Experimental Investigation on Direct Micro Milling of Cemented Carbide

Abstract

:1. Introduction

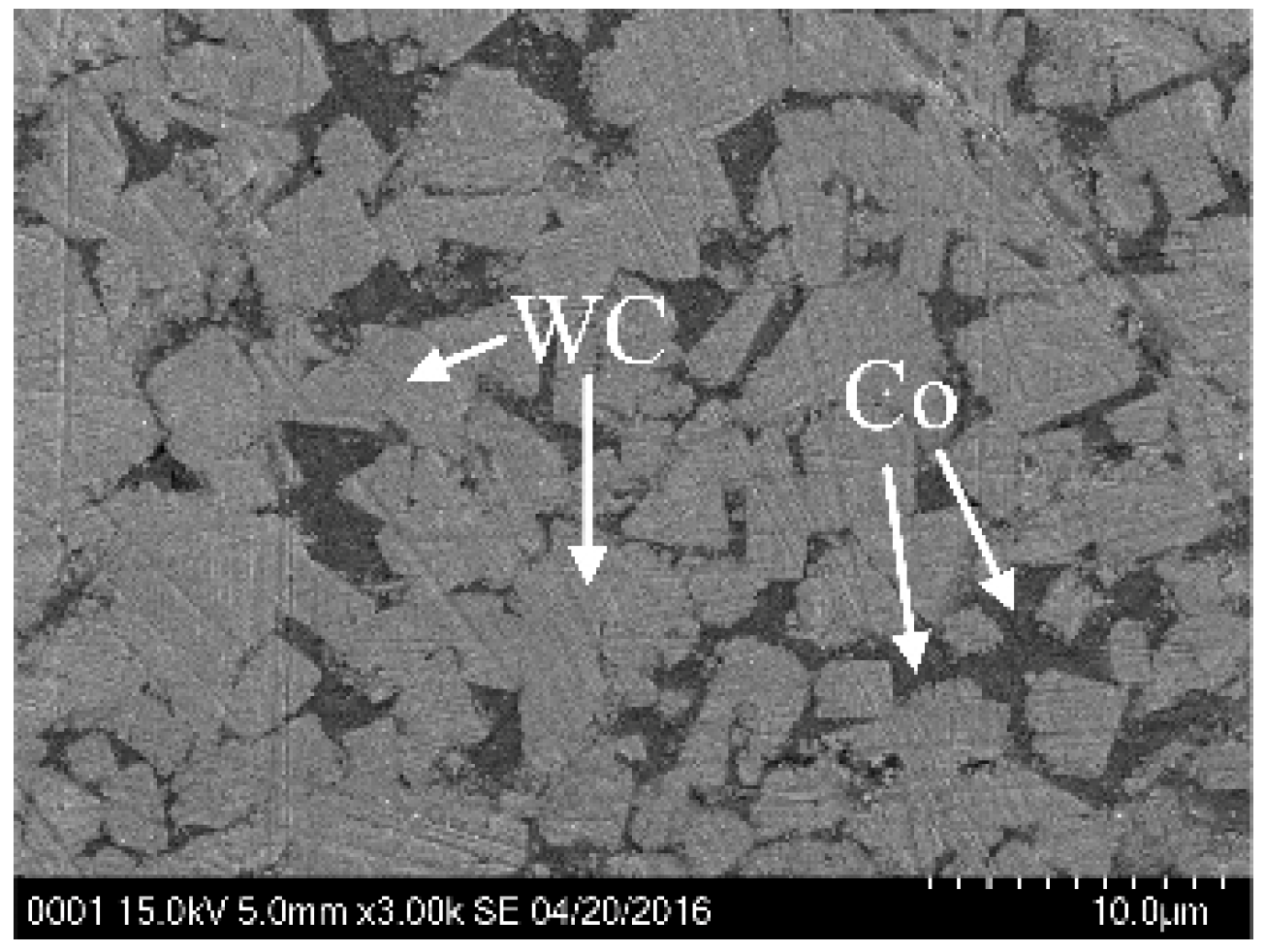

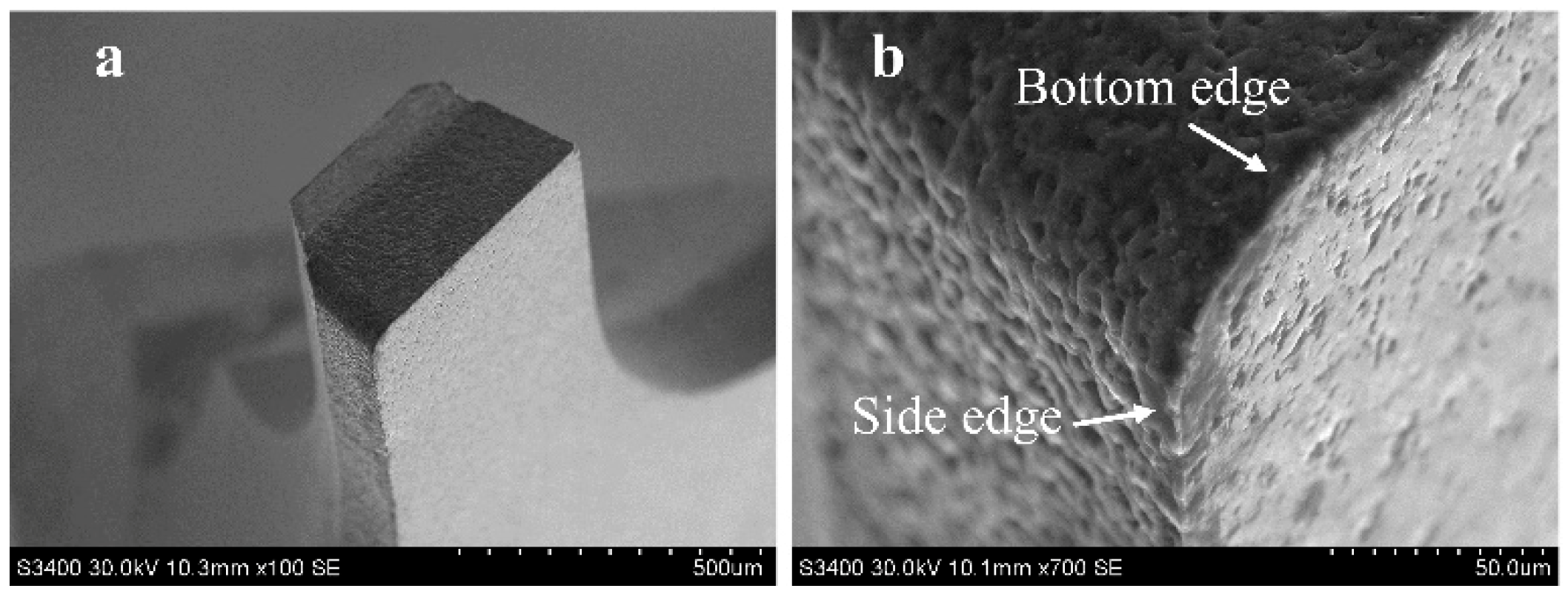

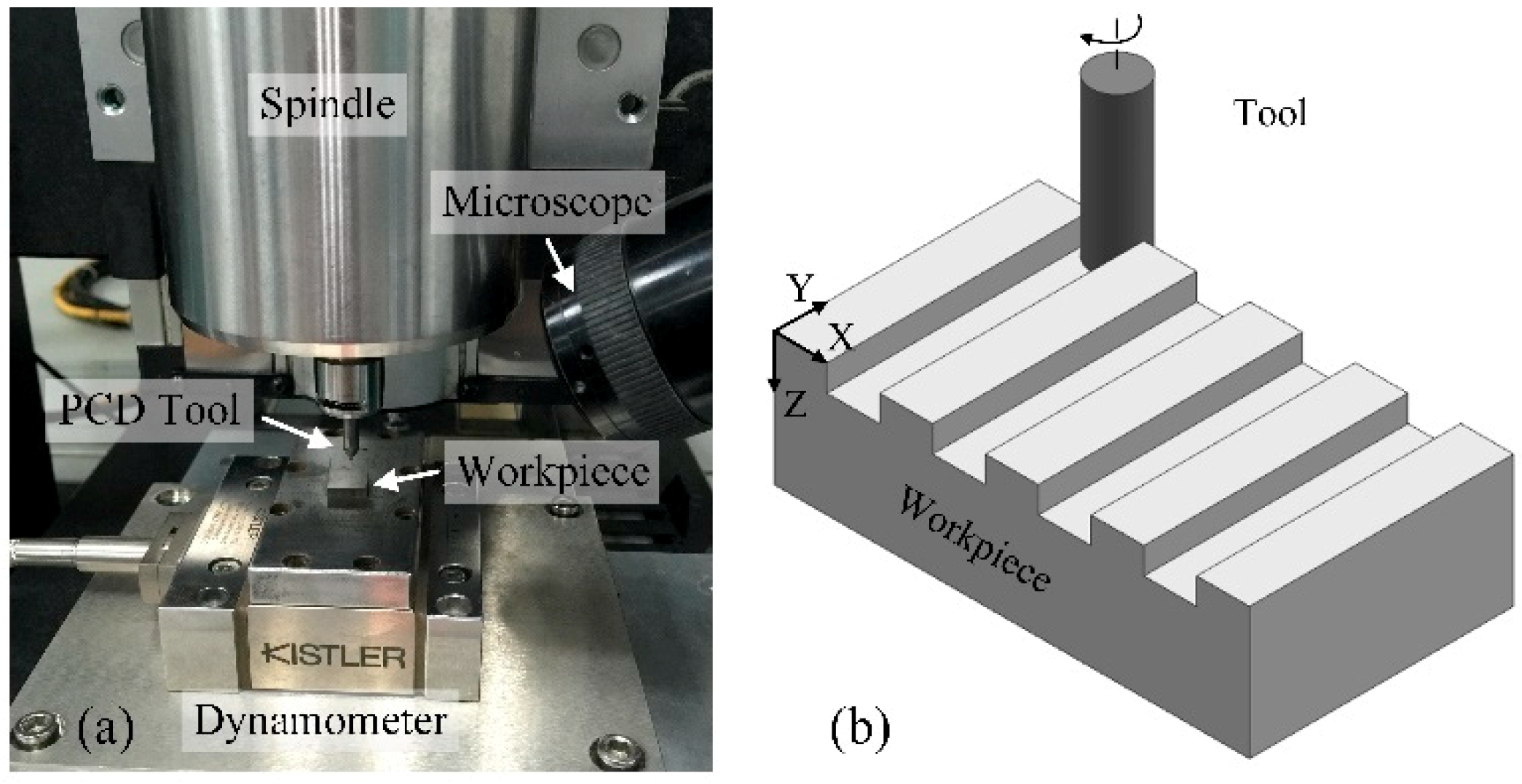

2. Experimental Procedure

3. Results and Discussion

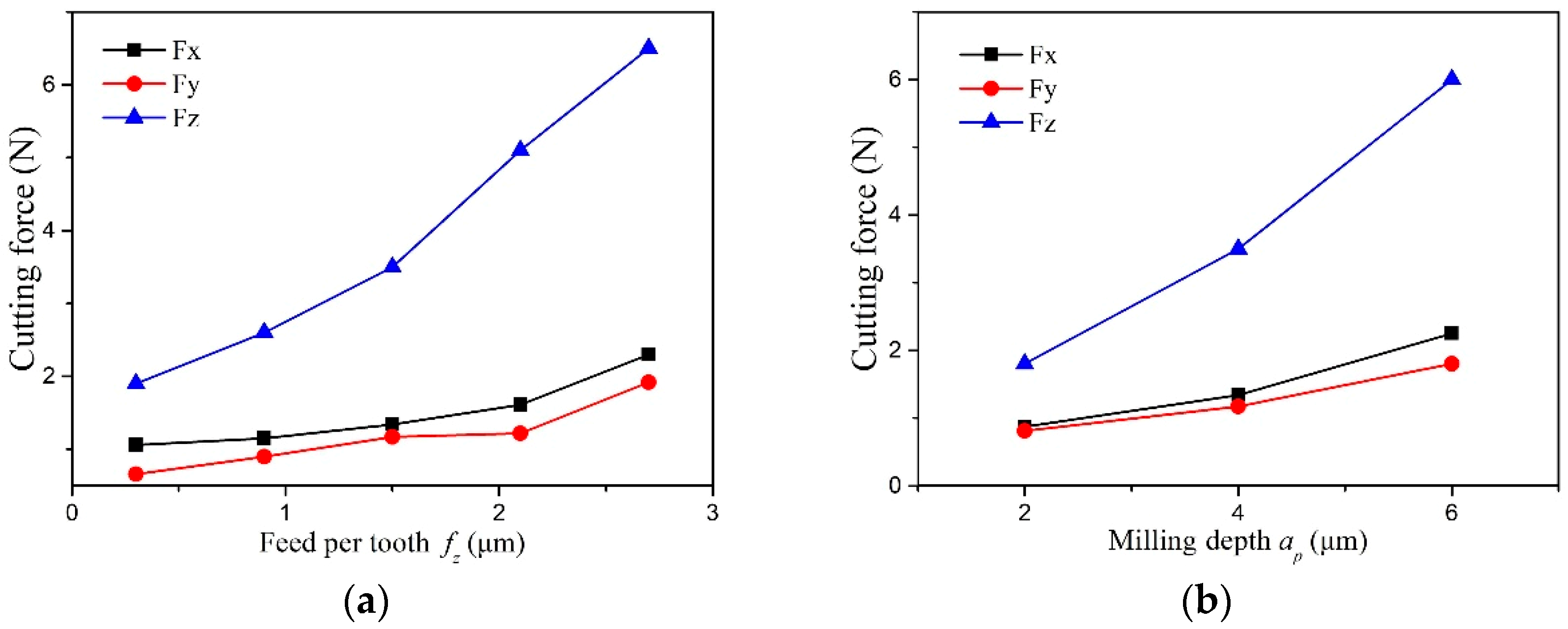

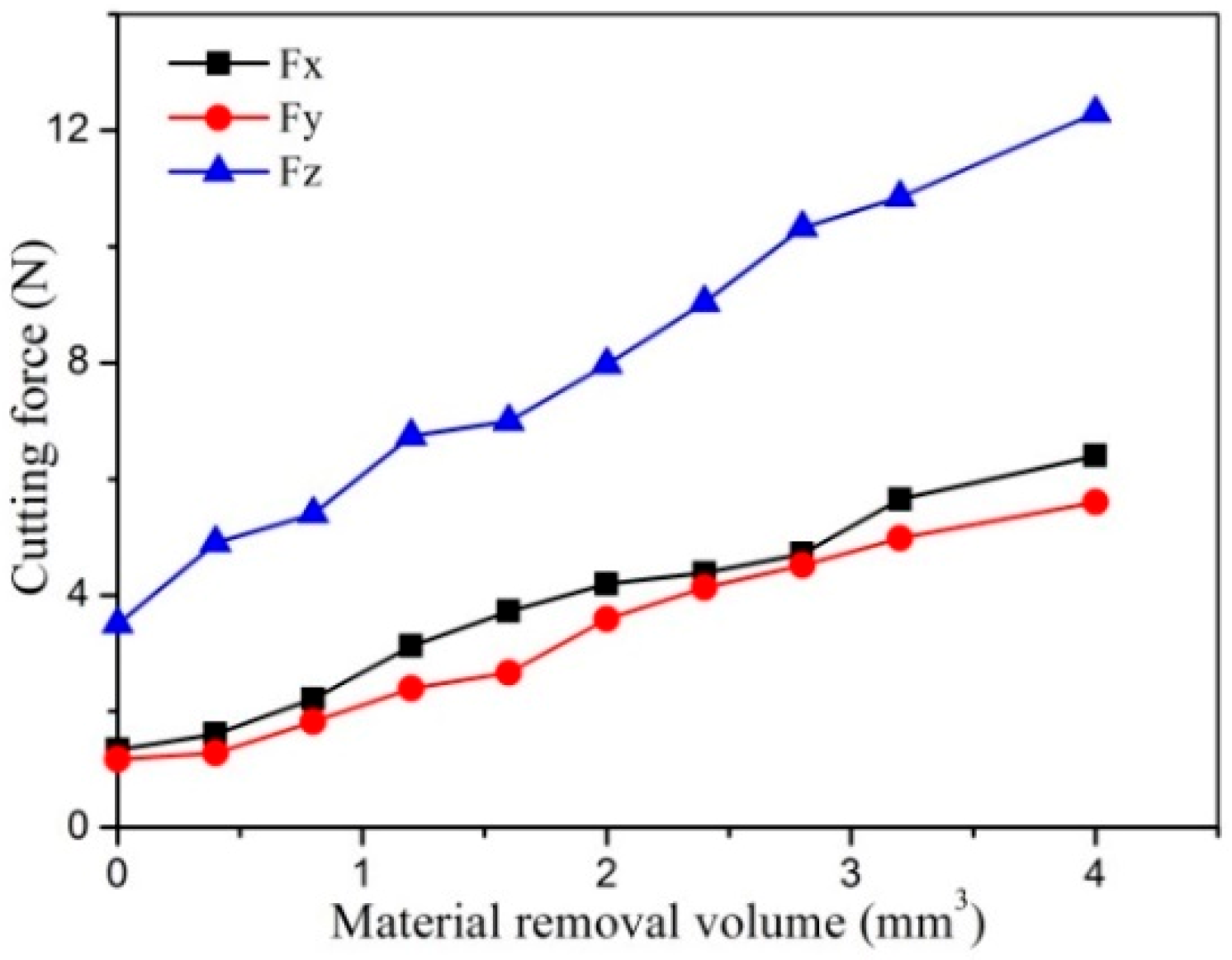

3.1. Cutting Force Analysis

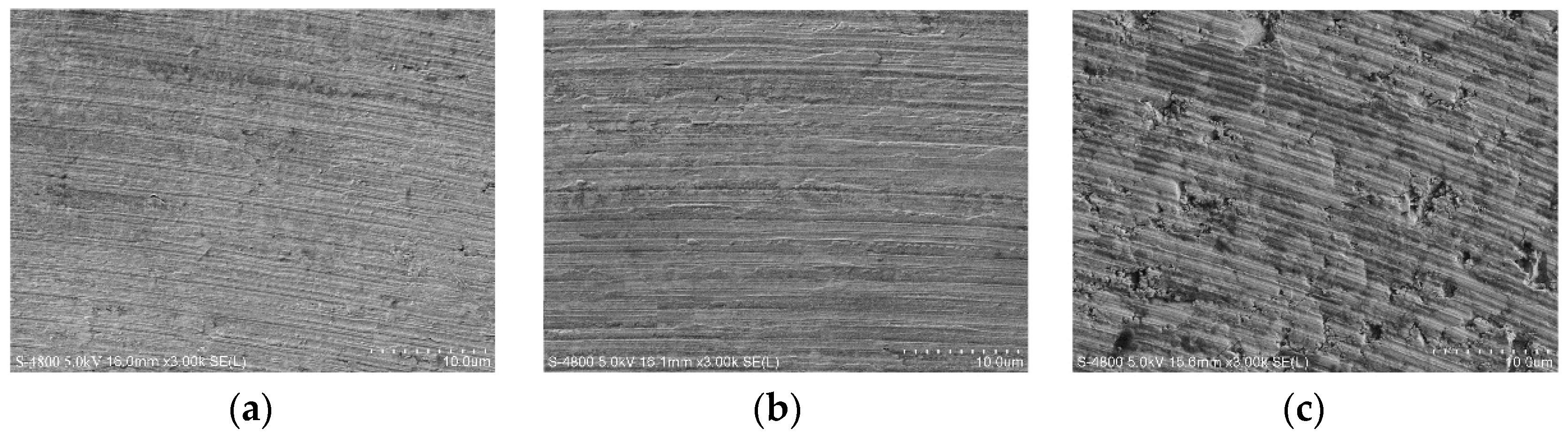

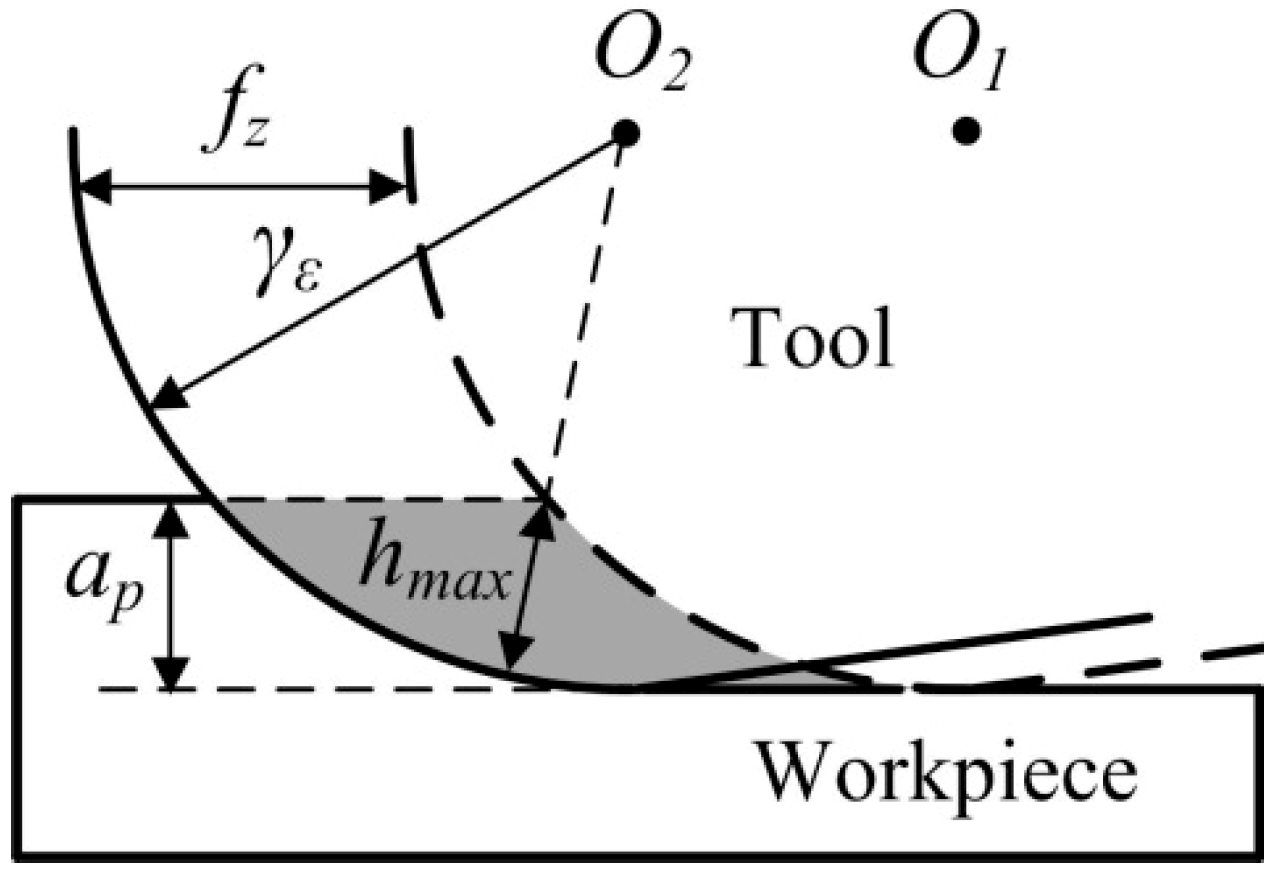

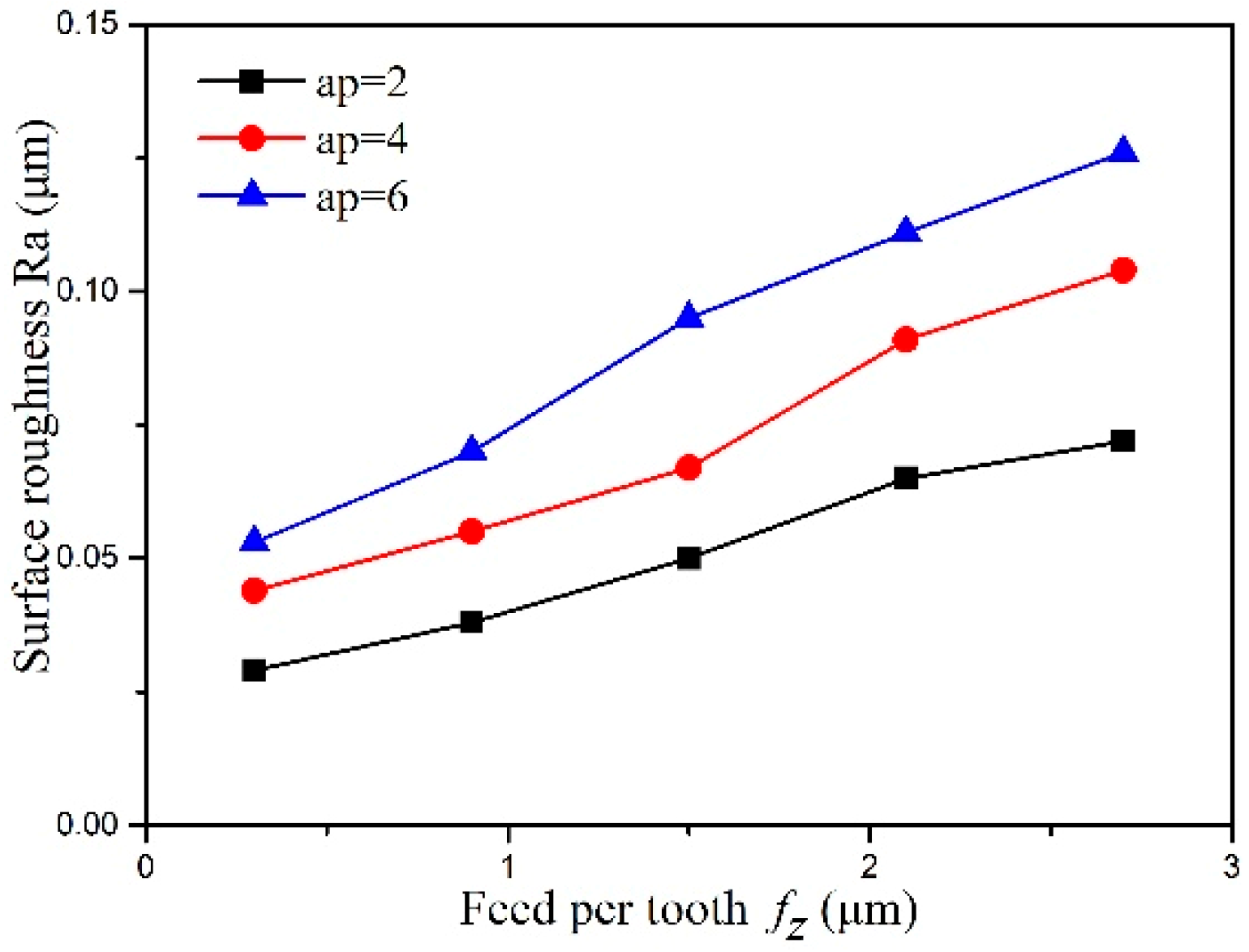

3.2. Surface Formation Mechanism

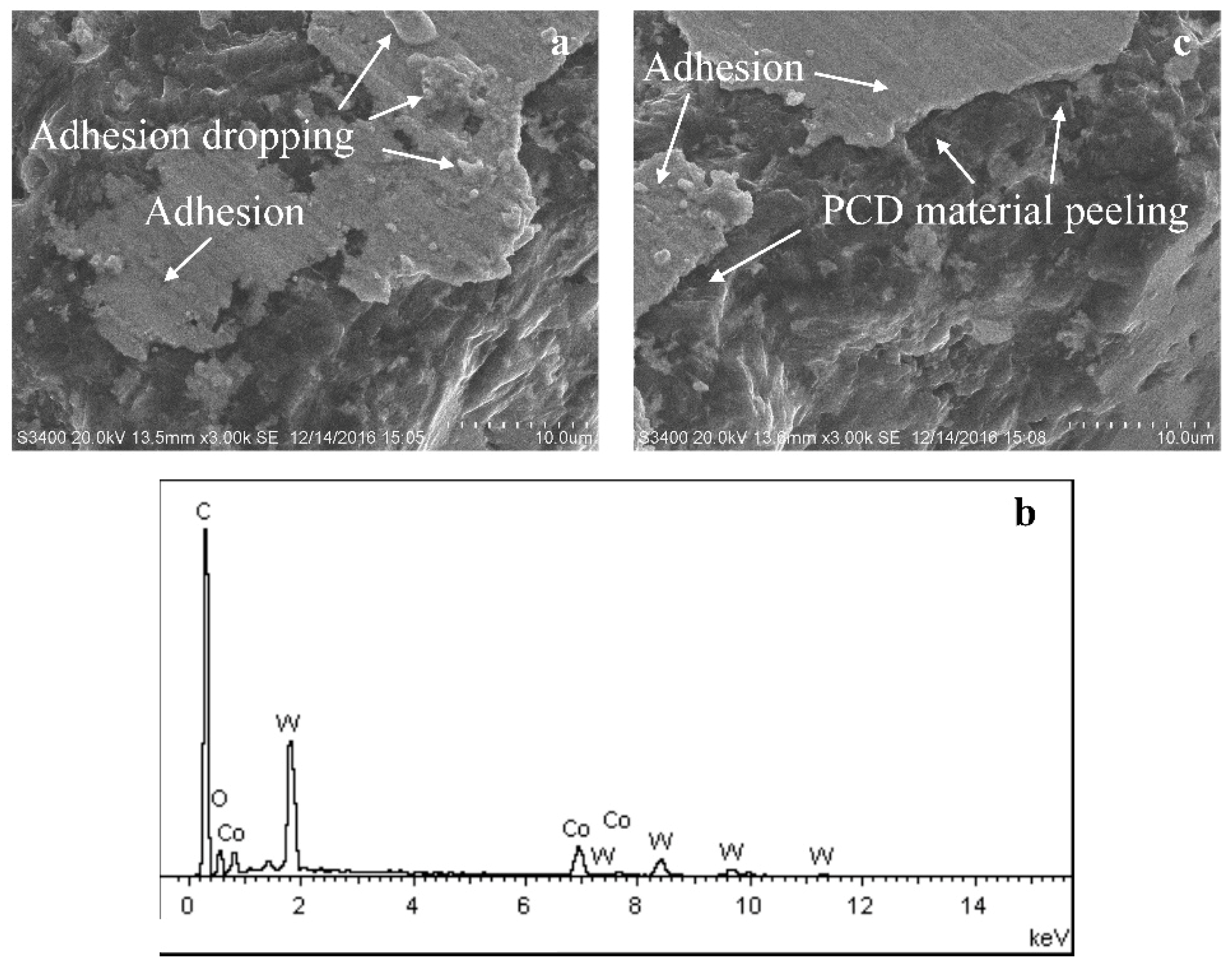

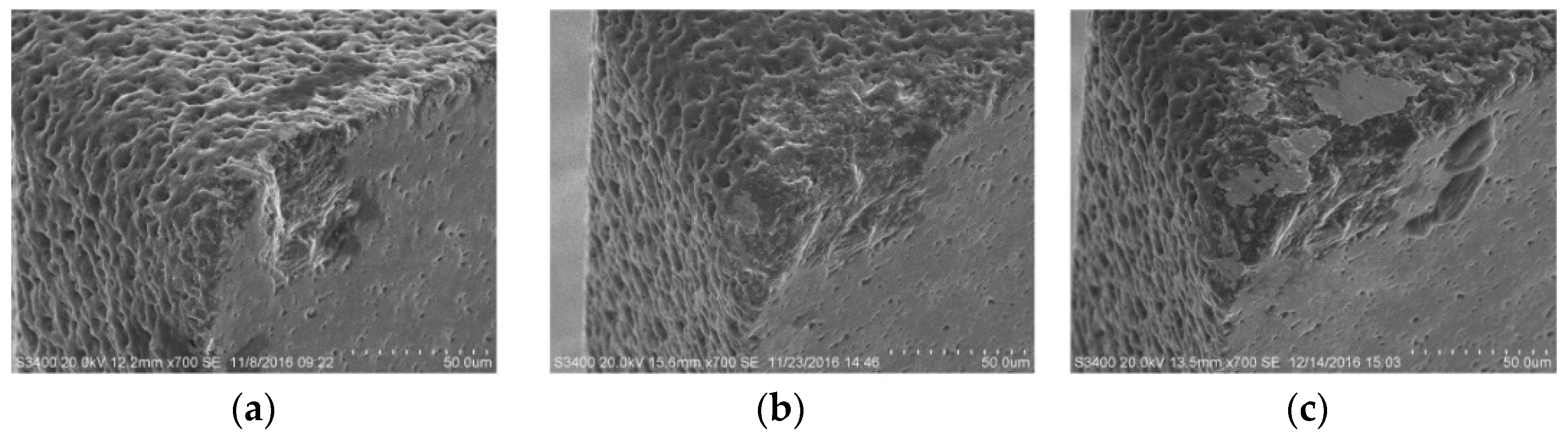

3.3. Tool Wear Mechanism

4. Summary and Conclusions

