Numerical Investigation on the Optimum Thermal Design of the Shape and Geometric Parameters of Microchannel Heat Exchangers with Cavities

Abstract

1. Introduction

2. Computational Method

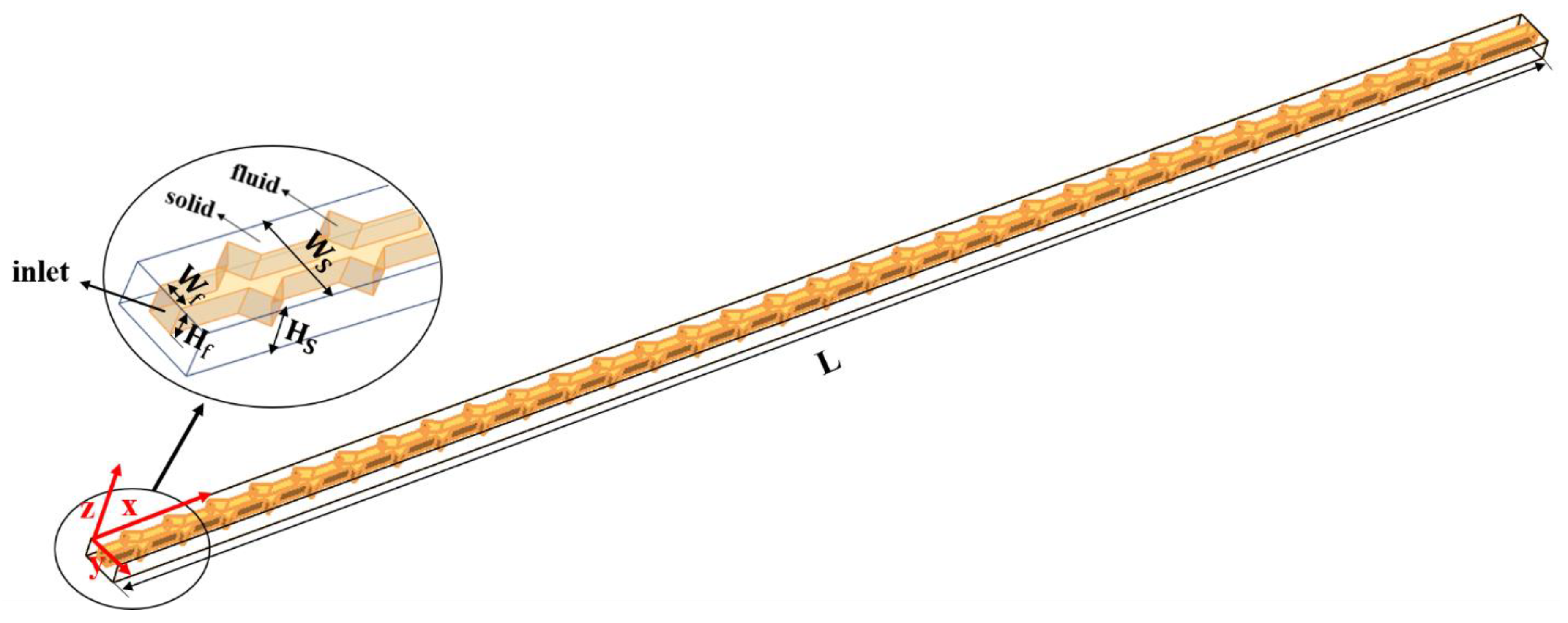

2.1. Computational Domain and Boundary Conditions

2.2. Mathematical Foundation

- (1)

- Steady, incompressible, laminar, three-dimensional fluid flow.

- (2)

- The effect of body forces is negligible.

- (3)

- The radiation heat transfer is neglected.

