Bottom-Up (Cu, Ag, Au)/Al2O3/Bi2Te3 Assembled Thermoelectric Heterostructures

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

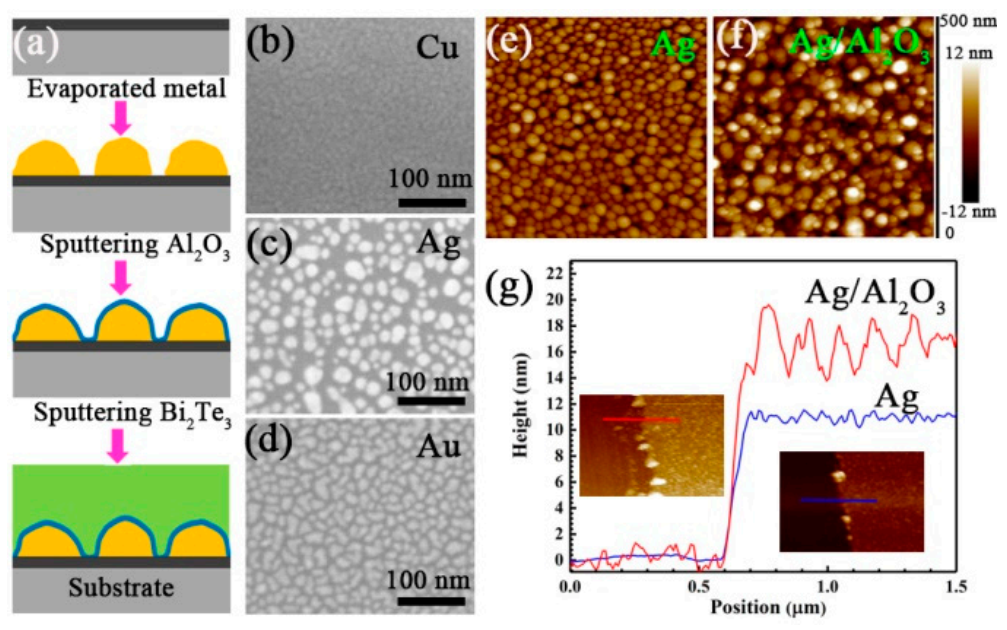

3.1. Heterostructure Characterization

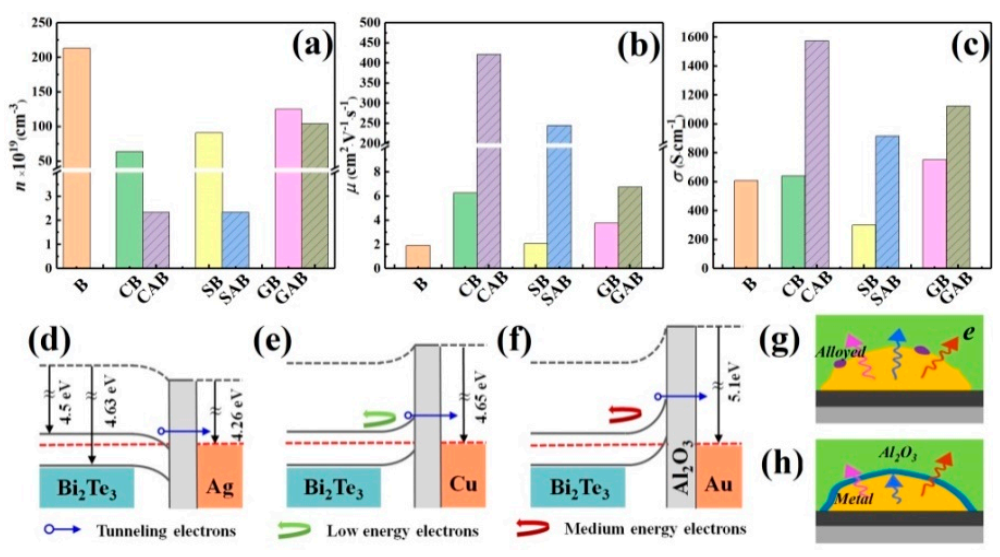

3.2. Carrier Transport Characteristics

3.3. Thermoelectric Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Shi, X.L.; Zou, J.; Chen, Z.G. Advanced thermoelectric design: From materials and structures to devices. Chem. Rev. 2020, 120, 7399–7515. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Feng, T.; Agne, M.T.; Zhou, L.; Ruan, X.; Snyder, G.J.; Wu, Y. Highly porous thermoelectric nanocomposites with low thermal conductivity and high figure of merit from large-scale solution-synthesized Bi2Te2.5Se0.5 hollow nanostructures. Angew. Chem. Int. Ed. 2017, 56, 3546–3551. [Google Scholar] [CrossRef] [PubMed]

- Giulia, P. Thermoelectric materials: The power of pores. Nat. Rev. Mater. 2017, 2, 17006. [Google Scholar] [CrossRef]

