Interfacial Interactions during Demolding in Nanoimprint Lithography

Abstract

:1. Characteristics and Issues in Thermal and UV Nanoimprint Lithography

2. Process Simulations for NIL

2.1. Process Simulation for Thermal NIL

2.2. Process Simulation for UV NIL

2.3. Simulations for the Demolding Process

3. Mold Surface Modifications

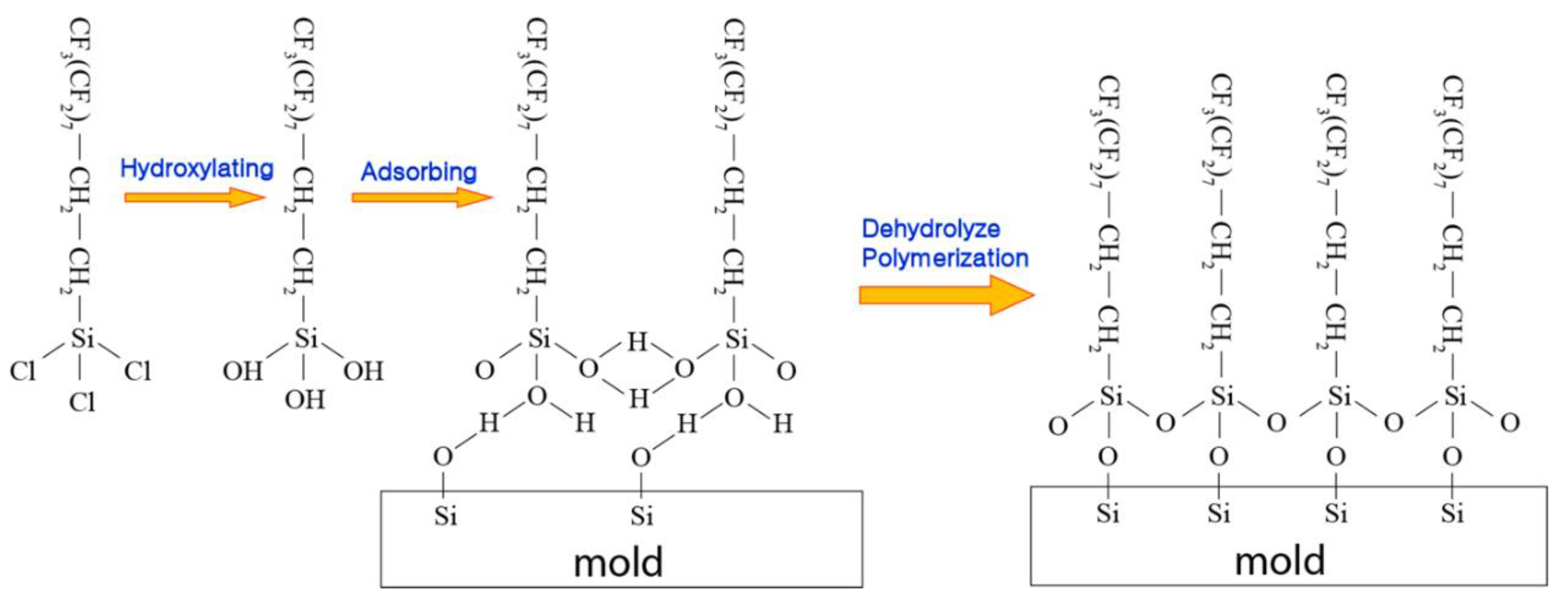

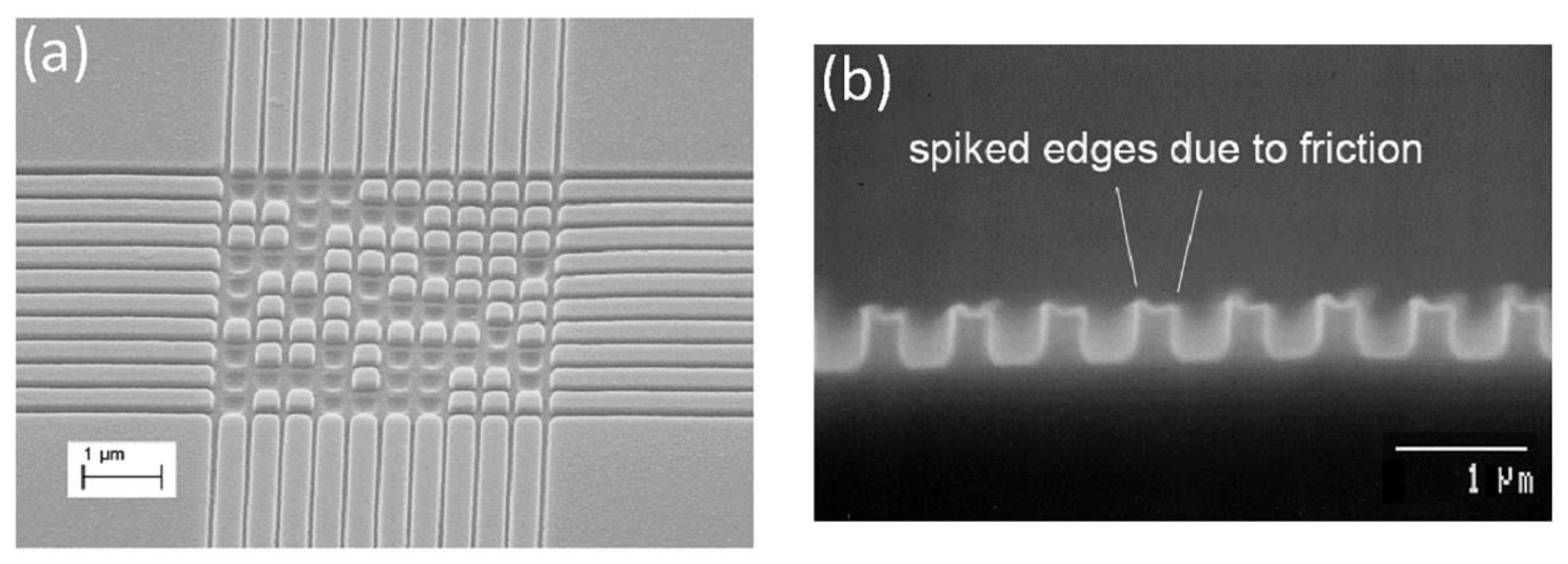

3.1. Surface Treatment for Nanoimprint Molds

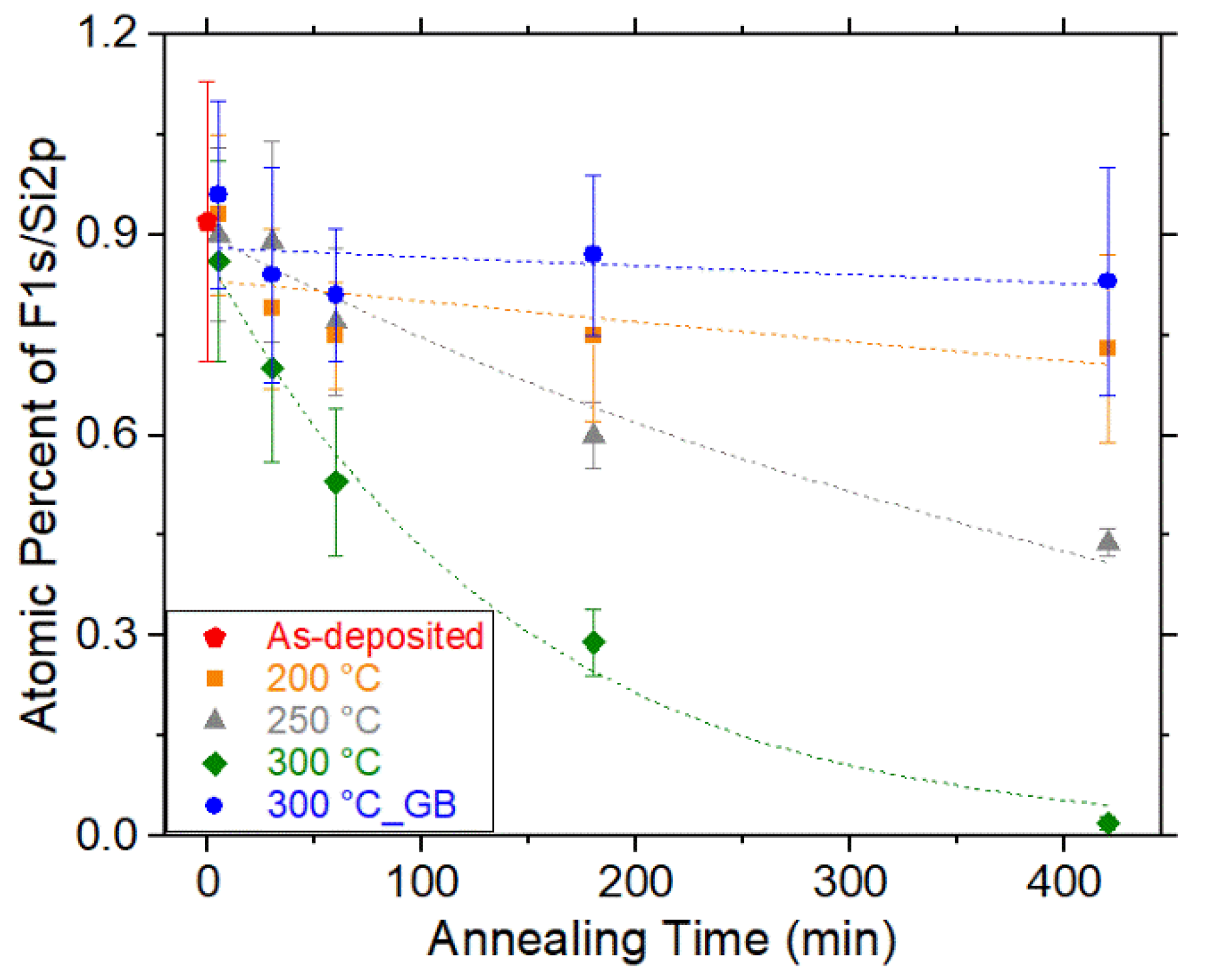

3.2. Stability of Surfactant Coating on Mold

3.3. Surfactant Additive in Resist as Inner Release Agent

3.4. Surface Modification by ALD