- The PCD tool with a large tool tip radius is conducive to perform ductile cutting of cemented carbide. The damage features on the ductile cutting surface are micro scale-stab and burrs that are attributed to the severe plowing and material side-flow. Micro-pits and cracks are the main damage features on the brittle cutting surface morphology. The machining parameters present a greater influence on the surface roughness when material is removed with brittle fracture compared to plastic deformation due to the different surface morphology characteristics.

- The PCD tool wear region is focused on the bottom cutting edge near the tool tip. The tool wear mechanisms mainly include microchipping on the cutting edge, exfoliation on the rake face, and abrasive and adhesive wear on the bottom face. The tool wear process shows microchipping and exfoliating in the early stage, and subsequently, severe abrasive and adhesive wear in the later stage.

Author Contributions

Funding

Conflicts of Interest

References

- Hansen, H.N.; Hocken, R.J.; Tosello, G. Replication of micro and nano surface geometries. CIRP Ann. Manuf. Technol. 2011, 60, 695–714. [Google Scholar] [CrossRef]

- Firestone, G.C.; Yi, A.Y. Precision compression molding of glass microlenses and microlens arrays-an experimental study. Appl. Opt. 2005, 44, 6115–6122. [Google Scholar] [CrossRef]

- Choi, W.; Lee, J.; Kim, W.B.; Min, B.K.; Kang, S. Design and fabrication of tungsten carbide mould with micro patterns imprinted by micro lithography. J. Micromech. Microeng. 2004, 14, 1519–1525. [Google Scholar] [CrossRef]

