Silicon Carbide Converters and MEMS Devices for High-temperature Power Electronics: A Critical Review

Abstract

:1. Introduction

2. High-Temperature Components

2.1. The Properties of SiC Material

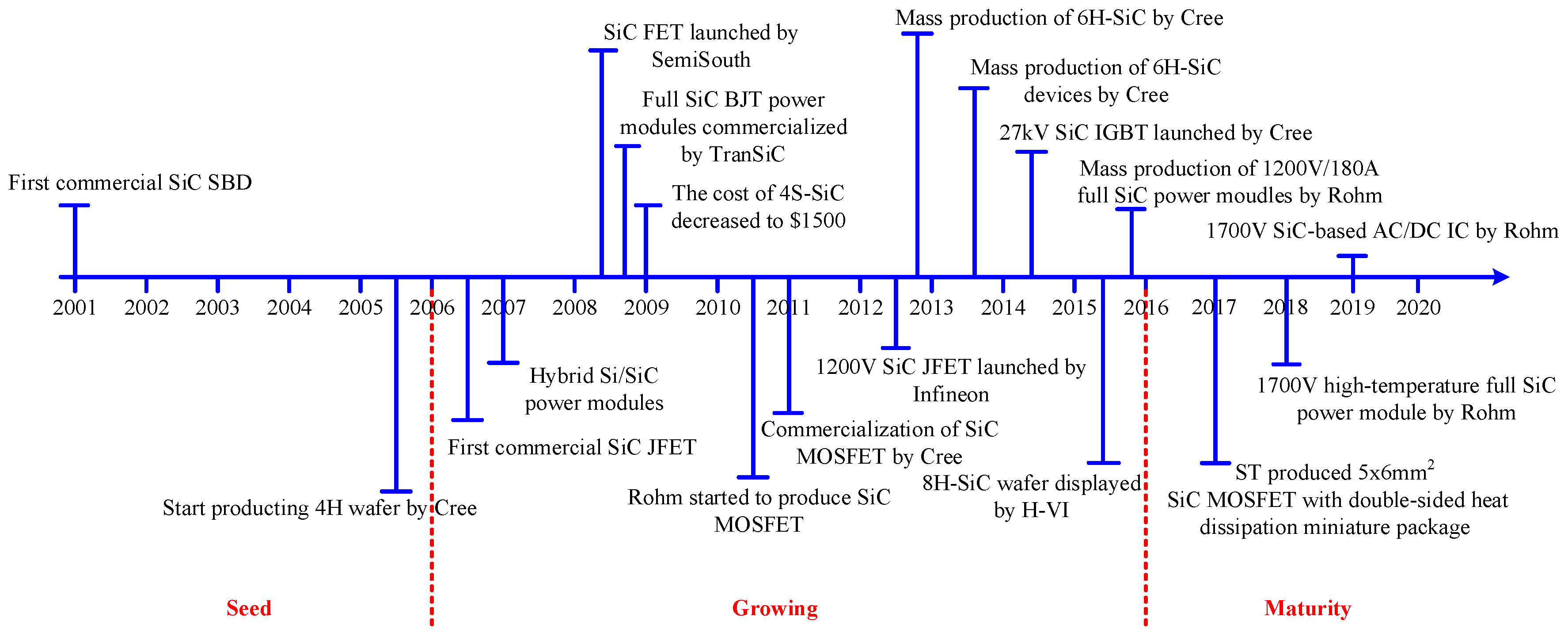

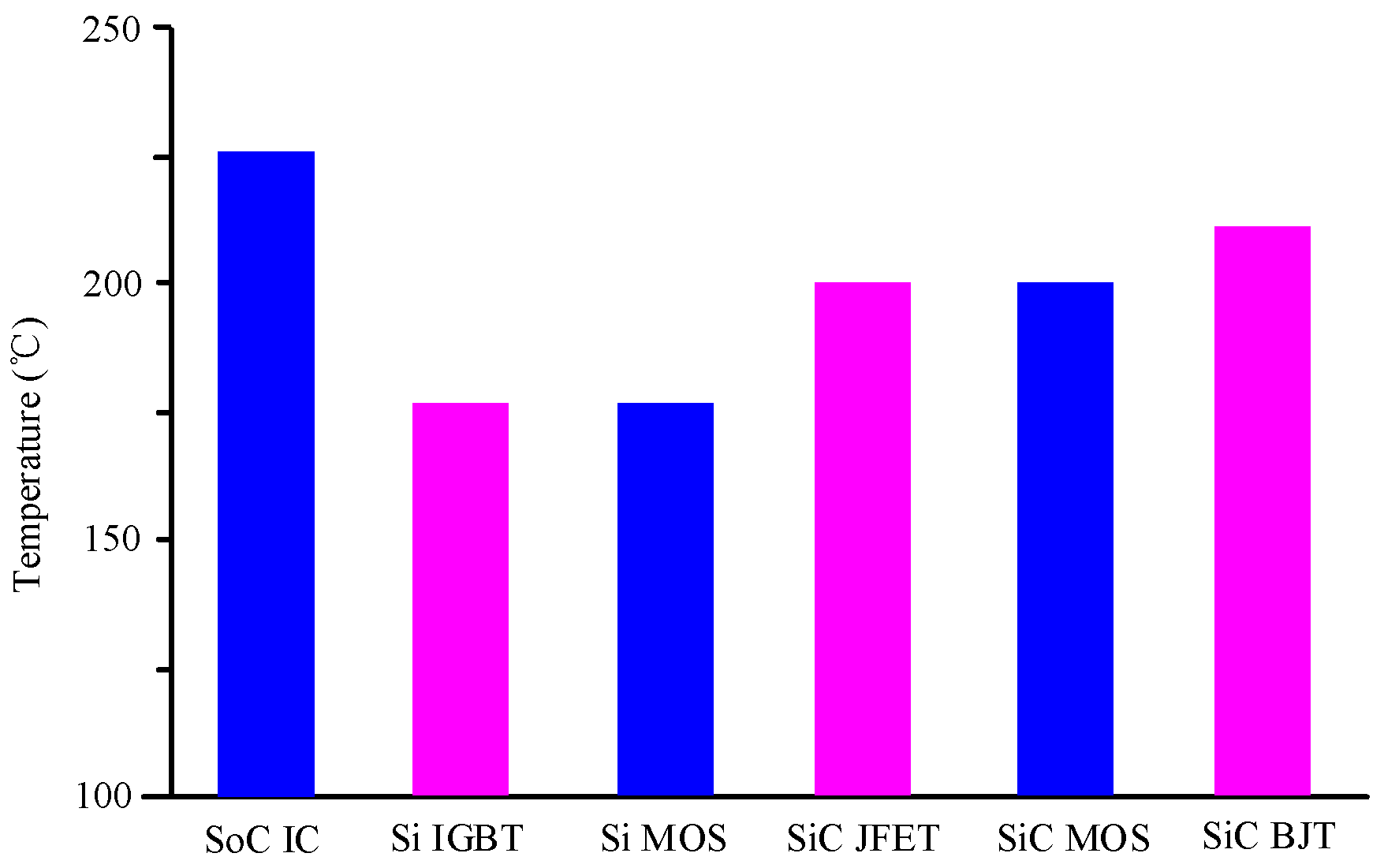

2.2. SiC-based Power Electronic Devices

2.3. High-temperature Gate Drives

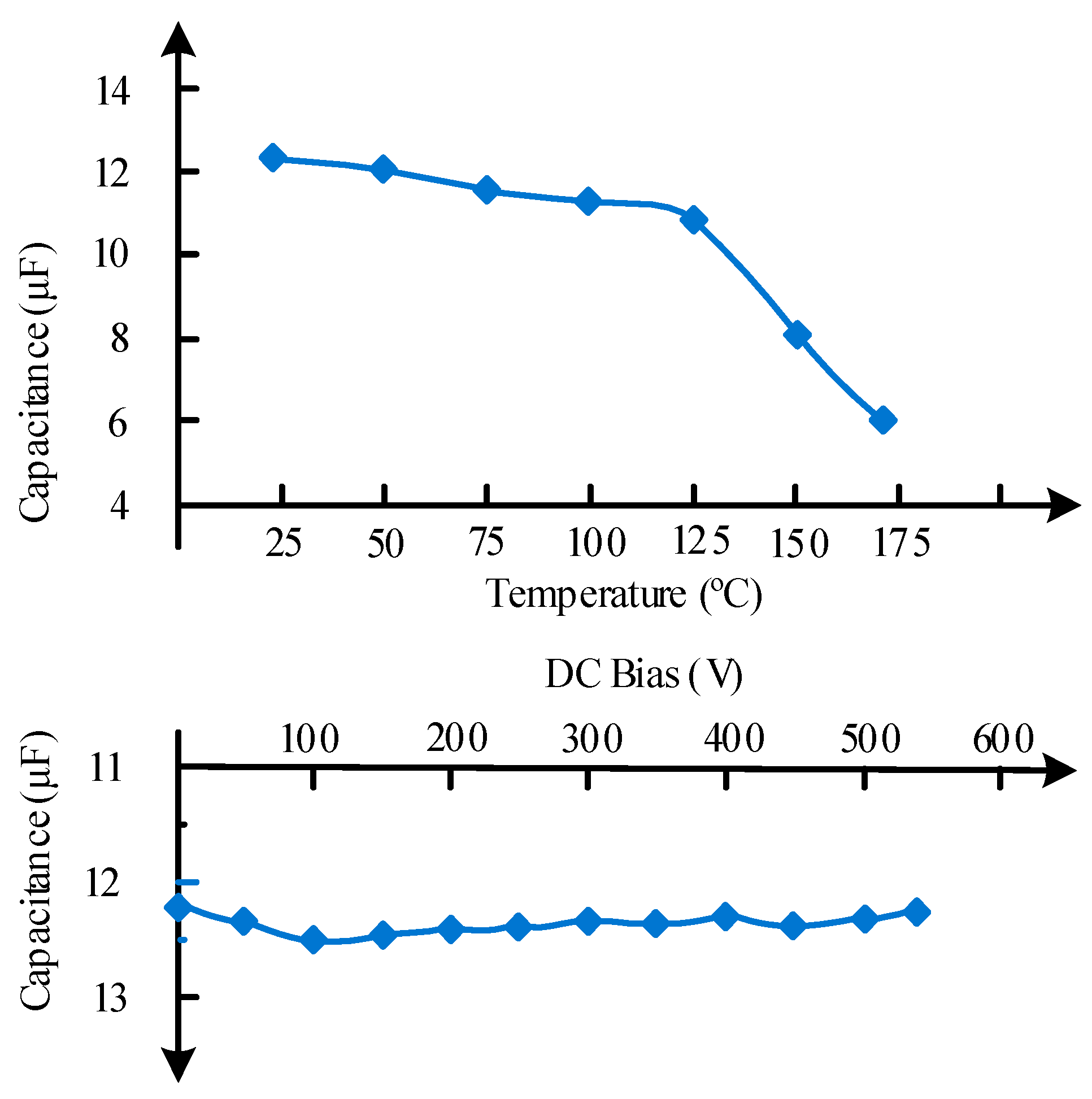

2.4. High-temperature Passive Components

3. High-Temperature Converter and MEMS Devices

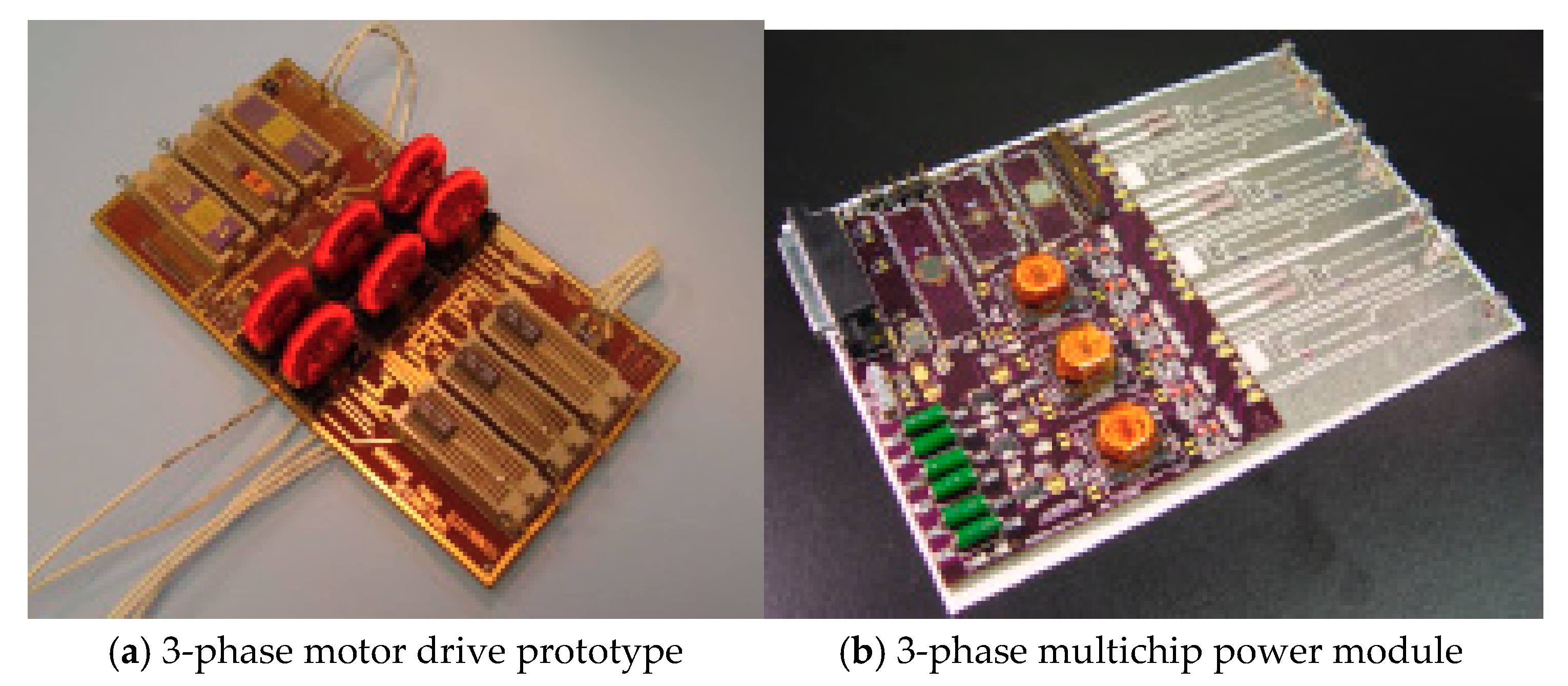

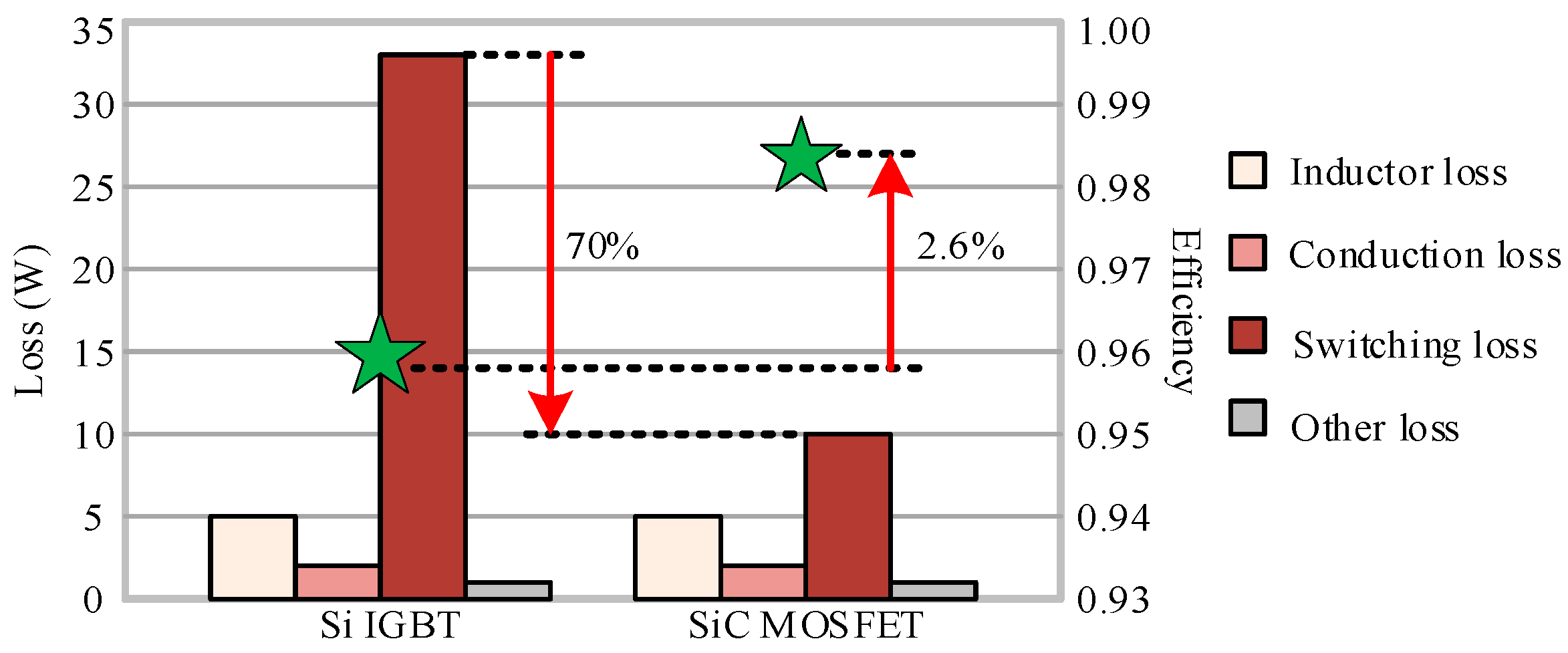

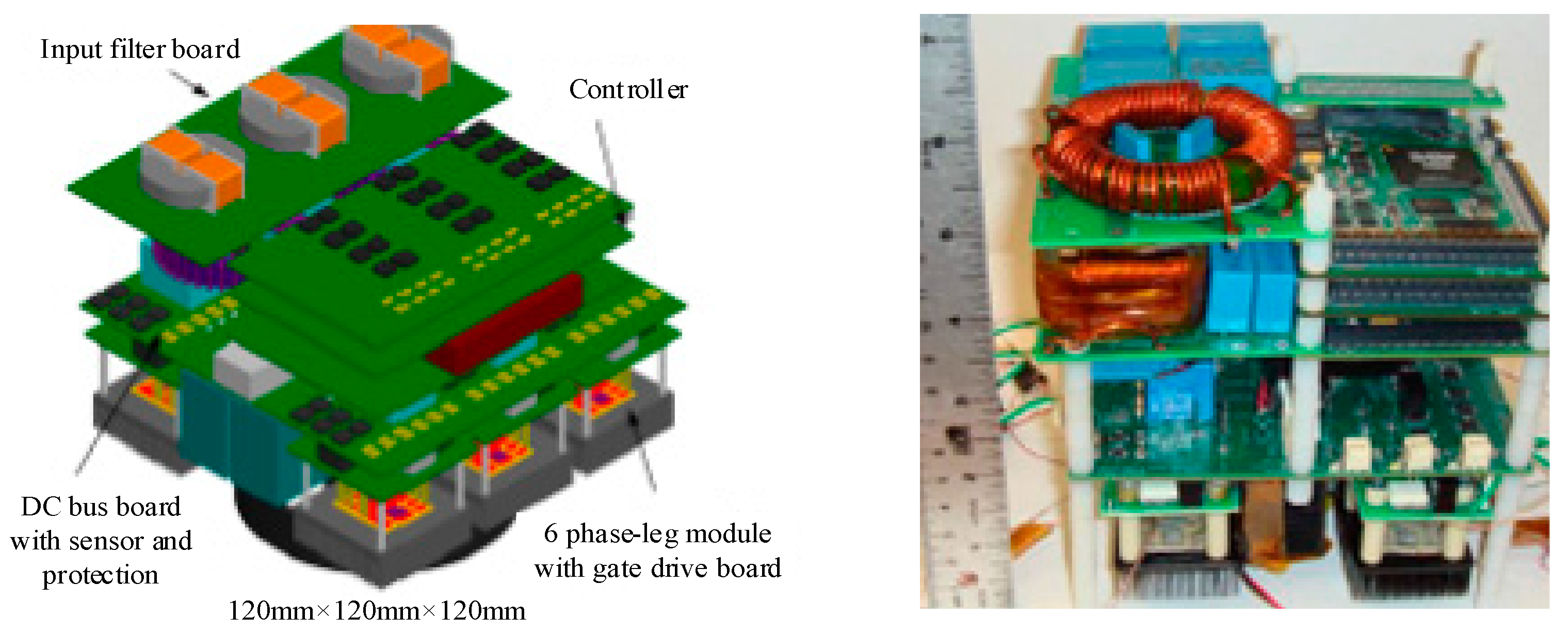

3.1. SiC-based Motor Drive

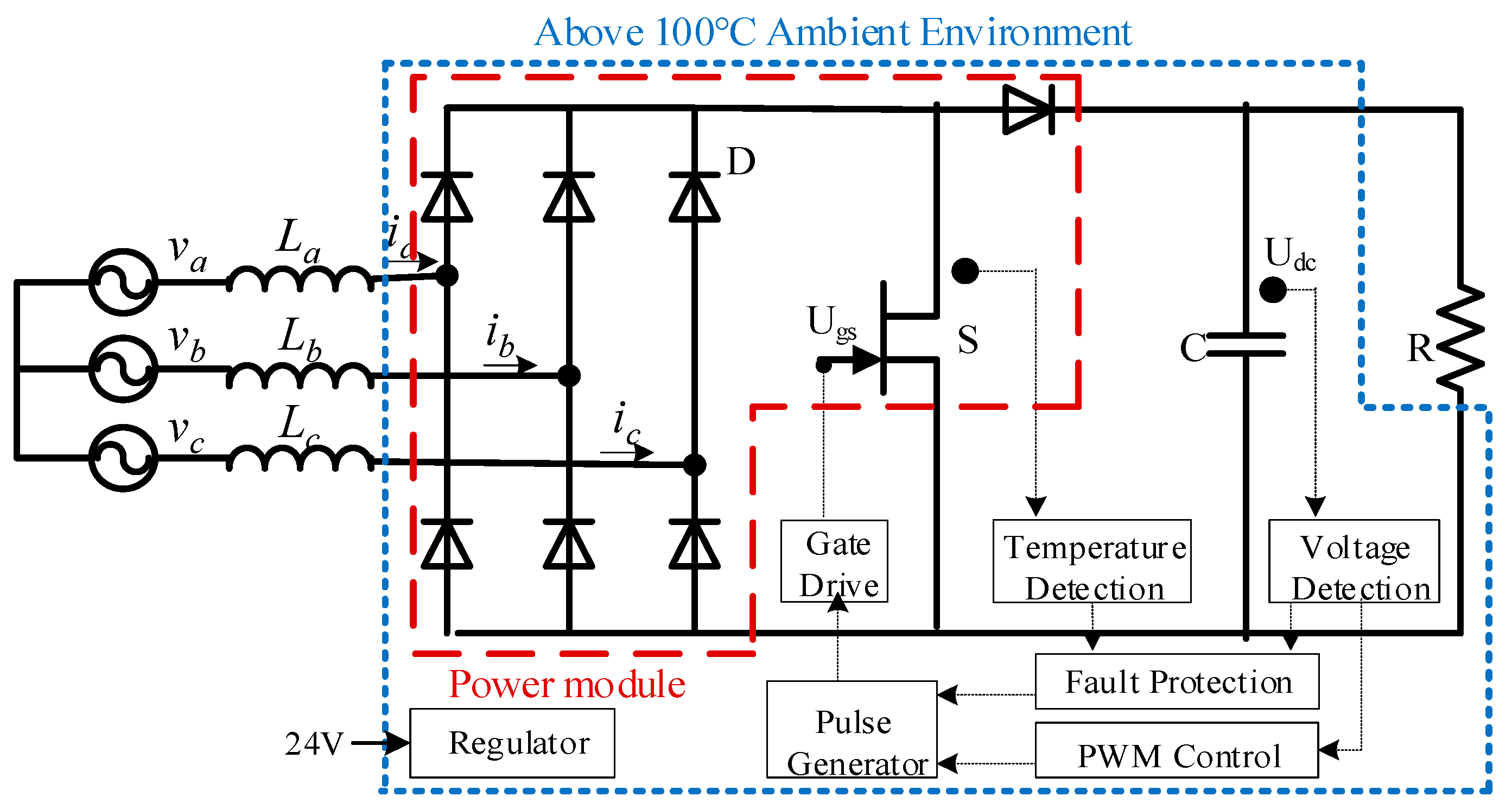

3.2. SiC-based Rectifier Unit

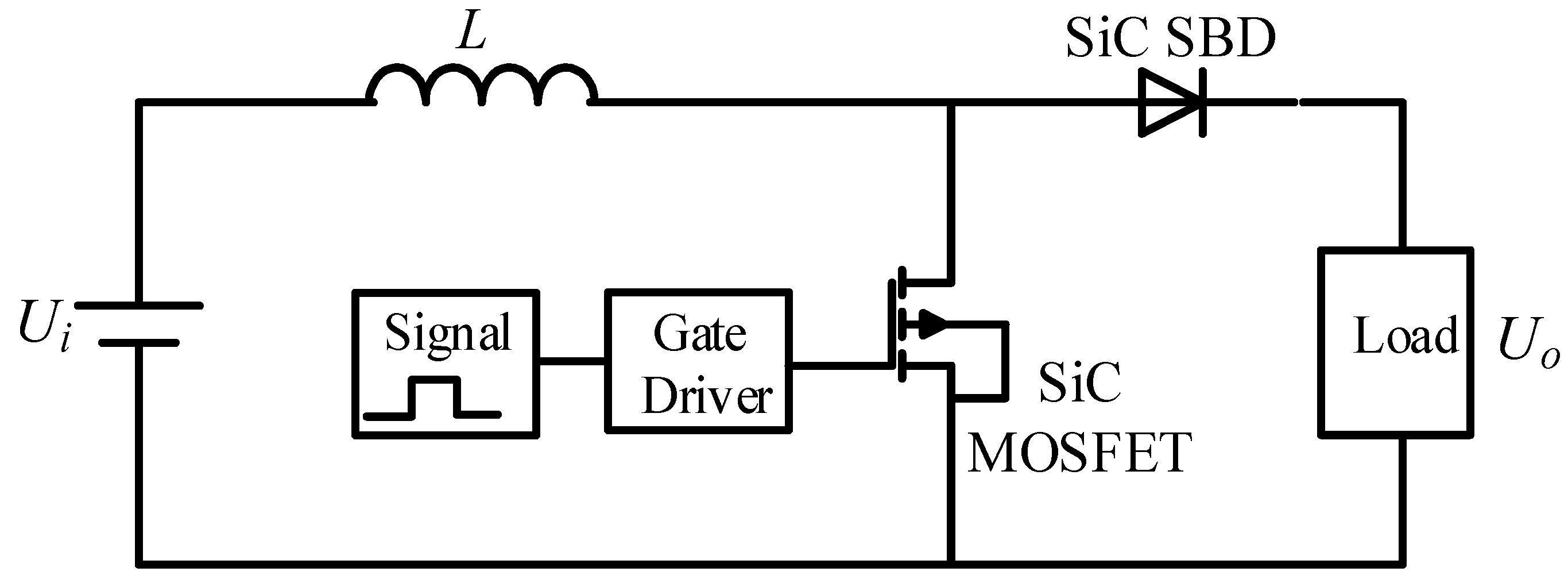

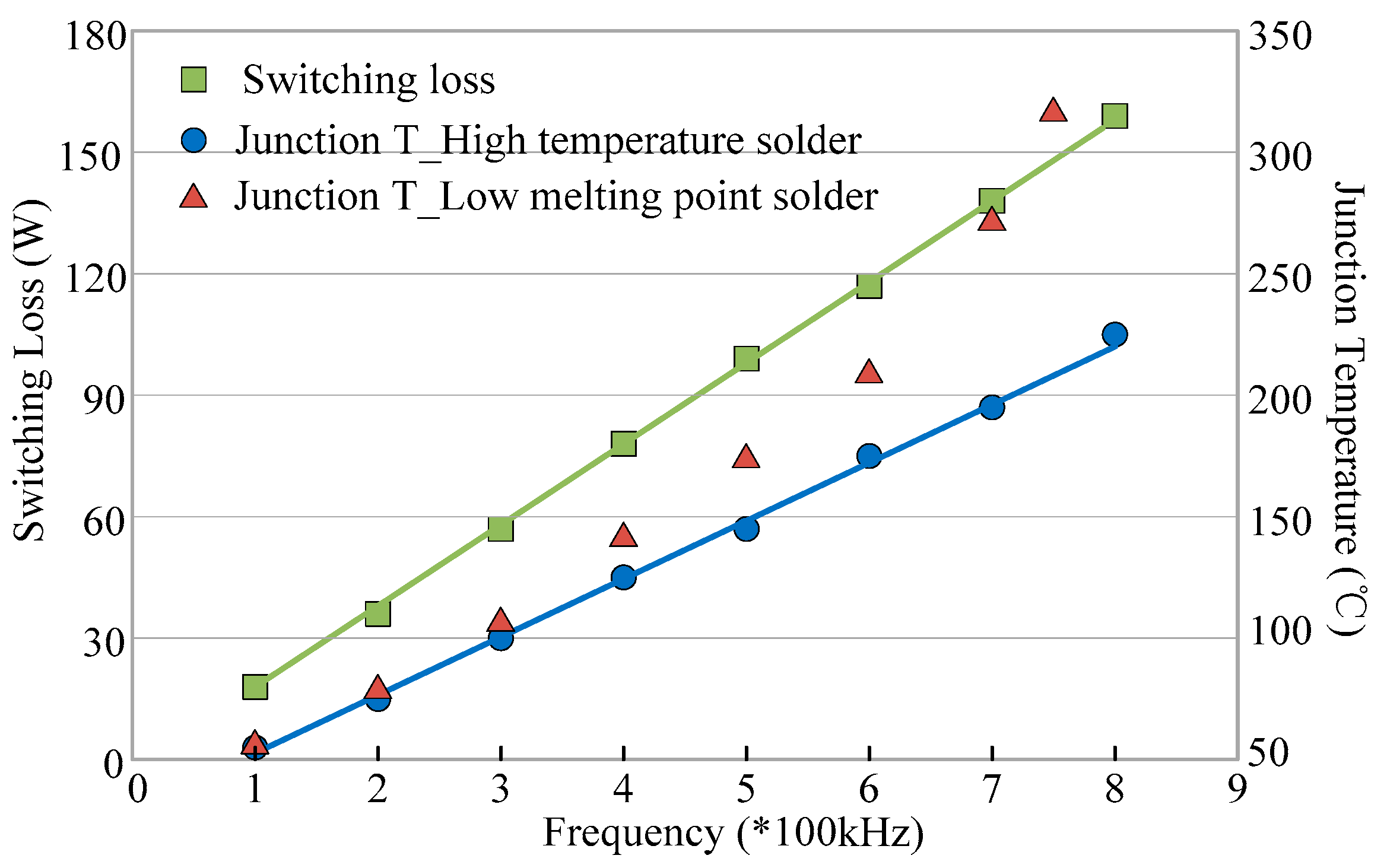

3.3. SiC-based DC–DC Converter

3.4. SiC-based MEMS Devices

4. Challenges in High-Temperature Power Electronics

4.1. Design of High-temperature Gate Drives

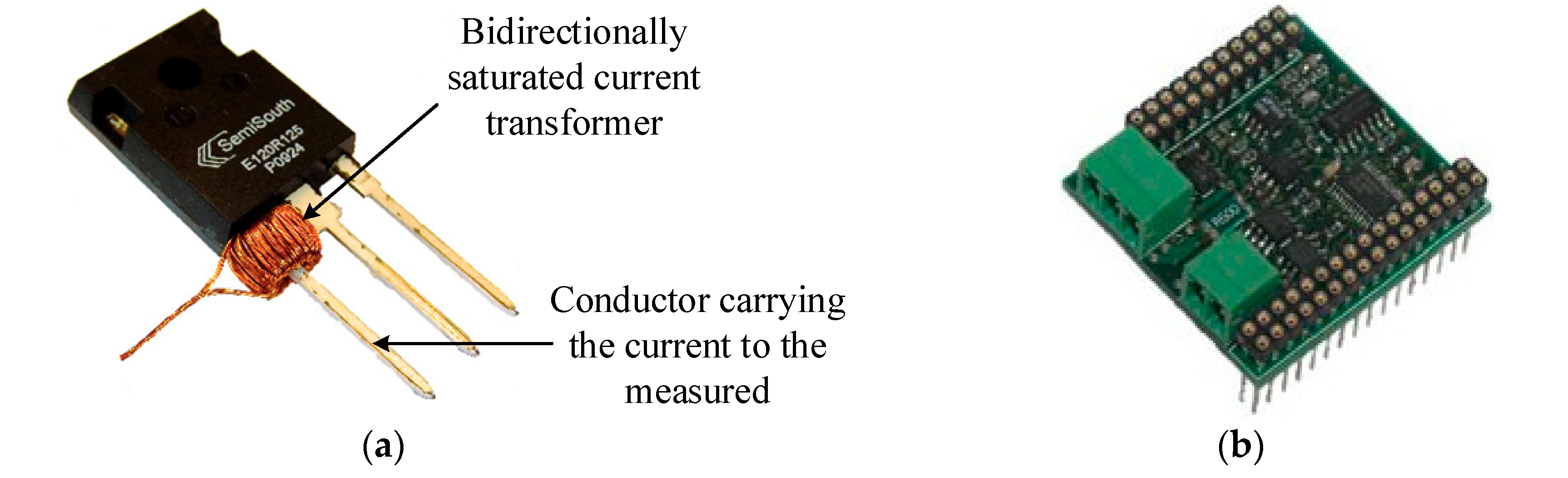

