Recent Progress of Miniature MEMS Pressure Sensors

Abstract

:1. Introduction

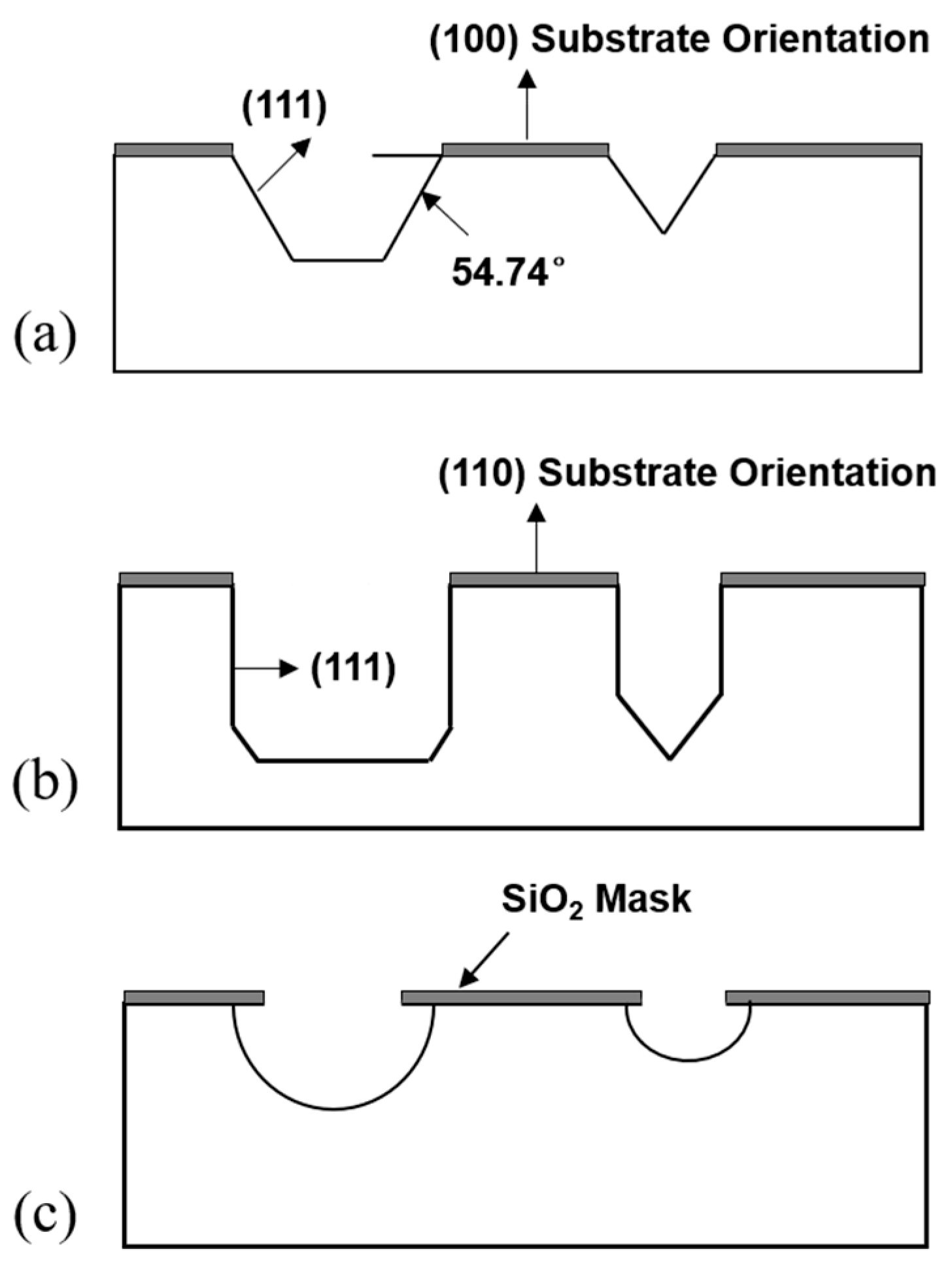

2. Size Change with Process Development

3. Application of Small Pressure Sensors

3.1. Medical Applications

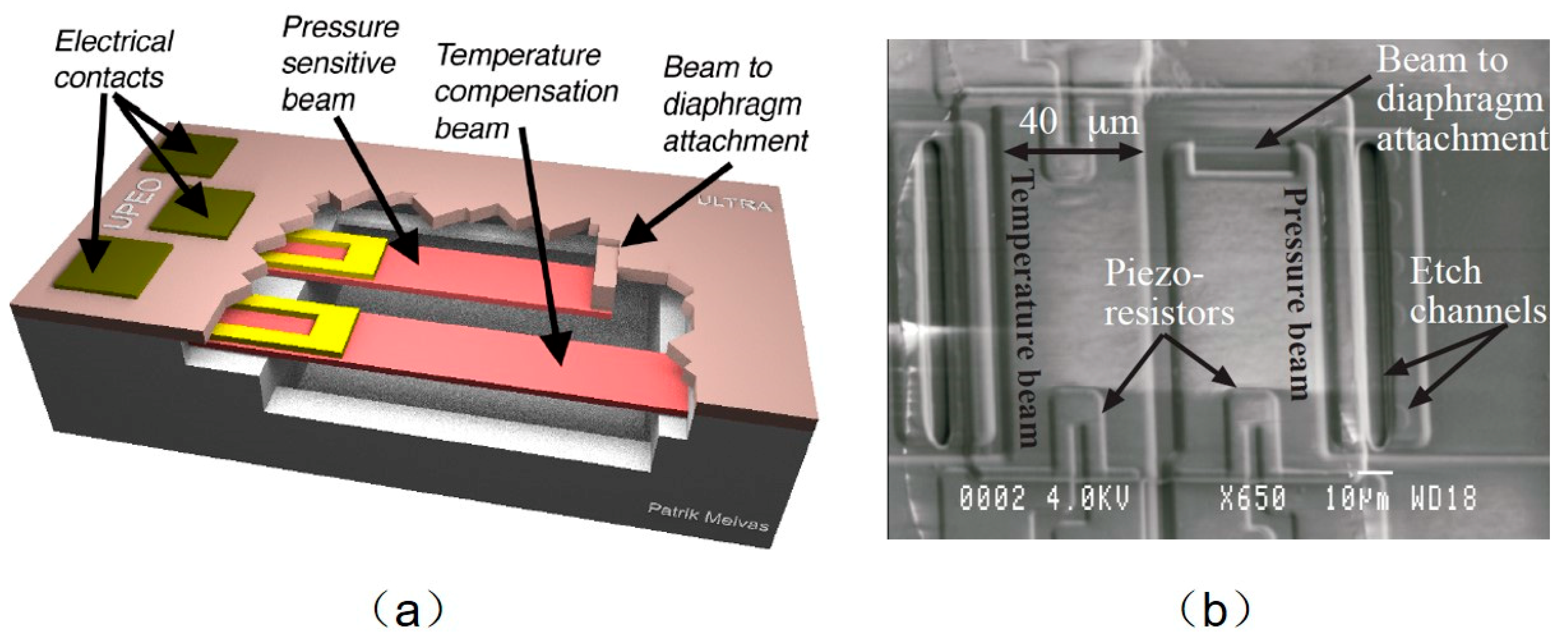

3.1.1. Blood Pressure

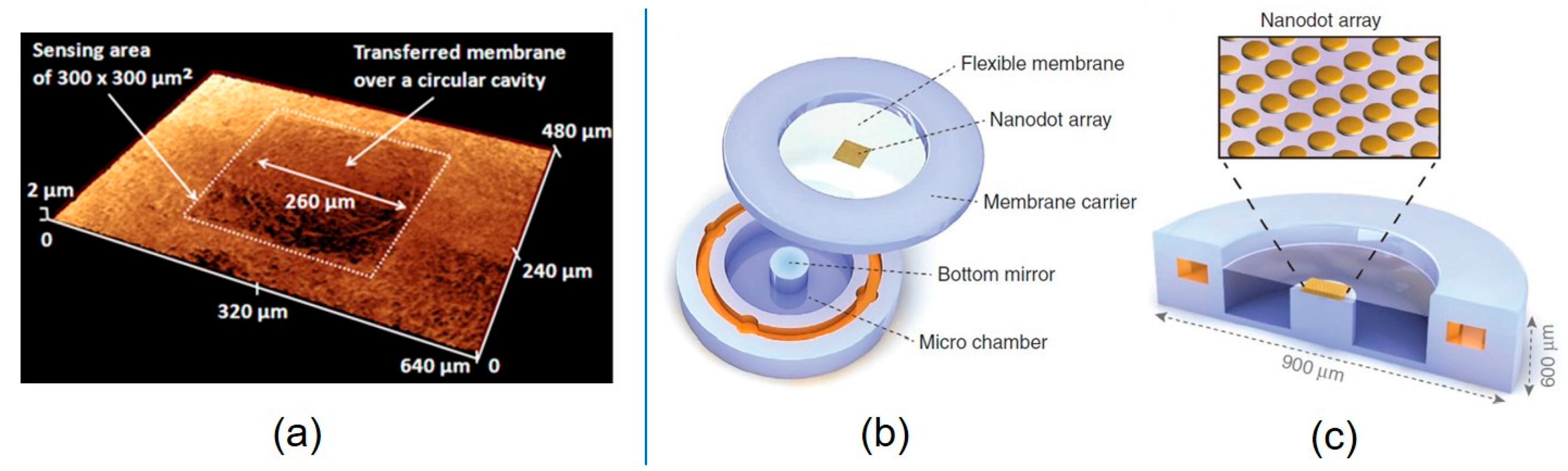

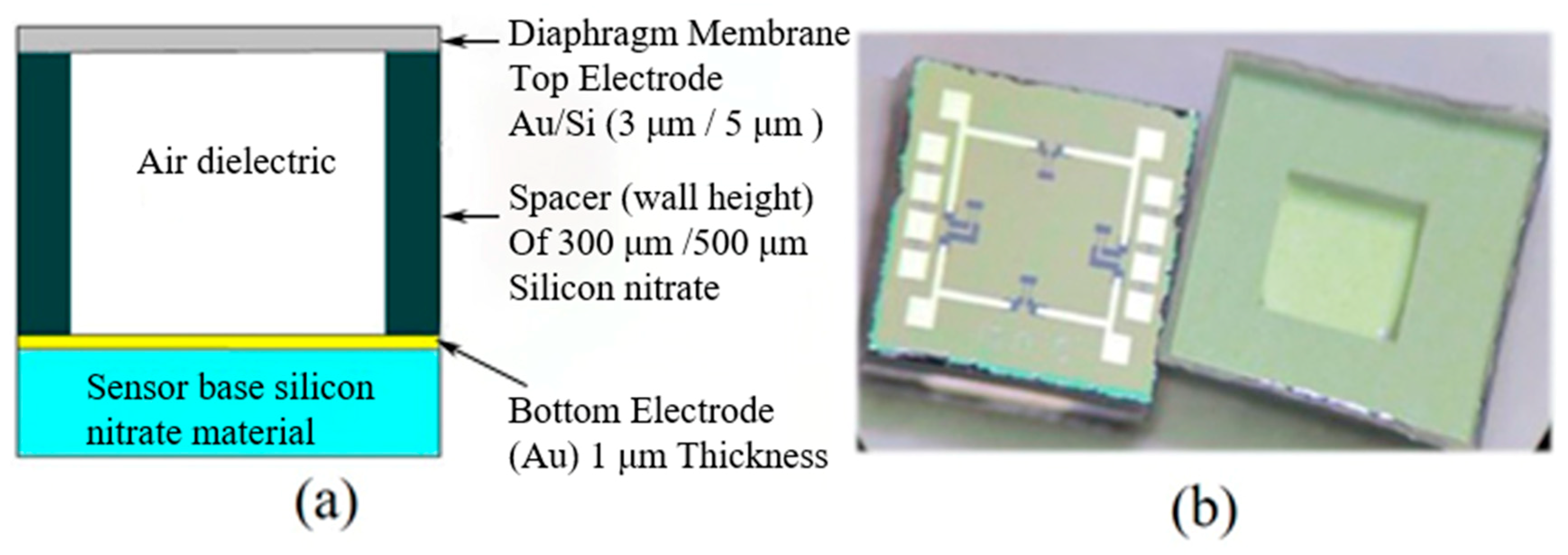

3.1.2. Intraocular Pressure

3.1.3. Intracranial Pressure

3.1.4. Biocompatibility Issue

3.2. Aerospace

3.3. Industry

3.4. Consumer Electronics

4. The Condition of Sensor Size Reduction

4.1. Problems Faced

4.2. The Solution

4.3. Possible Development Directions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mukhopadhyay, S.C. Wearable Sensors for Human Activity Monitoring: A Review. IEEE Sens. J. 2014, 15, 1321–1330. [Google Scholar] [CrossRef]