- Lee, S.; Lee, K.H.; Kim, Y.M.; Kim, H.S.; Snyder, G.J.; Baik, S.; Kim, S.W. Simple and efficient synthesis of nanograin structured single phase filled skutterudite for high thermoelectric performance. Acta Mater. 2018, 142, 8–17. [Google Scholar] [CrossRef]

- Xie, K.; Gupta, M.C. Thermoelectric properties of SiGe thin films prepared by laser sintering of nanograin powders. J. Alloys Compd. 2020, 820, 153182. [Google Scholar] [CrossRef]

- Zhang, Y.; Bahk, J.H.; Lee, J.; Birkel, C.S.; Snedaker, M.L.; Liu, D.; Zeng, H.; Moskovits, M.; Shakouri, A.; Stucky, G.D. Hot carrier filtering in solution processed heterostructures: A paradigm for improving thermoelectric efficiency. Adv. Mater. 2014, 26, 2755–2761. [Google Scholar] [CrossRef] [Green Version]

- Mao, J.; Chen, G.; Ren, Z. Thermoelectric cooling materials. Nat. Mater. 2020. [Google Scholar] [CrossRef]

- Mu, E.; Wu, Z.; Wu, Z.; Chen, X.; Liu, Y.; Fu, X.; Hu, Z. A novel self-powering ultrathin TEG device based on micro/nano emitter for radiative cooling. Nano Energy 2019, 55, 494–500. [Google Scholar] [CrossRef]

- Wu, Z.; Mu, E.; Che, Z.; Liu, Y.; Sun, F.; Wang, X.; Hu, Z. Nanoporous (00l)-oriented Bi2Te3 nanoplate film for improved thermoelectric performance. J. Alloys Compd. 2020, 828, 154239. [Google Scholar] [CrossRef]

- Jin, Q.; Jiang, S.; Zhao, Y.; Wang, D.; Qiu, J.; Tang, D.M.; Tan, J.; Sun, D.M.; Hou, P.X.; Chen, X.Q. Flexible layer-structured Bi2Te3 thermoelectric on a carbon nanotube scaffold. Nat. Mater. 2019, 18, 62–68. [Google Scholar] [CrossRef]

- Hu, X.; Hu, J.; Feng, B.; Pan, Z.; Liu, P.; Zhang, Y.; Li, R.; He, Z.; Li, G.; Li, Y. Artificial porous structure: An effective method to improve thermoelectric performance of Bi2Te3 based alloys. J. Solid State Chem. 2020, 282, 121060. [Google Scholar] [CrossRef]

- Dun, C.; Hewitt, C.A.; Li, Q.; Guo, Y.; Jiang, Q.; Xu, J.; Marcus, G.; Schall, D.C.; Carroll, D.L. Self-assembled heterostructures: Selective growth of metallic nanoparticles on V2–VI3 nanoplates. Adv. Mater. 2017, 29, 1702968. [Google Scholar] [CrossRef]

- Wu, Z.; Mu, E.; Wang, Z.; Chen, X.; Wu, Z.; Liu, Y.; Hu, Z. Bi2Te3 nanoplates’ selective growth morphology on different interfaces for enhancing thermoelectric properties. Cryst. Growth Des. 2019, 19, 3639–3646. [Google Scholar] [CrossRef]

- Zhu, T.; Hu, L.; Zhao, X.; He, J. New insights into intrinsic point defects in V2VI3 thermoelectric materials. Adv. Sci. 2016, 3, 1600004. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, W.; Zhang, C.; Xie, S.; Li, Z.; Hua, F.; Luo, J.; Wang, Z.; Wang, W.; Yan, F. Identifying the manipulation of individual atomic-scale defects for boosting thermoelectric performances in artificially controlled Bi2Te3 Films. ACS Nano 2021, 15, 5706–5714. [Google Scholar] [CrossRef]

- Gayner, C.; Amouyal, Y. Energy filtering of charge carriers: Current trends, challenges, and prospects for thermoelectric materials. Adv. Funct. Mater. 2020, 30, 1901789. [Google Scholar] [CrossRef]

- Zhang, Q.; Ai, X.; Wang, L.; Chang, Y.; Luo, W.; Jiang, W.; Chen, L. Improved thermoelectric performance of silver nanoparticles-dispersed Bi2Te3 composites deriving from hierarchical two-phased heterostructure. Adv. Funct. Mater. 2015, 25, 966–976. [Google Scholar] [CrossRef]

- Wu, H.J.; Yen, W.T. High thermoelectric performance in Cu-doped Bi2Te3 with carrier-type transition. Acta Mater. 2018, 157, 33–41. [Google Scholar] [CrossRef]

- Hao, F.; Qiu, P.; Tang, Y.; Bai, S.; Xing, T.; Chu, H.-S.; Zhang, Q.; Lu, P.; Zhang, T.; Ren, D. High efficiency Bi2Te3-based materials and devices for thermoelectric power generation between 100 and 300 °C. Energ. Environ. Sci. 2016, 9, 3120–3127. [Google Scholar] [CrossRef]

