Advances in Liquid Metal-Enabled Flexible and Wearable Sensors

Abstract

:1. Introduction

2. Materials

2.1. Composition

2.2. Property

3. Fabrication

3.1. Printing Technology

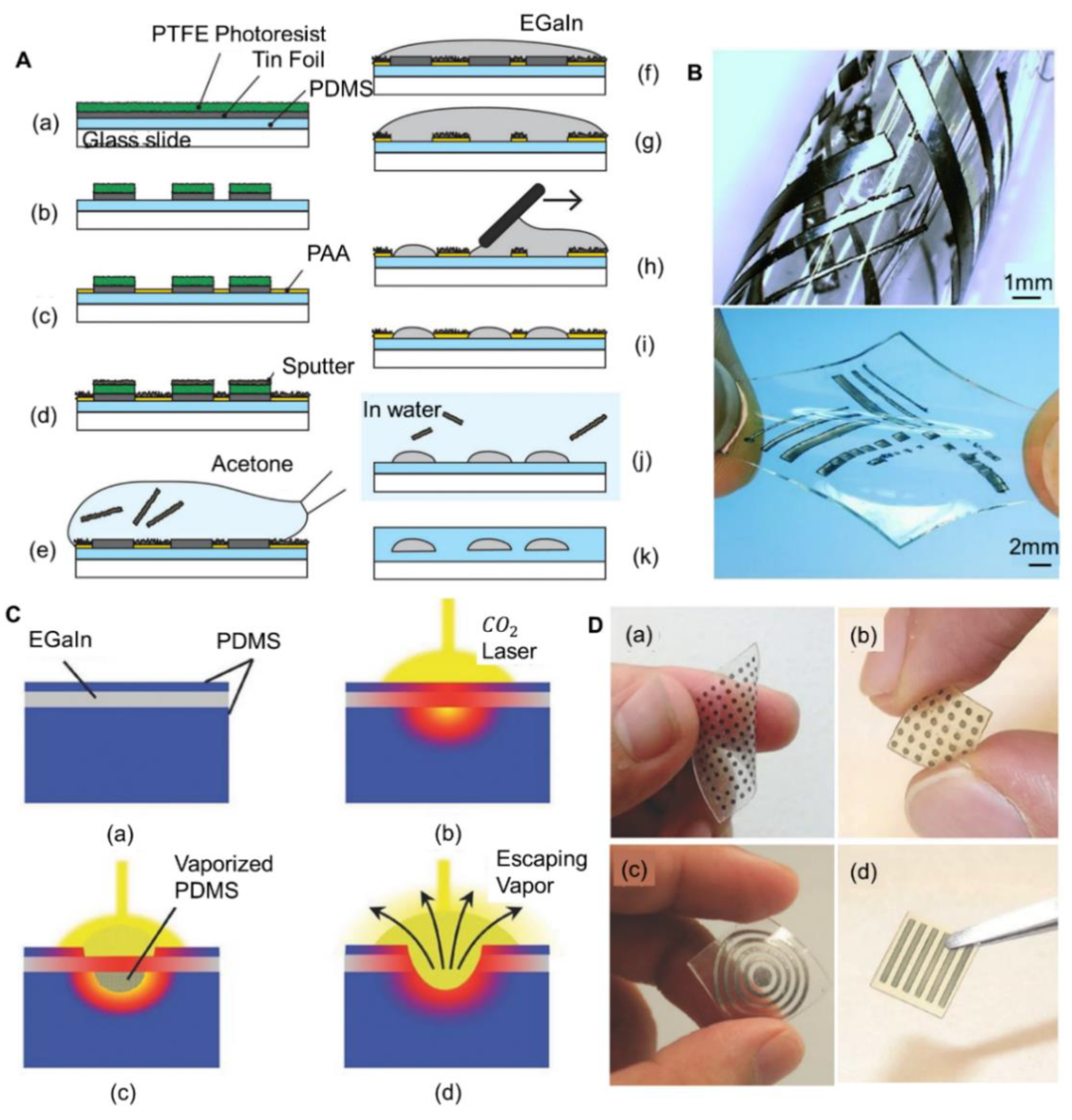

3.2. Microfluidic Technology

3.3. Selective Wetting

3.4. Laser Engraving

3.5. Dewetting and Wiping

4. Basic Principle of Liquid-Metal Sensors

4.1. Liquid Metal as Soft Connection

4.2. Resistive Sensors

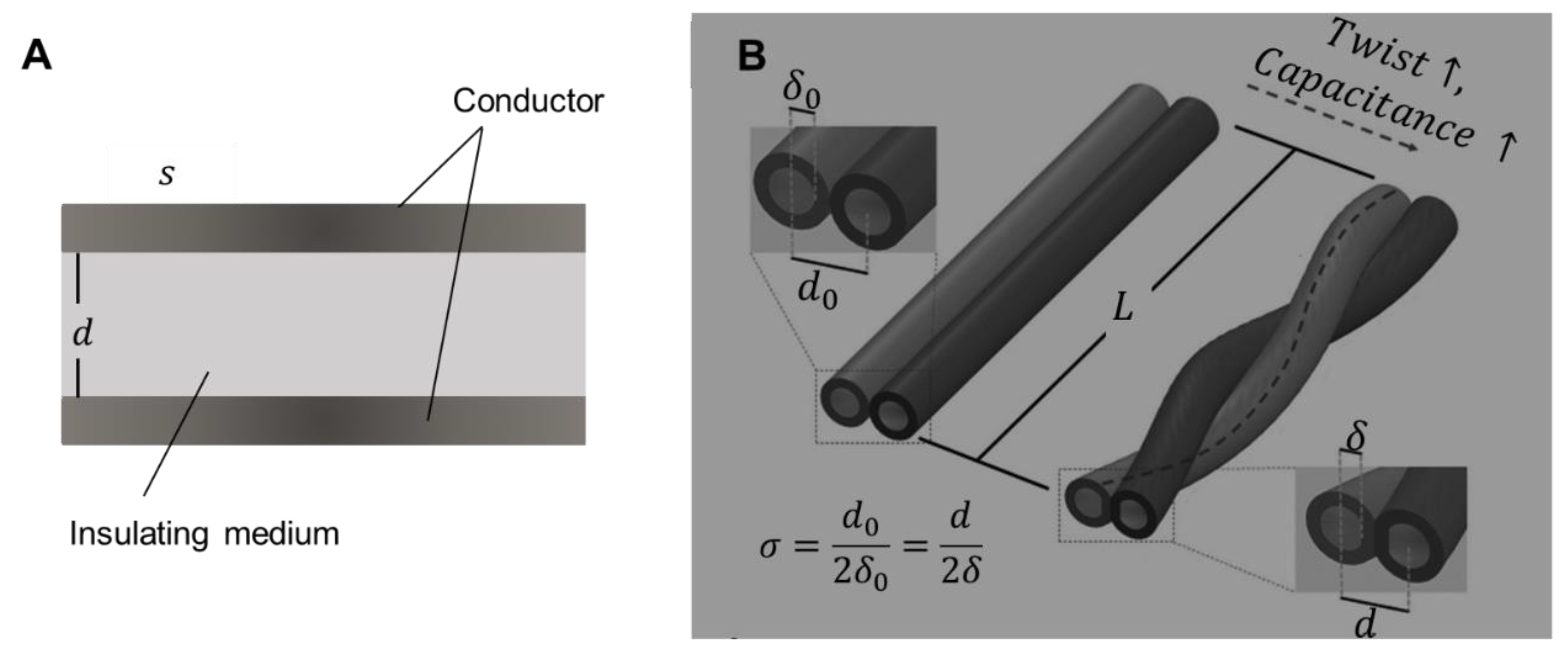

4.3. Capacitive Sensors

4.4. Electrochemical Sensors

4.5. Metamaterial Biosensors

4.6. Liquid-Metal Antenna

5. Typical Applications

5.1. Force Sensors

5.2. Temperature Sensors

5.3. Blood Glucose Sensors

5.4. Sensor Array

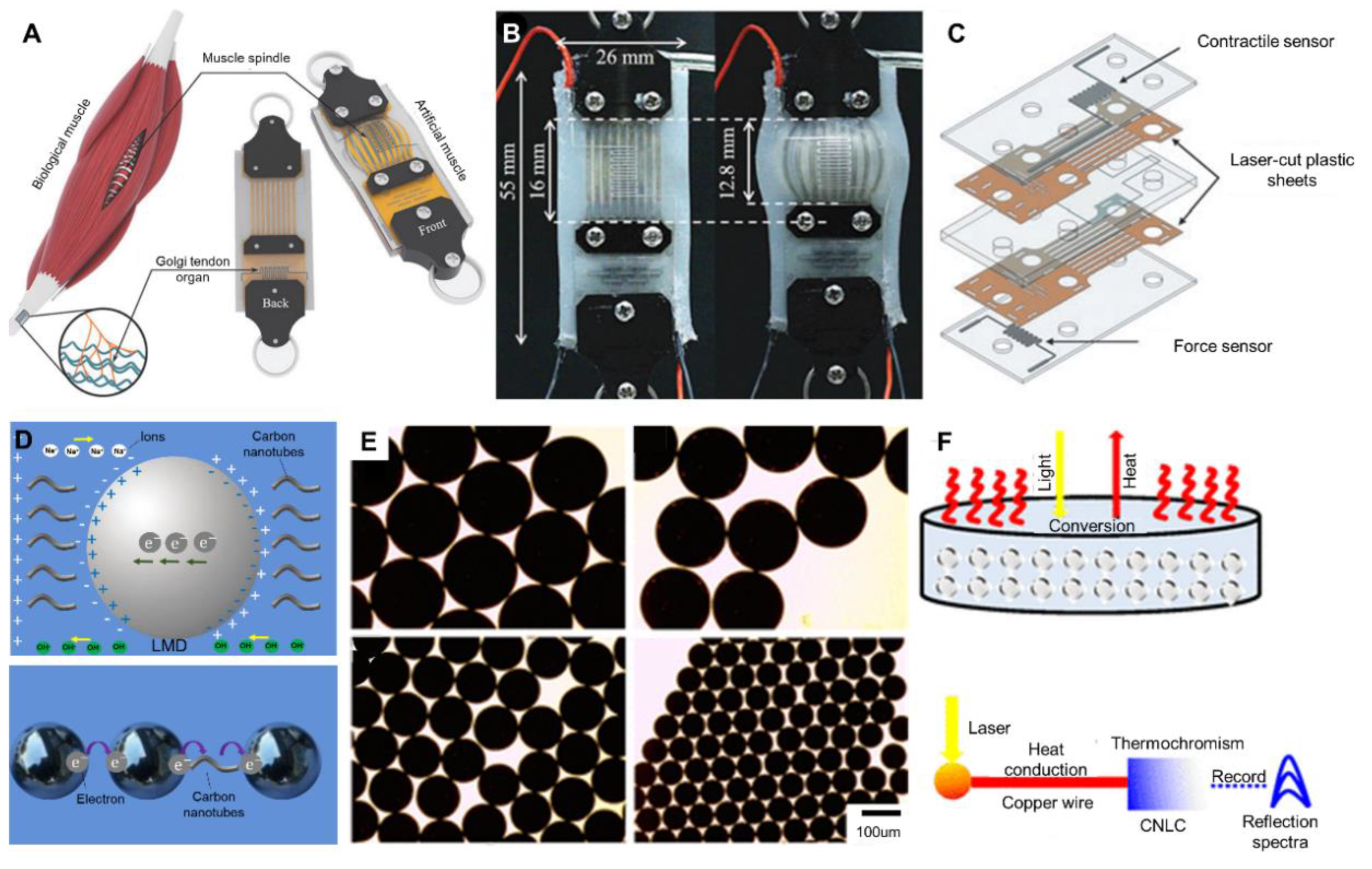

5.5. Pneumatic Artificial Muscles

5.6. Liquid-Metal Microsphere Sensors

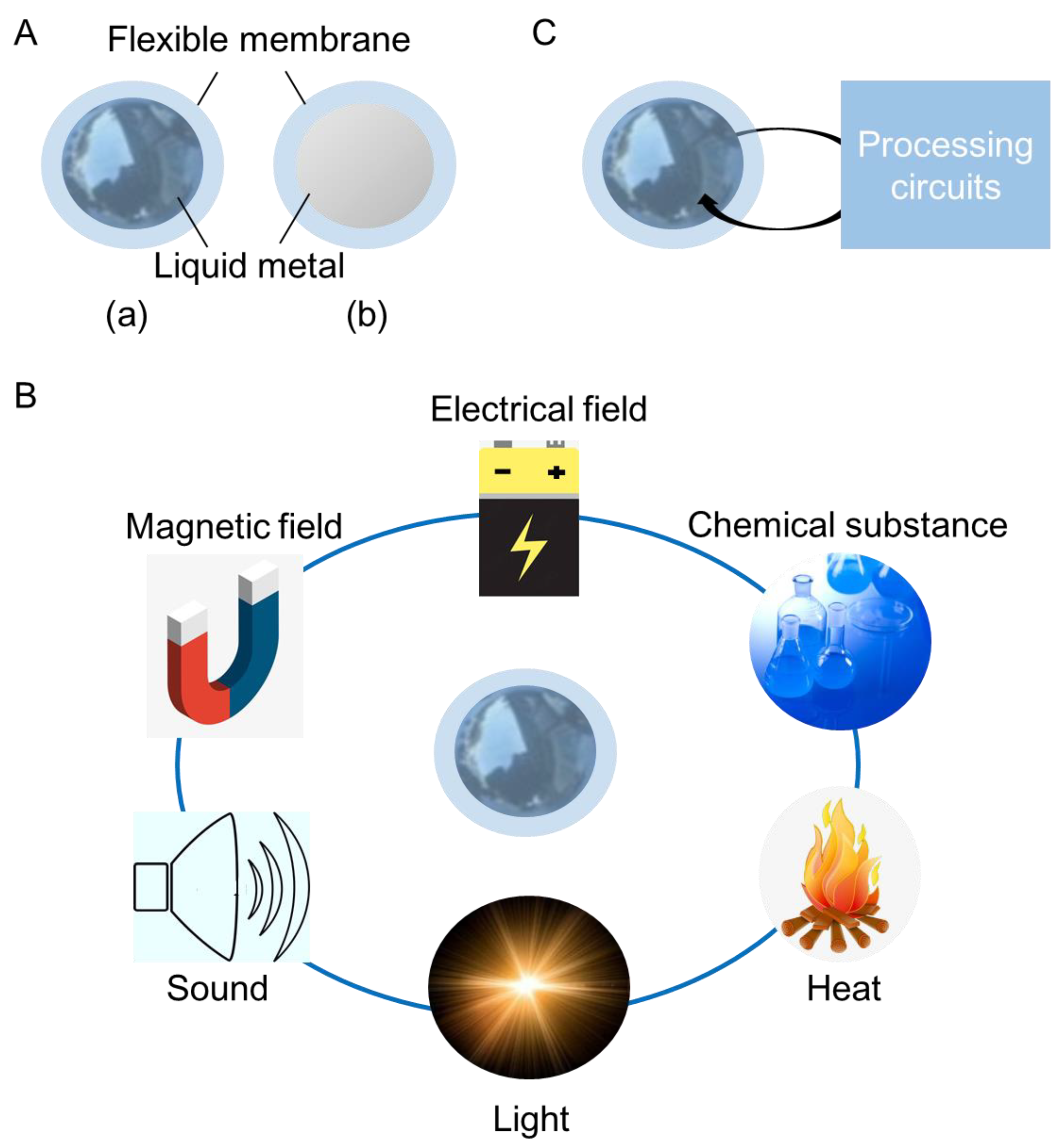

6. Perspective

6.1. Concept of Liquid Sensors

6.2. Working Principle of Liquid Sensors

7. Discussion

8. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Webster, J.G. Medical Instrumentation: Application and Design; John Wiley & Sons Inc.: Hoboken, NJ, USA, 1998. [Google Scholar]