2.3. Solutions Methods and Convergence Criteria

3. Results and Discussion

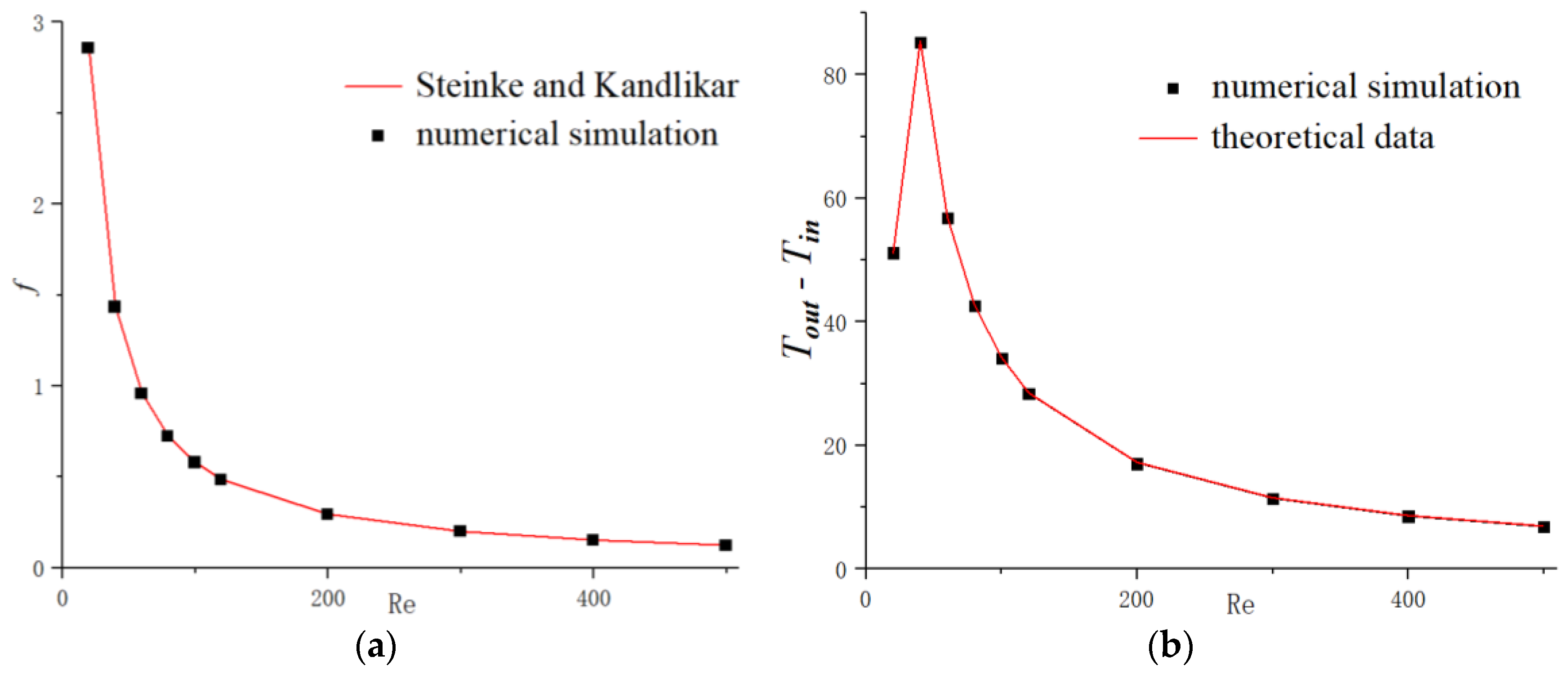

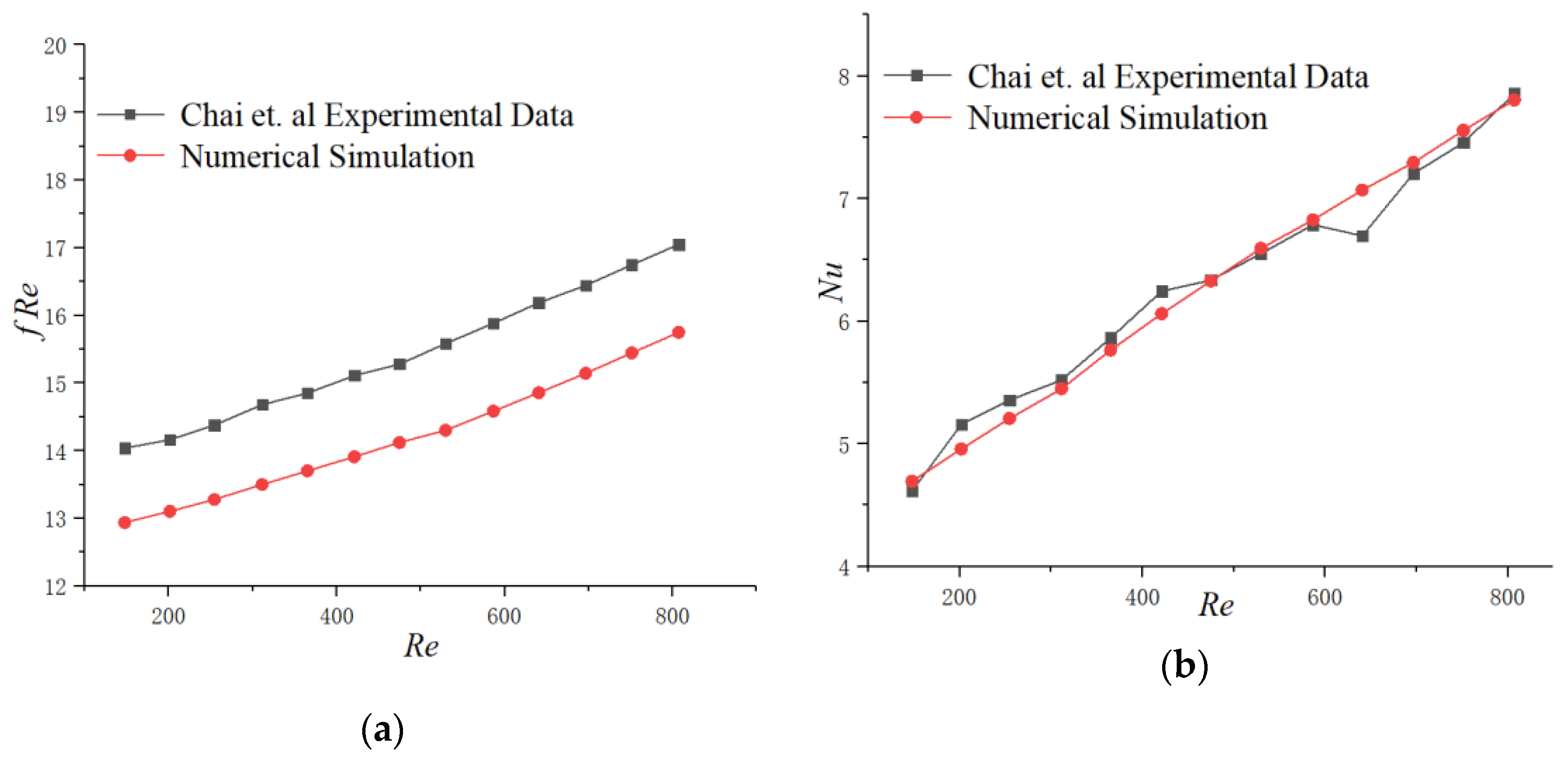

3.1. Validation for the Smooth Microchannel Heat Sink

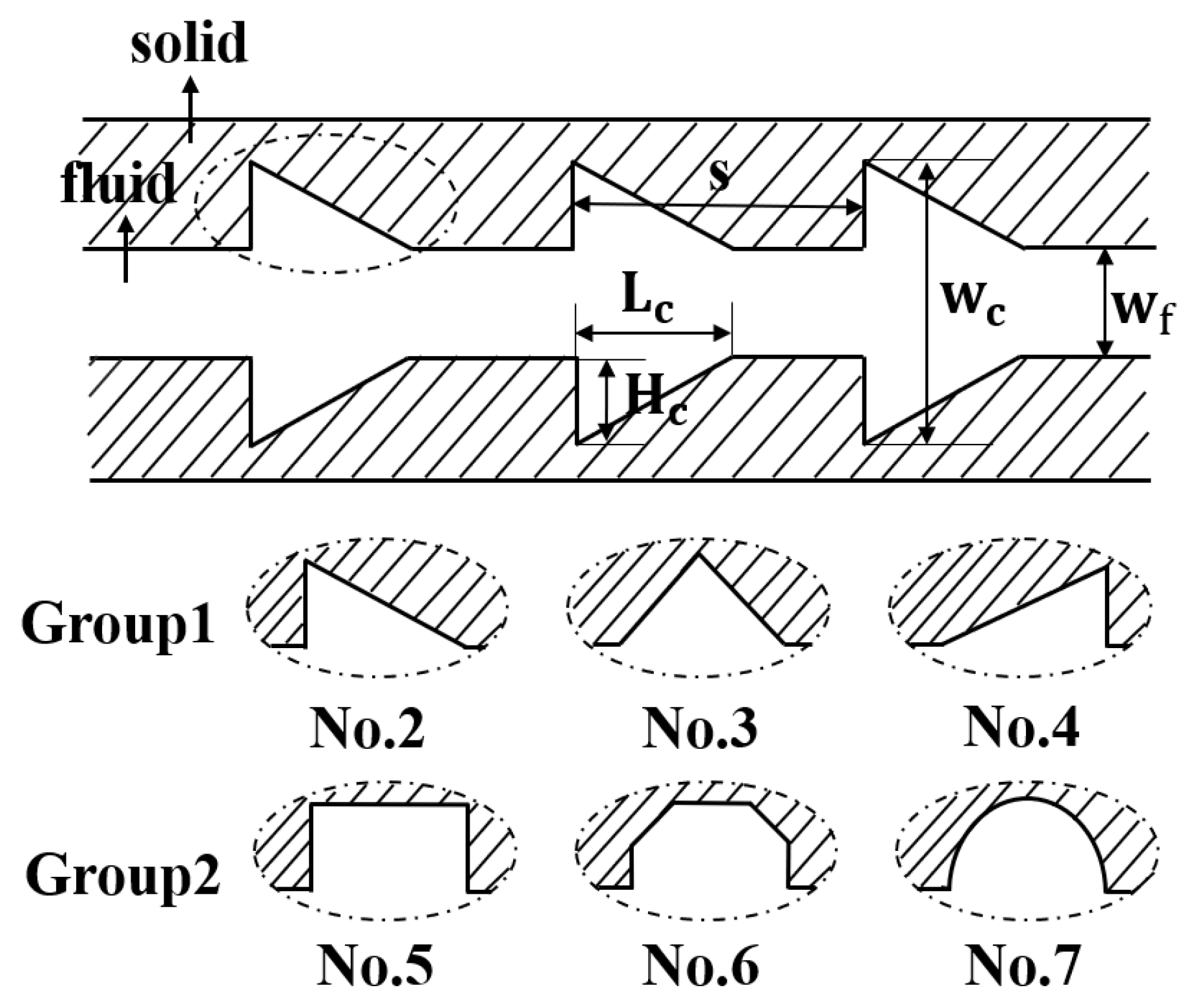

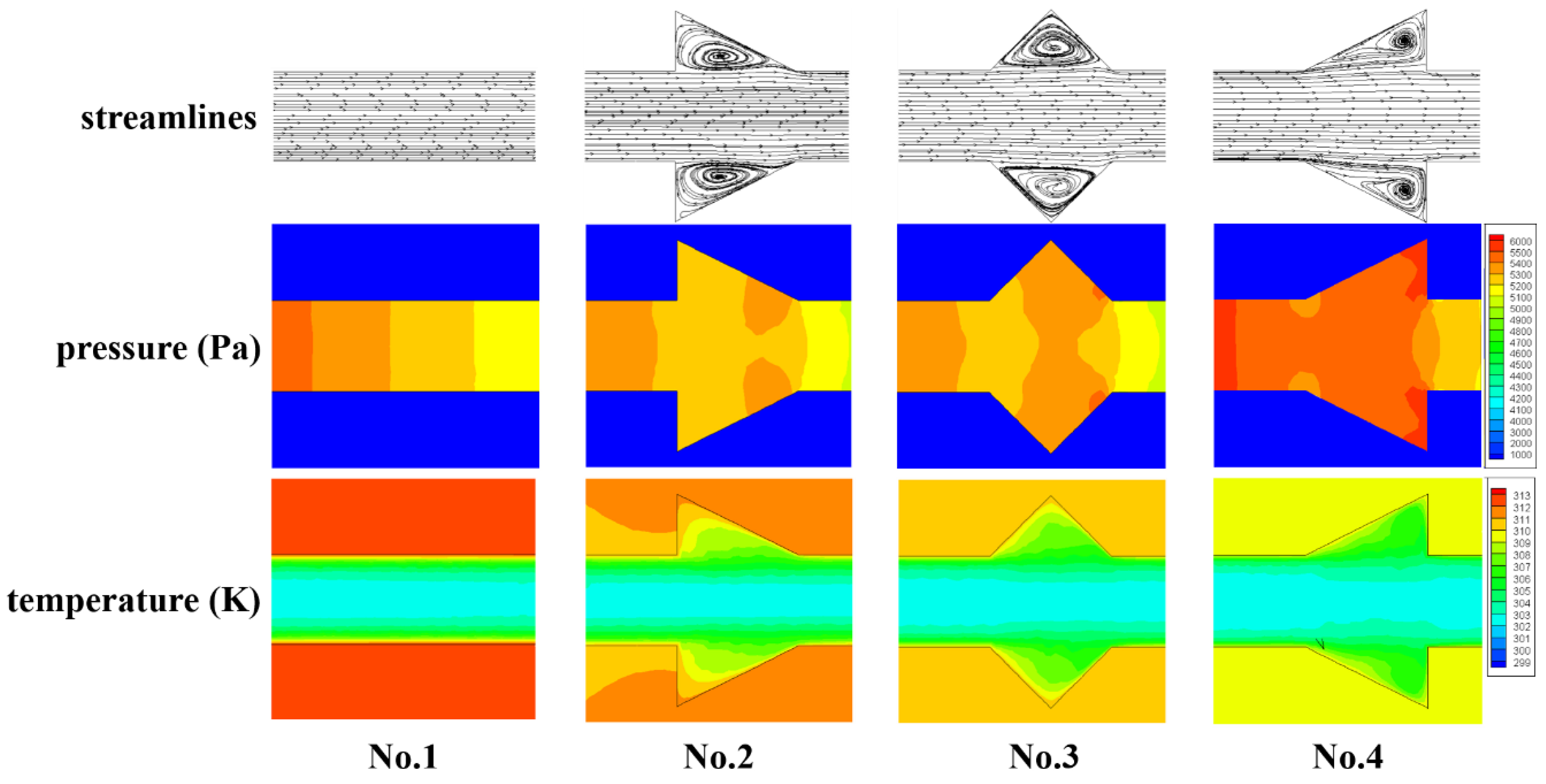

3.2. The Effect of Cavity Shape

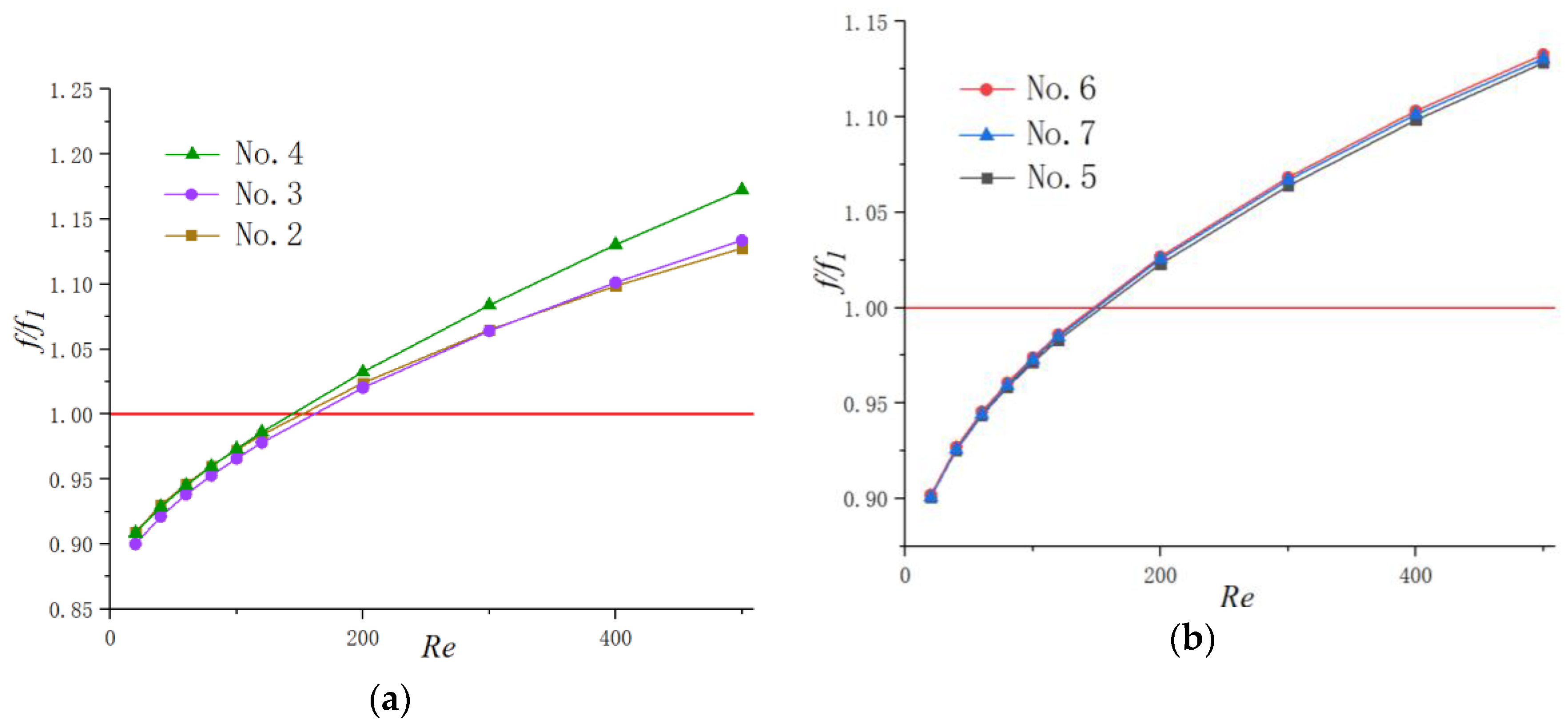

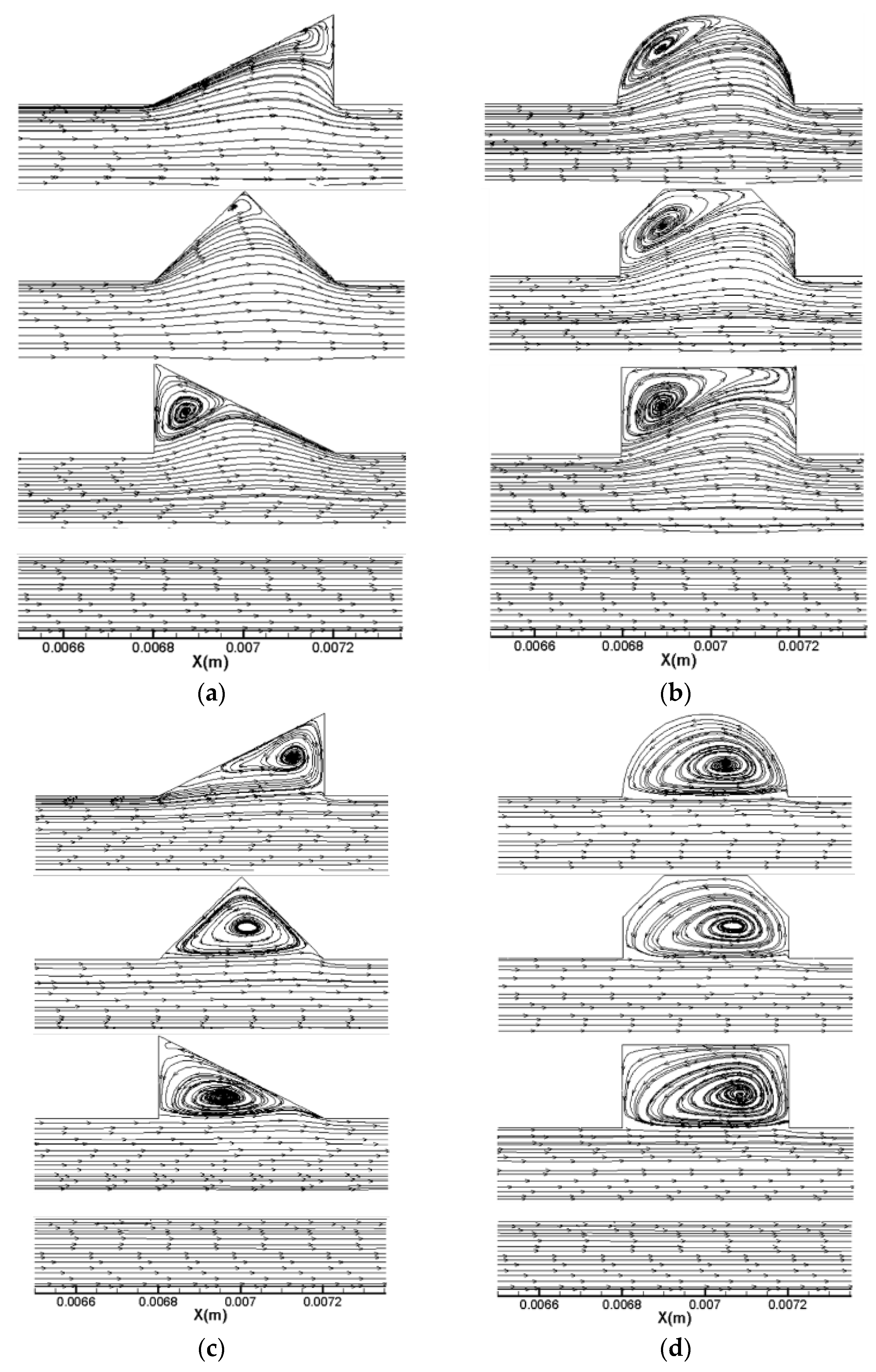

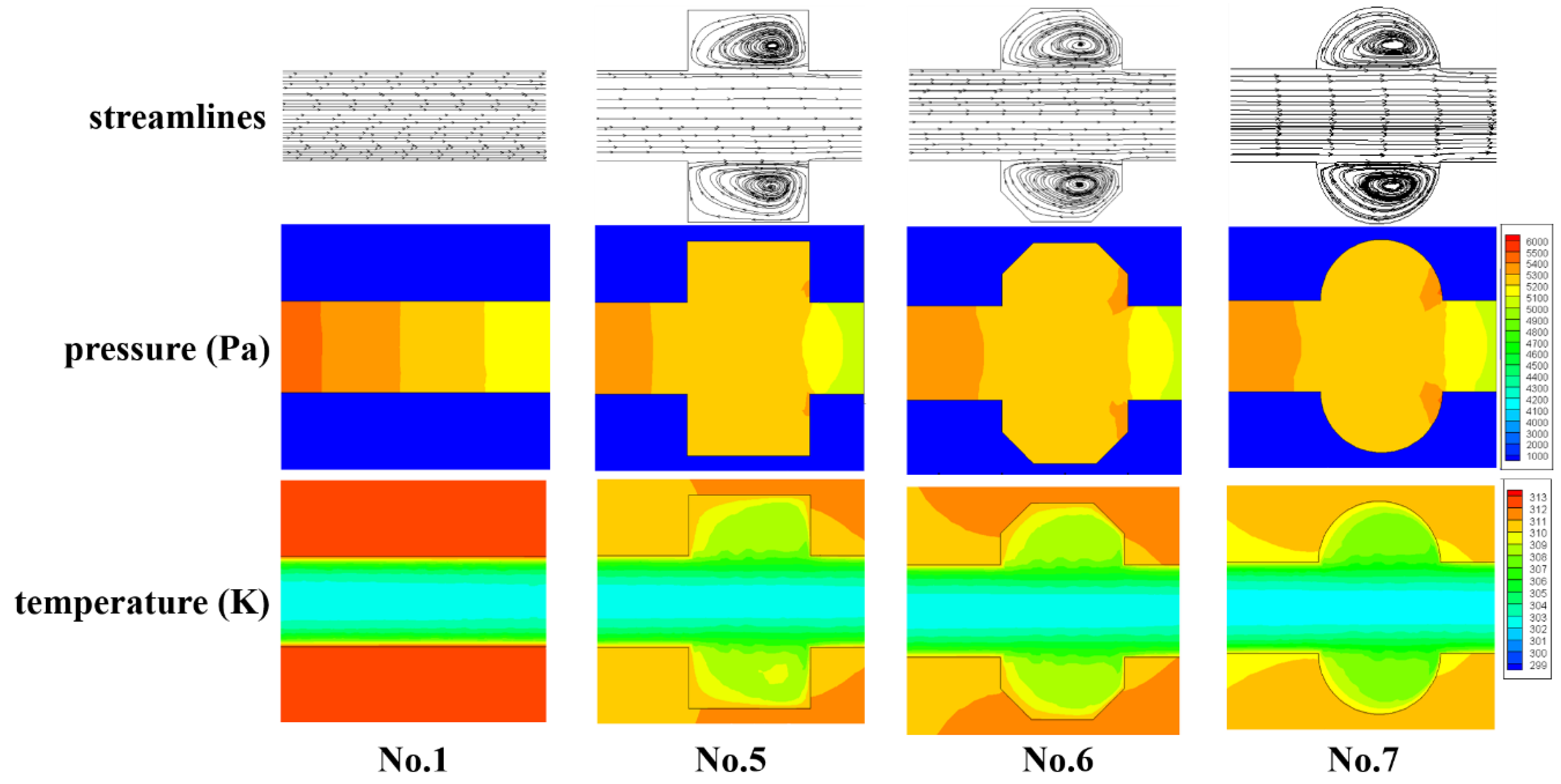

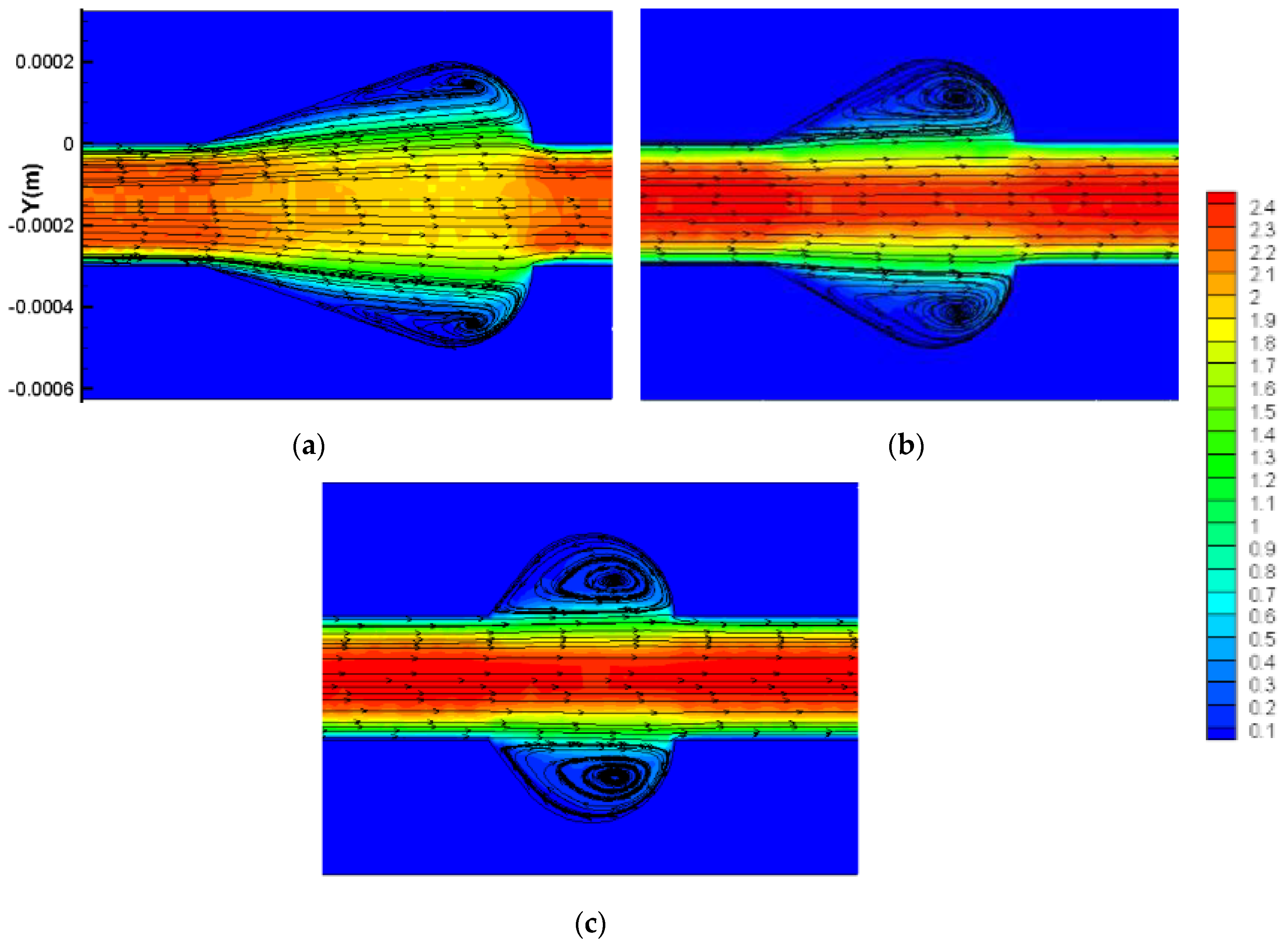

3.2.1. Flow Characteristics

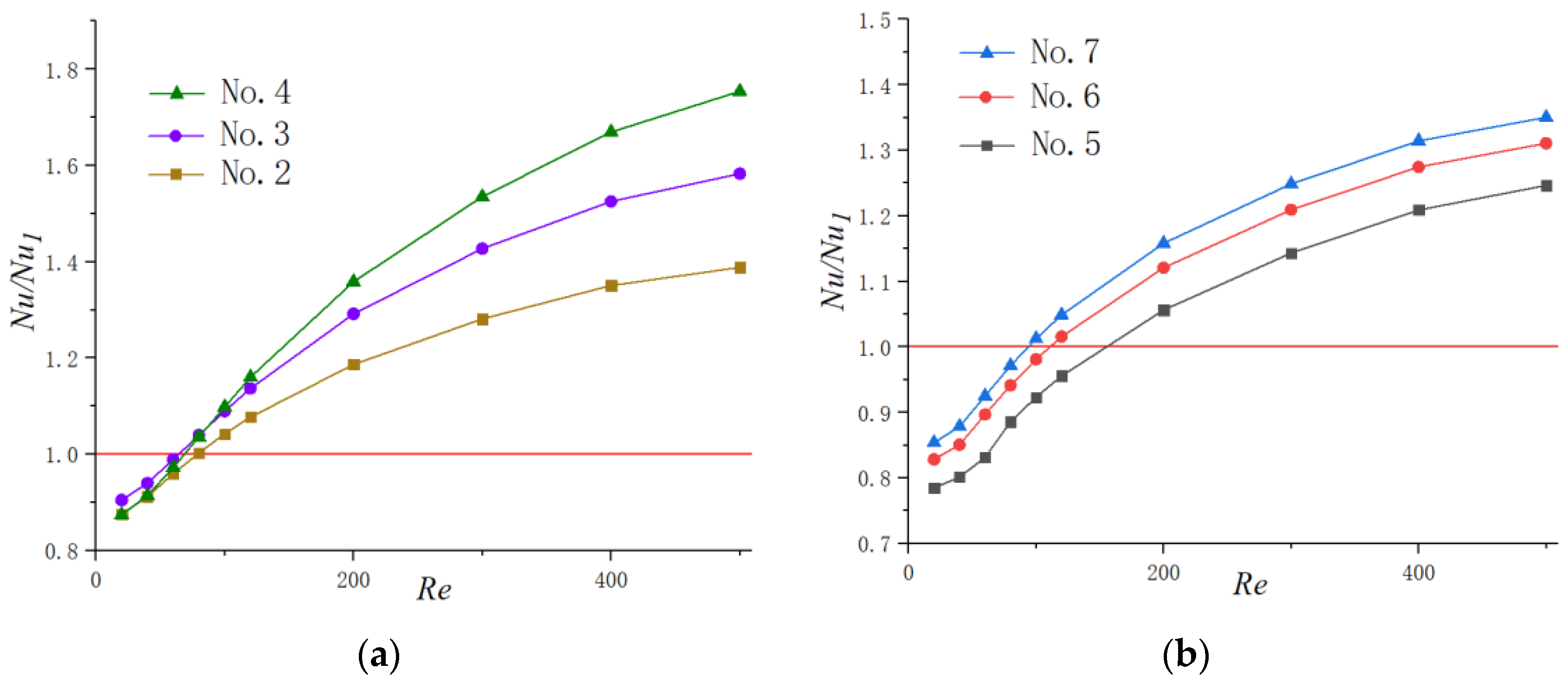

3.2.2. Heat Transfer

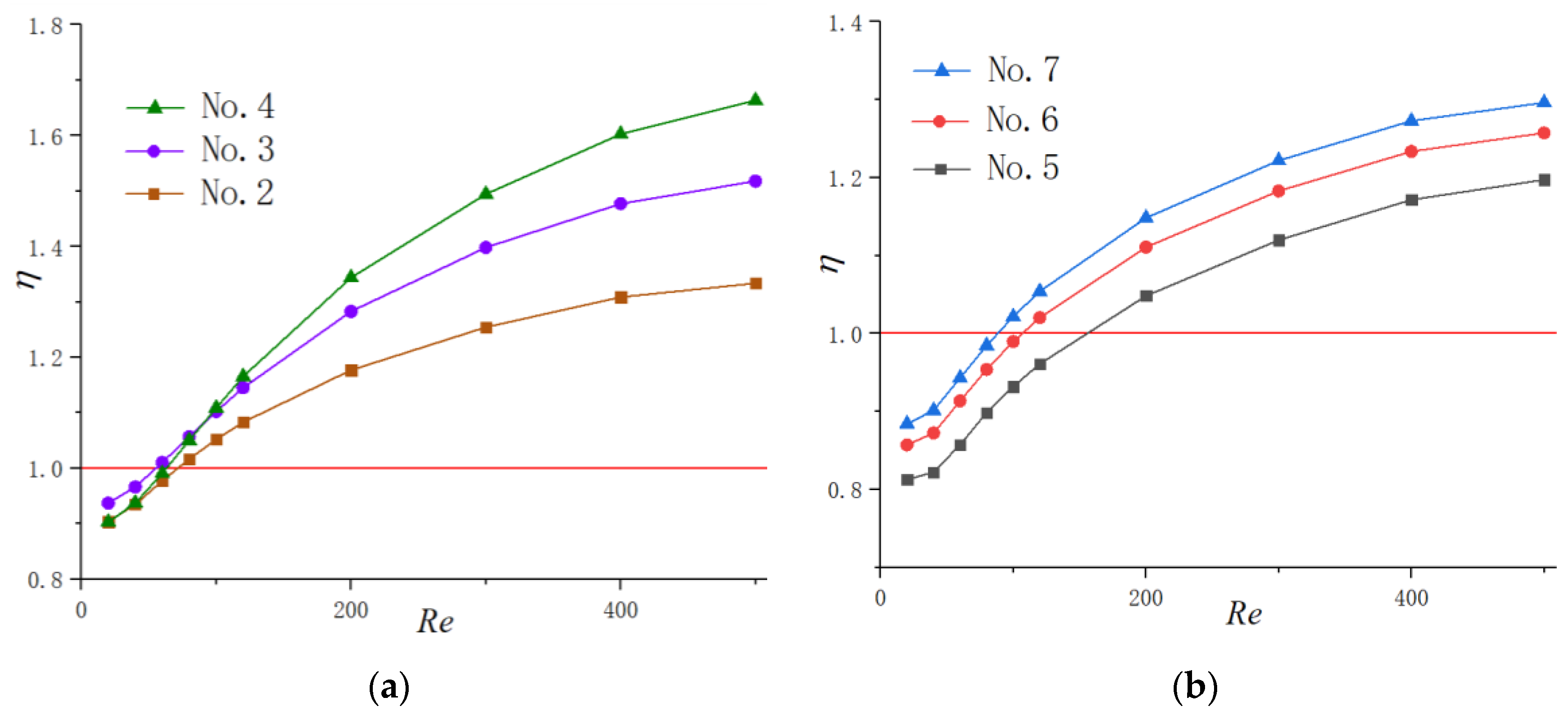