- Ottersbach, M.; Zhao, W. Experimental investigations on the machinability of tungsten carbides in orthogonal cutting with diamond-coated tools. Procedia CIRP 2016, 46, 416–419. [Google Scholar] [CrossRef]

- Guo, B.; Zhang, L.; Zhang, T.; Jiang, F.; Yan, L. The correction of temperature-dependent Vickers hardness of cemented carbide base on the developed high-temperature hardness tester. J. Mater. Process. Technol. 2018, 255, 426–433. [Google Scholar] [CrossRef]

- Chae, J.; Park, S.S.; Freiheit, T. Investigation of micro-cutting operations. Int. J. Mach. Tools Manuf. 2006, 46, 313–332. [Google Scholar] [CrossRef]

- Dornfeld, D.; Min, S.; Takeuchi, Y. Recent advances in mechanical micromachining. CIRP Ann. Manuf. Technol. 2006, 55, 745–768. [Google Scholar] [CrossRef]

- Zhang, S.J.; To, S.; Wang, S.J.; Zhu, Z.W. A review of surface roughness generation in ultra-precision machining. Int. J. Mach. Tools Manuf. 2015, 91, 76–95. [Google Scholar] [CrossRef]

- Ducobu, F.; Filippi, E.; Riviere, E. Chip formation and minimum chip thickness in micro-milling. In Proceedings of the 12th CIRP Conference on Modeling of Machining Operations, Donostia-San Sebastián, Spain, 7–8 May 2009; pp. 339–346. [Google Scholar]

- Liu, X.; Devor, R.E.; Kapoor, S.G. An analytical model for the prediction of minimum chip thickness in micromachining. J. Manuf. Sci. Eng. 2006, 128, 474–481. [Google Scholar] [CrossRef]

