The Characteristics and Locking Process of Nonlinear MEMS Gyroscopes

Abstract

1. Introduction

2. Analysis and Methods

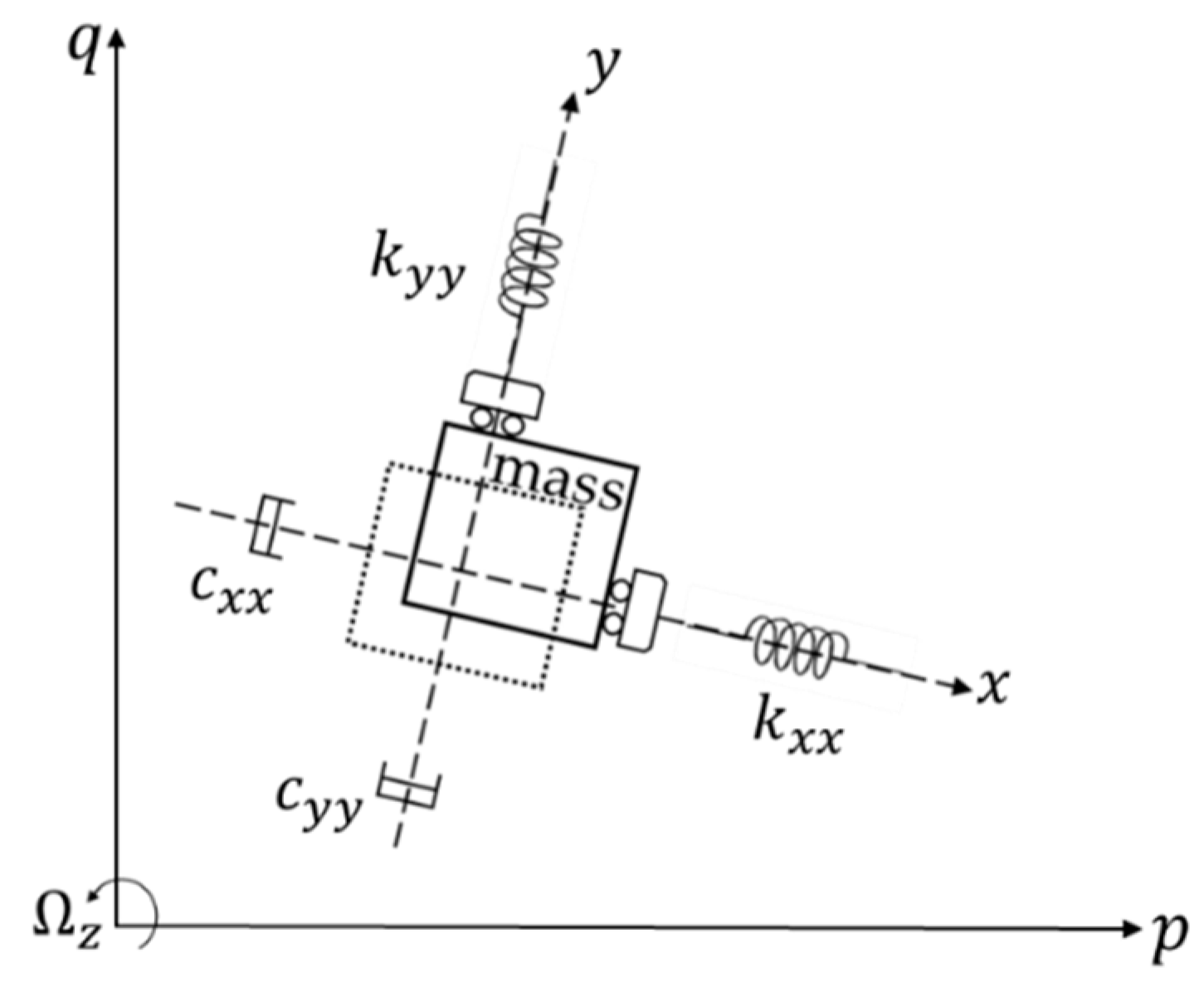

2.1. The Working Principle and Characteristics of Gyroscopes

2.2. The Characteristics and PLL’s Locking Process of Nonlinear Gyroscopes and the Related Improvement

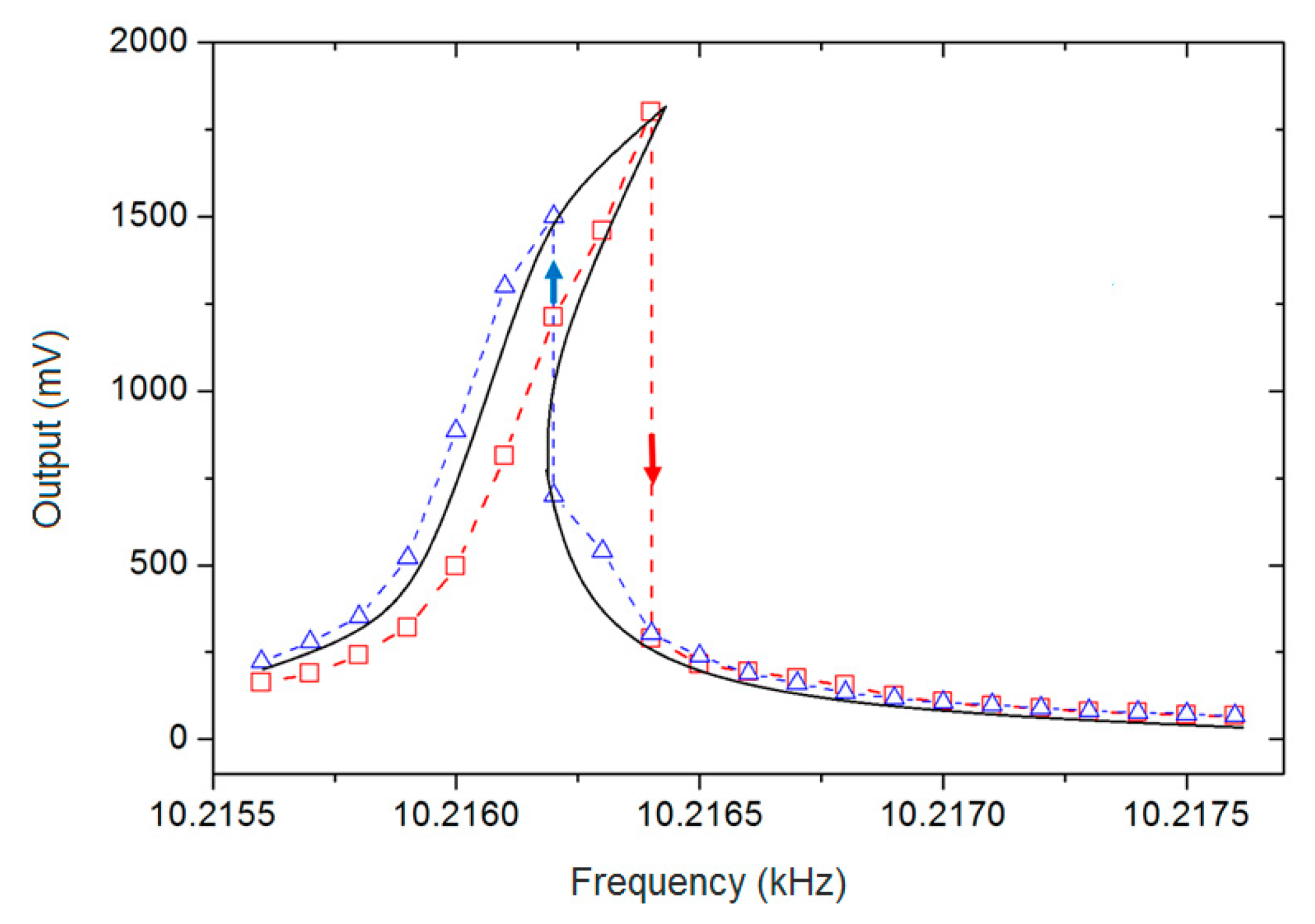

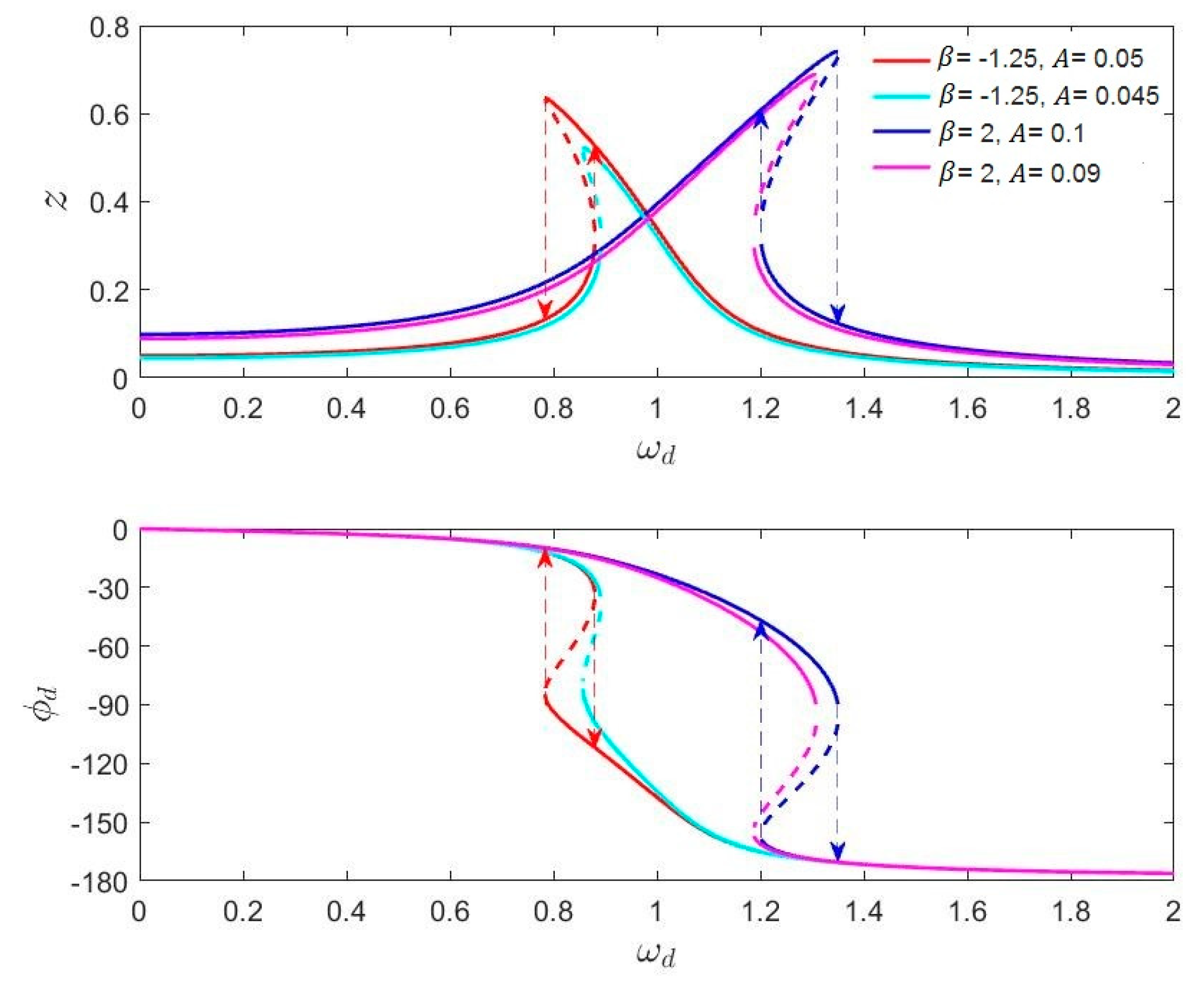