- Harsanyi, G. Sensors in Biomedical Applications: Fundamentals, Technology and Applications; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Viry, L.; Levi, A.; Totaro, M.; Mondini, A.; Mattoli, V.; Mazzolai, B. Flexible three-axial force sensor for soft and highly sensitive artificial touch. Adv. Mater. 2014, 26, 2659–2664. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Water, W.; Chen, S.E. Using ZnO nanorods to enhance sensitivity of liquid sensor. Sensor. Actuat. B Chem. 2009, 136, 371–375. [Google Scholar] [CrossRef]

- Schneditz, D.; Kenner, T.; Heimel, H.; Stabinger, H. A sound-speed sensor for the measurement of total protein concentration in disposable, blood-perfused tubes. J. Acoust. Soc. Am. 1989, 86, 2073. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, Y.; Su, Y.; Chen, J.; Adams, K.; Lee, S.; Hu, C.; Wang, Z. Triboelectric nanogenerator for harvesting vibration energy in full space and as self-powered acceleration sensor. Adv. Funct. Mater. 2014, 24, 1401–1407. [Google Scholar] [CrossRef]

- Peet, D.J.; Pryor, M.D. Evaluation of a mosfet radiation sensor for the measurement of entrance surface dose in diagnostic radiology. Br. J. Radiol. 1999, 72, 562–568. [Google Scholar] [CrossRef]

- Yang, H.; Qi, D.; Liu, Z.; Chandran, B.K.; Wang, T.; Yu, J.; Chen, X. Soft thermal sensor with mechanical adaptability. Adv. Mater. 2016, 28, 9175–9181. [Google Scholar] [CrossRef]

