Fabrication Methods for Microfluidic Devices: An Overview

Abstract

1. Introduction

- The cost of substrate per unit area is high. The cost of Corning Pyrex is in the range of 10–20 cents/cm2, whilst the cost of polymers such as polymethylmethacrylate (PMMA) is an order of magnitude lower in the range of 0.2–2 cents/cm2 [11].

- The process time is long and expensive. Iterative steps for cleaning, patterning, etching, and deposition, as well as reagents, are usually required, and all the processes are conducted in cleanroom environment.

- The finished profile is limited, with channels being shallow or circular, due to the characteristics of the etching process, whereas typically deep channels are preferred for most applications as they give higher surface areas and packing densities. High-aspect ratio silicon structures may be achieved with deep reactive ion etching (DRIE), but this is an expensive process.

- Some physical properties of traditional materials are not desirable. Biomolecules, for example, tend to adhere to a silicon surface. Prior chemical treatment may prevent the sticking problem, but the risk of contamination is increased. Silicon is also not an electrical insulator and can pose problems for electro-osmotic pumping. Moreover, silicon is also not transparent and therefore unsuitable for optical sensing. Quartz and glass require high temperatures and voltages for bonding, which may be problematic for device manufacturing.

- They are relatively cheap compared to silicon or glass in their unit area price. This characteristic is especially important for mass production or disposable usage in biomedical applications.

- They have a wide range of available material properties to fit with the requirements of processes and devices.

- They can offer good optical transparency, electrical insulation, or good gas permeability, which is important for cellular applications.

- The potential for the transfer of plastics processing knowledge from macro to microstructuring in the drive to mass produce microfluidic devices.

Polymer Types and Physical Properties

2. Mould or Master Manufacture

2.1. Mechanical Methods

2.1.1. Micro-Cutting

2.1.2. Ultrasonic Machining

2.2. Energy-Assisted Methods

2.2.1. Electrodischarge Machining

2.2.2. Micro-Electrochemical Machining

2.2.3. Laser Ablation

2.2.4. Electron Beam Machining

2.2.5. Focused Ion Beam Machining

2.3. Traditional MEMS Process

2.4. Mould Fabrication on Curved Surfaces

3. Low-Volume Production

3.1. Casting

3.2. Laminate Manufacturing

3.3. Laser Fabrication

3.4. 3D Printing

4. High Volume Production

4.1. Hot Embossing

- The polymer film is inserted between moulds, and both the film and moulds are heated to or above the glass transition temperature of the polymer in a vacuum environment.

- The moulds are pressed against the softened polymer and the features are transferred.

- All parts are cooled to below the glass transition temperature of the polymer, and the processed polymer is demoulded (see Figure 6A).

- Polymer has a lower thermal cycle since the glass transition temperature is lower than the melting temperature. The polymer also has shorter run into the mould because the material is on top of the mould directly instead of flowing through channels. Both aspects help reduce residual stress.

- The process uses lower pressure, lower flow rate, and a cooling rate of the polymer. As a consequence, hot embossed parts may achieve higher aspect ratio and smaller features. The finished parts tend to have smaller internal stress, which is particularly important for optical devices.

4.2. Injection Moulding

- Injection compression moulding: A combination of injection moulding and compression moulding; it unifies the advantages of both manufacturing processes, and the de-moulding process is easier when compared to other techniques. Plasticised polymer is injected into a tool, and the mould halves are then pressed together to force the melt into the desired shape [13]. The moulded parts have high geometrical accuracy, narrow tolerances, high class surfaces, low residual stresses, and excellent mechanical properties. It has been found that the replication results improved when using injection compression moulding for features 10 μm wide and 5 μm deep [187].

- Macro level of imperfection: Typical replication imperfections include shrinkage, warp, sink marks, flash, brittleness, burn marks, dimension variation, delaminating, black specks, etc.

- Micro level of imperfection: Replication at this level is dependent on surface topographic transcription between the mould and the part [188]. Prominent among the defects are slip, burst, and shrinkage, incomplete filing, etc.

- Mould pressure;

- Mould temperature;

- Injection speed;

- Injection pressure;

- Holding pressure;

- Holding time;

- Cooling time.

4.3. Film or Sheet Operations

4.3.1. Roller Embossing

4.3.2. Microthermoforming

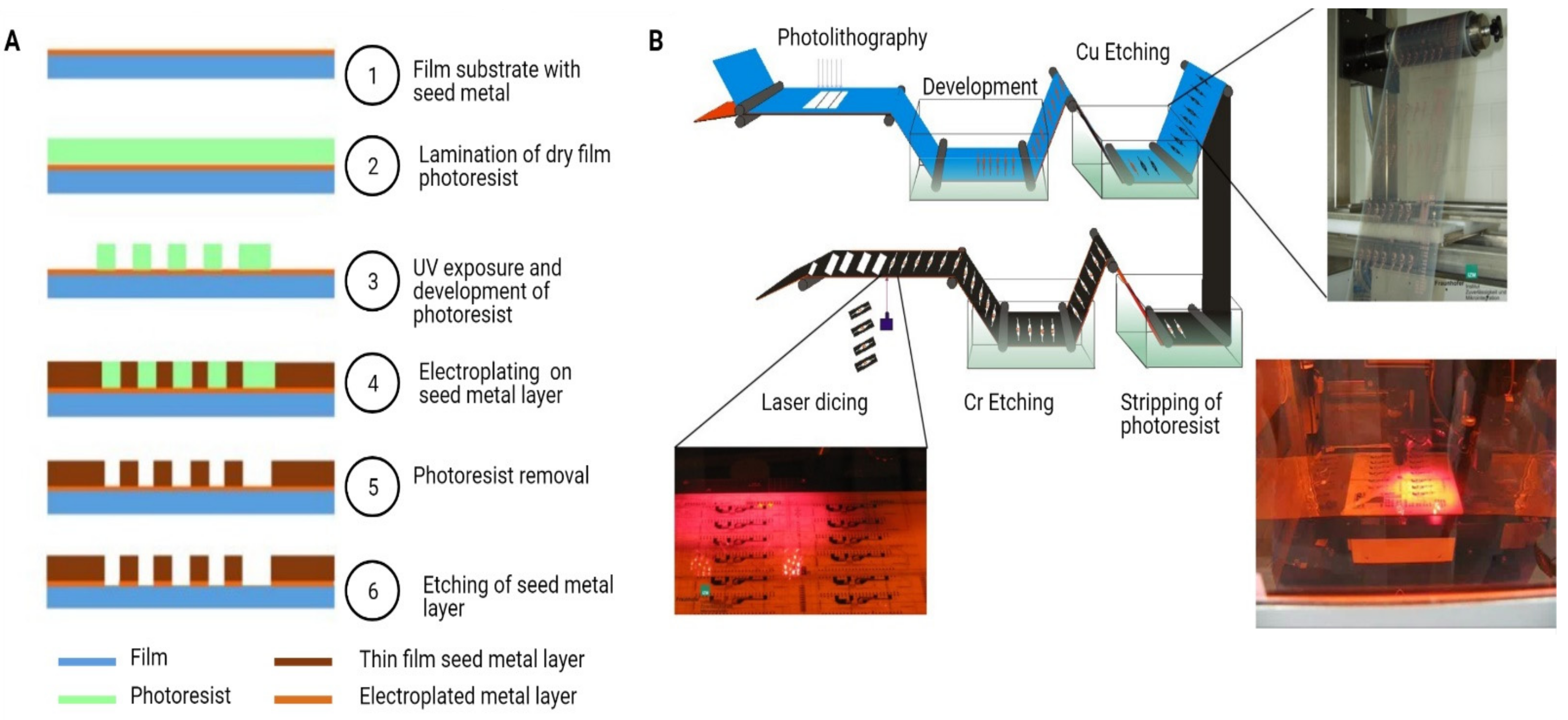

4.3.3. Roll-to-Roll (R2R) Processing for Flexible Electronics

5. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McDonald, J.C.; Duffy, D.C.; Anderson, J.R.; Chiu, D.T.; Wu, H.; Schueller, O.J.A.; Whitesides, G.M. Fabrication of microfluidic systems in poly(dimethylsiloxane). Electrophoresis 2000, 21, 27–40. [Google Scholar] [CrossRef]

- Fiorini, G.S.; Chiu, D.T. Disposable microfluidic devices: Fabrication, function, and application. Biotechniques 2005, 38, 429–446. [Google Scholar] [CrossRef]

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef]

- Convery, N.; Gadegaard, N. 30 Years of Microfluidics. Micro. Nano Eng. 2019, 2, 76–91. [Google Scholar] [CrossRef]

- Gale, B.K.; Jafek, A.R.; Lambert, C.J.; Goenner, B.L.; Moghimifam, H.; Nze, U.C.; Kamarapu, S.K. A review of current methods in microfluidic device fabrication and future commercialization prospects. Inventions 2018, 3. [Google Scholar] [CrossRef]

- Harrison, D.J.; Fluri, K.; Seiler, K.; Fan, Z.; Effenhauser, C.S.; Manz, A. Micromachining a Miniaturized Capillary Electrophoresis-Based Chemical Analysis System on a Chip. Science 1993, 261, 895–897. [Google Scholar] [CrossRef] [PubMed]

- Jacobson, S.C.; Hergenroeder, R.; Koutny, L.B.; Ramsey, J.M. Open Channel Electrochromatography on a Microchip. Anal. Chem. 1994, 66, 2369–2373. [Google Scholar] [CrossRef]

- Jacobson, S.C.; Moore, A.W.; Ramsey, J.M. Fused Quartz Substrates for Microchip Electrophoresis. Anal. Chem. 1995, 67, 2059–2063. [Google Scholar] [CrossRef]

