Numerical Study on Flow and Heat Transfer Characteristics of Trapezoidal Printed Circuit Heat Exchanger

Abstract

:1. Introduction

2. Model and Methods

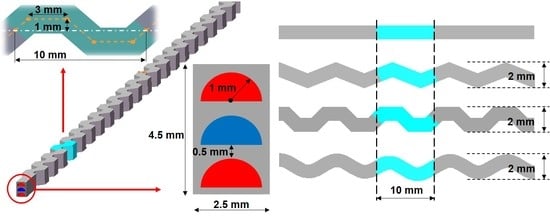

2.1. Model and System

2.2. Grid and Independence Verification

- 1

- The continuous medium flows uniformly in every channel of the PCHE.

- 2

- The total mass flow of sCO2 is distributed equally in each hot/cold channel because the flow resistance is the same.

- 3

- The inlet temperature and pressure of all hot/cold channels are the same and identical to the hot/cold pipe of the PCHE.

- 4

- The effect of pressure changes on the CO2 properties is neglectable in the flowing process, as the pressure loss is much smaller than the working pressure.

2.3. Properties of sCO2

2.4. Calculation Method

3. Results and Discussion

3.1. Thermal and Hydraulic Performance

3.2. Comparison between the Trapezoidal and Previous Channel Structures

3.3. Optimization of Trapezoidal PCHE

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ishizuka, T.; Kato, Y.; Muto, Y.; Nikitin, K.; Tr, N.L.; Hashimoto, H. Thermal hydraulic characteristics of a printed circuit heat exchanger in a supercritical CO2 loop. In Proceedings of the 11th International Topical Meeting on Nuclear Reactor Thermal-Hydraulics (NURETH-11), Avignon, France, 2–6 October 2005; pp. 218–232. [Google Scholar]

- Nikitin, K.; Kato, Y.; Ngo, L. Printed circuit heat exchanger thermal-hydraulic performance in supercritical CO2 experimental loop. Int. J. Refrig. 2006, 29, 807–814. [Google Scholar] [CrossRef]

- Ngo, L.; Kato, Y.; Nikitin, K.; Ishizuka, T. New printed circuit heat exchanger with S-shaped fins for hot water supplier. Exp. Therm. Fluid Sci. 2006, 29, 811–819. [Google Scholar] [CrossRef]

- Ngo, L.; Kato, Y.; Nikitin, K.; Tsuzuki, N. Heat transfer and pressure drop correlations of microchannel heat exchangers with S-shaped and zigzag fins for carbon dioxide cycles. Exp. Therm. Fluid Sci. 2007, 32, 560–570. [Google Scholar] [CrossRef]

- Kim, I.H.; No, H.C.; Lee, J.I.; Jeon, B.G. Thermal hydraulic performance analysis of the printed circuit heat exchanger using a helium test facility and CFD simulations. Nucl. Eng. Des. 2009, 239, 2399–2408. [Google Scholar] [CrossRef]

- Kim, I.H.; No, H.C. Thermal hydraulic performance analysis of a printed circuit heat exchanger using a helium-water test loop and numerical simulations. Appl. Therm. Eng. 2011, 31, 4064–4073. [Google Scholar] [CrossRef]

- Kim, I.H.; NO, H.C. Thermal-hydraulic physical models for a Printed Circuit Heat Exchanger covering He, He-CO2 mixture, and water fluids using experimental data and CFD. Exp. Therm. Fluid Sci. 2013, 48, 213–221. [Google Scholar] [CrossRef]

- Mylavarapu, S.K.; Sun, X.; Glosup, R.E.; Christensen, R.N.; Patterson, M. Thermal hydraulic performance testing of printed circuit heat exchangers in a high-temperature helium test facility. Appl. Therm. Eng. 2014, 65, 605–614. [Google Scholar] [CrossRef]