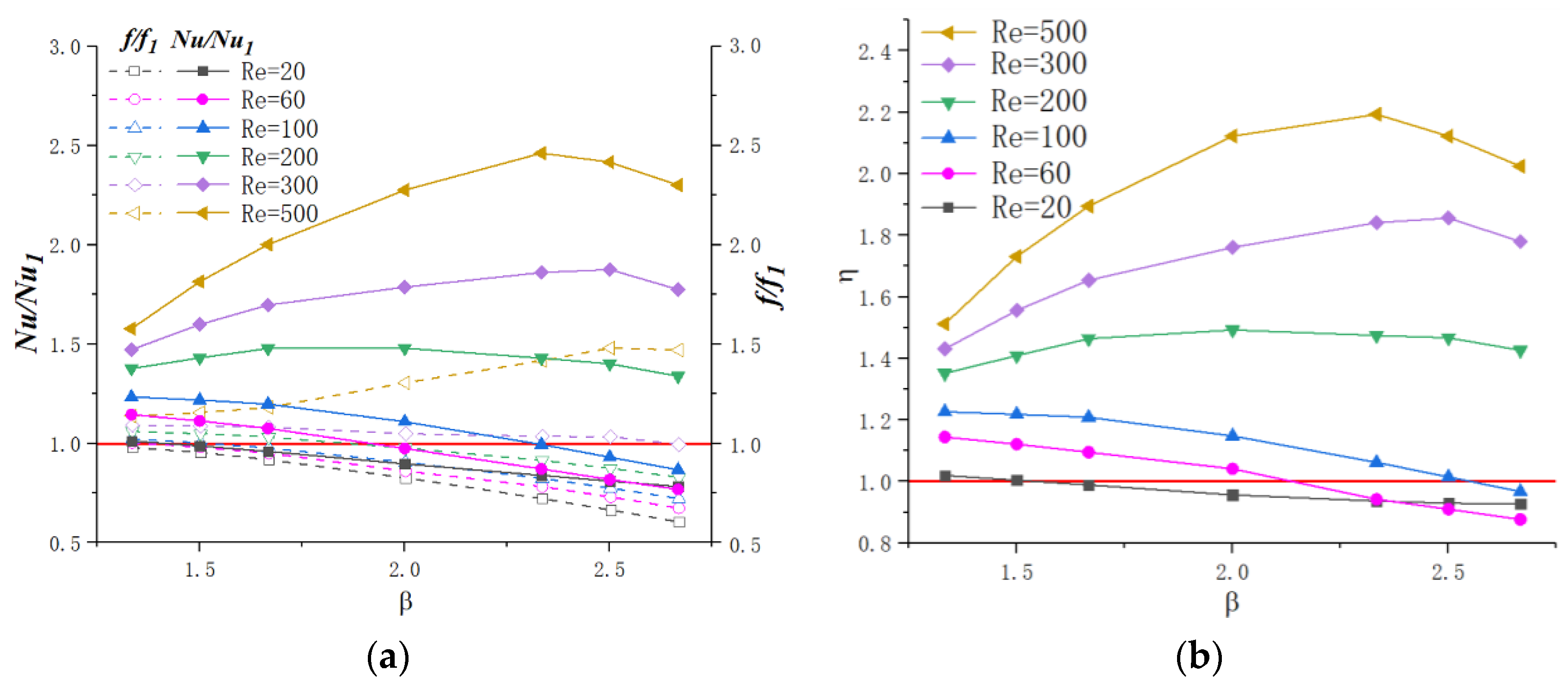

3.2.3. Thermal Enhancement Factor

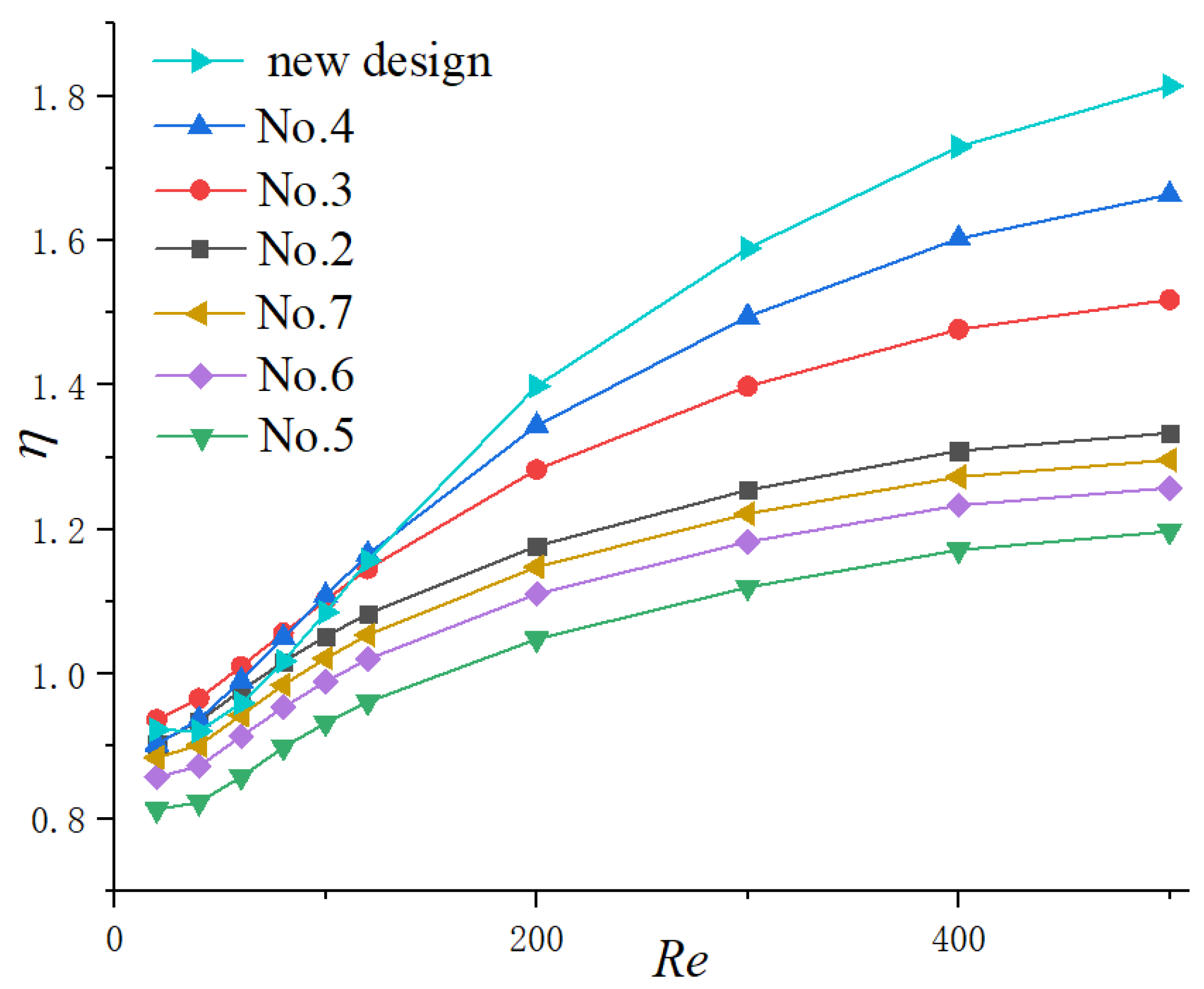

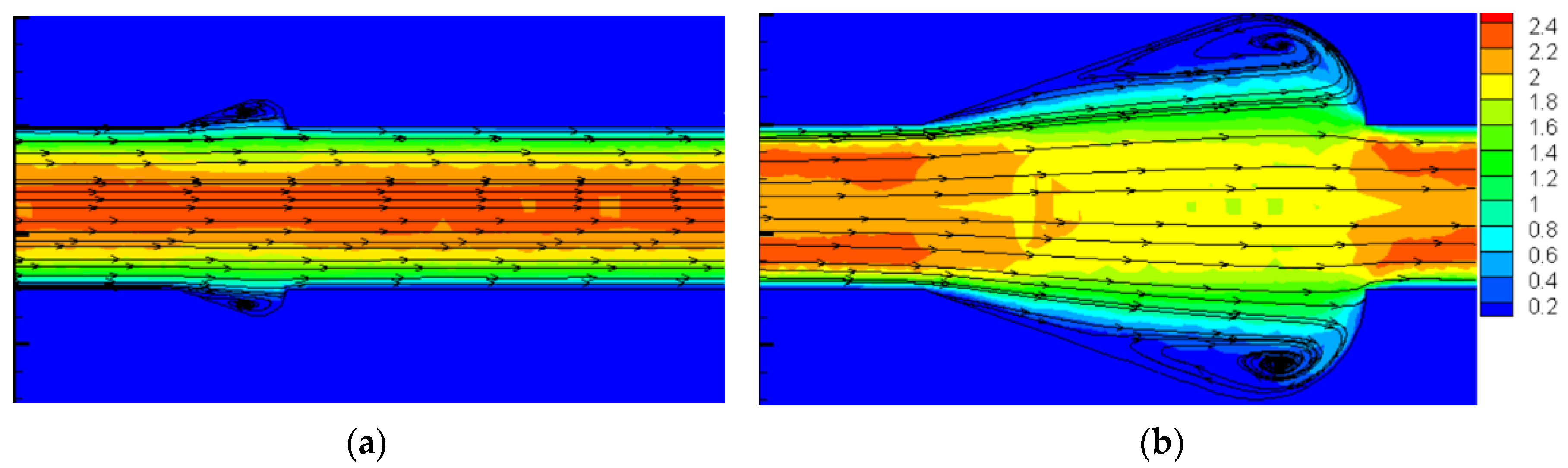

3.2.4. New Cavity Shape Design

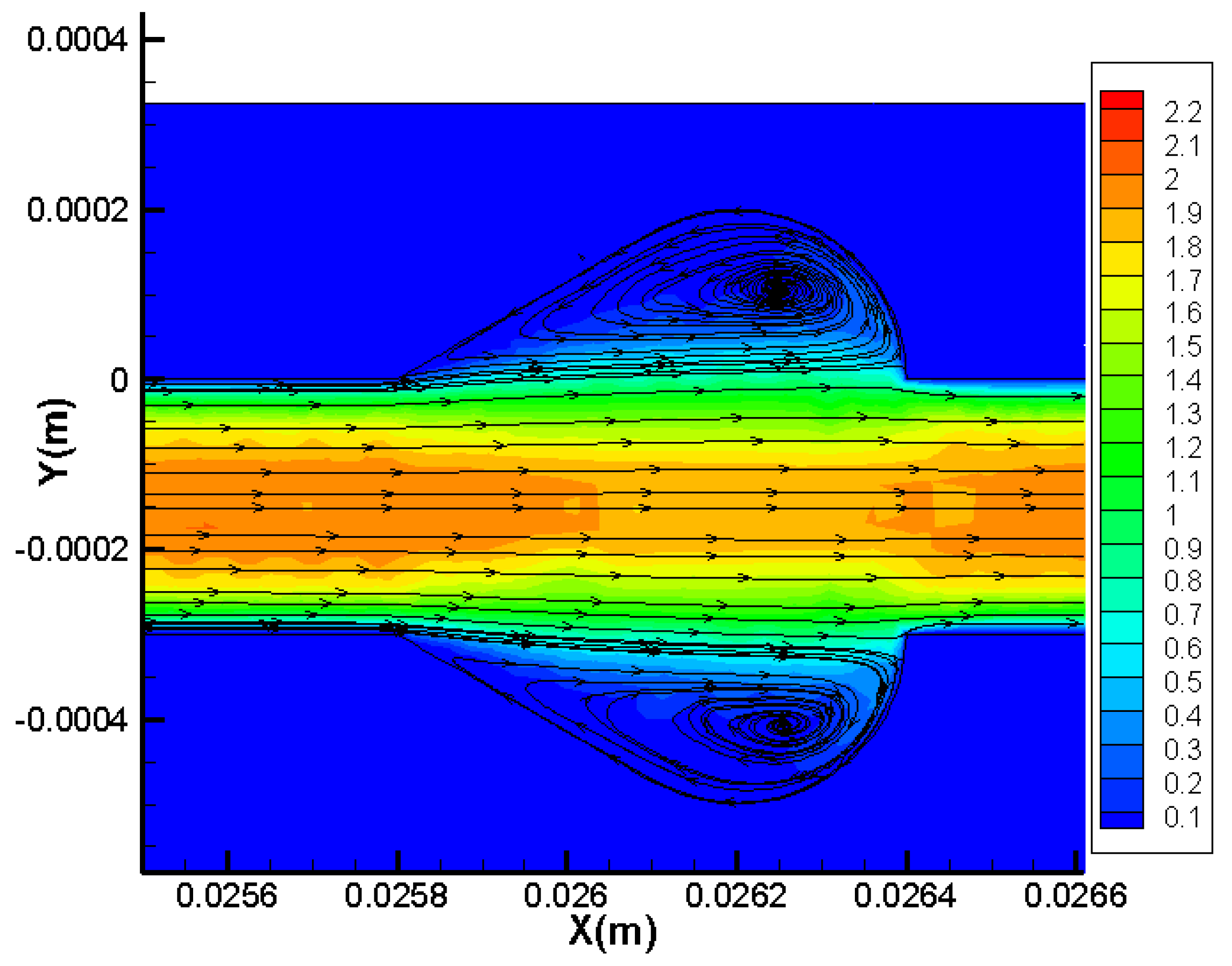

3.3. The Optimized Design for Cavity Parameters

3.3.1. Optimization Design for the Parameter

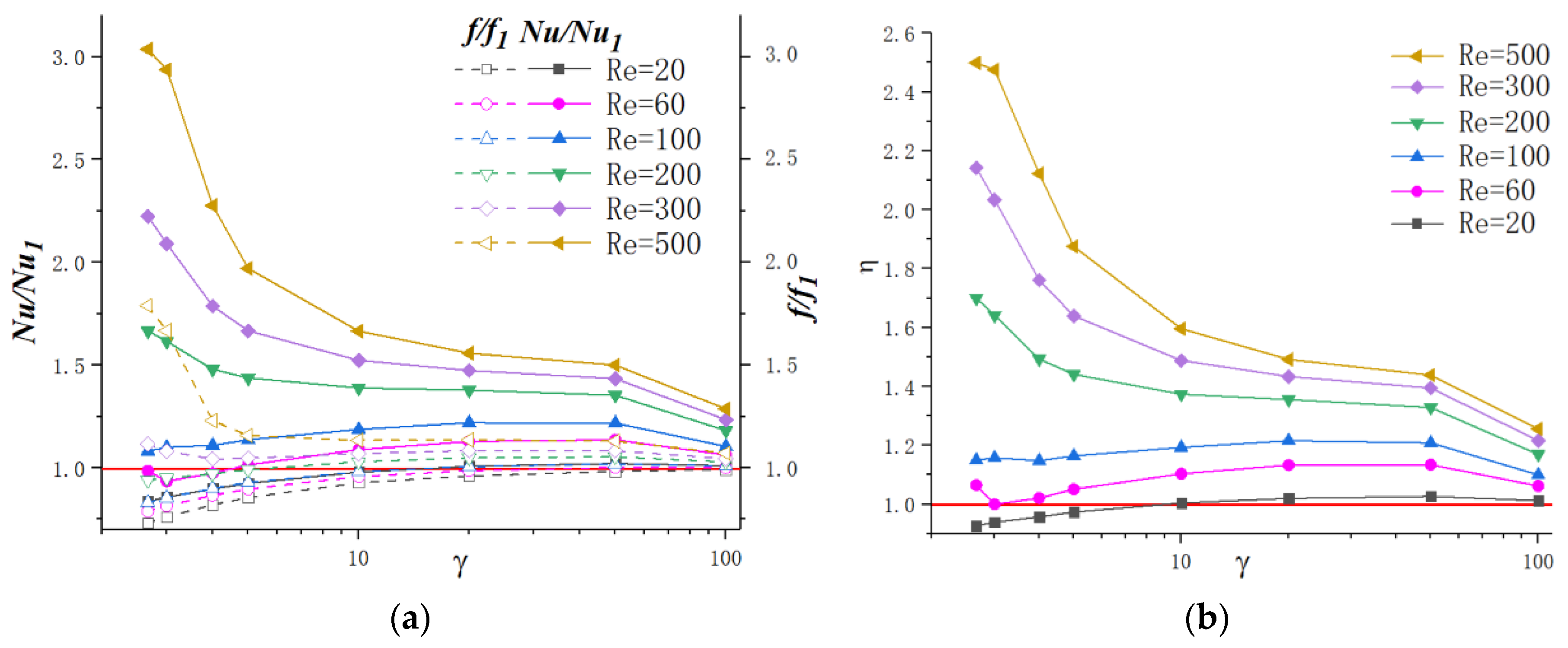

3.3.2. Optimization Design for the Parameter

3.3.3. Optimization Design for the Parameter

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| length of the microchannel, m | |

| width of the silicon basement, m | |

| height of the silicon basement, m | |

| width of the microchannel, m | |