- Wang, C.F.; Wang, C.H.; Huang, Z.L.; Xu, S. Materials and structures toward soft electronics. Adv. Mater. 2018, 30. [Google Scholar] [CrossRef] [Green Version]

- Koo, J.H.; Song, J.; Kim, D. Solution-processed thin films of semiconducting carbon nanotubes and their application to soft electronics. Nanotechnology 2019, 30, 13. [Google Scholar] [CrossRef]

- Djenizian, T.; Tee, B.; Ramuz, M.; Fang, L. Advances in flexible and soft electronics. APL Mater. 2019, 7. [Google Scholar] [CrossRef] [Green Version]

- Kang, B.; Lee, S.K.; Jung, J.; Joe, M.; Lee, S.B.; Kim, J.; Lee, C.; Cho, K. Nanopatched graphene with molecular self-assembly toward graphene-organic hybrid soft electronics. Adv. Mater. 2018, 30. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Wang, B.; Jiang, J.; Wu, K.; Guo, C.F.; Wu, Z. High fidelity conformal printing of 3D liquid alloy circuits for soft electronics. ACS Appl. Mater. Inter. 2019, 11, 7148–7156. [Google Scholar] [CrossRef] [PubMed]

- Valentine, A.D.; Busbee, T.A.; Boley, J.W.; Raney, J.R.; Lewis, J.A. Hybrid 3D printing of soft electronics. Adv. Mater. 2017, 29, 29. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Xia, K.; Zhang, Y.; Kaplan, D.L. Silk-based advanced materials for soft electronics. Acc. Chem. Res. 2019, 52, 2916–2927. [Google Scholar] [CrossRef]

