Additive Manufacturing of a Special-Shaped Energetic Grain and Its Performance

Abstract

:1. Introduction

2. Experimental Section

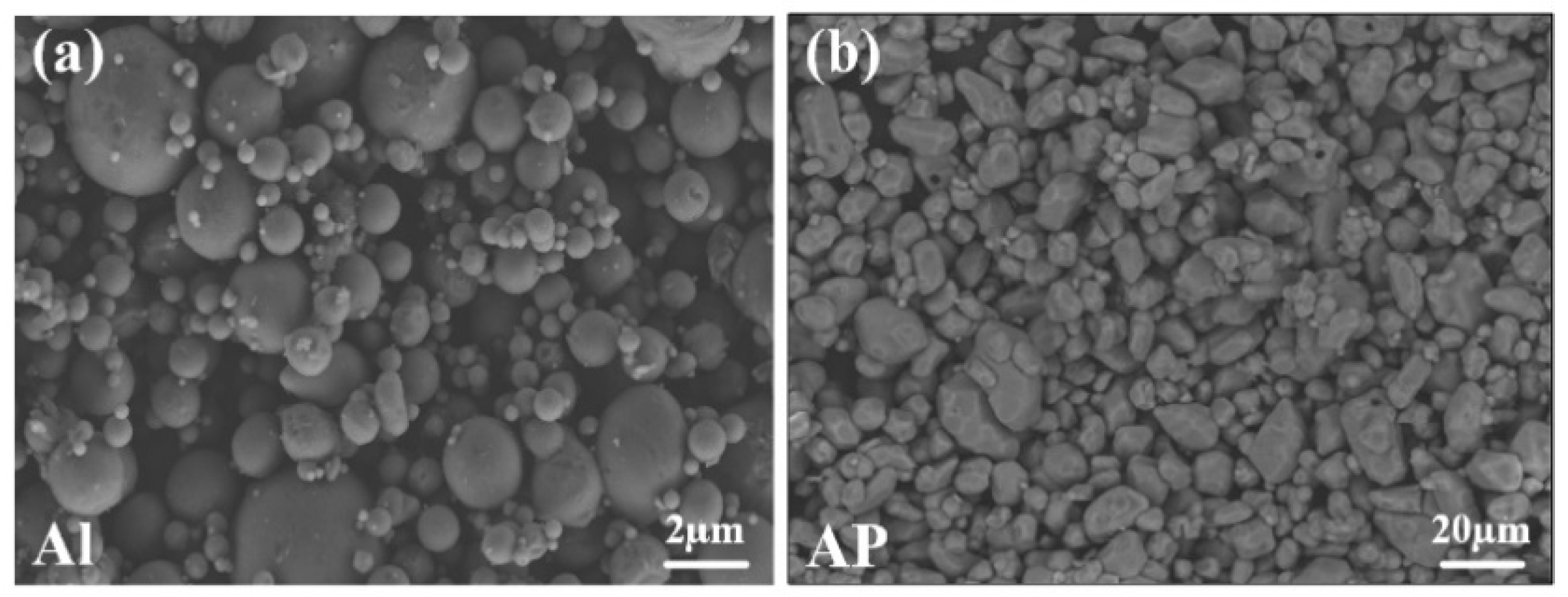

2.1. Experimental Materials

2.2. Characterization and Testing

2.3. Formula and Printing Process Parameters

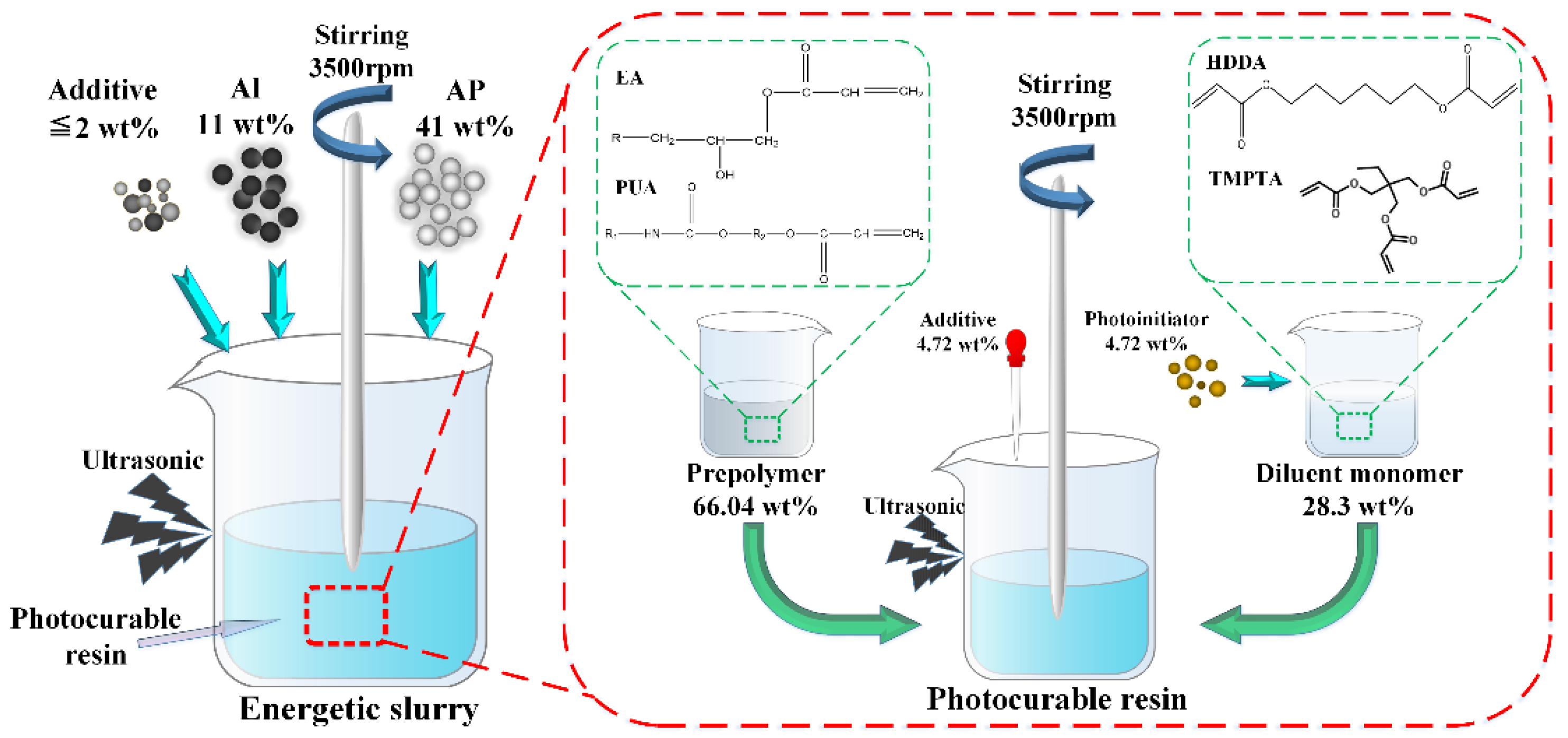

