1. Introduction

The microelectromechanical systems (MEMS) vibrating gyroscope is used to measure the rotation rate of a body based on the Coriolis effect. The MEMS gyroscope has various advantages over the conventional gyroscope, such as its light weight, compact size, economical aspect, and easy integration with mainstream complimentary metal-oxide-semiconductor (CMOS) technology. The MEMS gyroscope has a variety of applications in the area of consumer electronics, navigation systems, automobiles and robot control [

1,

2,

3].

Over the past few decades, intensive research has been carried out to improve the performance of MEMS gyroscopes. This research journey started from a single-axis MEMS gyroscope capable of measuring angular rate in only one axis [

4,

5], and extended to a single-drive, 3-axis MEMS gyroscope which can measure the angular rate in all three axes [

2,

6,

7,

8,

9]. The working principle of any kind of MEMS vibratory gyroscope is based on the Coriolis effect, to realize the energy transfer between the drive and sense resonant modes [

10,

11,

12]. To meet today’s demanding industry specifications, the sound performance of the gyroscope is vital, particularly in terms of sensitivity and accuracy [

13,

14]. MEMS products have relatively more manufacturing uncertainties compared with macro-scale products. Such uncertainties affect the performance of the MEMS products [

15,

16]. Therefore, performance evaluation is necessary before fabrication to achieve a reliable design for the MEMS gyroscope.

Many efforts have been made by researchers using system-level analysis and a finite element analysis (FEA) simulation approach to estimate the mechanical sensitivity of the MEMS gyroscope. A MEMS tuning fork gyroscope (TFG) with an anchored leverage mechanism was designed and analyzed for mechanical sensitivity using the ANSYS Workbench [

14]. Three types of mechanical structures and their different spring stiffnesses were analyzed to improve the mechanical sensitivity. The computed mechanical sensitivity was validated theoretically and showed improvement by

,

, and

, respectively. A single-axis, in-plane MEMS vibratory rate gyroscope was simulated for sensitivity estimation using CoventorWare software. A maximum Coriolis displacement of

was computed by applying an input angular rate of 400 degrees per second (dps), resulting in a

scale factor [

17]. A ring gyroscope was analyzed and a maximum driving displacement of

, along with a mechanical sensitivity of

, was computed using the ANSYS Workbench [

18]. System level simulations were carried out for the drive-mode and sense-mode operations of a single-drive, 3-axis MEMS gyroscope [

19]. A system-level simulation approach was presented to estimate the effect of imperfection and fabrication errors in the MEMS gyroscope [

20]. The transient and steady responses for sense-modes, and response to angular rate were performed for a fence structured MEMS gyroscope through system level simulations in PSpice [

21]. All the aforementioned researches were either about a single-axis gyroscope or were limited to theoretical and system-level approaches.

This paper focuses on the development of an FEA simulation-based methodology, using the solid mechanics module of COMSOL Multiphysics, which can be used for the evaluation of a single-drive, 3-axis MEMS gyroscope, as well as a single-axis gyroscope. In the gyroscope development process, FEA simulation is one of the powerful and important tools to determine the design parameters and it is necessary for robust optimization [

22,

23]. Cross-axis sensitivity and quadrature error evaluation for a single-drive, 3-axis MEMS gyroscope is difficult through analytical or Matlab/Simulink analysis. However, COMSOL Multiphysics provides an easier approach for these estimations, which is comparatively more realistic and informative than other approaches. A simplified design for a single-drive, 3-axis MEMS gyroscope presented in a previous work [

24] is analyzed in this study. That simplified design of a single-drive, 3-axis MEMS gyroscope was simulated employing the established FEA methodology, and mechanical sensitivity was computed. The simulation results were validated by comparing them with system-level and analytical results, respectively.