4.2. Current Measurement in High Temperature

4.3. Parameters Matching within Wide Range of Temperature

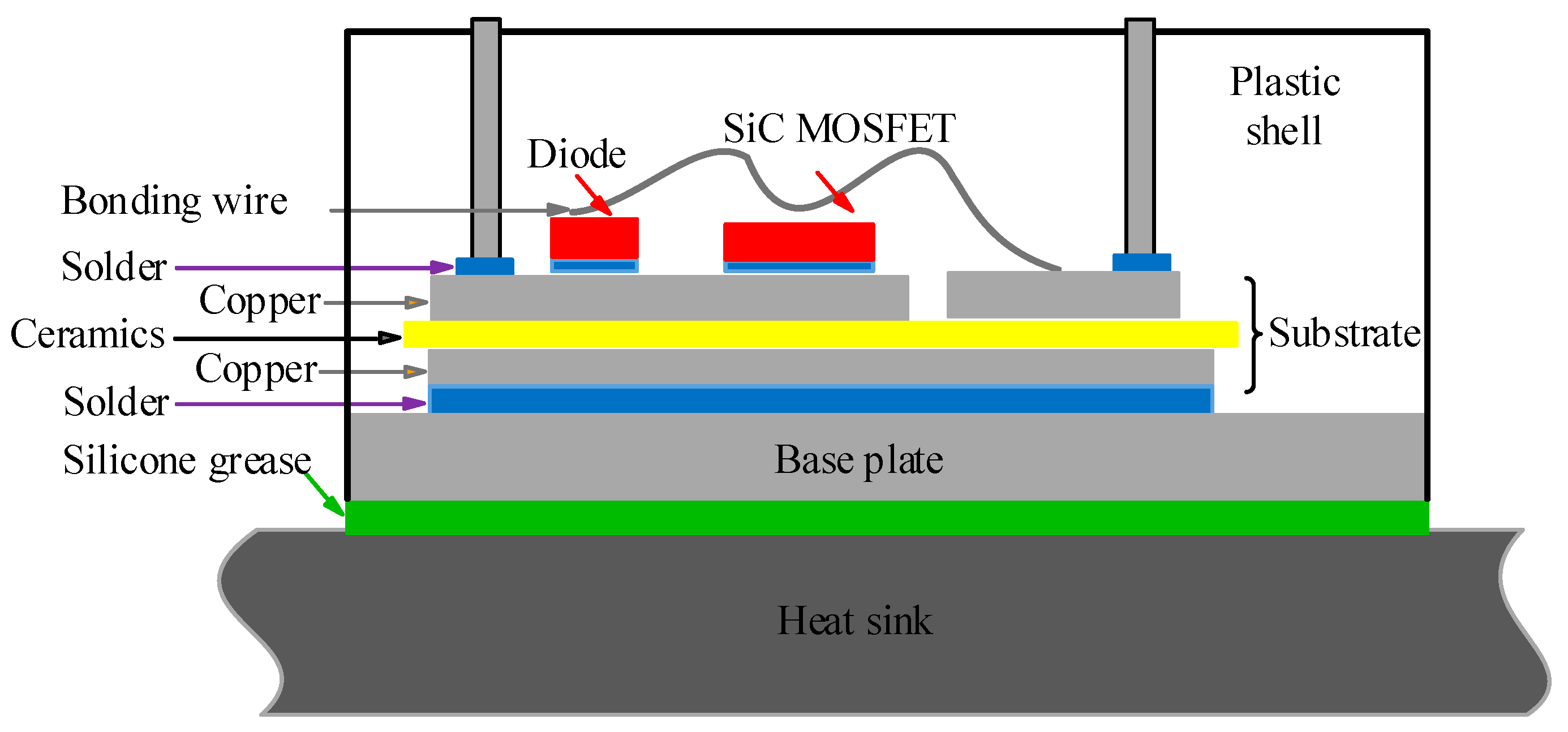

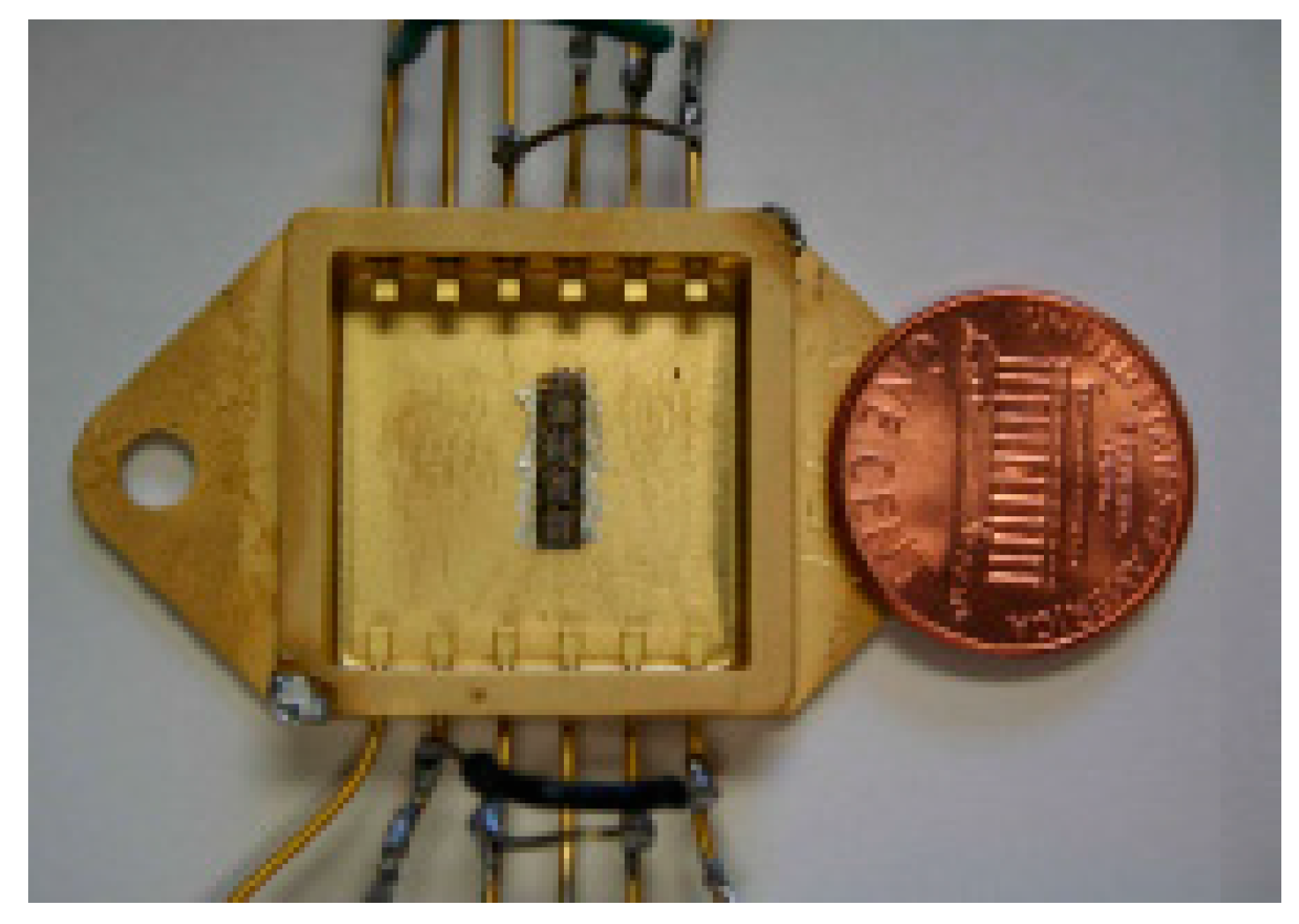

4.4. High-temperature Packaging Technology

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Iacopi, F.; Van Hove, M.; Charles, M.; et al. Power electronics with wide band-gap materials: Toward greener, more efficient technologies. MRS Bull. 2015, 40, 390–395. [Google Scholar] [CrossRef]

- Fraga, M.A. Comparison between the piezoresistive properties of a-SiC films obtained by PECVD and magnetron sputtering. Silicon Carbide Relat. Mater. 2010, 679, 217–220. [Google Scholar] [CrossRef]

- Fraga, M.A.; Furlan, H.; Pessoa, R.S.; Rasia, L.A.; Mateus, C.F.R. Studies on SiC, DLC and TiO2 thin films as piezoresistive sensor materials for high temperature application. Microsyst. Technol. 2011, 17, 477–483. [Google Scholar] [CrossRef]

