A 3D-Printed Fin Ray Effect Inspired Soft Robotic Gripper with Force Feedback

Abstract

:1. Introduction

- (1)

- A monolithic 3D-printed soft adaptive gripper based on Fin Ray effect is proposed with ease of fabrication;

- (2)

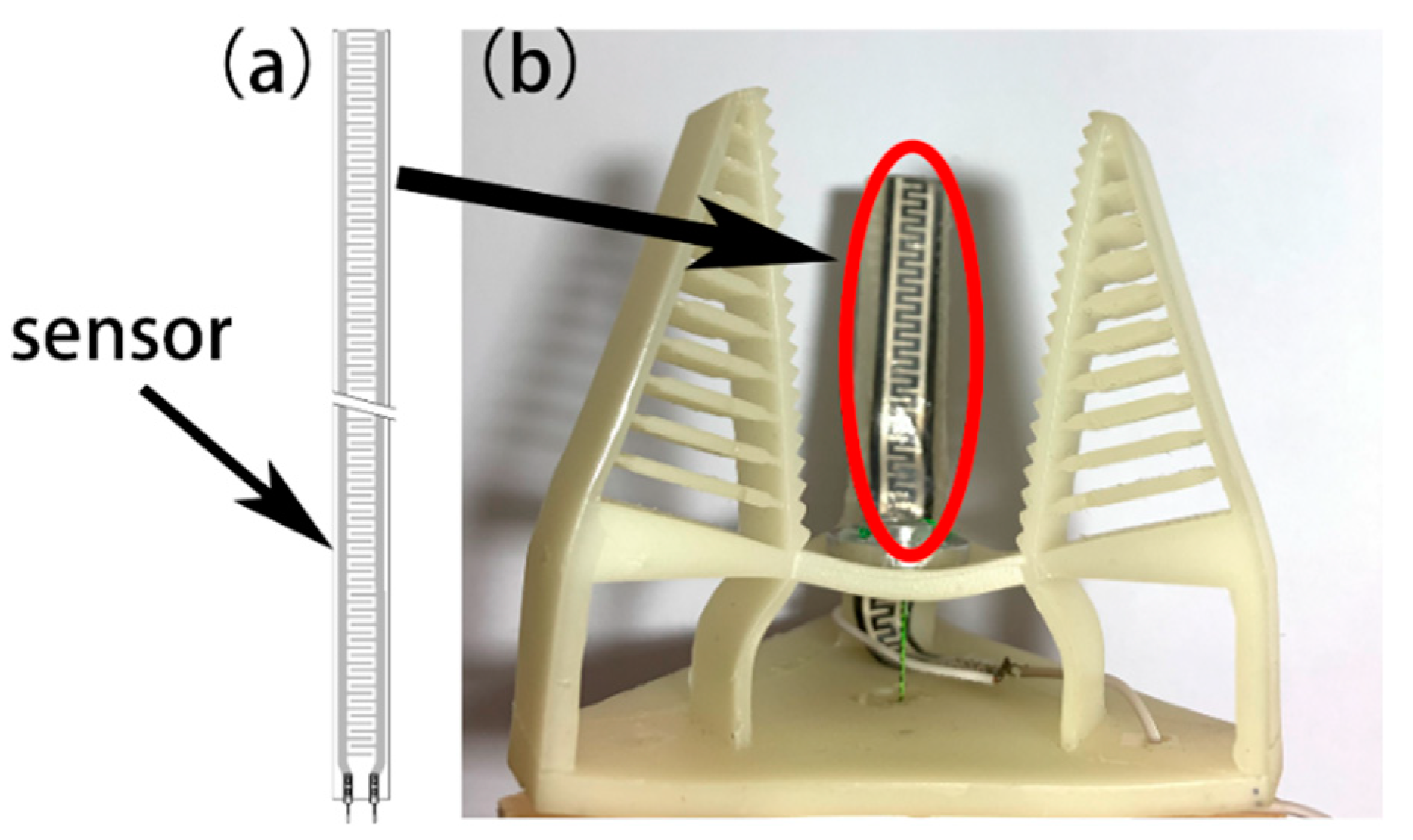

- A pressure sensor is integrated in the soft gripper to realize force feedback during grasping;

- (3)

- Experiments are conducted to characterize the gripper and to demonstrate the improved grasping performance with force feedback.