4. Interaction Forces between Mold and Resist during Demolding

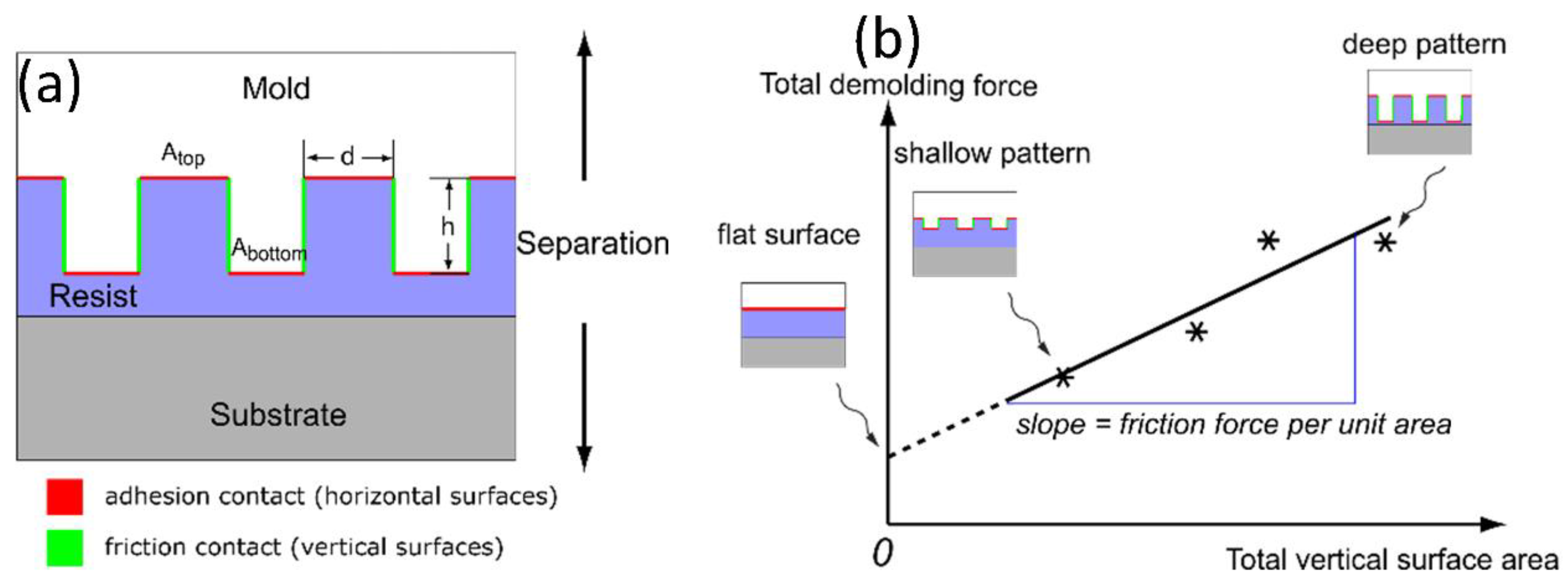

4.1. Origins of Demolding Forces in Nanoimprint

4.2. Thermal Stress in Nanoimprint and the Impact of Demolding Temperature

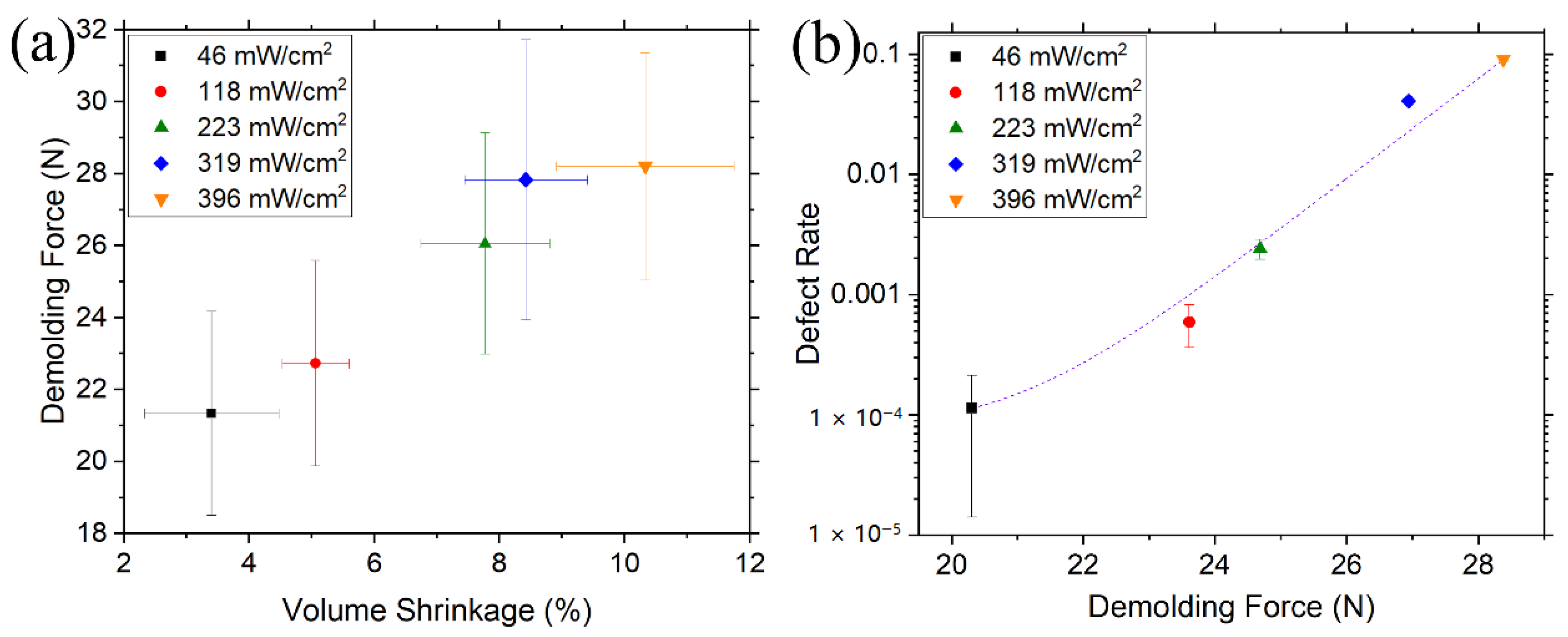

4.3. Resist Shrinkage in UV-NIL and Its Impact on Adhesion and Friction Forces

4.4. Decoupling Adhesion and Friction Forces during Demolding

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yu, C.-C.; Chen, H.-L. Nanoimprint technology for patterning functional materials and its applications. Microelectron. Eng. 2015, 132, 98–119. [Google Scholar] [CrossRef]