2.2.1. The Frequency Characteristics of Nonlinear Gyroscopes

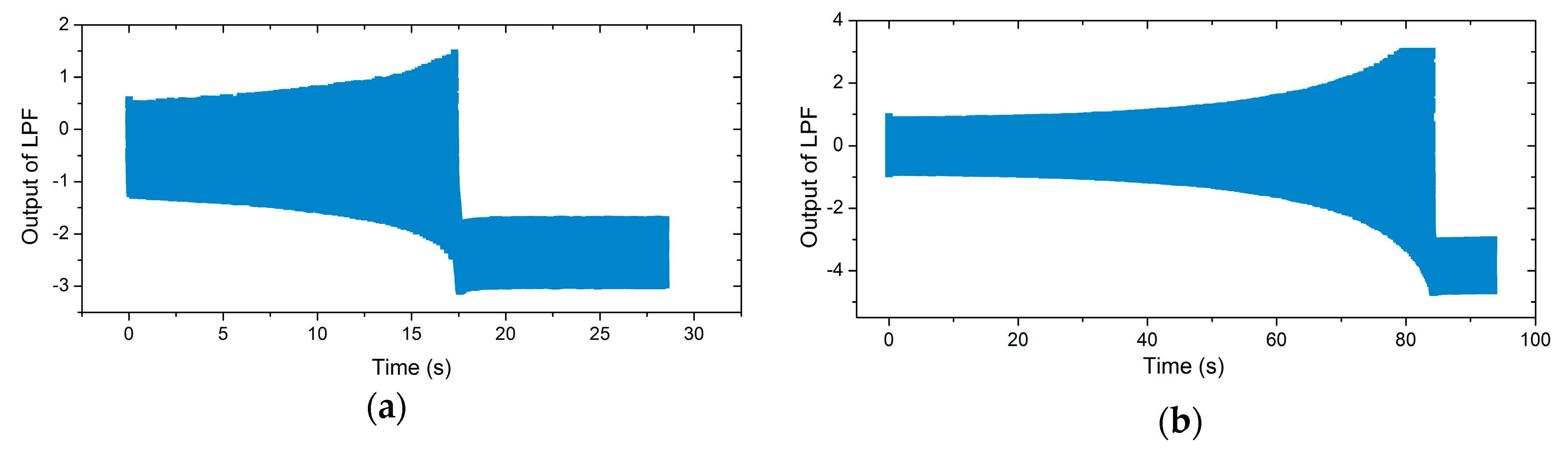

2.2.2. The Effect of Nonlinearity on PLL’s Locking Process

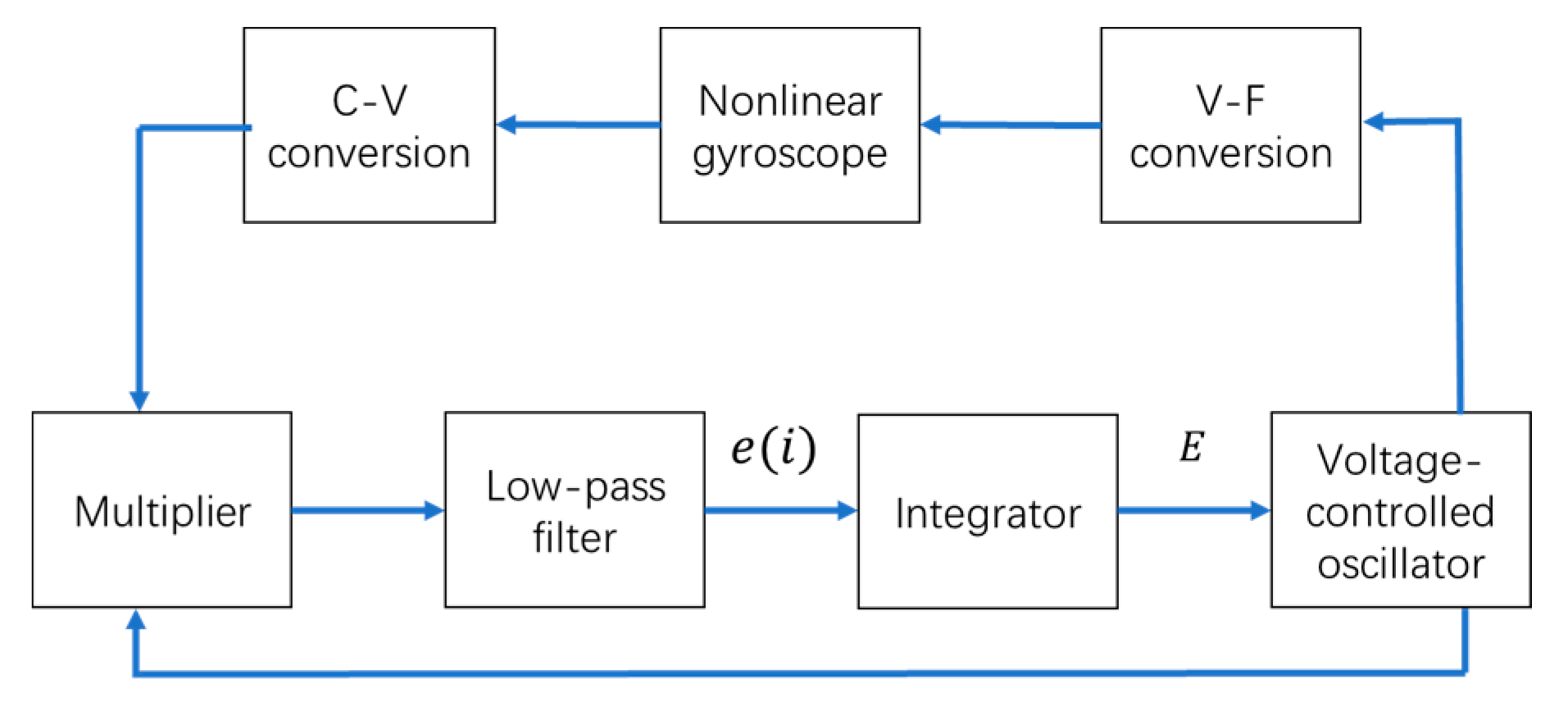

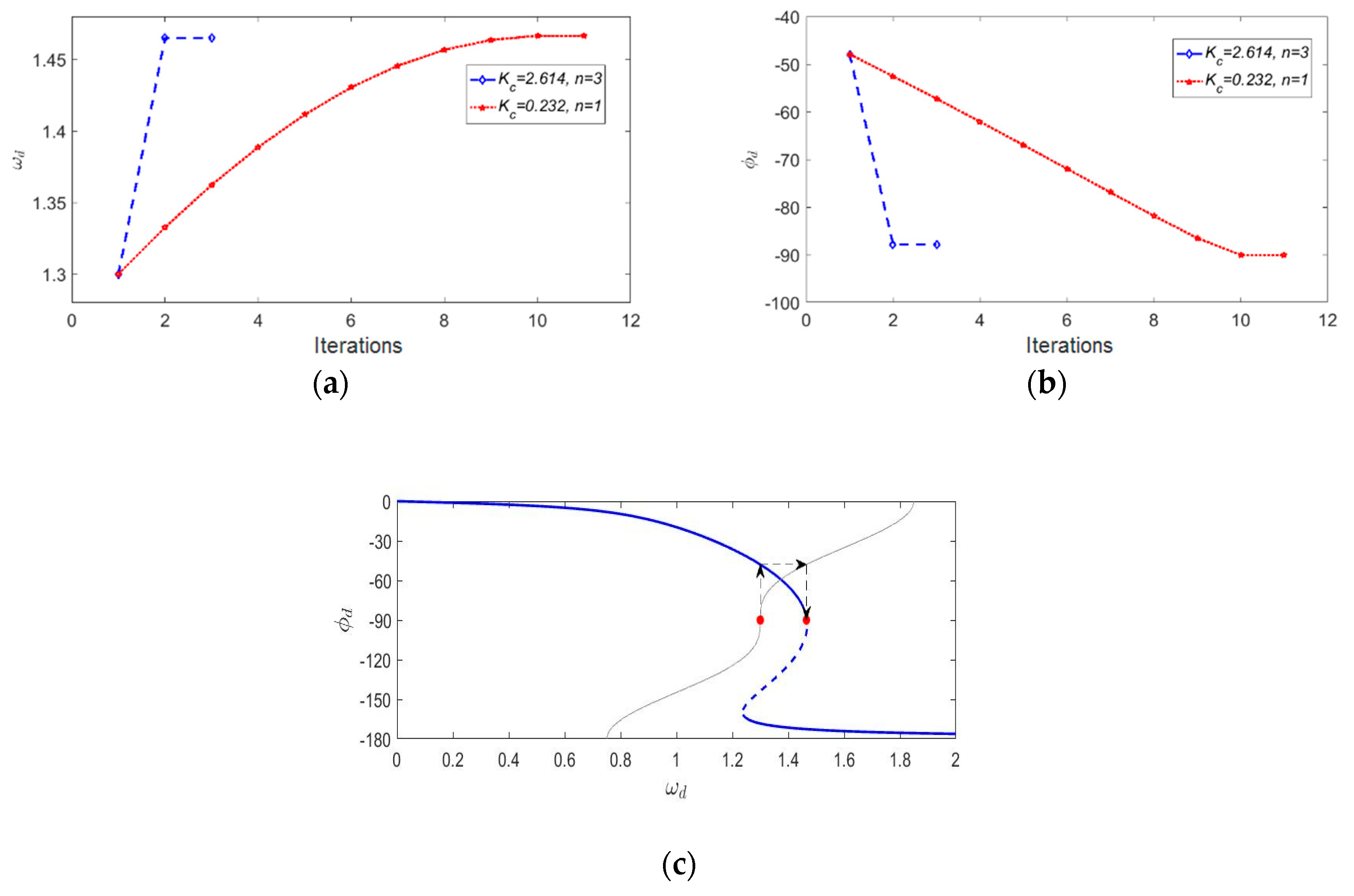

2.2.3. The Design of a Nonlinear PLL

3. Results and Discussion

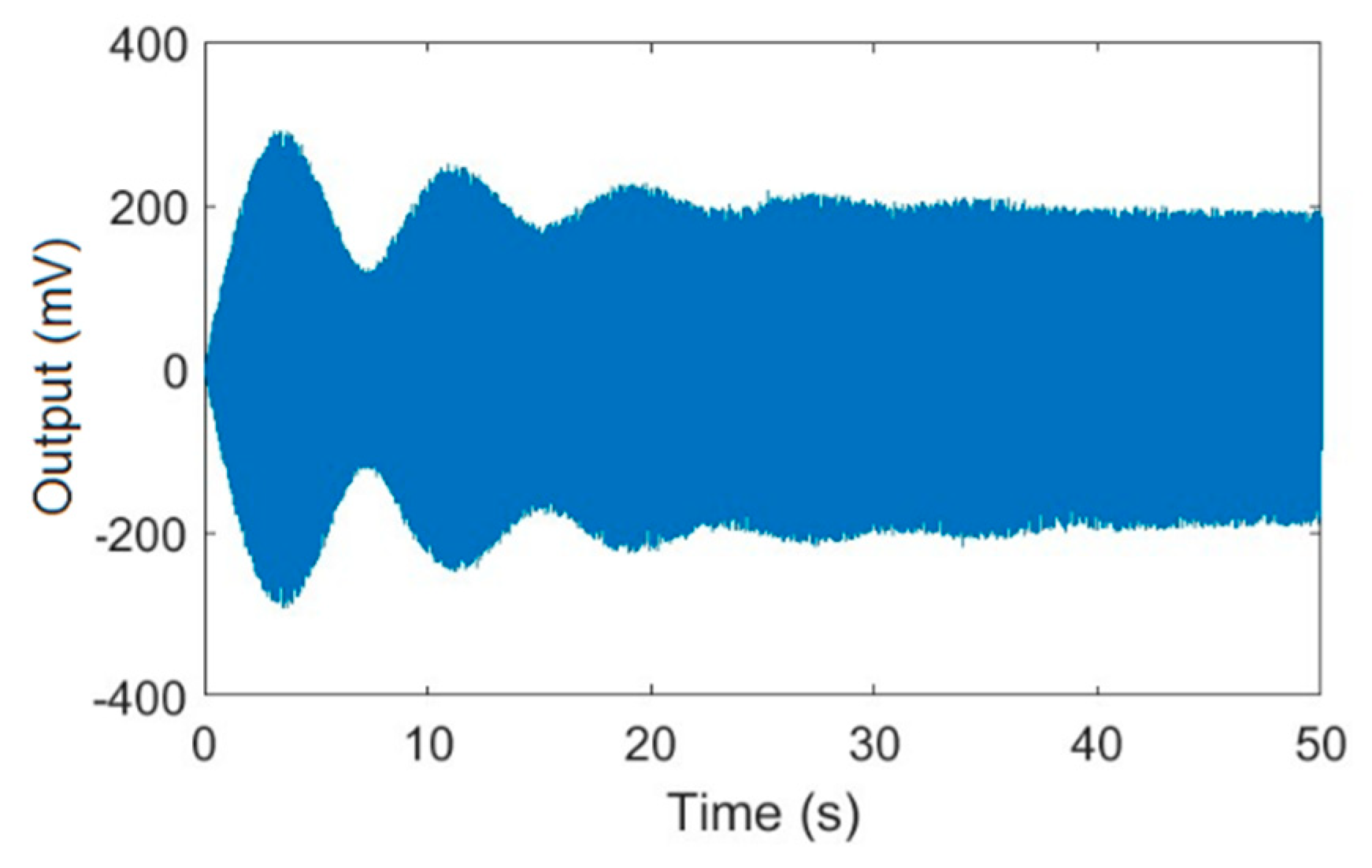

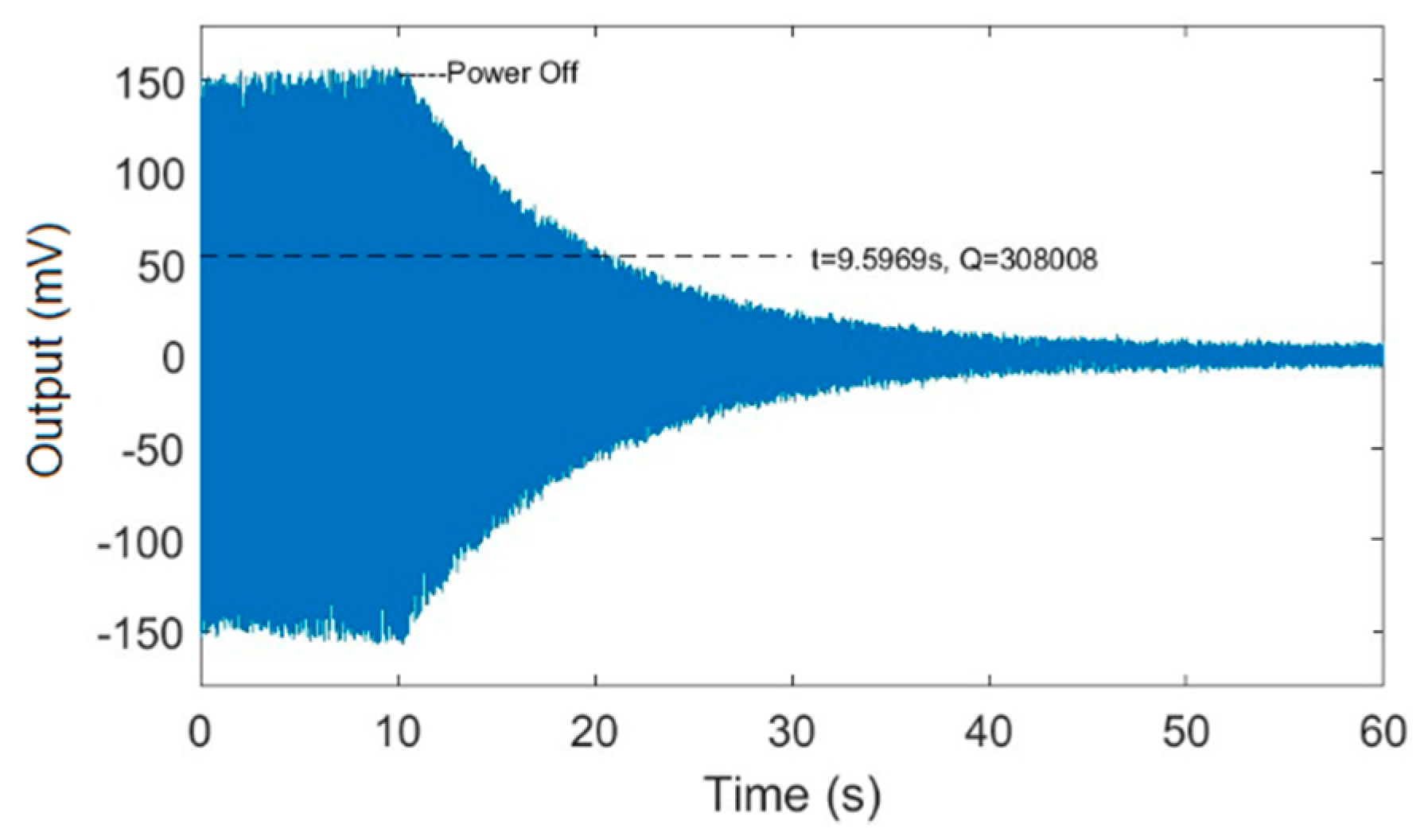