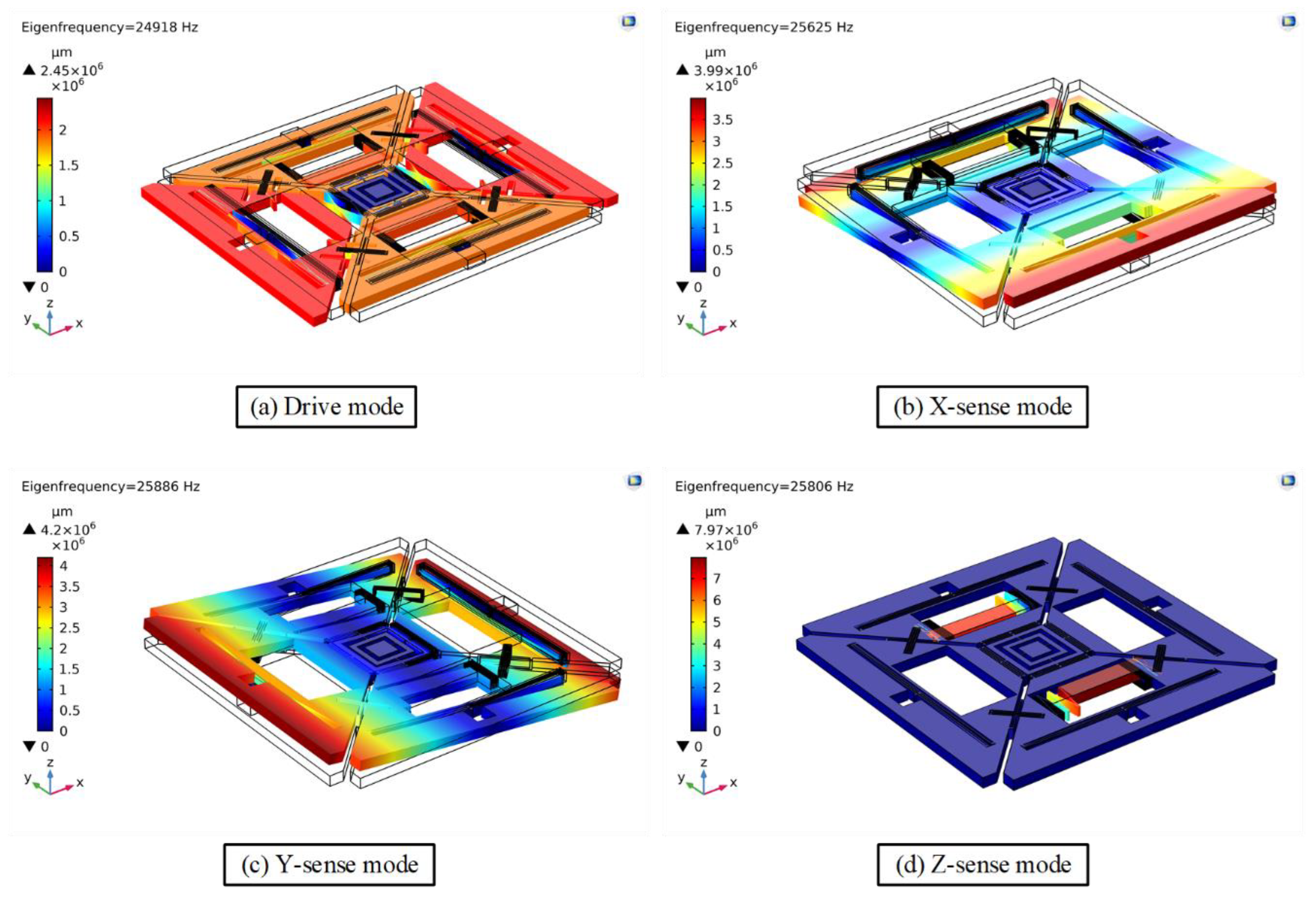

This paper is structured as follows. In

Section 2, the mechanical structure and the working principle of a single-drive, 3-axis MEMS gyroscope are presented. In

Section 3, the proposed methodology is discussed in detail, including modal analysis, drive-analysis, and mechanical sensitivity analysis using three approaches, followed by their comparison. The paper is concluded in

Section 4.

