The Influence of AlN Intermediate Layer on the Structural and Chemical Properties of SiC Thin Films Produced by High-Power Impulse Magnetron Sputtering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Deposition Method

2.2. Characterization Techniques

3. Results and Discussion

3.1. Chemical Composition and Stoichiometry

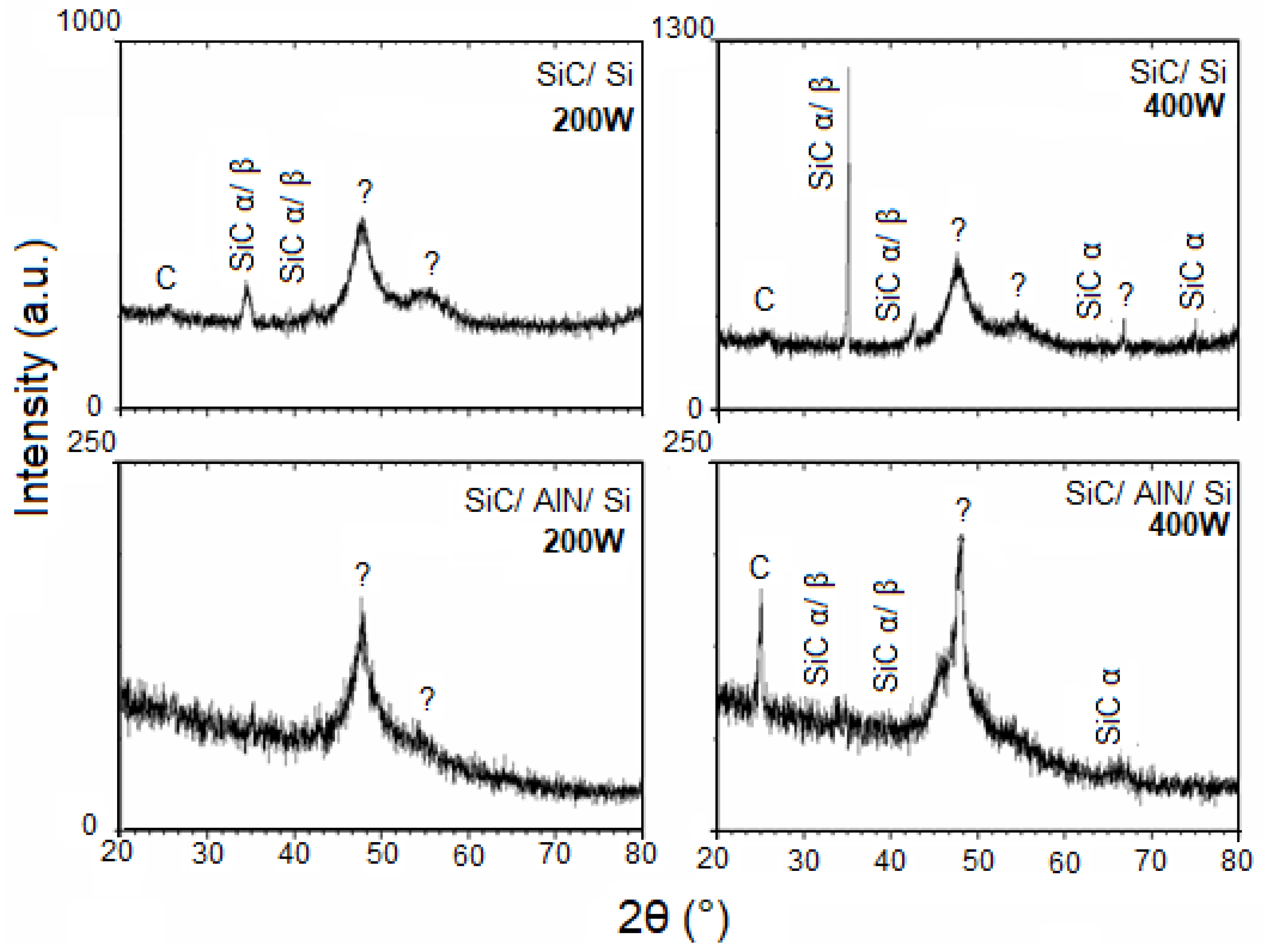

3.2. Structural Analysis

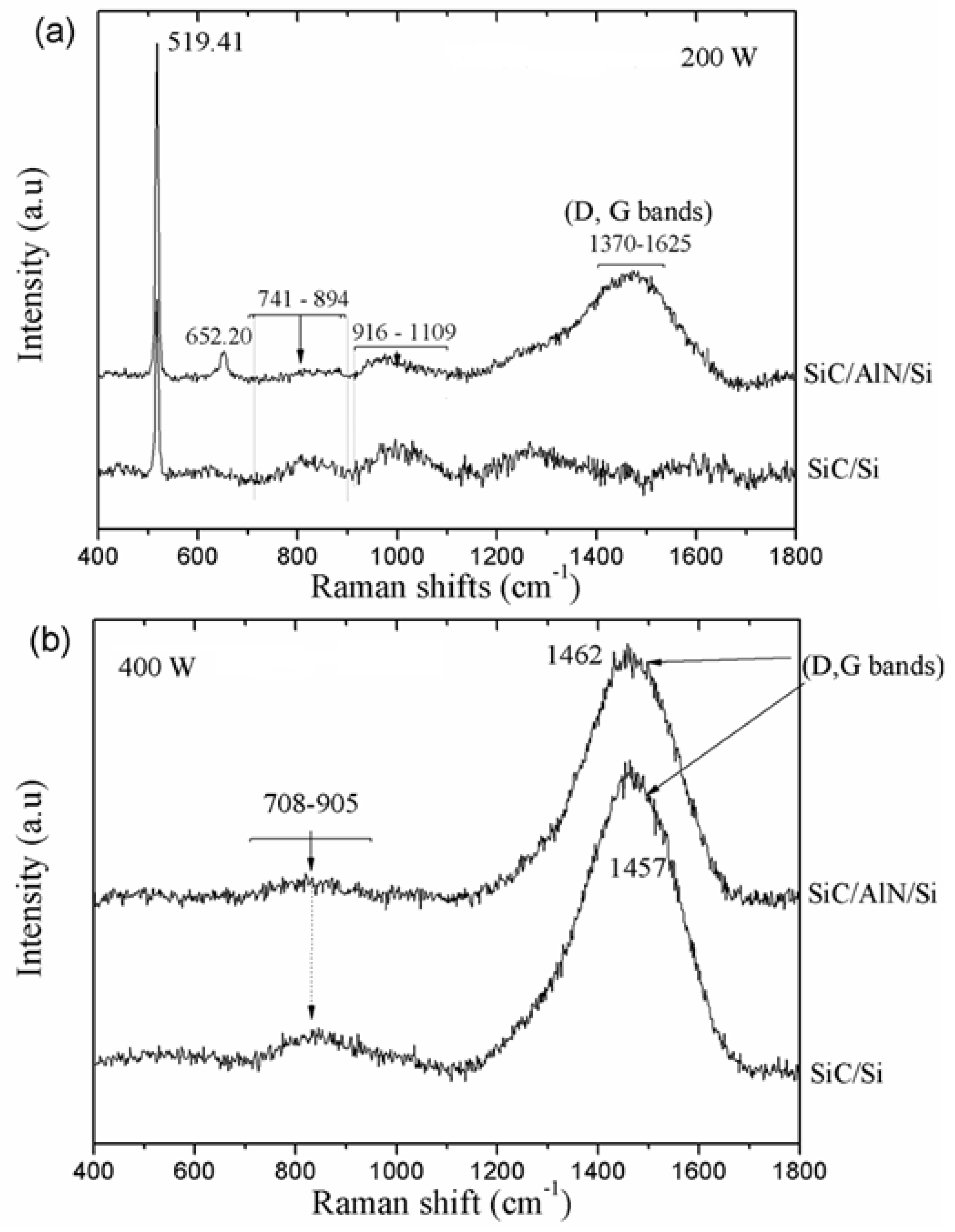

3.3. Raman Spectroscopy

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fraga, M.A.; Bosi, M.; Negri, M. Silicon Carbide in Microsystem Technology—Thin Film Versus Bulk Material. In Advanced Silicon Carbide Devices and Processing, 1st ed.; Saddow, S., la Via, F., Eds.; InTech: Rijeka, Croatia, 2015; pp. 1–31. [Google Scholar]

- Fraga, M.A.; Furlan, H.; Pessoa, R.S.; Massi, M. Wide bandgap semiconductor thin films for piezoelectric and piezoresistive MEMS sensors applied at high temperatures: An overview. Microsyst. Technol. 2014, 20, 9–21. [Google Scholar] [CrossRef]