- Feng, Y.; Zhu, J. Copper nanomaterials and assemblies for soft electronics. Sci. China Mater. 2019, 62, 1679–1708. [Google Scholar] [CrossRef] [Green Version]

- Kang, J.; Tok, J.; Bao, Z. Self-healing soft electronics. Nat. Electron. 2019, 2, 144–150. [Google Scholar] [CrossRef]

- Li, R.; Wang, L.; Yin, L. Materials and devices for biodegradable and soft biomedical electronics. Materials 2018, 11, 2108. [Google Scholar] [CrossRef] [Green Version]

- Choi, C.; Choi, M.K.; Hyeon, T.; Kim, D. Nanomaterial-based soft electronics for healthcare applications. ChemNanoMat 2016, 2. [Google Scholar] [CrossRef]

- Hoshi, T. Robot skin based on touch-area-sensitive tactile element. In Proceedings of the Presented at IEEE International Conference on Robotics & Automation, Orlando, FL, USA, 15–19 May 2006. [Google Scholar]

- Bartlett, M.D.; Markvicka, E.J.; Majidi, C. Rapid fabrication of soft, multilayered electronics for wearable biomonitoring. Adv. Funct. Mater. 2016, 26, 8496–8504. [Google Scholar] [CrossRef]

- Gong, S.; Lai, D.; Su, B.; Si, K.J.; Ma, Z.; Yap, L.W.; Guo, P.; Cheng, W. Highly stretchy black gold E-skin nanopatches as highly sensitive wearable biomedical sensors. Adv. Electron. Mater. 2015, 1. [Google Scholar] [CrossRef]

- Jeong, S.H.; Zhang, S.; Hjort, K.; Hilborn, J.; Wu, Z. PDMS-based elastomer tuned soft, stretchable, and sticky for epidermal electronics. Adv. Mater. 2016, 28, 5830–5836. [Google Scholar] [CrossRef] [PubMed]

- Yuan, W.; Dong, S.; Adelson, E. GelSight: High-resolution robot tactile sensors for estimating geometry and force. Sensors 2017, 17, 2762. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tian, L.; Li, Y.; Webb, R.; Krishnan, S.; Bian, Z.; Song, J.; Ning, X.; Crawford, K.; Kurniawan, J.F.; Bofinas, A.P.; et al. Flexible and stretchable 3ω sensors for thermal characterization of human skin. Adv. Funct. Mater. 2017, 27, 26. [Google Scholar] [CrossRef]

- Sonar, H.A.; Paik, J. Soft pneumatic actuator skin with piezoelectric sensors for vibrotactile feedback. Front. Robot. AI 2016, 2, 10–3389. [Google Scholar] [CrossRef] [Green Version]

- Hu, T.; Xuan, S.; Ding, L.; Gong, X. Stretchable and magneto-sensitive strain sensor based on silver nanowire-polyurethane sponge enhanced magnetorheological elastomer. Mater. Des. 2018, 156, 528–537. [Google Scholar] [CrossRef]

- Jiong, Y.; Cheng, W.; Kourosh, K. Electronic skins based on liquid metals. Proc. IEEE 2019, 107, 2168–2184. [Google Scholar]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [Green Version]

- Rajan, K.; Garofalo, E.; Chiolerio, A. Wearable Intrinsically Soft, Stretchable, Flexible Devices for Memories and Computing. Sensors 2018, 18, 367. [Google Scholar] [CrossRef] [Green Version]

- Roh, E.; Hwang, B.U.; Kim, D.; Kim, B.Y.; Lee, N.E. Stretchable, transparent, ultrasensitive, and patchable strain sensor for human–machine interfaces comprising a nanohybrid of carbon nanotubes and conductive elastomers. ACS Nano 2015, 9, 6252–6261. [Google Scholar] [CrossRef]

- Chen, S.; Jiang, K.; Lou, Z.; Chen, D.; Shen, G. Recent developments in graphene-based tactile sensors and e-skins. Adv. Mater. Technol. 2017, 3. [Google Scholar] [CrossRef]

- Wang, C.; Xia, K.; Zhang, M.; Jian, M.; Zhang, Y. An all silk-derived, dual-mode e-skin for simultaneous temperature-pressure detection. ACS Appl. Mater. Inter. 2017, 9, 39484–39492. [Google Scholar] [CrossRef] [PubMed]

- Tajima, R.; Kagami, S.; Inaba, M.; Inoue, H. Development of soft and distributed tactile sensors and the application to a humanoid robot. Adv. Robot. 2002, 16, 381–397. [Google Scholar] [CrossRef] [Green Version]

- Ozel, S.; Keskin, N.A.; Khea, D.; Onal, C.D. A precise embedded curvature sensor module for soft-bodied robots. Sensor. Actuat. A Phys. 2015, 236, 349–356. [Google Scholar] [CrossRef]

- Li, S.; Zhao, H.; Shepherd, R.F. Flexible and stretchable sensors for fluidic elastomer actuated soft robots. MRS Bull. 2017, 42, 138–142. [Google Scholar] [CrossRef]

- Yeo, J.C.; Lim, C.T. Emerging flexible and wearable physical sensing platforms for healthcare and biomedical applications. Microsyst. Nanoeng. 2016, 2. [Google Scholar] [CrossRef]

- Dinh, T.; Phan, H.; Nguyen, K.; Qamar, A.; Md Foisal, A.R.; Viet, T.; Tran, C.D.; Zhu, Y.; Nguyen, N.T.; Dao, D.V. Environment-friendly carbon nanotube based flexible electronics for noninvasive and wearable healthcare. J. Mater. Chem. C 2016, 4. [Google Scholar] [CrossRef]

- Wang, D.; Mei, Y.; Huang, G. Printable inorganic nanomaterials for flexible transparent electrodes: From synthesis to application. J. Semicond. 2018, 39. [Google Scholar] [CrossRef] [Green Version]

- Fu, K.; Yao, Y.; Dai, J.; Hu, L. Progress in 3D printing of carbon materials for energy-related applications. Adv. Mater. 2016, 29. [Google Scholar] [CrossRef]