- Baik, S.; Kim, S.G.; Lee, J.; Lee, J.I. Study on CO2-water printed circuit heat exchanger performance operating under various CO2 phases for S-CO2 power cycle application. Appl. Therm. Eng. 2017, 113, 1536–1546. [Google Scholar] [CrossRef]

- Chu, W.-X.; Li, X.-H.; Ma, T.; Chen, Y.-T.; Wang, Q.-W. Experimental investigation on SCO2-water heat transfer characteristics in a printed circuit heat exchanger with straight channels. Int. J. Heat Mass Transf. 2017, 113, 184–194. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, J.; Cui, X.; Zhou, J.; Huai, X.; Zhang, H.; Cheng, K.; Han, Z. Experimental and numerical investigations of thermal-hydraulic characteristics in a novel airfoil fin heat exchanger. Int. J. Heat Mass Transf. 2021, 175, 121333. [Google Scholar] [CrossRef]

- Tsuzuki, N.; Kato, Y.; Ishiduka, T. High performance printed circuit heat exchanger. Appl. Therm. Eng. 2007, 27, 1702–1707. [Google Scholar] [CrossRef]

- Tsuzuki, N.; Kato, Y.; Nikitin, K.; Ishiduka, T. Advanced microchannel heat exchanger with S-shaped fins. J. Nucl. Sci. Technol. 2009, 46, 403–412. [Google Scholar] [CrossRef]

- Tsuzuki, N.; Utamura, M.; Ngo, T.L. Nusselt number correlations for a microchannel heat exchanger hot water supplier with S-shaped fins. Appl. Therm. Eng. 2009, 29, 3299–3308. [Google Scholar] [CrossRef]

- Kim, D.E.; Kim, M.H.; Cha, J.E.; Kim, S.O. Numerical investigation on thermal-hydraulic performance of new printed circuit heat exchanger model. Nucl. Eng. Des. 2008, 238, 3269–3276. [Google Scholar] [CrossRef]

- Bartel, N.; Chen, M.; Utgikar, V.; Sun, X.; Kim, I.-H.; Christensen, R.; Sabharwall, P. Comparative analysis of compact heat exchangers for application as the intermediate heat exchanger for advanced nuclear reactors. Ann. Nucl. Energy 2015, 81, 143–149. [Google Scholar] [CrossRef] [Green Version]

- Khan, H.H.; Aneesh, A.M.; Sharma, A.; Srivastava, A.; Chaudhuri, P. Thermal-hydraulic characteristics and performance of 3D wavy channel based printed circuit heat exchanger. Appl. Therm. Eng. 2015, 87, 519–528. [Google Scholar] [CrossRef]

- Kim, S.G.; Lee, Y.; Ahn, Y.; Lee, J.I. CFD aided approach to design printed circuit heat exchangers for supercritical CO2 Brayton cycle application. Ann. Nucl. Energy 2016, 92, 175–185. [Google Scholar] [CrossRef]

- Baik, Y.-J.; Jeon, S.; Kim, B.; Jeon, D.; Byon, C. Heat transfer performance of wavy-channeled PCHEs and the effects of waviness factors. Int. J. Heat Mass Transf. 2017, 114, 809–815. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, L.; Huai, X.; Li, J.; Zhang, H.; Liu, Z. Comprehensive performance comparison of airfoil fin PCHEs with NACA 00XX series airfoil. Nucl. Eng. Des. 2017, 315, 42–50. [Google Scholar] [CrossRef]

- Aneesh, A.; Sharma, A.; Srivastava, A.; Chaudhury, P. Effects of wavy channel configurations on thermal-hydraulic characteristics of Printed Circuit Heat Exchanger (PCHE). Int. J. Heat Mass Transf. 2018, 118, 304–315. [Google Scholar] [CrossRef]

- Ren, Z.; Zhao, C.-R.; Jiang, P.-X.; Bo, H.-L. Investigation on local convection heat transfer of supercritical CO2 during cooling in horizontal semicircular channels of printed circuit heat exchanger. Appl. Therm. Eng. 2019, 157, 113697. [Google Scholar] [CrossRef]