2. Mechanical Structure and Working Principle

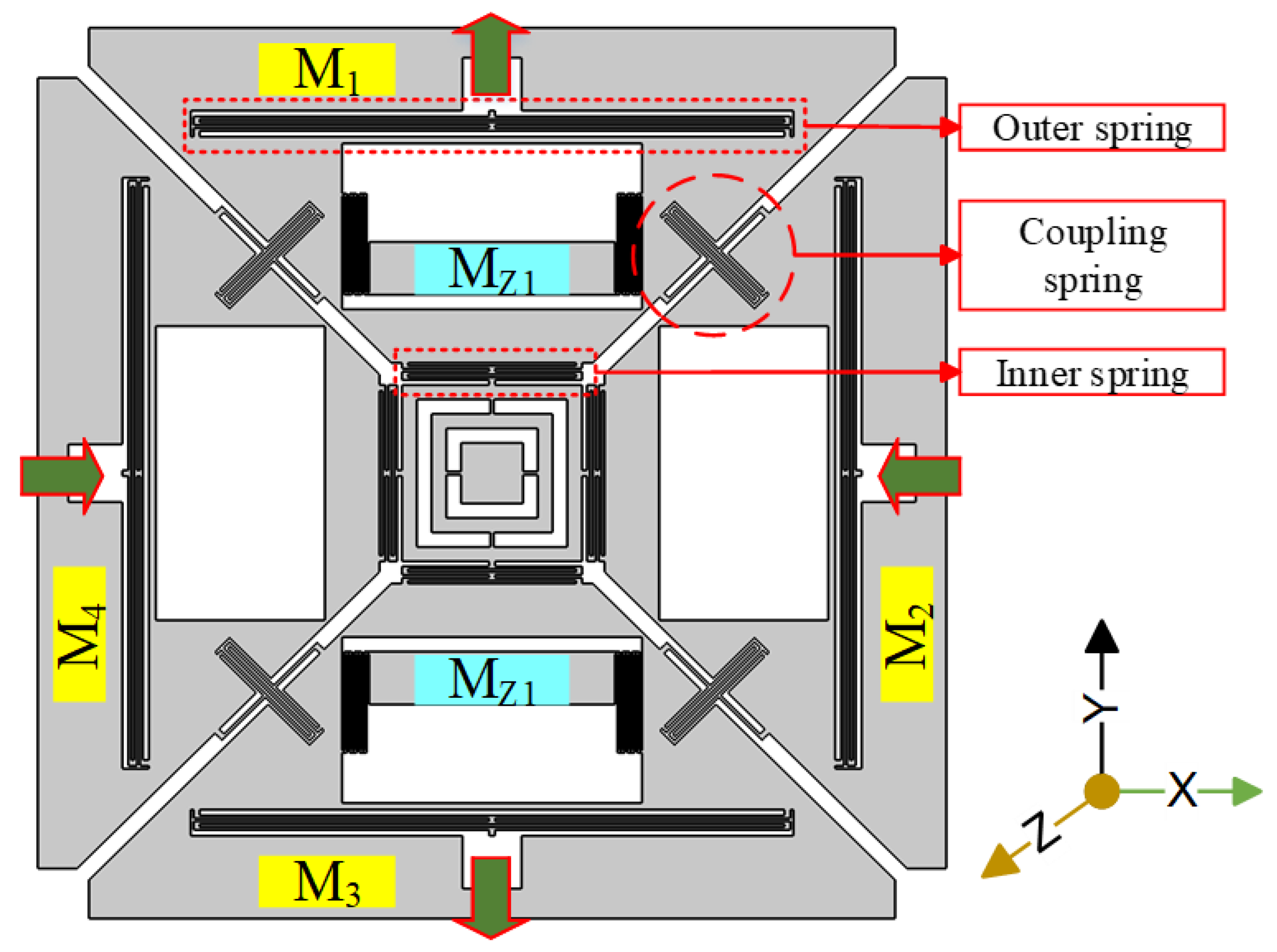

The mechanical structure of the proposed single-drive, 3-axis MEMS gyroscope consisted of four drive masses named M

1, M

2, M

3, and M

4, suspended in the x-y plane, as shown in

Figure 1. These masses were coupled by a unique coupling mechanism consisting of one z-shaped coupling spring. This type of coupling spring has the quality to suppress the unwanted modes of drive masses while keeping the target sense modes close to the drive-mode. In the drive-scheme of the proposed design, M

1 and M

3, which were opposite to each other, moved outward, while the two other opposite masses, M

2 and M

4, moved inward. This kind of drive-scheme was capable of reducing the slide film damping [

10]. There were two z-sense masses named M

z1 and M

z2 as shown in

Figure 1. There were eight lateral double-folded springs, four outside and four inside the structure. The outer double-folded springs were anchored at one point to the substrate and the other sides were connected at two points to each mass, providing an out-of-plane motion from the outside. The roll and pitch modes exhibited out-of-plane motion, whereas the yaw mode exhibited in-plane motion.

The working principle of the vibrating MEMS gyroscope is based on the Coriolis effect. Whenever the driving masses are driven at resonance and an input angular rate is applied to a movable sense-mass, the sense-mass experiences a force called the Coriolis force. This Coriolis force generates a displacement in the movable sense-mass perpendicular to the direction of drive motion, as well as to the axis of rotation, called sense-displacement.

4. Conclusion and Future Work

In this paper, the FEA simulation methodology using COMSOL Multiphysics was established to evaluate the mechanical sensitivity of single-drive, 3-axis MEMS gyroscope. Driving analysis and sensitivity analysis for the single-drive, 3-axis MEMS gyroscope were carried out using the established FEA model in COMSOL Multiphysics. The proposed method was successfully validated by comparison with analytical and Matlab/Simulink model results. The proposed FEA model provided an easy and informative approach for evaluation of the 3-axis, as well as the single-axis MEMS gyroscope, compared with analytical and Matlab/Simulink approaches. Scale factors of the proposed single-drive, 3-axis MEMS gyroscope for the x-axis, y-axis, and z-axis were computed as 0.014, 0.011, and 0.013 nm/dps, respectively, using the FEA model. The proposed FEA model provided information about the quadrature errors which were difficult to design analytically or in a system-level approach for the single-drive, 3-axis MEMS gyroscope due to its complex mechanical structure compared with a single-axis MEMS gyroscope. The reported results and validation of the proposed FEA model prove that this method is more realistic compared with other approaches. Moreover, the proposed FEA model is feasible to estimate the cross-axis sensitivity in a single-drive, 3-axis MEMS gyroscope, which is not possible at a system-level design. Likewise, this model is helpful for researchers in the designing and optimization of single-drive, 3 axis MEMS gyroscope as well as in its performance evaluation. In MEMS research, the fabrication process and experimental work are the expensive and time consuming phases. However, to minimize the cost and time of the research process, the proposed FEA simulation methodology can be employed for a wide range of MEMS gyroscopes based on Coriolis-force, for evaluation and design optimization. Cross-axis sensitivity and fabrication errors were not considered in this work, which will be evaluated in our future work, along with further analysis on quadrature error.