Development of a Novel Modular Compliant Gripper for Manipulation of Micro Objects

Abstract

:1. Introduction

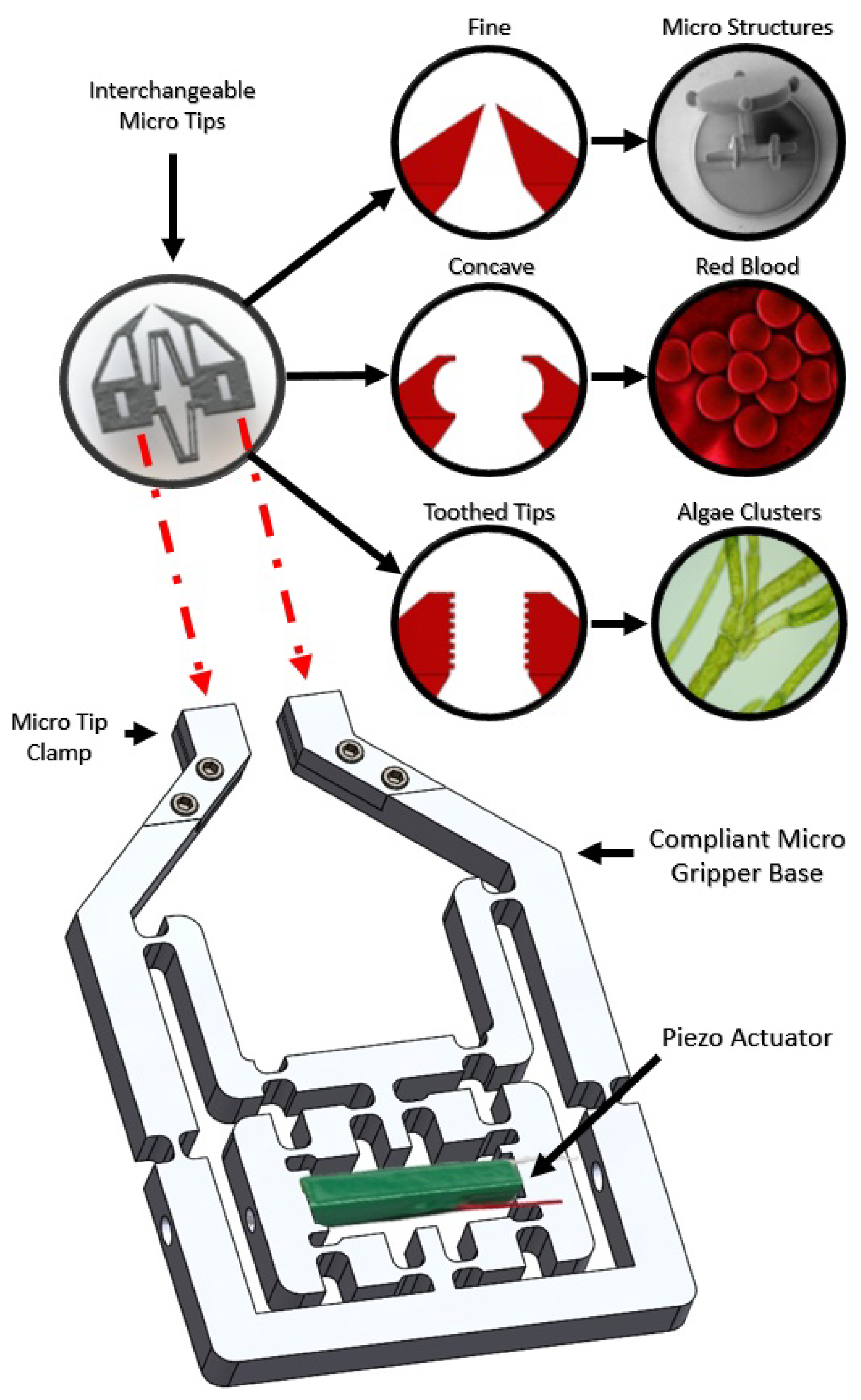

2. Materials and Methods

2.1. Kinematic Modelling of the Micro Gripper

2.2. Compliant Gripper Fabrication

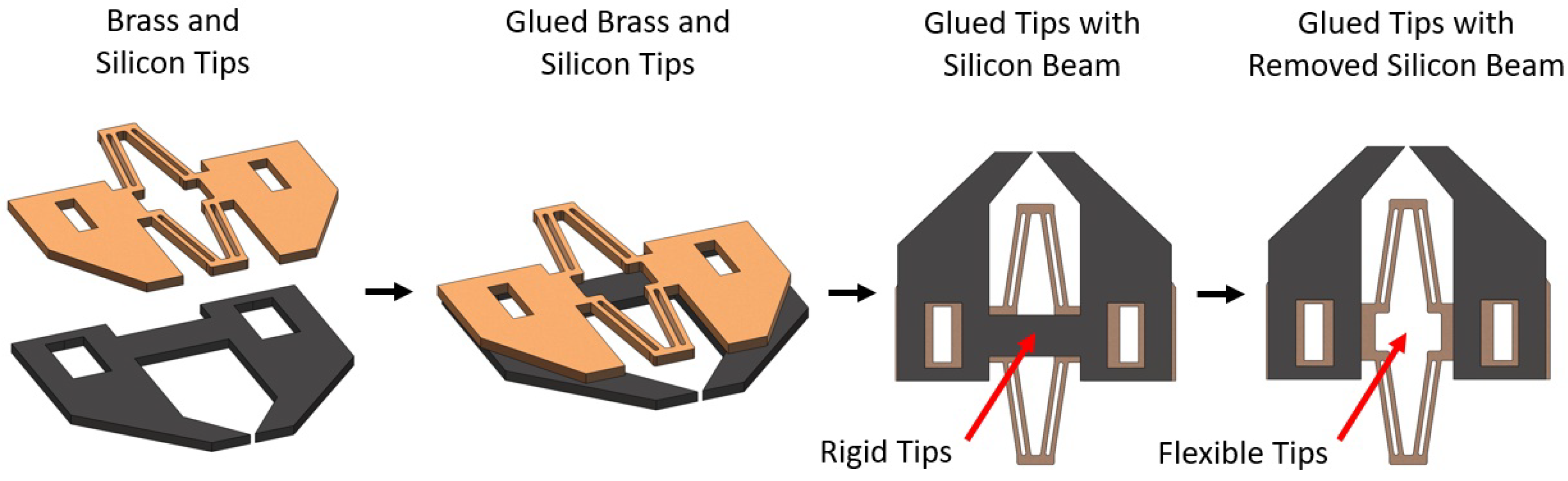

2.3. Micro Tip Fabrication

2.3.1. Silicon Tip Fabrication

2.3.2. Brass Tip Fabrication

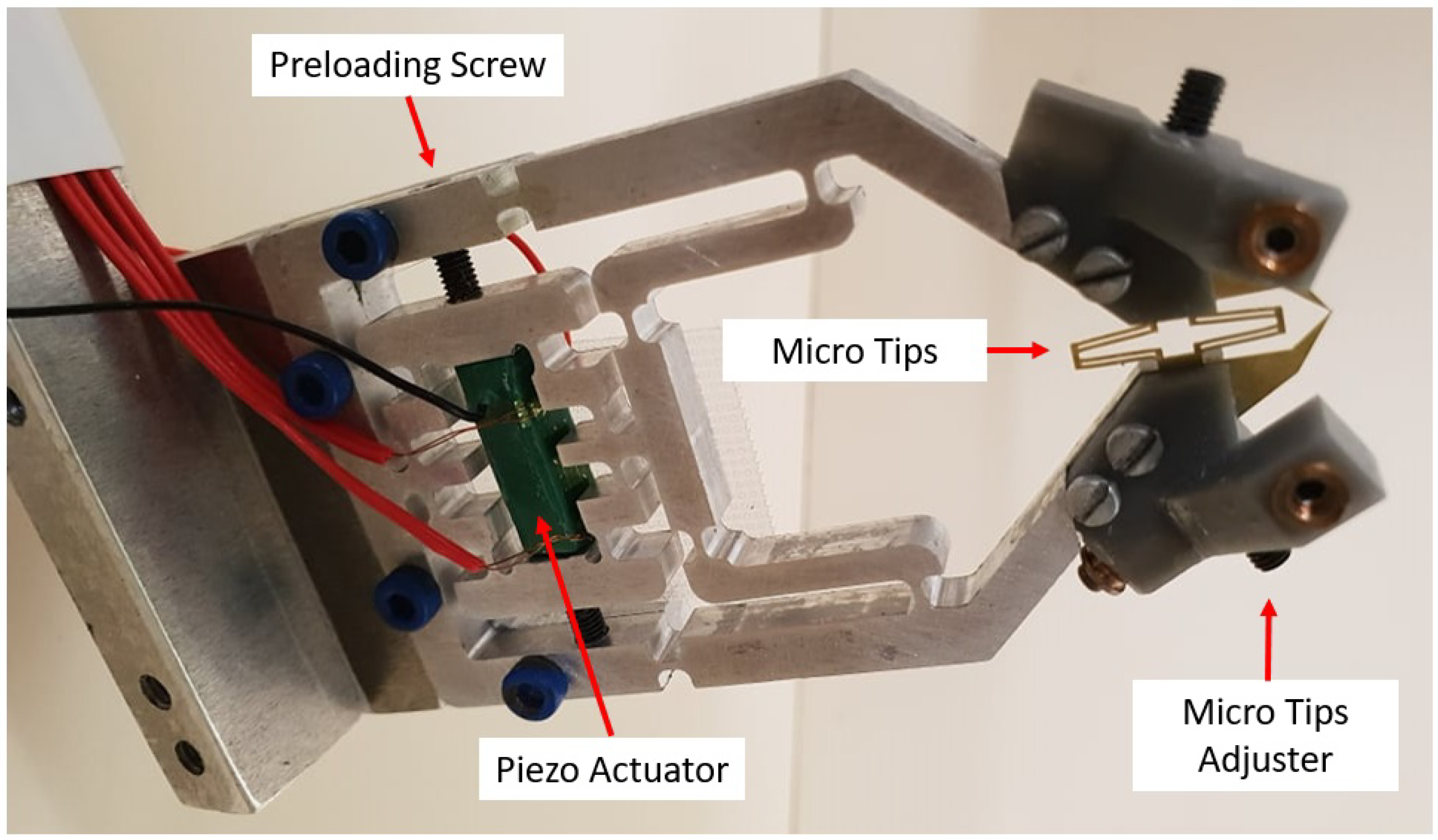

2.4. Gripper Tip Alignment