- Cox, L.M.; Martinez, A.M.; Blevins, A.K.; Sowan, N.; Ding, Y.; Bowman, C.N. Nanoimprint lithography: Emergent materials and methods of actuation. Nano Today 2020, 31, 100838. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Zhang, W.; Guo, L.; Zhuang, L. Sub-10 nm imprint lithography and applications. J. Vac. Sci. Technol. B 1997, 15, 2897–2904. [Google Scholar] [CrossRef]

- Austin, M.D.; Ge, H.; Wu, W.; Li, M.; Yu, Z.; Wasserman, D.; Lyon, S.A.; Chou, S.Y. Fabrication of 5nm linewidth and 14nm pitch features by nanoimprint lithography. Appl. Phys. Lett. 2004, 84, 5299–5301. [Google Scholar] [CrossRef] [Green Version]

- Guo, L.J. Nanoimprint Lithography: Methods and Material Requirements. Adv. Mater. 2007, 19, 495–513. [Google Scholar] [CrossRef] [Green Version]

- Kooy, N.; Mohamed, K.; Pin, L.T.; Guan, O.S. A review of roll-to-roll nanoimprint lithography. Nanoscale Res. Lett. 2014, 9, 320. [Google Scholar] [CrossRef] [Green Version]

- Zhou, W.; Min, G.; Zhang, J.; Liu, Y.; Wang, J.; Zhang, Y.; Sun, F. Nanoimprint Lithography: A Processing Technique for Nanofabrication Advancement. Nano-Micro Lett. 2011, 3, 135–140. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Mielczarek, K.; Aryal, M.; Zakhidov, A.; Hu, W. Nanoimprinted Polymer Solar Cell. ACS Nano 2012, 6, 2877–2892. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114–3116. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Chen, Y.; Luo, W.; Cheng, X. Nanoindentation Behavior of UV-Curable Resist and Its Correlation with Pat-terning Defect in Nanoimprint Lithography. J. Micromech. Microeng. 2020, 30, 065010. [Google Scholar] [CrossRef]

- Li, M.; Huang, X.; Luo, W.; Chen, Y.; Han, F.; Cheng, X. Thermal degradation behavior of self-assembled monolayer surfactant on silicon substrate. J. Vac. Sci. Technol. B 2020, 38, 032602. [Google Scholar] [CrossRef] [Green Version]

- Cheng, X.; Guo, L.J. A combined-nanoimprint-and-photolithography patterning technique. Microelectron. Eng. 2004, 71, 277–282. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, Z.; Li, F. Fabrication of a curved linear grating by using a laser direct writer system. Opt. Commun. 2006, 266, 249–252. [Google Scholar] [CrossRef]

- Vieu, C.; Carcenac, F.; Pépin, A.; Chen, Y.; Mejias, M.; Lebib, A.; Manin-Ferlazzo, L.; Couraud, L.; Launois, H. Electron beam lithography: Resolution limits and applications. Appl. Surf. Sci. 2000, 164, 111–117. [Google Scholar] [CrossRef]

- Chen, Y. Nanofabrication by electron beam lithography and its applications: A review. Microelectron. Eng. 2015, 135, 57–72. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, R.; Zhang, Y.; Liu, D.; Deng, H. Indiscriminate revelation of dislocations in single crystal SiC by inductively coupled plasma etching. J. Eur. Ceram. Soc. 2019, 39, 2831–2838. [Google Scholar] [CrossRef]

- Lian, Y.; Mu, C.; Xie, C.; Yao, B. Experimental investigation of inductively coupled plasma etching on cemented carbides. Vacuum 2019, 162, 101–109. [Google Scholar] [CrossRef]

- Chang, B.; Leussink, P.; Jensen, F.; Hübner, J.; Jansen, H. DREM: Infinite etch selectivity and optimized scallop size distribution with conventional photoresists in an adapted multiplexed Bosch DRIE process. Microelectron. Eng. 2018, 191, 77–83. [Google Scholar] [CrossRef]

- Jo, S.-B.; Lee, M.-W.; Lee, S.-G.; Lee, E.-H.; Park, S.-G.; O, B.-H. Characterization of a modified Bosch-type process for silicon mold fabrication. J. Vac. Sci. Technol. A 2005, 23, 905. [Google Scholar] [CrossRef]

- Jansen, H.V.; De Boer, M.J.; Unnikrishnan, S.; Louwerse, M.C.; Elwenspoek, M.C. Black silicon method: X. A review on high speed and selective plasma etching of silicon with profile control: An in-depth comparison between Bosch and cryostat DRIE processes as a roadmap to next generation equipment. J. Micromech. Microeng. 2009, 19, 033001. [Google Scholar] [CrossRef]

- Okulova, N.; Johansen, P.; Christensen, L.; Taboryski, R.J. Replication of micro-sized pillars in polypropylene using the extrusion coating process. Microelectron. Eng. 2017, 176, 54–57. [Google Scholar] [CrossRef] [Green Version]

- Akter, T.; Desai, S. Developing a predictive model for nanoimprint lithography using artificial neural networks. Mater. Des. 2018, 160, 836–848. [Google Scholar] [CrossRef]

- Schift, H. Nanoimprint lithography: An old story in modern times? A review. J. Vac. Sci. Technol. B 2008, 26, 458. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Luo, B.; Cheng, X. Enhanced Thermal Stability of Thermoplastic Polymer Nanostructures for Nanoim-print Lithography. Materials 2019, 12, 545. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.; Ro, H.W.; Douglas, J.F.; Jones, R.L.; Hine, D.R.; Karim, A.; Soles, C.L. Polymer Viscoelasticity and Residual Stress Effects on Nanoimprint Lithography. Adv. Mater. 2007, 19, 1377–1382. [Google Scholar] [CrossRef]

- Leveder, T.; Rognin, E.; Landis, S.; Davoust, L. Reflow of supported sub-100nm polymer films as a characterization process for NanoImprint lithography. Microelectron. Eng. 2011, 88, 1867–1870. [Google Scholar] [CrossRef]

- Sreenivasan, S.V. Nanoimprint lithography steppers for volume fabrication of leading-edge semiconductor integrated circuits. Microsyst. Nanoeng. 2017, 3, 17075. [Google Scholar] [CrossRef] [Green Version]

- Liang, X.; Tan, H.; Fu, Z.; Chou, S.Y. Air bubble formation and dissolution in dispensing nanoimprint lithography. Nanotechnology 2006, 18, 025303. [Google Scholar] [CrossRef] [Green Version]

- Hiroshima, H.; Komuro, M.; Kasahara, N.; Kurashima, Y.; Taniguchi, J. Elimination of Pattern Defects of Nanoim-print under Atmospheric Conditions. Jpn. J. Appl. Phys. 2003, 42, 3849–3853. [Google Scholar] [CrossRef]

- Chauhan, S.; Palmieri, F.; Bonnecaze, R.T.; Willson, C.G. Pinning at template feature edges for step and flash imprint lithography. J. Appl. Phys. 2009, 106, 034902. [Google Scholar] [CrossRef]

- Chauhan, S.; Palmieri, F.; Bonnecaze, R.T.; Willson, C.G. Feature filling modeling for step and flash imprint lithography. J. Vac. Sci. Technol. B 2009, 27, 1926–1932. [Google Scholar] [CrossRef]

- Kirchner, R.; Nüske, L.; Finn, A.; Lu, B.; Fischer, W.-J. Stamp-and-repeat UV-imprinting of spin-coated films: Pre-exposure and imprint defects. Microelectron. Eng. 2012, 97, 117–121. [Google Scholar] [CrossRef]

