In Situ Image Acquisition and Measurement of Microdroplets Based on Delay Triggering

Abstract

:1. Introduction

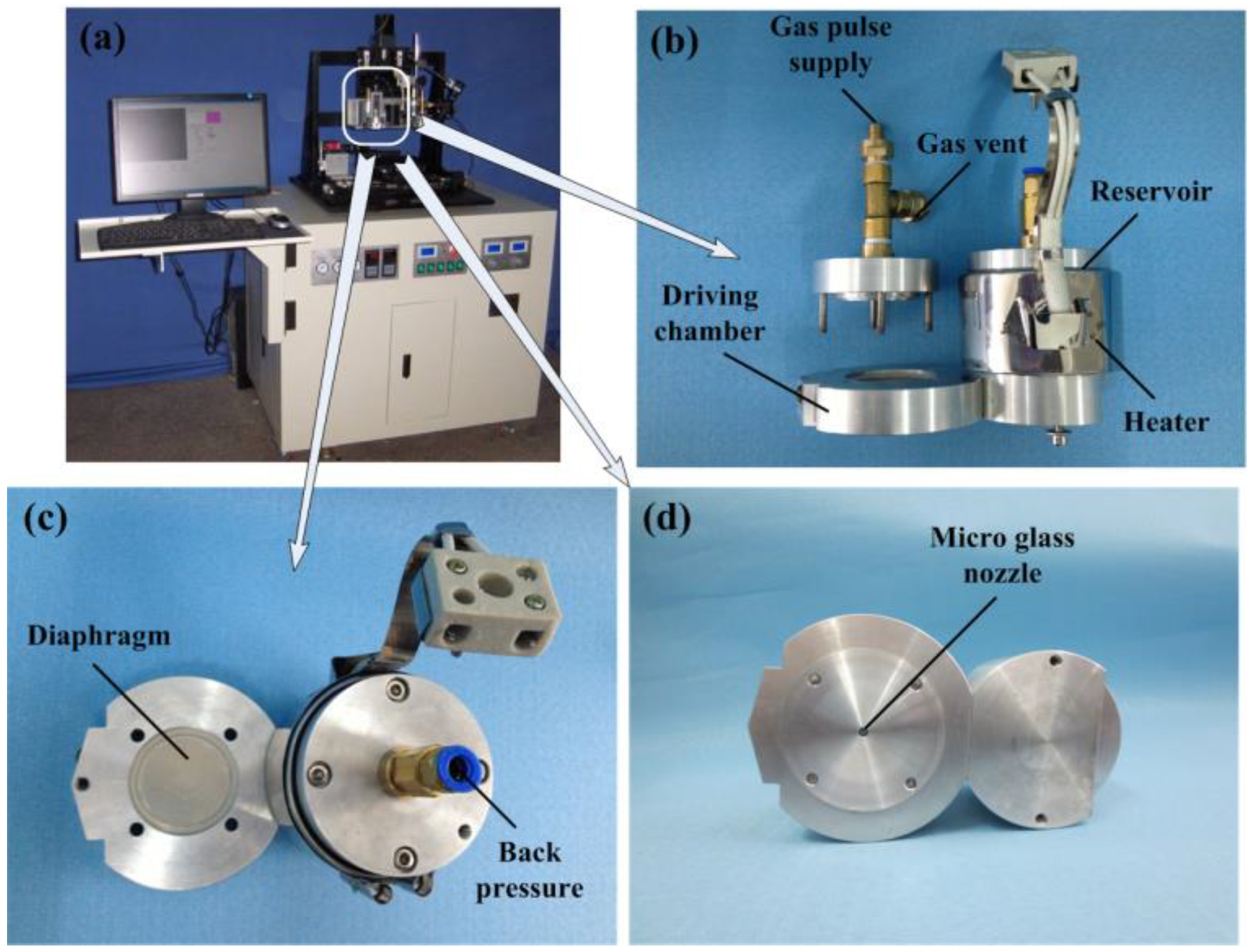

2. Experimental Set-Up

2.1. Pneumatically Diaphragm-Driven Actuator

2.2. In Situ Imaging System

3. Image Acquisition

4. Image Processing

4.1. Pretreatment of Droplet Images

4.2. Segmentation of Droplet Images

4.3. Circle Fitting of the Droplet Profile

5. Measurement of Micro-Drops

5.1. The Volume of the Drops

5.2. The Speed of the Drops

5.3. Microsolder Ball Volume Measurement

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Dong, H.; Carr, W.W.; Morris, J.F. An experimental study of drop-on-demand drop formation. Phys. Fluids 2006, 18, 51–59. [Google Scholar] [CrossRef]