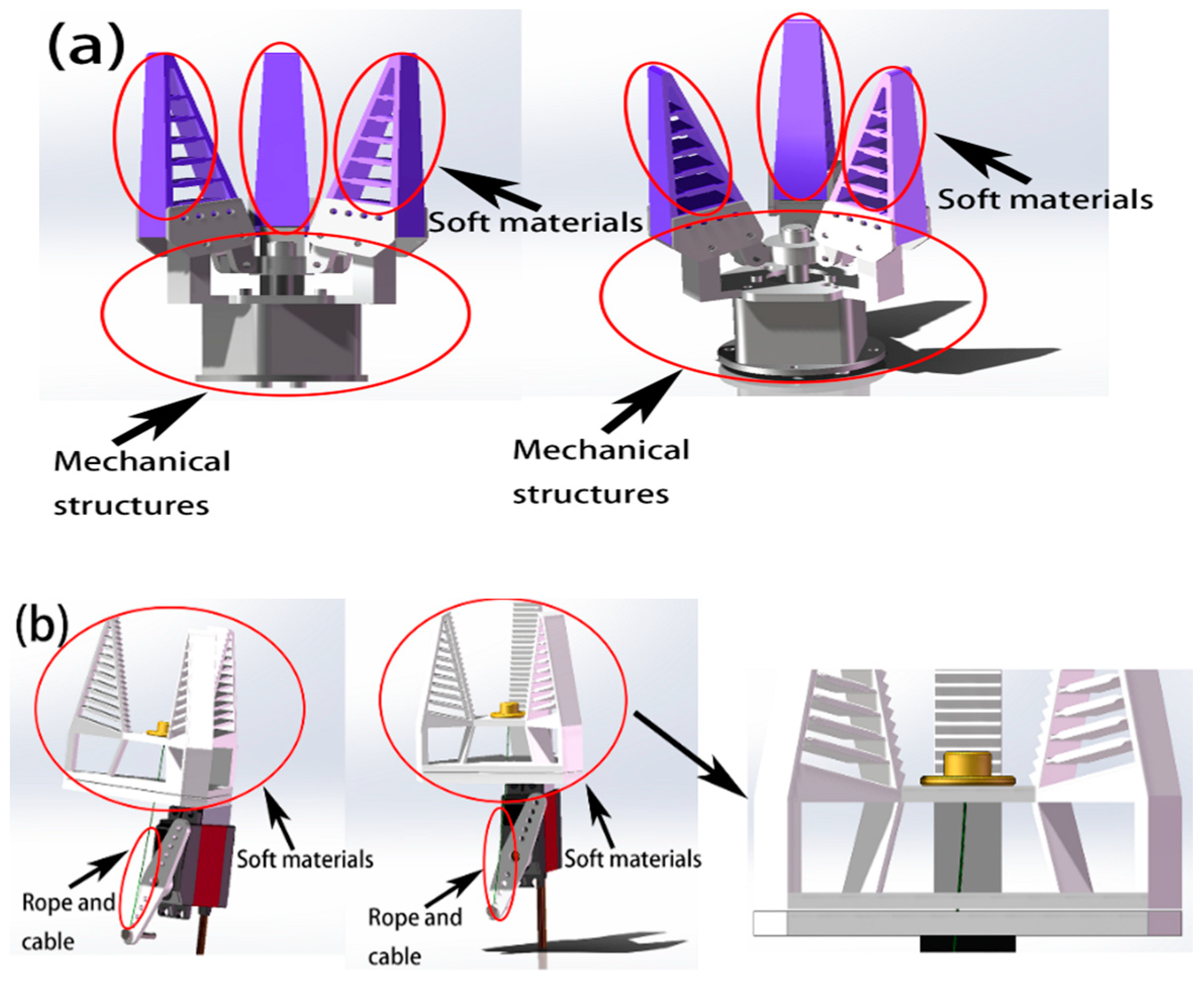

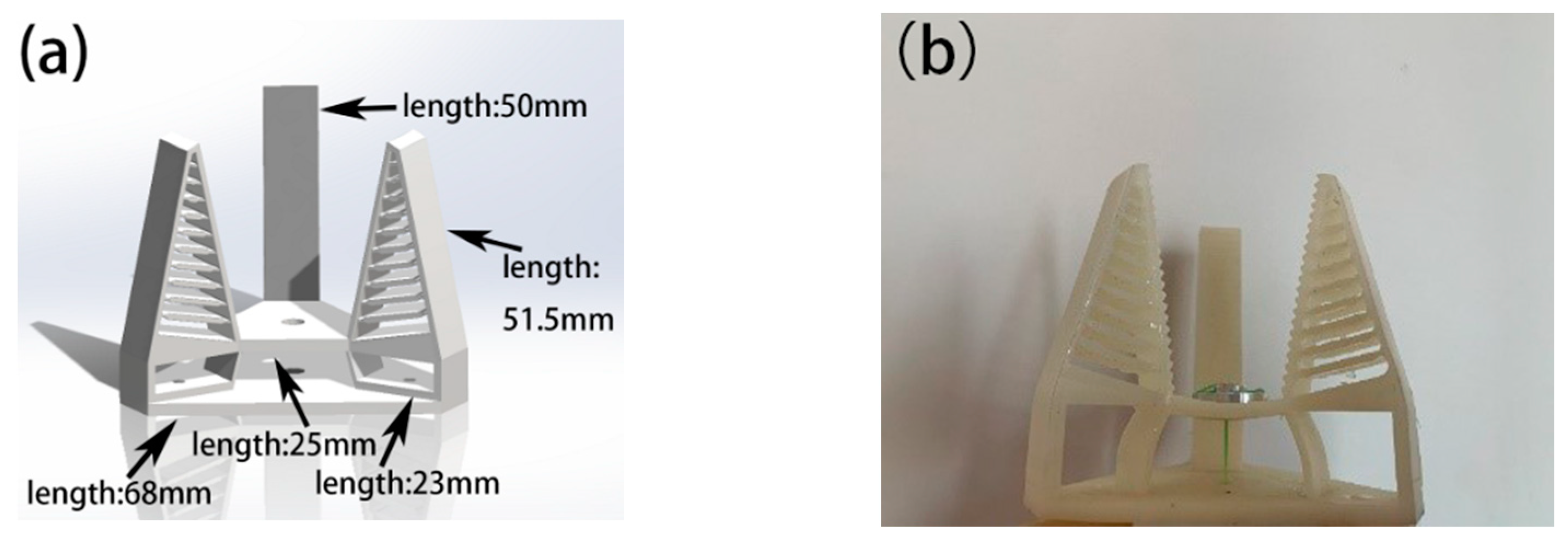

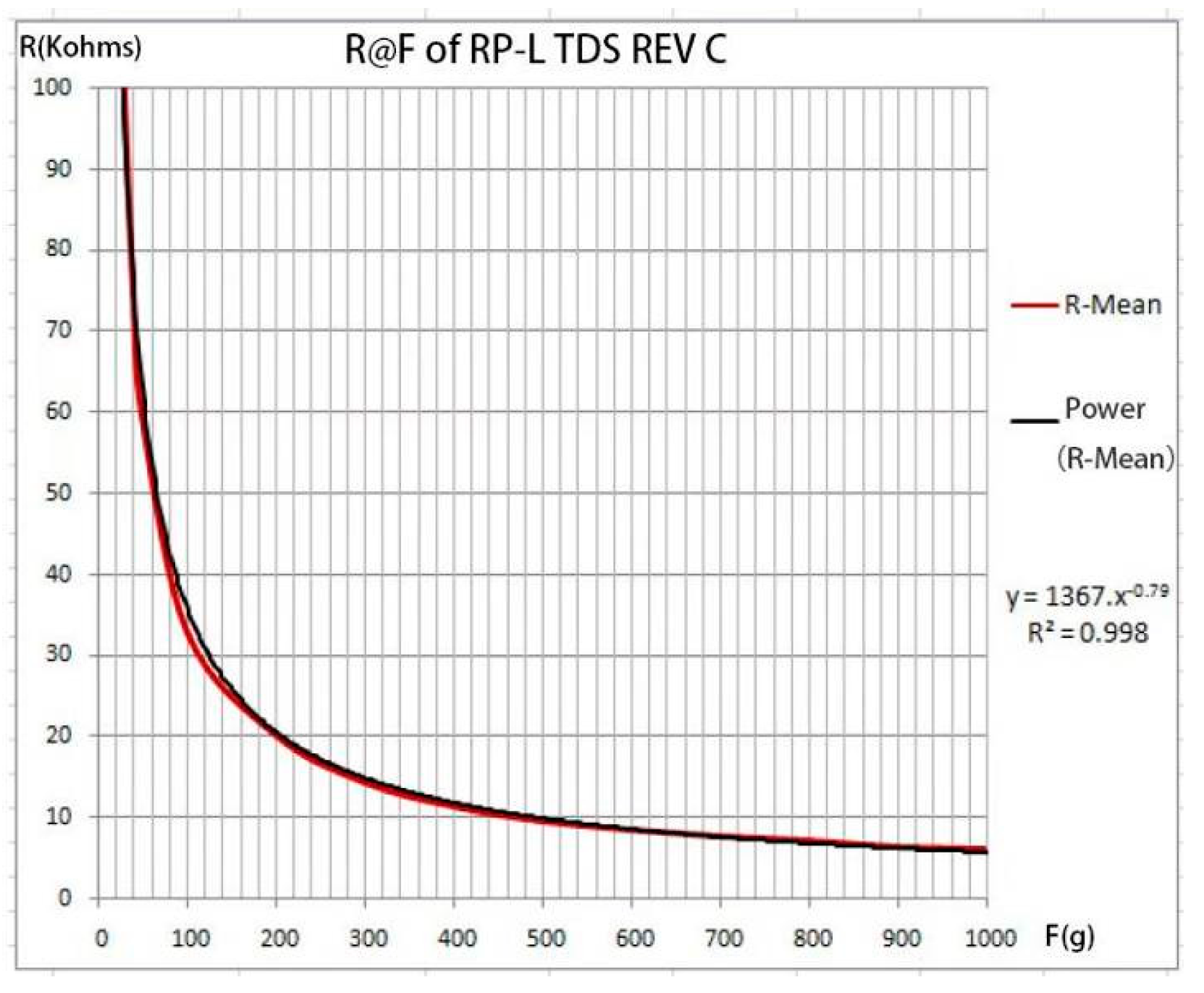

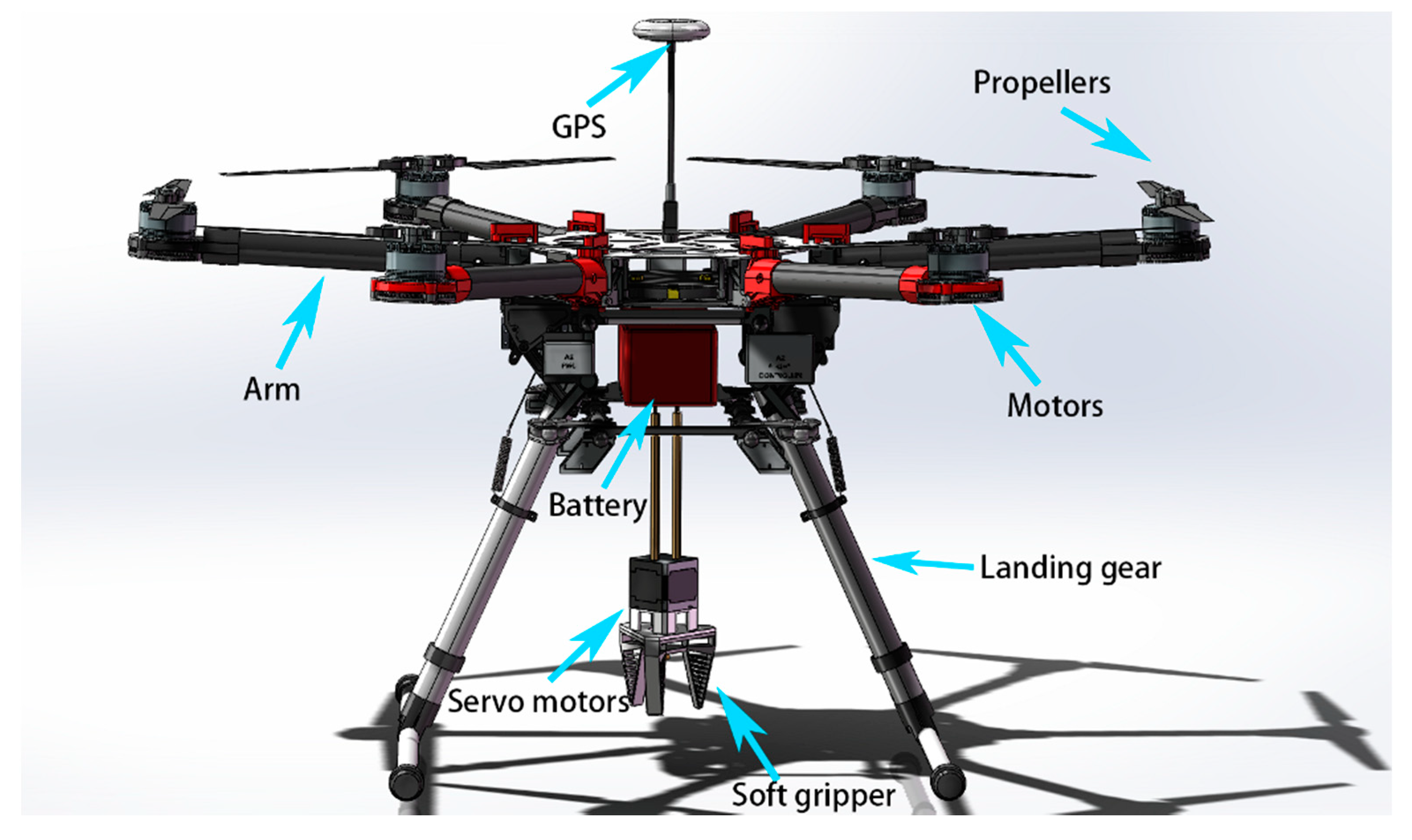

2. Design and Analysis

3. Experiment

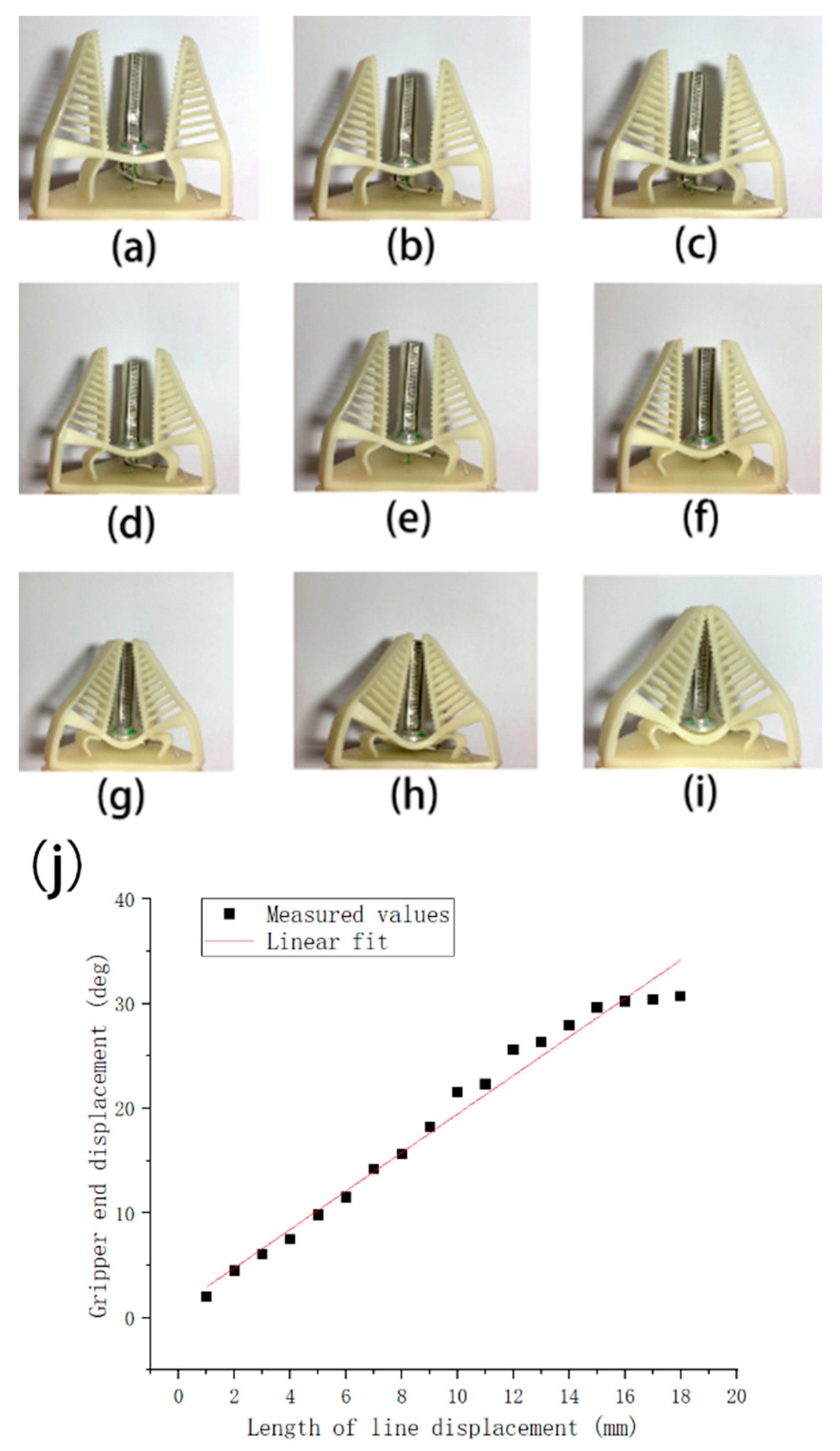

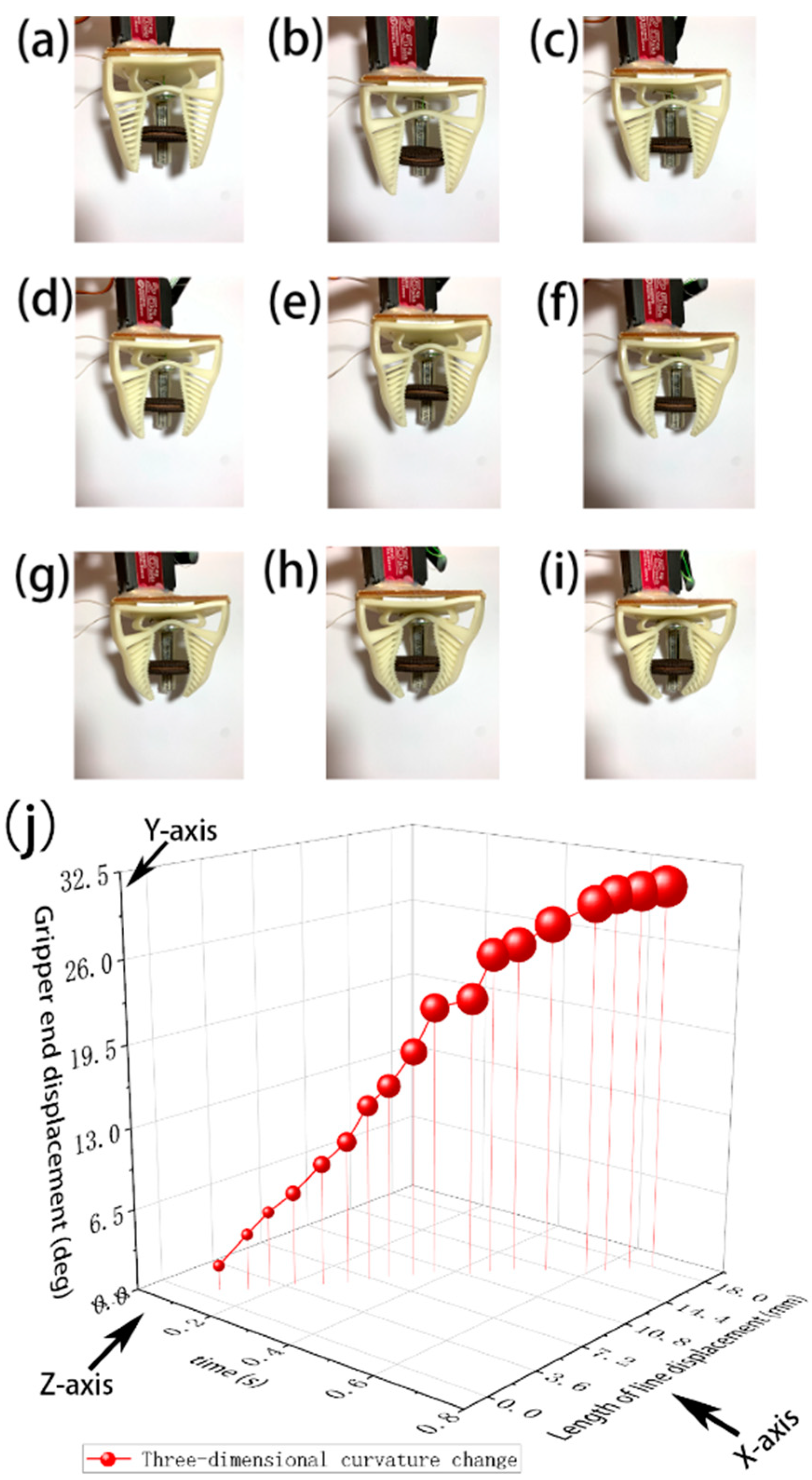

3.1. Characterization of the Gripper

3.2. Wrap-Around Grasping

3.3. Pinch Grasping

3.4. Comparative Experiment

4. Conclusion and Future Work

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Balasubramanian, R.; Santos, V.J. (Eds.) The Human Hand as an Inspiration for