- Matzke, C.M.; Kottenstette, R.J.; Casalnuovo, S.A.; Frye-Mason, G.C.; Hudson, M.L.; Sasaki, D.Y.; Manginell, R.P.; Wong, C.C. Microfabricated silicon gas chromatographic microchannels: Fabrication and performance. In Micromachining and Microfabrication Process Technology IV; Smith, J.H., Ed.; International Society for Optics and Photonics: Bellingham, WA, USA, 1998; Volume 3511, pp. 262–268. [Google Scholar]

- Moore, A.W.; Jacobson, S.C.; Ramsey, J.M. Microchip Separations of Neutral Species via Micellar Electrokinetic Capillary Chromatography. Anal. Chem. 1995, 67, 4184–4189. [Google Scholar] [CrossRef]

- Becker, H.; Gärtner, C. Polymer microfabrication methods for microfluidic analytical applications. Electrophoresis 2000, 21, 12–26. [Google Scholar] [CrossRef]

- Waldbaur, A.; Rapp, H.; Länge, K.; Rapp, B.E. Let there be chip—Towards rapid prototyping of microfluidic devices: One-step manufacturing processes. Anal. Methods 2011, 3, 2681–2716. [Google Scholar] [CrossRef]

- Heckele, M.; Schomburg, W.K. Review on micro molding of thermoplastic polymers. J. Micromech. Microeng. 2004, 14, R1–R14. [Google Scholar] [CrossRef]

- Attia, U.M.; Marson, S.; Alcock, J.R. Micro-injection moulding of polymer microfluidic devices. Microfluid. Nanofluidics 2009, 7, 1–28. [Google Scholar] [CrossRef]

- Alting, L.; Kimura, F.; Hansen, H.N.; Bissacco, G. Micro Engineering. CIRP Ann. 2003, 52, 635–657. [Google Scholar] [CrossRef]

- Benavides, G.L.; Bieg, L.F.; Saavedra, M.P.; Bryce, E.A. High aspect ratio meso-scale parts enabled by wire micro-EDM. Microsyst. Technol. 2002, 8, 395–401. [Google Scholar] [CrossRef]

- Brousseau, E.B.; Dimov, S.S.; Pham, D.T. Some recent advances in multi-material micro- and nano-manufacturing. Int. J. Adv. Manuf. Technol. 2010, 47, 161–180. [Google Scholar] [CrossRef]

- Kim, B.H.; Ryu, S.H.; Choi, D.K.; Chu, C.N. Micro electrochemical milling. J. Micromech. Microeng. 2005, 15, 124–129. [Google Scholar] [CrossRef]

- Kock, M.; Kirchner, V.; Schuster, R. Electrochemical micromachining with ultrashort voltage pulses–a versatile method with lithographical precision. Electrochim. Acta 2003, 48, 3213–3219. [Google Scholar] [CrossRef]

- Niggemann, M.; Ehrfeld, W.; Weber, L.; Günther, R.; Sollböhmer, O. Miniaturized plastic micro plates for applications in HTS. Microsyst. Technol. 1999, 6, 48–53. [Google Scholar] [CrossRef]

- Stokes, C.; Palmer, P.J. 3D micro-fabrication processes: A review. In Proceedings of the Institution of Engineering and Technology Seminar on MEMS Sensors and Actuators, Shanghai, China, 26–29 August 2006; ICEPT: Hong Kong, China, 2006; pp. 289–298. [Google Scholar]

- Masuzawa, T. State of the Art of Micromachining. CIRP Ann. 2000, 49, 473–488. [Google Scholar] [CrossRef]

- Qin, Y.; Brockett, A.; Ma, Y.; Razali, A.; Zhao, J.; Harrison, C.; Pan, W.; Dai, X.; Loziak, D. Micro-manufacturing: Research, technology outcomes and development issues. Int. J. Adv. Manuf. Technol. 2010, 47, 821–837. [Google Scholar] [CrossRef]

- Uriarte, L.; Herrero, A.; Ivanov, A.; Oosterling, H.; Staemmler, L.; Tang, P.T.; Allen, D. Comparison between microfabrication technologies for metal tooling. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2006, 220, 1665–1676. [Google Scholar] [CrossRef]

- Madou, M.J. Fundamentals of Microfabrication; CRC Press: Boca Raton, FL, USA, 2002; ISBN 9781482274004. [Google Scholar]

- Friedrich, C.R.; Vasile, M.J. Development of the micromilling process for high-aspect-ratio microstructures. J. Microelectromech. Syst. 1996, 5, 33–38. [Google Scholar] [CrossRef]

- Weber, L.; Ehrfeld, W.; Freimuth, H.; Lacher, M.; Lehr, H.; Pech, B. Micromolding: A powerful tool for large-scale production of precise microstructures. In Micromachining and Microfabrication Process Technology II, Proceedings of the Micromachining and Microfabrication ’96, Austin, TX, USA, 14–15 October 1996; Stella, W.S., Chang, S.-C., Eds.; SPIE: Bellingham, WA, USA, 1996; Volume 2879, pp. 156–167. [Google Scholar]

- Castaldo, V.; Hagen, C.W.; Kruit, P.; van Veldhoven, E.; Maas, D. On the influence of the sputtering in determining the resolution of a scanning ion microscope. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2009, 27, 3196. [Google Scholar] [CrossRef]

- Allen, D.M.; Shore, P.; Evans, R.W.; Fanara, C.; O’Brien, W.; Marson, S.; O’Neill, W. Ion beam, focused ion beam, and plasma discharge machining. CIRP Ann. 2009, 58, 647–662. [Google Scholar] [CrossRef]

- Tseng, A.A. Recent Developments in Nanofabrication Using Focused Ion Beams. Small 2005, 1, 924–939. [Google Scholar] [CrossRef]

- McGeough, J.A.; Leu, M.C.; Rajurkar, K.P.; De Silva, A.K.M.; Liu, Q. Electroforming Process and Application to Micro/Macro Manufacturing. CIRP Ann. 2001, 50, 499–514. [Google Scholar] [CrossRef]

- Williams, J.D. Study on the postbaking process and the effects on UV lithography of high aspect ratio SU-8 microstructures. J. Micro/Nanolithography MEMS MOEMS 2004, 3, 563. [Google Scholar] [CrossRef]

- Bhavsar, S.N.; Aravindan, S.; Rao, P.V. A Critical Review on Microtools Fabrication by Focused Ion Beam (FIB) Technology. Lect. Notes Eng. Comput. Sci. 2009, 2177, 1510–1515. [Google Scholar]

- Gale, B.K.; Eddings, M.A.; Sundberg, S.O.; Hatch, A.; Kim, J.; Ho, T. Low-Cost MEMS Technologies. In Comprehensive Microsystems; Elsevier: Amsterdam, The Netherlands, 2008; Volume 1, pp. 341–378. ISBN 9780444521903. [Google Scholar]

- Adams, D.P.; Vasile, M.J.; Benavides, G.; Campbell, A.N. Micromilling of metal alloys with focused ion beam–fabricated tools. Precis. Eng. 2001, 25, 107–113. [Google Scholar] [CrossRef]

- Mei, Q.; Xia, Z.; Xu, F.; Soper, S.A.; Fan, Z.H. Fabrication of Microfluidic Reactors and Mixing Studies for Luciferase Detection. Anal. Chem. 2008, 80, 6045–6050. [Google Scholar] [CrossRef] [PubMed]

- Shadpour, H.; Soper, S.A. Two-Dimensional Electrophoretic Separation of Proteins Using Poly(methyl methacrylate) Microchips. Anal. Chem. 2006, 78, 3519–3527. [Google Scholar] [CrossRef] [PubMed]

- Chantiwas, R.; Hupert, M.L.; Pullagurla, S.R.; Balamurugan, S.; Tamarit-López, J.; Park, S.; Datta, P.; Goettert, J.; Cho, Y.-K.; Soper, S.A. Simple replication methods for producing nanoslits in thermoplastics and the transport dynamics of double-stranded DNA through these slits. Lab Chip 2010, 10, 3255. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Boswell, B.; Islam, M.N.; Davies, I.J. A review of micro-mechanical cutting. Int. J. Adv. Manuf. Technol. 2018, 94, 789–806. [Google Scholar] [CrossRef]

- Giboz, J.; Copponnex, T.; Mélé, P. Microinjection molding of thermoplastic polymers: A review. J. Micromech. Microeng. 2007, 17, R96–R109. [Google Scholar] [CrossRef]

- Gandarias, E.; Dimov, S.; Pham, D.T.; Ivanov, A.; Popov, K.; Lizarralde, R.; Arrazola, P.J. New Methods for Tool Failure Detection in Micromilling. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 137–144. [Google Scholar] [CrossRef]