- Seresinhe, R.; Lawson, C.; Madani, I. Improving the operating efficiency of the more electric aircraft concept through optimized flight procedures. CEAS Aeronaut. J. 2019, 10, 463–478. [Google Scholar] [CrossRef]

- Phan, H.P.; Dao, D.V.; Nakamura, K.; Dimitrijev, S.; Nguyen, N. The piezoresistive effect of SiC for MEMS sensors at high temperatures: A review. J. Microelectro Mech. Syst. 2015, 24, 1663–1677. [Google Scholar] [CrossRef]

- Balakrishnan, V.; Phan, H.P.; Dinh, T.; Dao, D.V.; Nguyen, N.-T. Thermal flow sensors for harsh environments. Sensors 2017, 17, 2061. [Google Scholar] [CrossRef] [PubMed]

- Johnson, R.; Evans, J.; Jacobsen, P.; Thompson, J.R.; Christopher, M. The changing automotive environment: High temperature electronics. IEEE Trans. Electron. Packag. Manuf. 2004, 27, 164–176. [Google Scholar] [CrossRef]

- Efthymiopoulos, I.; Hellier, P.; Ladommatos, N.; Russo-Profili, A.; Eveleigha, A.; Aliev, A.; Kay, A.; Mills-Lamptey, B. Influence of solvent selection and extraction temperature on yield and composition of lipids extracted from spent coffee grounds. Ind. Crop. Prod. 2018, 119, 49–56. [Google Scholar] [CrossRef]

