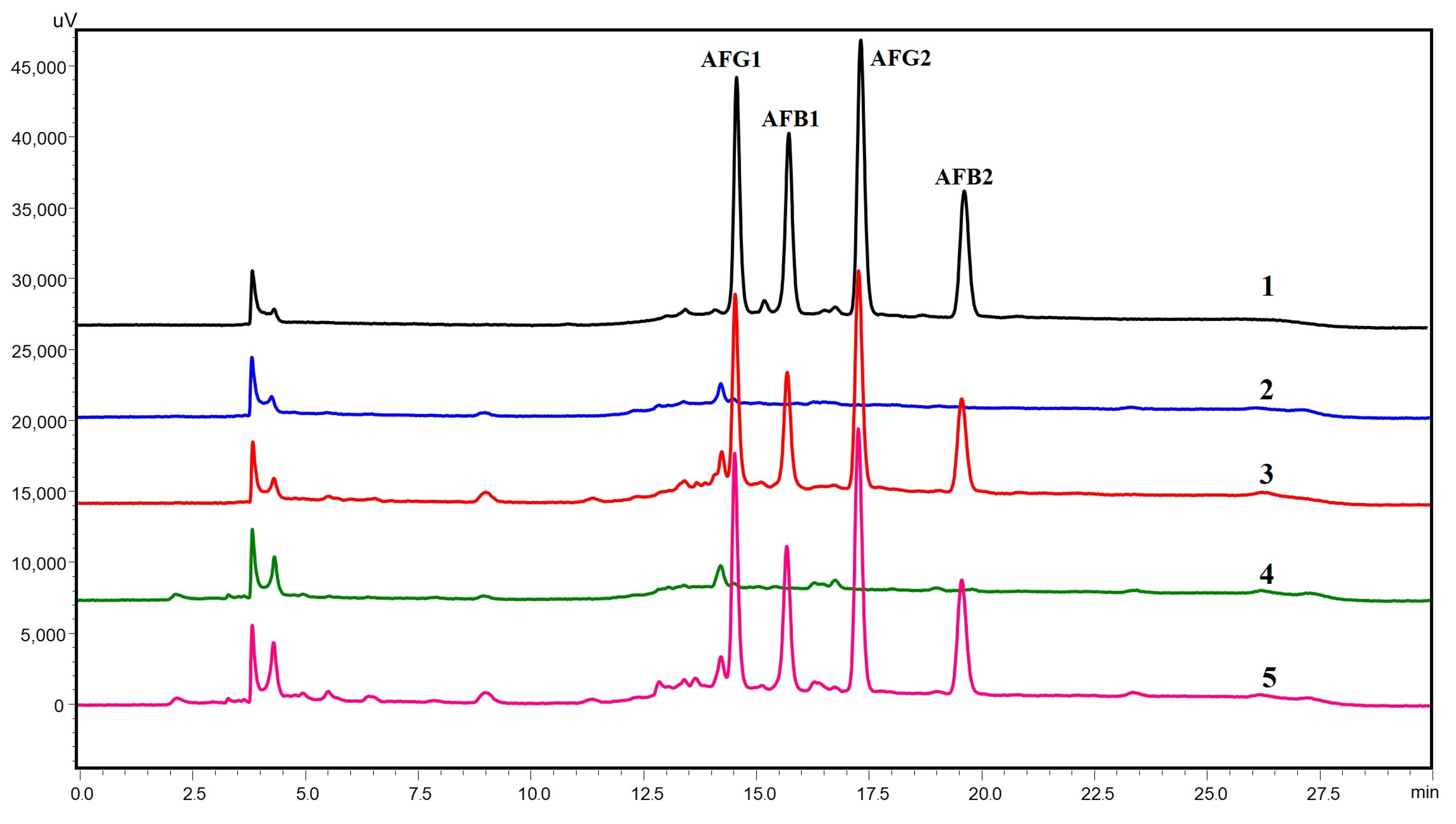

2.3. Method Validation

2.3.1. Matrix Effect (ME)

2.3.2. Linearity, Sensitivity, Accuracy, and Precision

2.4. Application of Developed Method to Real Senna Samples

3. Conclusions

4. Material and Methods

4.1. Chemicals and Reagents

4.2. Sample Extraction

4.3. Optimization of DLLME Process

4.4. DLLME Process

4.5. Derivatization

4.6. HPLC-FLD Analysis

4.7. Method Validation

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Elansary, H.O.; Szopa, A.; Kubica, P.; Ekiert, H.; Ali, H.M.; Elshikh, M.S.; Abdel-Salam, E.M.; El-Esawi, M.; El-Ansary, D.O. Bioactivities of traditional medicinal plants in Alexandria. Evid.-Based Complement. Altern. Med. 2018, 2018, 1463579. [Google Scholar] [CrossRef] [PubMed]