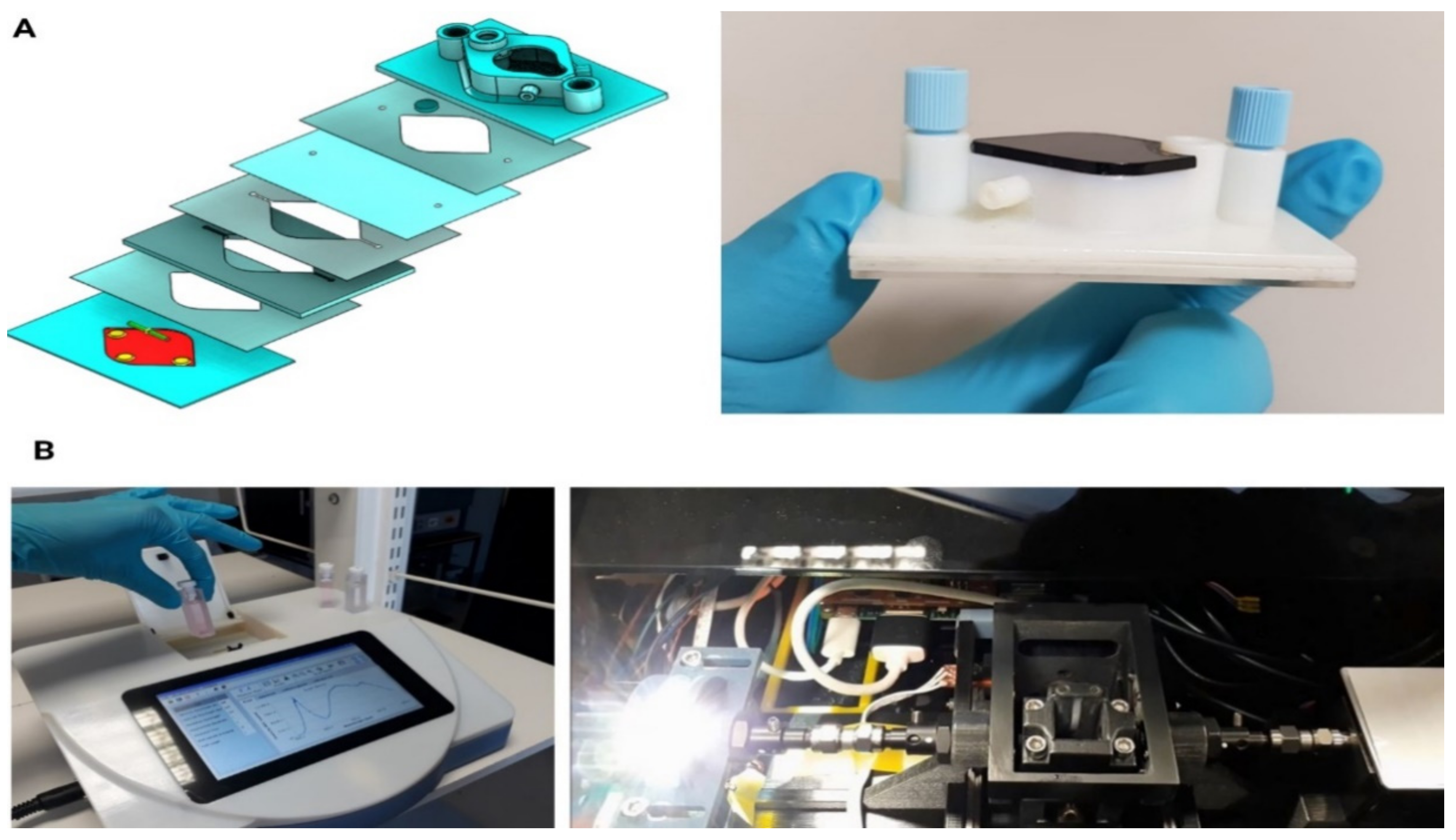

- Zoupanou, S.; Chiriacò, M.S.; Tarantini, I.; Ferrara, F. Innovative 3D Microfluidic Tools for On-Chip Fluids and Particles Manipulation: From Design to Experimental Validation. Micromachines 2021, 12, 104. [Google Scholar] [CrossRef] [PubMed]

- Sayad, A.; Ibrahim, F.; Mukim Uddin, S.; Cho, J.; Madou, M.; Thong, K.L. A microdevice for rapid, monoplex and colorimetric detection of foodborne pathogens using a centrifugal microfluidic platform. Biosens. Bioelectron. 2018, 100, 96–104. [Google Scholar] [CrossRef] [PubMed]

- Layouni, Y.; Girardin, G.; Benilov, A.; Semet, V.; Morin, P.; Cabrera, M. Onboard electrochemical fabrication of microelectrodes for micro EDM milling. Micro Nanosyst. 2011, 3, 215–221. [Google Scholar] [CrossRef]

- Kern, P.; Veh, J.; Michler, J. New developments in through-mask electrochemical micromachining of titanium. J. Micromech. Microeng. 2007, 17, 1168–1177. [Google Scholar] [CrossRef]

- Zinger, O.; Zhao, G.; Schwartz, Z.; Simpson, J.; Wieland, M.; Landolt, D.; Boyan, B. Differential regulation of osteoblasts by substrate microstructural features. Biomaterials 2005, 26, 1837–1847. [Google Scholar] [CrossRef]

- Schuster, R. Electrochemical Micromachining. Science 2000, 289, 98–101. [Google Scholar] [CrossRef]

- Datta, M.; Landolt, D. Fundamental aspects and applications of electrochemical microfabrication. Electrochim. Acta 2000, 45, 2535–2558. [Google Scholar] [CrossRef]

- Landolt, D.; Chauvy, P.-F.; Zinger, O. Electrochemical micromachining, polishing and surface structuring of metals: Fundamental aspects and new developments. Electrochim. Acta 2003, 48, 3185–3201. [Google Scholar] [CrossRef]

- Ehrfeld, W. Electrochemistry and microsystems. Electrochim. Acta 2003, 48, 2857–2868. [Google Scholar] [CrossRef]

- Trotta, G.; Volpe, A.; Ancona, A.; Fassi, I. Flexible micro manufacturing platform for the fabrication of PMMA microfluidic devices. J. Manuf. Process. 2018, 35, 107–117. [Google Scholar] [CrossRef]

- Rännar, L.; Glad, A.; Gustafson, C.-G. Efficient cooling with tool inserts manufactured by electron beam melting. Rapid Prototyp. J. 2007, 13, 128–135. [Google Scholar] [CrossRef]

- Klein, K.L.; Randolph, S.J.; Fowlkes, J.D.; Allard, L.F.; III, H.M.M.; Simpson, M.L.; Rack, P.D. Single-crystal nanowires grown via electron-beam-induced deposition. Nanotechnology 2008, 19. [Google Scholar] [CrossRef]

- Ghodssi, R.; Lin, P. (Eds.) MEMS Materials and Processes Handbook; MEMS Reference Shelf; Springer: Boston, MA, USA, 2011; Volume 1, ISBN 978-0-387-47316-1. [Google Scholar]

- Chan-Park, M.B.; Zhang, J.; Yan, Y.; Yue, C.Y. Fabrication of large SU-8 mold with high aspect ratio microchannels by UV exposure dose reduction. Sens. Actuators B Chem. 2004, 101, 175–182. [Google Scholar] [CrossRef]

- Koerner, T.; Brown, L.; Xie, R.; Oleschuk, R.D. Epoxy resins as stamps for hot embossing of microstructures and microfluidic channels. Sens. Actuators B Chem. 2005, 107, 632–639. [Google Scholar] [CrossRef]

- Steigert, J.; Haeberle, S.; Brenner, T.; Müller, C.; Steinert, C.P.; Koltay, P.; Gottschlich, N.; Reinecke, H.; Rühe, J.; Zengerle, R.; et al. Rapid prototyping of microfluidic chips in COC. J. Micromech. Microeng. 2007, 17, 333–341. [Google Scholar] [CrossRef]

- Huang, Y.; Paloczi, G.T.; Yariv, A.; Zhang, C.; Dalton, L.R. Fabrication and Replication of Polymer Integrated Optical Devices Using Electron-Beam Lithography and Soft Lithography. J. Phys. Chem. B 2004, 108, 8606–8613. [Google Scholar] [CrossRef]

- Jo, B.-H.; Van Lerberghe, L.M.; Motsegood, K.M.; Beebe, D.J. Three-dimensional micro-channel fabrication in polydimethylsiloxane (PDMS) elastomer. J. Microelectromech. Syst. 2000, 9, 76–81. [Google Scholar] [CrossRef]

- Ro, K.W.; Lim, K.; Kim, H.; Hahn, J.H. Poly(dimethylsiloxane) microchip for precolumn reaction and micellar electrokinetic chromatography of biogenic amines. Electrophoresis 2002, 23, 1129–1137. [Google Scholar] [CrossRef]

- Abgrall, P.; Conedera, V.; Camon, H.; Gue, A.-M.; Nguyen, N.-T. SU-8 as a structural material for labs-on-chips and microelectromechanical systems (review). Electrophoresis 2007, 28, 4539–4551. [Google Scholar] [CrossRef]

- Del Campo, A.; Greiner, C. SU-8: A photoresist for high-aspect-ratio and 3D submicron lithography. J. Micromech. Microeng. 2007, 17, R81–R95. [Google Scholar] [CrossRef]

- Malek, C.K.; Saile, V. Applications of LIGA technology to precision manufacturing of high-aspect-ratio micro-components and -systems: A review. Microelectron. J. 2004, 35, 131–143. [Google Scholar] [CrossRef]

- Romankiw, L.T. A path: From electroplating through lithographic masks in electronics to LIGA in MEMS. Electrochim. Acta 1997, 42, 2985–3005. [Google Scholar] [CrossRef]

- Yoo, G.; Lee, H.; Radtke, D.; Stumpf, M.; Zeitner, U.; Kanicki, J. A maskless laser-write lithography processing of thin-film transistors on a hemispherical surface. Microelectron. Eng. 2010, 87, 83–87. [Google Scholar] [CrossRef]

- Bowen, A.M.; Nuzzo, R.G. Fabrication of Flexible Binary Amplitude Masks for Patterning on Highly Curved Surfaces. Adv. Funct. Mater. 2009, 19, 3243–3253. [Google Scholar] [CrossRef]

- Nishiyama, H.; Mizoshiri, M.; Kawahara, T.; Nishii, J.; Hirata, Y. SiO_2-based nonplanar structures fabricated using femtosecond laser lithography. Opt. Express 2008, 16, 17288. [Google Scholar] [CrossRef] [PubMed]