- Khalil, A.; Puel, F.; Chevalier, Y.; Galvan, J.M.; Rivoire, A.; Klein, J.P. Study of droplet size distribution during an emulsification process using in situ video probe coupled with an automatic image analysis. Chem. Eng. J. 2010, 165, 946–957. [Google Scholar] [CrossRef]

- Kwon, K.S.; Kim, W. A waveform design method for high-speed inkjet printing based on self-sensing measurement. Sens. Actuators A 2007, 140, 75–83. [Google Scholar] [CrossRef]

- Shin, Y.J.; Lee, J.B. Machine vision for digital microfluidics. Rev. Sci. Instrum. 2010, 81, 014302. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Carr, W.W.; Morris, J.F. Visualization of drop-on-demand inkjet: Drop formation and deposition. Rev. Sci. Instrum. 2006, 77, 085101. [Google Scholar] [CrossRef]

- Hutchings, I.; Martin, G.; Hoath, S. High speed imaging and analysis of jet and drop formation. J. Imaging Sci. Technol. 2007, 51, 438–444. [Google Scholar] [CrossRef]

- Kwon, K.S. Speed measurement of ink droplet by using edge detection techniques. Measurement 2009, 42, 44–50. [Google Scholar] [CrossRef]

- Fan, K.C.; Chen, J.Y.; Wang, C.H.; Pan, W.C. Precision in situ volume measurement of micro droplets. J. Opt. A Pure Appl. Opt. 2008, 11, 015503. [Google Scholar] [CrossRef]

- Jo, B.W.; Lee, A.; Ahn, K.H.; Lee, S.J. Evaluation of jet performance indrop-on-demand (DOD) inkjet printing. Korean J. Chem. Eng. 2009, 26, 339–348. [Google Scholar] [CrossRef]

- Thurow, K.; Krü, T.; Stoll, N. An optical approach for the determination of droplet volumes in nanodispensing. J. Anal. Methods Chem. 2009, 2009, 1–9. [Google Scholar] [CrossRef] [PubMed]

- IEC 62899-302-1:2017 Printed Electronics—Part 302-1: Equipment—Inkjet—Imaging Based Measurement of Jetting Speed. Available online: https://webstore.iec.ch/preview/info_iec62899-302-1%7Bed1.0%7Den.pdf (accessed on 21 February 2019).

- IEC 62899-302-2:2018 Printed Electronics—Part 302-2: Equipment—Inkjet—Imaging-Based Measurement of Droplet Volume. Available online: https://webstore.iec.ch/preview/info_iec62899-302-2%7Bed1.0%7Den.pdf (accessed on 21 February 2019).

- Jia, C.; Chen, G.; Li, X.; Liu, J.; Zhao, L. Droplet Surface Tension Calculation Method Based on Contour Fitting. J. Comput. Inf. Syst. 2013, 9, 2075–2082. [Google Scholar]

- Fan, K.C.; Wang, N.; Wang, Z.W.; Zhang, H. Development of a roundness measuring system for microspheres. Meas. Sci. Technol. 2014, 25, 064009. [Google Scholar] [CrossRef]

- King, B.A.; Winward, T.W.; Bjorneberg, D.L. Comparison of drop size and velocity measurements by a laser precipitation meter and low-speed photography for an agricultural sprinkler. Appl. Eng. Agric. 2014, 30, 413–421. [Google Scholar]

- Ravasio, C.S.; Hoath, S.D.; Martin, G.D.; Boltryk, P.; Dorrestijn, M. Meniscus Motion Inside A DoD Inkjet Print-Head Nozzle. In Proceedings of the 32nd International Conference on Digital Printing Technologies (NIP): Printing for Fabrication 2016, Manchester, UK, 12–16 September 2016. [Google Scholar]