- Lee, J.O.; Park, H.; Du, J.; Balakrishna, A.; Chen, O.; Sretavan, D.; Choo, H. A microscale optical implant for continuous in vivo monitoring of intraocular pressure. Microsyst. Nanoeng. 2017, 3, 17057. [Google Scholar] [CrossRef] [Green Version]

- Wu, N.; Tian, Y.; Zou, X.; Zhai, Y.; Barringhaus, K.; Wang, X. A miniature fiber optic blood pressure sensor and its application in in vivo blood pressure measurements of a swine model. Sens. Actuators B Chem. 2013, 181, 172–178. [Google Scholar] [CrossRef]

- Hao, X.; Tanaka, S.; Masuda, A.; Nakamura, J.; Sudoh, K.; Maenaka, K.; Takao, H.; Higuchi, K. Application of Silicon on Nothing Structure for Developing a Novel Capacitive Absolute Pressure Sensor. IEEE Sens. J. 2013, 14, 808–815. [Google Scholar] [CrossRef]

- Pedersen, T.; Fragiacomo, G.; Hansen, O.; Thomsen, E. Highly sensitive micromachined capacitive pressure sensor with reduced hysteresis and low parasitic capacitance. Sens. Actuators A Phys. 2009, 154, 35–41. [Google Scholar] [CrossRef]

- Bae, B.; Flachsbart, B.R.; Park, K.; Shannon, M.A. Design optimization of a piezoresistive pressure sensor considering the output signal-to-noise ratio. J. Micromech. Microeng. 2004, 14, 1597–1607. [Google Scholar] [CrossRef]

- Mahmoodi, M.; Ghazanfari, L. Physics and Technology of Silicon Carbide Devices; GmbH: Weinheim, Germany, 2012; pp. 349–378. [Google Scholar]

- Lee, Y.; Wise, K. A batch-fabricated silicon capacitive pressure transducer with low temperature sensitivity. IEEE Trans. Electron Devices 1982, 29, 42–48. [Google Scholar] [CrossRef]

- Hierold, C.; Clasbrummel, B.; Behrend, D.; Scheiter, T.; Steger, M.; Oppermann, K.; Kapels, H.; Landgraf, E.; Wenzel, D.; Etzrodt, D. Low power integrated pressure sensor system for medical applications. Sens. Actuators A Phys. 1999, 73, 58–67. [Google Scholar] [CrossRef]

- Palasagaram, J.N.; Ramadoss, R. MEMS-Capacitive Pressure Sensor Fabricated Using Printed-Circuit-Processing Techniques. IEEE Sens. J. 2006, 6, 1374–1375. [Google Scholar] [CrossRef]

- Van Der Heyden, F.; Blom, M.; Gardeniers, J.; Chmela, E.; Elwenspoek, M.; Tijssen, R.; Berg, A.V.D. A low hydraulic capacitance pressure sensor for integration with a micro viscosity detector. Sens. Actuators B Chem. 2003, 92, 102–109. [Google Scholar] [CrossRef]

- Starr, P.; Bartels, K.; Agrawal, C.M.; Bailey, S. A thin-film pressure transducer for implantable and intravascular blood pressure sensing. Sens. Actuators A Phys. 2016, 248, 38–45. [Google Scholar] [CrossRef]

- Muhammad, H.; Oddo, C.M.; Beccai, L.; Recchiuto, C.; Anthony, C.; Adams, M.; Carrozza, M.; Hukins, D.; Ward, M. Development of a bioinspired MEMS based capacitive tactile sensor for a robotic finger. Sens. Actuators A Phys. 2011, 165, 221–229. [Google Scholar] [CrossRef]

- Xu, M.; Reekie, L.; Chow, Y.; Dakin, J. Optical in-fibre grating high pressure sensor. Electron. Lett. 1993, 29, 398. [Google Scholar] [CrossRef] [Green Version]

- Xu, M.; Geiger, H.; Dakin, J. Fibre grating pressure sensor with enhanced sensitivity using a glass-bubble housing. Electron. Lett. 1996, 32, 128. [Google Scholar] [CrossRef] [Green Version]

- Arkwright, J.W.; Underhill, I.D.; Maunder, S.A.; Jafari, A.; Cartwright, N.; Lemckert, C. Fiber Optic Pressure Sensing Arrays for Monitoring Horizontal and Vertical Pressures Generated by Traveling Water Waves. IEEE Sens. J. 2014, 14, 2739–2742. [Google Scholar] [CrossRef]

- Xu, J.; Wang, X.; Cooper, K.L.; Wang, A. Miniature all-silica fiber optic pressure and acoustic sensors. Opt. Lett. 2005, 30, 3269–3271. [Google Scholar] [CrossRef]

- Sabry, Y.M.; Khalil, D.; Bourouina, T. Monolithic silicon-micromachined free-space optical interferometers onchip. Laser Photonics Rev. 2015, 9, 1–24. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, M.; Yang, Z. Facile fabrication of graphene oxide/Nafion/indium oxide for humidity sensing with highly sensitive capacitance response. Sens. Actuators B Chem. 2019, 292, 187–195. [Google Scholar] [CrossRef]

- Arash, B.; Jiang, J.-W.; Rabczuk, T. A review on nanomechanical resonators and their applications in sensors and molecular transportation. Appl. Phys. Rev. 2015, 2, 021301. [Google Scholar] [CrossRef]

- Greenwood, J.; Satchell, D. Miniature silicon resonant pressure sensor. IEE Proc. D Control Theory Appl. 1988, 135, 369. [Google Scholar] [CrossRef]

- Morten, B.; De Cicco, G.; Prudenziati, M. Resonant pressure sensor based on piezoelectric properties of ferroelectric thick films. Sens. Actuators A Phys. 1992, 31, 153–158. [Google Scholar] [CrossRef]

- Wang, J.; Shi, X.; Liu, L.; Wu, Z.; Chen, D.; Zhao, J.; Li, S. A novel resonant pressure sensor with boron diffused silicon resonator. Proc. SPIE 2008, 7159. [Google Scholar] [CrossRef]

- Miller, J.M.L.; Ansari, A.; Heinz, D.B.; Chen, Y.; Flader, I.B.; Shin, D.D.; Villanueva, L.G.; Kenny, T.W. Effective quality factor tuning mechanisms in micromechanical resonators. Appl. Phys. Rev. 2018, 5, 041307. [Google Scholar] [CrossRef]

- Young, D.; Du, J.; Zorman, C.; Ko, W. High-Temperature Single-Crystal 3C-SiC Capacitive Pressure Sensor. IEEE Sens. J. 2004, 4, 464–470. [Google Scholar] [CrossRef]

- Petersen, K.E. Silicon as a mechanical material. Proc. IEEE 1982, 70, 420–457. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, L.; Wang, L.; Wang, F.; Pan, G. A Flexible e-skin based on micro-structured PZT thin films prepared via a low-temperature PLD method. J. Mater. Chem. C 2019, 7, 4760–4769. [Google Scholar] [CrossRef]

- Akiyama, M.; Morofuji, Y.; Kamohara, T.; Nishikubo, K.; Tsubai, M.; Fukuda, O.; Ueno, N. Flexible piezoelectric pressure sensors using oriented aluminum nitride thin films prepared on polyethylene terephthalate films. J. Appl. Phys. 2006, 100, 114318. [Google Scholar] [CrossRef]

- Dauksevicius, R.; Gaidys, R.; O’Reilly, E.P.; Seifikar, M. Finite Element Analysis of Polymer-encapsulated ZnO Nanowire-based Sensor Array Intended for Pressure Sensing in Biometric Applications. Procedia Eng. 2016, 168, 864–867. [Google Scholar] [CrossRef]

- Toprak, A.; Tigli, O. Piezoelectric energy harvesting: State-of-the-art and challenges. Appl. Phys. Rev. 2014, 1, 31104. [Google Scholar] [CrossRef]

- Wei, H.; Wang, H.; Xia, Y.; Cui, D.; Shi, Y.; Dong, M.; Liu, C.; Ding, T.; Zhang, J.-X.; Ma, Y.; et al. An overview of lead-free piezoelectric materials and devices. J. Mater. Chem. C 2018, 6, 12446–12467. [Google Scholar] [CrossRef]

- Jindal, S.K.; Raghuwanshi, S.K. Study of materials for the design of MEMS capacitive pressure sensor. AIP Conf. Proc. 2016, 1724, 020118. [Google Scholar] [CrossRef]

- Mosser, V.; Suski, J.; Goss, J.; Obermeier, E. Piezoresistive pressure sensors based on polycrystalline silicon. Sens. Actuators A Phys. 1991, 28, 113–132. [Google Scholar] [CrossRef]

- Starr, P.; Bartels, K.; Agrawal, M.; Bailey, S. Evolution of micromachined pressure transducers for cardiovascular applications. Sens. Actuators A Phys. 2015, 225, 8–19. [Google Scholar] [CrossRef]

- Voiculescu, I.; Nordin, A.N. Acoustic wave based MEMS devices for biosensing applications. Biosens. Bioelectron. 2012, 33, 1–9. [Google Scholar] [CrossRef]

- Su, J.; Zhang, X.; Zhou, G.; Xia, C.; Zhou, W.; Huang, Q. A review: Crystalline silicon membranes over sealed cavities for pressure sensors by using silicon migration technology. J. Semicond. 2018, 39, 071005. [Google Scholar] [CrossRef]

- Kumar, S.S.; Pant, B.D. Design principles and considerations for the ‘ideal’ silicon piezoresistive pressure sensor: A focused review. Microsyst. Technol. 2014, 20, 1213–1247. [Google Scholar] [CrossRef]

- Smith, C.S. Piezoresistance Effect in Germanium and Silicon. Phys. Rev. 1954, 94, 42–49. [Google Scholar] [CrossRef]

- Sanchez, J. Semiconductor strain-gauge pressure sensors. Instrum. Control Syst. 1963, 20, 117. [Google Scholar]

- Robbins, H.; Schwartz, B. Chemical etching of silicon I. The system, and. J. Electrochem. Soc. 1959, 106, 505–508. [Google Scholar] [CrossRef]

- Bean, K. Anisotropic etching of silicon. IEEE Trans. Electron Devices 1978, 25, 1185–1193. [Google Scholar] [CrossRef]

- Terry, S.C. A Gas Chromatography System Fabricated on a Silicon Wafer Using Integrated Circuit Technology. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 1975. [Google Scholar]