- Fuchs, A.; Bender, M.; Plachetka, U.; Hermanns, U.; Kurz, H. Ultraviolet-based nanoimprint at reduced environ-mental pressure. J. Vac. Sci. Technol. B 2005, 23, 2925–2928. [Google Scholar] [CrossRef]

- Matsui, S.; Hiroshima, H.; Hirai, Y.; Nakagawa, M. Innovative UV nanoimprint lithography using a condensable alternative chlorofluorocarbon atmosphere. Microelectron. Eng. 2015, 133, 134–155. [Google Scholar] [CrossRef]

- Hiroshima, H.; Komuro, M. Control of Bubble Defects in UV Nanoimprint. Jpn. J. Appl. Phys. 2007, 46, 6391–6394. [Google Scholar] [CrossRef]

- Iyoshi, S.; Okada, M.; Katase, T.; Tone, K.; Kobayashi, K.; Kaneko, S.; Haruyama, Y.; Nakagawa, M.; Hiroshima, H.; Matsui, S. Step and Repeat Ultraviolet Nanoimprinting under Pentafluoropropane Gas Ambient. Jpn. J. Appl. Phys. 2012, 51, 06FJ08. [Google Scholar] [CrossRef]

- Nakagawa, M.; Endo, A.; Tsukidate, Y. Investigation of nonreactive fluoroalkyl-containing surfactants for reducing release energy of ultraviolet-cured acrylate resins. J. Vac. Sci. Technol. B 2012, 30, 06FB10. [Google Scholar] [CrossRef]

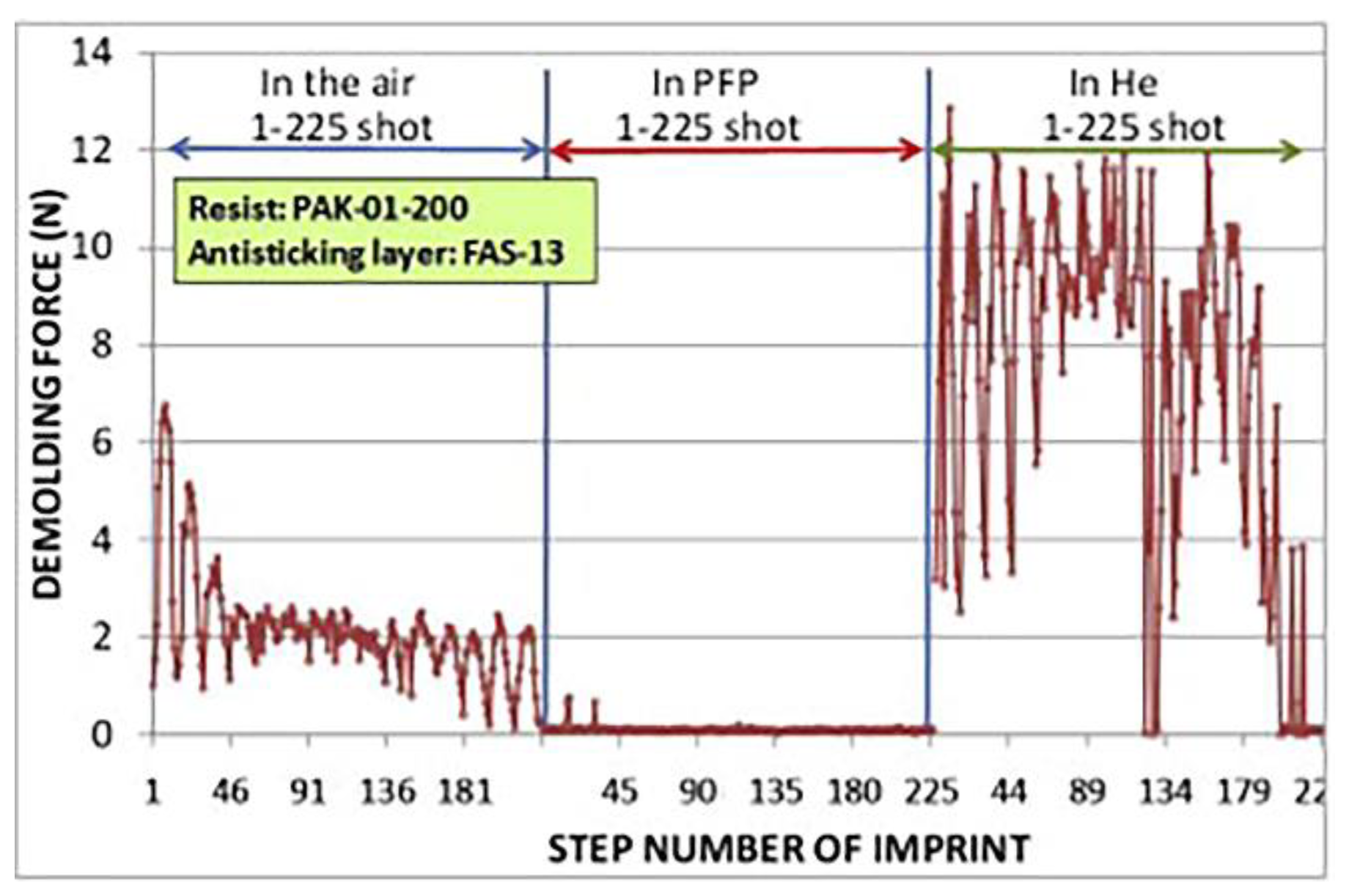

- Hiroshima, H. Release force reduction in UV nanoimprint by mold orientation control and by gas environment. J. Vac. Sci. Technol. B 2009, 27, 2862. [Google Scholar] [CrossRef]

- Wang, Q.; Hiroshima, H. Effects of Environmental Gas in UV Nanoimprint on the Characteristics of UV-Curable Resin. Jpn. J. Appl. Phys. 2010, 49, 06GL04. [Google Scholar] [CrossRef]

- Kaneko, S.; Kobayashi, K.; Tsukidate, Y.; Hiroshima, H.; Matsui, S.; Nakagawa, M. Morphological Changes in Ultraviolet-Nanoimprinted Resin Patterns Caused by Ultraviolet-Curable Resins Absorbing Pentafluoropropane. Jpn. J. Appl. Phys. 2012, 51, 06FJ05. [Google Scholar] [CrossRef]

- Decker, C.; Jenkins, A.D. Kinetic approach of oxygen inhibition in ultraviolet- and laser-induced polymerizations. Macromolecules 1985, 18, 1241–1244. [Google Scholar] [CrossRef]

- Dickey, M.D.; Burns, R.L.; Kim, E.K.; Johnson, S.C.; Stacey, N.A.; Willson, C.G. Study of the kinetics of step and flash imprint lithography photopolymerization. AIChE J. 2005, 51, 2547–2555. [Google Scholar] [CrossRef]

- Decker, C. Kinetic Study and New Applications of UV Radiation Curing. Macromol. Rapid Commun. 2002, 23, 1067–1093. [Google Scholar] [CrossRef]

- Cao, H.; Currie, E.; Tilley, M.; Jean, Y.C. Oxygen Inhibition Effect on Surface Properties of UV-Curable Acrylate Coatings, Photoinitiated Polymerization; American Chemical Society (ACS): Washington, DC, USA, 2003; pp. 152–164. [Google Scholar]

- Azeredo, B.P.; Lin, Y.-W.; Avagyan, A.; Sivaguru, M.; Hsu, K.; Ferreira, P. Direct Imprinting of Porous Silicon via Metal-Assisted Chemical Etching. Adv. Funct. Mater. 2016, 26, 2929–2939. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, J.; Yuan, D.; Han, L.; Zhou, J.-Z.; Tian, Z.-W.; Tian, Z.-Q.; Zhan, D. Electrochemical nanoimprint lithography directly on n-type crystalline silicon (111) wafer. Electrochem. Commun. 2017, 75, 1–4. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Han, L.; Tian, Z.-W.; Tian, Z.-Q.; Zhan, D. Electrochemical nanoimprint lithography: When nanoimprint lithography meets metal assisted chemical etching. Nanoscale 2017, 9, 7476–7482. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, L.; Wang, W.; Han, L.; Jia, J.-C.; Tian, Z.-W.; Tian, Z.-Q.; Zhan, D. Contact electrification induced interfacial reactions and direct electrochemical nanoimprint lithography in n-type gallium arsenate wafer. Chem. Sci. 2016, 8, 2407–2412. [Google Scholar] [CrossRef] [Green Version]