3.1. The Start-Up Oscillation Process of MEMS Gyroscopes

3.2. The Simulation and Experimental Results of Nonlinear Gyroscopes

3.2.1. The Frequency Characteristics of Nonlinear Gyroscopes

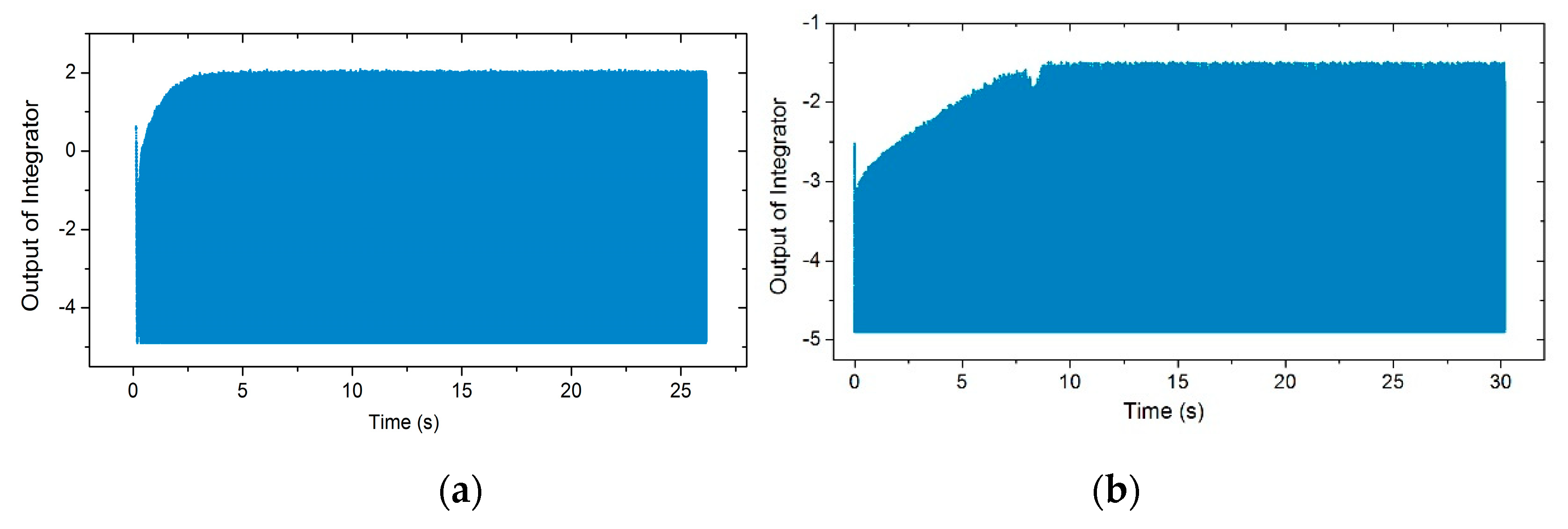

3.2.2. The PLL’s Locking Process of Nonlinear Gyroscopes

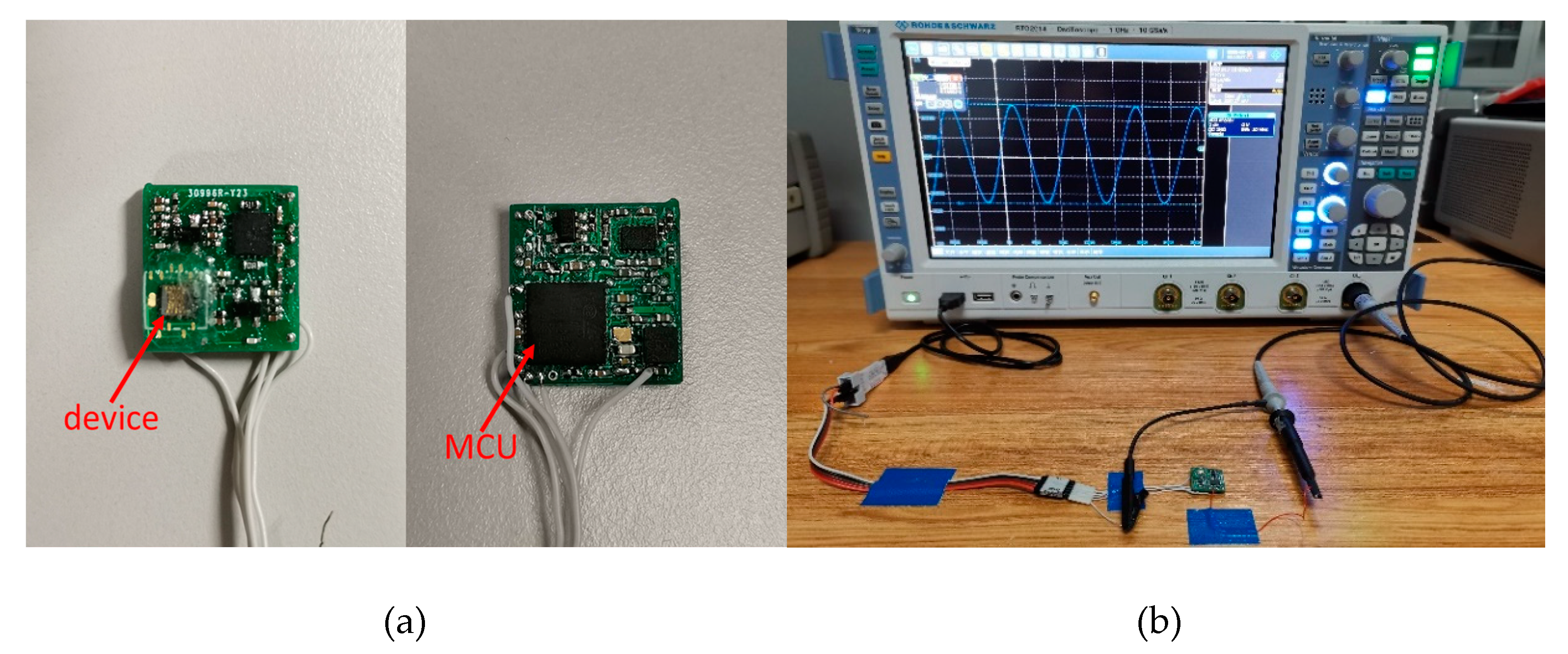