- Lv, Y.-G.; Wen, Z.-X.; Li, Q.; Qiu, Y. Numerical investigation on thermal hydraulic performance of hybrid wavy channels in a supercritical CO2 precooler. Int. J. Heat Mass Transf. 2021, 181, 121891. [Google Scholar] [CrossRef]

- Li, M.-J.; Zhu, H.-H.; Guo, J.-Q.; Wang, K.; Tao, W.-Q. The development technology and applications of supercritical CO2 power cycle in nuclear energy, solar energy and other energy industries. Appl. Therm. Eng. 2017, 126, 255–275. [Google Scholar] [CrossRef]

- Saeed, M.; Kim, M.-H. Thermal and hydraulic performance of SCO2 PCHE with different fin configurations. Appl. Therm. Eng. 2017, 127, 975–985. [Google Scholar] [CrossRef]

| Structure | Medium | Temperature (℃) | Pressure (MPa) | Flow Rate (kg/h) | Deficiency | Ref. |

|---|---|---|---|---|---|---|

| Straight | Helium | Hot side: 208–790 Cold side: 85–390 | Hot side: 1.0–2.7 Cold side:1.0–2.7 | 15–49 | No sCO2 Low pressure One channel only | [8] |

| Straight | Hot side: sCO2 Cold side: water | Hot side: 37–102 Cold side: - | Hot side: 8–11 Cold side: - | sCO2: 150–650 | Not sCO2 heat exchange Low temperature One channel only | [10] |

| Zigzag | CO2 | Hot side: 280–300 Cold side: 90–108 | Hot side: 2.2–3.2 Cold side: 6.5–10.5 | 40–80 | Low pressure under supercritical state One channel only | [2] |

| Zigzag S-shape | CO2 | Hot side: 120 Cold side: 35–55 | Hot side: 6 Cold side: 7.7–12 | 40–150 | Low pressure at hot side | [3,4] |

| Zigzag | Hot side: He-CO2 Cold side: water | Hot side: 104.5–217.6 Cold side: 23.6–25.2 | Hot side: 1.17–1.72 Cold side: 0.104–0.306 | He-CO2: 154–329 Water: 389–1966 | Mixed sCO2 Low pressure Low temperature One channel only | [5,6,7] |

| Zigzag | Hot side: CO2 Cold side: water | Hot side: 26–43 Cold side: 15 | Hot side: 7.3–8.6 Cold side: - | - | Not sCO2 heat exchange Transcritical phase exists Low temperature One channel only | [9] |

| Airfoil | Hot side: CO2 Cold side: water | Hot side: 70–110 Cold side: 16–25 | Hot side: 7.6–9.0 Cold side: Approx. 0.1 | CO2: 500–1800 Water: Approx. 3000 | Not sCO2 heat exchange Low temperature One channel only | [11] |

| Structure | Medium | Temperature (℃) | Pressure (MPa) | Flow Rate (kg/h) | Deficiency | Ref. |

|---|---|---|---|---|---|---|

| Straight | Hot side: CO2 Cold side: water | Hot side: 40–100 Cold side: 14–50 | Hot side: 7.5/8.1 Cold side: 0.101325 | Hot side: 2.22–8.87 Cold side: 22.17–26.60 | Not sCO2 heat exchange Low temperature One channel only | [22] |

| Straight S-shape | sCO2 | 101.85 | 8 | 1.44 | Not a heat exchanger One side only Low temperature | [23] |

| Zigzag Airfoil | CO2 | Hot side: 279.9 Cold side: 107.9 | Hot side: 2.52 Cold side: 8.28 | Hot side: 0.52 Cold side: 1.13 | Low pressure under supercritical state Low temperature | [15] |

| Zigzag | Helium | Hot side: 800 Cold side: 520 | Hot side: 7 Cold side: 7.97 | 450 | No sCO2 One channel only | [16] |