Robot Hand Development; Springer: Berlin/Heidelberg, Germany, 2014; Volume 95. [Google Scholar]

- Bicchi, A. On the closure properties of robotic grasping. Int. J. Robot. Res. 1995, 14, 319–334. [Google Scholar] [CrossRef]

- Catalano, M.G.; Grioli, G.; Farnioli, E.; Serio, A.; Piazza, C.; Bicchi, A. Adaptive synergies for the design and control of the Pisa/IIT SoftHand. Int. J. Robot. Res. 2014, 33, 768–782. [Google Scholar] [CrossRef] [Green Version]

- Gu, G.; Zhang, N.; Xu, H.; Lin, S.; Yu, Y.; Chai, G.; Ge, L.; Yang, H.; Shao, Q.; Sheng, X.; et al. A soft neuroprosthetic hand providing simultaneous myoelectric control and tactile feedback. Nat. Biomed. Eng. 2021. [Google Scholar] [CrossRef] [PubMed]

- Kang, L.; Seo, J.T.; Yoon, D.; Kim, S.H.; Suh, I.H.; Yi, B.J. Design of a 3-DOF Linkage-Driven Underactuated Finger for Multiple Grasping. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 5608–5613. [Google Scholar]

- Hawkes, E.W.; Majidi, C.; Tolley, M.T. Hard questions for soft robotics. Sci. Robot. 2021, 6, eabg6049. [Google Scholar] [CrossRef] [PubMed]