3.2.3. The Simulation and Experimental Results of the NPLLs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Guo, Z.S.; Cheng, F.C.; Li, B.Y.; Cao, L.; Lu, C.; Song, K. Research development of silicon MEMS gyroscopes: A review. Microsyst. Technol. 2015, 21, 2053–2066. [Google Scholar]

- Cechowicz, R. Bias drift estimation for mems gyroscope used in inertial navigation. Acta Mech. Autom. 2017, 11, 104–110. [Google Scholar] [CrossRef]

- Seeger, J.; Lim, M.; Nasiri, S. Development of high-performance, high-volume consumer MEMS gyroscopes. In Proceedings of the Solid-State Sensors, Actuators, and Microsystems Workshop 2010, Hilton Head Island, SC, USA, 6–10 June 2010. [Google Scholar]

- Shkel, A. Precision navigation and timing enabled by microtechnology: Are we there yet? Proceedings of SENSORS, 2010 IEEE, Kona, HI, USA, 1–4 November 2010; pp. 5–9. [Google Scholar]

- Brown, T.G.; Davis, B.; Hepner, D.; Faust, J.; Myers, C.; Muller, C.; Harkins, T.; Holis, M.; Placzankis, B. Strap-down microelectromechanical (MEMS) sensors for high-g munition applications. IEEE Trans. Magn. 2001, 37, 336–342. [Google Scholar] [CrossRef]

- Xia, G.M.; Yang, B.; Wang, S.R. Digital self-oscillation driving technology for silicon micro machined gyroscopes. Opt. Precis. Eng. 2011, 19, 635–640. [Google Scholar]

- Lin, L.T.; Liu, D.C.; Cui, J.; Guo, Z.Y.; Yang, Z.C.; Yan, G.Z. Digital closed-loop controller design of a micromachined gyroscope based on auto frequency swept. In Proceedings of the 2011 6th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Kaohsiung, Taiwan, 20–23 February 2011; pp. 654–657. [Google Scholar]