- Gieles, A. Subminiature silicon pressure transducer. In Proceedings of the 1969 IEEE International Solid-State Circuits Conference, Philadelphia, PA, USA, 19–21 February 1969; pp. 108–109. [Google Scholar]

- Gieles, A.; Somers, G. Miniature pressure transducers with a silicon diaphragm. Philips Tech. Rev. 1973, 33, 14–20. [Google Scholar]

- Wu, D.F.; Wu, Y.T.; Chu, J.R. New progress of anodic bonding technology and its applications in micro-sensor. J. Transducer Technol. 2002, 21, 4–7. [Google Scholar]

- Sander, C.S.; Knutti, J.W.; Meindl, J.D. A monolithic capacitive pressure sensor with pulse-period output. IEEE Trans. Electron Devices 1980, 27, 927–930. [Google Scholar] [CrossRef]

- Balavalad, K.B.; Sheeparamatti, B. A critical review of MEMS capacitive pressure sensors. Sens. Transducers 2015, 187, 120. [Google Scholar]

- Wise, K.D. Integrated silicon sensors: Technology and microstructures. In Proceedings of the IEEE/Cornell Conference on Advanced Concepts in High Speed Semiconductor Devices and Circuits, Ithaca, NY, USA, 5–7 August 1991; pp. 412–424. [Google Scholar]

- McIntosh, R.B.; Paquin, R.A. Chemical-mechanical polishing of low-scatter optical surfaces. Appl. Opt. 1980, 19, 2329. [Google Scholar] [CrossRef] [PubMed]

- Payne, C.C. Process for Polishing Semi-Conductor Materials. U.S. Patent Application No. US4169337A, 2 October 1979. [Google Scholar]

- Walsh, R.J.; Herzog, A.H. Process for Polishing Semiconductor Materials. U.S. Patent Application No. US3170273A, 23 February 1965. [Google Scholar]

- Ko, W.H.; Wang, Q. Touch mode capacitive pressure sensors. Sens. Actuators A Phys. 1999, 75, 242–251. [Google Scholar] [CrossRef]

- Kim, Y.; Neikirk, D. Micromachined Fabry-Perot cavity pressure transducer. IEEE Photonic Technol. Lett. 1995, 7, 1471–1473. [Google Scholar] [CrossRef]

- Maboudian, R. Surface processes in MEMS technology. Surf. Sci. Rep. 1998, 30, 207–269. [Google Scholar] [CrossRef]

- Core, T.A.; Tsang, W.; Sherman, S.J. Fabrication technology for an integrated surface-micromachined sensor. Solid State Technol. 1993, 36, 39–45. [Google Scholar]

- Sugiyama, S.; Shimaoka, K.; Tabata, O. Surface micromachined micro-diaphragm pressure sensors. In Proceedings of the TRANSDUCERS ’91: 1991 International Conference on Solid-State Sensors and Actuators, San Francisco, CA, USA, 24–27 June 1991; pp. 188–191. [Google Scholar]

- Esashi, M.; Nakano, A.; Shoji, S.; Hebiguchi, H. Low-temperature silicon-to-silicon anodic bonding with intermediate low melting point glan. Sens. Actuators A Phys. 1990, 23, 931–934. [Google Scholar] [CrossRef]

- Eaton, W.P.; Smith, J.H. Planar surface-micromachined pressure sensor with a sub-surface, embedded reference pressure cavity. Proc. SPIE 1996, 2882. [Google Scholar] [CrossRef] [Green Version]

- Eaton, W.P.; Smith, J.H. CMOS-compatible surface-micromachined pressure sensor for aqueous ultrasonic application. SPIE Proc. 1995, 2448, 258–265. [Google Scholar]

- Dudaicevs, H.; Kandler, M.; Manoli, Y.; Mokwa, W.; Spiegel, E. Surface micromachined pressure sensors with integrated CMOS read-out electronics. Sens. Actuators A Phys. 1994, 43, 157–163. [Google Scholar] [CrossRef]

- Howe, R.T. Surface micromachining for microsensors and microactuators. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1988, 6, 1809. [Google Scholar] [CrossRef]

- Bustillo, J.M.; Fedder, G.K.; Nguyen, C.T.-C.; Howe, R.T. Process technology for the modular integration of CMOS and polysilicon microstructures. Microsyst. Technol. 1994, 1, 30–41. [Google Scholar] [CrossRef]

- Eaton, W.P.; Smith, J.H. Characterization of a surface micromachined pressure sensor array. Micromach. Microfabr. 1995, 2642, 256–264. [Google Scholar]

- Armbruster, S.; Schafer, F.; Lammel, G.; Artmann, H.; Schelling, C.; Benzel, H.; Finkbeiner, S.; Larmer, F.; Rüther, R.; Paul, O. A novel micromachining process for the fabrication of monocrystalline Si-membranes using porous silicon. In Proceedings of the 12th International Conference on Solid-State Sensors, Actuators and Microsystems, Boston, MA, USA, 8–12 June 2003; pp. 246–249. [Google Scholar]

- Gan, L.; Sun, L.; He, H.; Ye, Z. Tuning the photoluminescence of porous silicon nanowires by morphology control. J. Mater. Chem. C 2014, 2, 2668. [Google Scholar] [CrossRef]

- Park, J.-H.; Gu, L.; Von Maltzahn, G.; Ruoslahti, E.; Bhatia, S.N.; Sailor, M.J. Biodegradable luminescent porous silicon nanoparticles for in vivo applications. Nat. Mater. 2009, 8, 331–336. [Google Scholar] [CrossRef]

- Zhao, M.; McCormack, A.; Keswani, M. The formation mechanism of gradient porous Si in a contactless electrochemical process. J. Mater. Chem. C 2016, 4, 4204–4210. [Google Scholar] [CrossRef] [Green Version]

- De Sagazan, O.; Denoual, M.; Guil, P.; Gaudin, D.; Bonnaud, O. Horizontal buried channels in monocrystalline silicon. Microsyst. Technol. 2006, 12, 959–963. [Google Scholar] [CrossRef]

- Sato, T.; Mizushima, I.; Taniguchi, S.; Takenaka, K.; Shimonishi, S.; Hayashi, H.; Hatano, M.; Sugihara, K.; Tsunashima, Y. Fabrication of Silicon-on-Nothing Structure by Substrate Engineering Using the Empty-Space-in-Silicon Formation Technique. Jpn. J. Appl. Phys. 2004, 43, 12–18. [Google Scholar] [CrossRef]

- Jurczak, M.; Skotnicki, T.; Paoli, M.; Tormen, B.; Martins, J.; Regolini, J.; Dutartre, D.; Ribot, P.; Lenoble, D.; Pantel, R.; et al. Silicon-on-Nothing (SON)-an innovative process for advanced CMOS. IEEE Trans. Electron Devices 2000, 47, 2179–2187. [Google Scholar] [CrossRef] [Green Version]

- Klaassen, E.H.; Petersen, K.; Noworolski, J.; Logan, J.; Maluf, N.I.; Brown, J.; Storment, C.; McCulley, W.; Kovacs, G.T. Silicon fusion bonding and deep reactive ion etching: A new technology for microstructures. Sens. Actuators A Phys. 1996, 52, 132–139. [Google Scholar] [CrossRef]

- Gowrishetty, U.; Walsh, K.M.; Aebersold, J.; Jackson, D.; Millar, H.; Roussel, T. Development of Ultra-Miniaturized Piezoresistive Pressure Sensors for Biomedical Applications. In Proceedings of the 2008 17th Biennial University/Government/Industry Micro/Nano Symposium, Louisville, KY, USA, 13–16 July 2008; pp. 89–92. [Google Scholar]

- Gigan, O.; Chen, H.; Robert, O.; Renard, S.; Marty, F. Fabrication and characterization of resonant SOI micromechanical silicon sensors based on DRIE micromachining, freestanding release process and silicon direct bonding. Smart Mater. Nano Micro-Smart Syst. 2002, 4936, 194–204. [Google Scholar]

- Godovitsyn, I.; Amelichev, V.; Pankov, V. A high sensitivity surface-micromachined pressure sensor. Sens. Actuators A Phys. 2013, 201, 274–280. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, L.; Gao, F.; Yang, W.; Du, Z.; Chen, D.; Chen, S. The N and P co-doping-induced giant negative piezoresistance behaviors of SiC nanowires. J. Mater. Chem. C 2019, 7, 3181–3189. [Google Scholar] [CrossRef]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef] [Green Version]

- De La Mata, M.; Zhou, X.; Furtmayr, F.; Teubert, J.; Gradečak, S.; Eickhoff, M.; Morral, A.F.I.; Arbiol, J. A review of MBE grown 0D, 1D and 2D quantum structures in a nanowire. J. Mater. Chem. C 2013, 1, 4300. [Google Scholar] [CrossRef]

- Soon, B.W.; Neuzil, P.; Wong, C.C.; Reboud, J.; Feng, H.H.; Lee, C. Ultrasensitive nanowire pressure sensor makes its debut. Procedia Eng. 2010, 5, 1127–1130. [Google Scholar] [CrossRef] [Green Version]

- Lou, L.; Yan, H.; Park, W.-T.; Kwong, D.-L.; Lee, C. Characterization of Piezoresistive-Si-Nanowire-Based Pressure Sensors by Dynamic Cycling Test with Extralarge Compressive Strain. IEEE Trans. Electron Devices 2012, 59, 3097–3103. [Google Scholar] [CrossRef]

- Booth, J. A Short History of Blood Pressure Measurement; SAGE Publications: Sauzend Oakes, CA, USA, 1977; Volume 70, pp. 793–799. [Google Scholar]

- Druzhinin, A.; Lavitska, E.; Maryamova, I. Medical pressure sensors on the basis of silicon microcrystals and SOI layers. Sens. Actuators B Chem. 1999, 58, 415–419. [Google Scholar] [CrossRef]

- Eaton, W.P.; Smith, J.H. Micromachined pressure sensors: Review and recent developments. Smart Mater. Struct. 1997, 6, 530. [Google Scholar] [CrossRef]

- Ferrario, D.; Falhi, A.; Grossenbacher, O.; Sola, J.; Proenca, M.; Porchet, J.-A.; Allemann, Y.; Rimoldi, S.F.; Sartori, C. Noninvasive and Nonocclusive Blood Pressure Estimation Via a Chest Sensor. IEEE Trans. Biomed. Eng. 2013, 60, 3505–3513. [Google Scholar]

- Huang, S.-C.; Hung, P.-H.; Hong, C.-H.; Wang, H.-M. A New Image Blood Pressure Sensor Based on PPG, RRT, BPTT, and Harmonic Balancing. IEEE Sens. J. 2014, 14, 3685–3692. [Google Scholar] [CrossRef] [Green Version]

- Vaddiraju, S.; Tomazos, I.; Burgess, D.J.; Jain, F.C.; Papadimitrakopoulos, F. Emerging synergy between nanotechnology and implantable biosensors: A review. Biosens. Bioelectron. 2010, 25, 1553–1565. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chau, H.-L.; Wise, K. An ultraminiature solid-state pressure sensor for a cardiovascular catheter. IEEE Trans. Electron Devices 1988, 35, 2355–2362. [Google Scholar] [CrossRef]

- Ji, J.; Cho, S.; Zhang, Y.; Najafi, K.; Wise, K.D. An ultraminiature CMOS pressure sensor for a multiplexed cardiovascular catheter. IEEE Trans. Electron Devices 1992, 39, 2260–2267. [Google Scholar] [CrossRef]

- Kalvesten, E.; Smith, L.; Tenerz, L.; Stemme, G. The first surface micromachined pressure sensor for cardiovascular pressure measurements. In Proceedings of the Eleventh Annual International Workshop on Micro Electro Mechanical Systems, An Investigation of Micro Structures, Sensors, Actuators, Machines and Systems (Cat. No.98CH36176), Heidelberg, Germany, 25–29 January 2002; pp. 574–579. [Google Scholar]