- Przestacki, D.; Chwalczuk, T.; Wojciechowski, S. The study on minimum uncut chip thickness and cutting forces during laser-assisted turning of WC/NiCr clad layers. Int. J. Adv. Manuf. Technol. 2017, 91, 3887–3898. [Google Scholar] [CrossRef] [Green Version]

- Twardowski, P.; Wojciechowski, S.; Wieczorowski, M.; Mathia, T. Surface roughness analysis of hardened steel after high-speed milling. Scanning 2011, 33, 386–395. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.J.; To, S. The effects of spindle vibration on surface generation in ultra-precision raster milling. Int. J. Mach. Tools Manuf. 2013, 71, 52–56. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Mrozek, K. Mechanical and technological aspects of micro ball end milling with various tool inclinations. Int. J. Mech. Sci. 2017, 134, 424–435. [Google Scholar] [CrossRef]

- Harano, K.; Satoh, T.; Sumiya, H. Cutting performance of nano-polycrystalline diamond. Diam. Relat. Mater. 2012, 24, 78–82. [Google Scholar] [CrossRef]

- Okada, M.; Suzuki, R.; Kondo, A.; Watanabe, H.; Miura, T.; Otsu, M. Evaluation of finished surface of cemented carbide by direct cutting using diamond-coated carbide end mill. Procedia CIRP 2018, 77, 114–117. [Google Scholar] [CrossRef]

- Mao, C.; Zhang, Y.; Peng, X.; Zhang, B.; Hu, Y.; Bi, Z. Wear mechanism of single cBN-WC-10Co fiber cutter in machining of Ti-6Al-4V alloy. J. Mater. Process. Technol. 2018, 259, 45–57. [Google Scholar] [CrossRef]