- Xia, D.Z.; Hu, Y.W.; Wang, Y.L. Design and comparison of the application of EPLL and QPLL in a digitalized gyroscope system. Sens. Actuators A: Phys. 2016, 248, 257–271. [Google Scholar] [CrossRef]

- Ekinci, K.L.; Roukes, M.L. Nanoelectromechanical systems. Rev. Sci. Instrum. 2005, 76, 061101. [Google Scholar] [CrossRef]

- Rhoads, J.F.; Shaw, S.W.; Turner, K.L. Nonlinear dynamics and its applications in micro-and nanoresonators. J.Dyn. Syst. Meas. Control 2010, 132, 034001. [Google Scholar] [CrossRef]

- Yang, Y.S.; Ng, E.J.; Polunin, P.M.; Chen, Y.H.; Flader, I.B.; Shaw, S.W.; Dykman, M.I.; Kenny, T.W. Nonlinearity of Degenerately Doped Bulk-Mode Silicon MEMS Resonators. J. Microelectromechanical Syst. 2016, 25, 859–869. [Google Scholar] [CrossRef]

- Kaajakari, V.; Mattila, T.; Oja, A.; Seppa, H. Nonlinear limits for single-crystal silicon microresonators. J. Microelectromechanical Syst. 2004, 13, 715–724. [Google Scholar] [CrossRef]

- Tiwari, S.; Candler, R.N. Using flexural MEMS to study and exploit nonlinearities: A review. J. Micromech. Microeng. 2019, 29, 083002. [Google Scholar] [CrossRef]

- Cao, H.L.; Liu, Y.; Kou, Z.W.; Zhang, Y.J.; Shao, X.L.; Gao, J.Y.; Huang, K.; Shi, Y.B.; Tang, J.; Shen, C.; et al. Design, Fabrication and Experiment of Double U-Beam MEMS Vibration Ring Gyroscope. Micromachines 2019, 10, 186. [Google Scholar] [CrossRef] [PubMed]

- Kogan, O. Controlling transitions in a Duffing oscillator by sweeping parameters in time. Phys. Rev. E 2007, 76, 037203. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.K.; Melamud, R.; Chandorkar, S.; Salvia, J.; Yoneoka, S.; Kenny, T.W. Stable Operation of MEMS Oscillators Far Above the Critical Vibration Amplitude in the Nonlinear Regime. J. Microelectromechanical Syst. 2011, 20, 1228–1230. [Google Scholar] [CrossRef]

- Tatar, E.; Mukherjee, T.; Fedder, G.K. Tuning of nonlinearities and quality factor in a mode-matched gyroscope. In Proceedings of the 2014 IEEE 27th International Conference on Micro Electro Mechanical Systems (MEMS), San Francisco, CA, USA, 26–30 January 2014; pp. 801–804. [Google Scholar]

- Tatar, E.; Mukherjee, T.; Fedder, G.K. Nonlinearity tuning and its effects on the performance of a MEMS gyroscope. In Proceedings of the 2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 1133–1136. [Google Scholar]

- Vatanparvar, D.; Asadian, M.H.; Askari, S.; Shkel, A.M. Characterization of Scale Factor Nonlinearities in Coriolis Vibratory Gyroscopes. In Proceedings of the 2019 IEEE Symposium on Inertial Sensors and Systems (INERTIAL), Naples, FL, USA, 1–5 April 2019; pp. 1–4. [Google Scholar]

- Sohanian-Haghighi, H.; Davaie-Markazi, A.H. Resonance Tracking of Nonlinear MEMS Resonators. IEEE/ASME Trans. Mechatron. 2011, 17, 617–621. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, J.; He, Y.R.; Yang, F.; Yang, F.H.; Han, G.W.; Si, C.W.; Ning, J. Research on a 3D Encapsulation Technique for Capacitive MEMS Sensors Based on Through Silicon Via. Sensors 2018, 19, 93. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Zhao, J.; Wang, X.; Xia, G.M.; Shi, Q.; Qiu, A.P.; Xu, Y.P. A sub-0.1°/h bias-instability split-mode MEMS gyroscope with CMOS readout circuit. IEEE J. Solid-State Circuits 2018, 53, 2636–2650. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Y.; Xu, P.; Han, G.; Si, C.; Ning, J.; Yang, F. The Characteristics and Locking Process of Nonlinear MEMS Gyroscopes. Micromachines 2020, 11, 233. https://doi.org/10.3390/mi11020233

Su Y, Xu P, Han G, Si C, Ning J, Yang F. The Characteristics and Locking Process of Nonlinear MEMS Gyroscopes. Micromachines. 2020; 11(2):233. https://doi.org/10.3390/mi11020233

Chicago/Turabian StyleSu, Yan, Pengfei Xu, Guowei Han, Chaowei Si, Jin Ning, and Fuhua Yang. 2020. "The Characteristics and Locking Process of Nonlinear MEMS Gyroscopes" Micromachines 11, no. 2: 233. https://doi.org/10.3390/mi11020233

APA StyleSu, Y., Xu, P., Han, G., Si, C., Ning, J., & Yang, F. (2020). The Characteristics and Locking Process of Nonlinear MEMS Gyroscopes. Micromachines, 11(2), 233. https://doi.org/10.3390/mi11020233