- Martin, G.D.; Castrejónpita, J.R.; Hutchings, I.M. Holographic Measurement of Drop-on-Demand Drops in Flight. In Proceedings of the 27th International Conference on Digital Printing Technologies, Minneapolis, MN, USA, 2–6 October 2011. [Google Scholar]

- Castrejón-García, R.; Castrejón-Pita, J.R.; Martin, G.D.; Hutchings, I.M. The shadowgraph imaging technique and its modern application to fluid jets and drops. Rev. Mex. Fis. 2011, 57, 266–275. [Google Scholar]

- Hsiao, W.K.; Chun, J.H.; Saka, N. The Effects of Wetting and Surface Roughness on Liquid Metal Droplet Bouncing. J. Manuf. Sci. Eng. 2009, 131, 267–272. [Google Scholar] [CrossRef]

- Jung, S. Fluid Characterisation and Drop Impact in Inkjet Printing for Organic Semiconductor Devices. Ph.D. Thesis, University of Cambridge, Cambridge, UK, April 2011. [Google Scholar]

- Jiang, H.; Merritt, B.A.; Tan, H. A Low-Cost Flash Photographic System for Visualization of Droplets in Drop-on-Demand Inkjet. J. Imaging Sci. Technol. 2018, 62, 60502-1–60502-9. [Google Scholar] [CrossRef]

- Martin, G.D.; Price, W.C.; Hutchings, I.M. Measurement of Inkjet Drop Volume Estimation—The Role of Image Processing. In Proceedings of the 32nd International Conference on Digital Printing Technologies (NIP): Printing for Fabrication 2016, Manchester, UK, 12–16 September 2016. [Google Scholar]

| Ref. | Printhead Type | Jetting Material | Number of Signals | Control Object by Trigger Signals | ||

|---|---|---|---|---|---|---|

| [5] | Trident printhead by piezo transducer | Glycerin and water mixture in the weight ratio 48/52 | 3 | Trident printhead by piezo transducer | Pulsed Cu vapor laser | CCD camera |

| [6] | Xaar 126-200 print head with a linear array of 50 µm diameter nozzles | Semi-transparent UV-curable ink | 3 | Print head | Flash source | Camera |

| [7] | Piezo inkjet printhead | Nanoparticles dissolved in DI (deionized) water | 3 | Piezo inkjet printhead | Strobe LED light | CCD camera |

| [8] | Piezo inkjet printhead | Liquid crystal | 3 | Piezo inkjet printhead | Stroboscopic light | CCD camera |

| [9] | Piezoelectric sleeve transducer printhead | Glycerol and water mixture | 3 | Piezoelectric sleeve transducer printhead | Strobe LED light | CCD camera |

| [10] | Piezo inkjet printhead | Water, DMSO, NMP, Acetonitrile, Dichloromethane, Methanol | 3 | Piezo inkjet printhead | Strobe LED light | CCD camera |

| Proposed article | Pneumatically diaphragm-driven actuator | Glycerin and water mixture (60/40, mass ratio) | 2 | Pneumatically diaphragm-driven actuator | CCD camera | |

| Illumination Intensity at Light Guide Receptacle | Uniformly Illuminated Light Guide Diameter | Rated Lamp Life | Color Temperature | Light Adjustment | Max Housing Temp | Lamp-EPV |

|---|---|---|---|---|---|---|

| 320,000 ftc | 10 mm | 1000 hrs | 3150 °K, constant | Crescent shaped diaphragm | 100 °K | Halogen reflector, 14.5 V/90 W |

| Time (μs) | Average Horizontal Coordinate (pixel) | Horizontal Coordinate Standard Deviation | Average Vertical Coordinate (pixel) | Vertical Coordinate Standard Deviation | Average Velocity (m/s) | Velocity Standard Deviation |