- Hirai, Y.; Fujiwara, M.; Okuno, T.; Tanaka, Y.; Endo, M.; Irie, S.; Nakagawa, K.; Sasago, M. Study of the resist defor-mation in nanoimprint lithography. J. Vac. Sci. Technol. B 2001, 19, 2811–2815. [Google Scholar] [CrossRef]

- Hirai, Y.; Yoshida, S.; Takagi, N. Defect analysis in thermal nanoimprint lithography. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2003, 21, 2765. [Google Scholar] [CrossRef]

- Johnson, S.; Burns, R.; Kim, E.K.; Dickey, M.; Schmid, G.; Meiring, J.; Burns, S.; Willson, C.G.; Convey, D.; Wei, Y.; et al. Effects of etch barrier densification on step and flash imprint lithography. J. Vac. Sci. Technol. B 2005, 23, 2553. [Google Scholar] [CrossRef]

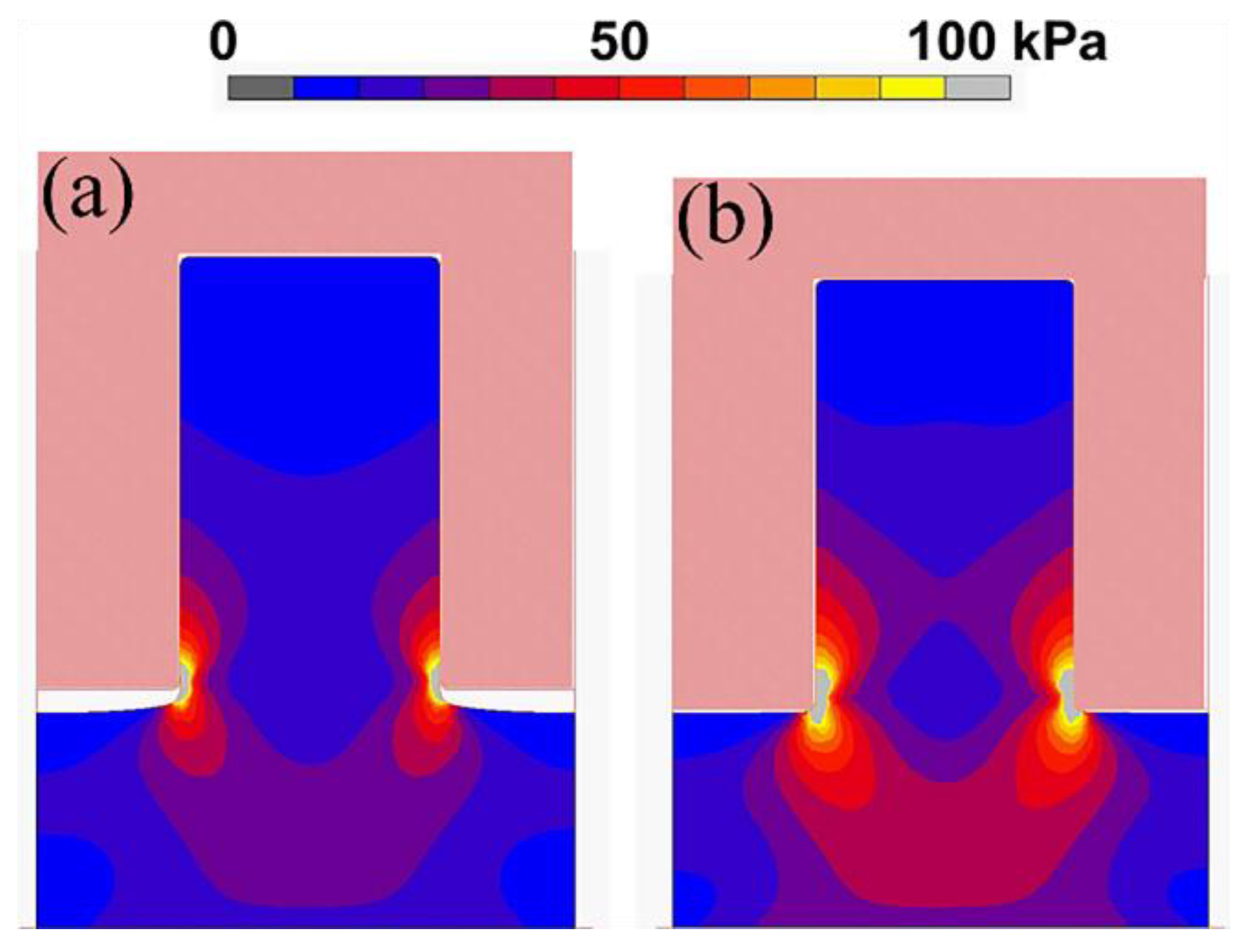

- Shibata, M.; Horiba, A.; Nagaoka, Y.; Kawata, H.; Yasuda, M.; Hirai, Y. Process-simulation system for UV-nanoimprint lithography. J. Vac. Sci. Technol. B 2010, 28, C6M108–C6M113. [Google Scholar] [CrossRef]

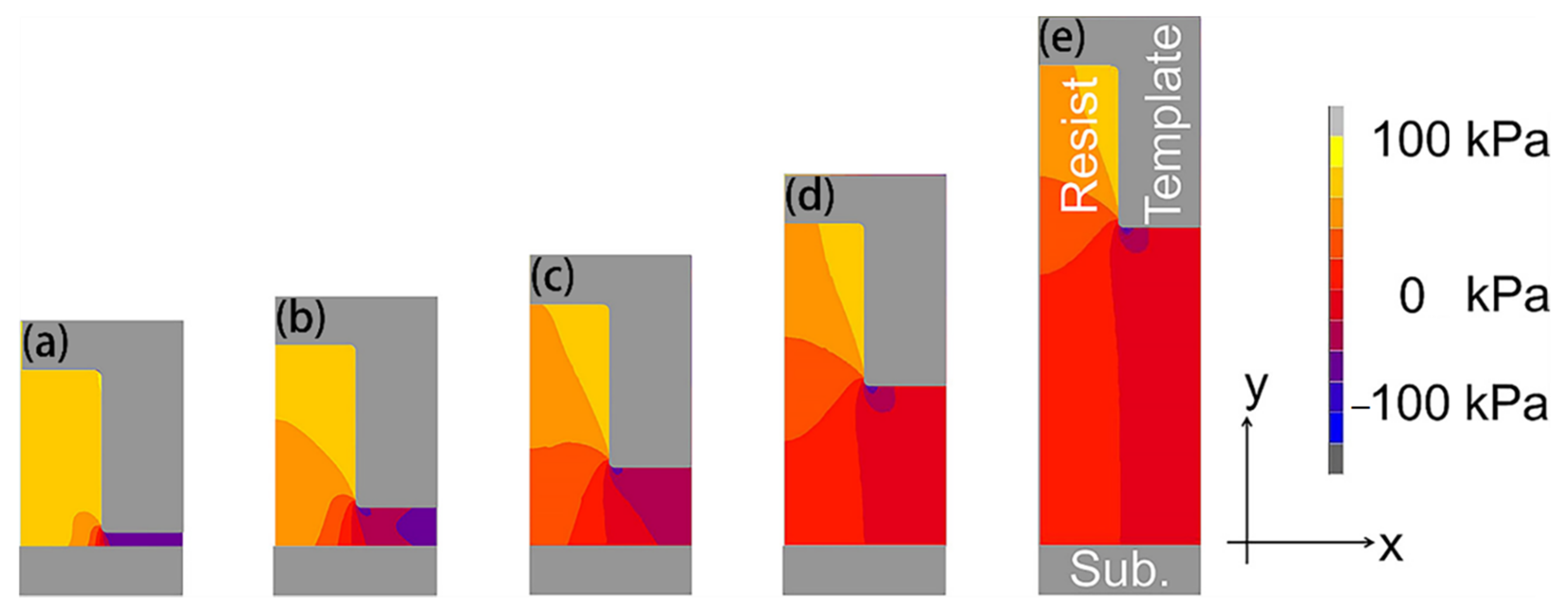

- Takai, R.; Yasuda, M.; Tochino, T.; Kawata, H.; Hirai, Y. Computational study of the demolding process in nanoimprint lithography. J. Vac. Sci. Technol. B 2014, 32, 06FG02. [Google Scholar] [CrossRef]