- Singh, D. Venus night side surface temperature. Sci. Rep. 2019, 9, 1137. [Google Scholar] [CrossRef]

- Ning, P.; Wang, F.; Ngo, K. Forced-air cooling system design underweight constraint for high-temperature SiC converter. IEEE Trans. Power Electron. 2014, 29, 1998–2007. [Google Scholar] [CrossRef]

- Xu, S.Z.; Peng, Y.F.; Li, S.Y. Application thermal research of forced-air cooling system in high power NPC three-level inverter based on power module block. Case Stud. Therm. Eng. 2016, 8, 387–397. [Google Scholar] [CrossRef]

- Wu, R.; Hong, T.; Cheng, Q.; Zhou, H.; Fan, Y.; Luo, X. Thermal modeling and comparative analysis of jet impingement liquid cooling for high power electronics. Int. J. Heat Mass Transf. 2019, 137, 42–51. [Google Scholar] [CrossRef]

- Mishra, M.K.; Dubey, V.; Mishra, P.M.; Khan, I. MEMS Technologies: A Review. J. Eng. Res. Rep. 2019, 4, 1–24. [Google Scholar]

- Hazra, S.; De, A.; Cheng, L.; Palmour, J.; Schupbach, M.; Hull, B.A.; Allen, S.; Bhattacharya, S. High switching performance of 1700-V, 50-A SiC power MOSFET over Si IGBT/Bi MOSFET for advanced power conversion applications. IEEE Trans. Power Electron. 2016, 31, 4742–4754. [Google Scholar]

- Garrido-Diez, D.; Baraia, L. Review of wide band-gap materials and their impact in new power devices. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and Their Application to Mechatronics (ECMSM), Donostia-San Sebastian, Spain, 24–26 May 2017; pp. 1–6. [Google Scholar]

- Tian, Y.; Zetterling, C.M. A fully integrated silicon-carbide sigma-delta modulator operating up to 500 °C. IEEE Trans. Electron. Devices 2017, 64, 2782–2788. [Google Scholar] [CrossRef]

- Dreike, P.; Fleetwood, D.; King, D.; Sprauer, D.C.; Zipperian, T.E. An overview of high-temperature electronic device technologies and potential applications. IEEE Trans. Compon. Package Manuf. Technol. 1993, 17, 594–609. [Google Scholar] [CrossRef]