- Allen, H.; Ramzan, K.; Withers, S.; Knutti, J. A Novel Ultra-miniature catheter tip pressure sensor fabricated using silicon and glass thinning techniques. MRS Proc. 2001, 681. [Google Scholar] [CrossRef]

- Melvås, P.; Kälvesten, E.; Stemme, G. A temperature compensated dual beam pressure sensor. Sens. Actuators A Phys. 2002, 100, 46–53. [Google Scholar] [CrossRef]

- Melvås, P.; Kälvesten, E.; Enoksson, P.; Stemme, G. Miniaturized pressure sensor using a free hanging strain-gauge with leverage effect for increased sensitivity. In Transducers ’01 Eurosensors XV: The 11th International Conference on Solid-State Sensors and Actuators, 10–14 June 2001, Munich, Germany; Springer: Berlin/Heidelberg, Germany, 2001; pp. 494–497. [Google Scholar]

- Melvås, P. Ultraminiaturized Pressure Sensor for Catheter Based Applications. Doctoral dissertation, KTH, Stockholm, Sweden, 2002. [Google Scholar]

- Rogers, T.; Kowal, J. Selection of glass, anodic bonding conditions and material compatibility for silicon-glass capacitive sensors. Sens. Actuators A Phys. 1995, 46, 113–120. [Google Scholar] [CrossRef]

- Henmi, H.; Shoji, S.; Shoji, Y.; Yoshimi, K.; Esashi, M. Vacuum packaging for microsensors by glass-silicon anodic bonding. Sens. Actuators A Phys. 1994, 43, 243–248. [Google Scholar] [CrossRef]

- Kameda, M.; Seki, H.; Makoshi, T.; Amao, Y.; Nakakita, K. A fast-response pressure sensor based on a dye-adsorbed silica nanoparticle film. Sens. Actuators B Chem. 2012, 171, 343–349. [Google Scholar] [CrossRef]

- Haga, Y. A fiber-optic ultra-miniature pressure sensor. In Proceedings of the Technical Digest of the 12th Sensor Symposium, Osaka, Japan, 8–12 August 1994; pp. 135–138. [Google Scholar]

- Katsumata, T.; Haga, Y.; Minami, K.; Esashi, M. Micromachined 125μm diameter ultra miniature fiber-optic pressure sensor for catheter. IEEJ Trans. Sens. Micromach. 2000, 120, 58–63. [Google Scholar] [CrossRef]

- Toda, R.; Minami, K.; Esashi, M. Thin-beam bulk micromachining based on RIE and xenon difluoride silicon etching. Sens. Actuators A Phys. 1998, 66, 268–272. [Google Scholar] [CrossRef]

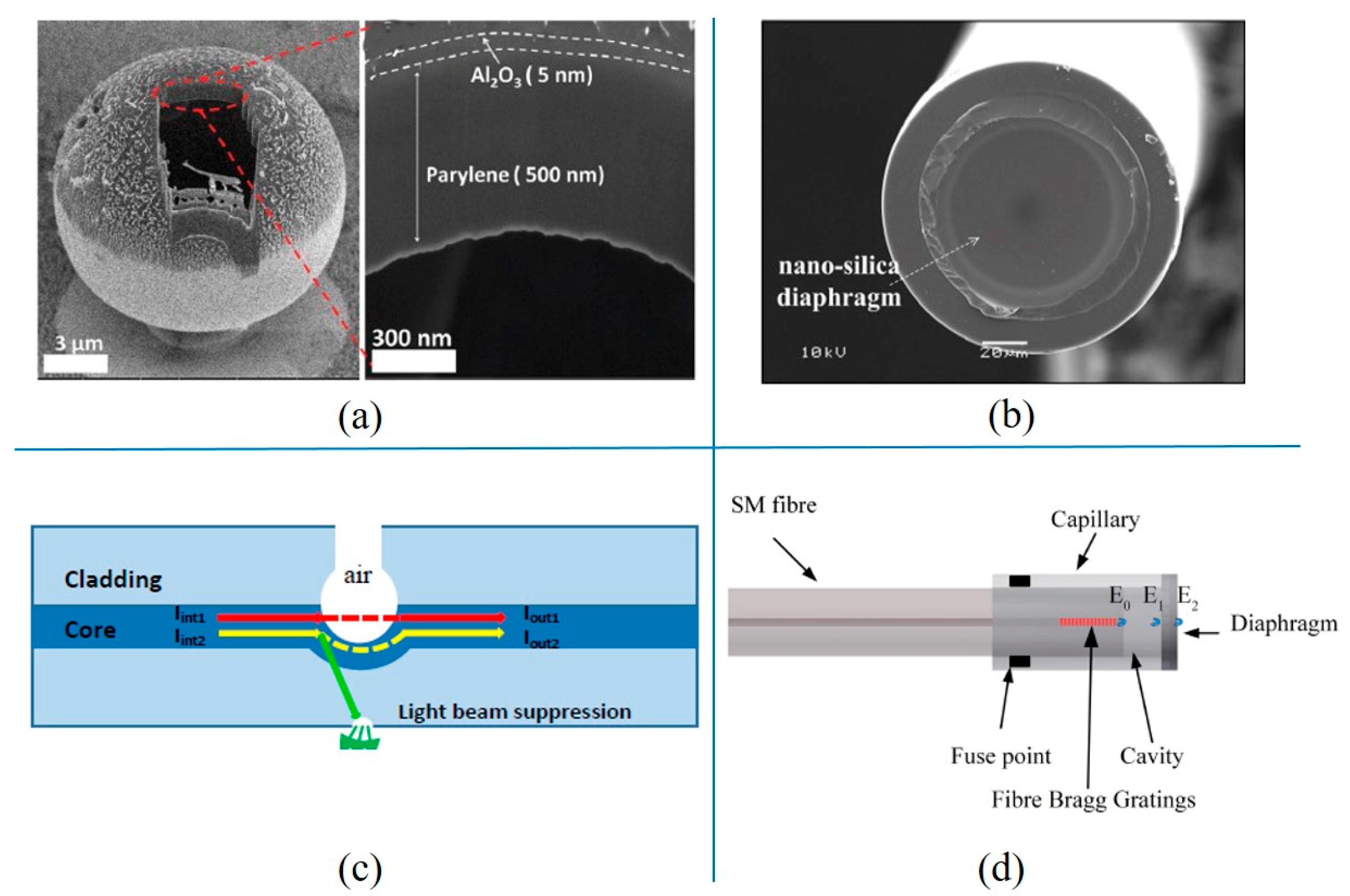

- Wu, J.; Yao, M.; Xiong, F.; Zhang, A.P.; Tam, H.-Y.; Wai, P.K.A. Optical Fiber-Tip Fabry–Pérot Interferometric Pressure Sensor Based on an In Situ μ-Printed Air Cavity. J. Light. Technol. 2018, 36, 3618–3623. [Google Scholar] [CrossRef]

- Nemani, K.V.; Moodie, K.L.; Brennick, J.B.; Su, A.; Gimi, B. In vitro and in vivo evaluation of SU-8 biocompatibility. Mater. Sci. Eng. C 2013, 33, 4453–4459. [Google Scholar] [CrossRef]

- Wang, T.; Ge, Y.; Ni, H.; Chang, J.; Zhang, J.; Ke, W. Miniature fiber pressure sensor based on an in-fiber confocal cavity. Optik 2018, 171, 869–875. [Google Scholar] [CrossRef]

- Wang, T.; Wang, M.; Ni, H. Micro-Fabry–Pérot Interferometer with High Contrast Based on an In-Fiber Ellipsoidal Cavity. IEEE Photonic Technol. Lett. 2012, 24, 948–950. [Google Scholar] [CrossRef]

- Quigley, H.A.; Broman, A.T. The number of people with glaucoma worldwide in 2010 and 2020. Br. J. Ophthalmol. 2006, 90, 262–267. [Google Scholar] [CrossRef] [Green Version]

- Walsh, A.C. Binocular Optical Coherence Tomography. Ophthalmic Surgery Lasers Imaging Retin. 2011, 42, S95–S105. [Google Scholar] [CrossRef]

- Chen, P.-J.; Rodger, D.; Saati, S.; Humayun, M.; Tai, Y.-C. Microfabricated Implantable Parylene-Based Wireless Passive Intraocular Pressure Sensors. J. Microelectromech. Syst. 2008, 17, 1342–1351. [Google Scholar] [CrossRef]

- Chen, P.-J.; Rodger, D.C.; Humayun, M.S.; Tai, Y.-C. Unpowered spiral-tube parylene pressure sensor for intraocular pressure sensing. Sens. Actuators A Phys. 2006, 127, 276–282. [Google Scholar] [CrossRef]

- Cao, H. Intraocular Pressure (IOP) Passive Sensor Modeling, Design, Fabrication and Measurement. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2008. [Google Scholar]

- Cao, H.; Weber, R.J.; Hamouche, N.G. A passive intraocular pressure sensor and a wireless sensing technique using an intermediate LC resonator. In Proceedings of the 2011 IEEE/NIH Life Science Systems and Applications Workshop (LiSSA), Bethesda, MD, USA, 7–8 April 2011; pp. 5–8. [Google Scholar]

- He, X.L.; Garcia-Gancedo, L.; Jin, P.C.; Zhou, J.; Wang, W.B.; Dong, S.R.; Luo, J.K.; Flewitt, A.J.; Milne, W.I. Film bulk acoustic resonator pressure sensor with self temperature reference. J. Micromech. Microeng. 2012, 22, 125005. [Google Scholar] [CrossRef]

- Pedroós, J.; Garciía-Gancedo, L.; Ford, C.J.B.; Barnes, C.H.W.; Griffiths, J.P.; Jones, G.A.C.; Flewitt, A. Guided propagation of surface acoustic waves and piezoelectric field enhancement in ZnO/GaAs systems. J. Appl. Phys. 2011, 110, 103501. [Google Scholar] [CrossRef]

- Garcia-Gancedo, L.; Pedrós, J.; Zhao, X.; Ashley, G.; Flewitt, A.; Milne, W.; Ford, C.; Lu, J.; Luo, J. Dual-mode thin film bulk acoustic wave resonators for parallel sensing of temperature and mass loading. Biosens. Bioelectron. 2012, 38, 369–374. [Google Scholar] [CrossRef]

- Shahiri-Tabarestani, M.; Ganji, B.A.; Sabbaghi-Nadooshan, R. Design and simulation of new micro-electromechanical pressure sensor for measuring intraocular pressure. In Proceedings of the 2012 16th IEEE Mediterranean Electrotechnical Conference, Yasmine Hammamet, Tunisia, 25–28 March 2012; pp. 208–211. [Google Scholar]

- Shahiri-Tabarestani, M.; Ganji, B.A.; Sabbaghi-Nadooshan, R. Design and simulation of high sensitive capacitive pressure sensor with slotted diaphragm. In Proceedings of the 2012 International Conference on Biomedical Engineering (ICoBE), Penang, Malaysia, 27–28 February 2012; pp. 484–489. [Google Scholar]

- Zang, X.; Jiang, Y.; Wang, X.; Wang, X.; Ji, J.; Xue, M. Highly sensitive pressure sensors based on conducting polymer-coated paper. Sens. Actuators B Chem. 2018, 273, 1195–1201. [Google Scholar] [CrossRef]

- Ha, D.; de Vries, W.N.; John, S.W.; Irazoqui, P.P.; Chappell, W.J. Polymer based miniature flexible capacitive pressure sensor for intraocular pressure (IOP) monitoring inside a mouse eye. Biomed. Microdevices 2012, 14, 207–215. [Google Scholar] [CrossRef]