- Choi, Y.; Kang, J.; Secor, E.; Sun, J.; Kim, H.; Lim, J. Capacitively coupled hybrid ion gel and carbon nanotube thin-film transistors for low voltage flexible logic circuits. Adv. Funct. Mater. 2018, 28, 28. [Google Scholar] [CrossRef]

- Zhang, D.; Chi, B.; Li, B.; Gao, Z.; Du, Y.; Guo, J.; Wei, J. Fabrication of highly conductive graphene flexible circuits by 3D printing. Synth. Met. 2016, 27, 79–86. [Google Scholar] [CrossRef]

- Saidina, D.; Eawwiboonthanakit, N.; Jaafar, M.; Fontana, S.; Hérold, C. Recent development of graphene-based ink and other conductive material-based inks for flexible electronics. J. Electron. Mater. 2019, 48, 3428–3450. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Wang, C. Graphene and the related conductive inks for flexible electronics. J. Mater. Chem. C 2016, 4, 7193–7207. [Google Scholar] [CrossRef]

- Park, J.; Zhou, C.; Yang, C.Y. Carbon-based Nanostructures for Flexible Electronics. In Proceedings of the IEEE International Conference on Electron Devices and Solid State Circuits, Shenzhen, China, 6–8 June 2018. [Google Scholar]

- Hao, Y.; Gao, J.; Xu, Z.; Zhang, N.; Luo, J.; Liu, X. Preparation of silver nanoparticles with hyperbranched polymers as a stabilizer for inkjet printing of flexible circuits. New J. Chem. 2019, 43, 2797–2803. [Google Scholar] [CrossRef]

- Stephan, T.D.; Vimolvan, P. Humic acid assisted synthesis of silver nanoparticles and its application to herbicide detection. Mater. Lett. 2008, 62, 2661–2663. [Google Scholar]

- Sun, J.; Zhou, W.; Yang, H.; Zhen, X.; Ma, L.; Williams, D.; Sun, D.; Lang, M. Highly transparent and flexible circuits through patterning silver nanowires into microfluidic channels. Chem. Commun. 2018, 54, 4923–4926. [Google Scholar] [CrossRef]

- Seung, H.K. Low temperature thermal engineering of nanoparticle ink for flexible electronics applications. Semicond. Sci. Technol. 2016, 31, 31. [Google Scholar] [CrossRef]

- Tan, S.; Zu, X.; Yi, G.; Liu, X. Synthesis of highly environmental stable copper-silver core-shell nanoparticles for direct writing flexible electronics. J. Mater. Sci. Mater. Electron. 2017, 28, 15899–15906. [Google Scholar] [CrossRef]

- Shao, W.; Li, G.; Zhu, P.; Zhang, Y.; Ouyang, Q.; Sun, R.; Chen, C.; Wong, C.P. Facile synthesis of low temperature sintering Ag nanopaticles for printed flexible electronics. J. Mater. Sci. Mater. Electron. 2018, 29, 4432–4440. [Google Scholar] [CrossRef]

- Chiolerio, A.; Rajan Roppolo, I.; Chiappone, A.; Bocchini, S.; Perrone, D. Silver nanoparticle ink technology: State of the art. Nanotech. Sci. Appl. 2016, 9, 1. [Google Scholar] [CrossRef] [Green Version]

- Yi, L.; Liu, J. Liquid metal biomaterials: A newly emerging area to tackle modern biomedical challenges. Inter. Mater. Rev. 2017, 62, 1–26. [Google Scholar] [CrossRef]

- Wang, Q.; Yu, Y.; Liu, J. Preparations, characteristics and applications of the functional liquid metal materials. Adv. Eng. Mater. 2017, 20. [Google Scholar] [CrossRef]

- Jackson, N.; Buckley, J.; Clarke, C.; Stam, F. Manufacturing methods of stretchable liquid metal-based antenna. Microsyst. Technol. 2019, 25, 3175–3184. [Google Scholar] [CrossRef]

- Ordonez, R.; Hayashi, C.; Torres, C.; Hafner, N.; Adleman, J.; Acosta, N.; Melcher, J.; Kamin, N.M.; Garmire, D. Conformal Liquid-Metal Electrodes for Flexible Graphene Device Interconnects. IEEE Trans. Electron Dev. 2016, 63, 4018–4023. [Google Scholar] [CrossRef]

- Li, Q.; Lin, J.; Liu, T.; Zheng, H.; Liu, J. Printed flexible thin-film transistors based on different types of modified liquid metal with good mobility. Sci. China Informa. Sci. 2019, 62. [Google Scholar] [CrossRef] [Green Version]

- Nayak, S.; Li, Y.; Tay, W.; Zamburg, E.; Singh, D.; Lee, C.; Koh, S.J.A.; Chia, P.; Thean, A.V.Y. Liquid-metal-elastomer foam for moldable multi-functional triboelectric energy harvesting and force sensing. Nano Energy 2019, 64. [Google Scholar] [CrossRef]

- Kim, S.; Oh, J.; Jeong, D.; Bae, J. Direct wiring of eutectic gallium-indium to a metal electrode for soft sensor systems. ACS Appl. Mater. Inter. 2019, 11, 20557–20565. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.; Kim, D.; Lee, B.; Lee, J. Soft and Deformable Sensors Based on Liquid Metals. Sensors 2019, 19, 4250. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Jie, Z.; Jing, L.; Sabato, D. Biomedical implementation of liquid metal ink as drawable ECG electrode and skin circuit. PLoS ONE 2013, 8. [Google Scholar] [CrossRef]

- Zhao, Z.N.; Ju, L.; Jie, Z.; Yang, Y.; Bo, Y.; Fan, C.C.; Wang, L.; Liu, J. Liquid metal enabled flexible electronic system for eye movement tracking. IEEE Sens. J. 2018, 18, 2592–2598. [Google Scholar] [CrossRef]

- Jin, C.; Zhang, J.; Li, X.; Yang, X.; Li, J.; Liu, J. Injectable 3-D fabrication of medical electronics at the target biological tissues. Sci. Rep. 2013, 3, 3442. [Google Scholar] [CrossRef] [Green Version]

- Sun, X.; Yuan, B.; Rao, W.; Liu, J. Amorphous liquid metal electrodes enabled conformable electrochemical therapy of tumors. Biomaterials 2017, 146, 156–167. [Google Scholar] [CrossRef] [PubMed]

- Varga, M.; Ladd, C.; Ma, S.; Holbery, J.; Tröster, G. On-skin liquid metal inertial sensor. Lab. Chip. 2017, 17, 3272–3278. [Google Scholar] [CrossRef] [PubMed]