- Radtke, D.; Duparré, J.; Zeitner, U.D.; Tünnermann, A. Laser lithographic fabrication and characterization of a spherical artificial compound eye. Opt. Express 2007, 15, 3067. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Lu, Z.; Li, F. Lithographic fabrication of large curved hologram by laser writer. Opt. Express 2004, 12, 1810–1814. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Lu, Z.; Li, F.; Zhao, J.; Weng, Z. Lithographic fabrication of large diffractive optical elements on a concave lens surface. Opt. Express 2002, 10, 1043–1047. [Google Scholar] [CrossRef] [PubMed]

- Ruchhoeft, P.; Colburn, M.; Choi, B.; Nounu, H.; Johnson, S.; Bailey, T.; Damle, S.; Stewart, M.; Ekerdt, J.; Sreenivasan, S.V.; et al. Patterning curved surfaces: Template generation by ion beam proximity lithography and relief transfer by step and flash imprint lithography. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 1999, 17, 2965. [Google Scholar] [CrossRef]

- Von Woedtke, T.; Abel, P.; Krüger, J.; Kautek, W. Subpicosecond-pulse laser microstructuring for enhanced reproducibility of biosensors. Sens. Actuators B Chem. 1997, 42, 151–156. [Google Scholar] [CrossRef]

- Parikh, D.; Craver, B.; Nounu, H.N.; Fong, F.-O.; Wolfe, J.C. Nanoscale Pattern Definition on Nonplanar Surfaces Using Ion Beam Proximity Lithography and Conformal Plasma-Deposited Resist. J. Microelectromech. Syst. 2008, 17, 735–740. [Google Scholar] [CrossRef]

- Stephens, L.S.; Siripuram, R.; Hayden, M.; McCartt, B. Deterministic Micro Asperities on Bearings and Seals Using a Modified LIGA Process. J. Eng. Gas Turbines Power 2004, 126, 147–154. [Google Scholar] [CrossRef]

- Marques, C.; Desta, Y.M.; Rogers, J.; Murphy, M.C.; Kelly, K. Fabrication of high-aspect-ratio microstructures on planar and nonplanar surfaces using a modified LIGA process. J. Microelectromech. Syst. 1997, 6, 329–336. [Google Scholar] [CrossRef]

- Huang, T.-C.; Wu, J.-T.; Yang, S.-Y.; Huang, P.-H.; Chang, S.-H. Direct fabrication of microstructures on metal roller using stepped rotating lithography and electroless nickel plating. Microelectron. Eng. 2009, 86, 615–618. [Google Scholar] [CrossRef]

- Wu, J.-T.; Lai, H.-C.; Yang, S.-Y.; Huang, T.-C.; Wu, S.-H. Dip coating cooperated with stepped rotating lithography to fabricate rigid microstructures onto a metal roller. Microelectron. Eng. 2010, 87, 2091–2096. [Google Scholar] [CrossRef]

- Park, J.; Fujita, H.; Kim, B. Fabrication of metallic microstructure on curved substrate by optical soft lithography and copper electroplating. Sens. Actuators A Phys. 2011, 168, 105–111. [Google Scholar] [CrossRef]

- Childs, W.R.; Nuzzo, R.G. Decal transfer microlithography: A new soft-lithographic patterning method. J. Am. Chem. Soc. 2002, 124, 13583–13596. [Google Scholar] [CrossRef] [PubMed]

- Erhardt, M.K.; Jin, H.-C.; Abelson, J.R.; Nuzzo, R.G. Low-Temperature Fabrication of Si Thin-Film Transistor Microstructures by Soft Lithographic Patterning on Curved and Planar Substrates. Chem. Mater. 2000, 12, 3306–3315. [Google Scholar] [CrossRef]

- Jackman, R.J.; Brittain, S.T.; Whitesides, G.M. Fabrication of three-dimensional microstructures by electrochemically welding structures formed by microcontact printing on planar and curved substrates. J. Microelectromech. Syst. 1998, 7, 261–266. [Google Scholar] [CrossRef]

- Jackman, R.; Wilbur, J.; Whitesides, G. Fabrication of submicrometer features on curved substrates by microcontact printing. Science 1995, 269, 664–666. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Whitesides, G.M. Soft Lithography. Annu. Rev. Mater. Sci. 1998, 28, 153–184. [Google Scholar] [CrossRef]

- Ko, H.C.; Stoykovich, M.P.; Song, J.; Malyarchuk, V.; Choi, W.M.; Yu, C.-J.; Geddes III, J.B.; Xiao, J.; Wang, S.; Huang, Y.; et al. A hemispherical electronic eye camera based on compressible silicon optoelectronics. Nature 2008, 454, 748–753. [Google Scholar] [CrossRef] [PubMed]

- Meitl, M.A.; Zhu, Z.-T.; Kumar, V.; Lee, K.J.; Feng, X.; Huang, Y.Y.; Adesida, I.; Nuzzo, R.G.; Rogers, J.A. Transfer printing by kinetic control of adhesion to an elastomeric stamp. Nat. Mater. 2006, 5, 33–38. [Google Scholar] [CrossRef]

- Jung, S.N.; Kang, C.K.; Jung, I.D.; Lee, S.M.; Jung, P.G.; Ko, J.S. Fabrication of curved copper micromesh sheets using flexible PDMS molds. Microsyst. Technol. 2008, 14, 829–833. [Google Scholar] [CrossRef]

- Wang, W.; Holl, M.R.; Schwartz, D.T. Rapid Prototyping of Masks for Through-Mask Electrodeposition of Thick Metallic Components. J. Electrochem. Soc. 2001, 148, C363. [Google Scholar] [CrossRef]

- Jiang, L.-T.; Huang, T.-C.; Chang, C.-Y.; Ciou, J.-R.; Yang, S.-Y.; Huang, P.-H. Direct fabrication of rigid microstructures on a metallic roller using a dry film resist. J. Micromech. Microeng. 2008, 18. [Google Scholar] [CrossRef]

- Chang, C.-Y.; Yang, S.-Y.; Chu, M.-H. Rapid fabrication of ultraviolet-cured polymer microlens arrays by soft roller stamping process. Microelectron. Eng. 2007, 84, 355–361. [Google Scholar] [CrossRef]

- Liu, S.-J.; Chang, Y.-C. A novel soft-mold roller embossing method for the rapid fabrication of micro-blocks onto glass substrates. J. Micromech. Microeng. 2007, 17, 172–179. [Google Scholar] [CrossRef]

- Chang, C.Y.; Yang, S.Y.; Sheh, J.L. A roller embossing process for rapid fabrication of microlens arrays on glass substrates. Microsyst. Technol. 2006, 12, 754–759. [Google Scholar] [CrossRef]

- Mäkelä, T.; Haatainen, T.; Majander, P.; Ahopelto, J.; Lambertini, V. Continuous Double-Sided Roll-to-Roll Imprinting of Polymer Film. Jpn. J. Appl. Phys. 2008, 47, 5142–5144. [Google Scholar] [CrossRef]

- Ng, S.H.; Wang, Z.F. Hot roller embossing for microfluidics: Process and challenges. Microsyst. Technol. 2009, 15, 1149–1156. [Google Scholar] [CrossRef]

- Yeo, L.P.; Ng, S.H.; Wang, Z.; Wang, Z.; de Rooij, N.F. Micro-fabrication of polymeric devices using hot roller embossing. Microelectron. Eng. 2009, 86, 933–936. [Google Scholar] [CrossRef]

- Yeo, L.P.; Ng, S.H.; Wang, Z.F.; Xia, H.M.; Wang, Z.P.; Thang, V.S.; Zhong, Z.W.; de Rooij, N.F. Investigation of hot roller embossing for microfluidic devices. J. Micromech. Microeng. 2010, 20, 015017. [Google Scholar] [CrossRef]

- Ishizawa, N.; Idei, K.; Kimura, T.; Noda, D.; Hattori, T. Resin micromachining by roller hot embossing. Microsyst. Technol. 2008, 14, 1381–1388. [Google Scholar] [CrossRef]

- Velten, T.; Bauerfeld, F.; Schuck, H.; Scherbaum, S.; Landesberger, C.; Bock, K. Roll-to-roll hot embossing of microstructures. Microsyst. Technol. 2011, 17, 619–627. [Google Scholar] [CrossRef]

- Shan, X.; Jin, L.; Soh, Y.C.; Lu, C.W. A polymer-metal hybrid flexible mould and application for large area hot roller embossing. Microsyst. Technol. 2010, 16, 1393–1398. [Google Scholar] [CrossRef]

- Shan, X.; Soh, Y.C.; Shi, C.W.P.; Jin, L.; Lu, C.W. A micro roller embossing process for structuring large-area substrates of laminated ceramic green tapes. Microsyst. Technol. 2009, 15, 1319–1325. [Google Scholar] [CrossRef]

- Becker, H.; Gärtner, C. Polymer microfabrication technologies for microfluidic systems. Anal. Bioanal. Chem. 2008, 390, 89–111. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lo, C.-W.; Taylor, J.A.; Yang, S. Replica molding of high-aspect-ratio polymeric nanopillar arrays with high fidelity. Langmuir 2006, 22, 8595–8601. [Google Scholar] [CrossRef]

- Liu, Z.; He, Q.; Xiao, P.; He, N.; Lu, Z.; Bo, L. Fabrication of polyurethane molecular stamps for the synthesis of DNA microarray. In Micromachining and Microfabrication Process Technology and Devices, Proceedings of the International Symposium on Optoelectonics and Microelectronics, Nanjing, China, 7–10 November 2001; Tien, N.C., Huang, Q.-A., Eds.; SPIE: Bellingham, WA, USA, 2001; Volume 4601, p. 412. [Google Scholar]

