Implementation of a Single Emulsion Mask for Three-Dimensional (3D) Microstructure Fabrication of Micromixers Using the Grayscale Photolithography Technique

Abstract

:1. Introduction

2. Methodology

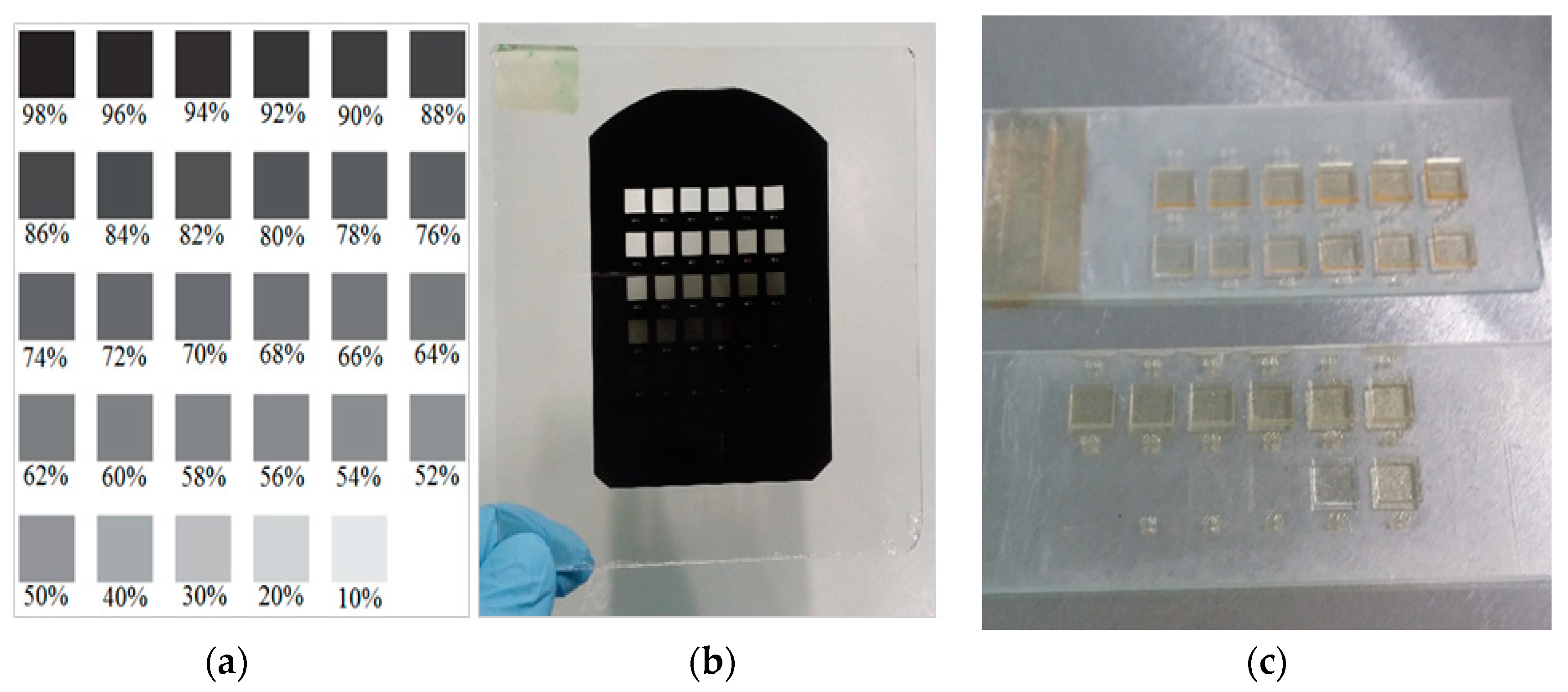

2.1. Grayscale Thickness Profiling

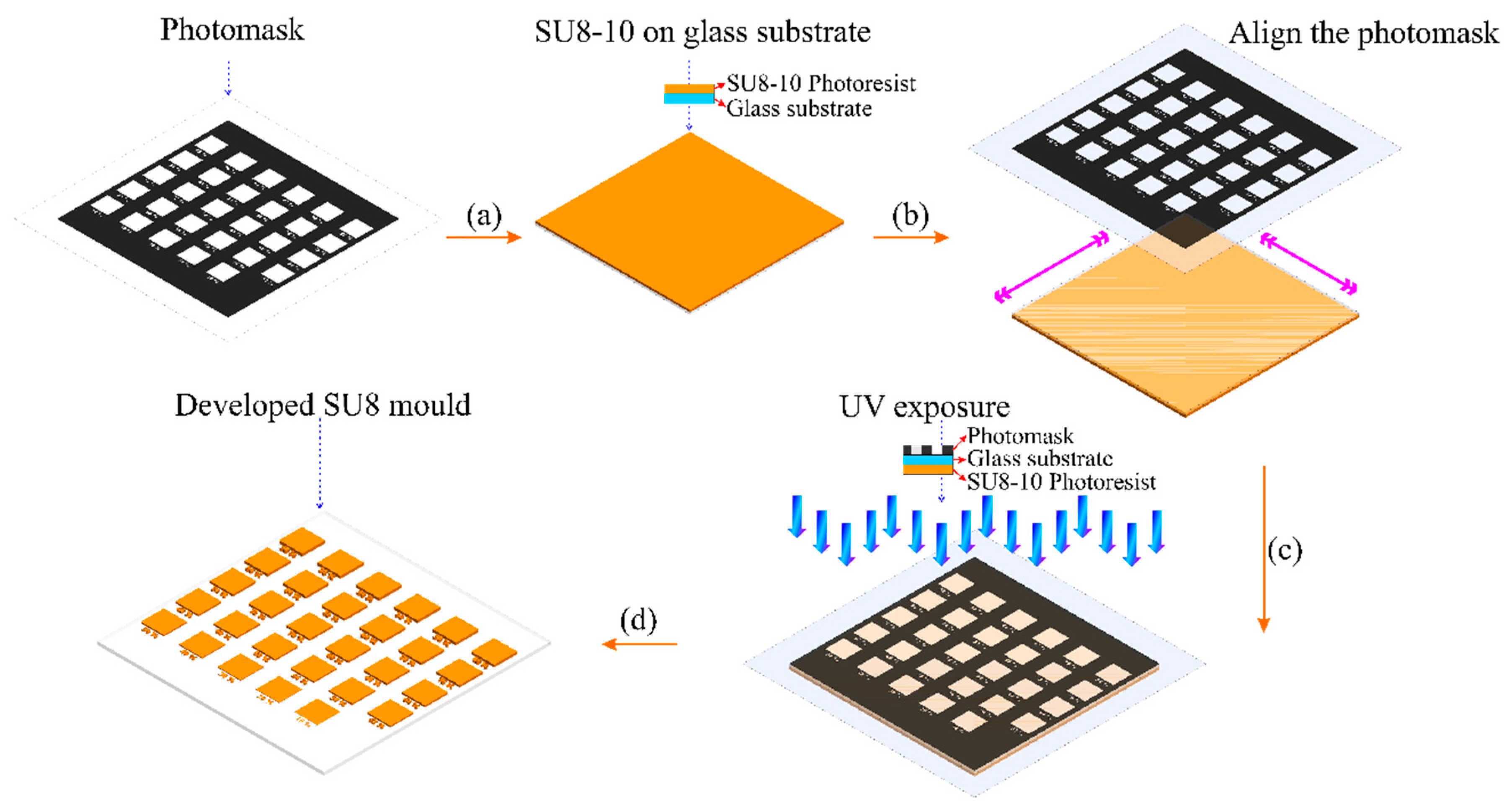

2.2. Application of the Grayscale Fabrication Technique for Passive Micromixer Development