- Pessoa, R.S.; Fraga, M.A.; Santos, L.V.; Massi, M.; Maciel, H.S. Nanostructured thin films based on TiO2 and/or SiC for use in photoelectrochemical cells: A review of the material characteristics, synthesis and recent applications. Mater. Sci. Semicond. Process. 2015, 29, 56–68. [Google Scholar] [CrossRef]

- Maboudian, R.; Carraro, C.; Senesky, D.G.; Roper, C.S. Advances in silicon carbide science and technology at the micro- and nanoscales. J. Vac. Sci. Technol. A 2013, 31, 050805. [Google Scholar] [CrossRef]

- Müller, G.; Krötz, G.; Niemann, E. SiC for sensors and high-temperature electronics. Sens. Actuators A Phys. 1994, 43, 259–268. [Google Scholar] [CrossRef]

- Huang, J.; Wang, L.; Wen, J.; Wang, Y.; Lin, C.; Ostling, M. Effect of annealing on SiC thin films prepared by pulsed laser deposition. Diam. Relat. Mater. 1999, 8, 2099–2102. [Google Scholar] [CrossRef]

- Ledermann, N.; Baborowski, J.; Muralt, P.; Xantopoulos, N.; Tellenbach, J. Sputtered silicon carbide thin films as protective coating for MEMS applications. Surf. Coat. Technol. 2000, 125, 246–250. [Google Scholar] [CrossRef]

- Sarro, P.M. Silicon carbide as a new MEMS technology. Sens. Actuators A Phys. 2000, 82, 210–218. [Google Scholar] [CrossRef]

- Fraga, M.A.; Pessoa, R.S.; Massi, M.; Maciel, H.S. Applications of SiC-Based Thin Films in Electronic and MEMS Devices. In Physics and Technology of Silicon Carbide Devices, 1st ed.; Hijikata, Y., Ed.; InTech: Rijeka, Croatia, 2012; pp. 313–336. [Google Scholar]

- Dinh, T.; Phan, H.P.; Kashaninejad, N.; Nguyen, T.K.; Dao, D.V.; Nguyen, N.T. An On-Chip SiC MEMS Device with Integrated Heating, Sensing, and Microfluidic Cooling Systems. Adv. Mater. Interfaces 2018, 5, 1800764. [Google Scholar] [CrossRef]

- Phan, H.P.; Nguyen, T.K.; Dinh, T.; Cheng, H.H.; Mu, F.; Lacopi, A.; Hold, L.; Dao, D.V.; Suga, T.; Senesky, D.G.; et al. Strain Effect in Highly-Doped n-Type 3C-SiC-on-Glass Substrate for Mechanical Sensors and Mobility Enhancement. Phys. Status Solidi A 2018, 215, 1870054. [Google Scholar] [CrossRef]

- Balakrishnan, V.; Dinh, T.; Phan, H.P.; Kozeki, T.; Namazu, T.; Dao, D.V.; Nguyen, N.T. Steady-state analytical model of suspended p-type 3C–SiC bridges under consideration of Joule heating. J. Micromech. Microeng. 2017, 27, 075008. [Google Scholar] [CrossRef]

- Roumié, M.; Tabbal, M.; Nsouli, B.; Said, A. Determination of stoichiometry in silicon carbide materials using elastic backscattering spectrometry. Nucl. Instrum. Methods Phys. Res. B 2007, 260, 637–641. [Google Scholar] [CrossRef]

- Tabbal, M.; Said, A.; Hannoun, E.; Christidis, T. Amorphous to crystalline phase transition in pulsed laser deposited silicon carbide. Appl. Surf. Sci. 2007, 253, 7050–7059. [Google Scholar] [CrossRef]

- Zhao, Y.M.; Sun, G.S.; Liu, X.S.; Li, J.Y.; Zhao, W.S.; Wang, L.; Li, J.M.; Zeng, Y.P. Heteroepitaxial Growth of 3C-SiC on Si (111) Substrate Using AlN as a Buffer Layer. Mater. Sci. Forum 2009, 600–603, 251–254. [Google Scholar] [CrossRef]

- Severino, A. 3C-SiC epitaxial growth on large area silicon: Thin films. In Silicon Carbide Epitaxy, 1st ed.; la Via, F., Ed.; Research Singpost: Kerala, India, 2012; pp. 145–191. [Google Scholar]