- Ding, J.; Jiang, J.; Blanchetière, C.; Callender, C.L. Highly Fluorinated Aromatic–Aliphatic Copolyethers. Macromolecules 2008, 41, 758–763. [Google Scholar] [CrossRef]

- Duffy, D.C.; McDonald, J.C.; Schueller, O.J.A.; Whitesides, G.M. Rapid Prototyping of Microfluidic Systems in Poly(dimethylsiloxane). Anal. Chem. 1998, 70, 4974–4984. [Google Scholar] [CrossRef]

- Lee, J.N.; Park, C.; Whitesides, G.M. Solvent Compatibility of Poly(dimethylsiloxane)-Based Microfluidic Devices. Anal. Chem. 2003, 75, 6544–6554. [Google Scholar] [CrossRef]

- Rozkiewicz, D.I.; Kraan, Y.; Werten, M.W.T.; De Wolf, F.A.; Subramaniam, V.; Ravoo, B.J.; Reinhoudt, D.N. Covalent microcontact printing of proteins for cell patterning. Chem. A Eur. J. 2006, 12, 6290–6297. [Google Scholar] [CrossRef]

- Sia, S.K.; Whitesides, G.M. Microfluidic devices fabricated in Poly(dimethylsiloxane) for biological studies. Electrophoresis 2003, 24, 3563–3576. [Google Scholar] [CrossRef]

- Taylor, A.M.; Rhee, S.W.; Tu, C.H.; Cribbs, D.H.; Cotman, C.W.; Jeon, N.L. Microfluidic Multicompartment Device for Neuroscience Research. Langmuir 2003, 19, 1551–1556. [Google Scholar] [CrossRef]

- Chou, H.-P.; Spence, C.; Scherer, A.; Quake, S. A microfabricated device for sizing and sorting DNA molecules. Proc. Natl. Acad. Sci. USA 1999, 96, 11–13. [Google Scholar] [CrossRef]

- Effenhauser, C.S.; Bruin, G.J.M.; Paulus, A.; Ehrat, M. Integrated Capillary Electrophoresis on Flexible Silicone Microdevices: Analysis of DNA Restriction Fragments and Detection of Single DNA Molecules on Microchips. Anal. Chem. 1997, 69, 3451–3457. [Google Scholar] [CrossRef] [PubMed]

- Koschwanez, J.H.; Carlson, R.H.; Meldrum, D.R. Easily fabricated magnetic traps for single-cell applications. Rev. Sci. Instrum. 2007, 78, 044301. [Google Scholar] [CrossRef]

- Caelen, I.; Bernard, A.; Juncker, D.; Michel, B.; Heinzelmann, H.; Delamarche, E. Formation of Gradients of Proteins on Surfaces with Microfluidic Networks. Langmuir 2000, 16, 9125–9130. [Google Scholar] [CrossRef]

- Kenis, P.J. Microfabrication Inside Capillaries Using Multiphase Laminar Flow Patterning. Science 1999, 285, 83–85. [Google Scholar] [CrossRef] [PubMed]

- Michel, B.; Bernard, A.; Bietsch, A.; Delamarche, E.; Geissler, M.; Juncker, D.; Kind, H.; Renault, J.-P.; Rothuizen, H.; Schmid, H.; et al. Printing Meets Lithography: Soft Approaches to High-Resolution Patterning. Chim. Int. J. Chem. 2002, 56, 527–542. [Google Scholar] [CrossRef]

- Grzybowski, B.A.; Brittain, S.T.; Whitesides, G.M. Thermally actuated interferometric sensors based on the thermal expansion of transparent elastomeric media. Rev. Sci. Instrum. 1999, 70, 2031–2037. [Google Scholar] [CrossRef]

- Hosokawa, K.; Hanada, K.; Maeda, R. A polydimethylsiloxane (PDMS) deformable diffraction grating for monitoring of local pressure in microfluidic devices. J. Micromech. Microeng. 2002, 12, 1–6. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Datta, A.; Berg, J.M.; Gangopadhyay, S. Studies on surface wettability of poly(dimethyl) siloxane (PDMS) and glass under oxygen-plasma treatment and correlation with bond strength. J. Microelectromech. Syst. 2005, 14, 590–597. [Google Scholar] [CrossRef]

- Haubert, K.; Drier, T.; Beebe, D. PDMS bonding by means of a portable, low-cost corona system. Lab Chip 2006, 6, 1548–1549. [Google Scholar] [CrossRef]

- Unger, M.A.; Chou, H.P.; Thorsen, T.; Scherer, A.; Quake, S.R. Monolithic microfabricated valves and pumps by multilayer soft lithography. Science 2000, 288, 113–116. [Google Scholar] [CrossRef]

- Pasirayi, G.; Scott, S.M.; Islam, M.; O’Hare, L.; Bateson, S.; Ali, Z. Low cost microfluidic cell culture array using normally closed valves for cytotoxicity assay. Talanta 2014, 129, 491–498. [Google Scholar] [CrossRef] [PubMed]

- Weigl, B.H.; Bardell, R.; Schulte, T.; Battrell, F.; Hayenga, J. Design and rapid prototyping of thin-film laminate-based microfluidic devices. Biomed. Microdevices 2001, 3, 267–274. [Google Scholar] [CrossRef]

- Walsh, D.I.; Kong, D.S.; Murthy, S.K.; Carr, P.A. Enabling Microfluidics: From Clean Rooms to Makerspaces. Trends Biotechnol. 2017, 35, 383–392. [Google Scholar] [CrossRef] [PubMed]

- Martínez-López, J.I.; Mojica, M.; Rodríguez, C.A.; Siller, H.R. Xurography as a rapid fabrication alternative for point-of-care devices: Assessment of passive micromixers. Sensors 2016, 16, 705. [Google Scholar] [CrossRef] [PubMed]

- Bartholomeusz, D.A.; Boutté, R.W.; Andrade, J.D. Xurography: Rapid prototyping of microstructures using a cutting plotter. J. Microelectromech. Syst. 2005, 14, 1364–1374. [Google Scholar] [CrossRef]

- Nath, P.; Fung, D.; Kunde, Y.A.; Zeytun, A.; Branch, B.; Goddard, G. Rapid prototyping of robust and versatile microfluidic components using adhesive transfer tapes. Lab Chip 2010, 10, 2286–2291. [Google Scholar] [CrossRef] [PubMed]

- Tsao, C.W.; Syu, W.C. Bonding of thermoplastic microfluidics by using dry adhesive tape. RSC Adv. 2020, 10, 30289–30296. [Google Scholar] [CrossRef]

- Serra, M.; Pereiro, I.; Yamada, A.; Viovy, J.L.; Descroix, S.; Ferraro, D. A simple and low-cost chip bonding solution for high pressure, high temperature and biological applications. Lab Chip 2017, 17, 629–634. [Google Scholar] [CrossRef]

- Nguyen, T.; Jung, S.H.; Lee, M.S.; Park, T.E.; Ahn, S.K.; Kang, J.H. Robust chemical bonding of PMMA microfluidic devices to porous PETE membranes for reliable cytotoxicity testing of drugs. Lab Chip 2019, 19, 3706–3713. [Google Scholar] [CrossRef]

- Liga, A.; Morton, J.A.S.; Kersaudy-Kerhoas, M. Safe and cost-effective rapid-prototyping of multilayer PMMA microfluidic devices. Microfluid. Nanofluid. 2016, 20, 164. [Google Scholar] [CrossRef]

- Fan, Y.; Liu, S.; He, J.; Gao, K.; Zhang, Y. Rapid prototyping of flexible multilayer microfluidic devices using polyester sealing film. Microsyst. Technol. 2018, 24, 2847–2852. [Google Scholar] [CrossRef]

- Lin, H.; Zhao, Y.; Lin, S.; Wang, B.; Yeung, C.; Cheng, X.; Wang, Z.; Cai, T.; Yu, W.; King, K.; et al. A rapid and low-cost fabrication and integration scheme to render 3D microfluidic architectures for wearable biofluid sampling, manipulation, and sensing. Lab Chip 2019, 19, 2844–2853. [Google Scholar] [CrossRef]

- Malek, C.G.K. Laser processing for bio-microfluidics applications (part I). Anal. Bioanal. Chem. 2006, 385, 1351–1361. [Google Scholar] [CrossRef] [PubMed]

- Malek, C.G.K. Laser processing for bio-microfluidics applications (part II). Anal. Bioanal. Chem. 2006, 385, 1362–1369. [Google Scholar] [CrossRef]

- Volpe, A.; Krishnan, U.; Chiriacò, M.S.; Primiceri, E.; Ancona, A.; Ferrara, F. A smart procedure for the femtosecond laser-based fabrication of a polymeric lab-on-a-chip for capturing tumor cell. Engineering 2020. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, D.; Tang, W.; Jiang, D.; Chen, K.; Yi, H.; Xiang, N.; Ni, Z. A low cost and quasi-commercial polymer film chip for high-throughput inertial cell isolation. RSC Adv. 2016, 6, 9734–9742. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Zainal Alam, M.N.H.; Kouzani, A.; Gibson, I. Fabrication of microfluidic devices: Improvement of surface quality of CO2 laser machined poly(methylmethacrylate) polymer. J. Micromech. Microeng. 2017, 27, 15021. [Google Scholar] [CrossRef]

- Yan, S.; Zhu, Y.; Tang, S.Y.; Li, Y.; Zhao, Q.; Yuan, D.; Yun, G.; Zhang, J.; Zhang, S.; Li, W. A rapid, maskless 3D prototyping for fabrication of capillary circuits: Toward urinary protein detection. Electrophoresis 2018, 39, 957–964. [Google Scholar] [CrossRef]