- Tochino, T.; Shiotsu, T.; Uemura, K.; Yasuda, M.; Kawata, H.; Hirai, Y. Impact of resist shrinkage on the template release process in nanoimprint lithography. J. Vac. Sci. Technol. B 2014, 32, 06FG08. [Google Scholar] [CrossRef]

- Shiotsu, T.; Nishikura, N.; Yasuda, M.; Kawata, H.; Hirai, Y. Simulation study on the template release mechanism and damage estimation for various release methods in nanoimprint lithography. J. Vac. Sci. Technol. B 2013, 31, 6. [Google Scholar] [CrossRef]

- Watanabe, K.; Iida, T.; Yasuda, M.; Kawata, H.; Hirai, Y. Study on induced strain in direct nanoimprint lithography. Jpn. J. Appl. Phys. 2018, 57, 06HG04. [Google Scholar] [CrossRef]

- Taylor, H.; Boning, D.; Iliescu, C. A razor-blade test of the demolding energy in a thermoplastic embossing process. J. Micromech. Microeng. 2011, 21, 067002. [Google Scholar] [CrossRef]

- Taylor, H.; Lam, Y.C.; Boning, D. A computationally simple method for simulating the micro-embossing of thermoplastic layers. J. Micromech. Microeng. 2009, 19, 075007. [Google Scholar] [CrossRef]

- Taylor, H.; Hale, M.; Lam, Y.C.; Boning, D. A method for the accelerated simulation of micro-embossed topographies in thermoplastic polymers. J. Micromech. Microeng. 2010, 20, 065001. [Google Scholar] [CrossRef]

- Taylor, H.; Lam, Y.C.; Boning, D. An investigation of the detrimental impact of trapped air in thermoplastic microembossing. J. Micromech. Microeng. 2010, 20, 065014. [Google Scholar] [CrossRef]

- Taylor, H.K. Defectivity prediction for droplet-dispensed UV nanoimprint lithography, enabled by fast simulation of resin flow at feature, droplet, and template scales. Altern. Lithogr. Technol. VIII 2016, 9777, 97770E. [Google Scholar] [CrossRef]

- Colburn, M.; Suez, I.; Choi, B.J.; Meissl, M.; Bailey, T.; Sreenivasan, S.V.; Ekerdt, J.G.; Willson, C.G. Characterization and modeling of volumetric and mechanical properties for step and flash imprint lithography photopolymers. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2001, 19, 2685–2689. [Google Scholar] [CrossRef] [Green Version]

- Worgull, M.; Heckele, M.; Schomburg, W.K. Large-scale hot embossing. Microsyst. Technol. 2005, 12, 110–115. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, G.; Xiong, Y.; Tian, Y. Study of the demolding process—Implications for thermal stress, adhesion and friction control. J. Micromech. Microeng. 2006, 17, 9–19. [Google Scholar] [CrossRef]

- Kawata, H.; Kubo, K.; Watanabe, Y.; Sakamoto, J.; Yasuda, M.; Hirai, Y. Effects of Mold Side Wall Profile on Demolding Characteristics. Jpn. J. Appl. Phys. 2010, 49, 06GL15. [Google Scholar] [CrossRef]

- Landis, S.; Chaix, N.; Gourgon, C.; Leveder, T. Quantitative characterizations of a nanopatterned bonded wafer: Force determination for nanoimprint lithography stamp removal. Nanotechnology 2008, 19, 125305. [Google Scholar] [CrossRef] [PubMed]

- Beck, M.; Graczyk, M.; Maximov, I.; Sarwe, E.-L.; Ling, T.; Keil, M.; Montelius, L. Improving stamps for 10 nm level wafer scale nanoimprint lithography. Microelectron. Eng. 2002, 61–62, 441–448. [Google Scholar] [CrossRef]

- Fu, X.; Yang, W.; He, M.; Li, Y.; Hao, Z.; He, Y.; Yuan, C.; Cui, Y.; Ge, H. A titanium-nickel composite mold with low surface energy for thermal nanoimprint lithography. Mater. Lett. 2020, 260, 126867. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, J.; Liu, Y.; Li, X.; Niu, X.; Song, Z.; Min, G.; Wan, Y.; Shi, L.; Feng, S. Characterization of an-ti-adhesive self-assembled monolayer for nanoimprint lithography. Appl. Surf. Sci. 2008, 255, 2885–2889. [Google Scholar] [CrossRef]

- Bunker, B.C.; Carpick, R.W.; Assink, R.A.; Thomas, M.L.; Hankins, M.G.; Voigt, J.A.; Sipola, D.; De Boer, M.P.; Gulley, G.L. The Impact of Solution Agglomeration on the Deposition of Self-Assembled Monolayers. Langmuir 2000, 16, 7742–7751. [Google Scholar] [CrossRef] [Green Version]

- Jung, G.-Y.; Li, Z.; Wu, W.; Chen, Y.; Olynick, D.L.; Wang, S.-Y.; Tong, W.M.; Williams, R.S. Vapor-Phase Self-Assembled Monolayer for Improved Mold Release in Nanoimprint Lithography. Langmuir 2005, 21, 1158–1161. [Google Scholar] [CrossRef]

- Bossard, M.; Boussey, J.; le Drogoff, B.; Chaker, M. Alternative nano-structured thin-film materials used as dura-ble thermal nanoimprint lithography templates. Nanotechnology 2016, 27, 075302. [Google Scholar] [CrossRef] [PubMed]

- Houle, F.A.; Rettner, C.T.; Miller, D.C.; Sooriyakumaran, R. Antiadhesion considerations for UV nanoimprint lithography. Appl. Phys. Lett. 2007, 90, 213103. [Google Scholar] [CrossRef]

- Tao, L.; Ramachandran, S.; Nelson, C.T.; Lin, M.; Overzet, L.J.; Goeckner, M.; Lee, G.; Willson, C.G.; Wu, W.; Hu, W. Durable diamond-like carbon templates for UV nanoimprint lithography. Nanotechnol. 2008, 19, 105302. [Google Scholar] [CrossRef] [Green Version]

- Ramachandran, S.; Tao, L.; Lee, T.H.; Sant, S.; Overzet, L.J.; Goeckner, M.J.; Kim, M.J.; Lee, G.S.; Hu, W. Deposition and patterning of diamondlike carbon as antiwear nanoimprint templates. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2006, 24, 2993. [Google Scholar] [CrossRef] [Green Version]

- Jaszewski, R.W.; Schift, H.; Gröning, P.; Margaritondo, G. Properties of thin anti-adhesive films used for the replication of microstructures in polymers. Microelectron. Eng. 1997, 35, 381–384. [Google Scholar] [CrossRef]

- Lehmann, H.W.; Frick, K.; Widmer, R.; Vossen, J.L.; James, E. Reactive sputtering of PTFE films in argon-CF4 mixtures. Thin Solid Films 1978, 52, 231–235. [Google Scholar] [CrossRef]

- Lee, J.; Lee, J.; Lee, H.W.; Kwon, K.-H. Anti-adhesive characteristics of CHF3/O2 and C4F8/O2 plasma-modified silicon molds for nanoimprint lithography. Mater. Res. Bull. 2015, 69, 120–125. [Google Scholar] [CrossRef]

- Park, S.; Schift, H.; Padeste, C.; Schnyder, B.; Kötz, R.; Gobrecht, J. Anti-adhesive layers on nickel stamps for nanoimprint lithography. Microelectron. Eng. 2004, 73-74, 196–201. [Google Scholar] [CrossRef]