2.3.1. Formula and Preparation of Energetic Slurry

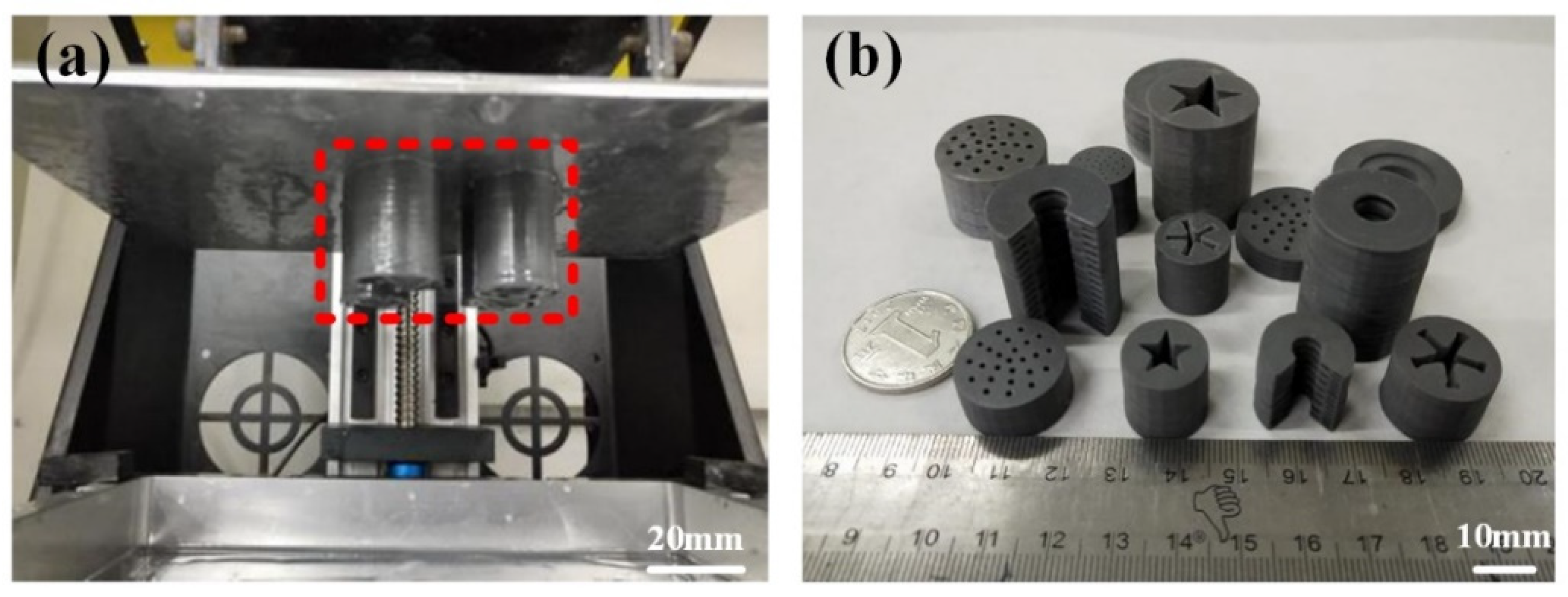

2.3.2. Optimization of Printing Parameters

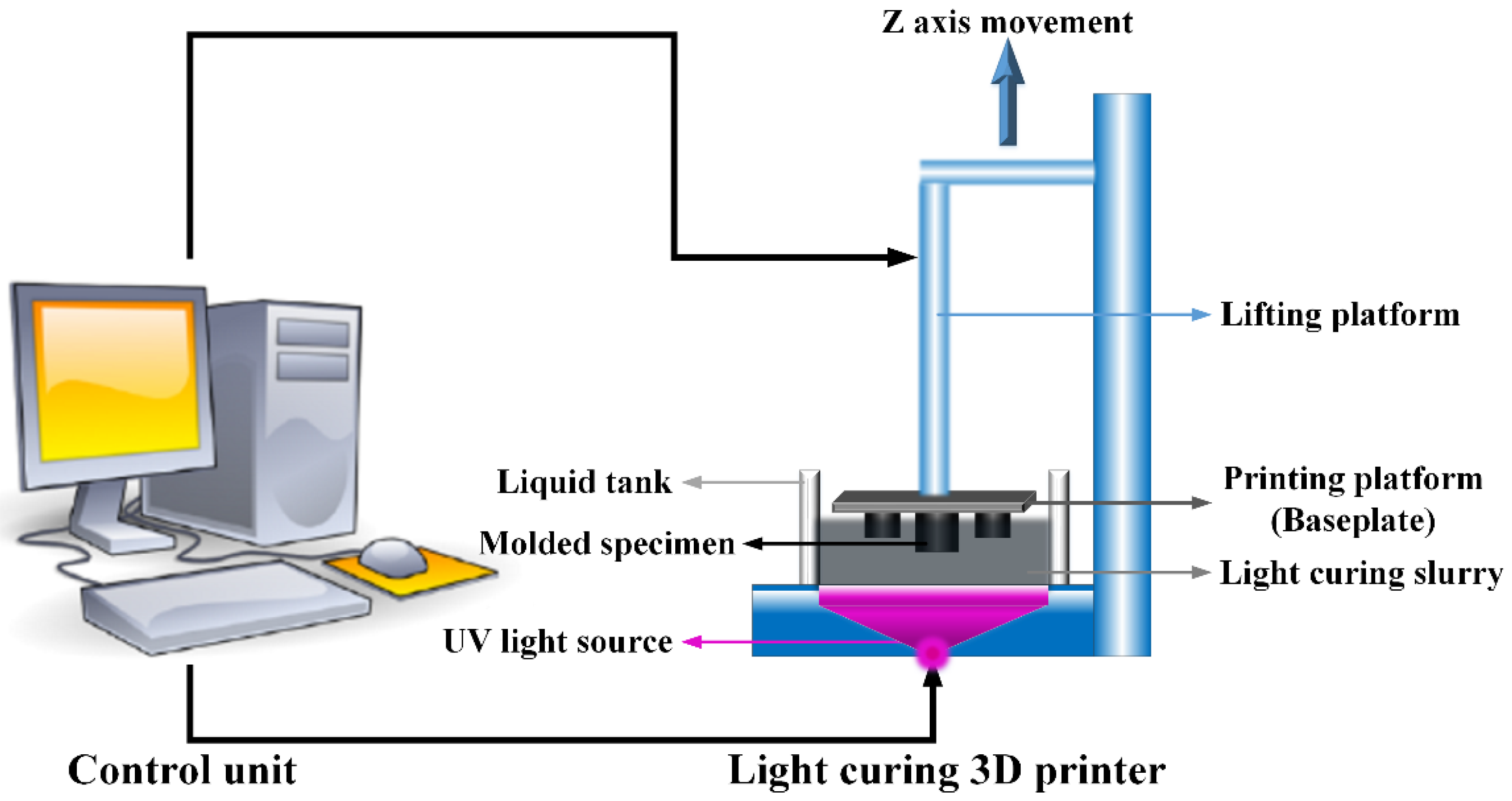

2.4. Experimental Process of Light-Curing 3D Printing

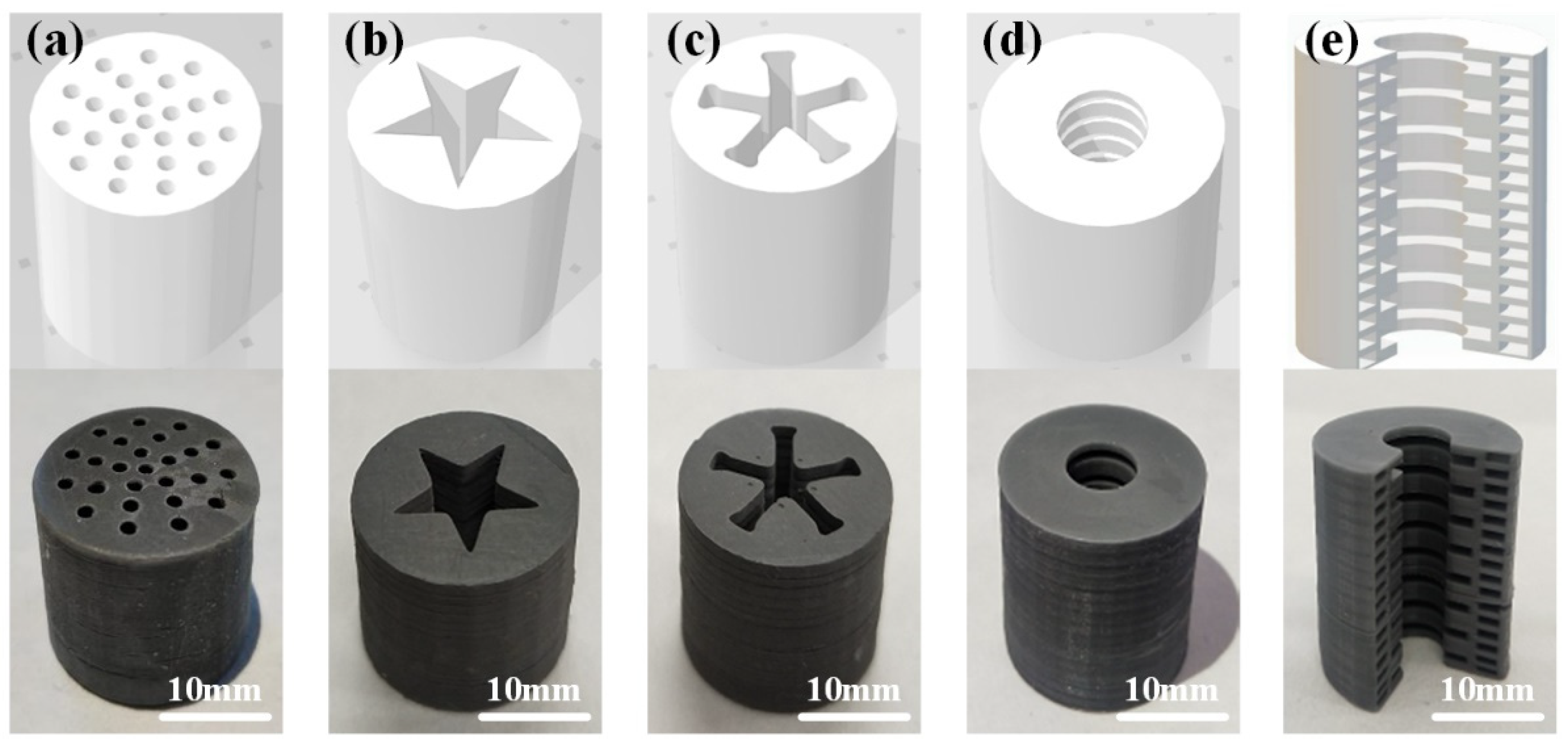

3. Results and Discussion

3.1. Density and Uniformity Test