- Ikram, A.; Khalid, W.; Saeed, F.; Arshad, M.S.; Afzaal, M.; Arshad, M.U. Senna: As immunity boosting herb against COVID-19 and several other diseases. J. Herb. Med. 2023, 37, 100626. [Google Scholar] [CrossRef] [PubMed]

- Monkheang, P.; Runglawan, S.; Tanee, T.; Noikotr, K.; Chaveerach, N. Species diversity, usages, molecular markers and barcode of medicinal Senna species (Fabaceae, Caesalpinioideae) in Thailand. J. Med. Plants 2011, 5, 6173–6181. [Google Scholar] [CrossRef]

- Kabak, B.; Dobson, A.D.W. Mycotoxins in spices and herbs–An update. Crit. Rev. Food Sci. Nutr. 2017, 57, 18–34. [Google Scholar] [CrossRef]

- Pallarés, N.; Berrada, H.; Font, G.; Ferrer, E. Mycotoxins occurrence in medicinal herbs dietary supplements and exposure assessment. J. Food Sci. Technol. 2022, 59, 2830–2841. [Google Scholar] [CrossRef]

- Chuaysrinule, C.; Maneeboon, T.; Mahakarnchanakul, W. Mutual effects on mycotoxin production during co-culture of ochratoxigenic and aflatoxigenic Aspergillus strains. Mycotoxin Res. 2023. ahead of print. [Google Scholar] [CrossRef]

- Pickova, D.; Ostry, V.; Toman, J.; Malir, F. Aflatoxins: History, significant milestones, recent data on their toxicity and ways to mitigation. Toxins 2021, 13, 399. [Google Scholar] [CrossRef]

- Joshi, P.; Chauysrinule, C.; Mahakarnchanakul, W.; Maneeboon, T. Multi-mycotoxin contamination, mold incidence and risk assessment of aflatoxin in maize kernels originating from Nepal. Microbiol. Res. 2022, 13, 21. [Google Scholar] [CrossRef]

- IARC. Aflatoxins: B1, B2, G1, G2, M1. In Some Traditional Herbal Medicines, Some Mycotoxins, Naphthalene and Styrene; IARC: Lyon, France, 2002; Volume 82, pp. 301–366. [Google Scholar]

- Dwipa, R.P.; Maneeboon, T.; Chuaysrinule, C.; Mahakarnchanakul, W. Interactive inhibition of aflatoxigenic Aspergillus flavus and ochratoxigenic Aspergillus carbonarius by Aspergillus oryzae under fluctuating temperatures. Microbiol. Res. 2022, 13, 9. [Google Scholar] [CrossRef]

- Hammami, W.; Fiori, S.; Al Thani, R.; Ali Kali, N.; Balmas, V.; Migheli, Q.; Jaoua, S. Fungal and aflatoxin contamination of marketed spices. Food Control 2014, 37, 177–181. [Google Scholar] [CrossRef]

- Nordin, S.; Samsudin, N.A.; Esah, E.M.; Zakaria, L.; Selamat, J.; Rahman, M.A.; Mahror, N. Prevalence, identification and mycotoxigenic potential of fungi in common spices used in local Malaysian cuisines. Foods 2022, 11, 2548. [Google Scholar] [CrossRef]

- Kortei, N.K.; Kumah, G.; Tettey, C.O.; Agyemang, A.O.; Annan, T.; Nortey, N.N.D.; Essuman, E.K.; Boakye, A.A. Mycoflora, aflatoxins, and antimicrobial properties of some Ghanaian local spices and herbs. J. Food Saf. 2022, 42, e12996. [Google Scholar] [CrossRef]