- Chow, E.Y.; Chlebowski, A.L.; Irazoqui, P.P. A Miniature-Implantable RF-Wireless Active Glaucoma Intraocular Pressure Monitor. IEEE Trans. Biomed. Circuits Syst. 2010, 4, 340–349. [Google Scholar] [CrossRef]

- Bello, S.A.; Passaglia, C.L. A Wireless Pressure Sensor for Continuous Monitoring of Intraocular Pressure in Conscious Animals. Ann. Biomed. Eng. 2017, 45, 2592–2604. [Google Scholar] [CrossRef]

- Gopinath, S.P.; Cherian, L.; Robertson, C.S.; Narayan, R.K.; Grossman, R.G. Evaluation of a microsensor intracranial pressure transducer. J. Neurosci. Methods 1993, 49, 11–15. [Google Scholar] [CrossRef]

- Raboel, P.H.; Bartek, J.; Andresen, M.; Bellander, B.M.; Romner, B. Intracranial Pressure Monitoring: Invasive versus Non-Invasive Methods—A Review. Crit. Care Res. Pract. 2012, 2012, 1–14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, X.; Yao, Y.; Ma, J.; Zhang, Y.; Wang, Q.; Zhang, Z.; Ren, T. Micro packaged MEMS pressure sensor for intracranial pressure measurement. J. Semicond. 2015, 36, 064009. [Google Scholar] [CrossRef]

- Fernandes, H.M.; Bingham, K.; Chambers, I.R.; Mendelow, A.D. Clinical evaluation of the Codman microsensor intracranial pressure monitoring system. Acta Neurochir. Suppl. 1998, 71, 44–46. [Google Scholar] [PubMed]

- Bo, P.; Zhao-Hua, Z.; Tian-Ling, R. Simulation and design of micro pressure sensors applied to measure the intracranial pressure. In Proceedings of the The 8th Annual IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Suzhou, China, 7–10 April 2013; pp. 120–123. [Google Scholar]

- Li, Y.; Zhang, W.; Li, F. A miniature Fabry-Perot pressure sensor for intracranial pressure measurement. In Proceedings of the 9th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Waikiki Beach, HI, USA, 13–16 April 2014; pp. 444–447. [Google Scholar]

- Borges-González, J.; Kousseff, C.J.; Nielsen, C.B. Organic semiconductors for biological sensing. J. Mater. Chem. C 2019, 7, 1111–1130. [Google Scholar] [CrossRef]

- Potkay, J.A. Long term, implantable blood pressure monitoring systems. Biomed. Microdevices 2008, 10, 379–392. [Google Scholar] [CrossRef]

- Yang, C.; Zhao, C.; Wold, L.; Kaufman, K.R. Biocompatibility of a physiological pressure sensor. Biosens. Bioelectron. 2003, 19, 51–58. [Google Scholar] [CrossRef]

- Timme, H.-J. Monolithic pressure sensor microsystems. In Proceedings of the Digest Tech Papers Sensor 97, 8th Int Congress for Sensors, Transducers & Systems, Nurnberg, Germany, 13–15 May 1997; pp. 65–70. [Google Scholar]

- Scheiter, T.; Kapels, H.; Oppermann, K.-G.; Steger, M.; Hierold, C.; Werner, W.; Timme, H.-J. Full integration of a pressure-sensor system into a standard BiCMOS process. Sens. Actuators A Phys. 1998, 67, 211–214. [Google Scholar] [CrossRef]

- Clausen, I.; Moe, S.T.; Tvedt, L.G.W.; Vogl, A.; Wang, D.T. A miniaturized pressure sensor with inherent biofouling protection designed for in vivo applications. In Proceedings of the 2011 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Boston, MA, USA, 30 August–3 September 2011; Volume 2011, pp. 1880–1883. [Google Scholar]

- Kang, S.-K.; Murphy, R.K.J.; Hwang, S.-W.; Lee, S.M.; Harburg, D.V.; Krueger, N.A.; Shin, J.; Gamble, P.; Cheng, H.; Yu, S.; et al. Bioresorbable silicon electronic sensors for the brain. Nature 2016, 530, 71–76. [Google Scholar] [CrossRef]

- Hwang, S.-W.; Tao, H.; Kim, D.-H.; Cheng, H.; Song, J.-K.; Rill, E.; Brenckle, M.A.; Panilaitis, B.; Won, S.M.; Kim, Y.-S.; et al. A physically transient form of silicon electronics. Science 2012, 337, 1640–1644. [Google Scholar] [CrossRef] [Green Version]

- Bettinger, C.J.; Bao, Z. Organic thin-film transistors fabricated on resorbable biomaterial substrates. Adv. Mater. 2010, 22, 651–655. [Google Scholar] [CrossRef] [Green Version]

- Irimia-Vladu, M. “Green” electronics: Biodegradable and biocompatible materials and devices for sustainable future. Chem. Soc. Rev. 2014, 43, 588–610. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, C.-H.; Zorman, C.; Mehregany, M. Fabrication and testing of bulk micromachined silicon carbide piezoresistive pressure sensors for high temperature applications. IEEE Sens. J. 2006, 6, 316–324. [Google Scholar]

- Eswaran, P.; Malarvizhi, S. Design Analysis of MEMS Capacitive Differential Pressure Sensor for Aircraft Altimeter. Int. J. Appl. Phys. Math. 2012, 2, 14–20. [Google Scholar] [CrossRef] [Green Version]

- Eswaran, P.; Malarvizhi, S. Simulation Analysis of MEMS Based Capacitive Differential Pressure Sensor for Aircraft Application. Adv. Mater. Res. 2011, 403, 4152–4156. [Google Scholar] [CrossRef]

- Senesky, D.; Jamshidi, B.; Cheng, K.B.; Pisano, A. Harsh Environment Silicon Carbide Sensors for Health and Performance Monitoring of Aerospace Systems: A Review. IEEE Sens. J. 2009, 9, 1472–1478. [Google Scholar] [CrossRef]

- Shor, J.; Goldstein, D.; Kurtz, A. Characterization of n-type beta -SiC as a piezoresistor. IEEE Trans. Electron Devices 1993, 40, 1093–1099. [Google Scholar] [CrossRef]

- Nguyen, T.-K.; Phan, H.-P.; Dinh, T.; Foisal, A.R.M.; Nguyen, N.-T.; Dao, D.V. High-temperature tolerance of the piezoresistive effect in p-4H-SiC for harsh environment sensing. J. Mater. Chem. C 2018, 6, 8613–8617. [Google Scholar] [CrossRef]

- Azevedo, R.G.; Jones, D.G.; Jog, A.V.; Jamshidi, B.; Myers, D.R.; Chen, L.; Fu, X.-A.; Mehregany, M.; Wijesundara, M.B.J.; Pisano, A.P. A SiC MEMS Resonant Strain Sensor for Harsh Environment Applications. IEEE Sens. J. 2007, 7, 568–576. [Google Scholar] [CrossRef]

- Tang, W.C.; Nguyen, T.-C.H.; Howe, R.T. Laterally Driven Polysilicon Resonant Microstructures. Sens. Actuators 1989, 20, 25–32. [Google Scholar] [CrossRef]

- Li, M.; Deng, J.; Gao, S. Novel touch mode capacitive pressure sensor based on SiC. In Proceedings of the 2009 9th International Conference on Electronic Measurement & Instruments, Chengdu, China, 16–19 August 2011; Volume 1, pp. 333–335. [Google Scholar]

- Bhat, K.N.; Nayak, M.M.; Kumar, V.; Thomas, L.; Manish, S.; Thyagarajan, V.; Pandian; Jeyabal; Gaurav, S.; Gurudat; et al. Design, Development, Fabrication, Packaging, and Testing of MEMS Pressure Sensors for Aerospace Applications. In Micro and Smart Devices and Systems; Springer: Berlin/Heidelberg, Germany, 2014; pp. 3–17. [Google Scholar]

- Lee, K.I.; Nayak, M.; Takao, H.; Sawada, K.; Ishida, M.; Rajanna, K. MEMS based high dose radiation resistant SOI pressure sensor for aerospace applications. Sens. Mater. 2005, 17, 237–247. [Google Scholar]

- Pulliam, W.J.; Russler, P.M.; Mlcak, R.; Murphy, K.A.; Kozikowski, C.L. Micromachined SiC fiber optic pressure sensors for high-temperature aerospace applications. Environ. Ind. Sens. 2000, 4202, 21–30. [Google Scholar]

- Fleming, W. Overview of automotive sensors. IEEE Sens. J. 2001, 1, 296–308. [Google Scholar] [CrossRef]

- Zhou, M.-X.; Huang, Q.-A.; Qin, M.; Zhou, W. A novel capacitive pressure sensor based on sandwich structures. J. Microelectromech. Syst. 2005, 14, 1272–1282. [Google Scholar] [CrossRef]

- Chen, H.; Buric, M.; Ohodnicki, P.R.; Nakano, J.; Liu, B.; Chorpening, B.T. Review and perspective: Sapphire optical fiber cladding development for harsh environment sensing. Appl. Phys. Rev. 2018, 5, 11102. [Google Scholar] [CrossRef]

- Foo, H.T.C.; Ebendorff-Heidepriem, H.; Sumby, C.J.; Monro, T.M. Towards microstructured optical fibre sensors: Surface analysis of silanised lead silicate glass. J. Mater. Chem. C 2013, 1, 6782. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Liao, C.; Wang, Y.; Xu, L.; Wang, N.; Dong, X.; Liu, S.; Wang, Q.; Yang, K.; Zhou, J. Highly-sensitive gas pressure sensor using twin-core fiber based in-line Mach-Zehnder interferometer. Opt. Express 2015, 23, 6673–6678. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, N.; Mastrangelo, C.H. Microballoon pressure sensors for particle imaging manometry in liquid and gaseous media. Analyst 2016, 141, 1413–1420. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Liao, C.; Wang, Y.; He, J.; Fu, C.; Yang, K.; Bai, Z.; Zhang, F. Nano silica diaphragm in-fiber cavity for gas pressure measurement. Sci. Rep. 2017, 7, 787. [Google Scholar] [CrossRef]

- Talataisong, W.; Wang, D.N.; Chitaree, R.; Liao, C.R.; Wang, C. High-pressure sensor based on fiber in-line Mach-Zehnder interferometer. In Proceedings of the 24th International Conference on Optical Fibre Sensors, Curitiba, Brazil, 28 September–2 October 2015; Volume 9634, p. 96345. [Google Scholar]

- Duraibabu, D.B.; Poeggel, S.; Omerdic, E.; Capocci, R.; Lewis, E.; Newe, T.; Leen, G.; Toal, D.; Dooly, G. An Optical Fibre Depth (Pressure) Sensor for Remote Operated Vehicles in Underwater Applications. Sensors 2017, 17, 406. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Liang, T.; Wang, W.; Hong, Y.; Zheng, T.; Xiong, J. A novel SOI pressure sensor for high temperature application. J. Semicond. 2015, 36, 14014. [Google Scholar] [CrossRef]

- Liu, G.; Gao, C.; Hu, H.; Hao, Y.; Zhang, F.; Zhang, Y.; Cui, W. Silicon on insulator pressure sensor based on a thermostable electrode for high temperature applications. Micro Nano Lett. 2015, 10, 496–499. [Google Scholar] [CrossRef]

- Zou, H.; Wang, J.; Li, X. High-Performance Low-Range Differential Pressure Sensors Formed with a Thin-Film Under Bulk Micromachining Technology. J. Microelectromech. Syst. 2017, 26, 879–885. [Google Scholar] [CrossRef]