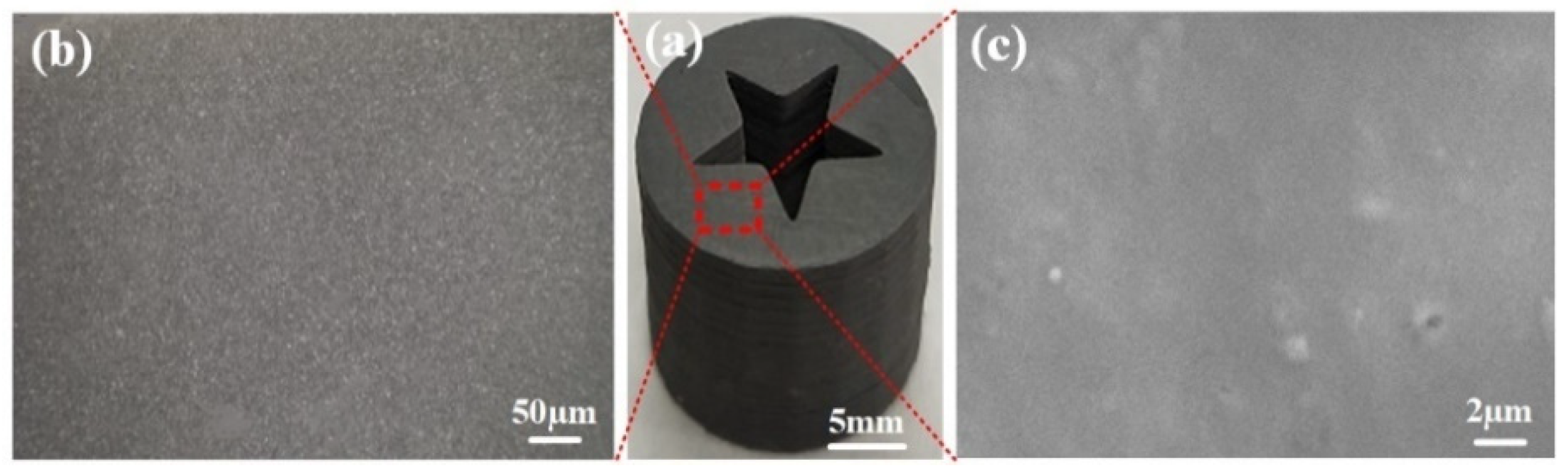

3.2. Surface and Internal Structure

3.3. Mechanical Property Test

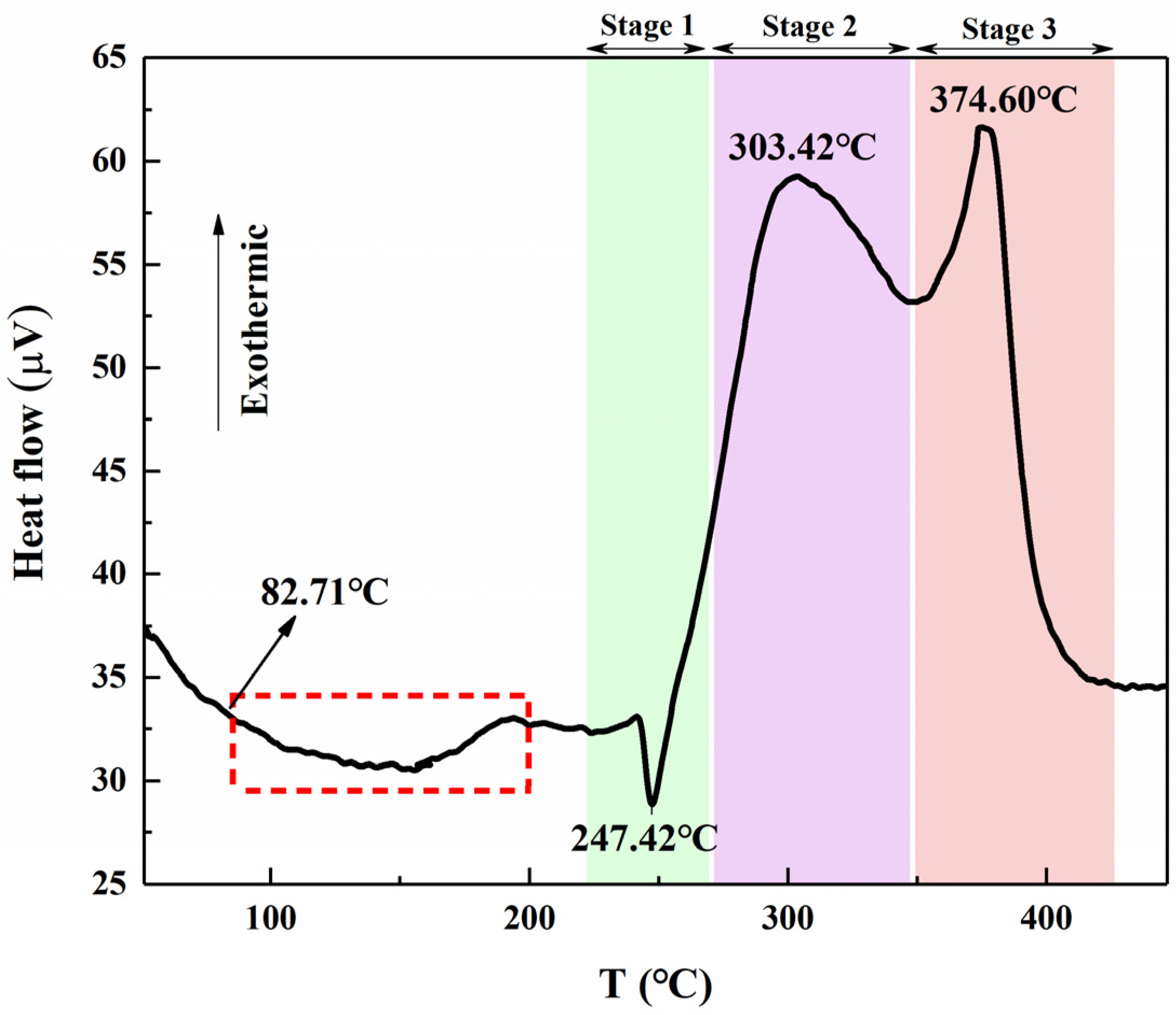

3.4. Analysis of Thermal Decomposition Behavior

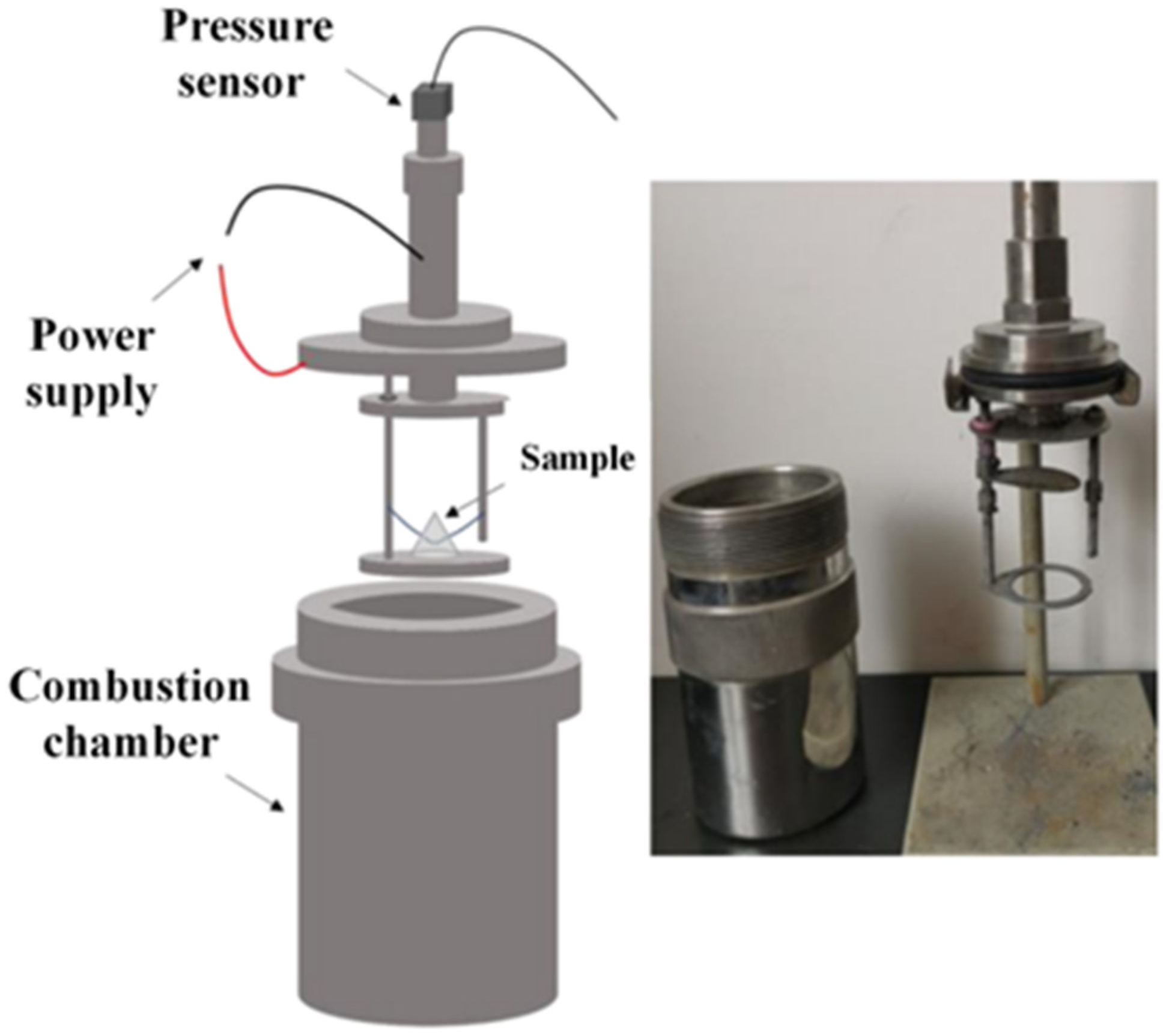

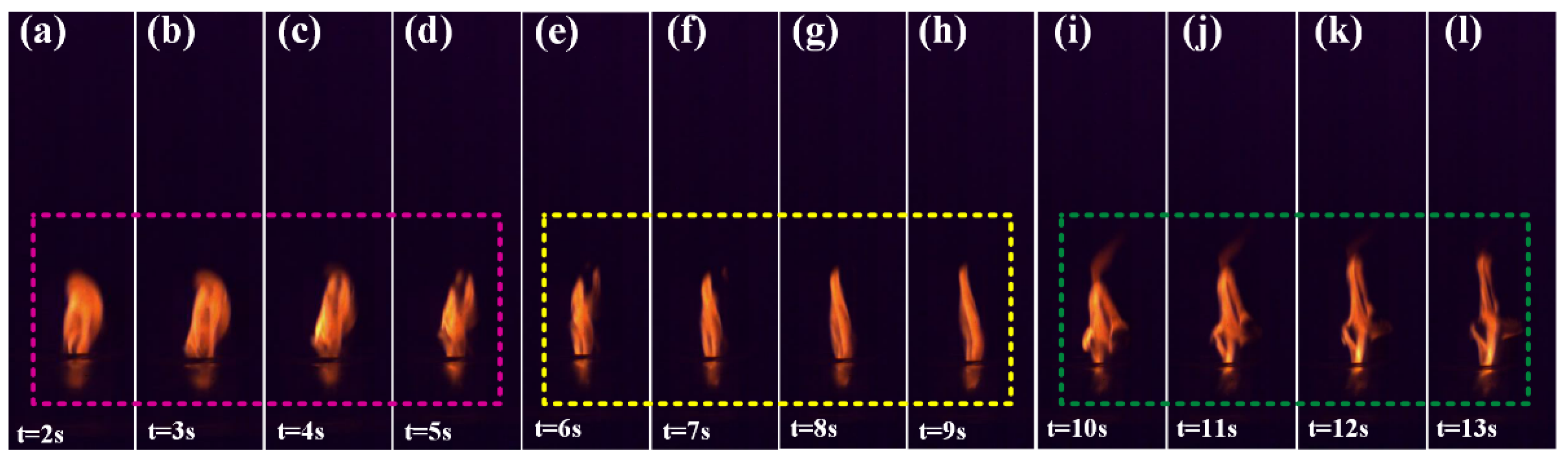

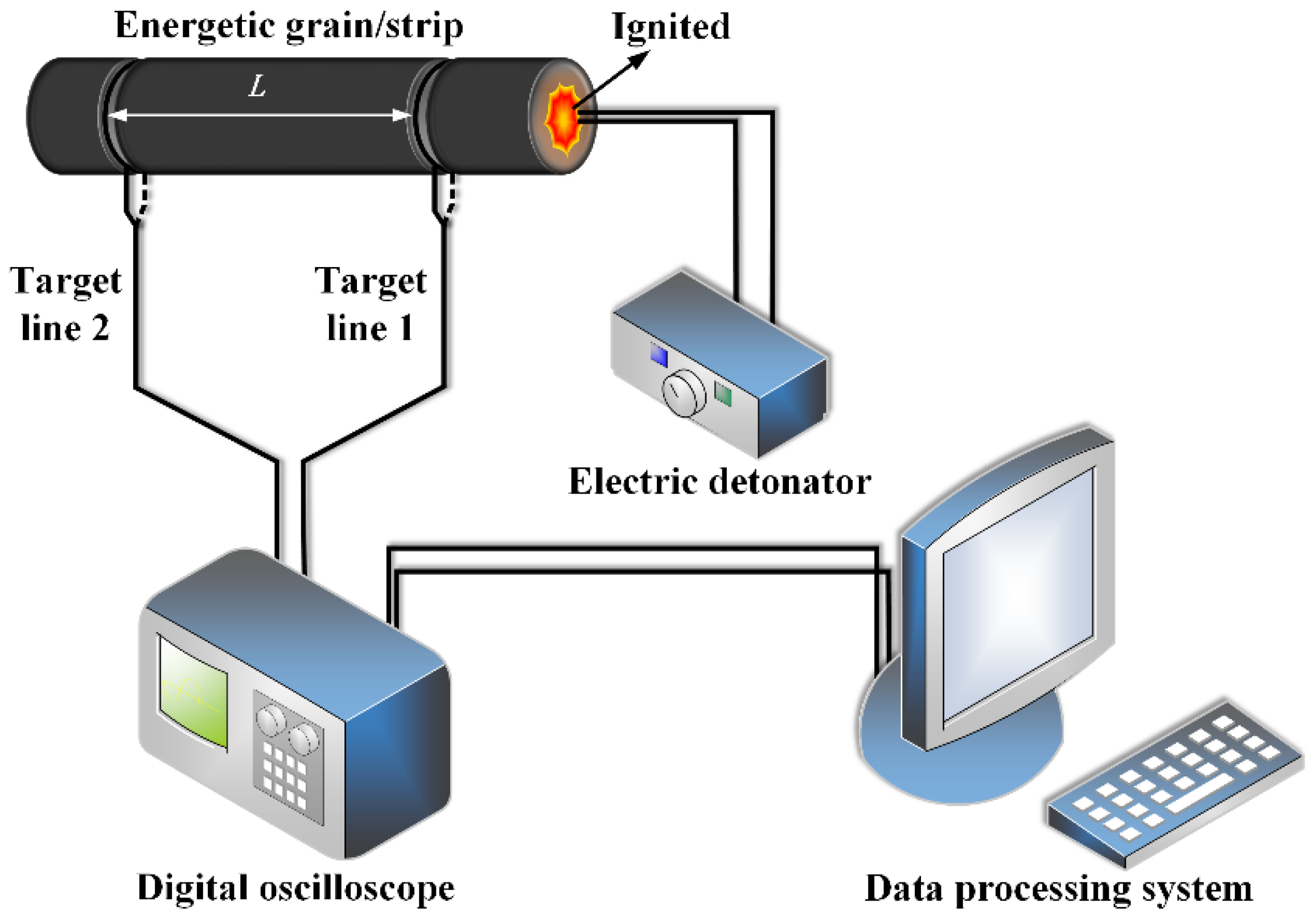

3.5. Analysis of Combustion Characteristics

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Billheimer, J.S.; Wagner, F.R. The Morphological Continuum in Solid Propellant Grain Design, Propulsion Re-Entry Physics, 1st ed.; Contensou, P., Duboshin, G.N., Hilton, W.F., Eds.; Elsevier Ltd.: Pergamon, Turkey; New York, NY, USA, 1970; pp. 152–187. [Google Scholar] [CrossRef]

- Wang, Z.S. Introduction to Energetic Materials, 1st ed.; Harbin Institute of Technology Press: Harbin, China, 2006; pp. 1–13. Available online: https://xueshu.baidu.com/usercenter/paper/show?paperid=0fb4e373956e8c2f55a4639316675751&site=xueshu_se (accessed on 30 October 2021).