- Gajewska, M.; Anna, S.; Bartodziejska, B. Prevalence of aflatoxins and ochratoxine A in organically and conventionally produced herbs and spices. Farm. Pol. 2022, 78, 66–73. [Google Scholar] [CrossRef]

- Lu, Q.; Ruan, H.-N.; Sun, X.-Q.; Luo, J.-Y.; Yang, M.-H. Contamination status and health risk assessment of 31 mycotoxins in six edible and medicinal plants using a novel green defatting and depigmenting pretreatment coupled with LC-MS/MS. LWT 2022, 161, 113401. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EC) No. 165/2010 of 26 February 2010 amending Regulation (EC) No.1881/2006 setting maximum levels for certain contaminants in foodstuffs as regards aflatoxins. Off. J. Eur. Union 2010, 50, 8–12. [Google Scholar]

- Qin, L.; Jiang, J.-Y.; Zhang, L.; Dou, X.-W.; Ouyang, Z.; Wan, L.; Yang, M.-H. Occurrence and analysis of mycotoxins in domestic Chinese herbal medicines. Mycology 2020, 11, 126–146. [Google Scholar] [CrossRef]

- Food Safety and Standards Authority of India. Food Safety and Standards (Contaminants, Toxins, and Residues) Regulations. Available online: https://www.fssai.gov.in/upload/uploadfiles/files/Contaminants_Regulations.pdf (accessed on 15 May 2022).

- Food and Drug Administration Guidance for Industry: Action Levels for Poisonous or Deleterious Substances in Human Food and Animal Feed. Available online: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/guidance-industry-action-levels-poisonous-or-deleterious-substances-human-food-and-animal-feed#afla (accessed on 22 June 2022).

- Ministry of Public Health. Notification of Ministry of Public Health (No 414) B.E. 2563 Issued by Virtue of the Food Act B.E. 2522 Re: Standards for Contaminants in Food. Available online: https://food.fda.moph.go.th/law/data/announ_moph/V.English/P414_E.pdf (accessed on 1 October 2022).

- Quigley, A.; Cummins, W.; Connolly, D. Dispersive liquid-liquid microextraction in the analysis of milk and dairy products: A review. J. Chem. 2016, 2016, 4040165. [Google Scholar] [CrossRef]

- Saraji, M.; Boroujeni, M.K. Recent developments in dispersive liquid–liquid microextraction. Anal. Bioanal. Chem. 2014, 406, 2027–2066. [Google Scholar] [CrossRef]

- Luan, C.; Wang, L.; Chen, F.; Wang, S.; Zhao, L.; Shao, L. Determination of ochratoxin A in pig muscle using dispersive liquid-liquid microextraction combined with high-performance liquid chromatography. Food Anal. Methods 2016, 9, 1490–1494. [Google Scholar] [CrossRef]

- Hamed, A.M.; Abdel-Hamid, M.; Gámiz-Gracia, L.; García-Campaña, A.M.; Arroyo-Manzanares, N. Determination of aflatoxins in plant-based milk and dairy products by dispersive liquid–liquid microextraction and high-performance liquid chromatography with fluorescence detection. Anal. Lett. 2019, 52, 363–372. [Google Scholar] [CrossRef]

- Pi, J.; Jin, P.; Zhou, S.; Wang, L.; Wang, H.; Huang, J.; Gan, L.; Yuan, T.; Fan, H. Combination of ultrasonic-assisted aqueous two-phase extraction with solidifying organic drop-dispersive liquid–liquid microextraction for simultaneous determination of nine mycotoxins in medicinal and edible foods by HPLC with In-series DAD and FLD. Food Anal. Methods 2022, 15, 428–439. [Google Scholar] [CrossRef]

- Luo, Q.; Wang, S.; Adeel, M.; Shan, Y.; Wang, H.; Sun, L.-N. Solvent demulsification-dispersive liquid-liquid microextraction based on solidification of floating organic drop coupled with ultra-high-performance liquid chromatography-tandem mass spectrometry for simultaneous determination of 13 organophosphate esters in aqueous samples. Sci. Rep. 2019, 9, 11292. [Google Scholar] [PubMed]