- Yu, F.; Xu, P.; Wang, J.; Li, X. Length-extensional resonating gas sensors with IC-foundry compatible low-cost fabrication in non-SOI single-wafer. Microelectron. Eng. 2015, 136, 1–7. [Google Scholar] [CrossRef]

- Wang, J.C.; Xia, X.Y.; Zou, H.S.; Song, F.; Li, X. Piezoresistive pressure sensor with dual-unit configuration for on-chip self-compensation and suppression of temperature drift. In Proceedings of the 2013 Transducers & Eurosensors XXVII: The 17th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS & EUROSENSORS XXVII), Barcelona, Spain, 16–20 June 2013; pp. 1763–1766. [Google Scholar]

- Wang, J.; Li, X. Single-Side Fabricated Pressure Sensors for IC-Foundry-Compatible, High-Yield, and Low-Cost Volume Production. IEEE Electron Device Lett. 2011, 32, 979–981. [Google Scholar] [CrossRef]

- Ni, Z.; Jiao, D.; Zou, H.; Wang, J.; Li, X. 0.4mm×0.4mm barometer sensor-chip fabricated by a scar-free ‘MIS’ (minimally invasive surgery) process for 0.01US$/die product. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 774–777. [Google Scholar]

- Wei, C.; Zhou, W.; Wang, Q.; Xia, X.; Li, X. TPMS (tire-pressure monitoring system) sensors: Monolithic integration of surface-micromachined piezoresistive pressure sensor and self-testable accelerometer. Microelectron. Eng. 2012, 91, 167–173. [Google Scholar] [CrossRef]

- Bowen, C.; Arafa, M. Energy harvesting technologies for tire pressure monitoring systems. Adv. Energy Mater. 2015, 5, 1401787. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Li, X. A dual-unit pressure sensor for on-chip self-compensation of zero-point temperature drift. J. Micromech. Microeng. 2014, 24, 85010. [Google Scholar] [CrossRef]

- Wang, J.; Li, X. A high-performance P-in-G sensor with multiple-level 3D micro-structure fabricated from one side of single wafer. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 172–175. [Google Scholar]

- Nagaraju, M.B.; Lingley, A.R.; Sridharan, S.; Gu, J.; Ruby, R.; Otis, B.P. 27.4 A 0.8 mm3 ±0.68 psi single-chip wireless pressure sensor for TPMS applications. In Proceedings of the 2015 IEEE International Solid-State Circuits Conference—(ISSCC) Digest of Technical Papers, San Francisco, CA, USA, 22–26 February 2015; pp. 1–3. [Google Scholar]

- Wang, J.; Li, X. Single-Side Fabrication of Multilevel 3-D Microstructures for Monolithic Dual Sensors. J. Microelectromech. Syst. 2015, 24, 531–533. [Google Scholar] [CrossRef]

- Zhang, Y.-H.; Yang, C.; Zhang, Z.-H.; Lin, H.-W.; Liu, L.-T.; Ren, T.-L. A Novel Pressure Microsensor with 30-μm-Thick Diaphragm and Meander-Shaped Piezoresistors Partially Distributed on High-Stress Bulk Silicon Region. IEEE Sens. J. 2007, 7, 1742–1748. [Google Scholar] [CrossRef]

- Power, M.; Thompson, A.J.; Anastasova, S.; Yang, G.-Z. A Monolithic Force-Sensitive 3D Microgripper Fabricated on the Tip of an Optical Fiber Using 2-Photon Polymerization. Small 2018, 14, 1703964. [Google Scholar] [CrossRef] [Green Version]

- Thompson, A.J.; Power, M.; Yang, G.-Z. Micro-scale fiber-optic force sensor fabricated using direct laser writing and calibrated using machine learning. Opt. Express 2018, 26, 14186–14200. [Google Scholar] [CrossRef] [PubMed]

- Horowitz, S.; Nishida, T.; Cattafesta, L.; Sheplak, M. Development of a micromachined piezoelectric microphone for aeroacoustics applications. J. Acoust. Soc. Am. 2007, 122, 3428. [Google Scholar] [CrossRef] [PubMed]

- Kressmann, R.; Klaiber, M.; Hess, G. Silicon condenser microphones with corrugated silicon oxide/nitride electret membranes. Sens. Actuators A Phys. 2002, 100, 301–309. [Google Scholar] [CrossRef]

- Lu, X.; Wu, Y.; Gong, Y.; Rao, Y.-J. A Miniature Fiber-Optic Microphone Based on an Annular Corrugated MEMS Diaphragm. J. Light. Technol. 2018, 36, 5224–5229. [Google Scholar] [CrossRef]

- Sniegowski, J.; Rodgers, M. Multi-layer enhancement to polysilicon surface-micromachining technology. In Proceedings of the International Electron Devices Meeting, IEDM Technical Digest, Washington, DC, USA, 10 December 1997; pp. 903–906. [Google Scholar]

- Martin, D.T.; Liu, J.; Kadirvel, K.; Fox, R.M.; Sheplak, M.; Nishida, T. A Micromachined Dual-Backplate Capacitive Microphone for Aeroacoustic Measurements. J. Microelectromech. Syst. 2007, 16, 1289–1302. [Google Scholar] [CrossRef]

- Cotton, D.P.J.; Graz, I.M.; Lacour, S.P. A Multifunctional Capacitive Sensor for Stretchable Electronic Skins. IEEE Sens. J. 2009, 9, 2008–2009. [Google Scholar] [CrossRef]

- Cai, F.; Yi, C.; Liu, S.; Wang, Y.; Liu, L.; Liu, X.; Xu, X.; Wang, L. Ultrasensitive, passive and wearable sensors for monitoring human muscle motion and physiological signals. Biosens. Bioelectron. 2016, 77, 907–913. [Google Scholar] [CrossRef]

- Vlassis, S.; Laopoulos, T.; Siskos, S. Pressure sensors interfacing circuit with digital output. IEE Proc. Circuits Devices Syst. 1998, 145, 332. [Google Scholar] [CrossRef]

- Timoshenko, S.P.; Woinowsky-Krieger, S. Theory of Plates and Shells; McGraw-Hill: New York, NY, USA, 1959. [Google Scholar]

- Corradetti, A.; Leoni, R.; Carluccio, R.; Fortunato, G.; Reita, C.; Plais, F.; Pribat, D. Evidence of carrier number fluctuation as origin of 1/f noise in polycrystalline silicon thin film transistors. Appl. Phys. Lett. 1995, 67, 1730–1732. [Google Scholar] [CrossRef]

- DelRio, F.W.; Cook, R.F.; Boyce, B.L. Fracture strength of micro- and nano-scale silicon components. Appl. Phys. Rev. 2015, 2, 021303. [Google Scholar] [CrossRef] [Green Version]

- Clark, S.; Wise, K. Pressure sensitivity in anisotropically etched thin-diaphragm pressure sensors. IEEE Trans. Electron Devices 1979, 26, 1887–1896. [Google Scholar] [CrossRef]

- Gad-el-Hak, M. The MEMS Handbook; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Chau, H.-L.; Wise, K. Noise due to Brownian motion in ultrasensitive solid-state pressure sensors. IEEE Trans. Electron Devices 1987, 34, 859–865. [Google Scholar] [CrossRef]

- Bhat, K.; Nayak, M. MEMS pressure sensors-an overview of challenges in technology and packaging. J. Smart Struct. Syst. 2013, 2, 1–10. [Google Scholar]

- Barth, P.W. Silicon fusion bonding for fabrication of sensors, actuators and microstructures. Sens. Actuators A Phys. 1990, 23, 919–926. [Google Scholar] [CrossRef]

- Xu, T.; Hebibul, R.; Jiang, Z.; Ding, J.; Peng, N.; Wang, H.; Zhao, L.; Zhao, Y.; Guo, X.; Xu, Y. A bossed diaphragm piezoresistive pressure sensor with a peninsula–island structure for the ultra-low-pressure range with high sensitivity. Meas. Sci. Technol. 2016, 27, 124012. [Google Scholar] [CrossRef]

- Li, C.; Xie, J.; Cordovilla, F.; Zhou, J.; Jagdheesh, R.; Ocaña, J.L.; Radhakrishnan, J. Design, fabrication and characterization of an annularly grooved membrane combined with rood beam piezoresistive pressure sensor for low pressure measurements. Sens. Actuators A Phys. 2018, 279, 525–536. [Google Scholar] [CrossRef]

- Toriyama, T.; Tanimoto, Y.; Sugiyama, S. Single crystal silicon nano-wire piezoresistors for mechanical sensors. J. Microelectromech. Syst. 2002, 11, 605–611. [Google Scholar] [CrossRef]

- Milne, J.S.; Rowe, A.C.H.; Arscott, S.; Renner, C. Giant Piezoresistance Effects in Silicon Nanowires and Microwires. Phys. Rev. Lett. 2010, 105, 226802. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Chen, S.; Lin, Y.; Yuan, X.; Liu, L. Silver nanowires coated on cotton for flexible pressure sensors. J. Mater. Chem. C 2016, 4, 935–943. [Google Scholar] [CrossRef]

- Chen, Y.; An, X.; Liao, X. Mechanical behaviors of nanowires. Appl. Phys. Rev. 2017, 4, 031104. [Google Scholar] [CrossRef]

- Grzelak, J.; Sulowska, K.; Leśniewski, A.; Rozniecka, E.; Janczuk-Richter, M.; Richter, Ł.; Łoś, M.; Jönsson-Niedziółka, M.; Maćkowski, S.; Niedziółka-Jönsson, J. Capturing fluorescing viruses with silver nanowires. Sens. Actuators B Chem. 2018, 273, 689–695. [Google Scholar] [CrossRef]

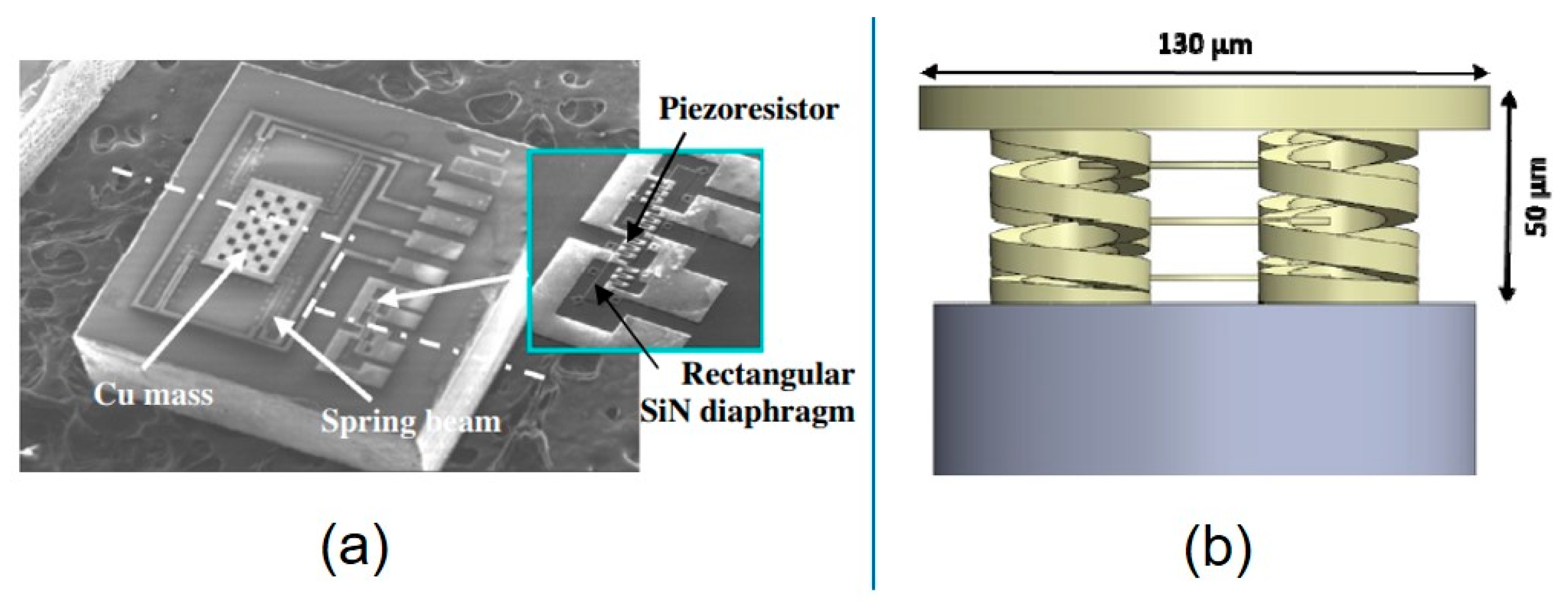

- Lou, L.; Zhang, S.; Lim, L.; Park, W.-T.; Feng, H.; Kwong, D.-L.; Lee, C. Characteristics of NEMS Piezoresistive Silicon Nanowires Pressure Sensors With various Diaphragm Layers. Procedia Eng. 2011, 25, 1433–1436. [Google Scholar] [CrossRef] [Green Version]