- Yang, W.T.; Li, Y.X.; Ying, S.J. Fabrication of graded porous and skin-core structure RDX-based propellants via supercritical CO2 concentration profile. J. Energ. Mater. 2015, 33, 91–101. [Google Scholar] [CrossRef]

- Krier, H.; Summerfield, M. Interior Ballistics of Guns; American Institute of Aeronautics and Astronautics, Inc.: Washington, DA, USA; New York, NY, USA, 1979; pp. 409–412. Available online: https://ui.adsabs.harvard.edu/abs/1979PrAA…66.....K/abstract (accessed on 30 October 2021).

- Reid, D.L.; Kreitz, K.R.; Stephens, M.A.; King, E.S.; Nachimuthu, P.; Petersen, E.L.; Seal, S. Development of highly active titania-based nanoparticles for energetic materials. J. Phys. Chem. C. 2011, 115, 10412–10418. [Google Scholar] [CrossRef]

- Konečný, P.; Hrubý, V.; Křižan, Z. Design optimization of solid propellant rocket motor. In Proceedings of the 23rd International Symposium on Ballistics, Tarragona, Spain, 16 April 2007; pp. 515–522. Available online: http://aux.ciar.org/ttk/mbt/papers/isb2007/paper.x.isb2007.IB35.design_optimization_of_solid_propellant_rocket_motor.an.2007.pdf (accessed on 30 October 2021).

- Pérez-Roca, S.; Marzat, J.L.; Piet-Lahanier, H.; Langlois, N.; Farago, F.; Galeotta, M.; Gonidecd, S.L. A survey of automatic control methods for liquid-propellant rocket engines. Prog. Aerosp. Sci. 2019, 107, 63–84. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Mao, Y.F.; Zheng, D.W.; Zhong, L.; Wang, R.H.; Gao, B.; Wang, D.J. 3D printing of RDX-based aluminized high explosives with gradient structure, significantly altering the critical dimensions. J. Mater. Sci. 2021, 56, 9171–9182. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologiesm; Springer: Cham, Switzerland, 2014; pp. 23–51. Available online: https://link.springer.com/book/10.1007%2F978-3-030-56127-7 (accessed on 30 October 2021).

- Zhakeyev, A.; Wang, P.F.; Zhang, L.; Shu, W.M.; Wang, H.Z.; Xuan, J. Additive manufacturing: Unlocking the evolution of energy materials. Adv. Sci. 2017, 4, 1700187. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Morales, J.C.; Tarancón, A.; Canales-Vázquez, J.; Mendez-Ramos, J.; Hernandez-Afonso, L.; Acosta-Mora, P.; Marin Rueda, J.R.; Fernandez-Gonzalez, R. Three dimensional printing of components and functional devices for energy and environmental applications. Energy Environ. Sci. 2017, 10, 846–859. [Google Scholar] [CrossRef] [Green Version]

- Zunino III, J.L.; Schmidt, D.P.; Petrock, A.M.; Fuchs, B.E. Inkjet printed devices for armament applications. Nanotechnology 2010, 21, 542–545. Available online: https://briefs.techconnect.org/papers/inkjet-printed-devices-for-armament-applications/ (accessed on 30 October 2021).

- Adedeji, B.B.; Vhance, V.V.; David, L. Additive Manufacturing Handbook: Product Development for the Defense Industry; CRC Press: Boca Raton, FL, USA, 2017; pp. 127–168. Available online: https://www.routledge.com/Additive-Manufacturing-Handbook-Product-Development-for-the-Defense-Industry/Badiru-Valencia-Liu/p/book/9780367871215 (accessed on 30 October 2021).

- Hernandez, R.N.; Singh, H.; Messimer, S.L.; Patterson, A.E. Design and performance of modular 3-D printed solid-propellant rocket airframes. Aerospace 2017, 4, 17–25. [Google Scholar] [CrossRef] [Green Version]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Valentina, C.; Laurent, P. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Fateri, M.; Kaouk, A.; Cowley, A.; Siarov, S.; Palou, M.V.; González, F.G.; Marchant, R.; Cristoforetti, S.; Sperl, M. Feasibility study on additive manufacturing of recyclable objects for space applications. Addit. Manuf. 2018, 24, 400–404. [Google Scholar] [CrossRef]

- Wang, D.J.; Guo, C.P.; Wang, R.H.; Zheng, B.H.; Gao, B.; Nie, F.D. Additive manufacturing and combustion performance of CL-20 composites. J. Mater. Sci. 2020, 55, 2836–2845. Available online: https://link.springer.com/article/10.1007/s10853-019-04209-w (accessed on 30 October 2021).

- Mao, Y.F.; Zhong, L.; Zhou, X.; Zheng, D.W.; Zhang, X.Q.; Duan, T.; Nie, F.D.; Gao, B.; Wang, D.J. 3D Printing of Micro-Architected Al/CuO-Based Nanothermite for Enhanced Combustion Performance. Adv. Eng. Mater. 2019, 21, 1900825. [Google Scholar] [CrossRef]

- Xu, C.H.; An, C.W.; He, Y.N.; Zhang, Y.R.; Li, Q.B.; Wang, J.Y. Direct ink writing of DNTF based composite with high performance. Propellants Explos. Pyrotech. 2018, 43, 754–758. [Google Scholar] [CrossRef]

- Xu, C.H.; An, C.W.; Li, Q.B.; Xu, S.; Wang, S.; Guo, H.; Wang, J.Y. Preparation and Performance of Pentaerythrite Tetranitrate-Based Composites by Direct Ink Writing. Propellants Explos. Pyrotech. 2018, 43, 1149–1156. [Google Scholar] [CrossRef]