- Shirafuji, S.; Ikemoto, S.; Hosoda, K. Development of a tendon-driven robotic finger for an anthropomorphic robotic hand. Int. J. Robot. Res. 2014, 33, 677–693. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft robotic grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Belter, J.T.; Segil, J.L.; Dollar, A.M.; Weir, R.F. Mechanical design and performance specifications of anthropomorphic prosthetic hands: A review. J. Rehabil. Res. Dev. 2013, 50, 599–618. [Google Scholar] [CrossRef]

- Deimel, R.; Brock, O. A novel type of compliant and underactuated robotic hand for dexterous grasping. Int. J. Robot. Res. 2016, 35, 161–185. [Google Scholar] [CrossRef] [Green Version]

- Xiang, C.; Guo, J.; Rossiter, J. Soft-smart robotic end effectors with sensing, actuation, and gripping capabilities. Smart Mater. Struct. 2019, 28, 055034. [Google Scholar] [CrossRef]

- Crooks, W.; Vukasin, G.; O’Sullivan, M.; Messner, W.; Rogers, C. Fin ray® effect inspired soft robotic gripper: From the robosoft grand challenge toward optimization. Front. Robot. AI 2016, 3, 70. [Google Scholar] [CrossRef]

- Tangorra, J.L.; Lauder, G.V.; Hunter, I.W.; Mittal, R.; Madden, P.G.; Bozkurttas, M. The effect of fin ray flexural rigidity on the propulsive forces generated by a biorobotic fish pectoral fin. J. Exp. Biol. 2010, 213, 4043–4054. [Google Scholar] [CrossRef] [Green Version]

- Shan, X.; Birglen, L. Modeling and analysis of soft robotic fingers using the fin ray effect. Int. J. Robot. Res. 2020, 39, 1686–1705. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Z.; Wang, Y.; Liu, S.; Wang, M.Y. A compact and low-cost robotic manipulator driven by supercoiled polymer actuators. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 1827–18533. [Google Scholar]