- Ressier, L.; Martin, C.; Viallet, B.; Grisolia, J.; Peyrade, J.-P. Control of micro- and nanopatterns of octadecyltri-methoxysilane monolayers using nanoimprint lithography and atmospheric chemical vapor deposition. J. Vac. Sci. Technol. B 2006, 25, 17–20. [Google Scholar] [CrossRef]

- Zhuang, Y.X.; Hansen, O.; Knieling, T.; Wang, C.; Rombach, P.; Lang, W.; Benecke, W.; Kehlenbeck, M.; Koblitz, J. Thermal stability of vapor phase deposited self-assembled monolayers for MEMS anti-stiction. J. Micromech. Microeng. 2006, 16, 2259–2264. [Google Scholar] [CrossRef]

- Kim, B.H.; Chung, T.D.; Oh, C.H.; Chun, K. A new organic modifier for anti-stiction. J. Microelectromech. Syst. 2001, 10, 33–40. [Google Scholar] [CrossRef]

- Stevens, M.J. Thoughts on the Structure of Alkylsilane Monolayers. Langmuir 1999, 15, 2773–2778. [Google Scholar] [CrossRef]

- Genzer, J.; Efimenko, K.; Fischer, D.A. Molecular Orientation and Grafting Density in Semifluorinated Self-Assembled Monolayers of Mono-, Di-, and Trichloro Silanes on Silica Substrates. Langmuir 2002, 18, 9307–9311. [Google Scholar] [CrossRef]

- Fréchette, J.; Maboudian, R.; Carraro, C. Thermal Behavior of Perfluoroalkylsiloxane Monolayers on the Oxidized Si(100) Surface. Langmuir 2006, 22, 2726–2730. [Google Scholar] [CrossRef]

- Hair, M.; Tripp, C. Alkylchlorosilane reactions at the silica surface. Colloids Surf. A Physicochem. Eng. Asp. 1995, 105, 95–103. [Google Scholar] [CrossRef]

- Tripp, C.P.; Hair, M.L. Reaction of chloromethylsilanes with silica: A low-frequency infrared study. Langmuir 1991, 7, 923–927. [Google Scholar] [CrossRef]

- Tripp, C.P.; Hair, M.L. An infrared study of the reaction of octadecyltrichlorosilane with silica. Langmuir 1992, 8, 1120–1126. [Google Scholar] [CrossRef]

- Okada, M.; Yamashita, D.; Unno, N.; Taniguchi, J. Defect analysis and lifetime evaluation of a release-coated nanoimprint mold. Microelectron. Eng. 2014, 123, 117–120. [Google Scholar] [CrossRef]

- Tallal, J.; Gordon, M.; Berton, K.; Charley, A.; Peyrade, D. AFM characterization of anti-sticking layers used in nanoimprint. Microelectron. Eng. 2006, 83, 851–854. [Google Scholar] [CrossRef]

- Matsubara, H.; Kikugawa, G.; Bessho, T.; Yamashita, S.; Ohara, T. Understanding the chain length dependence of thermal conductivity of liquid alcohols at 298 K on the basis of molecular-scale energy transfer. Fluid Phase Equilibria 2017, 441, 24–32. [Google Scholar] [CrossRef]

- Matsubara, H.; Kikugawa, G.; Bessho, T.; Yamashita, S.; Ohara, T. Effects of molecular structure on microscopic heat transport in chain polymer liquids. J. Chem. Phys. 2015, 142, 164509. [Google Scholar] [CrossRef]

- Gao, Y.; Müller-Plathe, F. Effect of grafted chains on the heat transfer between carbon nanotubes in a polyam-ide-6.6 matrix: A molecular dynamics study. Polymers 2017, 129, 228–234. [Google Scholar] [CrossRef]

- Yan, X.Z.; Hansen, O.; Knieling, T.; Wang, C.; Rombach, P.; Lang, W.; Benecke, W.; Kehlenbeck, M.; Koblitz, J. Vapor-Phase Self-Assembled Monolayers for Anti-Stiction Applications in MEMS. J. Microelectromech. Syst. 2007, 16, 1451–1460. [Google Scholar]

- Ye, T.; Wynn, D.; Dudek, A.R.; Borguet, E. Photoreactivity of Alkylsiloxane Self-Assembled Monolayers on Silicon Oxide Surfaces. Langmuir 2001, 17, 4497–4500. [Google Scholar] [CrossRef]

- Tasker, S.; Chambers, R.D.; Badyal, J.P.S. Surface Defluorination of PTFE by Sodium Atoms. J. Phys. Chem. 1994, 98, 12442–12446. [Google Scholar] [CrossRef]

- Houle, F.A.; Guyer, E.; Miller, D.C.; Dauskardt, R. Adhesion between template materials and UV-cured nanoim-print resists. J. Vac. Sci. Technol. B 2007, 25, 1179–1185. [Google Scholar] [CrossRef]

- Wasserman, S.R.; Tao, Y.T.; Whitesides, G.M. Structure and reactivity of alkylsiloxane monolayers formed by reaction of alkyltrichlorosilanes on silicon substrates. Langmuir 1989, 5, 1074–1087. [Google Scholar] [CrossRef]

- Brzoska, J.B.; Shahidzadeh, N.; Rondelez, F. Evidence of a transition temperature for the optimum deposition of grafted monolayer coatings. Nat. Cell Biol. 1992, 360, 719–721. [Google Scholar] [CrossRef]

- Wu, K.; Wang, X.; Kim, E.K.; Willson, C.G.; Ekerdt, J.G. Experimental and Theoretical Investigation on Surfactant Segregation in Imprint Lithography. Langmuir 2007, 23, 1166–1170. [Google Scholar] [CrossRef] [PubMed]

- Bongiovanni, R.; Sangermano, M.; Malucelli, G.; Priola, A.; Leonardi, A.; Ameduri, B.; Pollicino, A.; Recca, A. Fluorinated vinyl ethers as new surface agents in the photocationic polymerization of vinyl ether resins. J. Polym. Sci. Part A Polym. Chem. 2003, 41, 2890–2897. [Google Scholar] [CrossRef]

- Ameduri, B.; Bongiovanni, R.; Lombardi, V.; Pollicino, A.; Priola, A.; Recca, A. Effect of the structural parameters of a series of fluoromonoacrylates on the surface properties of cured films. J. Polym. Sci. Part A Polym. Chem. 2001, 39, 4227–4235. [Google Scholar] [CrossRef]

- Weber, T.; Käsebier, T.; Szeghalmi, A.; Knez, M.; Kley, E.-B.; Tünnermann, A. Iridium wire grid polarizer fabricated using atomic layer deposition. Nanoscale Res. Lett. 2011, 6, 558. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hsu, Y.; Fang, X.; Wang, L.A.; Zan, H.-W.; Meng, H.-F.; Yang, S.-H. Sub-100 nm ALD-assisted nanoimprint lithography for realizing vertical organic transistors with high ON/OFF ratio and high output current. Org. Electron. 2014, 15, 3609–3614. [Google Scholar] [CrossRef]

- Hussain, M.M.; Labelle, E.; Sassman, B.; Gebara, G.; Lanee, S.; Moumen, N.; Larson, L. Deposition thickness based high-throughput nano-imprint template. Microelectron. Eng. 2007, 84, 594–598. [Google Scholar] [CrossRef]

- Güder, F.; Yang, Y.; Krüger, M.; Stevens, G.B.; Zacharias, M. Atomic Layer Deposition on Phase-Shift Lithography Generated Photoresist Patterns for 1D Nanochannel Fabrication. ACS Appl. Mater. Interfaces 2010, 2, 3473–3478. [Google Scholar] [CrossRef]

- Oda, H.; Ohtake, T.; Takaoka, T.; Nakagawa, M. Dewetting Photocontrol of Poly(styrene) Thin Films by a Photo-crosslinkable Monolayer in Thermal Nanoimprint Lithography. J. Photopolym. Sci. Technol. 2009, 22, 195–199. [Google Scholar] [CrossRef] [Green Version]

- Zhong, Z.W.; Shan, X.C.; Yao, Y.C. Investigation of Antiadhesive Coatings for Nanoimprinting Lithography. Mater. Manuf. Process. 2010, 25, 658–664. [Google Scholar] [CrossRef]