- Lou, L.; Zhang, S.; Park, W.-T.; Tsai, J.M.; Kwong, D.-L.; Lee, C. Optimization of NEMS pressure sensors with a multilayered diaphragm using silicon nanowires as piezoresistive sensing elements. J. Micromech. Microeng. 2012, 22, 55012. [Google Scholar] [CrossRef]

- Bi, J.; Wei, G.; Wang, L.; Gao, F.; Zheng, J.; Tang, B.; Yang, W. Highly sensitive piezoresistance behaviors of n-type 3C-SiC nanowires. J. Mater. Chem. C 2013, 1, 4514. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly Stretchable and Sensitive Strain Sensor Based on Silver Nanowire–Elastomer Nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef] [PubMed]

- Kushner, M.J. Modelling of microdischarge devices: Plasma and gas dynamics. J. Phys. D: Appl. Phys. 2005, 38, 1633–1643. [Google Scholar] [CrossRef]

- Foest, R.; Schmidt, M.; Becker, K. Microplasmas, an emerging field of low-temperature plasma science and technology. Int. J. Mass Spectrom. 2006, 248, 87–102. [Google Scholar] [CrossRef]

- Dau, V.T.; Bui, T.T.; Dinh, T.X.; Terebessy, T. Pressure sensor based on bipolar discharge corona configuration. Sens. Actuators A Phys. 2016, 237, 81–90. [Google Scholar] [CrossRef]

- Luo, X.; Gianchandani, Y.B. A Microdischarge-Based Pressure Sensor Fabricated Using Through-Wafer Isolated Bulk-Silicon Lead Transfer. J. Microelectromech. Syst. 2018, 27, 365–373. [Google Scholar] [CrossRef]

- Eun, C.K.; Luo, X.; Wang, J.-C.; Xiong, Z.; Kushner, M.; Gianchandani, Y. A Microdischarge-Based Monolithic Pressure Sensor. J. Microelectromech. Syst. 2014, 23, 1300–1310. [Google Scholar] [CrossRef]

- Luo, X.; Eun, C.K.; Gianchandani, Y.B. Fabrication of a monolithic microdischarge-based pressure sensor for harsh environments. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 64–67. [Google Scholar]

- Wright, S.; Gianchandani, Y. Discharge-Based Pressure Sensors for High-Temperature Applications Using Three-Dimensional and Planar Microstructures. J. Microelectromech. Syst. 2009, 18, 736–743. [Google Scholar] [CrossRef]

- Wright, S.; Zipperian, H.; Gianchandani, Y. A 15 ATM. Pressure Sensor Utilizing Microdischarges in a 1.6 mm3 Ceramic Package. Available online: http://gianchandani.engin.umich.edu/wp-content/uploads/sites/360/2018/01/HH10_DischPressure_Wright.pdf (accessed on 30 December 2019).

- Wright, S.A.; Harvey, H.Z.; Gianchandani, Y.B. A microdischarge based deflecting-cathode pressure sensor in a ceramic package. J. Microelectromech. Syst. 2013, 22, 80–86. [Google Scholar] [CrossRef]

- Popov, V.N. Carbon nanotubes: Properties and application. Mater. Sci. Eng. R: Rep. 2004, 43, 61–102. [Google Scholar] [CrossRef]

- Wang, C.; Madou, M. From MEMS to NEMS with carbon. Biosens. Bioelectron. 2005, 20, 2181–2187. [Google Scholar] [CrossRef] [PubMed]

- Katageri, A.C.; Sheeparamatti, B. Design and Simulation of Carbon Nanotube based Piezoresistive Pressure Sensor for Patient Monitoring Application. In Proceedings of the Eighth ISSS National Conference on MEMS, Smart Materials, Structures and Systems, Kanpur, India, 28–30 September 2016; pp. 28–30. [Google Scholar]

- Rahman, S.A.; Soin, N.; Ibrahim, F. Analysis of MEMS diaphragm of piezoresistive intracranial pressure sensor. In Proceedings of the 2014 IEEE Conference on Biomedical Engineering and Sciences (IECBES), Kuala Lumpur, Malaysia, 8–10 December 2014; pp. 681–685. [Google Scholar]

- Ponnamma, D.; Sadasivuni, K.K.; Grohens, Y.; Guo, Q.; Thomas, S. Carbon nanotube based elastomer composites—An approach towards multifunctional materials. J. Mater. Chem. C 2014, 2, 8446–8485. [Google Scholar] [CrossRef]

- Ramos, A.; García-Sánchez, P.; Morgan, H.; A-Sánchez, P.G. AC electrokinetics of conducting microparticles: A review. Curr. Opin. Colloid Interface Sci. 2016, 24, 79–90. [Google Scholar] [CrossRef] [Green Version]

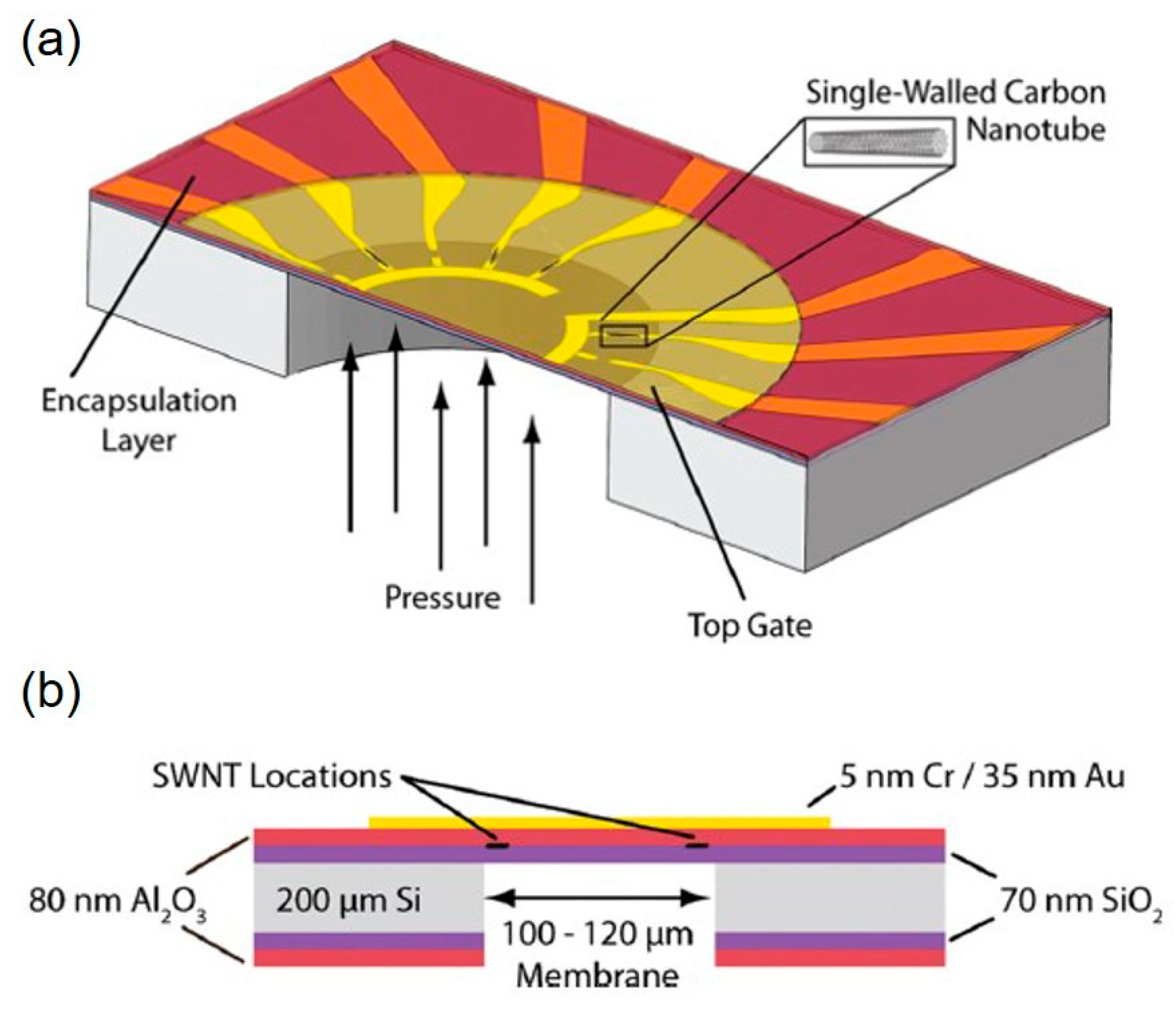

- Burg, B.R.; Helbling, T.; Hierold, C.; Poulikakos, D. Piezoresistive pressure sensors with parallel integration of individual single-walled carbon nanotubes. J. Appl. Phys. 2011, 109, 64310. [Google Scholar] [CrossRef]

- Helbling, T.; Drittenbass, S.; Durrer, L.; Román, C.; Hierold, C. Ultra Small Single Walled Carbon Nanotube Pressure Sensors. In Proceedings of the 2009 IEEE 22nd International Conference on Micro Electro Mechanical Systems, Sorrento, Italy, 25–29 January 2009; pp. 575–578. [Google Scholar]

- Süss, T.; Liu, W.; Chikkadi, K.; Román, C.; Hierold, C. Ultra-Miniature and Low-Power Pressure Sensors Using Individual Carbon Nanotubes. J. Microelectromech. Syst. 2016, 25, 422–424. [Google Scholar] [CrossRef]

- Stampfer, C.; Jungen, A.; Hierold, C. Fabrication of discrete nanoscaled force sensors based on single-walled carbon nanotubes. IEEE Sens. J. 2006, 6, 613–617. [Google Scholar] [CrossRef]

- Durrer, L.; Helbling, T.; Zenger, C.; Jungen, A.; Stampfer, C.; Hierold, C. SWNT growth by CVD on Ferritin-based iron catalyst nanoparticles towards CNT sensors. Sens. Actuators B Chem. 2008, 132, 485–490. [Google Scholar] [CrossRef]

- Plutnar, J.; Pumera, M.; Sofer, Z. The chemistry of CVD graphene. J. Mater. Chem. C 2018, 6, 6082–6101. [Google Scholar] [CrossRef]

- Bolotin, K.; Sikes, K.; Jiang, Z.; Klima, M.; Fudenberg, G.; Hone, J.; Kim, P.; Stormer, H. Ultrahigh electron mobility in suspended graphene. Solid State Commun. 2008, 146, 351–355. [Google Scholar] [CrossRef] [Green Version]