| height of the microchannel, m | |

| velocity component at the microchannel inlet, m/s | |

| temperature of the fluid, K | |

| temperature at the microchannel inlet, K | |

| static pressure of the fluid, Pa | |

| static pressure at the microchannel outlet. Pa | |

| velocity component in the direction, m/s | |

| velocity component in the direction, m/s | |

| velocity component in the direction, m/s | |

| temperature of the silicon basement, K | |

| heat flux per area, W/ | |

| cavity spacing, m | |

| longitudinal length of a single cavity, m | |

| height of a single cavity, m | |

| total width of the microchannel plus cavities, m | |

| three coordinates shown in Figure 1, m | |

| density, kg/m3 | |

| dynamic viscosity, Pa s | |

| specific heat of fluid, J Kg−1 K−1 | |

| thermal conductivity of fluid, W m−1 K−1 | |

| thermal conductivity of silicon, W m−1 K−1 | |

| Re | Reynolds number |

| f | friction factor |

| Nu | Nusselt number |

| Ƞ | thermal enhancement factor |

| average velocity, m/s | |

| hydraulic diameter, m | |

| pressure drop, Pa | |

| h | heat transfer coefficient, W m−2 K−1 |

| area of contact surface between the fluid zone and solid zone | |

| n | local coordinate normal to the wall |

| AR | aspect ratio |

| friction factor of fully developed flow |