- Karami-Osboo, R.; Miri, R.; Javidnia, K.; Kobarfard, F.; AliAbadi, M.H.S.; Maham, M. A validated dispersive liquid-liquid microextraction method for extraction of ochratoxin A from raisin samples. J. Food Sci. Technol. 2015, 52, 2440–2445. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Tan, Z.-C.; Huang, K.-C.; Wen, Y.; Li, X.-Y.; Zhao, J.-L.; Liu, C.-L. A vortex-assisted dispersive liquid-liquid microextraction followed by UPLC-MS/MS for simultaneous determination of pesticides and aflatoxins in herbal tea. Molecules 2019, 24, 1029. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Tong, S.; Chang, Y.; Jia, Q.; Zhou, W. Ionic liquid-based dispersive liquid–liquid microextraction with back-extraction coupled with capillary electrophoresis to determine phenolic compounds. Electrophoresis 2012, 33, 1331–1338. [Google Scholar] [CrossRef]

- Hashemi, P.; Beyranvand, S.; Mansur, R.S.; Ghiasvand, A.R. Development of a simple device for dispersive liquid–liquid microextraction with lighter than water organic solvents: Isolation and enrichment of glycyrrhizic acid from licorice. Anal. Chim. Acta 2009, 655, 60–65. [Google Scholar] [CrossRef]

- Rahbar, N.; Hesami, M.M.; Ramezani, Z.; Savarizadeh, A. Ultra rapid and highly sensitive disperser-less Liquid-liquid microextraction of organophosphate pesticides prior to gas chromatography with mass spectrometry detection. Jundishapur J. Health Sci. 2020, 12, e109594. [Google Scholar] [CrossRef]

- Chuaysrinule, C.; Mahakarnchanakul, W.; Maneeboon, T. Comparative study on the effect of temperature and water activity on Aspergillus flavus and Aspergillus carbonarius isolates growth and mycotoxin production on a chili powder medium. Cogent Food Agric. 2020, 6, 1782097. [Google Scholar] [CrossRef]

- Chauhan, B.; Gupta, R. Application of statistical experimental design for optimization of alkaline protease production from Bacillus sp. RGR-14. Process Biochem. 2004, 39, 2115–2122. [Google Scholar] [CrossRef]

- Rai, A.; Mohanty, B.; Bhargava, R. Supercritical extraction of sunflower oil: A central composite design for extraction variables. Food Chem. 2016, 192, 647–659. [Google Scholar] [CrossRef]

- Maham, M.; Kiarostami, V.; Waqif-Husain, S.; Sharifabadi, M.K. Analysis of chlorpheniramine in human urine samples using dispersive liquid-liquid microextraction combined with high-performance liquid chromatography. Braz. J. Pharm. Sci. 2014, 50, 551–557. [Google Scholar] [CrossRef]

- Kiarostami, V.; Rouini, M.-R.; Mohammadian, R.; Lavasani, H.; Ghazaghi, M. Binary solvents dispersive liquid—Liquid microextraction (BS-DLLME) method for determination of tramadol in urine using high-performance liquid chromatography. DARU J. Pharm. Sci. 2014, 22, 25. [Google Scholar] [CrossRef]

- Li, Y.; Peng, G.; He, Q.; Zhu, H.; Al-Hamadani, S.M.Z.F. Dispersive liquid–liquid microextraction based on the solidification of floating organic drop followed by ICP-MS for the simultaneous determination of heavy metals in wastewaters. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2015, 140, 156–161. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, J.-J.; Huang, B.-F.; Cai, Z.-X.; Ren, Y.-P. High-performance liquid chromatographic determination of multi-mycotoxin in cereals and bean foodstuffs using interference-removal solid-phase extraction combined with optimized dispersive liquid–liquid microextraction. J. Sep. Sci. 2017, 40, 2141–2150. [Google Scholar] [CrossRef]

- Zhang, H.-F.; Shi, Y.-P. Temperature-assisted ionic liquid dispersive liquid–liquid microextraction combined with high performance liquid chromatography for the determination of anthraquinones in Radix et Rhizoma Rhei samples. Talanta 2010, 82, 1010–1016. [Google Scholar] [CrossRef]