- Shaegh, S.A.M.; Pourmand, A.; Nabavinia, M.; Avci, H.; Tamayol, A.; Mostafalu, P.; Ghavifekr, H.B.; Aghdam, E.N.; Dokmeci, M.R.; Khademhosseini, A.; et al. Rapid prototyping of whole-thermoplastic microfluidics with built-in microvalves using laser ablation and thermal fusion bonding. Sens. Actuators B Chem. 2018, 255, 100–109. [Google Scholar] [CrossRef]

- Mamleyev, E.R.; Heissler, S.; Nefedov, A.; Weidler, P.G.; Nordin, N.; Kudryashov, V.V.; Länge, K.; MacKinnon, N.; Sharma, S. Laser-induced hierarchical carbon patterns on polyimide substrates for flexible urea sensors. NPJ Flex. Electron. 2019, 3. [Google Scholar] [CrossRef]

- Nielsen, A.V.; Beauchamp, M.J.; Nordin, G.P.; Woolley, A.T. 3D Printed Microfluidics. Annu. Rev. Anal. Chem. 2020, 13, 45–65. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharjee, N.; Urrios, A.; Kang, S.; Folch, A. The upcoming 3D-printing revolution in microfluidics. Lab Chip 2016, 16, 1720–1742. [Google Scholar] [CrossRef]

- Tasoglu, S.; Folch, A. 3D Printed Microfluidic Devices; MDPI: Basel, Switzerland, 2019; ISBN 9783038974673. [Google Scholar]

- Au, A.K.; Lee, W.; Folch, A. Mail-order microfluidics: Evaluation of stereolithography for the production of microfluidic devices. Lab Chip 2014, 14, 1294–1301. [Google Scholar] [CrossRef]

- Waheed, S.; Cabot, J.M.; Macdonald, N.P.; Lewis, T.; Guijt, R.M.; Paull, B.; Breadmore, M.C. 3D printed microfluidic devices: Enablers and barriers. Lab Chip 2016, 16, 1993–2013. [Google Scholar] [CrossRef]

- Parekh, M.; Ali, A.; Ali, Z.; Bateson, S.; Abugchem, F.; Pybus, L.; Lennon, C. Microbioreactor for Lower Cost and Faster Optimisation of Protein Production. Analyst 2020, 6148–6161. [Google Scholar] [CrossRef]

- Teggert, A.; Datta, H.; McIntosh, S.; Warden, B.; Bateson, S.; Abugchem, F.; Ali, Z. Portable, low cost and sensitive cavity enhanced absorption (CEA) detection. Analyst 2021, 146, 196–206. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Guzman, A.R.; Wippold, J.A.; Li, Y.; Dai, J.; Huang, C.; Han, A. An ultra high-efficiency droplet microfluidics platform using automatically synchronized droplet pairing and merging. Lab Chip 2020, 20, 3948–3959. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, L.; Fan, S.; Zhou, W.; Li, X.; Lu, Y. 3D printed micro-mechanical device (MMD) for in situ tensile testing of micro/nanowires. Extrem. Mech. Lett. 2019, 33, 100575. [Google Scholar] [CrossRef]

- Zhao, Z.; Tian, X.; Song, X. Engineering materials with light: Recent progress in digital light processing based 3D printing. J. Mater. Chem. C 2020, 8, 13896–13917. [Google Scholar] [CrossRef]

- Rusling, J.F. Developing Microfluidic Sensing Devices Using 3D Printing. ACS Sens. 2018, 3, 522–526. [Google Scholar] [CrossRef]

- Razavi Bazaz, S.; Kashaninejad, N.; Azadi, S.; Patel, K.; Asadnia, M.; Jin, D.; Ebrahimi Warkiani, M. Rapid Softlithography Using 3D-Printed Molds. Adv. Mater. Technol. 2019, 4, 1900425. [Google Scholar] [CrossRef]

- Lee, Y.S.; Bhattacharjee, N.; Folch, A. 3D-printed Quake-style microvalves and micropumps. Lab Chip 2018, 18, 1207–1214. [Google Scholar] [CrossRef] [PubMed]

- Beckwith, A.L.; Borenstein, J.T.; Velasquez-Garcia, L.F. Monolithic, 3D-Printed microfluidic platform for recapitulation of dynamic tumor microenvironments. J. Microelectromech. Syst. 2018, 27, 1009–1022. [Google Scholar] [CrossRef]

- Gong, H.; Bickham, B.P.; Woolley, A.T.; Nordin, G.P. Custom 3D printer and resin for 18 μm × 20 μm microfluidic flow channels. Lab Chip 2017, 17, 2899–2909. [Google Scholar] [CrossRef]

- Van Der Linden, P.J.E.M.; Popov, A.M.; Pontoni, D. Accurate and rapid 3D printing of microfluidic devices using wavelength selection on a DLP printer. Lab Chip 2020, 20, 4128–4140. [Google Scholar] [CrossRef]

- Greer, A.I.M.; Barbour, E.; Cutiongco, M.F.; Stormonth-Darling, J.M.; Convery, N.; Alsaigh, R.E.; Lavery, M.P.J.; Gadegaard, N. Large volume nanoscale 3D printing: Nano-3DP. Appl. Mater. Today 2020, 21, 100782. [Google Scholar] [CrossRef]

- Ching, T.; Li, Y.; Karyappa, R.; Ohno, A.; Toh, Y.C.; Hashimoto, M. Fabrication of integrated microfluidic devices by direct ink writing (DIW) 3D printing. Sens. Actuators B Chem. 2019, 297, 126609. [Google Scholar] [CrossRef]

- Gonzalez, G.; Chiappone, A.; Dietliker, K.; Pirri, C.F.; Roppolo, I. Fabrication and Functionalization of 3D Printed Polydimethylsiloxane-Based Microfluidic Devices Obtained through Digital Light Processing. Adv. Mater. Technol. 2020, 5, 1–10. [Google Scholar] [CrossRef]

- Han, D.; Lee, H. Recent advances in multi-material additive manufacturing: Methods and applications. Curr. Opin. Chem. Eng. 2020, 28, 158–166. [Google Scholar] [CrossRef]

- Han, D.; Yang, C.; Fang, N.X.; Lee, H. Rapid multi-material 3D printing with projection micro-stereolithography using dynamic fluidic control. Addit. Manuf. 2019, 27, 606–615. [Google Scholar] [CrossRef]

- Valentine, A.D.; Busbee, T.A.; Boley, J.W.; Raney, J.R.; Chortos, A.; Kotikian, A.; Berrigan, J.D.; Durstock, M.F.; Lewis, J.A. Hybrid 3D Printing of Soft Electronics. Adv. Mater. 2017, 29, 1–8. [Google Scholar] [CrossRef]

- Lebib, A.; Chen, Y.; Cambril, E.; Youinou, P.; Studer, V.; Natali, M.; Pépin, A.; Janssen, H.M.; Sijbesma, R.P. Room-temperature and low-pressure nanoimprint lithography. Microelectron. Eng. 2002, 61–62, 371–377. [Google Scholar] [CrossRef]

- Cao, H.; Yu, Z.; Wang, J.; Tegenfeldt, J.O.; Austin, R.H.; Chen, E.; Wu, W.; Chou, S.Y. Fabrication of 10 nm enclosed nanofluidic channels. Appl. Phys. Lett. 2002, 81, 174–176. [Google Scholar] [CrossRef]

- Liang, Y.; Liu, C.; Sun, H.L.; Li, J.M.; Liu, J.S.; Gao, X.N. Experimental Study on Hot Embossing of Micro/Nano Grating. Adv. Mater. Res. 2009, 60–61, 450–455. [Google Scholar] [CrossRef]

- Hong, S.-H.; Hwang, J.; Lee, H. Replication of cicada wing’s nano-patterns by hot embossing and UV nanoimprinting. Nanotechnology 2009, 20, 385303. [Google Scholar] [CrossRef]

- Roos, N.; Luxbacher, T.; Glinsner, T.; Pfeiffer, K.; Schulz, H.; Scheer, H.-C. Nanoimprint lithography with a commercial 4-in. bond system for hot embossing. In Emerging Lithographic Technologies V, Proceedings of the 26th Annual International Symposium on Microlithography, Santa Clara, CA, USA, 25 February–2 March 2001; Dobisz, E.A., Ed.; SPIE: Bellingham, WA, USA, 2001; Volume 4343, pp. 427–435. [Google Scholar]

- Novak, R.; Ng, C.F.; Ingber, D.E. Rapid prototyping of thermoplastic microfluidic devices. Methods Mol. Biol. 2018, 1771, 161–170. [Google Scholar] [CrossRef]

- Lin, T.Y.; Do, T.; Kwon, P.; Lillehoj, P.B. 3D printed metal molds for hot embossing plastic microfluidic devices. Lab Chip 2017, 17, 241–247. [Google Scholar] [CrossRef]

- Chien, R.-D. Micromolding of biochip devices designed with microchannels. Sens. Actuators A Phys. 2006, 128, 238–247. [Google Scholar] [CrossRef]

- Jena, R.K.; Taylor, H.K.; Lam, Y.C.; Boning, D.S.; Yue, C.Y. Effect of polymer orientation on pattern replication in a micro-hot embossing process: Experiments and numerical simulation. J. Micromech. Microeng. 2011, 21, 065007. [Google Scholar] [CrossRef]

- Jena, R.K.; Yue, C.Y.; Lam, Y.C.; Wang, Z.Y. High fidelity hot-embossing of COC microdevices using a one-step process without pre-annealing of polymer substrate. Sens. Actuators B Chem. 2010, 150, 692–699. [Google Scholar] [CrossRef]