References

- Ling, W.; Zhou, W.; Yu, W.; Zhou, F.; Chen, J.; Hui, K.S. Experimental investigation on thermal and hydraulic performance of microchannels with interlaced configuration. Energy Convers. Manag. 2019, 174, 4394–4452. [Google Scholar] [CrossRef]

- Wang, R.; Wang, J.; Yuan, E. Analysis and optimization of a microchannel heat sink with V-Ribs using nanofluids for micro solar cells. Micromachines 2019, 10, 620. [Google Scholar] [CrossRef] [PubMed]

- Mario Di Capua, H.; Escobar, R.; Diaz, A.J.; Guzmán, A.M. Enhancement of the cooling capability of a high concentration photovoltaic system using microchannels with forward triangular ribs on sidewalls. Appl. Energy 2018, 226, 1601–1680. [Google Scholar]

- Liu, Z.; Qin, S.; Chen, X.; Chen, D.; Wang, F. PDMS-PDMS micro channels filled with phase-change material for chip cooling. Micromachines 2018, 9, 165. [Google Scholar] [CrossRef] [PubMed]

- Duan, Z.; Ma, H.; He, B.; Su, L.; Zhang, X. Pressure drop of microchannel plate fin heat sinks. Micromachines 2019, 10, 80. [Google Scholar] [CrossRef]

- Joo, Y.; Yeh, H.; Dieu, K.; Kim, C. Air cooling of a microelectronic chip with diverging metal microchannels monolithically processed using a single mask. J. Micromech. Microeng. 2008, 18, 115022. [Google Scholar] [CrossRef]