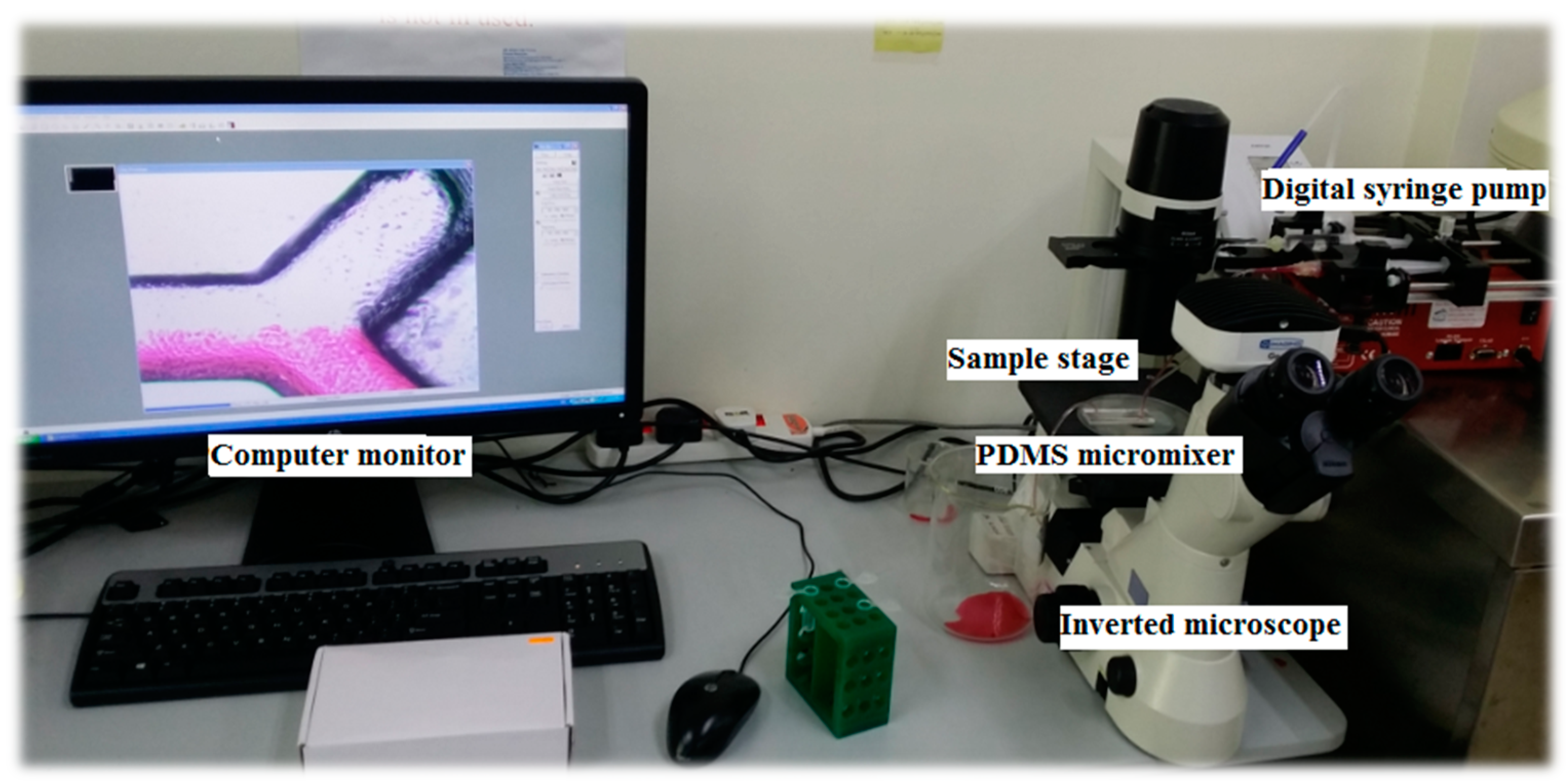

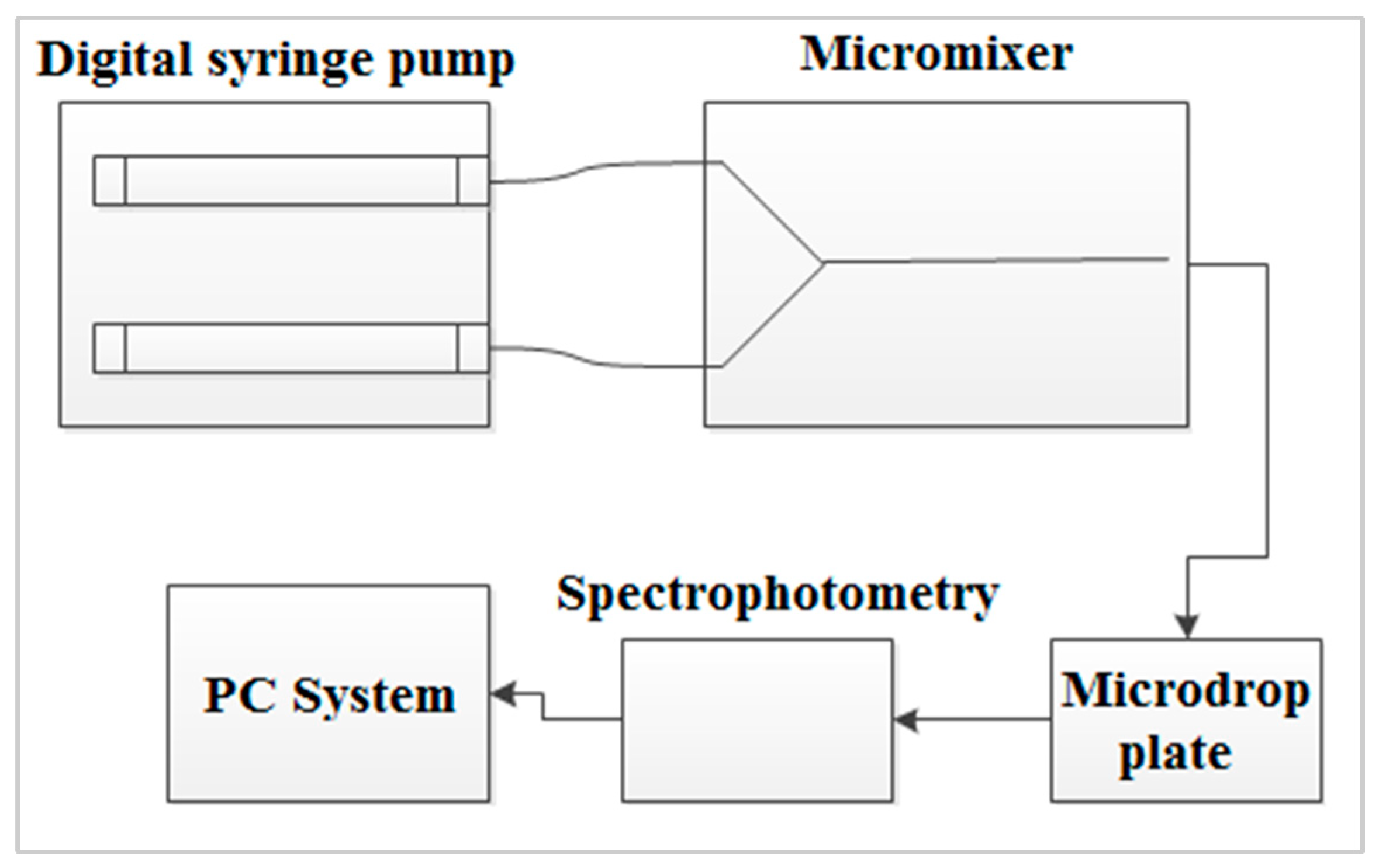

2.3. Mixing Performance Evaluation

3. Results and Discussion

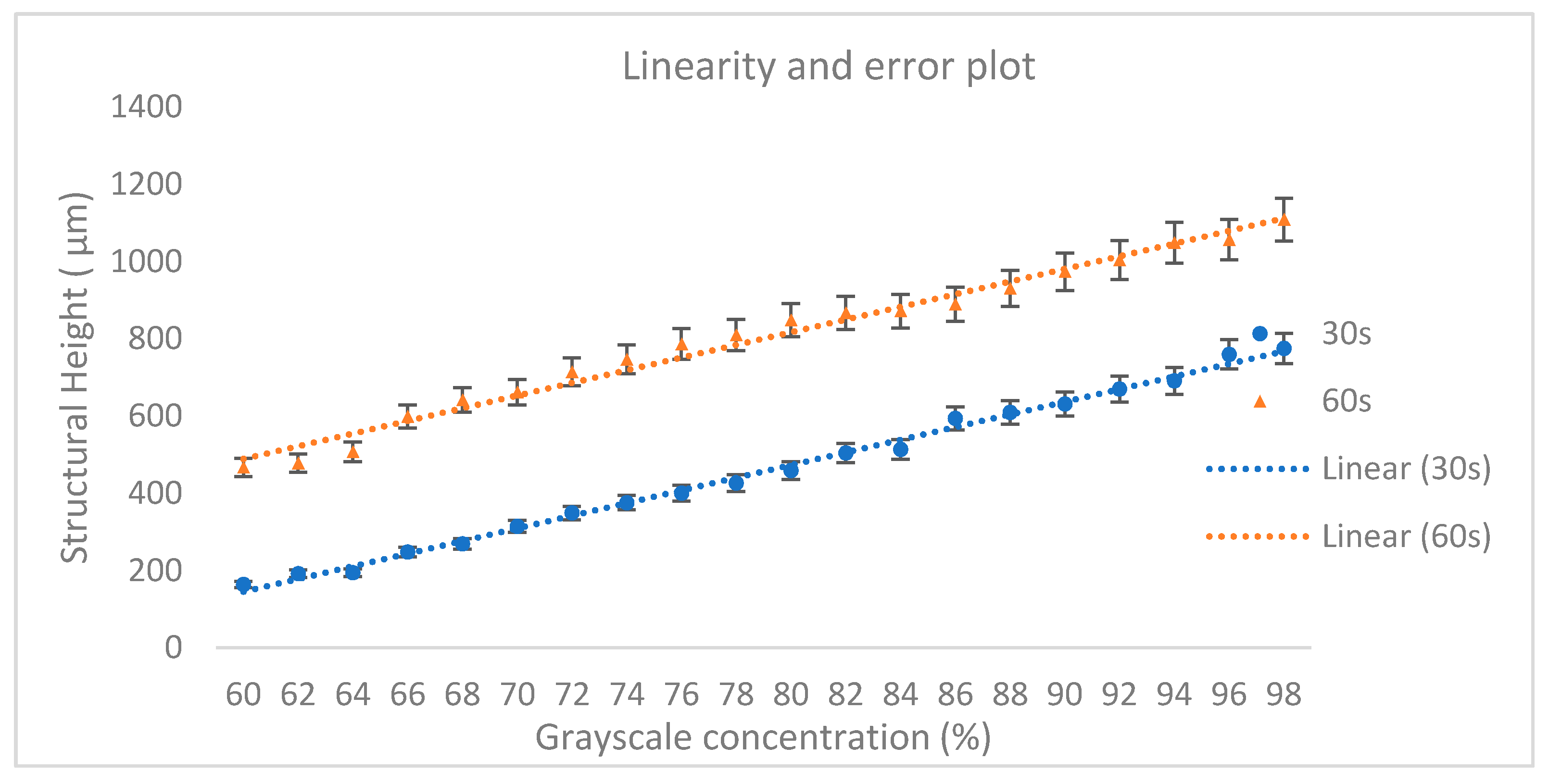

3.1. Grayscale Concentration–Thickness Relationship