- Chiolerio, A.; Quadrelli, M. Smart Fluid Systems: The advent of autonomous liquid robotics. Adv. Sci. 2017, 4. [Google Scholar] [CrossRef] [PubMed]

- Adamatzky, A.; Chiolerio, A.; Szacilowski, K. Liquid metal solves maze. Soft Matter 2019. [CrossRef]

- Zhang, Q.; Zheng, Y.; Liu, J. Direct writing of electronics based on alloy and metal (dream) ink: A newly emerging area and its impact on energy, environment and health sciences. Front. Energy. 2012, 6, 311–340. [Google Scholar] [CrossRef]

- Guo, R.; Wang, X.; Chang, H.; Yu, W.; Liang, S.; Rao, W. Ni-GaIn amalgams enabled rapid and customizable fabrication of wearable and wireless healthcare electronics. Adv. Eng. Mater. 2018, 20. [Google Scholar] [CrossRef]

- Chang, H.; Guo, R.; Sun, Z.Q.; Wang, H.Z.; Hou, Y.; Wang, Q.; Rao, W.; Liu, J. Flexible conductive materials: Direct writing and repairable paper flexible electronics using nickel-liquid metal ink. Adv. Mater. Interfaces 2018, 5. [Google Scholar] [CrossRef] [Green Version]

- Guo, R.; Yao, S.; Sun, X.; Liu, J. Semi-liquid metal and adhesion-selection enabled rolling and transfer (SMART) printing: A general method towards fast fabrication of flexible electronics. Sci. China Mater. 2019, 62, 982–994. [Google Scholar] [CrossRef] [Green Version]

- Tang, J.; Zhao, X.; Li, J.; Guo, R.; Zhou, Y.; Liu, J. Gallium-based liquid metal amalgams: Transitional-state metallic mixtures (TransM2ixes) with enhanced and tunable electrical, thermal, and mechanical properties. ACS Appl. Mater. Interfaces 2017, 9, 35977–35987. [Google Scholar] [CrossRef]

- Li, H.; Mei, S.; Wang, L.; Gao, Y.; Liu, J. Splashing phenomena of room temperature liquid metal droplet striking on the pool of the same liquid under ambient air environment. Inter. J. Heat Fluid FL 2014, 47, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Sen, P.; Kim, C.J. Characterization of nontoxic liquid-metal alloy galinstan for applications in microdevices. J. Microelectromech. Syst. 2012, 21, 443–450. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.; Lee, J.B. Magnetic-field-induced liquid metal droplet manipulation. J. Korean Phys. Soc. 2015, 66, 282–286. [Google Scholar] [CrossRef]

- Ren, Y.; Liu, J. Liquid-metal enabled droplet circuits. Micromachines 2018, 9, 218. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tan, S.C.; Yuan, B.; Liu, J. Electrical method to control the running direction and speed of self-powered tiny liquid metal motors. Proc. Roy. Soc. A Math. Phy. 2015, 471, 32–38. [Google Scholar] [CrossRef] [Green Version]

- Khondoker, M.A.H.; Sameoto, D. Fabrication methods and applications of microstructured gallium based liquid metal alloys. Smart Mater. Struct. 2016, 25. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Li, H.; Liu, J. Direct writing of flexible electronics through room temperature liquid metal ink. PLoS ONE 2012, 7. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J. Advances in the Development of Liquid Metal-Based Printed Electronic Inks. Front. Mater. 2019, 6. [Google Scholar] [CrossRef]

- Sheng, L.; Teo, S.; Liu, J. Liquid-metal-painted stretchable capacitor sensors for wearable healthcare electronics. J. Med. Biol. Eng. 2016, 36, 265–272. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, Q.; Liu, J. Pervasive liquid metal based direct writing electronics with roller-ball pen. AIP Adv. 2013, 3, 6459–6463. [Google Scholar] [CrossRef]

- Zheng, Y.; He, Z.; Gao, Y.; Liu, J. Direct desktop printed-circuits-on-paper flexible electronics. Sci. Rep. 2013, 3, 1786. [Google Scholar] [CrossRef]

- Tabatabai, A.; Fassler, A.; Usiak, C.; Majidi, C. Liquid-phase gallium–indium alloy electronics with microcontact printing. Langmuir 2013, 29, 6194–6200. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Yu, Y.; Yang, J.; Liu, J. Fast fabrication of flexible functional circuits based on liquid metal dual-trans printing. Adv. Mater. 2015, 27, 7109–7116. [Google Scholar] [CrossRef] [PubMed]

- Votzke, C.; Daalkhaijav, U.; Mengüç, Y.; Johnston, M. Highly-stretchable biomechanical strain sensor using printed liquid metal paste. In Proceedings of the IEEE Biomedical Circuits and Systems Conference, Cleveland, OH, USA, 17–19 October 2018. [Google Scholar]

- Gannarapu, A.; Gozen, B.A. Freeze-printing of liquid metal alloys for manufacturing of 3D, conductive, and flexible networks. Adv. Mater. Technol. 2016, 1. [Google Scholar] [CrossRef]

- Liang, B.; Wei, J.; Fang, L.; Cao, Q.; Tu, T.; Ren, H. High-resolution rapid prototyping of liquid metal electronics by direct Writing on Highly Prestretched Substrates. ACS Omega 2019, 4, 21072–21077. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Q.; Gao, Y.; Liu, J. Atomized spraying of liquid metal droplets on desired substrate surfaces as a generalized way for ubiquitous printed electronics. Appl. Phys. A 2013, 116, 1091–1097. [Google Scholar]

- Roberts, P.; Damian, D.D.; Shan, W.; Lu, T.; Majidi, C. Soft-matter capacitive sensor for measuring shear and pressure deformation. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation (ICRA), Karlsruhe, Germany, 6–10 May 2013. [Google Scholar]

- Jeong, S.H.; Hagman, A.; Hjort, K.; Jobs, M.; Sundqvist, J.; Wu, Z. Liquid alloy printing of microfluidic stretchable electronics. Lab. Chip. 2012, 12, 4657. [Google Scholar] [CrossRef]

- Kim, K.; Choi, J.; Jeong, Y.; Cho, I.; Kim, M.; Kim, S.; Oh, Y.; Park, I. Highly Sensitive and Wearable Liquid Metal-Based Pressure Sensor for Health Monitoring Applications: Integration of a 3D-Printed Microbump Array with the Microchannel. Adv. Healthc. Mater. 2019, 8. [Google Scholar] [CrossRef]