| Zigzag | CO2 | Hot side: 303.3 Cold side: 61.9 | Hot side: 1.9 Cold side: 1.9 | - | Low pressure under supercritical state Low temperature One channel only | [17] |

| Zigzag | CO2 | Hot side: 280 Cold side: 108 | Hot side: 3.2 Cold side: 10.5 | 30–400 | Low pressure under supercritical state Low temperature One channel only | [18] |

| Zigzag Airfoil | CO2 | Hot side: 279.9 Cold side: 107.9 | Hot side: 2.52 Cold side: 8.28 | Hot side: 3.12 Cold side: 3.4 | Low pressure under supercritical state Low temperature One channel only | [20] |

| S-shape | Hot side: LNG flue gas Cold side: sCO2 | Hot side: 650 Cold side: 224 | Hot side: 0.1 Cold side: 13.6 | - | Not sCO2 heat exchange Low pressure Low temperature One channel only | [19] |

| S-shape | CO2 | Hot side: 280 Cold side: 108 | Hot side: 2.5 Cold side: 7.4 | 64.7 | Low pressure under supercritical state Low temperature One channel only | [12,13,14] |

| Zigzag S-shaped Trapezoidal | Helium | Hot side: 900 Cold side: 540 | Hot side: 3 Cold side: 3 | 10–50 | No sCO2 Low pressure | [21] |

| Serial Number | Grid Number | The Hot Outlet Temperature (K) | GCI |

|---|---|---|---|

| 1 | 3,780,000 | 473.37 | |

| 2 | 2,780,000 | 478.32 | |

| 3 | 2,080,000 | 485.94 |

| Hot Side | |

|---|---|

| Physical parameters | Correlations |

| Density (kg/) | |

| Specific heat (J/(kg K)) | |

| Thermal conductivity (W/(mK)) | |

| Viscosity (Pa s) | |

| Cold side | |

| Physical parameters | Correlations |

| Density (kg/) | |

| Specific heat (J/(kg K)) | |

| Thermal conductivity (W/(mK)) | |

| Viscosity (Pa s) | |

| PEC-cold | Trapezoid/Zigzag | Trapezoid/S-shape | Trapezoid/Straight |

| 0.978 | 1.154 | 1.157 | |

| PEC-hot | Trapezoid/Zigzag | Trapezoid/S-shape | Trapezoid/Straight |

| 1.034 | 1.211 | 1.214 |

| Reynolds Number of the Cold Side | Pressure Loss (kPa) | |||

|---|---|---|---|---|

| Double-Channel Structure | Sandwich Structure | |||

| Cold Side | Hot Side | Cold Side | Hot Side | |

| 33,366 | 42.62 | 154.81 | 41.94 | 38.37 |

| 22,244 | 19.73 | 71.11 | 18.60 | 17.77 |

| 16,683 | 11.07 | 39.65 | 11.04 | 10.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, Y.; Xing, K.; Cen, K.; Ni, M.; Xu, H.; Xiao, G. Numerical Study on Flow and Heat Transfer Characteristics of Trapezoidal Printed Circuit Heat Exchanger. Micromachines 2021, 12, 1589. https://doi.org/10.3390/mi12121589

Ji Y, Xing K, Cen K, Ni M, Xu H, Xiao G. Numerical Study on Flow and Heat Transfer Characteristics of Trapezoidal Printed Circuit Heat Exchanger. Micromachines. 2021; 12(12):1589. https://doi.org/10.3390/mi12121589

Chicago/Turabian StyleJi, Yuxuan, Kaixiang Xing, Kefa Cen, Mingjiang Ni, Haoran Xu, and Gang Xiao. 2021. "Numerical Study on Flow and Heat Transfer Characteristics of Trapezoidal Printed Circuit Heat Exchanger" Micromachines 12, no. 12: 1589. https://doi.org/10.3390/mi12121589