- Becker, H.; Dietz, W. Microfluidic devices for μTAS applications fabricated by polymer hot embossing. In Microfluidic Devices and Systems, Proceedings of the Micromachining and Microfabrication, Santa Clara, CA, USA, 20–24 September 1998; Frazier, A.B., Ahn, C.H., Eds.; SPIE: Bellingham, WA, USA, 1998; Volume 3515, p. 177. [Google Scholar]

- Becker, H.; Locascio, L.E. Polymer microfluidic devices. Talanta 2002, 56, 267–287. [Google Scholar] [CrossRef]

- Liu, S.-J.; Dung, Y.-T. Ultrasonic Vibration Hot Embossing. Int. Polym. Process. 2005, 20, 449–452. [Google Scholar] [CrossRef]

- Mekaru, H.; Goto, H.; Takahashi, M. Development of ultrasonic micro hot embossing technology. Microelectron. Eng. 2007, 84, 1282–1287. [Google Scholar] [CrossRef]

- Schomburg, W.K.; Burlage, K.; Gerhardy, C. Ultrasonic hot embossing. Micromachines 2011, 2, 157–166. [Google Scholar] [CrossRef]

- Moore, S.; Gomez, J.; Lek, D.; You, B.H.; Kim, N.; Song, I.H. Experimental study of polymer microlens fabrication using partial-filling hot embossing technique. Microelectron. Eng. 2016, 162, 57–62. [Google Scholar] [CrossRef]

- Hu, C.; Lin, S.; Li, W.; Sun, H.; Chen, Y.; Chan, C.W.; Leung, C.H.; Ma, D.L.; Wu, H.; Ren, K. A one-step strategy for ultra-fast and low-cost mass production of plastic membrane microfluidic chips. Lab Chip 2016, 16, 3909–3918. [Google Scholar] [CrossRef]

- Attia, U.M.; Alcock, J.R. An evaluation of process-parameter and part-geometry effects on the quality of filling in micro-injection moulding. Microsyst. Technol. 2009, 15, 1861–1872. [Google Scholar] [CrossRef]

- Hanemann, T.; Pfleging, W.; Haußelt, J.; Zum, K.-H. Laser micromaching and light induced reaction injection molding as suitable process sequence for the rapid fabrication of microcomponents. Microsyst. Technol. 2002, 7, 209–214. [Google Scholar] [CrossRef]

- Maghsoudi, K.; Jafari, R.; Momen, G.; Farzaneh, M. Micro-nanostructured polymer surfaces using injection molding: A review. Mater. Today Commun. 2017, 13, 126–143. [Google Scholar] [CrossRef]

- Pirskanen, J.; Immonen, J.; Kalima, V.; Pietarinen, J.; Siitonen, S.; Kuittinen, M.; Mönkkönen, K.; Pakkanen, T.; Suvanto, M.; Pääkkönen, E.J. Replication of sub-micrometre features using microsystems technology. Plast. Rubber Compos. 2005, 34, 222–226. [Google Scholar] [CrossRef]

- Lee, S.K.; Thomas, C.L. Geometric variation of micro-features in injection molding experiment. In Proceedings of the Annual Technical Conference—ANTEC, Nashville, TN, USA, 4–8 May 2003; Volume 1, pp. 597–601. [Google Scholar]

- Niggemann, M.; Ehrfeld, W.; Weber, L. Fabrication of miniaturized biotechnical devices. In Proceedings of the Microfluidic Devices and Systems, Proceedings of the Micromachining and Microfabrication, Santa Clara, CA, USA, 20–24 September 1998; Smith, J.H., Ed.; SPIE: Bellingham, WA, USA, 1998; Volume 3511, pp. 204–213. [Google Scholar]

- Hanemann, T.; Heckele, M.; Piotter, V. Current Status of Micromolding Technology. Polym. News 2000, 25, 224–229. [Google Scholar]

- Piotter, V.; Hanemann, T.; Ruprecht, R.; Haußelt, J. Injection molding and related techniques for fabrication of microstructures. Microsyst. Technol. 1997, 3, 129–133. [Google Scholar] [CrossRef]

- Huang, M.-S.; Chung, C.-F. Injection molding and injection compression molding of thin-walled light-guided plates with V-grooved microfeatures. J. Appl. Polym. Sci. 2011, 121, 1151–1159. [Google Scholar] [CrossRef]

- Theilade, U.A.; Hansen, H.N. Surface microstructure replication in injection molding. Int. J. Adv. Manuf. Technol. 2007, 33, 157–166. [Google Scholar] [CrossRef]

- Sha, B.; Dimov, S.; Griffiths, C.; Packianather, M.S. Investigation of micro-injection moulding: Factors affecting the replication quality. J. Mater. Process. Technol. 2007, 183, 284–296. [Google Scholar] [CrossRef]

- Hoyle, R. Creating micro and nano structures in polymers by moulding. Med. Device Technol. 2007, 18, 18–20. [Google Scholar]

- Masato, D.; Sorgato, M.; Lucchetta, G. Analysis of the influence of part thickness on the replication of micro-structured surfaces by injection molding. Mater. Des. 2016, 95, 219–224. [Google Scholar] [CrossRef]

- Kim, D.S.; Lee, S.H.; Kwon, T.H.; Ahn, C.H. A serpentine laminating micromixer combining splitting/recombination and advection. Lab Chip 2005, 5, 739. [Google Scholar] [CrossRef]

- Mair, D.A.; Geiger, E.; Pisano, A.P.; Fréchet, J.M.J.; Svec, F. Injection molded microfluidic chips featuring integrated interconnects. Lab Chip 2006, 6, 1346–1354. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Saeed, A.; Johnson, C.; Gadegaard, N.; Cass, A.E. Rapid, low cost prototyping of transdermal devices for personal healthcare monitoring. Sens. Bio-Sens. Res. 2017, 13, 104–108. [Google Scholar] [CrossRef] [PubMed]

- Velten, T.; Schuck, H.; Richter, M.; Klink, G.; Bock, K.; Malek, C.K.; Roth, S.; Schoo, H.; Bolt, P.J. Microfluidics on foil: State of the art and new developments. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 107–116. [Google Scholar] [CrossRef]

- Becker, H. It’s the economy. Lab Chip 2009, 9, 2759–2762. [Google Scholar] [CrossRef] [PubMed]

- Liedert, C.; Rannaste, L.; Kokkonen, A.; Huttunen, O.-H.; Liedert, R.; Hiltunen, J.; Hakalahti, L. Roll-to-Roll Manufacturing of Integrated Immunodetection Sensors. ACS Sens. 2020, 5, 2010–2017. [Google Scholar] [CrossRef]

- Focke, M.; Kosse, D.; Müller, C.; Reinecke, H.; Zengerle, R.; von Stetten, F. Lab-on-a-Foil: Microfluidics on thin and flexible films. Lab Chip 2010, 10, 1365. [Google Scholar] [CrossRef]

- Mäkelä, T.; Haatainen, T.; Majander, P.; Ahopelto, J. Continuous roll to roll nanoimprinting of inherently conducting polyaniline. Microelectron. Eng. 2007, 84, 877–879. [Google Scholar] [CrossRef]

- Striegel, A.; Schneider, M.; Schneider, N.; Benkel, C.; Worgull, M. Seamless tool fabrication for Roll-to-Roll microreplication. Microelectron. Eng. 2018, 194, 8–14. [Google Scholar] [CrossRef]

- Kodihalli Shivaprakash, N.; Ferraguto, T.; Panwar, A.; Banerjee, S.S.; Barry, C.F.; Mead, J. Fabrication of Flexible Polymer Molds for Polymer Microstructuring by Roll-to-Roll Hot Embossing. ACS Omega 2019, 4, 12480–12488. [Google Scholar] [CrossRef] [PubMed]

- Velten, T.; Schuck, H.; Haberer, W.; Bauerfeld, F. Investigations on reel-to-reel hot embossing. Int. J. Adv. Manuf. Technol. 2010, 47, 73–80. [Google Scholar] [CrossRef]

- Fagan, M.D.; Kim, B.H.; Yao, D. A novel process for continuous thermal embossing of large-area nanopatterns onto polymer films. Adv. Polym. Technol. 2009, 28, 246–256. [Google Scholar] [CrossRef]

- Ahn, S.H.; Guo, L.J. Large-Area Roll-to-Roll and Roll-to-Plate Nanoimprint Lithography: A Step toward High-Throughput Application of Continuous Nanoimprinting. ACS Nano 2009, 3, 2304–2310. [Google Scholar] [CrossRef] [PubMed]

- Ahn, S.H.; Kim, J.-S.; Guo, L.J. Bilayer metal wire-grid polarizer fabricated by roll-to-roll nanoimprint lithography on flexible plastic substrate. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2007, 25, 2388. [Google Scholar] [CrossRef]

- Toren, P.; Smolka, M.; Haase, A.; Palfinger, U.; Nees, D.; Ruttloff, S.; Kuna, L.; Schaude, C.; Jauk, S.; Rumpler, M.; et al. High-throughput roll-to-roll production of polymer biochips for multiplexed DNA detection in point-of-care diagnostics. Lab Chip 2020, 20, 4106–4117. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.-C.; Ciou, J.-R.; Huang, P.-H.; Hsieh, K.-H.; Yang, S.-Y. Fast fabrication of integrated surface-relief and particle-diffusing plastic diffuser by use of a hybrid extrusion roller embossing process. Opt. Express 2008, 16, 440. [Google Scholar] [CrossRef]

- Jiang, L.-T.; Huang, T.-C.; Chiu, C.-R.; Chang, C.-Y.; Yang, S.-Y. Fabrication of plastic microlens arrays using hybrid extrusion rolling embossing with a metallic cylinder mold fabricated using dry film resist. Opt. Express 2007, 15, 12088. [Google Scholar] [CrossRef]