2.5. System Configuration

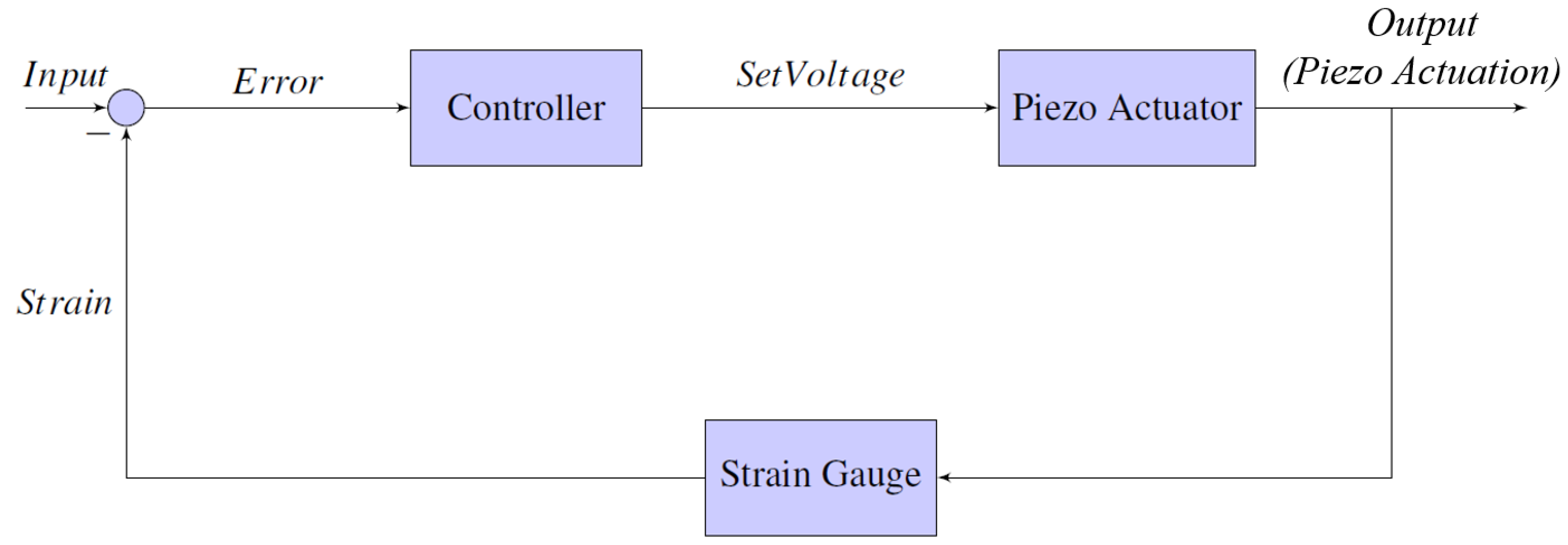

2.6. Gripper Control

Object Grasping Process

3. Experiments

3.1. Gripper Calibration

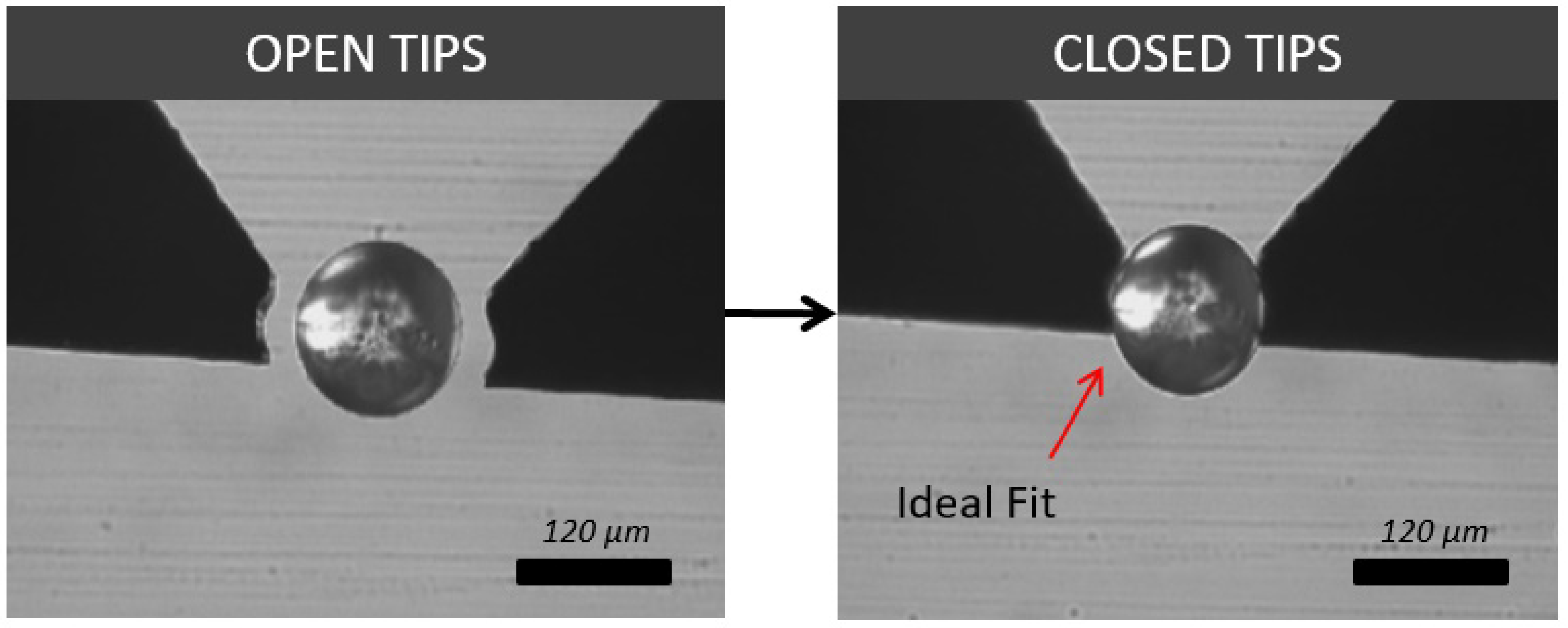

3.2. Shaped Gripper Tip Manipulation

3.2.1. Method

3.2.2. Results and Discussion

3.3. Biological Object Manipulation

3.4. Silicon Tips as Micro Tools

3.5. Smaller Scale Manipulation

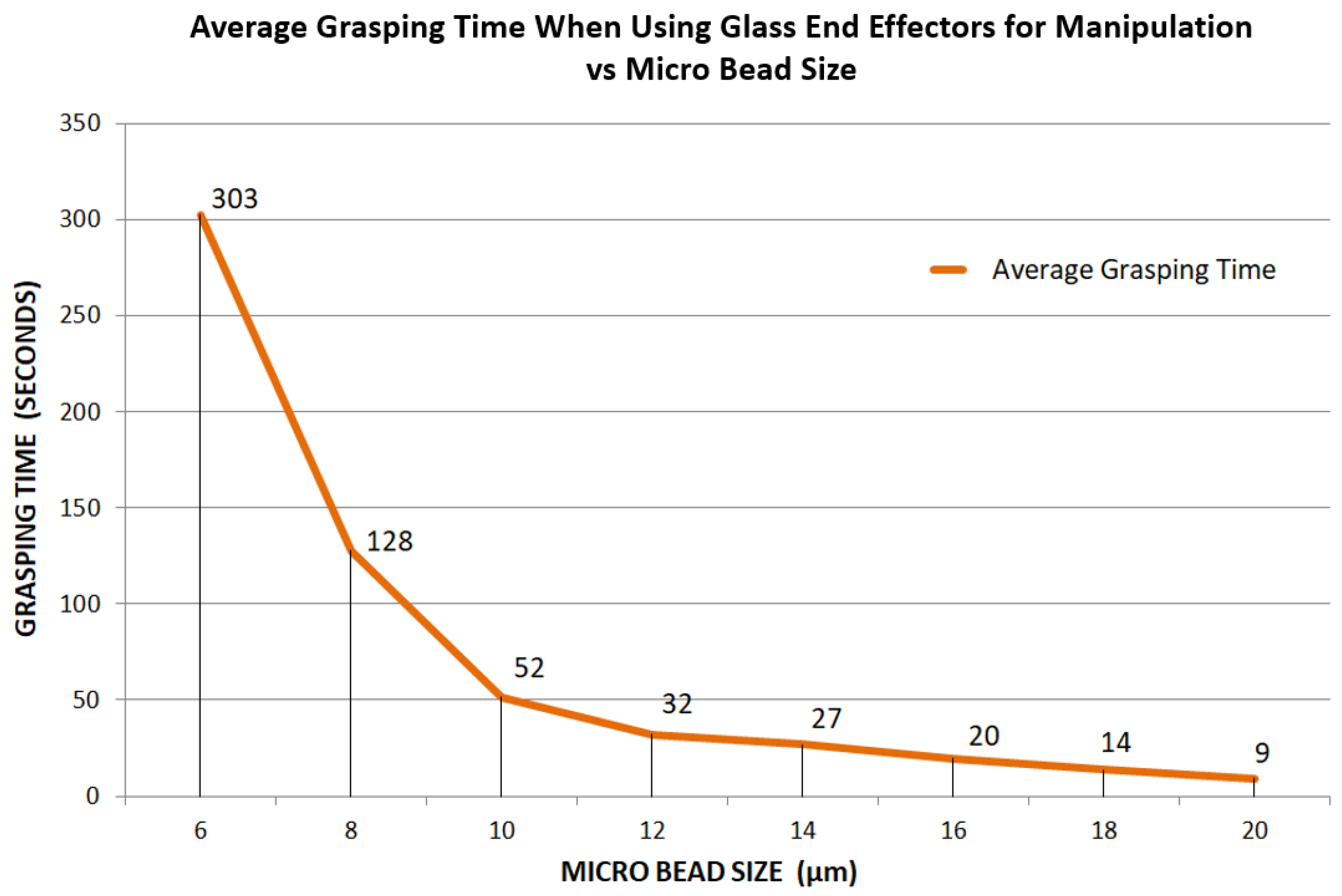

Manipulation Time