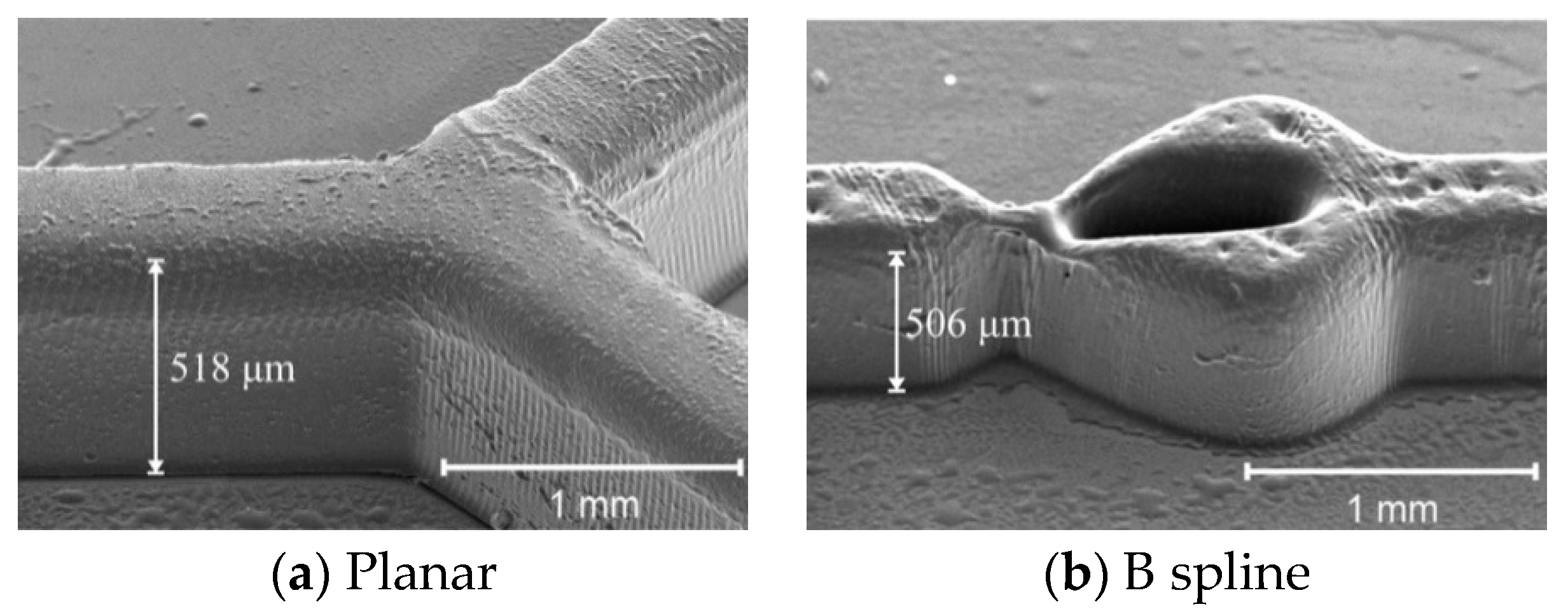

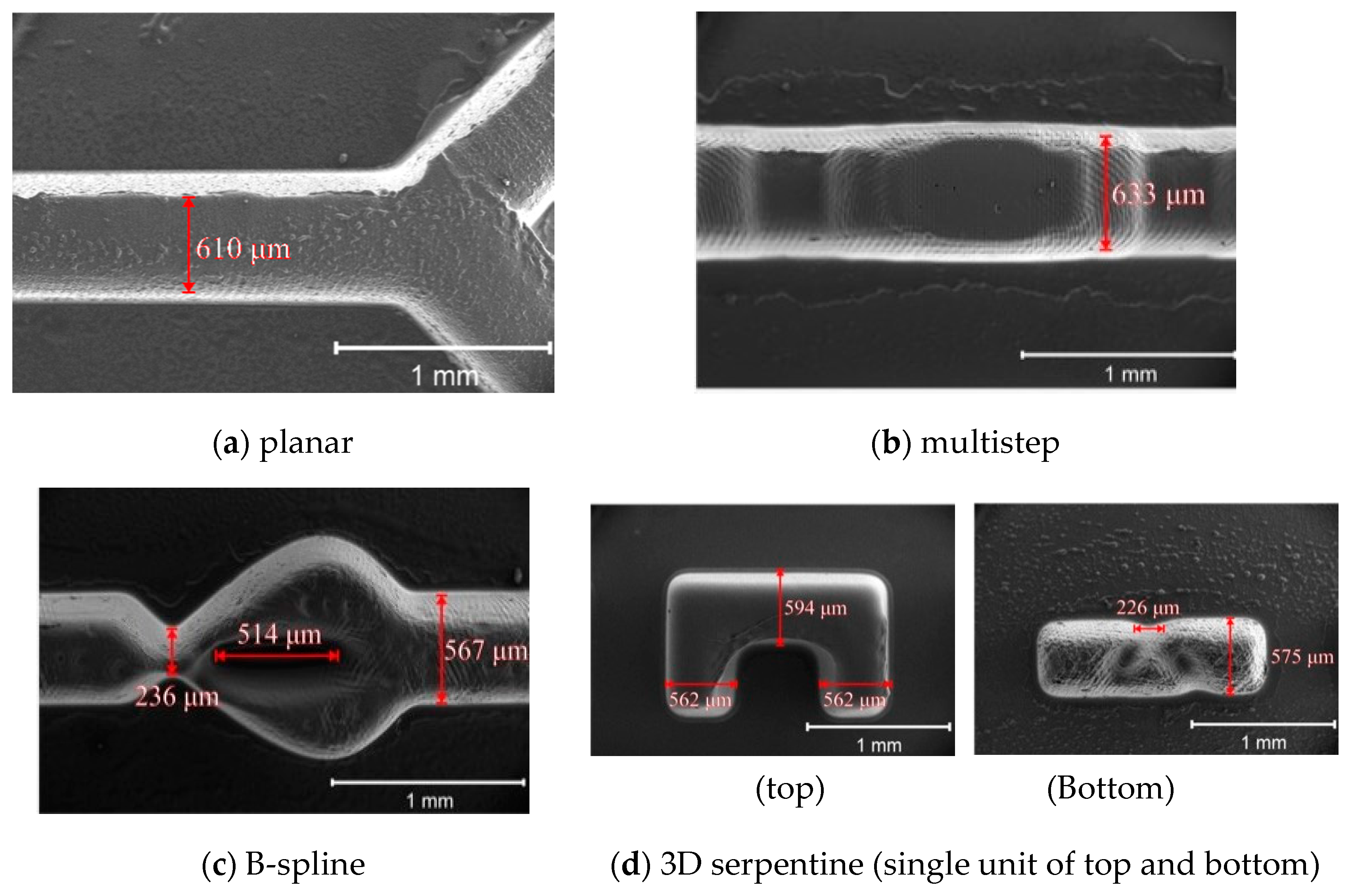

3.2. Fabrication of Passive Micromixer

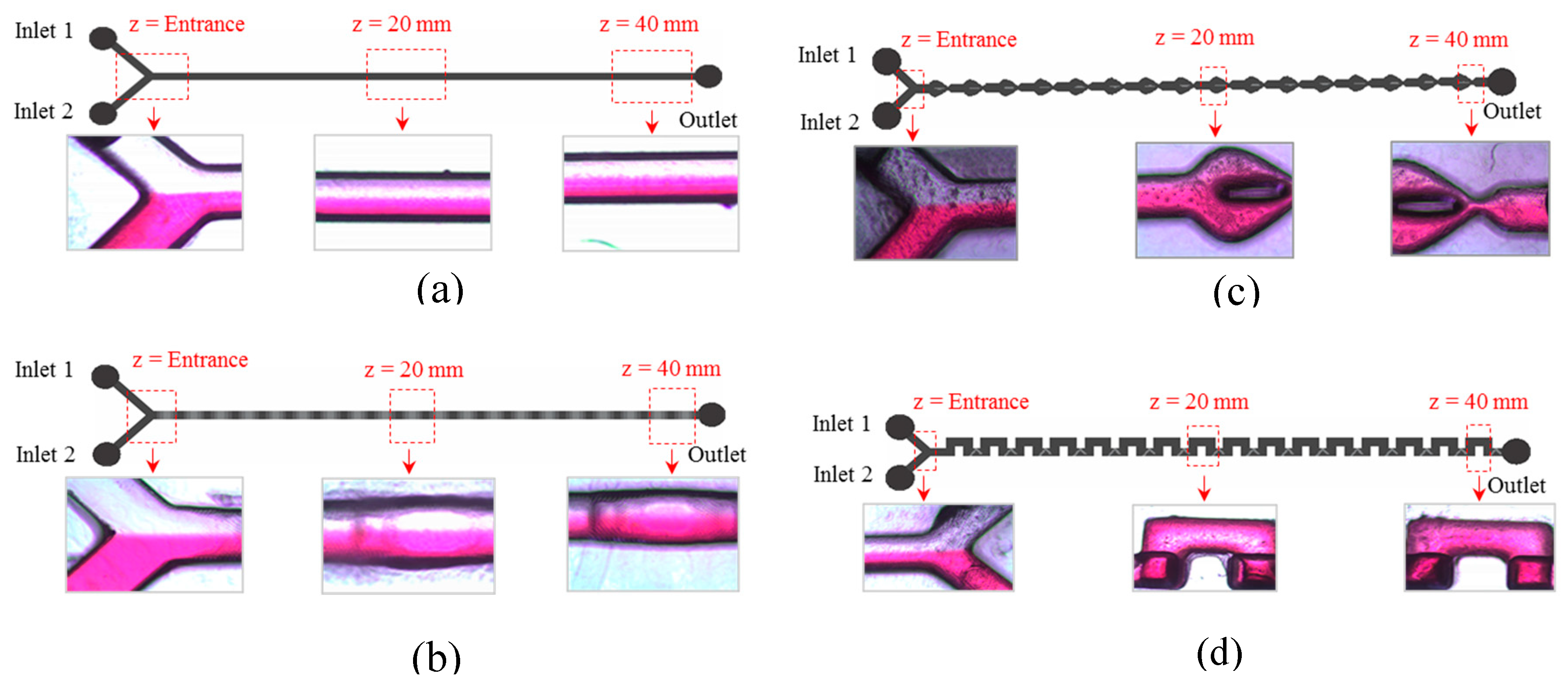

3.3. Mixing Performance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Faustino, V.; Catarino, S.O.; Lima, R.; Minas, G. Biomedical microfluidic devices by using low-cost fabrication technique. Biomechanics 2016, 49, 2280–2292. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Derkus, B. Applying the minituarisation technologies for biosensor design. Biosens. Bioelectron. 2016, 79, 901–913. [Google Scholar] [CrossRef] [PubMed]