- Xu, F.; Han, T.J.; Jiang, D.; Tolbert, L.M.; Wang, F.; Nagashima, J.; Kim, S.J.; Kulkarni, S. Development of a SiC JFET-based six-pack power module for a fully integrated inverter. IEEE Trans. Power Electron. 2013, 28, 1464–1478. [Google Scholar] [CrossRef]

- Wang, R.; Chen, Z.; Boroyevich, D.; Jiang, L.; Yao, Y.; Rajashekara, K. A novel hybrid packaging structure for high-temperature SiC power modules. IEEE Trans. Ind. Appl. 2013, 49, 1609–1618. [Google Scholar] [CrossRef]

- Khazaka, R.; Mendizabal, L.; Henry, D.; et al. Survey of high-temperature reliability of power electronics packaging components. IEEE Trans. Power Electron. 2015, 30, 2456–2464. [Google Scholar] [CrossRef]

- Zetterling, C.M. Integrated circuits in silicon carbide for high-temperature applications. Mater. Res. Soc. Bull. 2015, 40, 431–438. [Google Scholar] [CrossRef]

- Wright, N.G.; Horsfall, A.B. SiC sensors: A review. J. Phys. D Appl. Phys. 2007, 40, 6345–6354. [Google Scholar] [CrossRef]

- Buttay, C.; Planson, D.; Allard, B.; Bergogne, D.; Bevilacqua, P.; Joubert, C.; Lazar, M.; Martin, C.; Morel, H.; Tournier, D.; et al. State of the art of high-temperature power electronics. Mater. Sci. Eng. B 2011, 176, 283–288. [Google Scholar] [CrossRef]

- Watson, J.; Castro, G. A review of high-temperature electronics technology and applications. J. Mater. Sci. Mater. Electron. 2015, 26, 9226–9235. [Google Scholar] [CrossRef]

- Horowitz, K.; Remo, T.; Reese, S. A Manufacturing Cost and Supply Chain Analysis of SiC Power Electronics Applicable to Medium-Voltage Motor Drives. Technical Report Clean Energy Manufacturing Analysis Center; National Renewable Energy Laboratory: Golden, CO, USA, 2017.

- Xun, Q.; Xun, B.Y.; Li, Z.X.; Wang, P.L.; Cai, Z.D. Application of SiC power electronic devices in secondary power source for aircraft. Renew. Sustain. Energy Rev. 2017, 70, 1336–1342. [Google Scholar] [CrossRef]

- STW100N65G2AG datasheet. Automotive-Grade Silicon Carbide Power MOSFET 650 V, 100 A, 2 0mΩ (typ., TJ = 25 °C), in a HiP247TM Package. 2018. Available online: https://www.st.com/en/power-transistors/sctw100n65g2ag.html (accessed on 19 June 2019).

- Sarnago, H.; Lucia, O.; Mediano, A.; Burdío, J.M. Improve operation of SiC-BJT based series resonant inverter with optimized base drive. IEEE Trans. Power Electron. 2014, 29, 5097–5101. [Google Scholar] [CrossRef]

- Chen, Z.; Yao, Y.; Boroyevich, D.; Ngo, k.D.T.; Mattavelli, P.; Rajashekara, K. A 1200-V, 60-A SiC MOSFET multichip phase-leg module for high-temperature, high-frequency applications. IEEE Trans. Power Electron. 2014, 29, 2307–2320. [Google Scholar] [CrossRef]

- Schupbach, R.M.; McPherson, B.; McNutt, T.; Lostetter, A.B.; Kajs, J.P.; Castagno, S.G. High temperature (250 °C) SiC power module for military hybrid electrical vehicle applications. In Proceedings of the NDIA Ground Vehicle Systems Engineering and Technology Symposium, Dearborn, MI, USA, 9–11 August 2011; pp. 1–7. [Google Scholar]

- Palmour, J.W.; Kong, H.S.; Davis, R.F. Characterization of device parameters in high-temperature metal-oxide-semiconductor field-effect transistors in N-SiC thin films. Appl. Phys. 1988, 64, 2168–2177. [Google Scholar] [CrossRef]

- Kimoto, T.; Cooper, J.A. Fundamentals of Silicon Carbide Technology; Wiley: New York, NY, USA, 2014. [Google Scholar]

- Moench, S.; Costa, M.S.; Barner, A.; Weimer, J.; Holz, R.; Schwindt, E.; Zehelein, M.; Roth-Stielow, J.; Kallfass, I. High thermal conductance AlN power module with hybrid integrated gate drivers and SiC trench MOSFETs for 2kW single-phase PV inverter. In Proceedings of the 18th European Conference on Power Electronics and Applications (EPE’16 ECCE Europe), Karlsruhe, Germany, 5–9 September 2016; pp. 1–8. [Google Scholar]

- Passmore, B.S.; Lostetter, A.B. A review of SiC power module packaging technologies: Attaches, interconnections, and advanced heat transfer. In Proceedings of the 2017 IEEE International Workshop on Integrated Power Packaging (IWIPP), Delft, The Netherlands, 5–7 April 2017; pp. 1–5. [Google Scholar]

- Cook, G.O.; Sorensen, C.D. Overview of transient liquid phase and partial transient liquid phase bonding. J. Mater. Sci. 2011, 46, 5305–5323. [Google Scholar] [CrossRef] [Green Version]

- Shen, Z.Z.; Johnson, R.W.; Hamilton, M.C. SiC power device die attach for extreme environments. IEEE Trans. Electron. Devices 2015, 62, 346–353. [Google Scholar] [CrossRef]

- Menon, S.; George, E.; Osterman, M.; Pecht, M. High lead solder (Over 85%) solder in the electronics industry: RoHS exemptions and alternatives. J. Mater. Sci. Mater. Electron. 2015, 26, 4021–4030. [Google Scholar] [CrossRef]

- Mallampati, S.; Yin, L.; Shaddock, D.; Schoeller, H.; Cho, J. Lead-free alternatives for interconnects in high-temperature electronics. Asme J. Electron. Packag. 2018, 140, 010906. [Google Scholar] [CrossRef]

- Wintrich, A.; Nicolai, U.; Tursky, W.; Reimann, T. Application Manual Power Semiconductors, 2nd ed.; SEMIKRON International GmbH: Nuremberg, Germany, 2015. [Google Scholar]

- Zhang, T.; Sammakia, B.G.; Yang, Z.; Wang, H. Hybrid nanocomposite thermal interface materials: The thermal conductivity and the packing density. Asme J. Electron. Packag. 2018, 140, 031006. [Google Scholar] [CrossRef]

- Peacock, M.A.; Roy, C.K.; Hamilton, M.C.; Johnson, R.W.; Knight, R.W.; Harris, D.K. Characterization of transferred vertically aligned carbon nanotubes arrays as thermal interface materials. Int. J. Heatmass Transf. 2016, 97, 94–100. [Google Scholar] [CrossRef]

- Broughton, J.; Smet, V.; Tummala, R.R.; Joshi, Y.K. Review of thermal packaging technologies for automotive power electronics for traction purposes. J. Electron. Packag. 2018, 140, 40801. [Google Scholar] [CrossRef]

- Liang, G.; Mudawar, I. Review of spray cooling—Part 1: Single-phase and nucleate boiling regimes, and critical heat flux. Int. J. Heat Mass Transf. 2017, 115, 1174–1205. [Google Scholar] [CrossRef]

- Huang, H.; Borhani, N.; Richard Thome, J. Thermal response of multi-microchannelevaporators during flow boiling of refrigerants under transient heat loads with flow visualization. Asme J. Electron. Packag. 2016, 138, 031004. [Google Scholar] [CrossRef]

- Lee, H.; Agonafer, D.D.; Won, Y.; Houshmand, F.; Gorle, C.; Asheghi, M.; Goodson, K.E. Thermal modeling of extreme heat flux micro channel coolers for GaN-on-SiC semiconductor devices. Asme J. Electron. Packag. 2016, 138, 010907. [Google Scholar] [CrossRef]

- Huque, M.A.; Tolbert, L.M.; Blalock, B.J.; Islam, S.K. Silicon-on-insulator-based high-voltage, high-temperature integrated circuit gate driver for silicon carbide-based power field effect transistors. IET Power Electron. 2010, 3, 1001–1009. [Google Scholar] [CrossRef]

- Qi, F.; Xu, L.Y. Development of a High-Temperature Gate Drive and Protection Circuit Using Discrete Components. IEEE Trans. Power Electron. 2017, 32, 2957–2963. [Google Scholar] [CrossRef]

- Huque, M.A.; Islam, S.K.; Tolbert, L.M.; Blalock, B.J. A 200 °C universal gate driver integrated circuit for extreme environment applications. IEEE Trans. Power Electron. 2012, 27, 4153–4162. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Shi, X.J.; Tolbert, L.M.; Wang, F.; Liang, Z.; Costinett, D.; Blalock, B.J. A high temperature silicon carbide MOSFET power module with integrated silicon-on-insulator-based gate drive. IEEE Trans. Power Electron. 2015, 30, 1432–1445. [Google Scholar] [CrossRef]

- Yao, Y.Y.; Lu, G.Q.; Boroyevich, D.; Ngo, K.D.T. Survey of high-temperature polymeric encapsulants for power electronics packaging. IEEE Trans. Compon. Packag. Manuf. Technol. 2015, 5, 168–181. [Google Scholar]