- Choi, H.; Jeong, K.; Chae, J.; Park, H.; Baeck, J.; Kim, T.H.; Song, J.Y.; Park, J.; Jeong, K.H.; Cho, M.-H. Enhancement in thermoelectric properties of Te-embedded Bi2Te3 by preferential phonon scattering in heterostructure interface. Nano Energy 2018, 47, 374–384. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Y.; Qiao, J.; Jiang, S.; Mao, P.; Qiu, J.; Kang, S.; Tan, J.; Tai, K.; Liu, C. Decoupling phonon and carrier scattering at carbon nanotube/Bi2Te3 interfaces for improved thermoelectric performance. Carbon 2020, 170, 191–198. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, X.; Mu, E.; Liu, Y.; Che, Z.; Dun, C.; Sun, F.; Wang, X.; Zhang, Y.; Hu, Z. Lattice strain enhances thermoelectric properties in Sb2Te3/Te heterostructure. Adv. Electron. Mater. 2020, 6, 1900735. [Google Scholar] [CrossRef]

- Bludska, J.; Jakubec, I.; Drašar, Č.; Lošťák, P.; Horak, J. Structural defects in Cu-doped Bi2Te3 single crystals. Philos. Mag. 2007, 87, 325–335. [Google Scholar] [CrossRef]

- Keys, J.D.; Dutton, H.M. Diffusion and solid solubility of gold in single-crystal bismuth telluride. J. Appl. Phys. 1963, 34, 1830–1831. [Google Scholar] [CrossRef]

- Keys, J.D.; Dutton, H.M. Diffusion and solid solubility of silver in single-crystal bismuth telluride. J. Phys. Chem. Solids 1963, 24, 563–571. [Google Scholar] [CrossRef]

- Chen, S.; Hutabalian, Y.; Hu, Z.; Chen, H.; Shih, H.; Wang, W. Liquation phenomena in Sn/Bi2Te3, In/Bi2Te3 and Cu/Bi2Te3 couples. Acta Mater. 2020, 196, 418–429. [Google Scholar] [CrossRef]

- Heyrovska, R. The Golden ratio, ionic and atomic radii and bond lengths. Mol. Phys. 2005, 103, 877–882. [Google Scholar] [CrossRef]

- Minnich, A.; Dresselhaus, M.S.; Ren, Z.; Chen, G. Bulk nanostructured thermoelectric materials: Current research and future prospects. Energ. Environ. Sci. 2009, 2, 466–479. [Google Scholar] [CrossRef]

- Ioffe, I.F. Semiconductor Thermoelements and Thermoelectric Cooling; Infosearch Ltd.: London, UK, 1957. [Google Scholar]

- Yang, J.; Xi, L.; Qiu, W.; Wu, L.; Shi, X.; Chen, L.; Yang, J.; Zhang, W.; Uher, C.; Singh, D.J. On the tuning of electrical and thermal transport in thermoelectrics: An integrated theory–experiment perspective. NPJ Comput. Mater. 2016, 2, 1–17. [Google Scholar] [CrossRef] [Green Version]

| Sample | B | CB | CAB | SB | SAB | GB | GAB |

|---|---|---|---|---|---|---|---|

| m*/m0 | 6.38 | 2.56 | 0.26 | 3.80 | 0.30 | 3.92 | 3.12 |

| L (V2·K−2) | 2.04 × 10−8 | 2.08 × 10−8 | 2.12 × 10−8 | 2.01 × 10−8 | 2.05 × 10−8 | 2.09 × 10−8 | 2.14 × 10−8 |

| κe (W·m−1·K−1) | 0.37 | 0.40 | 1.00 | 0.18 | 0.56 | 0.47 | 0.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Zhang, S.; Liu, Z.; Lu, C.; Hu, Z. Bottom-Up (Cu, Ag, Au)/Al2O3/Bi2Te3 Assembled Thermoelectric Heterostructures. Micromachines 2021, 12, 480. https://doi.org/10.3390/mi12050480

Wu Z, Zhang S, Liu Z, Lu C, Hu Z. Bottom-Up (Cu, Ag, Au)/Al2O3/Bi2Te3 Assembled Thermoelectric Heterostructures. Micromachines. 2021; 12(5):480. https://doi.org/10.3390/mi12050480

Chicago/Turabian StyleWu, Zhenhua, Shuai Zhang, Zekun Liu, Cheng Lu, and Zhiyu Hu. 2021. "Bottom-Up (Cu, Ag, Au)/Al2O3/Bi2Te3 Assembled Thermoelectric Heterostructures" Micromachines 12, no. 5: 480. https://doi.org/10.3390/mi12050480

APA StyleWu, Z., Zhang, S., Liu, Z., Lu, C., & Hu, Z. (2021). Bottom-Up (Cu, Ag, Au)/Al2O3/Bi2Te3 Assembled Thermoelectric Heterostructures. Micromachines, 12(5), 480. https://doi.org/10.3390/mi12050480