- Xu, C.H.; An, C.W.; Long, Y.L.; Li, Q.B.; Guo, H.; Wang, S.; Wang, J.Y. Inkjet printing of energetic composites with high density. RSC Adv. 2018, 8, 35863–35869. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.Y.; Xu, C.H.; An, C.W.; Song, C.K.; Liu, B.; Wu, B.D.; Geng, X.H. Preparation and Properties of CL-20 based Composite by Direct Ink Writing. Propellants Explos. Pyrotech. 2017, 42, 1139–1142. [Google Scholar] [CrossRef]

- Li, Q.B.; An, C.W.; Han, X.; Xu, C.H.; Song, C.K.; Ye, B.Y.; Wu, B.D.; Wang, J.Y. CL-20 based Explosive Ink of Emulsion Binder System for Direct Ink Writing. Propellants Explos. Pyrotech. 2018, 43, 533–537. [Google Scholar] [CrossRef]

- Bencomo, J.A.; Iacono, S.T.; McCollum, J. 3D printing multifunctional fluorinated nanocomposites: Tuning electroactivity, rheology and chemical reactivity. J. Mater. Chem. A. 2018, 6, 12308–12315. [Google Scholar] [CrossRef]

- Ihnen, A.C.; Lee, W.Y.; Fuchs, B.; Petrock, A.M.; Stec II, D. Ink jet printing and patterning of explosive materials. U.S. Patent 929624, 29 March 2016. [Google Scholar]

- Ihnen, A.C.; Petrock, A.M.; Chou, T.; Fuchs, B.E.; Lee, W.Y. Organic Nanocomposite Structure Tailored by Controlling Droplet Coalescence during Inkjet Printing. ACS Appl. Mater. Interfaces 2012, 4, 4691–4699. [Google Scholar] [CrossRef]

- Ihnen, A.C.; Petrock, A.M.; Chou, T.; Samuels, P.J.; Fuchs, B.E.; Lee, W.Y. Crystal morphology variation in inkjet-printed organic materials. Appl. Surf. Sci. 2011, 258, 827–833. [Google Scholar] [CrossRef]

- Muray, A.K.; Novotny, W.A.; Fleck, T.J.; Emre Gunduz, I.; Son, S.; Chiu, G.T.-C.; Rhoads, J.F. Selectively-deposited energetic materials: A feasibility study of the piezoelectric inkjet printing of nanothermites. Addit. Manuf. 2018, 22, 69–74. [Google Scholar] [CrossRef]

- Sullivan, K.T.; Zhu, C.; Duoss, E.B.; Gash, A.E.; Kolesky, D.B.; Kuntz, J.D.; Lewis, J.A.; Spadaccini, C.M. Controlling material reactivity using architecture. Adv. Mater. 2016, 28, 1934–1939. [Google Scholar] [CrossRef] [PubMed]

- Nafday, O.A.; Pitchimani, R.; Weeks, B.L.; Haaheim, J. Patterning high explosives at the nanoscale. Propellants Explos. Pyrotech. 2006, 31, 376–381. [Google Scholar] [CrossRef]

- Knepper, R.; Tappan, A.S.; Wixom, R.R.; Rodriguez, M.A. Controlling the microstructure of vapor-deposited pentaerythritol tetranitrate films. J. Mater. Res. 2011, 26, 1605–1613. [Google Scholar] [CrossRef]

- Knepper, R.; Browning, K.; Wixom, R.R.; Tappan, A.S.; Rodriguez, M.A.; Alamet, M.K. Microstructure Evolution during Crystallization of Vapor-Deposited Hexanitroazobenzene Films. Propellants Explos. Pyrotech. 2012, 37, 459–467. [Google Scholar] [CrossRef]

- Meeks, K.; Pantoya, M.L.; Apblett, C. Deposition and characterization of energetic thin films. Combust. Flame 2014, 16, 1117–1124. [Google Scholar] [CrossRef]

- Meeks, K.A.; Clark, B.R.; Cano, J.E.; Apblett, C.A.; Pantoya, M.L. Effects of rheological properties on reactivity of energetic thin films. Combust. Flame 2015, 162, 3288–3293. [Google Scholar] [CrossRef] [Green Version]

- Clark, B.; McCollum, J.; Pantoya, M.L.; Heaps, R.J.; Daniels, M.A. Development of flexible, free-standing, thin films for additive manufacturing and localized energy generation. AIP Adv. 2015, 5, 087128. [Google Scholar] [CrossRef] [Green Version]

- Clark, B.; Zhang, Z.H.; Christopher, G.; Pantoya, M.L. 3D processing and characterization of acrylonitrile butadiene styrene (ABS) energetic thin films. J. Mater. Sci. 2017, 52, 993–1004. [Google Scholar] [CrossRef]

- Knepper, R.; Wixom, R.R.; Marquez, M.P.; Tappan, A.S. Near-failure detonation behavior of vapor-deposited hexanitrostilbene (HNS) films. In Proceedings of the AIP Conference Proceedings, Tampa Bay, FL, USA, 13 January 2017; p. 030014. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Wang, J.; Mao, Y.F.; Xu, R.J.; Zeng, G.Y.; Yang, Z.J.; Nie, F.D. Preparation of CL-20/TATB Composite Charge Structure by 3D Printing Technology. Chin. J. Energ. Mater. 2019, 27, 931–935. [Google Scholar] [CrossRef]

- Chandru, R.A.; Balasubramanian, N.; Oommen, C.; Raghunandan, B.N. Additive manufacturing of solid rocket propellant grains. J. Propuls. Power 2018, 34, 1090–1093. [Google Scholar] [CrossRef]

- Fleck, T.J.; Murray, A.K.; Gunduz, I.E.; Son, S.F.; CChiu, G.T.; Rhoads, J.F. Additive manufacturing of multifunctional reactive materials. Addit Manuf. 2017, 17, 176–182. [Google Scholar] [CrossRef]

- Mezger, M.J.; Tindle, K.J.; Pantoya, M.; Groven, L.J.; Kalyon, D. Energetic Materials: Advanced Processing Technologies for Next-Generation Materials, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 115–128. Available online: https://books.google.ae/books?hl=zh-CN&lr=&id=hkUrDwAAQBAJ&oi=fnd&pg=PP9&dq=Energetic+Materials:+Advanced+Processing+Technologies+for+Next-Generation+Materials&ots=wk4CEChgNT&sig=ZJhg7dXIUZLXXFMzteOIjKPfxSE&redir_esc=y#v=onepage&q=Energetic%20Materials%3A% (accessed on 30 October 2021).