- Meguro, K.; Narita, T.; Noto, K.; Nakazawa, H. Formation of an interfacial buffer layer for 3C-SiC heteroepitaxy on AlN/Si substrates. Mater. Sci. Forum 2014, 778–780, 251–254. [Google Scholar] [CrossRef]

- Nakazawa, H.; Suzuki, D.; Narita, T.; Meguro, K.; Tsuchiya, M. Growth of silicon carbide on Si (100) substrate with an intermediate aluminum nitride layer by ultralow-pressure chemical vapor deposition using monomethylsilane. J. Cryst. Growth 2015, 418, 52–56. [Google Scholar] [CrossRef]

- Jeong, J.; Jang, K.; Lee, H.S.; Chung, G.; Kim, G. Raman scattering studies of polycrystalline 3C-SiC deposited on SiO2 and AlN thin films. Phys. B Condens. Matter 2009, 404, 7–10. [Google Scholar] [CrossRef]

- Huang, S.Y.; Xu, S.; Long, J.D.; Sun, Z.; Chen, T. Plasma-reactive SiC quantum dots on polycrystalline AlN films. Phys. Plasmas 2006, 13, 023506. [Google Scholar] [CrossRef]

- Fraga, M.A.; Pessoa, R.S.; Maciel, H.S.; Massi, M. Recent Developments on Silicon Carbide Thin Films for Piezoresistive Sensors Applications. In Silicon Carbide—Materials, Processing and Applications in Electronic Devices; Mukherjee, M., Ed.; InTech: Rijeka, Croatia, 2011; pp. 369–388. [Google Scholar]

- Tang, H.; Tan, S.; Huang, Z.; Dong, S.; Jiang, D. Surface morphology of α-SIC coatings deposited by RF magnetron sputtering. Surf. Coat. Technol. 2005, 197, 161–167. [Google Scholar] [CrossRef]

- Gou, L.; Qi, C.; Ran, J.; Zheng, C. SiC film deposition by DC magnetron sputtering. Thin Solid Film. 1999, 345, 42–44. [Google Scholar] [CrossRef]

- Medeiros, H.S.; Pessoa, R.S.; Maciel, H.S.; Massi, M.; Tezani, L.L.; Leal, G.; Galvão, N.K.A.M.; da Silva Sobrinho, A.S. Amorphous Silicon Carbide Thin Films Deposited by Magnetron Co-Sputtering: Effect of Applied Power and Deposition Pressure on Film Characteristics. ECS Trans. 2012, 49, 375–382. [Google Scholar] [CrossRef]

- Lei, Y.M.; Yu, L.H.; Cheng, L.L.; Ren, C.X.; Zou, S.C.; Wong, S.P.; Chen, D.H.; Wilson, I.H. IR studies of reactive DC magnetron sputtered SiC films on silicon using effective medium theory. Mater. Lett. 2000, 43, 215–219. [Google Scholar] [CrossRef]

- Pusch, C.; Hoche, H.; Berger, C.; Riedel, R.; Ionescu, E.; Klein, A. Influence of the PVD sputtering method on structural characteristics of SiCN-coatings—Comparison of RF, DC and HiPIMS sputtering and target configurations. Surf. Coat. Technol. 2011, 205, s119–s123. [Google Scholar] [CrossRef]

- Bräuer, G.; Szyszka, B.; Vergo, M.; Bandorf, R. Magnetron sputtering—Milestones of 30 years. Vacuum 2010, 84, 1354–1359. [Google Scholar] [CrossRef]

- Anders, A. High power impulse magnetron sputtering and related discharges: Scalable plasma sources for plasma-based ion implantation and deposition. Surf. Coat. Technol. 2010, 204, 2864–2868. [Google Scholar] [CrossRef] [Green Version]

- Aijaz, A.; Lundin, D.; Larsson, P.; Helmersson, U. Dual-magnetron open field sputtering system for sideways deposition of thin films. Surf. Coat. Technol. 2010, 204, 2165–2169. [Google Scholar] [CrossRef] [Green Version]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Gudmundsson, J.T. The high power impulse magnetron sputtering discharge as an ionized physical vapor deposition tool. Vacuum 2010, 84, 1360–1364. [Google Scholar] [CrossRef]

- Alami, J.; Bolz, S.; Sarakinos, K. High power pulsed magnetron sputtering: Fundamentals and applications. J. Alloys Compd. 2009, 483, 530–534. [Google Scholar] [CrossRef]