- Ma, B.; Tae, H.; Stephen, L.; Dorris, E.; Koritala, R.E.; Balachandran, U. Flexible ceramic film capacitors for high-temperature power electronics. Mater. Sci. Energy Technol. 2019, 2, 96–103. [Google Scholar] [CrossRef]

- Ericson, N.; Frank, S.; Britton, C.; Marlino, L.; Ryu, S.-H.; Grider, D.; Mantooth, A.; Francis, M.; Lamichhane, R.; Mudholkar, M.; et al. A 4H silicon carbide gate buffer for integrated power systems. IEEE Trans. Power Electron. 2014, 29, 539–542. [Google Scholar] [CrossRef]

- Alexandru, M.; Banu, V.; Jordà, X.; Montserrat, J.; Vellvehi, M.; Tournier, D.; Millán, J.; Godignon, P. SiC integrated circuit control electronics for high-temperature operation. IEEE Trans. Ind. Electron. 2015, 62, 3182–3191. [Google Scholar] [CrossRef]

- Ghandi, R.; Chen, C.P.; Yin, L.; Zhu, X.; Yu, L.; Arthur, S.; Ahmad, F.; Sandvik, P. silicon carbide integrated circuits with stable operation over a wide temperature range. IEEE Trans. Electron. Device 2014, 35, 1206–1208. [Google Scholar] [CrossRef]

- Peftitsis, D.; Rabkowski, J. Gate and base drivers for silicon carbide power transistors: An overview. IEEE Trans. Power Electron. 2016, 31, 7194–7213. [Google Scholar] [CrossRef]

- Nayak, P.; Pramanick, S.K.; Rajashekara, K. A high-temperature gate driver for silicon carbide MOSFET. IEEE Trans. Ind. Electron. 2018, 65, 1955–1964. [Google Scholar] [CrossRef]

- Wang, R.X.; Boroyevich, D.; Ning, P.Q.; Wang, Z.Q.; Wang, F.; Mattavelli, P.; Ngo, K.D.T.; Rajashekara, K. A high temperature SiC three-phase ac-dc converter design for >100 °C ambient temperature. IEEE Trans. Power Electron. 2013, 28, 555–572. [Google Scholar] [CrossRef]

- Li, Q.; Chen, L.; Gadinsk, M.R.; Zhang, S.; Zhang, G.; Li, H.U.; Iagodkine, E.; Haque, A.; Chen, L.Q.; Jackson, T.N.; et al. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef]

- Reynolds, C. Tantalum capacitor technology: Options for high0temperature and harsh-environment applications. IEEE Power Electron. Mag. 2017, 4, 43–47. [Google Scholar] [CrossRef]

- Bunel, C.; Lengignon, L. Silicon capacitors with extremely high stability and reliability ideal for high temperature applications. Addit. Conf. 2012, 2012, 273–277. [Google Scholar] [CrossRef]

- Bartnitzek, T.; Thelemann, T.; Apel, S.; Suphan, K.H. Advantages and limitations of ceramic packaging technologies in harsh applications. Int. Symp. Microelectron. 2016, 1, 581–585. [Google Scholar] [CrossRef]

- Hessien, M.M.; Rashad, M.M.; El-Barawy, K.; Ibrahim, I.A. Influence of manganese substitution and annealing temperature on the formation, microstructure and magnetic properties of Mn-Zn ferrites. J. Magn. Magn. Mater. 2008, 320, 1615–1621. [Google Scholar] [CrossRef]

- Cooke, M. Wide load potential for electric vehicles. Compd. Adv. Silicon 2009, 4, 70–75. [Google Scholar]

- Qin, H.; Ma, C.; Zhu, Z.; Yan, Y. Influence of Parasitic Parameters on Switching Characteristics and Layout Design Considerations of SiC MOSFETs. J. Power Electron. 2018, 18, 1255–1267. [Google Scholar]

- Zhang, H.; Tolbert, L.M.; Han, J.H.; Chinthavali, M.S.; Barlow, F. 18 kW three phase inverter system using hermetically sealed SiC phase-leg power modules. In Proceedings of the twenty-fifth annual IEEE applied power electronics conference and exposition (APEC), Palm Springs, CA, USA, 21–25 February 2010; pp. 1108–1112. [Google Scholar]

- APEI Company. Multichip Power Module Technology. Available online: https://arpa-e.energy.gov/?q=impact-sheet/apei-adept (accessed on 19 June 2019).

- Cao, W.; Mecrow Barrie, C.; Glynn, J.; Bennett, J.W.; Atkinson, D.J. Overview of electric motor technologies used for more electric aircraft (MEA). IEEE Trans. Ind. Electron. 2012, 59, 3523–3531. [Google Scholar]

- Wada, K.J.; Ando, M. Limitation of DC-side stray inductance by considering over voltage and short-circuit current. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013; pp. 1–8. [Google Scholar]

- Li, H.; Munk-Nielsen, S.; Wang, X.; Maheshwari, R.; Bęczkowski, S.; Uhrenfeldt, C.; Franke, W.T. Influences of device and circuit mismatches on paralleling silicon carbide MOSFETs. IEEE Trans. Power Electron. 2016, 31, 621–634. [Google Scholar] [CrossRef]

- Ning, P.Q.; Lei, T.G.; Wang, F.; Lu, G.Q.; Ngo, K.D.T.; Rajashekara, K. A novel high-temperature planar package for SiC multichip phase-leg power module. IEEE Trans. Power Electron. 2010, 25, 2059–2067. [Google Scholar] [CrossRef]

- Zhang, D.; Ning, P.; Boroyevich, D. Development of an all SiC high-power density three-phase rectifier with interleaving. In Proceedings of the IEEE Energy Conversion Congress and Exposition, Phoenix, AZ, USA, 17–22 September 2011; pp. 4073–4080. [Google Scholar]

- Sun, P.W.; Lai, J.S.; Liu, C.; Yu, W. A 55-kW three-phase inverter based on hybrid-switch soft-switching modules for high-temperature hybrid electric vehicle drive application. IEEE Trans. Ind. Appl. 2012, 48, 962–969. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, L.; Lei, Y.; Li, X.; Xue, F.; Yu, W.; Huang, A.Q. 3.38MHz operation of 1.2kV SiC MOSFET with integrated ultra-fast gate drive. In Proceedings of the IEEE 3rd Workshop on Wide Band-Gap Power Devices and Applications (WiPDA), Blacksburg, VA, USA, 2–4 November 2015; pp. 390–395. [Google Scholar]

- Zhong, X.Q.; Wu, X.K.; Zhou, W.C.; Sheng, K. An all-SiC high-frequency boost DC–DC converter operating at 320 °C junction temperature. IEEE Trans. Power Electron. 2014, 29, 5091–5096. [Google Scholar] [CrossRef]

- Mazumder, S.K.; Acharya, K.; Jedraszczak, P. High-temperature all-SiC bidirectional DC/DC converter for plug-in-hybrid vehicle (PHEV). In Proceedings of the 34th Annual Conference of IEEE Industrial Electronics, Orlando, FL, USA, 10–13 November 2008; pp. 2873–2878. [Google Scholar]

- Kosai, H.; Scofield, J.; McNeal, S.; Jordan, B.; Ray, B. Design and performance evaluation of a 200 °C interleaved boost converter. IEEE Trans. Power Electron. 2013, 28, 1691–1699. [Google Scholar] [CrossRef]

- Sheng, K.; Zhang, Y.; Su, M.; Zhao, J.H.; Li, X.; Alexandrov, P.; Fursin, L. Demonstration of the first SiC power integrated circuit. Solid State Electron. 2008, 52, 1636–1646. [Google Scholar] [CrossRef]

- Lanni, L.; Ghandi, R.; Zetterling, C.M.; Malm, B.G.; Östling, M. 500 °C bipolar integrated OR/NOR gate in 4H-SiC. IEEE Electron. Device Lett. 2013, 34, 1091–1093. [Google Scholar] [CrossRef]

- Hedayati, R.; Lanni, L.; Rodriguez, S.; Malm, B.G.; Rusu, A.; Zetterling, C.-M. A monolithic, 500 °C operational amplifiers in 4H-SiC bipolar technology. IEEE Electron. Device Lett. 2014, 35, 693–695. [Google Scholar]

- Patil, A.C.; Fu, X.; Mehregany, M.; Garverick, S.L. Fully-monolithic, 600 °C differential amplifiers in 6H-SiC JFET IC technology. In Proceedings of the IEEE Custom Integrated Circuits Conference, Rome, Italy, 13–16 September 2009; pp. 73–76. [Google Scholar]

- Kargarrazi, S.; Lanni, L.; Zetterling, C. Design and characterization of 500 °C Schmitt Trigger in 4H-SiC. Mater. Sci. Forum 2014, 821, 897–901. [Google Scholar] [CrossRef]

- JValle-Mayorga, A.; Rahman, A.; Mantooth, H.A. A siC NMOS linear voltage regulator for high-temperature applications. IEEE Trans. Power Electron. 2014, 29, 2321–2328. [Google Scholar] [CrossRef]

- Kargarrazi, S.; Lanni, L.; Saggini, S.; Rusu, A.; Zetterling, C.-M. 500 °C bipolar SiC linear voltage regulator. IEEE Trans. Electron. Devices 2015, 62, 1–5. [Google Scholar] [CrossRef]

- Siddiqui, A.; Elgabra, H.; Singh, S. Design considerations for 4H-SiC lateral BJTs for high temperature logic applications. J. Electron. Devices Soc. 2018, 6, 126–134. [Google Scholar] [CrossRef]