- Liu, K.; Li, X.P.; Rahman, M. Characteristics of high speed micro-cutting of tungsten carbide. J. Mater. Process. Technol. 2003, 140, 352–357. [Google Scholar] [CrossRef]

- Liu, K.; Li, X.P.; Rahman, M.; Liu, X.D. A study of the cutting modes in the grooving of tungsten carbide. Int. J. Adv. Manuf. Technol. 2004, 24, 321–326. [Google Scholar] [CrossRef]

- Arif, M.; Rahman, M.; San, W.Y. Analytical modeling of ductile-regime machining of tungsten carbide by endmilling. Int. J. Adv. Manuf. Technol. 2011, 55, 53–64. [Google Scholar] [CrossRef]

- Bulla, B.; Klocke, F.; Dambon, O. Analysis on ductile mode processing of binderless, nano crystalline tungsten carbide through ultra precision diamond turning. J. Mater. Process. Technol. 2012, 212, 1022–1029. [Google Scholar] [CrossRef]

- Nath, C.; Rahman, M.; Neo, K.S. A study on ultrasonic elliptical vibration cutting of tungsten carbide. J. Mater. Process. Technol. 2009, 209, 4459–4464. [Google Scholar] [CrossRef]

- Hintze, W.; Steinbach, S.; Susemihl, C.; Falko, K. HPC-milling of WC-Co cemented carbides with PCD. Int. J. Refract. Met. Hard Mater. 2018, 72, 126–134. [Google Scholar] [CrossRef]

- Suzuki, H.; Moriwaki, T.; Yamamoto, Y.; Goto, Y. Precision cutting of aspherical ceramic molds with micro PCD milling Tool. CIRP Ann. Manuf. Technol. 2007, 56, 131–134. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, Z.; Nakamoto, K.; Yamazaki, K. Design and development of PCD micro straight edge end mills for micro/nano machining of hard and brittle materials. J. Mech. Sci. Technol. 2010, 24, 2261–2268. [Google Scholar] [CrossRef]

- Nakamoto, K.; Katahira, K.; Ohmori, H.; Yamazaki, K.; Aoyama, T. A study on the quality of micro-machined surfaces on tungsten carbide generated by PCD micro end-milling. CIRP Ann. Manuf. Technol. 2012, 61, 567–570. [Google Scholar] [CrossRef]

- Zhan, Z.; He, N.; Li, L.; Shrestha, R.; Liu, J.; Wang, S. Precision milling of tungsten carbide with micro PCD milling tool. Int. J. Adv. Manuf. Technol. 2015, 77, 2095–2103. [Google Scholar] [CrossRef]

- Liao, T.; Yan, L.; Cheng, X.; Jiang, F. Optimizing the geometric parameters of cutting edge for finishing machining of Fe-Cr-Ni stainless steel. Int. J. Adv. Manuf. Technol. 2017, 88, 2061–2073. [Google Scholar] [CrossRef]

- Liao, T.; Jiang, F.; Guo, B.; Wang, F. Optimization and influence of the geometrical parameters of chip breaker for finishing machining of Fe-Cr-Ni stainless steel. Int. J. Adv. Manuf. Technol. 2017, 93, 3663–3675. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, T.; Yan, L. Estimation of temperature-dependent heat transfer coefficients in near-dry cutting. Int. J. Adv. Manuf. Technol. 2016, 86, 1–12. [Google Scholar] [CrossRef]

- Jiang, F.; Zhang, T.; Yan, L. Analytical model of milling forces based on time-variant sculptured shear surface. Int. J. Mech. Sci. 2016, 115–116, 190–201. [Google Scholar] [CrossRef]

- Bifano, T.G.; Dow, T.A.; Scattergood, R.O. Ductile regime grinding-a new technology for machining brittle materials. J. Eng. Ind. 1991, 113, 184–189. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, Z.; Wan, Y. Definition and determination of the minimum uncut chip thickness of microcutting. Int. J. Adv. Manuf. Technol. 2013, 69, 1219–1232. [Google Scholar]

| Properties. | Density (g/cm3) | Hardness (HV10) | Elastic Modulus (GPa) | Fracture Toughness (MPa·m1/2) |

|---|---|---|---|---|

| Value | 13.9 | 1607 | 498 | 9.1 |

| Parameters | Cutting Speed v (m/min) | Milling Depth ap (μm) | Feed per Tooth fz (μm) |

|---|---|---|---|

| Value | 44 | 2, 4, 6 | 0.3, 0.9, 1.5, 2.1, 2.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Li, L.; He, N.; Zhao, G.; Shen, J. Experimental Investigation on Direct Micro Milling of Cemented Carbide. Micromachines 2019, 10, 147. https://doi.org/10.3390/mi10020147

Wu X, Li L, He N, Zhao G, Shen J. Experimental Investigation on Direct Micro Milling of Cemented Carbide. Micromachines. 2019; 10(2):147. https://doi.org/10.3390/mi10020147

Chicago/Turabian StyleWu, Xian, Liang Li, Ning He, Guolong Zhao, and Jianyun Shen. 2019. "Experimental Investigation on Direct Micro Milling of Cemented Carbide" Micromachines 10, no. 2: 147. https://doi.org/10.3390/mi10020147

APA StyleWu, X., Li, L., He, N., Zhao, G., & Shen, J. (2019). Experimental Investigation on Direct Micro Milling of Cemented Carbide. Micromachines, 10(2), 147. https://doi.org/10.3390/mi10020147