- Wong, R.D.P.; Posner, J.D.; Santos, V.J. Flexible microfluidic normal force sensor skin for tactile feedback. Sensor. Actuat. A Phys. 2012, 179, 62–69. [Google Scholar] [CrossRef]

- Taekeon, J.; Yang, S. Highly stable liquid metal-based pressure sensor integrated with a microfluidic channel. Sensors 2015, 15, 11823–11835. [Google Scholar]

- Zhang, L.J.; Gao, M.; Wang, R.H.; Deng, Z.; Gui, L. Stretchable pressure sensor with leakage-free liquid-metal electrodes. Sensors 2019, 19, 1316. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Sun, N.; Wen, Z.; Cheng, P.; Lee, S.T. Liquid metal-based super-stretchable and structure-designable triboelectric nanogenerator for wearable electronics. ACS Nano 2018, 12, 2027–2034. [Google Scholar] [CrossRef] [PubMed]

- Khoshmanesh, K.; Tang, S.; Zhu, J.; Schaefer, S.; Mitchell, A.; Kalantar-zadeh, K.; Dickey, M.D. Liquid Metal Enabled Microfluidics. Lab Chip. 2017, 17, 974–993. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Gui, L. Development of a fast thermal response microfluidic system using liquid metal. J. Micromech. Microeng. 2016, 26. [Google Scholar] [CrossRef]

- Kramer, R.K.; Majidi, C.; Wood, R.J. Masked deposition of gallium-indium alloys for liquid-embedded elastomer conductors. Adv. Funct. Mater. 2013, 23, 5292–5296. [Google Scholar] [CrossRef]

- Li, G.; Lee, D.W. Advanced selective liquid-metal plating technique for stretchable biosensor applications. Lab. Chip. 2017, 17. [Google Scholar] [CrossRef]

- Lu, T.; Finkenauer, L.; Wissman, J.; Majidi, C. Rapid prototyping for soft-matter electronics. Adv. Funct. Mater. 2014, 24, 3351–3356. [Google Scholar] [CrossRef]

- Pan, C.; Kumar, K.; Li, J.; Markvicka, E.; Herman, P.R.; Majidi, C. Visually imperceptible liquid-metal circuits for transparent, stretchable electronics with direct laser writing. Adv Mater. 2018, 30, 10–1002. [Google Scholar] [CrossRef]

- Kim, T.; Kim, K.; Kim, S.; Lee, J.; Kim, W. Micropatterning of liquid metal by dewetting. J. Microelectromech. Syst. 2017, 99, 1–4. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, X.L.; Liu, J. Fabrication of High-Resolution Flexible Circuits and Sensors based on Liquid Metal Inks by Spraying and Wiping Processing. IEEE Trans. Biomed. Circ. Syst. 2019, 1, 1545–1551. [Google Scholar] [CrossRef]

- Hong, S.Y.; Lee, Y.H.; Park, H.; Jin, S.W.; Jeong, Y.R.; Yun, J.; You, I.; Zi, G.; Ha, J.S. Stretchable active matrix temperature sensor array of polyaniline nanofibers for electronic skin. Adv. Mater. 2016, 28, 930–935. [Google Scholar] [CrossRef]

- Jiao, Y.; Young, C.; Yang, S.; Oren, S.; Ceylan, H.; Kim, S. Wearable graphene sensors with microfluidic liquid metal wiring for structural health monitoring and human body motion sensing. IEEE Sensor. J. 2016, 16, 7870–7875. [Google Scholar] [CrossRef]

- Hu, H.; Shaikh, K.; Liu, C. Super flexible sensor skin using liquid metal as interconnect. IEEE Sensor. 2007, 815–817. [Google Scholar] [CrossRef]

- Li, H.; Yang, Y.; Liu, J. Printable tiny thermocouple by liquid metal gallium and its matching metal. Appl. Phys. Lett. 2012, 101. [Google Scholar] [CrossRef]

- Mohammed, M.G.; Kramer, R. All-printed flexible and stretchable electronics. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef] [PubMed]

- Otake, S.; Konishi, S. Integration of flexible strain sensor using liquid metal into soft micro-actuator. In Proceedings of the IEEE Micro Electro Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018. [Google Scholar]

- Vogt, D.M.; Park, Y.L.; Wood, R.J. Design and characterization of a soft multi-axis force sensor using embedded microfluidic channels. IEEE Sensor. J. 2013, 13, 4056–4064. [Google Scholar] [CrossRef] [Green Version]

- Ali, S.; Maddipatla, D.; Narakathu, B.B.; Chlaihawi, A.A.; Emamian, S.; Janabi, F.; Bazuin, B.J.; Atashbar, M.Z. Flexible capacitive pressure sensor based on PDMS substrate and Ga-In liquid metal. IEEE Sensor J. 2018, 19, 97–104. [Google Scholar] [CrossRef]

- Cooper, C.B.; Arutselvan, K.; Liu, Y.; Armstrong, D.; Lin, Y.; Khan, M.R.; Genzer, J.; Dickey, M.D. Stretchable capacitive sensors of torsion, strain, and touch using double helix liquid metal fibers. Adv. Funct. Mater. 2017, 27. [Google Scholar] [CrossRef]

- Zhang, R.; Ye, Z.; Gao, M.; Gao, C.; Zhang, X.; Li, L.; Gui, L. Liquid metal electrode-enabled flexible microdroplet sensor. Lab. Chip. 2019, 20, 496–504. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, Y.; Sheng, L.; Liu, J. Self-Fueled Biomimetic Liquid Metal Mollusk. Adv. Mater. 2015, 27, 2648–2655. [Google Scholar] [CrossRef]

- Sivan, V.; Tang, S.; O'Mullane, A.; Petersen, P.; Eshtiaghi, N.; Kalantar Zadeh, K.; Mitchell, A. Enhanced electrochemical heavy metal ion sensor using liquid metal marbles - towards on-chip application. In Proceedings of the Optoelectronic & Microelectronic Materials & Devices, Melbourne, VIC, Australia, 12–14 December 2012. [Google Scholar]

- Xu, J.; Fan, Y.; Yang, R.; Fu, Q.; Zhang, F. Realization of switchable EIT metamaterial by exploiting fluidity of liquid metal. Opt. Express. 2019, 27, 2837–2843. [Google Scholar] [CrossRef]