|---|---|---|---|---|---|---|

| 900 | 141.6 | 0.100 | 21.3 | 0.134 | 0 | 0 |

| 1000 | 138.0 | 0.487 | 55.3 | 0.415 | 0.683 | 0.008 |

| 1100 | 137.7 | 0.239 | 64.1 | 0.383 | 0.177 | 0.012 |

| 1200 | 137.7 | 0.274 | 69.0 | 0.503 | 0.097 | 0.012 |

| 1300 | 138.1 | 0.288 | 77.2 | 0.546 | 0.166 | 0.017 |

| 1400 | 139.3 | 0.319 | 83.3 | 0.711 | 0.122 | 0.016 |

| 1500 | 143.5 | 0.235 | 89.8 | 0.460 | 0.131 | 0.012 |

| 1600 | 143.3 | 0.182 | 94.6 | 0.546 | 0.097 | 0.018 |

| 1700 | 143.1 | 0.148 | 99.8 | 0.502 | 0.103 | 0.014 |

| 1800 | 143.7 | 0.055 | 102.7 | 0.555 | 0.060 | 0.014 |

| 1900 | 143.6 | 0.055 | 106.6 | 0.327 | 0.077 | 0.006 |

| 2000 | 143.5 | 0.045 | 114.3 | 1.122 | 0.154 | 0.026 |

| 2100 | 143.4 | 0.055 | 120.3 | 0.349 | 0.122 | 0.022 |

| 2200 | 143.3 | 0.055 | 128.4 | 0.349 | 0.162 | 0 |

| 2300 | 143.3 | 0.055 | 139.1 | 2.472 | 0.217 | 0.054 |

| 2400 | 143.0 | 0.045 | 143.9 | 0.329 | 0.096 | 0.046 |

| 2500 | 143.0 | 0.084 | 152.7 | 0.409 | 0.176 | 0.010 |

| 2600 | 143.0 | 0.130 | 158.2 | 1.242 | 0.111 | 0.027 |

| 2700 | 142.9 | 0.045 | 169.0 | 0.365 | 0.218 | 0.020 |

| 2800 | 142.9 | 0 | 177.6 | 0.785 | 0.172 | 0.019 |

| 2900 | 142.9 | 0.045 | 185.7 | 1.447 | 0.163 | 0.045 |

| 3000 | 142.8 | 0.055 | 194.9 | 1.158 | 0.183 | 0.045 |

| 3100 | 142.8 | 0.045 | 200.8 | 0.404 | 0.120 | 0.031 |

| 3200 | 142.7 | 0.084 | 207.6 | 1.568 | 0.135 | 0.036 |

| 3300 | 142.8 | 0.055 | 219.0 | 1.816 | 0.233 | 0.057 |

| 3400 | 142.8 | 0.055 | 224.1 | 0.377 | 0.101 | 0.036 |

| 3500 | 142.8 | 0.055 | 232.3 | 0.230 | 0.166 | 0.007 |

| 3500 | 142.5 | 0 | 304.1 | 0.518 | 0.166 | 0.007 |

| 3600 | 141.9 | 0.822 | 300.7 | 1.055 | −0.068 | 0.025 |

| 3700 | 142.1 | 0.418 | 326.2 | 0.321 | 0.513 | 0.021 |

| 3800 | 142.1 | 0.313 | 360.4 | 0.522 | 0.689 | 0.010 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, X.; Zheng, K.; Xie, D.; Shu, X.; Xu, K.; Chen, W.; Li, B.; Wu, C. In Situ Image Acquisition and Measurement of Microdroplets Based on Delay Triggering. Micromachines 2019, 10, 148. https://doi.org/10.3390/mi10020148

Chang X, Zheng K, Xie D, Shu X, Xu K, Chen W, Li B, Wu C. In Situ Image Acquisition and Measurement of Microdroplets Based on Delay Triggering. Micromachines. 2019; 10(2):148. https://doi.org/10.3390/mi10020148

Chicago/Turabian StyleChang, Xuefeng, Kang Zheng, Dan Xie, Xiayun Shu, Keyu Xu, Wenhuan Chen, Bo Li, and Changjian Wu. 2019. "In Situ Image Acquisition and Measurement of Microdroplets Based on Delay Triggering" Micromachines 10, no. 2: 148. https://doi.org/10.3390/mi10020148