- Kargarrazi, S.; Lanni, L.; Rusu, A.; Zetterling, C.M. A monolithic SiC drive circuit for SiC power BJTs. In Proceedings of the International Symposium on Power Semiconductor Devices & IC’s, Hong Kong, China, 10–14 May 2015; pp. 285–288. [Google Scholar]

- Kargarrazi, S.; Elahipanah, H.; Asggini, S.; Senesky, D.; Zetterling, C.M. 500 °C SiC PWM integrated circuit. IEEE Trans. Power Electron. 2019, 34, 1997–2001. [Google Scholar] [CrossRef]

- Basu, A.; Adams, G.G.; McGruer, N.E. A review of micro-contact physics, materials, and failure mechanisms in direct-contact RF MEMS switches. J. Micromech. Microeng. 2016, 26, 104004. [Google Scholar] [CrossRef]

- Lee, T.; Bhunia, S.; Mehregany, M. Electromechanical computing at 500 °C with silicon carbide. Science 2010, 329, 1316–1318. [Google Scholar] [CrossRef] [PubMed]

- Yin, S.; Tseng, K.J.; Tong, C.F.; Simanjorang, R.; Gajanayake, C.J.; Nawawi, A.; Liu, Y.; Liu, Y.; See, K.Y.; Sakanova, A.; et al. Gate driver optimization to mitigate shoot-through in high-speed switching SiC half bridge module. In Proceedings of the IEEE International Conference on Power Electronics & Drive Systems, Sydney, Australia, 9–12 June 2015; pp. 484–491. [Google Scholar]

- Wrzecionko, B.; Steinmann, L.; Kolar, J.W. High-bandwidth high-temperature (250 °C/500 °F) isolated DC and AC current measurement: Bi-directionally saturated current transformer. IEEE Trans. Power Electron. 2013, 28, 5404–5413. [Google Scholar] [CrossRef]

- Trentin, A.; Zanchetta, P.; Wheeler, P.; Clare, J. Performance evaluation of 3 phase buck-type PWM rectifiers with integrated and symmetrical boost converter using SiC MOSFETs for aircraft application. In Proceedings of the IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013; pp. 1–6. [Google Scholar]

- Qi, F.; Xu, L.; Zhao, G.; Wang, J. Transformer isolated gate drive with protection for SiC MOSFET in high temperature application. In Proceedings of the IEEE in Energy Conversion Congress and Exposition, Pittsburgh, PA, USA, 14–18 September 2014; pp. 5723–5728. [Google Scholar]

- Siow, K.S. Are Sintered Silver Joints Ready for Use as Interconnect Material in Microelectronic Packaging? J. Electron. Mater. 2014, 43, 947–961. [Google Scholar] [CrossRef] [Green Version]

- Manikam, V.R.; Cheong, K.Y. Die attach materials for high temperature applications: A review. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 1, 457–478. [Google Scholar] [CrossRef]

| High Temperature Application | Peak Ambient | Current Technology | Future Technology |

|---|---|---|---|

| Automotive | |||

| Engine control electronics | 150 °C | Bulk Si and SOI | Bulk Si and SOI |

| Electric/ Hybrid vehicle power management and distribution (PMAD) | 150 °C | Bulk Si | WBG |

| Electric suspension and brakes | 250 °C | Bulk Si | WBG |

| On-cylinder and exhaust pipe | 850 °C | N/A | WBG |

| Turbine engine | |||

| Sensors, telemetry, control | 300 °C/600 °C | Bulk Si and SOI/N/A | WBG and SOI/WBG |

| Electric actuation | 150 °C/600 °C | Bulk Si and SOI/N/A | WBG |

| Deep-well drilling telemetry | |||

| Oil and gas | 300 °C | SOI | WBG and SOI |

| Geothermal | 600 °C | N/A | WBG |

| Industrial | |||

| High-temperature processing | 300 °C/600 °C | SOI/N/A | SOI/WBG |

| Spacecraft | |||

| Power management | 150 °C/500 °C | Bulk Si and SOI/N/A | WBG |

| Venus and Mercury exploration | 550 °C | N/A | WBG |

| Items | SiC | Si | GaAs | ||

|---|---|---|---|---|---|

| 4H-SiC | 6H-SiC | 3C-SiC | |||

| Band-gap (eV) | 3.2 | 3.0 | 2.2 | 1.12 | 1.43 |

| Maximum operation temperature (°C) | 1580 | 1580 | 1580 | 600 | 400 |

| Breakdown field strength (V/cm) | 2.2 × 106 | 2.5 × 106 | 2.0 × 106 | 0.3 × 106 | 0.4 × 106 |

| Maximum electron saturation velocity (cm/s) | 2.0 × 107 | 2.0 × 107 | 2.5 × 107 | 1.0 × 107 | 1.0 × 107 |

| Thermal conductivity (W/cm·K) | 3~4 | 3~4 | 3~4 | 1.7 | 0.5 |

| Electron mobility (cm2/s·V) | 980 | 370 | 1000 | 1350 | 8500 |

| Hole mobility (cm2/s·V) | 120 | 80 | 40 | 480 | 400 |

| Ceramic Materials | 96% Al (Al2O3) | 99% Al (Al2O3) | AlN | BeO | Si3N4 |

|---|---|---|---|---|---|

| Dielectric field intensity (kV/mm) | 12 | 12 | 15 | 12 | 10 |

| CTE (ppm/°C) | 60 | 7.2 | 4.5 | 7.0 | 2.7 |

| Thermal conductivity (W/m·K) | 24 | 33 | 170 | 270 | 60 |

| Structural strength (g/cm3) | 3.5 | 4.0 | 2.6 | 4.0 | 5.0 |

| Flexural strength (MPa) | 317 | 345 | 360 | 250 | 850 |

| Tensile strength (MPa) | 127 | 207 | 310 | 230 | 17 |

| Materials | 100 Cu | 100 Al | 85 Mo/15 Cu | 75 Mo/25 Cu | 65 Mo/35 Cu |

|---|---|---|---|---|---|

| CTE (ppm/°C) | 17.8 | 26.4 | 6.8 | 7.8 | 9.0 |

| Thermal conductivity (W/m·K) | 398 | 230 | 165 | 185 | 205 |

| Density (g/cm3) | 8.90 | 2.70 | 10.01 | 9.87 | 9.74 |

| Young modulus (MPa) | 128,000 | 70,000 | 274,000 | 274,000 | 274,000 |

| Yield strength (MPa) | 210 | 50 | / | / | / |

| Solder | Sn96.5 Ag3.5 | Sn95 Sb5 | Pb75 In25 | Sn10 Pb88 Ag2 | Sn10 Pb90 | Au20 Sn80 |

|---|---|---|---|---|---|---|

| Melting point (kV/mm) | 221 | 235 | 240 | 267 | 275 | 280 |

| Boiling point (ppm/°C) | 221 | 240 | 260 | 290 | 302 | 280 |

| Density (W/m·K) | 7.5 | 7.25 | 9.97 | 10.75 | 10.75 | 14.51 |

| Thermal conductivity (W/m·K) | 33 | 28 | 18 | 27 | 25 | 57 |

| CTE (ppm/°C) | 30 | 31 | 26 | 29 | 29 | 16 |

| Electrical conductivity (S/m) | 16 | 11.9 | 4.6 | 8.5 | 8.9 | / |

| Capacitor type | Packaging | Max. Temperature | Comments |

|---|---|---|---|

| Solid tantalum | SMT and through-hole | 230 °C | High capacitance value; voltage degradation 60–80% at 230 °C |

| Electrolytic wet tantalum | Axial through-hole | 200 °C | High capacitance value; most through-hole |

| Stacked ceramic | SMT-chip stacked gull-wing | 260 °C | Poor stability above 175 °C for X7R, but higher capacitance density than C0G |

| Resistor Type | Packaging | Max. Temperature | Comments |

|---|---|---|---|

| Metal foil | Through-hole, surface-mount device (SMD)-chip, flip-chip | 240 °C | High precision |

| Metal oxide | Through-hole | 275 °C | General purpose, power resistors, good frequency characteristics |

| Thin film | SMD-chip, flip-chip | 275 °C | Compact, low TC, high stability |

| Thick film | SMD-chip, flip-chip | 300 °C | General purpose, wide resistance range |

| Wire-wound | Through-hole | 350 °C | High surge capability, precision power |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Xun, Q.; Li, Z.; Du, S. Silicon Carbide Converters and MEMS Devices for High-temperature Power Electronics: A Critical Review. Micromachines 2019, 10, 406. https://doi.org/10.3390/mi10060406

Guo X, Xun Q, Li Z, Du S. Silicon Carbide Converters and MEMS Devices for High-temperature Power Electronics: A Critical Review. Micromachines. 2019; 10(6):406. https://doi.org/10.3390/mi10060406

Chicago/Turabian StyleGuo, Xiaorui, Qian Xun, Zuxin Li, and Shuxin Du. 2019. "Silicon Carbide Converters and MEMS Devices for High-temperature Power Electronics: A Critical Review" Micromachines 10, no. 6: 406. https://doi.org/10.3390/mi10060406

APA StyleGuo, X., Xun, Q., Li, Z., & Du, S. (2019). Silicon Carbide Converters and MEMS Devices for High-temperature Power Electronics: A Critical Review. Micromachines, 10(6), 406. https://doi.org/10.3390/mi10060406