- Ham, H.-J.; Sardar, S.W.; Ishag, A.E.; Choi, J.-Y.; Hur, J.-H. Optimization of an analytical method for indoxacarb residues in fourteen medicinal herbs Using GC-μECD, GC-MS/MS and LC-MS/MS. Separations 2022, 9, 232. [Google Scholar] [CrossRef]

- Rutkowska, E.; Łozowicka, B.; Kaczyński, P. Modification of multiresidue QuEChERS protocol to minimize matrix effect and improve recoveries for determination of pesticide residues in dried ferbs followed by GC-MS/MS. Food Anal. Methods 2018, 11, 709–724. [Google Scholar] [CrossRef]

- Xing, Y.; Meng, W.; Sun, W.; Li, D.; Yu, Z.; Tong, L.; Zhao, Y. Simultaneous qualitative and quantitative analysis of 21 mycotoxins in Radix Paeoniae Alba by ultra-high performance liquid chromatography quadrupole linear ion trap mass spectrometry and QuEChERS for sample preparation. J. Chromatogr. B 2016, 1031, 202–213. [Google Scholar] [CrossRef]

- Zhang, S.; Lu, J.; Wang, S.; Mao, D.; Miao, S.; Ji, S. Multi-mycotoxins analysis in Pheretima using ultra-high-performance liquid chromatography tandem mass spectrometry based on a modified QuEChERS method. J. Chromatogr. B 2016, 1035, 31–41. [Google Scholar] [CrossRef]

- Yogendrarajah, P.; Van Poucke, C.; De Meulenaer, B.; De Saeger, S. Development and validation of a QuEChERS based liquid chromatography tandem mass spectrometry method for the determination of multiple mycotoxins in spices. J. Chromatogr. A 2013, 1297, 1–11. [Google Scholar] [CrossRef]

- Colazzo, M.; Alonso, B.; Ernst, F.; Cesio, M.V.; Perez-Parada, A.; Heinzen, H.; Pareja, L. Determination of multiclass, semi-polar pesticide residues in fatty fish muscle tissue by gas and liquid chromatography mass spectrometry. Methods X 2019, 6, 929–937. [Google Scholar] [CrossRef] [PubMed]

- Tassaneeyakul, W.; Razzazi-Fazeli, E.; Porasuphatana, S.; Bohm, J. Contamination of aflatoxins in herbal medicinal products in Thailand. Mycopathologia 2004, 158, 239–244. [Google Scholar] [CrossRef] [PubMed]

- Jitjak, W. Assessment of toxin-producing genes in Aspergillus species from traditional herbal products in Khon Kaen province, Thailand using molecular method. Food Res. 2022, 6, 273–278. [Google Scholar] [CrossRef] [PubMed]

- Müller, P.; Basedow, T. Aflatoxin contamination of pods of Indian Cassia senna L. (Caesalpinaceae) before harvest, during drying and in storage: Reasons and possible methods of reduction. J. Stored Prod. Res. 2007, 43, 323–329. [Google Scholar] [CrossRef]

- European Commission. Commission Regulation (EC) No 401/2006 of 23 February 2006 laying down the methods of sampling and analysis for the official control of the levels of mycotoxins in foodstuffs. Off. J. Eur. Communities 2006, L70, 12–34. [Google Scholar]

- Azaiez, I.; Giusti, F.; Sagratini, G.; Mañes, J.; Fernández-Franzón, M. Multi-mycotoxins analysis in dried fruit by LC/MS/MS and a modified QuEChERS procedure. Food Anal. Methods 2014, 7, 935–945. [Google Scholar] [CrossRef]

| Run | Independent Variables | Responses: Enrichment Factor (EF) | |||||

|---|---|---|---|---|---|---|---|

| X1: Chloroform Volume (µL) | X2: NaCl (%, w/v) | X3: pH | AFG1 | AFB1 | AFG2 | AFB2 | |