- Gorissen, B.; Reynaerts, D.; Konishi, S.; Yoshida, K.; Kim, J.W.; De Volder, M. Elastic inflatable actuators for soft robotic applications. Adv. Mater. 2017, 29, 1604977. [Google Scholar] [CrossRef]

- Polygerinos, P.; Correll, N.; Morin, S.A.; Mosadegh, B.; Onal, C.D.; Petersen, K.; Cianchetti, M.; Tolley, M.T.; Shepherd, R.F. Soft robotics: Review of fluid-driven intrinsically soft devices; manufacturing, sensing, control, and applications in human-robot interaction. Adv. Eng. Mater. 2017, 19, 1700016. [Google Scholar] [CrossRef]

- Wang, W.; Ahn, S.H. Shape memory alloy-based soft gripper with variable stiffness for compliant and effective grasping. Soft Robot. 2017, 4, 379–389. [Google Scholar] [CrossRef]

- Rodrigue, H.; Wang, W.; Bhandari, B.; Han, M.W.; Ahn, S.H. SMA-based smart soft composite structure capable of multiple modes of actuation. Compos. Part B Eng. 2015, 82, 152–158. [Google Scholar] [CrossRef]

- Chen, F.; Wang, M.Y.; Zhu, J.; Zhang, Y.F. Interactions between dielectric elastomer actuators and soft bodies. Soft Robot. 2016, 3, 161–169. [Google Scholar] [CrossRef]

- Jung, K.; Nam, J.; Choi, H. Investigations on actuation characteristics of IPMC artificial muscle actuator. Sens. Actuators A Phys. 2003, 107, 183–192. [Google Scholar] [CrossRef]

- Available online: https://item.taobao.com/item.htm?spm=a1z10.5-c-s.w4002-15726392046.21.263e565bTuCPoT&id=625967195986 (accessed on 16 September 2021).

- Wang, H.; Totaro, M.; Beccai, L. Toward perceptive soft robots: Progress and challenges. Adv. Sci. 2018, 5, 1800541. [Google Scholar] [CrossRef]

- Gandarias, J.M.; Gómez-de-Gabriel, J.M.; García-Cerezo, A.J. Enhancing perception with tactile object recognition in adaptive grippers for human–robot interaction. Sensors 2018, 18, 692. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://www.festo.com/group/en/cms/10221.htm (accessed on 16 September 2021).

- Shin, J.H.; Park, J.G.; Kim, D.I.; Yoon, H.S. A Universal Soft Gripper with the Optimized Fin Ray Finger. Korean Soc. Precis. Eng. 2021, 8, 156–183. [Google Scholar]

- Wang, Z.; Torigoe, Y.; Hirai, S. A prestressed soft gripper: Design, modeling, fabrication, and tests for food handling. IEEE Robot. Autom. Lett. 2017, 2, 1909–1916. [Google Scholar] [CrossRef]

| Gripper Weight (without Motor) | Fabrication | Force Feedback | |

|---|---|---|---|

| The flexible gripper proposed in this paper | 68 g | Fully 3D printed without assembly | With force feedback |

| Commercially available gripper [22] | 200 g | 3D-printed parts assembled with mechanical connections | Without force feedback |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Jin, K.; Zhu, H.; Song, G.; Lu, H.; Kang, L. A 3D-Printed Fin Ray Effect Inspired Soft Robotic Gripper with Force Feedback. Micromachines 2021, 12, 1141. https://doi.org/10.3390/mi12101141

Yang Y, Jin K, Zhu H, Song G, Lu H, Kang L. A 3D-Printed Fin Ray Effect Inspired Soft Robotic Gripper with Force Feedback. Micromachines. 2021; 12(10):1141. https://doi.org/10.3390/mi12101141

Chicago/Turabian StyleYang, Yang, Kaixiang Jin, Honghui Zhu, Gongfei Song, Haojian Lu, and Long Kang. 2021. "A 3D-Printed Fin Ray Effect Inspired Soft Robotic Gripper with Force Feedback" Micromachines 12, no. 10: 1141. https://doi.org/10.3390/mi12101141

APA StyleYang, Y., Jin, K., Zhu, H., Song, G., Lu, H., & Kang, L. (2021). A 3D-Printed Fin Ray Effect Inspired Soft Robotic Gripper with Force Feedback. Micromachines, 12(10), 1141. https://doi.org/10.3390/mi12101141