- Zhai, J.; Li, H.; Wong, A.H.; Dong, C.; Yi, S.; Jia, Y.; Mak, P.; Deng, C.; Martins, R.P. A digital microfluidic system with 3D microstructures for single-cell culture. Micrsyst. Nanoeng. 2020, 6, 6. [Google Scholar] [CrossRef] [Green Version]

- Pranzo, D.; Larizza, P.; Filippini, D.; Percoco, G. Extrusion-Based 3D Printing of Microfluidic Devices for Chemical and Biomedical Applications: A Topical Review. Micromachines 2018, 9, 374. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dy, A.J.; Cosmanescu, A.; Sluka, J.; Glazier, J.A.; Stupack, D.; Amarie, D. Fabricating microfluidic valve master molds SU-8 photoresist. Micromech. Microeng. 2014, 24, 057001. [Google Scholar] [CrossRef] [Green Version]

- Meunier, M.; Blanchard-Dionne, A.-P. Electron beam lithography using a PMMA/P (MMA 8.5 MAA) bilayer for negative tone lift-off process. Vac. Sci. Technol. B 2015, 33, 061602. [Google Scholar]

- Grigali, S.T.V.; Lazauskas, A.; Jucius, D.; Vir, D.; Abakevi, B.; Smetona, S. Microlens fabrication by 3D electron beam lithography combined with thermal reflow technique. Microelectron. Eng. 2016, 164, 23–29. [Google Scholar] [CrossRef]

- Malinauskas, S.J.M.; Albertas, Ž.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V. Ultrafast laser processing of materials: From science to industry. Light Sci. Appl. 2016, 5, 3–5. [Google Scholar] [CrossRef] [Green Version]

- Xing, J.; Zheng, M.; Duan, X. Two-photon polymerization microfabrication of hydrogels: An advanced 3D printing technology for tissue engineering and drug delivery. Chem. Soc. Rev. 2015, 44, 5031–5039. [Google Scholar] [CrossRef] [Green Version]

- Gissibl, H.G.T.; Thiele, S.; Herkommer, A. Two-photon direct laser writing of ultracompact multi-lens objectives. Nat. Photonics 2016, 10, 554. [Google Scholar] [CrossRef]

- Lee, J.B.; Choi, K.; Yoo, K. Innovative SU-8 Lithography Techniques and Their Applications. Micromachines 2015, 6, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Mekaru, H. Performance of SU-8 Membrane Suitable for Deep X-ray Grayscale Lithography. Micromachines 2015, 6, 252–265. [Google Scholar] [CrossRef] [Green Version]

- Glick, L.L.C.C.; Srimongkol, M.T.; Schwartz, A.J.; Zhuang, W.S.; Lin, J.C.; Warren, R.H.; Tekell, D.R.; Satamalee, P.A. Rapid assembly of multilayer microfluidic structures via 3D-printed transfer molding and bonding. Microsyst. Nanoeng. 2016, 2, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Nam, W.H.H.; Yangfan, C.; Yiwei, S.; Yin, C.; Qian, T. Direct one-step molding of 3D—Printed structures for convenient fabrication of truly 3D PDMS microfluidic chips. Microfluid. Nanofluidics 2015, 19, 9–18. [Google Scholar]

- Rammohan, A.; Dwivedi, P.K.; Martinez-duarte, R.; Katepalli, H.; Madou, M.J.; Sharma, A. Sensors and Actuators B: Chemical One-step maskless grayscale lithography for the fabrication of 3-dimensional structures in SU-8. Sens. Actuators B Chem. 2010, 153, 125–134. [Google Scholar] [CrossRef]

- Zhong, K.; Gao, Y.; Li, F.; Zhang, Z.; Luo, N. Optik Fabrication of PDMS microlens array by digital maskless grayscale lithography and replica molding technique. Optik 2014, 125, 2413–2416. [Google Scholar] [CrossRef]

- Mori, R.; Hanai, K.; Matsumoto, Y. Three dimensional micromachining of SU-8 and application for PDMS microcapillaries. In Proceedings of the 6th International Conference on Miniaturized Systems for Chemistry and Life Sciences, Malmö, Sweden, 26–30 September 2004; p. 333. [Google Scholar]

- Grushina, A. Direct-write grayscale lithography. Adv. Opt. Technl. 2019, 8, 163–169. [Google Scholar] [CrossRef]

- Lee, T.P.; Mohamed, K. 3D Microfabrication Using Emulsion Mask Grayscale Photolithography Technique 3D Microfabrication Using Emulsion Mask Grayscale Photolithography Technique. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012032. [Google Scholar] [CrossRef] [Green Version]

- Hardt, S.; Drese, K.S.; Hessel, V.; Schönfeld, F. Passive micromixers for applications in the microreactor and μTAS fields. Microfluid Nanofluid 2005, 1, 108–118. [Google Scholar] [CrossRef]

- Jeong, G.S.; Chung, S.; Kim, C.B.; Lee, S.H. Applications of micromixing technology. Analyst 2010, 135, 460–473. [Google Scholar] [CrossRef]