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Drexler, K.E.; Peterson, C.; Pergamit, G. Unbounding the Future; William Morrow: New York, NY, USA, 1991; p. 294. [Google Scholar]

- Kummer, M.P.; Abbott, J.J.; Kratochvil, B.E.; Borer, R.; Sengul, A.; Nelson, B.J. OctoMag: An electromagnetic system for 5-DOF wireless micromanipulation. IEEE Trans. Robot. 2010, 26, 1006–1017. [Google Scholar] [CrossRef]

- Chowdhury, S.; Thakur, A.; Svec, P.; Wang, C.; Losert, W.; Gupta, S.K. Automated manipulation of biological cells using gripper formations controlled by optical tweezers. IEEE Trans. Autom. Sci. Eng. 2014, 11, 338–347. [Google Scholar] [CrossRef]

- Avci, E.; Grammatikopoulou, M.; Yang, G.Z. Laser-Printing and 3D Optical-Control of Untethered Microrobots. Adv. Opt. Mater. 2017, 5, 1700031. [Google Scholar] [CrossRef]

- Roman, G.T.; Chen, Y.; Viberg, P.; Culbertson, A.H.; Culbertson, C.T. Single-cell manipulation and analysis using microfluidic devices. Anal. Bioanal. Chem. 2007, 387, 9–12. [Google Scholar] [CrossRef]

- Schubert, C. Single-cell analysis: The deepest differences. Nature 2011, 480, 133. [Google Scholar] [CrossRef] [PubMed]

- Ashkin, A.; Dziedzic, J.M.; Bjorkholm, J.E.; Chu, S. Observation of a single-beam gradient force optical trap for dielectric particles. Opt. Lett. 1986, 11, 288–290. [Google Scholar] [CrossRef]

- Ding, X.; Lin, S.C.; Kiraly, B.; Yue, H.; Li, S.; Chiang, I.K.; Shi, J.; Benkovic, S.J.; Huang, T.J. On-chip manipulation of single microparticles, cells, and organisms using surface acoustic waves. Proc. Natl. Acad. Sci. USA 2012, 109, 11105–11109. [Google Scholar] [CrossRef] [Green Version]

- Varsos, K.; Luntz, J.; Welsh, M.; Sarabandi, K. Electric field-shaping microdevices for manipulation of collections of microscale objects. Proc. IEEE 2011, 12, 2112–2124. [Google Scholar] [CrossRef]