- Alami, J.; Eklund, P.; Emmerlich, J.; Wilhelmsson, O.; Jansson, U.; Högberg, H.; Hultman, L.; Helmersson, U. High-power impulse magnetron sputtering of Ti–Si–C thin films from a Ti3SiC2 compound target. Thin Solid Film. 2006, 515, 1731–1736. [Google Scholar] [CrossRef]

- Leal, G.; Campos, T.M.B.; da Silva Sobrinho, A.S.; Pessoa, R.S.; Maciel, H.S.; Massi, M. Characterization of SiC thin films deposited by HiPIMS. Mater. Res. 2014, 17, 472–476. [Google Scholar] [CrossRef] [Green Version]

- Medeiros, H.S.; Pessoa, R.S.; Sagas, J.C.; Fraga, M.A.; Santos, L.V.; Maciel, H.S.; Massi, M.; da Silva Sobrinho, A.S.; Costa, M.E.H.M. Effect of nitrogen content in amorphous SiCxNyOz thin films deposited by low temperature reactive magnetron co-sputtering technique. Surf. Coat. Technol. 2011, 206, 1787–1795. [Google Scholar] [CrossRef]

- Belkerk, B.E.; Soussou, A.; Carette, M.; Djouadi, M.A.; Scudeller, Y. Structural-dependent thermal conductivity of aluminium nitride produced by reactive direct current magnetron sputtering. Appl. Phys. Lett. 2012, 101, 151908. [Google Scholar] [CrossRef]

- Aissa, K.A.; Achour, A.; Camus, J.; Brizoual, L.L.; Jouan, P.; Djouadi, A. Comparison of the structural properties and residual stress of AlN films deposited by dc magnetron sputtering and high power impulse magnetron sputtering at different working pressures. Thin Solid Film. 2014, 550, 264–267. [Google Scholar] [CrossRef]

- Doolittle, L.R. Algorithms for the rapid simulation of Rutherford backscattering spectra. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 1985, 9, 344–351. [Google Scholar] [CrossRef]

- Pomaska, M.; Mock, J.; Köhler, F.; Zastrow, U.; Perani, M.; Astakhov, O.; Cavalcoli, D.; Carius, R.; Finger, F.; Ding, K. Role of oxygen and nitrogen in n-type microcrystalline silicon carbide grown by hot wire chemical vapor deposition. J. Appl. Phys. 2016, 120, 225105. [Google Scholar] [CrossRef]

- Diyatmika, W.; Liang, F.; Lou, B.; Lu, J.; Sun, D.; Lee, J. Superimposed high power impulse and middle frequency magnetron sputtering: Role of pulse duration and average power of middle frequency. Surf. Coat. Technol. 2018, 352, 680–689. [Google Scholar] [CrossRef]

- Anders, A. Deposition Rates of High-Power Impulse Magnetron Sputtering: Physics and Economics J. Vac. Sci. Technol. A 2010, 28, 783. [Google Scholar] [CrossRef]

- Nivedita, L.R.; Kumar, V.V.S.; Asokan, K.; Rajendrakumar, R.T. Growth and Magnetic Properties of RF Sputtered Fe-Ga Thin Films. Mater. Res. 2015, 18, 946–952. [Google Scholar] [CrossRef] [Green Version]

- Jung, C.-K.; Lim, D.-C.; Jee, H.-G.; Park, M.-G.; Ku, S.-J.; Yu, K.-S.; Hong, B.; Lee, S.-B.; Boo, J.-H. Hydrogenated amorphous and crystalline SiC thin films grown by RF-PECVD and thermal MOCVD; comparative study of structural and optical properties. Surf. Coat. Technol. 2003, 171, 46–50. [Google Scholar] [CrossRef]

- Galvão, N.; Vasconcelos, G.; Pessoa, R.; Machado, J.; Guerino, M.; Fraga, M.; Rodrigues, B.; Camus, J.; Djouadi, A.; Maciel, H. A Novel Method of Synthesizing Graphene for Electronic Device Applications. Materials 2018, 11, 1120. [Google Scholar] [CrossRef]

- Li, W.; Yuan, J.; Lin, Y.; Yao, S.; Ren, Z.; Wang, H.; Wang, M.; Bai, J. The controlled formation of hybrid structures of multi-walled carbon nanotubes on SiC plate-like particles and their synergetic effect as a filler in poly(vinylidene fluoride) based composites. Carbon 2013, 51, 355–364. [Google Scholar] [CrossRef]