- Truckenmüller, R.; Giselbrecht, S.; Rivron, N.; Gottwald, E.; Saile, V.; Van Den Berg, A.; Wessling, M.; Blitterswijk, C. Van Thermoforming of film-based biomedical microdevices. Adv. Mater. 2011, 23, 1311–1329. [Google Scholar] [CrossRef]

- Focke, M.; Stumpf, F.; Faltin, B.; Reith, P.; Bamarni, D.; Wadle, S.; Müller, C.; Reinecke, H.; Schrenzel, J.; Francois, P.; et al. Microstructuring of polymer films for sensitive genotyping by real-time PCR on a centrifugal microfluidic platform. Lab Chip 2010, 10, 2519. [Google Scholar] [CrossRef]

- Heilig, M.; Giselbrecht, S.; Guber, A.; Worgull, M. Microthermoforming of nanostructured polymer films: A new bonding method for the integration of nanostructures in 3-dimensional cavities. Microsyst. Technol. 2010, 16, 1221–1231. [Google Scholar] [CrossRef]

- Truckenmüller, R.; Giselbrecht, S.; Van Blitterswijk, C.; Dambrowsky, N.; Gottwald, E.; Mappes, T.; Rolletschek, A.; Saile, V.; Trautmann, C.; Weibezahn, K.F.; et al. Flexible fluidic microchips based on thermoformed and locally modified thin polymer films. Lab Chip 2008, 8, 1570–1579. [Google Scholar] [CrossRef]

- Strohmeier, O.; Keller, M.; Schwemmer, F.; Zehnle, S.; Mark, D.; Von Stetten, F.; Zengerle, R.; Paust, N. Centrifugal microfluidic platforms: Advanced unit operations and applications. Chem. Soc. Rev. 2015, 44, 6187–6229. [Google Scholar] [CrossRef]

- Stumpf, F.; Schwemmer, F.; Hutzenlaub, T.; Baumann, D.; Strohmeier, O.; Dingemanns, G.; Simons, G.; Sager, C.; Plobner, L.; Von Stetten, F.; et al. LabDisk with complete reagent prestorage for sample-to-answer nucleic acid based detection of respiratory pathogens verified with influenza A H3N2 virus. Lab Chip 2016, 16, 199–207. [Google Scholar] [CrossRef] [PubMed]

- Rombach, M.; Hin, S.; Specht, M.; Johannsen, B.; Lüddecke, J.; Paust, N.; Zengerle, R.; Roux, L.; Sutcliffe, T.; Peham, J.R.; et al. RespiDisk: A point-of-care platform for fully automated detection of respiratory tract infection pathogens in clinical samples. Analyst 2020, 145, 7040–7047. [Google Scholar] [CrossRef]

- Economou, A.; Kokkinos, C.; Prodromidis, M. Flexible plastic, paper and textile lab-on-a chip platforms for electrochemical biosensing. Lab Chip 2018, 18, 1812–1830. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.Q.; Chinnasamy, T.; Lifson, M.A.; Inci, F.; Demirci, U. Flexible Substrate-Based Devices for Point-of-Care Diagnostics. Trends Biotechnol. 2016, 34, 909–921. [Google Scholar] [CrossRef]

- Rashid, M.; Dou, Y.-H.; Auger, V.; Ali, Z. Recent developments in polymer microfluidic devices with capillary electrophoresis and electrochemical detection. Micro Nanosyst. 2010, 2. [Google Scholar] [CrossRef]

- Chung, H.U.; Rwei, A.Y.; Hourlier-Fargette, A.; Xu, S.; Lee, K.H.; Dunne, E.C.; Xie, Z.; Liu, C.; Carlini, A.; Kim, D.H.; et al. Skin-interfaced biosensors for advanced wireless physiological monitoring in neonatal and pediatric intensive-care units. Nat. Med. 2020, 26, 418–429. [Google Scholar] [CrossRef]

- Ochoa, M.; Rahimi, R.; Ziaie, B. Flexible sensors for chronic wound management. IEEE Rev. Biomed. Eng. 2014, 7, 73–86. [Google Scholar] [CrossRef]

- Ohlander, A.; Zilio, C.; Hammerle, T.; Zelenin, S.; Klink, G.; Chiari, M.; Bock, K.; Russom, A. Genotyping of single nucleotide polymorphisms by melting curve analysis using thin film semi-transparent heaters integrated in a lab-on-foil system. Lab Chip 2013, 13, 2075–2082. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Lakey, A.; Ali, Z.; Scott, S.M.; Chebil, S.; Korri-Youssoufi, H.; Hunor, S.; Ohlander, A.; Kuphal, M.; Marti, J.S. Impedimetric array in polymer microfluidic cartridge for low cost point-of-care diagnostics. Biosens. Bioelectron. 2019, 129. [Google Scholar] [CrossRef]

- Jolly, P.; Rainbow, J.; Regoutz, A.; Estrela, P.; Moschou, D. A PNA-based Lab-on-PCB diagnostic platform for rapid and high sensitivity DNA quantification. Biosens. Bioelectron. 2019, 123, 244–250. [Google Scholar] [CrossRef]

- Palavesam, N.; Marin, S.; Hemmetzberger, D.; Landesberger, C.; Bock, K.; Kutter, C. Roll-to-roll processing of film substrates for hybrid integrated flexible electronics. Flex. Print. Electron. 2018, 3. [Google Scholar] [CrossRef]

- Reyes, D.R.; van Heeren, H.; Guha, S.; Herbertson, L.; Tzannis, A.P.; Ducrée, J.; Bissig, H.; Becker, H. Accelerating innovation and commercialization through standardization of microfluidic-based medical devices. Lab Chip 2021, 21, 9–21. [Google Scholar] [CrossRef] [PubMed]

- Primiceri, E.; Chiriacò, M.; Notarangelo, F.; Crocamo, A.; Ardissino, D.; Cereda, M.; Bramanti, A.; Bianchessi, M.; Giannelli, G.; Maruccio, G. Key Enabling Technologies for Point-of-Care Diagnostics. Sensors 2018, 18, 3607. [Google Scholar] [CrossRef] [PubMed]

- Primiceri, E.; Chiriacò, M.S.; Rinaldi, R.; Maruccio, G. Cell chips as new tools for cell biology—Results, perspectives and opportunities. Lab Chip 2013, 13, 3789. [Google Scholar] [CrossRef]

- Pasirayi, G.; Auger, V.; Scott, M.S.; Rahman, P.K.S.M.; Islam, M.; O’Hare, L.; Ali, Z. Microfluidic Bioreactors for Cell Culturing: A Review. Micro Nanosyst. 2011, 3, 137–160. [Google Scholar] [CrossRef]

- Oliveira, A.F.; Pessoa, A.C.S.N.; Bastos, R.G.; de la Torre, L.G. Microfluidic tools toward industrial biotechnology. Biotechnol. Prog. 2016, 32, 1372–1389. [Google Scholar] [CrossRef]

- Van Den Berg, A.; Mummery, C.L.; Passier, R.; Van der Meer, A.D. Personalised organs-on-chips: Functional testing for precision medicine. Lab Chip 2019, 19, 198–205. [Google Scholar] [CrossRef]

- Mauk, M.G.; Song, J.; Liu, C.; Bau, H.H. Simple approaches to minimally-instrumented, microfluidic-based point-of-care Nucleic Acid Amplification Tests. Biosensors 2018, 8, 17. [Google Scholar] [CrossRef]

| Technology | Achievable Roughness Ra | Minimum Feature Size | Resolution/Feature Tolerance | Accuracy/Positional Tolerance | Typical Aspect Ratio | Typical Structural Dimension | References |

|---|---|---|---|---|---|---|---|

| Micro-cutting | 65 nm | 6.7 μm | 2 μm | 3 μm | <50 | <1 mm | [15,16,20,26] |

| Ultrasonic machining | NA | 5 μm | 5 μm | NA | <7 | NA | [15,16,20,21] |

| EDM | 100 nm | 5 μm | 3 μm | 1 μm | <20 | <1 mm | [18,19,24] |

| ECM | 28 nm | 150 nm | 5 μm | 2 μm | <10 | NA | [21] |

| Laser ablation | 100 nm | <1 μm | ≈1 μm | 3 μm | <10 | <500 μm | [15,20,21,27] |

| Focused ion beam | 0.58 nm | 40 nm | 5 nm | 100 nm | 10 | 500 nm | [16,28,29] |

| E-beam | NA | 10 nm | 20 nm | NA | <2 | <500 nm | [19,20,30] |

| X-ray LIGA | 10 nm | 50 nm | 20 nm | 300 nm | <100 | <1 mm | [15,16,20,31] |

| MEMS process | 10 nm | Some μm | NA | Some μm | <40 | <1 mm | [20,32] |

| μ-SL | NA | <1 μm | 120 nm | NA | NA | <1 mm | [21] |

| Laser Medium | F2 | ArF | KrF | XeCl | XeF |

|---|---|---|---|---|---|

| Wavelength (nm) | 157 | 193 | 248 | 308 | 351 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scott, S.M.; Ali, Z. Fabrication Methods for Microfluidic Devices: An Overview. Micromachines 2021, 12, 319. https://doi.org/10.3390/mi12030319

Scott SM, Ali Z. Fabrication Methods for Microfluidic Devices: An Overview. Micromachines. 2021; 12(3):319. https://doi.org/10.3390/mi12030319

Chicago/Turabian StyleScott, Simon M., and Zulfiqur Ali. 2021. "Fabrication Methods for Microfluidic Devices: An Overview" Micromachines 12, no. 3: 319. https://doi.org/10.3390/mi12030319

APA StyleScott, S. M., & Ali, Z. (2021). Fabrication Methods for Microfluidic Devices: An Overview. Micromachines, 12(3), 319. https://doi.org/10.3390/mi12030319