- Konig, K.; Liang, H.; Berns, M.W.; Tromberg, B.J. Cell damage in near-infrared multimode optical traps as a result of multiphoton absorption. Opt. Lett. 1996, 21, 1090–1092. [Google Scholar] [CrossRef] [Green Version]

- Avci, E.; Ohara, K.; Nguyen, C.N.; Theeravithayangkura, C.; Kojima, M.; Tanikawa, T.; Mae, Y.; Arai, T. High-speed automated manipulation of microobjects using a two-fingered microhand. IEEE Trans. Ind. Electron. 2015, 62, 1070–1079. [Google Scholar] [CrossRef]

- Chronis, N.; Lee, L.P. Electrothermally activated SU-8 microgripper for single cell manipulation in solution. J. Micro Electromech. Syst. 2005, 14, 857–863. [Google Scholar] [CrossRef]

- Solano, B.; Wood, D. Design and testing of a polymeric microgripper for cell manipulation. Microelectron. Eng. 2007, 84, 1219–1222. [Google Scholar] [CrossRef]

- Zhang, R.; Chu, J.; Wang, H.; Chen, Z. A multipurpose electrothermal microgripper for biological micro-manipulation. Microsyst. Technol. 2013, 19, 89–97. [Google Scholar] [CrossRef]

- Chen, B.K.; Zhang, Y.; Sun, Y. Active release of microobjects using a MEMS microgripper to overcome adhesion forces. J. Micro Electromech. Syst. 2009, 18, 652–659. [Google Scholar] [CrossRef]

- Kim, B.S.; Park, J.S.; Kang, B.H.; Moon, C. Fabrication and property analysis of a MEMS micro-gripper for robotic micro-manipulation. Robot. Comput.-Integr. Manuf. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- Beyeler, F.; Neild, A.; Oberti, S.; Bell, D.J.; Sun, Y.; Dual, J.; Nelson, B.J. Monolithically fabricated microgripper with integrated force sensor for manipulating microobjects and biological cells aligned in an ultrasonic field. J. Microelectromech. Syst. 2007, 16, 7–15. [Google Scholar] [CrossRef]

- Hao, Y.C.; Yuan, W.Z.; Zhang, H.M.; Chang, H.L. A microgripper with a ratchet self-locking mechanism. In Proceedings of the 2015 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 1106–1109. [Google Scholar]

- Nikoobin, A.; Niaki, M.H. Deriving and analyzing the effective parameters in microgrippers performance. Sci. Iran. 2012, 19, 1554–1563. [Google Scholar] [CrossRef] [Green Version]

- Chen, T.; Meng, K.; Liu, H.; Yang, Z.; Sun, L. Experimental Study of Micromanipulation System with Multi-Fingered Structure. In Proceedings of the 2017 IEEE 7th Annual International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), Honolulu, HI, USA, 31 July–4 August 2017; pp. 1141–1146. [Google Scholar]

- Dechev, N.; Ren, L.; Liu, W.; Cleghorn, W.L.; Mills, J.K. Development of a 6 degree of freedom robotic micromanipulator for use in 3D MEMS microassembly. In Proceedings of the 2006 IEEE International Conference on Robotics and Automation (ICRA 2006), Orlando, FL, USA, 15–19 May 2006; pp. 281–288. [Google Scholar]

- Pinskier, J.; Shirinzadeh, B.; Clark, L.; Qin, Y. Development of a 4-DOF haptic micromanipulator utilizing a hybrid parallel-serial flexure mechanism. Mechatronics 2018, 50, 55–68. [Google Scholar] [CrossRef]

- Doria, M.; Birglen, L. Design of an underactuated compliant gripper for surgery using nitinol. J. Med. Devices 2009, 3, 011007. [Google Scholar] [CrossRef]

- Kim, K.; Liu, X.; Zhang, Y.; Sun, Y. Nanonewton force-controlled manipulation of biological cells using a monolithic MEMS microgripper with two-axis force feedback. J. Micromech. Microeng. 2008, 18, 055013. [Google Scholar] [CrossRef]