- Amirsadeghi, A.; Lee, J.J.; Park, S. Polymerization shrinkage stress measurement for a UV-curable resist in nanoimprint lithography. J. Micromech. Microeng. 2011, 21, 115013. [Google Scholar] [CrossRef]

- Min, H.; Zheng, N.; Fan, Z.; Jiang, Y.; Cheng, X. UV-curable nanoimprint resist with liquid volume-expanding monomers. Microelectron. Eng. 2019, 205, 32–36. [Google Scholar] [CrossRef]

- Fernandez-Cuesta, I.; Borrisé, X.; Retolaza, A.; Merino, S.; Mendels, D.-A.; Hansen, O.; Kristensen, A.; Perez-Murano, F. Determination of stress build-up during nanoimprint process in triangular polymer structures. Microelectron. Eng. 2008, 85, 838–841. [Google Scholar] [CrossRef]

- Ro, H.W.; Ding, Y.; Lee, H.-J.; Hines, D.R.; Jones, R.L.; Lin, E.K.; Karim, A.; Wu, W.-L.; Soles, C.L. Evidence for internal stresses induced by nanoimprint lithography. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2006, 24, 2973. [Google Scholar] [CrossRef] [Green Version]

- Bogdanski, N.; Wissen, M.; Möllenbeck, S.; Scheer, H.-C. Structure size dependent recovery of thin polystyrene layers in thermal imprint lithography. Microelectron. Eng. 2007, 84, 860–863. [Google Scholar] [CrossRef]

- Scheer, H.-C.; Bogdanski, N.; Wissen, M.; Konishi, T.; Hirai, Y. Profile evolution during thermal nanoimprint. Microelectron. Eng. 2006, 83, 843–846. [Google Scholar] [CrossRef]

- Wang, B.; Xiao, X.; Astakhov, V.P.; Liu, Z. The effects of stress triaxiality and strain rate on the fracture strain of Ti6Al4V. Eng. Fract. Mech. 2019, 219, 106627. [Google Scholar] [CrossRef]

- Habib, S.A.; Lloyd, J.T.; Meredith, C.S.; Khan, A.S.; Schoenfeld, S.E. Fracture of an anisotropic rare-earth-containing magnesium alloy (ZEK100) at different stress states and strain rates: Experiments and modeling. Int. J. Plast. 2019, 122, 285–318. [Google Scholar] [CrossRef]

- Chan-Park, M.B.; Lam, Y.C.; Laulia, P.; Joshi, S.C. Simulation and Investigation of Factors Affecting High Aspect Ratio UV Embossing. Langmuir 2005, 21, 2000–2007. [Google Scholar] [CrossRef]

- Perumal, J.; Yoon, T.H.; Jang, H.S.; Lee, J.J.; Kim, D.P. Adhesion force measurement between the stamp and the resin in ultraviolet nanoimprint lithography—an investigative approach. Nanotechnology 2009, 20, 055704. [Google Scholar] [CrossRef] [PubMed]

- Taniguchi, J.; Kawasaki, T.; Tokano, Y.; Kogo, Y.; Miyamoto, I.; Komuro, M.; Hiroshima, H.; Sakai, N.; Tada, K. Measurement of Adhesive Force Between Mold and Photocurable Resin in Imprint Technology. Jpn. J. Appl. Phys. 2002, 41, 4194–4197. [Google Scholar] [CrossRef]

- Amirsadeghi, A.; Lee, J.J.; Park, S. Surface adhesion and demolding force dependence on resist composition in ultraviolet nanoimprint lithography. Appl. Surf. Sci. 2011, 258, 1272–1278. [Google Scholar] [CrossRef]

- Yang, C.; Li, M.; Wang, J.; Ye, H.; Qiu, J. Residual layer assisted demolding in roll-to-roll UV imprint lithography. Microelectron. Eng. 2019, 217, 111110. [Google Scholar] [CrossRef]

- Enns, J.B.; Gillham, J.K. Time–temperature–transformation (TTT) cure diagram: Modeling the cure behavior of thermosets. J. Appl. Polym. Sci. 1983, 28, 2567–2591. [Google Scholar] [CrossRef]

- Lu, H.; Stansbury, J.W.; Bowman, C.N. Impact of Curing Protocol on Conversion and Shrinkage Stress. J. Dent. Res. 2005, 84, 822–826. [Google Scholar] [CrossRef]

- Geiser, V.; Jin, Y.-H.; Leterrier, Y.; Månson, J.-A.E. Nanoimprint Lithography with UV-Curable Hyperbranched Polymer Nanocomposites. Macromol. Symp. 2010, 296, 144–153. [Google Scholar] [CrossRef]

- Vogler, M.; Wiedenberg, S.; Mühlberger, M.; Bergmair, I.; Glinsner, T.; Schmidt, H.; Kley, E.-B.; Grützner, G. Development of a novel, low-viscosity UV-curable polymer system for UV-nanoimprint lithography. Microelectron. Eng. 2007, 84, 984–988. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, S.; Gao, Y.; Nie, J.; Sun, F. Design of a disulfide bond-containing photoresist with extremely low volume shrinkage and excellent degradation ability for UV-nanoimprinting lithography. Chem. Eng. J. 2020, 390, 124625. [Google Scholar] [CrossRef]

- Lange, J.; Toll, S.; Månson, J.-A.E.; Hult, A. Residual stress build-up in thermoset films cured below their ultimate glass transition temperature. Polymers 1997, 38, 809–815. [Google Scholar] [CrossRef]

- Chan, E.P.; Crosby, A.J. Quantifying release in step-and-flash imprint lithography. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2006, 24, 2716. [Google Scholar] [CrossRef]

- Pollock, H.M.; Maugis, D.; Barquins, M. The force of adhesion between solid surfaces in contact. Appl. Phys. Lett. 1978, 33, 798–799. [Google Scholar] [CrossRef]

- Jung, G.-Y.; Li, Z.; Wu, W.; Ganapathiappan, S.; Li, X.; Olynick, D.L.; Wang, S.Y.; Tong, W.M.; Williams, R.S. Improved Pattern Transfer in Nanoimprint Lithography at 30 nm Half-Pitch by Substrate−Surface Functionalization. Langmuir 2005, 21, 6127–6130. [Google Scholar] [CrossRef]

- Al-Japairai, K.A.S.; Mahmood, S.; Almurisi, S.H.; Venugopal, J.R.; Hilles, A.R.; Azmana, M.; Raman, S. Current trends in polymer microneedle for transdermal drug delivery. Int. J. Pharm. 2020, 587, 119673. [Google Scholar] [CrossRef]

- Waghule, T.; Singhvi, G.; Dubey, S.K.; Pandey, M.M.; Gupta, G.; Singh, M.; Dua, K. Microneedles: A smart approach and increasing potential for transdermal drug delivery system. Biomed. Pharmacother. 2019, 109, 1249–1258. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Chen, Y.; Luo, W.; Cheng, X. Demolding force dependence on mold surface modifications in UV nanoim-print lithography. Microelectron. Eng. 2021, 236, 111470. [Google Scholar] [CrossRef]

- Kobrin, B.; Zhang, T.; Grimes, M.T.; Chong, K.; Wanebo, M.; Chinn, J.; Nowak, R. An Improved Chemical Resistance and Mechanical Durability of Hydrophobic FDTS Coatings. J. Phys. Conf. Ser. 2006, 34, 454–457. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Chen, Y.; Luo, W.; Cheng, X. Interfacial Interactions during Demolding in Nanoimprint Lithography. Micromachines 2021, 12, 349. https://doi.org/10.3390/mi12040349

Li M, Chen Y, Luo W, Cheng X. Interfacial Interactions during Demolding in Nanoimprint Lithography. Micromachines. 2021; 12(4):349. https://doi.org/10.3390/mi12040349

Chicago/Turabian StyleLi, Mingjie, Yulong Chen, Wenxin Luo, and Xing Cheng. 2021. "Interfacial Interactions during Demolding in Nanoimprint Lithography" Micromachines 12, no. 4: 349. https://doi.org/10.3390/mi12040349

APA StyleLi, M., Chen, Y., Luo, W., & Cheng, X. (2021). Interfacial Interactions during Demolding in Nanoimprint Lithography. Micromachines, 12(4), 349. https://doi.org/10.3390/mi12040349