- Colgan, E.; Furman, B.; Gaynes, M.; LaBianca, N.; Magerlein, J.; Polastre, R.; Bezama, R.; Marston, K.; Schmidt, R. High performance and subambient silicon microchannel cooling. J. Heat Transf. 2007, 129, 1046. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, Z.; Zheng, B. A new 3D chip cooling technology using micro-channels thermosyphon with super-moist fluids and nanofluids. Energy Convers. Manag. 2016, 128, 44–56. [Google Scholar] [CrossRef]

- Tuckerman, D.B.; Pease, R. High-performance heat sinking for VLSI. IEEE Electron Dev. Lett. 1981, 2, 126–129. [Google Scholar] [CrossRef]

- Steinke, M.E.; Kandlikar, S.G. Single-phase liquid friction factors in microchannels. Int. J. Therm. Sci. 2006, 45, 1073–1083. [Google Scholar] [CrossRef]

- Abubakar, S.B.; Nor Azwadi, C.S. Numerical prediction of laminar nanofluid flow in rectangular microchannel heat sink. J. Adv. Res. Fluid Mech. Therm. Sci. 2015, 7, 29–38. [Google Scholar]

- Abubakar, S.B.; Nor Azwadi, C.S.; Ahmad, A. The use of Fe3O4-H2O4 nanofluid for heat transfer enhancement in rectangular microchannel heatsink. J. Adv. Res. Mater. Sci. 2016, 23, 15–24. [Google Scholar]

- Noh, N.M.; Fazeli, A.; Nor Azwadi, C.S. Numerical simulation of nanofluids for cooling efficiency in microchannel heat sink. J. Adv. Res. Fluid Mech. Therm. Sci. 2014, 4, 13–23. [Google Scholar]

- Gunnasegaran, P.; Mohammed, H.; Shuaib, N.; Saidur, R. The effect of geometrical parameters on heat transfer characteristics of microchannels heat sink with different shapes. Int. Commun. Heat Mass Transf. 2010, 37, 1078–1086. [Google Scholar] [CrossRef]

- Weilin, Q.; Mala, G.M.; Dongqing, L. Pressure-driven water flows in trapezoidal silicon microchannels. Int. J. Heat Mass Transf. 2000, 43, 353–364. [Google Scholar] [CrossRef]

- Wang, G.; Hao, L.; Cheng, P. An experimental and numerical study of forced convection in a microchannel with negligible axial heat conduction. Int. J. Heat Mass Transf. 2009, 52, 1070–1074. [Google Scholar] [CrossRef]

- Tiselj, I.; Hetsroni, G.; Mavko, B.; Mosyak, A.; Pogrebnyak, E.; Segal, Z. Effect of axial conduction on the heat transfer in micro-channels. Int. J. Heat Mass Transf. 2004, 47, 2551–2565. [Google Scholar] [CrossRef]

- Xie, G.; Liu, J.; Liu, Y.; Sunden, B.; Zhang, W. Comparative study of thermal performance of longitudinal and transversal-wavy microchannel heat sinks for electronic cooling. J. Electron. Packag. 2013, 135, 021008. [Google Scholar] [CrossRef]

- Xie, G.; Liu, J.; Zhang, W.; Sunden, B. Analysis of flow and thermal performance of a water-cooled transversal wavy microchannel heat sink for chip cooling. J. Electron. Packag. 2012, 134, 041010. [Google Scholar] [CrossRef]

- Mohammed, H.; Gunnasegaran, P.; Shuaib, N. Influence of channel shape on the thermal and hydraulic performance of microchannel heat sink. Int. Commun. Heat Mass Transf. 2011, 38, 474–480. [Google Scholar] [CrossRef]

- Dai, Z.; Fletcher, D.F.; Haynes, B.S. Impact of tortuous geometry on laminar flow heat transfer in microchannels. Int. J. Heat Mass Transf. 2015, 83, 382–398. [Google Scholar] [CrossRef]

- Dai, Z.; Zheng, Z.; Fletcher, D.F.; Haynes, B.S. Experimental study of transient behaviour of laminar flow in zigzag semi-circular microchannels. Exp. Therm. Fluid Sci. 2015, 68, 644–651. [Google Scholar] [CrossRef]

- Ghaedamini, H.; Lee, P.S.; Teo, C.J. Developing forced convection in converging– diverging microchannels. Int. J. Heat Mass Transf. 2013, 65, 491–499. [Google Scholar] [CrossRef]

- Chai, L.; Xia, G.D.; Wang, H.S. Parametric study on thermal and hydraulic characteristics of laminar flow in microchannel heat sink with fan-shaped ribs. Int. J. Heat Mass Transf. 2016, 97, 1069–1080. [Google Scholar] [CrossRef]

- Chai, L.; Xia, G.D.; Zhou, M.Z. Optimum thermal design of interrupted microchannel heat sink with rectangular ribs in the transverse microchambers. Appl. Therm. Eng. 2013, 51, 880–989. [Google Scholar] [CrossRef]

- Hong, F.J.; Cheng, P. Three dimensional numerical analyses and optimization of offset strip-fin microchannel heat sinks. Int. Commun. Heat Mass Transf. 2009, 36, 651–656. [Google Scholar] [CrossRef]

- Liu, C.; Teng, J.; Chu, J.C. Experimental investigations on liquid flow and heat transfer in rectangular microchannel with longitudinal vortex generators. Int. J. Heat Mass Transf. 2011, 54, 3069–3080. [Google Scholar] [CrossRef]

- Ahmed, H.E.; Ahmed, M.I. Optimum thermal design of triangular, trapezoidal and rectangular grooved microchannel heat sinks. Int. Commun. Heat Mass Transf. 2015, 66, 47–57. [Google Scholar] [CrossRef]

- Xia, G.D.; Chai, L.; Zhou, M.Z. Effects of structural parameters on fluid flow and heat transfer in a microchannel with aligned fan-shaped reentrant cavities. Int. J. Therm. Sci. 2011, 50, 411–419. [Google Scholar] [CrossRef]

- Webb, R.L. Performance evaluation criteria for use of enhanced heat transfer surfaces in heat exchanger design. Int. J. Heat Mass Transf. 1981, 24, 715–726. [Google Scholar] [CrossRef]

- Karwa, R.; Sharma, C.; Karwa, N. Performance evaluation criteria at equal pumping power for enhanced performance heat transfer surfaces. J. Sol. Energy 2013, 37, 1–9. [Google Scholar]

- Chai, L.; Xia, G.; Wang, L.; Zhou, M.; Cui, Z. Heat transfer enhancement in microchannel heat sinks with periodic expansion-constriction cross-sections. Int. J. Heat Mass Transf. 2013, 62, 741–751. [Google Scholar] [CrossRef]

- Choi, S.B.; Barren, R.R.; Warrington, R.Q. Fluid flow and heat transfer in micro-tubes. ASME DSC 1991, 40, 89–93. [Google Scholar]

- Hetsroni, G.; Gurevich, M.; Mosyak, A.; Rozenblit, R. Drag reduction and heat transfer of surfactants flowing in a capillary tube. Int. J. Heat Mass Transf. 2004, 47, 3797–3809. [Google Scholar] [CrossRef]

| No. | Cell Numbers | Nu | Pressure Drop/Pa | ||

|---|---|---|---|---|---|

| 1 | 0.96 | 4.31 | 3.58 | 6358.83 | 4.01 |

| 2 | 1.86 | 4.38 | 2.01 | 6441.76 | 2.76 |

| 3 | 2.97 | 4.47 | 0 | 6620.92 | 0.55 |

| 4 | 4.78 | 4.47 | - | 6624.58 | - |

| 2.67 | 3 | 4 | 5 | 10 | 20 | 50 | 100 | |

|---|---|---|---|---|---|---|---|---|

| Number of Cavities | 48 | 43 | 32 | 26 | 13 | 7 | 3 | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Li, Y.; Huang, B.; Xu, T. Numerical Investigation on the Optimum Thermal Design of the Shape and Geometric Parameters of Microchannel Heat Exchangers with Cavities. Micromachines 2020, 11, 721. https://doi.org/10.3390/mi11080721

Li H, Li Y, Huang B, Xu T. Numerical Investigation on the Optimum Thermal Design of the Shape and Geometric Parameters of Microchannel Heat Exchangers with Cavities. Micromachines. 2020; 11(8):721. https://doi.org/10.3390/mi11080721

Chicago/Turabian StyleLi, Haiwang, Yujia Li, Binghuan Huang, and Tiantong Xu. 2020. "Numerical Investigation on the Optimum Thermal Design of the Shape and Geometric Parameters of Microchannel Heat Exchangers with Cavities" Micromachines 11, no. 8: 721. https://doi.org/10.3390/mi11080721

APA StyleLi, H., Li, Y., Huang, B., & Xu, T. (2020). Numerical Investigation on the Optimum Thermal Design of the Shape and Geometric Parameters of Microchannel Heat Exchangers with Cavities. Micromachines, 11(8), 721. https://doi.org/10.3390/mi11080721