- Lee, C.Y.; Fu, L.M. Recent advances and applications of micromixers. Sens. Actuators B Chem. 2018, 259, 677–702. [Google Scholar] [CrossRef]

- Cai, G.; Xue, L.; Zhang, H.; Lin, J. A Review on Micromixers. Micromachines 2017, 8, 274. [Google Scholar] [CrossRef]

- Mart, J.I.; Betancourt, H.A.; Garc, E.; Rodriguez, C.A.; Siller, H.R. Rapid Fabrication of Disposable Micromixing Arrays Using Xurography and Laser Ablation. Micromachines 2017, 8, 144. [Google Scholar]

- Sivashankar, S.; Agambayev, S.; Mashraei, Y. A ‘twisted’ microfluidic mixer suitable for a wide range of flow rate applications. Biomicrofluidics 2016, 10, 034120. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jain, M.; Yeung, A.; Nandakumar, K. Induced charge electro osmotic mixer: Obstacle shape optimization. Biomicrofluidics 2009, 3, 022413. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clark, J.; Kaufman, M.; Fodor, P.S. Mixing Enhancement in Serpentine Micromixers with a Non-Rectangular Cross-Section. Micromachines 2018, 9, 107. [Google Scholar] [CrossRef] [Green Version]

- Shaltut, A.; Gawad, A.A. Mixing Enhancement by Topology Optimization of Obstacles on Wall in Passive Micromixers using 3D Numerical Simulation. In Proceedings of the Thirteenth International Conference of Fluid Dynamics, Steigenberger Hotel El Tahrir, Cairo, Egypt, 21–22 December 2018. [Google Scholar]

- Tran-minh, N.; Dong, T.; Karlsen, F. An efficient passive planar micromixer with ellipse-like micropillars for continuous mixing of human blood. Comput. Methods Programs Biomed. 2014, 117, 20–29. [Google Scholar] [CrossRef]

- Hossain, S.; Lee, I.; Kim, S.M.; Kim, K.Y. A micromixer with two-layer serpentine crossing channels having excellent mixing performance at low Reynolds numbers. Chem. Eng. J. 2017, 327, 268–277. [Google Scholar] [CrossRef]

- Li, T.; Chen, X. Numerical investigation of 3D novel chaotic micromixers with obstacles. Int. J. Heat Mass Transf. 2017, 115, 278–282. [Google Scholar] [CrossRef]

- Nawi, M.N.M.; Manaf, A.A.; Rahman, M.F.A.; Arshad, M.R.; Sidek, O. One-side-electrode-type fluidic-based capacitive pressure sensor. IEEE Sens. J. 2014, 15, 1738–1746. [Google Scholar] [CrossRef]

| Type | Targeted Width (μm) | Actual Width (μm) | Deviation Error (%) |

|---|---|---|---|

| Planar | 600 | 610 | 1.7 |

| Multistep | 600 | 633 | 5.5 |

| B spline | 600 | 567 | 0.5 |

| 3D Serpentine (top) 3D serpentine (bottom) | 600 600 | 562 and 594 575 | 6.3 and 1.0 4.2 |

| Concentration of Red Dye | Calculated Percentage of Red Dye (%) | Absorbance Value |

|---|---|---|

| Highest concentration (1 mg/mL) | 100 | 1.3 (Spectroscopy measurement) |

| Complete mixing (0.5 mg/mL) | 50 | 0.65 (Calculated based on Beers law assumption |

| Lowest concentration (0 mg/L) | 0 | 0.1 (Spectroscopy measurement) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdul Hamid, I.S.L.; Khi Khim, B.; Sal Hamid, S.; Abd Rahman, M.F.; Abd Manaf, A. Implementation of a Single Emulsion Mask for Three-Dimensional (3D) Microstructure Fabrication of Micromixers Using the Grayscale Photolithography Technique. Micromachines 2020, 11, 548. https://doi.org/10.3390/mi11060548

Abdul Hamid ISL, Khi Khim B, Sal Hamid S, Abd Rahman MF, Abd Manaf A. Implementation of a Single Emulsion Mask for Three-Dimensional (3D) Microstructure Fabrication of Micromixers Using the Grayscale Photolithography Technique. Micromachines. 2020; 11(6):548. https://doi.org/10.3390/mi11060548

Chicago/Turabian StyleAbdul Hamid, Intan Sue Liana, Beh Khi Khim, Sofiyah Sal Hamid, Mohamad Faizal Abd Rahman, and Asrulnizam Abd Manaf. 2020. "Implementation of a Single Emulsion Mask for Three-Dimensional (3D) Microstructure Fabrication of Micromixers Using the Grayscale Photolithography Technique" Micromachines 11, no. 6: 548. https://doi.org/10.3390/mi11060548

APA StyleAbdul Hamid, I. S. L., Khi Khim, B., Sal Hamid, S., Abd Rahman, M. F., & Abd Manaf, A. (2020). Implementation of a Single Emulsion Mask for Three-Dimensional (3D) Microstructure Fabrication of Micromixers Using the Grayscale Photolithography Technique. Micromachines, 11(6), 548. https://doi.org/10.3390/mi11060548