| 1 | −1 (200) | −1 (0) | 0 (5) | 132.98 | 139.73 | 96.26 | 142.77 |

| 2 | 1 (500) | −1 (0) | 0 (5) | 62.67 | 43.13 | 57.44 | 66.58 |

| 3 | −1 (200) | 1 (0.2) | 0 (5) | 77.78 | 73.56 | 73.56 | 100.46 |

| 4 | 1 (500) | 1 (0.2) | 0 (5) | 51.79 | 47.06 | 40.74 | 71.59 |

| 5 | −1 (200) | 0 (0.1) | −1 (3) | 92.29 | 98.06 | 77.82 | 111.55 |

| 6 | 1 (500) | 0 (0.1) | −1 (3) | 47.59 | 43.66 | 41.93 | 57.18 |

| 7 | −1 (200) | 0 (0.1) | 1 (7) | 106.68 | 106.03 | 79.23 | 125.78 |

| 8 | 1 (500) | 0 (0.1) | 1 (7) | 54.77 | 48.41 | 47.87 | 60.76 |

| 9 | 0 (350) | −1 (0) | −1 (3) | 62.92 | 66.74 | 40.92 | 68.95 |

| 10 | 0 (350) | 1 (0.2) | −1 (3) | 16.88 | 28.60 | 21.71 | 49.66 |

| 11 | 0 (350) | −1 (0) | 1 (7) | 68.82 | 72.88 | 53.41 | 80.66 |

| 12 | 0 (350) | 1 (0.2) | 1 (7) | 32.08 | 36.08 | 18.71 | 52.97 |

| 13 | 0 (350) | 0 (0.1) | 0 (5) | 84.12 | 83.30 | 74.99 | 103.06 |

| 14 | 0 (350) | 0 (0.1) | 0 (5) | 78.41 | 66.73 | 67.50 | 94.29 |

| 15 | 0 (350) | 0 (0.1) | 0 (5) | 81.28 | 64.79 | 73.60 | 95.94 |

| Source | df | AFG1 | AFB1 | AFG2 | AFB2 | ||||

|---|---|---|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | ||

| Model | 9 | 126.39 | 0.000 * | 27.83 | 0.001 * | 63.15 | 0.000 * | 73.54 | 0.000 * |

| X1 | 1 | 454.35 | 0.000 * | 142.34 | 0.000 * | 197.41 | 0.000 * | 385.06 | 0.000 * |

| X2 | 1 | 270.55 | 0.000 * | 48.45 | 0.001 * | 89.09 | 0.000 * | 54.29 | 0.001 * |

| X3 | 1 | 22.21 | 0.005 * | 1.79 | 0.239 | 2.90 | 0.149 | 8.24 | 0.035 * |

| X12 | 1 | 82.20 | 0.000 * | 14.09 | 0.013 * | 39.95 | 0.001 * | 12.35 | 0.009 * |

| X22 | 1 | 81.79 | 0.000 * | 6.65 | 0.049 * | 82.56 | 0.000 * | 44.79 | 0.001 * |

| X32 | 1 | 159.56 | 0.000 * | 9.51 | 0.027 * | 143.86 | 0.000 * | 96.00 | 0.000 * |

| X1X2 | 1 | 47.95 | 0.001 * | 25.30 | 0.004 * | 0.74 | 0.430 | 34.24 | 0.002 * |

| X1X3 | 1 | 1.27 | 0.311 | 0.05 | 0.826 | 0.42 | 0.546 | 1.74 | 0.245 |

| X2X3 | 1 | 2.11 | 0.206 | 0.01 | 0.928 | 4.91 | 0.078 | 1.08 | 0.347 |

| Error | 5 | ||||||||

| Lack-of-Fit | 3 | 1.43 | 0.437 | 0.11 | 0.944 | 0.61 | 0.668 | 0.59 | 0.679 |

| Pure error | 2 | - | - | - | - | - | - | - | - |

| R2 | 0.995 | 0.980 | 0.991 | 0.992 | |||||

| Adjusted R2 | 0.987 | 0.945 | 0.975 | 0.979 | |||||

| Predicted R2 | 0.949 | 0.916 | 0.923 | 0.935 | |||||

| Matrix Effect (%) | Linear Range (µg/Kg) | Matrix-Matched Calibration Curve | R2 | LOD (µg/kg) | LOQ (µg/kg) | |