- Badini, C.; Fino, P.; Ortona, A.; Amelio, C. High temperature oxidation of multilayered SiC processed by tape casting and sintering. J. Eur. Ceram. Soc. 2002, 22, 2071–2079. [Google Scholar] [CrossRef]

- Wilhelm, M.; Wruss, W. Influence of annealing on the mechanical properties of SiC–Si composites with sub-micron SiC microstructures. J. Eur. Ceram. Soc. 2000, 20, 1205–1213. [Google Scholar] [CrossRef]

- Xia, A.; Huizhao, Z.; Li, Y.; Chengshan, X. Formation of carbon nanowires by annealing silicon carbide films deposited by magnetron sputtering. Appl. Surf. Sci. 2002, 193, 87–91. [Google Scholar] [CrossRef]

- Yang, W.S.; Biamino, S.; Padovano, E.; Pavese, M.; Marchisio, S.; D’Amico, G.; Mio, S.C.; Chen, X.; Fino, P.; Badini, C. Thermophysical properties of SiC multilayer prepared by tape casting and pressureless sintering. Compos. Struct. 2013, 96, 469–475. [Google Scholar] [CrossRef]

- Kuenle, M.; Janza, S.; Eibl, O.; Berthold, C.; Presser, V.; Nickel, K.-G. Thermal annealing of SiC thin films with varying stoichiometry. Mater. Sci. Eng. B 2009, 159–160, 355–360. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

| Sample | No. of Layers | Composition by Layer 1 | Layer Thickness |

|---|---|---|---|

| SiC/Si 200 W | 5 |

| 1. 260 nm 2. 400 nm 3. 250 nm 4. 170 nm 5. 145 nm |

| SiC/Si 400 W | 2 |

| 1. ~900 nm 2. ~600 nm |

| SiC/AlN/Si 200 W | 2 |

| 1. ~930 nm 2. ~1300 nm |

| SiC/AlN/Si 400 W | 2 |

| 1. ~1360 nm 2. ~1300 nm |

| Sample | Power (W) | Deposition Rate—RBS (nm/min) | Deposition Rate—Profilometer (nm/min) |

|---|---|---|---|

| SiC/Si | 200 | 20.0 | 14.0 ± 0.3 |

| SiC/Si | 400 | 25.0 | 19.6 ± 0.4 |

| SiC/AlN/Si | 200 | 15.5 | 12.5 ± 0.4 |

| SiC/AlN/Si | 400 | 22.7 | 24.0 ± 0.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galvão, N.; Guerino, M.; Campos, T.; Grigorov, K.; Fraga, M.; Rodrigues, B.; Pessoa, R.; Camus, J.; Djouadi, M.; Maciel, H. The Influence of AlN Intermediate Layer on the Structural and Chemical Properties of SiC Thin Films Produced by High-Power Impulse Magnetron Sputtering. Micromachines 2019, 10, 202. https://doi.org/10.3390/mi10030202

Galvão N, Guerino M, Campos T, Grigorov K, Fraga M, Rodrigues B, Pessoa R, Camus J, Djouadi M, Maciel H. The Influence of AlN Intermediate Layer on the Structural and Chemical Properties of SiC Thin Films Produced by High-Power Impulse Magnetron Sputtering. Micromachines. 2019; 10(3):202. https://doi.org/10.3390/mi10030202

Chicago/Turabian StyleGalvão, Nierlly, Marciel Guerino, Tiago Campos, Korneli Grigorov, Mariana Fraga, Bruno Rodrigues, Rodrigo Pessoa, Julien Camus, Mohammed Djouadi, and Homero Maciel. 2019. "The Influence of AlN Intermediate Layer on the Structural and Chemical Properties of SiC Thin Films Produced by High-Power Impulse Magnetron Sputtering" Micromachines 10, no. 3: 202. https://doi.org/10.3390/mi10030202

APA StyleGalvão, N., Guerino, M., Campos, T., Grigorov, K., Fraga, M., Rodrigues, B., Pessoa, R., Camus, J., Djouadi, M., & Maciel, H. (2019). The Influence of AlN Intermediate Layer on the Structural and Chemical Properties of SiC Thin Films Produced by High-Power Impulse Magnetron Sputtering. Micromachines, 10(3), 202. https://doi.org/10.3390/mi10030202