- Morozov, S.; Novoselov, K.; Katsnelson, M.I.; Schedin, F.; Elias, D.C.; Jaszczak, J.A.; Geim, A.K. Giant Intrinsic Carrier Mobilities in Graphene and Its Bilayer. Phys. Rev. Lett. 2008, 100, 016602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Loh, K.P.; Bao, Q.; Ang, P.K.; Yang, J. The chemistry of graphene. J. Mater. Chem. 2010, 20, 2277. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, J.; Wang, C.; Leng, X.; Xiao, Y.; Fu, L. Synthesis of graphene and related two-dimensional materials for bioelectronics devices. Biosens. Bioelectron. 2017, 89, 28–42. [Google Scholar] [CrossRef]

- Hyeon, J.S.; Park, J.W.; Baughman, R.H.; Kim, S.J. Electrochemical graphene/carbon nanotube yarn artificial muscles. Sens. Actuators B Chem. 2019, 286, 237–242. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Lee, G.-H.; Cooper, R.C.; An, S.J.; Lee, S.; Van Der Zande, A.; Petrone, N.; Hammerberg, A.G.; Lee, C.; Crawford, B.; Oliver, W.; et al. High-Strength Chemical-Vapor-Deposited Graphene and Grain Boundaries. Science 2013, 340, 1073–1076. [Google Scholar] [CrossRef]

- Wagner, S.; Weisenstein, C.; Smith, A.; Östling, M.; Kataria, S.; Lemme, M. Graphene transfer methods for the fabrication of membrane-based NEMS devices. Microelectron. Eng. 2016, 159, 108–113. [Google Scholar] [CrossRef]

- Cho, B.; Yoon, J.; Hahm, M.G.; Kim, D.-H.; Kim, A.R.; Kahng, Y.H.; Park, S.-W.; Lee, Y.-J.; Park, S.-G.; Kwon, J.-D.; et al. Graphene-based gas sensor: Metal decoration effect and application to a flexible device. J. Mater. Chem. C 2014, 2, 5280–5285. [Google Scholar] [CrossRef]

- Ruiz-Vargas, C.S.; Zhuang, H.L.; Huang, P.Y.; Van Der Zande, A.M.; Garg, S.; McEuen, P.L.; Muller, D.A.; Hennig, R.G.; Park, J. Softened Elastic Response and Unzipping in Chemical Vapor Deposition Graphene Membranes. Nano Lett. 2011, 11, 2259–2263. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.D.; Niklaus, F.; Paussa, A.; Schröder, S.; Fischer, A.C.; Sterner, M.; Wagner, S.; Vaziri, S.; Forsberg, F.; Esseni, D.; et al. Piezoresistive Properties of Suspended Graphene Membranes under Uniaxial and Biaxial Strain in Nanoelectromechanical Pressure Sensors. ACS Nano 2016, 10, 9879–9886. [Google Scholar] [CrossRef] [PubMed]

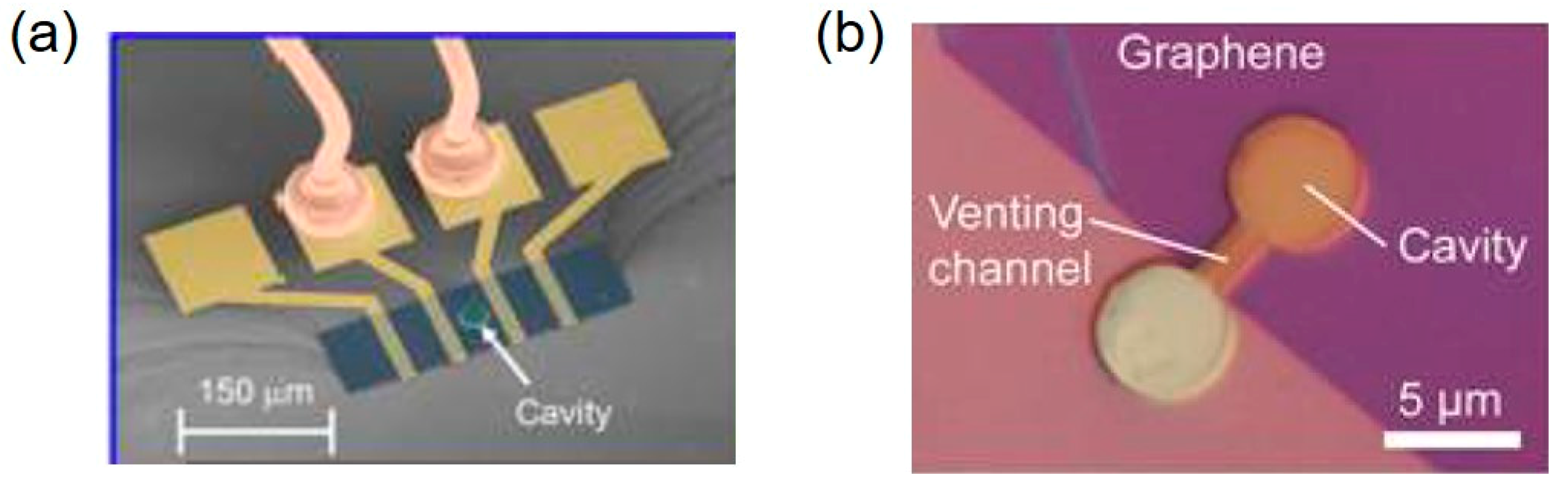

- Smith, A.D.; Niklaus, F.; Paussa, A.; Vaziri, S.; Fischer, A.C.; Sterner, M.; Forsberg, F.; Delin, A.; Esseni, D.; Palestri, P.; et al. Electromechanical Piezoresistive Sensing in Suspended Graphene Membranes. Nano Lett. 2013, 13, 3237–3242. [Google Scholar] [CrossRef] [PubMed]

- Dolleman, R.J.; Davidovikj, D.; Cartamil-Bueno, S.J.; Van Der Zant, H.S.J.; Steeneken, P.G. Graphene Squeeze-Film Pressure Sensors. Nano Lett. 2015, 16, 568–571. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, S.-E.; Ghatkesar, M.K.; Zhang, C.; Janssen, G.C.A.M. Graphene based piezoresistive pressure sensor. Appl. Phys. Lett. 2013, 102, 161904. [Google Scholar] [CrossRef] [Green Version]

- Berger, C.; Phillips, R.; Centeno, A.; Zurutuza, A.; Vijayaraghavan, A. Capacitive pressure sensing with suspended graphene–polymer heterostructure membranes. Nanoscale 2017, 9, 17439–17449. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Gao, X.; Guo, T.; Xiao, J.; Fan, S.; Jin, W. Analyzing the applicability of miniature ultra-high sensitivity Fabry–Perot acoustic sensor using a nanothick graphene diaphragm. Meas. Sci. Technol. 2015, 26, 085101. [Google Scholar] [CrossRef]

- Kwon, O.K.; Lee, J.H.; Kim, K.-S.; Kang, J.W. Developing ultrasensitive pressure sensor based on graphene nanoribbon: Molecular dynamics simulation. Phys. E Low-Dimens. Syst. Nanostruct. 2013, 47, 6–11. [Google Scholar] [CrossRef]

- Li, C.; Xiao, J.; Guo, T.; Fan, S.; Jin, W. Interference characteristics in a Fabry–Perot cavity with graphene membrane for optical fiber pressure sensors. Microsyst. Technol. 2015, 21, 2297–2306. [Google Scholar] [CrossRef]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Wearable Flexible Sensors: A Review. IEEE Sens. J. 2017, 17, 3949–3960. [Google Scholar] [CrossRef] [Green Version]

- Xu, M.; Obodo, D.; Yadavalli, V.K. The design, fabrication, and applications of flexible biosensing devices—A review. Biosens. Bioelectron. 2018, 124, 96–114. [Google Scholar] [PubMed]

| Diaphragm Material | Substrate Material | Assembly Technology |

|---|---|---|

| Single crystal silicon | Glass | Anodic bonding |

| Single crystal silicon | Silicon | Fusion bonding |

| Polysilicon | Silicon | Surface micromachining |

| Silicon nitride | Silicon | Surface micromachining |

| Polymeric materials | Silicon | Surface micromachining |

| Metal | Glass/ceramic | Eutectic bonding, soldering |

| Metal | Polymer | Polymeric seals |

| Ceramic(metalized) | Ceramic | Glass seal, metal seal |

| Polymeric materials (metalized) | Polymers | Polymeric seals, glue |

| Micromachining Methods | Transduction Mechanisms | Characteristic Dimensions (µm) | Pressure Range | Application | Reference |

|---|---|---|---|---|---|

| Bulk silicon process | CAP (Si) | 1500 × 547 × 5 | 0–140 psi | Industrial | [52] |

| Surface silicon process | PZR (Si3N4) | 100 × 100 × 0.8 | 0–300 kPa | Ultrasonic | [56,59] |

| CAP (PolySi) | 120 × 120 × 1.5 | 0–10 bar | [60] | ||

| PZR (PolySi) | 103 × 103 × 0.4 | −3–40 kPa | Blood | [88] | |

| PZR (Si) | 280 × 130 × 5 | −40–66 kPa | Blood | [89] | |

| Fiber laser micromachining | PZR (Si) | 550 × 550 × 4 | 0–10 kPa | IOP | [112] |

| Optical (Si3N4) | π6002 × 0.3 | 0–7 kPa | IOP | [2] | |

| PZR (Si) | 100 × 100 × 2 | 0–2 kPa | ICP | [122] | |

| CAP (SiC) | 200 × 200 × 0.5 | 0.2–3.5 atm | Gas turbine | [142] | |

| PZR (Si) | 750 × 750 × 210 | 0–400 bar | Aerospace | [144] | |

| Optical (parylene) | 4/3π123 × 0.4 | 0–20 Psi | Imaging | [151] | |

| Optical (fiber) | 24 × 24 | 0–8 bar | [153] | ||

| Optical (silica) | 200 × 200 × 4 | 0–5 bar | Ocean | [154] | |

| Optical (silica) | 130 × 130 × 50 | 0–10 N | Imaging | [170] | |

| DRIE with SOI | PZR (PolySi) | π802 × 1.2 | 0–100 kPa | Size demanding | [74] |

| PZR (SiO2) | 200 × 200 × 3.5 | 0–40 kPa | Medical | [78,79] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, P.; Ma, Z.; Ma, J.; Yang, L.; Wei, J.; Zhao, Y.; Zhang, M.; Yang, F.; Wang, X. Recent Progress of Miniature MEMS Pressure Sensors. Micromachines 2020, 11, 56. https://doi.org/10.3390/mi11010056

Song P, Ma Z, Ma J, Yang L, Wei J, Zhao Y, Zhang M, Yang F, Wang X. Recent Progress of Miniature MEMS Pressure Sensors. Micromachines. 2020; 11(1):56. https://doi.org/10.3390/mi11010056

Chicago/Turabian StyleSong, Peishuai, Zhe Ma, Jing Ma, Liangliang Yang, Jiangtao Wei, Yongmei Zhao, Mingliang Zhang, Fuhua Yang, and Xiaodong Wang. 2020. "Recent Progress of Miniature MEMS Pressure Sensors" Micromachines 11, no. 1: 56. https://doi.org/10.3390/mi11010056

APA StyleSong, P., Ma, Z., Ma, J., Yang, L., Wei, J., Zhao, Y., Zhang, M., Yang, F., & Wang, X. (2020). Recent Progress of Miniature MEMS Pressure Sensors. Micromachines, 11(1), 56. https://doi.org/10.3390/mi11010056