|---|---|---|---|---|---|---|

| Dried senna leaves | ||||||

| AFG1 | −23.93 | 2–50 | y = 14,070x + 4958 | 0.999 | 1.22 | 3.70 |

| AFB1 | −33.70 | 2–50 | y = 8976x + 434 | 0.999 | 1.27 | 3.84 |

| AFG2 | −23.78 | 2–50 | y = 19,187x + 0.39 | 0.997 | 0.70 | 2.13 |

| AFB2 | −30.28 | 2–50 | y = 10,265x − 639 | 0.998 | 1.02 | 3.09 |

| Dried senna pods | ||||||

| AFG1 | −17.01 | 2–50 | y = 12,186x + 3553 | 0.999 | 1.03 | 3.14 |

| AFB1 | −22.65 | 2–50 | y = 7716x − 208 | 0.998 | 0.86 | 2.60 |

| AFG2 | −17.29 | 2–50 | y = 18,252x − 1245 | 0.996 | 1.13 | 3.42 |

| AFB2 | −18.23 | 2–50 | y = 8537x + 226 | 0.997 | 1.14 | 3.44 |

| Spiked Level (µg/kg) | Dried Senna Leaves | Dried Senna Pods | |||||

|---|---|---|---|---|---|---|---|

| Recovery (%) (n = 6) | RSD (%) | Recovery (%) (n = 6) | RSD (%) | ||||

| Inter-Day (n = 6) | Intra-Day (n = 6) | Inter-Day (n = 6) | Intra-Day (n = 6) | ||||

| AFG1 | 5 | 103.98 | 3.23 | 4.57 | 99.36 | 5.55 | 7.85 |

| 10 | 92.43 | 4.67 | 4.92 | 96.89 | 6.53 | 9.23 | |

| 20 | 91.77 | 3.41 | 4.47 | 91.91 | 7.18 | 10.15 | |

| AFB1 | 5 | 98.47 | 2.30 | 3.13 | 92.18 | 2.90 | 4.20 |

| 10 | 105.06 | 2.78 | 3.94 | 83.50 | 7.08 | 10.08 | |

| 20 | 99.22 | 7.93 | 10.59 | 93.99 | 7.12 | 9.75 | |

| AFG2 | 5 | 107.92 | 2.67 | 3.91 | 101.56 | 5.21 | 7.27 |

| 10 | 101.41 | 5.29 | 7.49 | 90.5 | 6.12 | 8.91 | |

| 20 | 80.15 | 7.02 | 9.15 | 88.23 | 3.38 | 4.39 | |

| AFB2 | 5 | 103.19 | 4.41 | 6.23 | 102.73 | 6.93 | 9.68 |

| 10 | 108.71 | 5.21 | 7.70 | 94.20 | 2.47 | 3.36 | |

| 20 | 92.02 | 6.58 | 9.52 | 89.59 | 4.92 | 7.16 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maneeboon, T.; Chuaysrinule, C.; Mahakarnchanakul, W. Optimization and Validation of Dispersive Liquid–Liquid Microextraction for Simultaneous Determination of Aflatoxins B1, B2, G1, and G2 in Senna Leaves and Pods Using HPLC-FLD with Pre-Column Derivatization. Toxins 2023, 15, 277. https://doi.org/10.3390/toxins15040277

Maneeboon T, Chuaysrinule C, Mahakarnchanakul W. Optimization and Validation of Dispersive Liquid–Liquid Microextraction for Simultaneous Determination of Aflatoxins B1, B2, G1, and G2 in Senna Leaves and Pods Using HPLC-FLD with Pre-Column Derivatization. Toxins. 2023; 15(4):277. https://doi.org/10.3390/toxins15040277

Chicago/Turabian StyleManeeboon, Thanapoom, Chananya Chuaysrinule, and Warapa Mahakarnchanakul. 2023. "Optimization and Validation of Dispersive Liquid–Liquid Microextraction for Simultaneous Determination of Aflatoxins B1, B2, G1, and G2 in Senna Leaves and Pods Using HPLC-FLD with Pre-Column Derivatization" Toxins 15, no. 4: 277. https://doi.org/10.3390/toxins15040277

APA StyleManeeboon, T., Chuaysrinule, C., & Mahakarnchanakul, W. (2023). Optimization and Validation of Dispersive Liquid–Liquid Microextraction for Simultaneous Determination of Aflatoxins B1, B2, G1, and G2 in Senna Leaves and Pods Using HPLC-FLD with Pre-Column Derivatization. Toxins, 15(4), 277. https://doi.org/10.3390/toxins15040277