- Ling, K.; Kim, K.; Lim, S. Flexible liquid metal-filled metamaterial absorber on polydimethylsiloxane (PDMS). Opt. Express. 2015, 23, 21375–21383. [Google Scholar] [CrossRef] [PubMed]

- Kyeongseob, K.; Dongju, L.; Seunghyun, E.; Sungjoon, L. Stretchable metamaterial absorber using liquid metal-filled polydimethylsiloxane (PDMS). Sensor 2016, 16, 521. [Google Scholar]

- Kenyu, L.; Hyung, K.; Minyeong, Y.; Sungjoon, L. Frequency-switchable metamaterial absorber injecting eutectic gallium-indium (EGaIn) liquid metal alloy. Sensor 2015, 15, 28154–28165. [Google Scholar]

- Reichel, K.S.; Lozada-Smith, N.; Joshipura, I.D.; Ma, J.J.; Shrestha, R.; Mendis, R.; Dickey, M.D.; Mittleman, D.M. Electrically reconfigurable terahertz signal processing devices using liquid metal components. Nat. Commun. 2018, 9, 4203. [Google Scholar] [CrossRef]

- Roychoudhury, S.; Rawat, V.; Jalal, A.H.; Kale, S.N.; Bhansali, S. Recent advances in metamaterial split-ring-resonator circuits as biosensors and therapeutic agents. Biosens. Bioelectron. 2016, 86, 595–608. [Google Scholar] [CrossRef] [Green Version]

- Rodrigo, D.; Jofre, L.; Cetiner, B. Circular beam-steering reconfigurable antenna with liquid metal parasitics. IEEE Trans. Antenn. Propag. 2012, 60, 1796–1802. [Google Scholar] [CrossRef]

- Mazlouman, S.; Jiang, X.; Menon, C.; Vaughan, R. A reconfigurable patch antenna using liquid metal embedded in a silicone substrate. IEEE Trans. Antenn. Propag. 2011, 59, 4406–4412. [Google Scholar] [CrossRef]

- Hayes, G.; So, J.; Qusba, A.; Dickey, M.; Lazzi, G. Flexible liquid metal alloy (EGaIn) microstrip patch antenna. IEEE Trans. Antenn. Propag. 2012, 60, 2151–2156. [Google Scholar] [CrossRef]

- Cheng, S.; Wu, Z.; Hallbjorner, P.; Hjort, K.; Rydberg, A. Foldable and stretchable liquid metal planar inverted cone antenna. IEEE Trans. Antenn. Propag. 2012, 57, 3765–3771. [Google Scholar] [CrossRef]

- Oh, J.; Woo, J.; Jo, S.; Han, C. Pressure-conductive rubber sensor based on liquid-metal-PDMS composite. Sensor. Actual. A Phys. 2019, 299. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, Y.; Asghar, W.; Ding, J.; Su, X.; Li, S. Asymmetric Structure Based Flexible Strain Sensor for Simultaneous Detection of Various Human Joint Motions. ACS Appl. Electron. Mater. 2019, 1, 1866–1872. [Google Scholar] [CrossRef]

- Shi, X.; Cheng, C.H. Artificial hair cell sensors using liquid metal alloy as piezoresistors. In Proceedings of the IEEE International Conference on Nano/micro Engineered & Molecular Systems, Suzhou, China, 7–10 April 2013. [Google Scholar]

- Liao, M.; Liao, H.; Ye, J.; Wan, P.; Zhang, L. Polyvinyl alcohol-stabilized liquid metal hydrogel for wearable transient epidermal sensors. ACS Appl. Mater. Inter. 2019, 11, 47358–47364. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Lee, M.; Shim, H.J.; Ghaffari, R.; Cho, H.R.; Son, D.; Jung, Y.H.; Soh, M.; Choi, C.; Jung, S.; et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 2014, 5. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Spina, F.; Pouryazdan, A.; Costa, J.; Ponce, C.L.; Münzenrieder, N. Directly 3D-printed monolithic soft robotic gripper with liquid metal microchannels for tactile sensing. Flex. Print. Electron. 2019, 4. [Google Scholar] [CrossRef]

- Yi, L.; Li, J.; Guo, C.; Li, L.; Liu, J. Liquid metal ink enabled rapid prototyping of electrochemical sensor for wireless glucose detection on the platform of mobile phone. J. Med. Devices. 2015, 9. [Google Scholar] [CrossRef]

- Feng, Y.; Huang, X.; Liu, S.; Guo, W.; Li, Y.; Wu, H. A self-powered smart safety belt enabled by triboelectric nanogenerators for driving status monitoring. Nano Energy 2019, 62, 197–204. [Google Scholar] [CrossRef]

- Wang, H.; Xiang, Z.; Giorgia, P.; Mu, X.; Yang, Y.; Wang, Z.L.; Lee, C. Triboelectric liquid volume sensor for self-powered lab-on-chip applications. Nano Energy 2016, 23, 80–88. [Google Scholar] [CrossRef]

- Wirekoh, J.; Valle, L.; Po, N.; Park, Y.L. Sensorized, flat, pneumatic artificial muscle embedded with biomimetic microfluidic sensors for proprioceptive feedback. Soft Robot. 2019, 6, 768–777. [Google Scholar] [CrossRef] [Green Version]

- Lin, P.; Zhan, W.Z.; Yan, Q.; Xie, J.; Fan, Y.; Wu, M.; Chen, Y.; Cheng, Z. Capillary-based microfluidic fabrication of liquid metal microspheres toward functional microelectrodes and photothermal medium. ACS Appl. Mater. Interfaces 2019, 11, 25295–25305. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Y.; Sun, X.; Liu, J. Advances in Liquid Metal-Enabled Flexible and Wearable Sensors. Micromachines 2020, 11, 200. https://doi.org/10.3390/mi11020200

Ren Y, Sun X, Liu J. Advances in Liquid Metal-Enabled Flexible and Wearable Sensors. Micromachines. 2020; 11(2):200. https://doi.org/10.3390/mi11020200

Chicago/Turabian StyleRen, Yi, Xuyang Sun, and Jing Liu. 2020. "Advances in Liquid Metal-Enabled Flexible and Wearable Sensors" Micromachines 11, no. 2: 200. https://doi.org/10.3390/mi11020200

APA StyleRen, Y., Sun, X., & Liu, J. (2020). Advances in Liquid Metal-Enabled Flexible and Wearable Sensors. Micromachines, 11(2), 200. https://doi.org/10.3390/mi11020200