- Xu, Q. Design and development of a novel compliant gripper with integrated position and grasping/interaction force sensing. IEEE Trans. Autom. Sci. Eng. 2017, 14, 1415–1428. [Google Scholar] [CrossRef]

- Chen, T.; Sun, L.; Chen, L.; Rong, W.; Li, X. A hybrid-type electrostatically driven microgripper with an integrated vacuum tool. Sens. Actuators A Phys. 2010, 158, 320–327. [Google Scholar] [CrossRef]

- Xu, Q. A new compliant microgripper with integrated position and force sensing. In Proceedings of the 2013 IEEE/ASME International Conference onAdvanced Intelligent Mechatronics (AIM), Wollongong, Australia, 9–12 July 2013; pp. 591–596. [Google Scholar]

- Liang, C.; Wang, F.; Tian, Y.; Zhao, X.; Zhang, H.; Cui, L.; Ferreira, P. A novel monolithic piezoelectric actuated flexure-mechanism based wire clamp for microelectronic device packaging. Rev. Sci. Instrum. 2015, 86, 045106. [Google Scholar] [CrossRef] [Green Version]

- Zeman, M.J.; Bordatchev, E.V.; Knopf, G.K. Design, kinematic modelling and performance testing of an electro-thermally driven microgripper for micromanipulation applications. J. Micromech. Microeng. 2006, 16, 1540. [Google Scholar] [CrossRef]

- Chen, G.; Wang, J.; Liu, X. Generalized equations for estimating stress concentration factors of various notch flexure hinges. J. Mech. Des. 2014, 136, 031009. [Google Scholar] [CrossRef]

- Cao, J.; Ling, M.; Inman, D.J.; Lin, J. Generalized constitutive equations for piezo-actuated compliant mechanism. Smart Mater. Struct. 2016, 25, 095005. [Google Scholar] [CrossRef]

- Gao, Q.; Zhang, D.; Xu, D.; Zhang, Z. A kinematics modelling and stress analysis method for flexible micro-gripper. In Proceedings of the 2012 International Conference on Mechatronics and Automation (ICMA), Chengdu, China, 5–8 August 2012; pp. 825–830. [Google Scholar]

- Sariola, V.; Jääskeläinen, M.; Zhou, Q. Hybrid microassembly combining robotics and water droplet self-alignment. IEEE Trans. Robot. 2010, 26, 965–977. [Google Scholar] [CrossRef]

- Nof, S.Y. (Ed.) Handbook of Industrial Robotics; John Wiley and Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Gauthier, M.; Regnier, S.; Rougeot, P.; Chaillet, N. Analysis of forces for micromanipulations in dry and liquid media. J. Micromech. 2006, 3, 389–413. [Google Scholar] [CrossRef] [Green Version]

| Bridge Amplifier Constants | |

| 7 mm | |

| 3.5 mm | |

| w | 7.8 mm |

| Upper Compliant Section Constants | |

| a | 17.8 mm |

| b | 23.1 mm |

| 6.3 mm | |

| 3.5 mm | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lofroth, M.; Avci, E. Development of a Novel Modular Compliant Gripper for Manipulation of Micro Objects. Micromachines 2019, 10, 313. https://doi.org/10.3390/mi10050313

Lofroth M, Avci E. Development of a Novel Modular Compliant Gripper for Manipulation of Micro Objects. Micromachines. 2019; 10(5):313. https://doi.org/10.3390/mi10050313

Chicago/Turabian StyleLofroth, Matthew, and Ebubekir Avci. 2019. "Development of a Novel Modular Compliant Gripper for Manipulation of Micro Objects" Micromachines 10, no. 5: 313. https://doi.org/10.3390/mi10050313

APA StyleLofroth, M., & Avci, E. (2019). Development of a Novel Modular Compliant Gripper for Manipulation of Micro Objects. Micromachines, 10(5), 313. https://doi.org/10.3390/mi10050313