- Woods, H.; Boddorff, A.; Ewaldz, E.; Adams, Z.; Ketcham, M.; Jang, D.J.; Sinner, E.; Thadhani, N.; Brettmann, B. Rheological Considerations for Binder Development in Direct Ink Writing of Energetic Materials. Propellants Explos. Pyrotech. 2020, 45, 26–35. [Google Scholar] [CrossRef]

- Selimis, A.; Mironov, V.; Farsari, M. Direct laser writing: Principles and materials for scaffold 3D printing. Microelectron Eng. 2015, 132, 83–89. [Google Scholar] [CrossRef]

- Zarek, M.; Layani, M.; Cooperstein, I.; Sachyani, E.; Cohn, D.; Magdassi, S. 3D printing of shape memory polymers for flexible electronic devices. Adv. Mater. 2016, 28, 4449–4454. [Google Scholar] [CrossRef] [PubMed]

- Straathof, M.H.; van Driel, C.A.; van Lingen, J.N.; Ingenhut, B.L.; Tessa ten Cate, A.; Maalderink, H.H. Development of Propellant Compositions for Vat Photopolymerization Additive Manufacturing. Propellants Explos. Pyrotech. 2020, 45, 36–52. [Google Scholar] [CrossRef]

- Driel, C.V.; Straathof, M.; Lingen, J.V. Developments in additive manufacturing of energetic materials at TNO. In Proceedings of the 30th International Symposium on Ballistics, Long Beach, CA, USA, 11 September 2017; DEStech Publications Inc.: California, CA, USA, 2017; pp. 11–15. [Google Scholar] [CrossRef]

- Yang, W.T.; Liu, Z.; Zhang, Y.C.; Yang, J.X. Calculation and Analysis on Energy Characteristics of Foamed Propellant. Chin. J. Energ. Mater. 2017, 25, 726–731. [Google Scholar] [CrossRef]

- Yang, W.T.; Hu, R.; Zheng, L.; Yan, G.H.; Yan, W.R. Fabrication and investigation of 3D-printed gun propellants. Mater. Des. 2020, 192, 108761. [Google Scholar] [CrossRef]

- Li, M.M.; Yang, W.T.; Xu, M.H.; Hu, R.; Zheng, L. Study of photocurable energetic resin based propellants fabricated by 3D printing. Mater. Des. 2021, 207, 109891. [Google Scholar] [CrossRef]

- McClain, M.S.; Gunduz, I.E.; Son, S.F. Additive manufacturing of ammonium perchlorate composite propellant with high solids loadings. Proc. Combust. Inst. 2019, 37, 3135–3142. [Google Scholar] [CrossRef]

- Yuan, J.F.; Liu, J.Z.; Zhou, Y.N.; Zhang, Y.W.; Cen, K.F. Thermal decomposition and combustion characteristics of Al/AP/HTPB propellant. J. Therm. Anal. Calorim. 2020, 143, 1–10. Available online: https://link.springer.com/article/10.1007/s10973-020-09297-4 (accessed on 30 October 2021). [CrossRef]

- Li, F.S.; Liu, L.L.; Ma, Z.Y. Catalytic Effect of Nanometer Metal Powders and Nanometer Fe2O3 on the Thermal Decomposition of Ammonium Perchlorate. In Proceedings of the 2004 Annual Meeting of Chinese Society of Particulates, Cross-Strait Particulate Technology Seminar, Yantai, China, 29 August 2004; Available online: https://xueshu.baidu.com/usercenter/paper/show?paperid=2ef82981081fde9da032412be1e80dfe&site=xueshu_se&hitarticle=1 (accessed on 30 October 2021).

- Dai, J.; Xu, J.B.; Wang, F.; Tai, Y.; Shen, Y.; Shen, R.Q.; Ye, Y.H. Facile formation of nitrocellulose-coated Al/Bi2O3 nanothermites with excellent energy output and improved electrostatic discharge safety. Mater. Des. 2018, 143, 93–103. [Google Scholar] [CrossRef]

| Component | Fraction (wt%) | |

|---|---|---|

| Prepolymer | EA | 44.06 |

| PUA | 21.98 | |

| Diluent monomer | HDDA | 14.15 |

| TMPTA | 14.15 | |

| TPO | 4.72 | |

| Additives | 0.94 | |

| Component | Fraction (wt%) |

|---|---|

| Photocurable resin (self-made) | 48 |

| Ultra-fine AP | 41 |

| Modified Al | 11 |

| Other additives | ≤2(in addition) |

| Layer | Exposure Time/ms | Up Speed mm/min | Down Speed mm/min | Lift Height/mm | Settle Time/ms |

|---|---|---|---|---|---|

| 0 | 200,000 | 20 | 40 | 100 | 3000 |

| 1 | 150,000 | 30 | 50 | 80 | 2600 |

| 3 | 100,000 | 40 | 60 | 60 | 2200 |

| 5 | 50,000 | 50 | 70 | 40 | 1800 |

| 10 | 10,000 | 60 | 80 | 20 | 1400 |

| 20 | 8000 | 70 | 90 | 10 | 1000 |

| 30 | 7000 | 70 | 90 | 10 | 1000 |

| 40 | 6000 | 70 | 90 | 10 | 1000 |

| 50 | 6000 | 70 | 90 | 10 | 1000 |

| 60 | … | … | … | … | … |

| Number | Grain Density /(g·cm−3) | Average Density /(g·cm−3) | Standard Deviation of Density /(g·cm−3) | Theoretical Density /(g·cm−3) |

|---|---|---|---|---|

| 1 | 1.606 | 1.606 | 0.002 | 1.619 |

| 2 | 1.609 | |||

| 3 | 1.604 |

| Compressive Strength (Sc)/MPa | Fracture Force (Fb)/N | Tensile Fracture Stress (σtb)/MPa | Tensile Strength (σtM)/MPa | Tensile Elastic Modulus (Et)/MPa |

|---|---|---|---|---|

| 9.8300 | 259.5060 | 6.4877 | 8.7845 | 1027.2150 |

| Strip Number | Distance between Target Lines (mm) | Burning Time (s) | Burning Rate (mm·s−1) | Average Burning Rate (mm·s−1) |

|---|---|---|---|---|

| 1 | 30 | 5.61 | 5.35 | 5.11 |

| 2 | 30 | 6.15 | 4.88 | |

| 3 | 30 | 5.35 | 5.61 | |

| 4 | 30 | 6.05 | 4.96 | |

| 5 | 30 | 6.34 | 4.73 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Ba, S.; Ren, H. Additive Manufacturing of a Special-Shaped Energetic Grain and Its Performance. Micromachines 2021, 12, 1509. https://doi.org/10.3390/mi12121509

Chen Y, Ba S, Ren H. Additive Manufacturing of a Special-Shaped Energetic Grain and Its Performance. Micromachines. 2021; 12(12):1509. https://doi.org/10.3390/mi12121509

Chicago/Turabian StyleChen, Yongjin, Shuhong Ba, and Hui Ren. 2021. "Additive Manufacturing of a Special-Shaped Energetic Grain and Its Performance" Micromachines 12, no. 12: 1509. https://doi.org/10.3390/mi12121509

APA StyleChen, Y., Ba, S., & Ren, H. (2021). Additive Manufacturing of a Special-Shaped Energetic Grain and Its Performance. Micromachines, 12(12), 1509. https://doi.org/10.3390/mi12121509